Abstract

The cost of raw materials has a major role in the wood industry. From this point of view, it is necessary to pay attention to the correct log-sawing pattern, which will optimize the sawing process and increase the quantity and quality of the material as well. For measurements, we used beech wood (Fagus sylvatica L.). Beech wood (Fagus sylvatica L.) is the most common wood species in the Slovak Republic; the total amount in forests is 34.8%. Beech wood has a high frequency of defects, such as red false heartwood, reaction wood (i.e., tension wood), dote, cracks, and so on. This research aimed to analyze the effect of the log-sawing patterns of through-and-through sawing, cant sawing, and quarter sawing on the resulting quantitative–qualitative yields of beech timber. The results showed that the highest quantitative yield was observed with the cant sawing pattern, at 84%, which was, on average, 17.3% higher compared to other types of cutting. It was found that quarter sawing resulted in a higher qualitative yield compared to through-and-through sawing or cant sawing (V5 = 62.69% and V6 = 47.86%).

1. Introduction

The processing of wood as a renewable and sustainable material is steadily gaining importance. Improving the log-sawing patterns is an option to make sawing processes more energy-efficient and sustainable, as well as for quality and quantity improvements [1]. The major factor in the sawmill that influences the yield of lumber is the use of the correct pattern of cutting [2]. From this point of view, it is necessary to pay attention to the correct log-sawing patterns that will optimize the sawing process and increase the quantity and quality of material as well [3]. There is limited information on the influence of different sawing patterns on lumber yield, workability, and sawn wood quality [4]. In [2], a comparison was made between the volume yield for the most common sawing pattern in China and the yield produced by a new sawing pattern. This study showed that a new sawing pattern called hexagon sawing gave a higher yield than the other sawing patterns. The mean yield for the whole diameter range was 82.7% for hexagon sawing, 53.3% for live (through-and-through) sawing, 56.7% for triangle sawing, and 63.2% for trapezoidal sawing. In the woodworking industry, different patterns of cutting can be applied to increase the final quantity. Through these operations, specific logs are into timber. There are several patterns of cutting that are used for hardwood species—for example, through-and-through sawing, cant sawing, or quarter sawing [5]. Cant sawing is the best-known method of cutting and is usually used for coniferous species. This type of sawing has some advantages; for example, the sawn lumber is characterized by balanced quality marks. Cant sawing can separate the zone from the pith, called juvenile wood (unstable zone for drying and processing), and this can provide more stable timber for wood construction as well. Quarter sawing is notably used for beech wood or other hardwood species with many growth defects [6].

A similar work [7] focused on sawmilling logs of oak via the sawing pattern of live (through-and-through) sawing. The diameter of the oak logs was in the range of 30 to 39 cm and they were 4 m long. The oak timber was sawn at 25 and 50 mm thicknesses. The research focused on the effect of the sawing pattern on the quantitative and qualitative yields of oak timber. Results confirmed that the sawing pattern had a strong influence on the final quantity of small-sawn products. The quantitative yield in the live sawing of the oak logs observed in this research was around 57.29%, and the quality yield was 87.89%. There are also other researchers [8,9,10] dealing with the issue of the influence of sawing patterns on the quantitative and qualitative yields of wood for similar wood species—for example, tropical hardwood species (Millettia stuhlmannii Taub. and Pterocarpus angolensis DC.) or coniferous species, such as Cryptomeria japonica, Pinus radiata, etc.

It has been known for a long time that if timber is sawn radially from the log, no or very small changes in shape occur [5,6,11]. It has also been shown that if the timber contains pith, or if any part of the timber has been sawn out close to the pith, the timber has a greater tendency to crack. These properties of the juvenile wood mean that it should be removed at the time of sawing, to obtain straight timber free from cracks [11]. In some studies [12,13], a system was described that was focused on production with log-sawing optimization using a simulator named AUTOSAW, while also addressing demands for timber products of differing quality. The efficiency of the system was tested with three order books via comparisons with volume- and value-optimized solutions obtained from the sawing of pruned (Pinus radiata D.) logs. The research was focused on four log-sawing patterns—through and through sawing, quarter sawing, cant sawing, and grade sawing. The results indicated that a product-controlled optimization system can potentially provide better quantitative and qualitative yields of logs. The effect of the increased demand for beech in Europe, as well as its better mechanical properties, has increased the interest in the usage of this wood species for structural applications [14]. Beech wood (Fagus sylvatica L.) is the most common wood species in the Slovak Republic [15]. Beech wood has a high frequency of defects, such as red heartwood, reaction wood (i.e., tension wood), and dote [16]. Based on the literature [17,18], the yield of beech lumber is related to the presence of red false heartwood. In general, the yield of wood material, as well as the quality and dimensional structure of sawn products, depends on the log-sawing pattern [18]. In [17], comparing the quantitative and qualitative yields of beech logs sawn by the three methods (through-and-through sawing, cant, and quarter), it was concluded that through-and-through sawing yielded the least favorable results, while the other two methods yielded similar results. The quantitative yield of the quarter sawing and cant sawing of beech logs was around 60.5%, whereas, in through-and-through sawing, it was nearly 4% lower (56.8%). The structures of large and small waste products were equal in all the patterns used. The structure of the products was strongly influenced by the methods of sawing. It was most favorable in cant sawing and least favorable in through-and-through sawing. Cant sawing yielded the most timber, which is especially important for the most valuable products, i.e., long-edged timber. Through-and-through sawing yielded the largest amount of small sawmill products as compared to the other two methods, and the share of red heart boards was the lowest because this product was produced by more precise, secondary machines. In all three methods, the most frequent boards among all boards composed of sapwood were flat-sawn boards; rift-sawn boards were almost half as frequent, and the presence of quarter-sawing boards was negligible, except in through-and-through sawing. This was as expected, considering the quality zones in beech logs, as well as the fact that most quarter-sawn products were classified as red heart boards. Round sawing yielded more timber of quality class I than other methods, but the most favorable structure was achieved by cant sawing (production of more valuable products). Therefore, the value yield of these two sawing methods was equal, while through-and-through sawing yielded the lowest-value products. This initial research is based on the needs of the woodworking industry to process beech cuts as efficiently as possible and use the most appropriate sawing patterns. This research aims to analyze the effect of the log-sawing patterns of through-and-through sawing, cant sawing, and quarter sawing on the resulting quantitative–qualitative yields of beech timber. We place great emphasis primarily on obtaining the largest possible amount of timber with the largest possible storage area (volume).

2. Materials and Methods

Beech wood (Fagus sylvatica L.) was used for the experimental measurements. Beech logs were harvested in the forest area Hronská Dúbrava (457 m.a.s.l.), which belongs to the Technical University Forestry Enterprise in Zvolen (Slovakia). This area was dominated by deciduous trees, especially hornbeam (Carpinus betulus L.), oak (Quercus robur L.), and beech (Fagus sylvatica L.). The selection of suitable logs was performed immediately after the logging of trees and on the same day. Six logs with a length of approximately six meters were selected for cutting.

The selected log-sawing patterns were chosen based on the diameters of the logs. According to the central diameters of the logs, they were assigned to a specific type of log-sawing pattern (Table 1). The diameters of the logs ranged from 43.0 to 65.0 cm. Three log-sawing patterns were applied to the cut: through-and-through sawing, cant sawing, and quarter sawing.

Table 1.

Measured the diameters of the logs and their assigned log-sawing patterns.

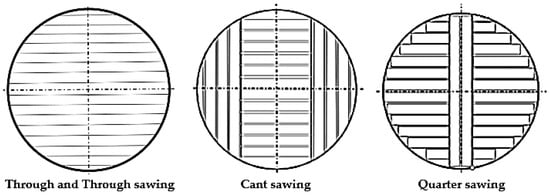

For each log (V1–V6), we selected a particular type of log-sawing pattern. The type of pattern was selected based on the previously measured central diameters. The log with the largest central diameter was used for cant sawing, that with the second-largest diameter was used for quarter sawing, and that with the smallest was used for through-and-through sawing. All log-sawing patterns are shown in Figure 1.

Figure 1.

Selected log-sawing patterns for beech logs (Fagus sylvatica L.).

Each log was sawn on a horizontal band saw, the MEBOR 1000 HTZ. For this research, a standard thickness of lumber of 33 mm was chosen. Each lumber was cleaned and then marked after cutting. Edged or unedged lumber was also measured. Its thickness, width, and length were measured to calculate the quantitative and qualitative yields. The dimensions were measured using a digital caliper based on the STN EN 1309-1 standard [19].

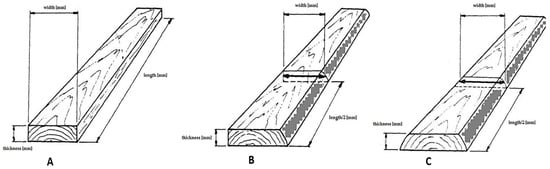

The manufactured lumber and its rounded sides could not be measured in full or partially in terms of volume. For this reason, to obtain higher quantitative yield values, it was necessary to use permissible measurements of rounded sides in the context of the standard used (STN EN 1309-1) [19]. The methods of width measurement are shown in Figure 2. Measurements of the width and thickness were performed by a caliper with accuracy ± 0.03 mm. The length was measured with a tape rule.

Figure 2.

Scheme showing three different methods of determining the width of lumber by STN EN 1309-1 [19]: (A) edged, (B) semi-edged, (C) unedged.

The timber was classified after cutting logs (Figure 3). It was classified into two groups: radial or tangential lumber. After cutting, all lumber was compared in terms of quantitative and qualitative yields. The quantitative yield consisted of the total amount of lumber obtained (tangentially and radially). Meanwhile, the qualitative yield focused on the amount of radial lumber.

Figure 3.

The choice of beech logs used for the experiment.

The results were processed at the level of inductive statistics. The method of analysis of variance (ANOVA) with a significance level (p = 0.05) was chosen for the mentioned evaluation. For this evaluation, we chose to use box plots.

3. Results and Discussion

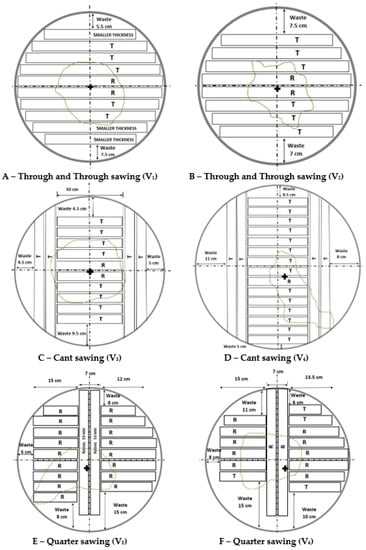

The beech logs were sawed into edged and unedged timber with a thickness of 33 mm. Three types of log-sawing patterns were used, which remarkably affected both the quantitative and qualitative yields. This can be observed from the resulting log-sawing patterns shown in Figure 4. The resulting sawing patterns (Figure 4) were likely influenced by several factors, such as the type of main saw machine (horizontal band saw), the curvature of the log (V3 or V6), and the ovality of the log (V5 or V6). Other authors [18,19,20,21] have reported many additional factors. Some research [21] has reported that the resulting visualization of the sawing patterns was influenced by the diameter of logs, length of logs, or age. In general, studies [19,20,22] have reported that the yield of raw material, as well as the quality and dimensions of the lumber, depend on the method of sawing [20,22], the quality of the raw material, or the technology applied [18].

Figure 4.

Applied log-sawing patterns with the resulting amount of radial (R) and tangential (T) lumber obtained ((A,B) through-and-through sawing, (C,D) cant sawing, (E,F) quarter sawing).

- Evaluation of Quantitative Yield

When comparing all selected log-sawing patterns, it was found that all three chosen patterns remarkably affected the overall quantitative yield of beech timber with and without bark. This is also demonstrated by the quantitative yield results presented in Table 2.

Table 2.

The results of quantitative yield using selected log-sawing patterns.

Based on our results, the highest quantitative yield was observed for cant sawing at 84% (which is marked in Table 2, in red color), which was, on average, 17.3% higher compared to other types of cutting. Other studies [4,6] show that cant sawing is characterized by obtaining timber with the maximum dimensions. In other research [17], it was discovered that round sawing and cant sawing had a higher quantitative yield compared to through-and-through sawing. The yield of through-and-through sawing was lower by 3.84% compared to round sawing and 3.73% compared to cant sawing. In general, the quantitative yield was higher than that reported in other papers [20,22,23].

Through-and-through sawing provided slightly lower results than cant sawing, at approximately a 12% lower yield (the average value of yield was 72.28%). The reason for this could be the greater tapering of the log in the V1-marked cut, which led to more waste in obtaining a parallel surface along the entire length or a smaller diameter of the cut. This result is also supported by a study [2] that applied through-and-through sawing to Masson pine (Pinus massoniana Lamb.), and its quantitative yield reached the lowest average value of 53.3%. A similar result for the quantity yield (around 57.29%) with the live sawing of the oak logs was observed [7].

- Evaluation of Qualitative Yield

For the evaluation method, a qualitative element was initially chosen. In our case, it was the amount of radial timber. According to several experiments [5,6], radial timber is characterized by less pronounced warping or drying, which results in obtaining more dimensionally stable timber. Our results showed that the highest proportion of radial timber (qualitative yield) was achieved with quarter sawing. It significantly outperformed other types of cutting, as can be seen in Table 3.

Table 3.

The results of qualitative yield using selected log-sawing patterns.

From the comparison of some results obtained with quarter sawing, higher qualitative (grade) yields were achieved compared to through-and-through sawing, which was also confirmed by our results. With the mentioned log-sawing patterns, the qualitative yield was found to be V5 = 62.69% and V6 = 47.86%. Other studies [3,4] describe this type of cutting as a method that leads to fewer losses caused by warping, especially in beech wood. The highest yield of tangential timber was observed with cant sawing, specifically with the same cut (V4), which was characterized by the highest quantitative yield.

Table 4 shows the qualitative and quantitative yields for comparison with other researchers’ work [7,17]. The comparison of the yields indicates that the wood species, the quality of the logs, and the technology used can significantly influence the resulting qualitative or quantitative yields.

Table 4.

Comparison of qualitative and quantitative yields with other researchers for three chosen sawing patterns.

- Effect of Log-Sawing Patterns on Quantitative and Qualitative Yields

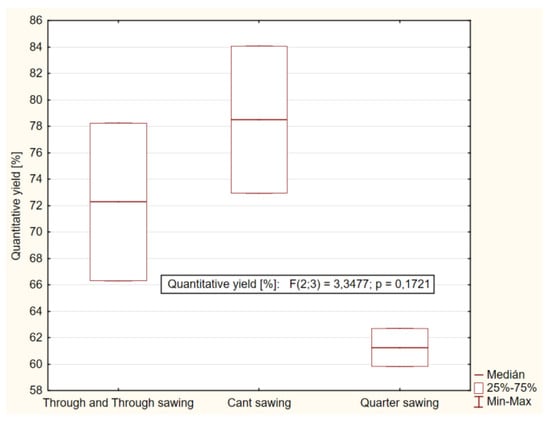

The results were also evaluated using statistical analysis (Figure 5), which confirmed that the choice of log-sawing pattern can have an impact on the qualitative yield. This was further supported by the 2D box plot graph, which assessed the statistical results (p = 0.0105) based on the determined significance level (p = 0.05). On the other hand, in terms of quantitative yield, this result was not confirmed, and the value of statistical significance was well above the level of p = 0.1721 (Figure 6). The same differences were presented in other research [17] and the level of significance was p = 0.057, probably due to large variation within groups.

Figure 5.

Effect of log-sawing pattern on qualitative yield evaluated by analysis of variance (ANOVA).

Figure 6.

Effect of log-sawing pattern on quantitative yield evaluated by analysis of variance.

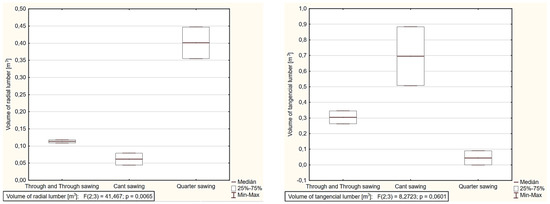

In the evaluation of the results, we also statistically analyzed the influence of the log-sawing patterns on the resulting volume of tangential or radial timber. Here, a statistically significant difference was confirmed only in the case of radial timber, where the significance value reached p = 0.0065 (Figure 7).

Figure 7.

The effect of the log-sawing pattern on the resulting volume of tangential (right side) or radial (left side) lumber as evaluated by analysis of variance (ANOVA).

The largest average yield was discovered with quarter sawing (0.400 m3). From the point of view of tangential lumber, the highest average yield was discovered with cant sawing (0.696 m3). According to the results in [17], a higher value was discovered for cant sawing and round sawing. However, in the other research [17], the statistically significant influence of the log-sawing pattern on the qualitative yield was not confirmed (p = 0.129).

4. Conclusions

This research aimed to analyze the effect of the cutting methods/patterns of through-and-through sawing, cant sawing, and quarter sawing on the resulting quantitative–qualitative yields of beech timber. Based on the results, we offer the following conclusions:

- The results of the research confirmed that the type of sawing pattern remarkably influenced the overall quantitative and qualitative yields of beech-edged and unedged timber. The results showed that the highest quantitative yield was observed with the cant sawing pattern at 84%, which was, on average, 17.3% higher compared to other types of cutting.

- The largest proportion of radial timber (quality) was achieved with the quarter sawing pattern on average, with a yield of 55%. The lowest yield of radial timber was achieved with cant sawing, with an average yield of only 7%. Based on the level of significance (p), which reached the value of p = 0.0105, the hypothesis that the sawing pattern affects the qualitative yield of lumber was confirmed.

In terms of quantitative yield, this was not confirmed, and the level of significance (p) was p = 0.1721. The influence of the log-sawing pattern on the resulting volume of radial timber was also confirmed, where the level of significance (p) was p = 0.0065.

In the future, this research can be applied to all hardwoods whose structures contain similar defects to beech—for example, oak, hornbeam, etc.—allowing researchers to obtain the best possible quantitative or qualitative yields with the selected pattern of sawing.

Author Contributions

Conceptualization, P.V. and T.V.; methodology, P.V. and I.K.; software, P.V. and I.K.; validation, P.V. and I.K.; formal analysis, P.V.; investigation, P.V.; resources, T.V.; data curation, I.K.; writing—original draft preparation, P.V.; writing—review and editing, T.V.; visualization, P.V.; supervision, I.K.; project administration, P.V. and T.V.; funding acquisition, P.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under contract no. APVV-21-0049. This work was also supported by the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences under project VEGA no. 1/0063/22.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was supported by the Slovak Research and Development Agency under contract no. APVV-21-0049. This work was supported by the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences—project VEGA no. 1/0063/22.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schmidt, J.; Schreiner, F.; Thorenz, B.; Döpper, F. Evaluation of Material Properties of Spruce Wood Samples to Improve the Development Process for More Sustainable Sawing Processes. In Manufacturing Driving Circular Economy; Kohl, H., Seliger, G., Dietrich, F., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Rongrong, L.; Cao, P.; Guo, X.; Ji, F.; Mats, E.; Xiaodong, W. Novel Sawing Method for Small-Diameter Log. Wood Res. 2015, 60, 239–300. [Google Scholar]

- Steele, P.H. Factors Determining Lumber Recovery in Sawmilling; General Technical Report FPL; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1984; Volume 39, 8p.

- Carreiro, G.D.; da Silva, P.Y.C.; Mulin, L.B.; da Silva, J.G.M.; Oliveira, M.P.; Moulin, J.C. Sawing Patterns for The Breakdown of Pinus caribaea var. caribaea Wood on Portable Sawmills. Floresta 2021, 51, 686–695. [Google Scholar]

- Klement, I.; Detvaj, J. Technológia Prvostupňového Spracovania Dreva; Technická Univerzita Vo Zvolene: Zvolen, Slovakia, 2007; ISBN 978-80-228-1811-7. [Google Scholar]

- Sandberg, D. Radially Sawn Timber: Star-Sawing—A New Method for Producing Timber with Vertical Annual Rings. Eur. J. Wood Wood Prod. 1996, 54, 145–151. [Google Scholar] [CrossRef]

- Ištvanić, J.; Obućina, M.; Jovanovic, J.; Smajic, S. Determination of Success Sawmill Processing of Pedunculate Oak (Quercus robur L.) Logs by Live Sawing Method. In Proceedings of the 14th International Scientific Conference WoodEMA, Koper, Slovenia, 16–18 June 2021. [Google Scholar]

- Shenga, P.; Bomark, P.; Broman, O.; Sandberg, D. Log sawing positioning optimization and log bucking of tropical hardwood species to increase the volume yield. Wood Mater. Sci. Eng. 2017, 12, 257–262. [Google Scholar] [CrossRef]

- Matsumura, Y.; Murata, K.; Ikami, Y.; Matsumura, J. Influence of Sawing Patterns on Lumber Quality and Yield in Large Sugi (Cryptomeria japonica) Logs. For. Prod. J. 2012, 62, 25–31. [Google Scholar] [CrossRef]

- Pang, S. Effects of Sawing Pattern on Lumber Drying: Model Simulation and Experimental Investigation. Dry. Technol. 2002, 20, 1769–1787. [Google Scholar] [CrossRef]

- Sandberg, D. Influence of Annual Ring Orientation on Crack Formation and Deformation in Water Soaked Pine (Pinus silvestris L.) and Spruce (Picea Abies Karst) Timber; Report Trita-Trä R-95-16; Royal Institue of Technology, Division of Wood Technology and Processing: Stockholm, Sweden, 1995. [Google Scholar]

- Todoroki, C. Autosaw System for Sawing Simulation. N. Z. J. For. Sci. 1990, 20, 332–348. [Google Scholar]

- Todoroki, C.; Rönnqvist, M. Dynamic Control of Timber Production at A Sawmill with Log Sawing Optimization. Scand. J. For. Res. 2002, 17, 79–89. [Google Scholar] [CrossRef]

- Kovryga, A.; Khaloian Sarnaghi, A.; Van De Kuilen, J.W.G. Strength Grading of Hardwoods Using Transversal Ultrasound. Eur. J. Wood Prod. 2020, 78, 951–960. [Google Scholar] [CrossRef]

- Čunderlík, I.; Vilkovský, P. Change adhesion wood/bark on the trunk of a beech during the dormant and growing period. Acta Fac. Xylologiae Zvolen 2015, 57, 5–13. [Google Scholar]

- Barański, J.; Klement, I.; Vilkovská, T.; Konopka, A. High-temperature drying process of beech wood (Fagus sylvatica L.) with different zones of sapwood and red false heartwood. BioResource 2017, 12, 1861–1870. [Google Scholar] [CrossRef]

- Popadić, R.; Šoškić, B.; Milić, G.; Todorović, N.; Furtula, M. Influence of the Sawing Method on Yield of Beech Logs with Red Heartwood. Drvna Industrija 2014, 65, 35–42. [Google Scholar] [CrossRef]

- Popadić, R.; Todorović, N. Uticaj Načina Primarnog Piljenja i Kvaliteta Bukove Oblovine na Učešće Radijalnih, Poluradijalnih i Tangencijalnih Sortimenata. Prerada Drveta 2009, 28, 28–34. [Google Scholar]

- STN EN 1309-1: 2000 (49 1013); Logs and lumber. Method of Measuring Dimensions. Office for Standardization, Metrology and Testing of the Slovak Republic: Bratislava, Slovakia, 2000; Part 1, Timber.

- Zubčević, R. Uticajni Faktori pri Izradi Grubih Obradaka iz Niskokvalitetne Bukove Pilanske Sirovine. Ph.D. Thesis, Mašinski Fakultet, Sarajevo, Bosnia and Herzegovina, 1973. [Google Scholar]

- Knoke, T. Predicting red heartwood formation in beech trees (Fagus sylvatica L.). Ecol. Model. 2003, 169, 163–179. [Google Scholar] [CrossRef]

- Skakić, D. Iskorišćenje Bukove Sirovine pri Izradi Elemenata za Stolove i Stolice. Ph.D. Thesis, Šumarski Fakultet, Belgrade, Serbia, 1985. [Google Scholar]

- Šoškić, B.; Milić, G. Uticaj Kvaliteta Bukovih Trupaca Na Iskorišćenje Pri Pilanskoj Preradi. Prerada Drveta 2005, 12, 15–22. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).