Buckling-Restrained Bracing System with Ultra-High-Performance Fiber Concrete

Abstract

:1. Introduction

2. Implementing UHPFRC Concrete in BRB Device

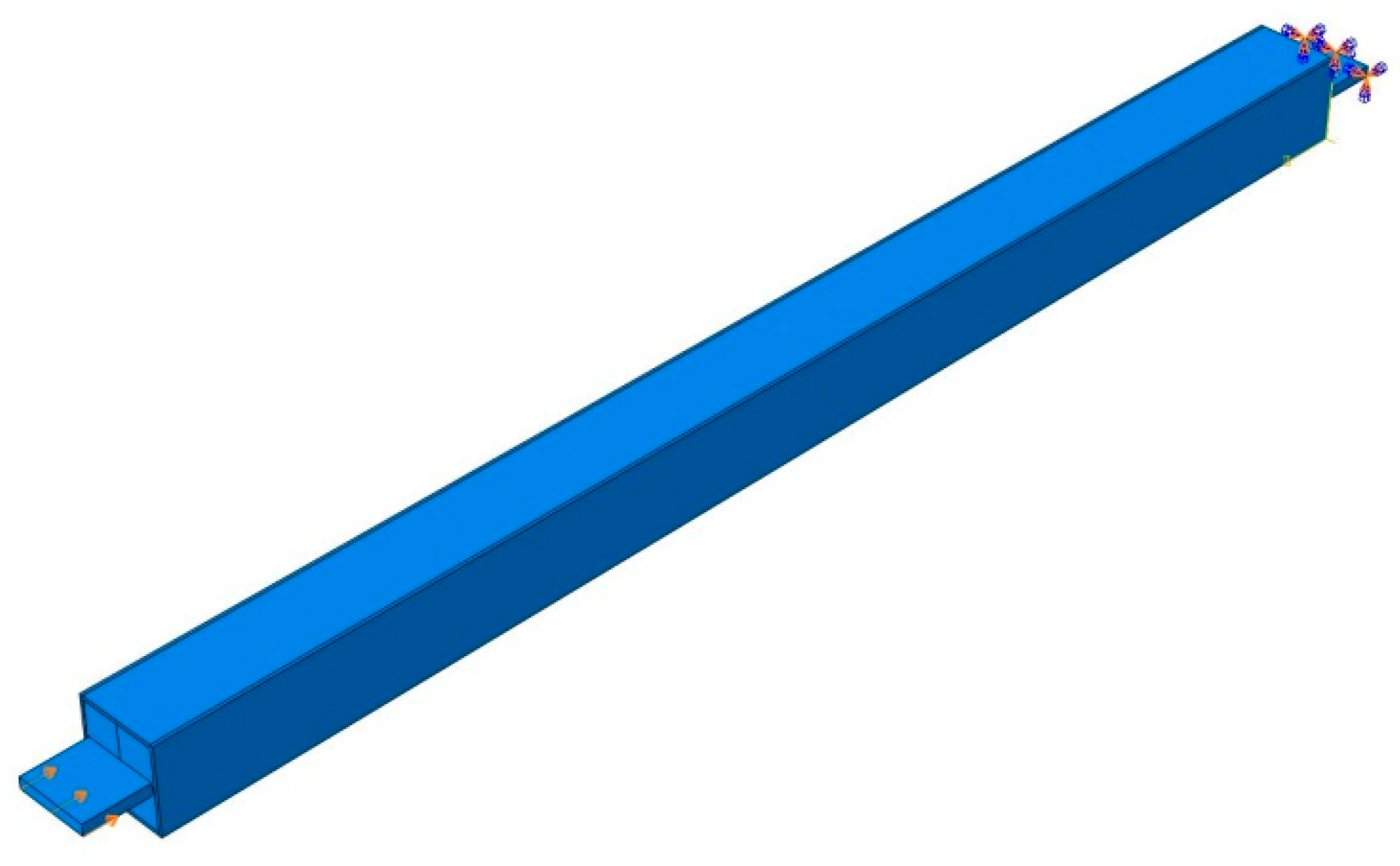

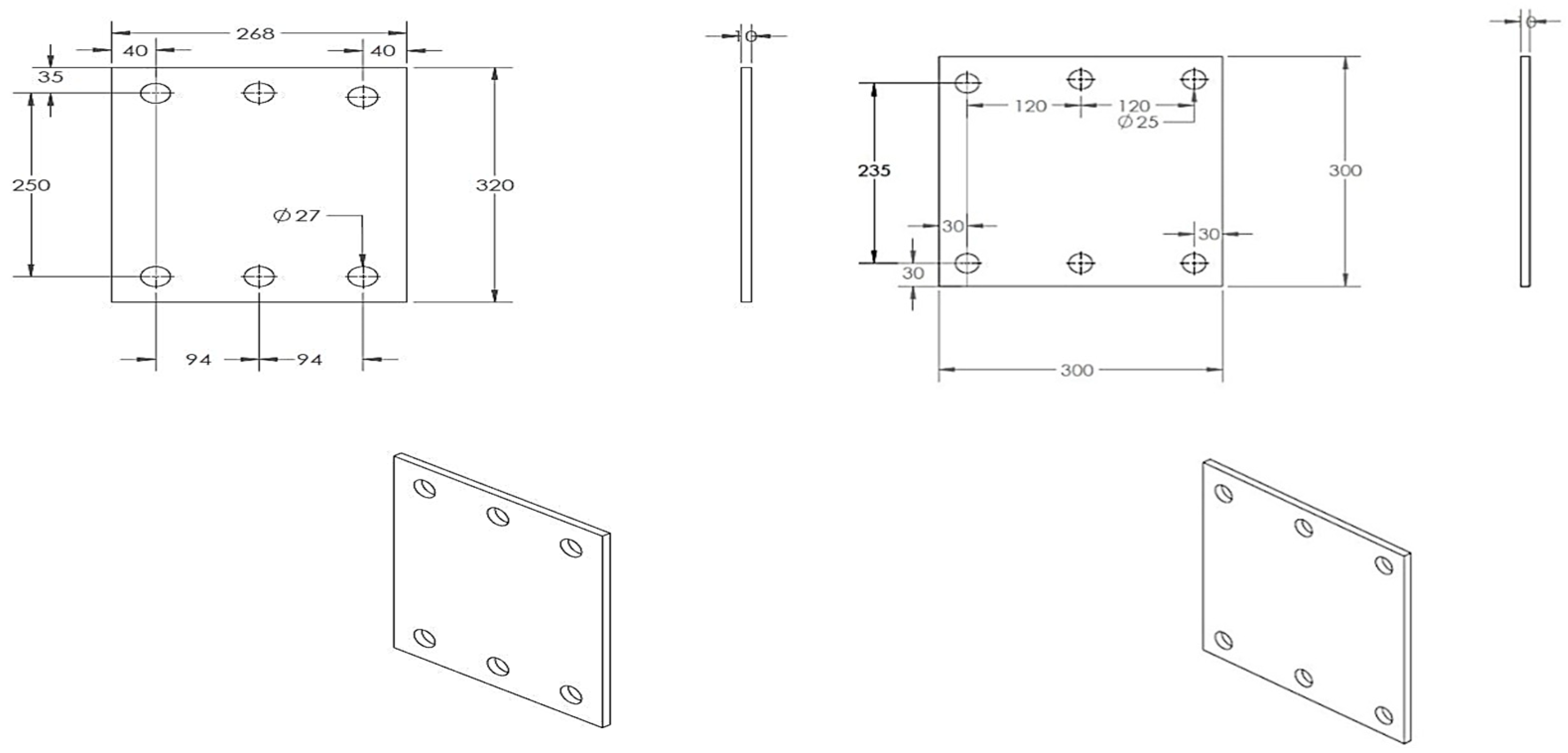

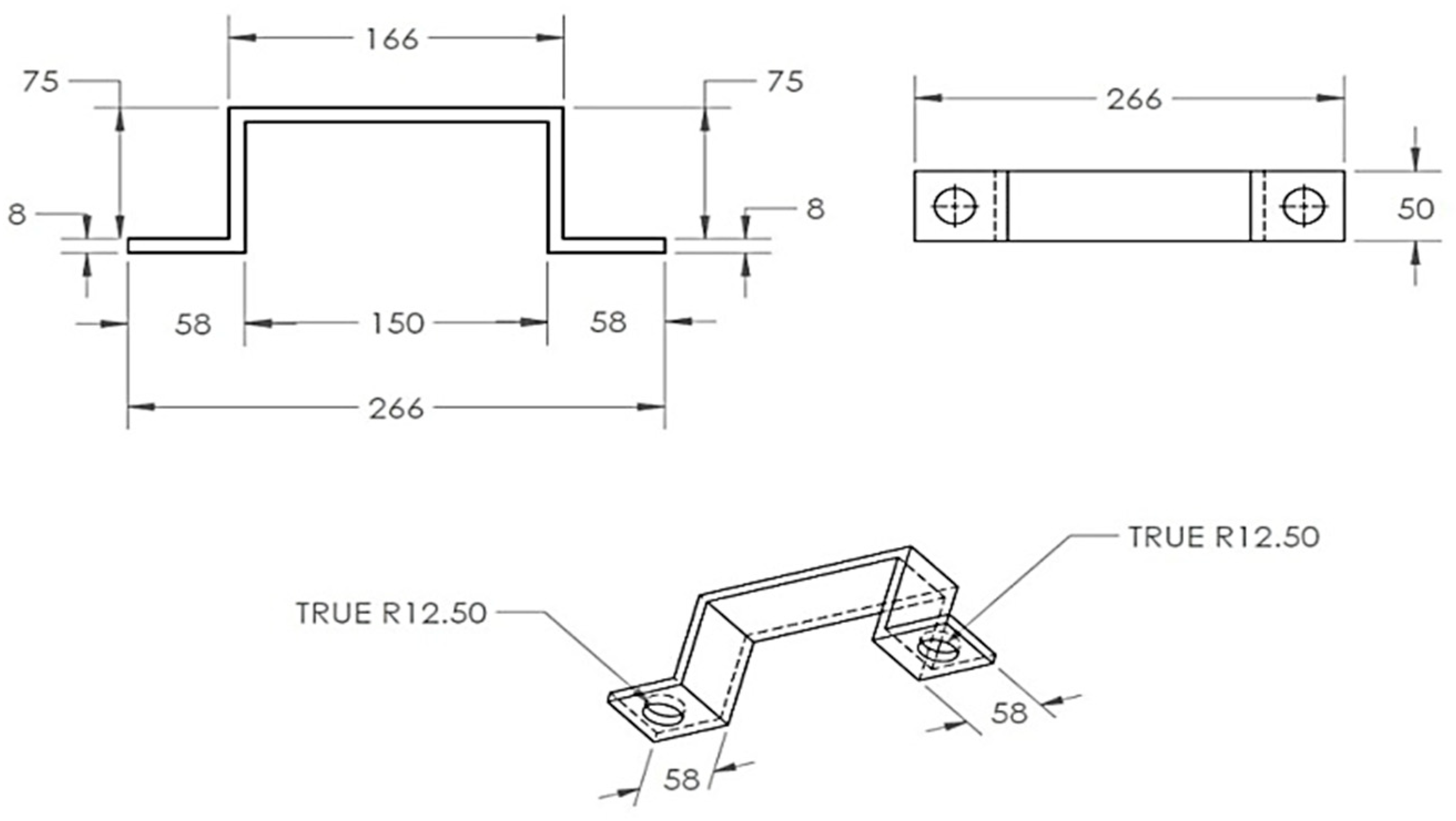

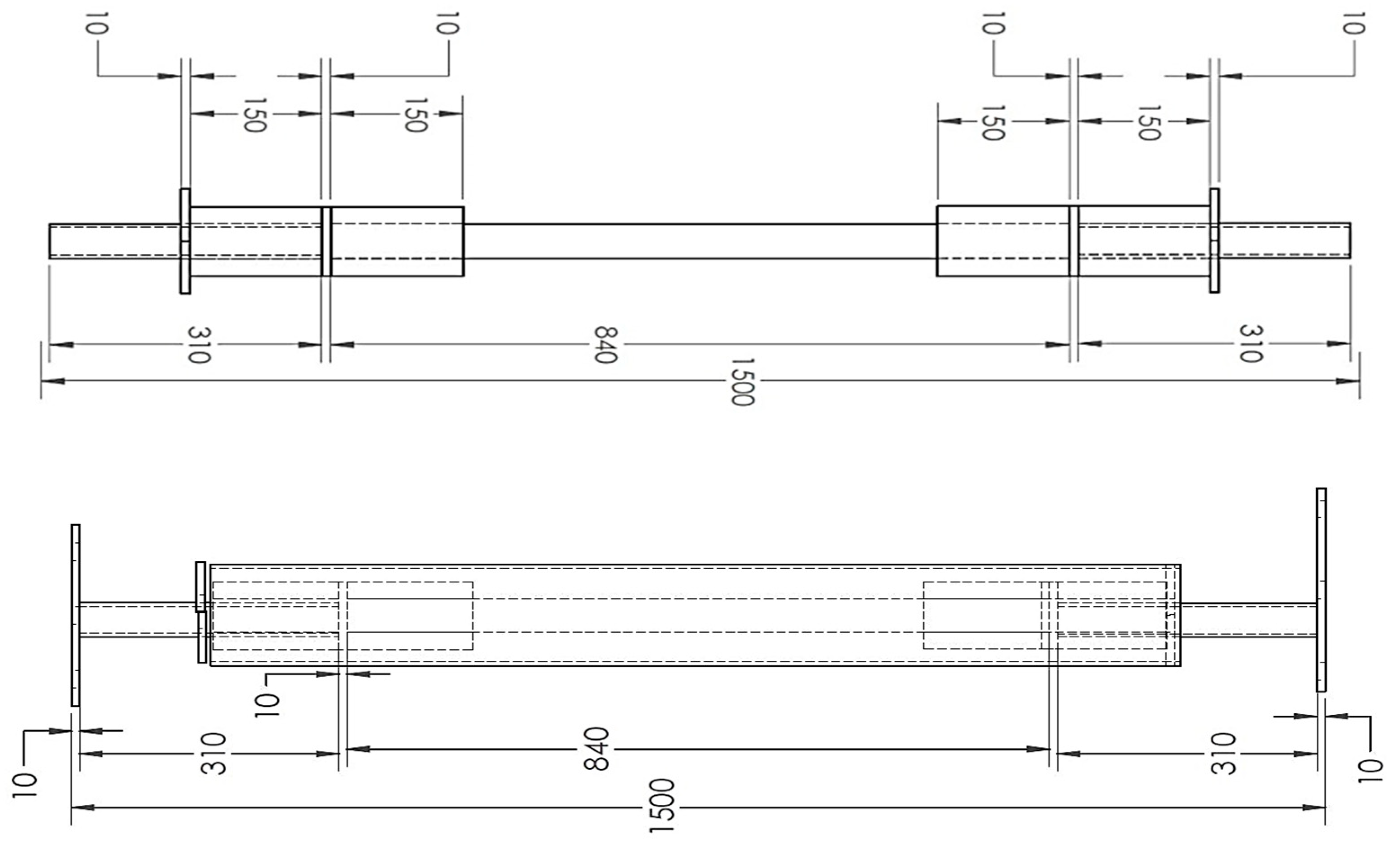

2.1. BRB Geometric Modeling

2.2. Material Properties

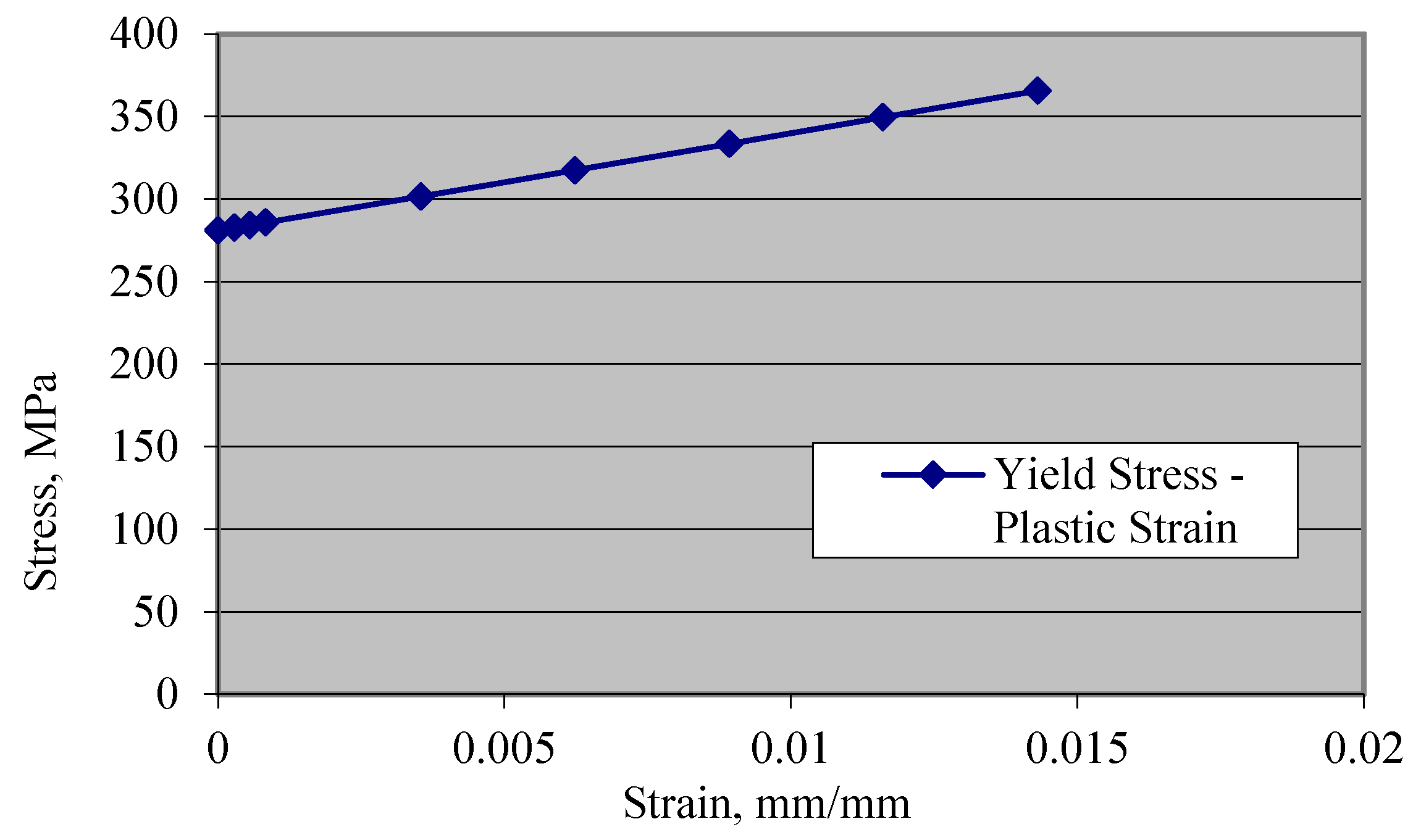

2.2.1. Steel Material Properties

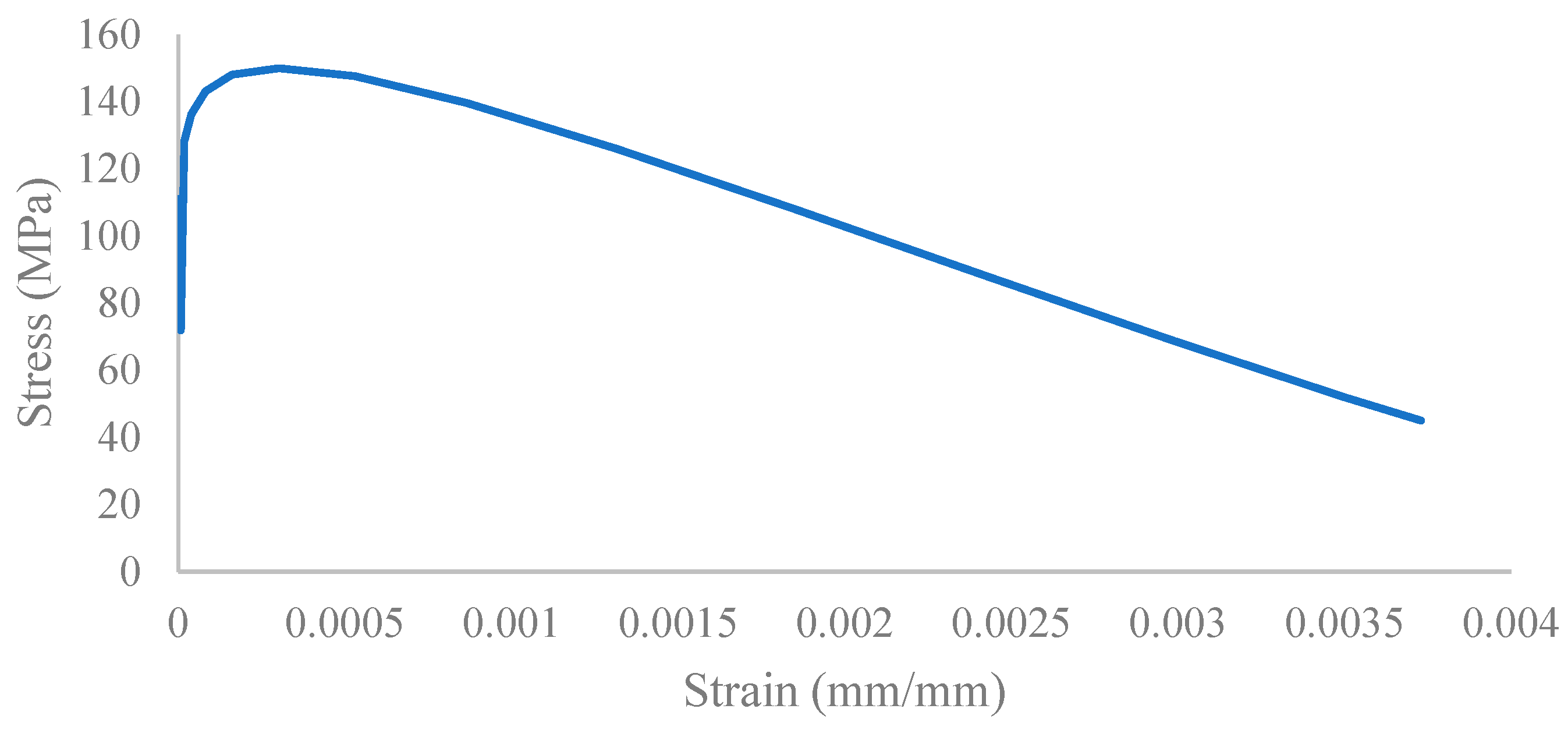

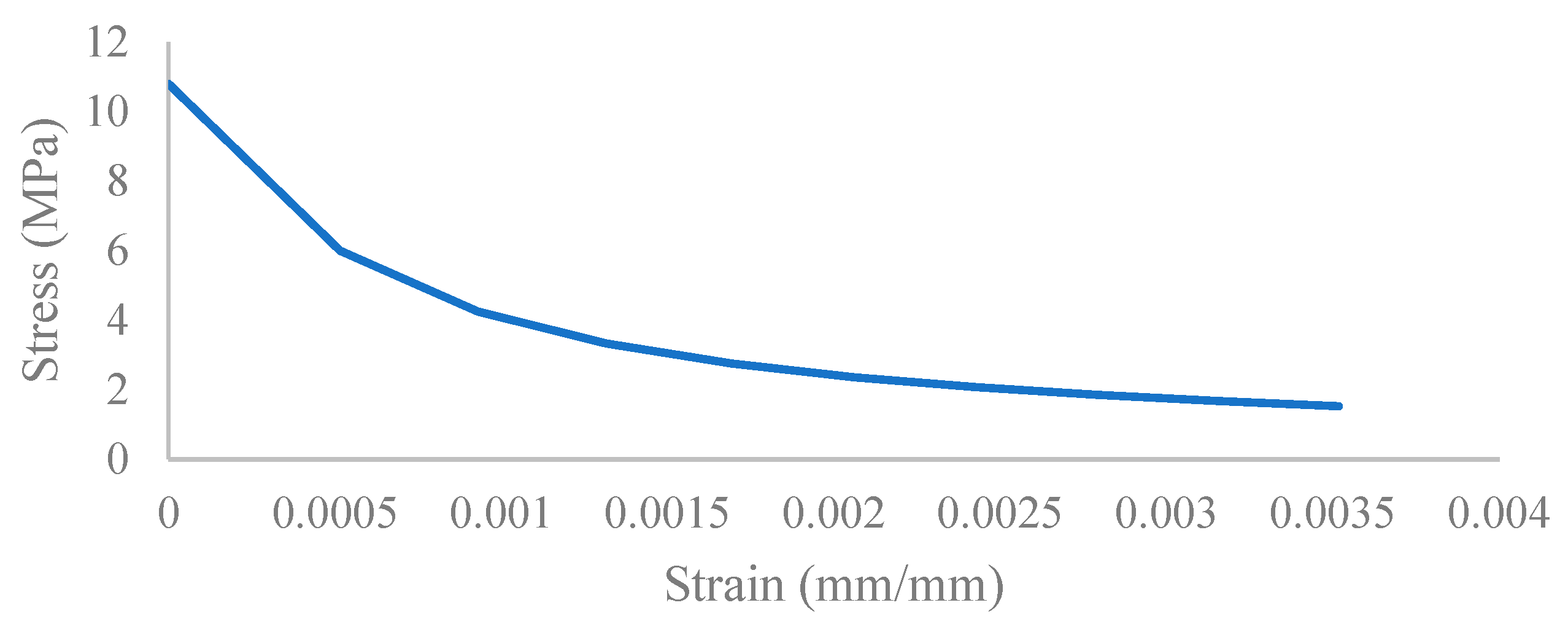

2.2.2. Concrete Material Properties

Ultra-High-Performance Fiber-Reinforced Concrete

Conventional Concrete

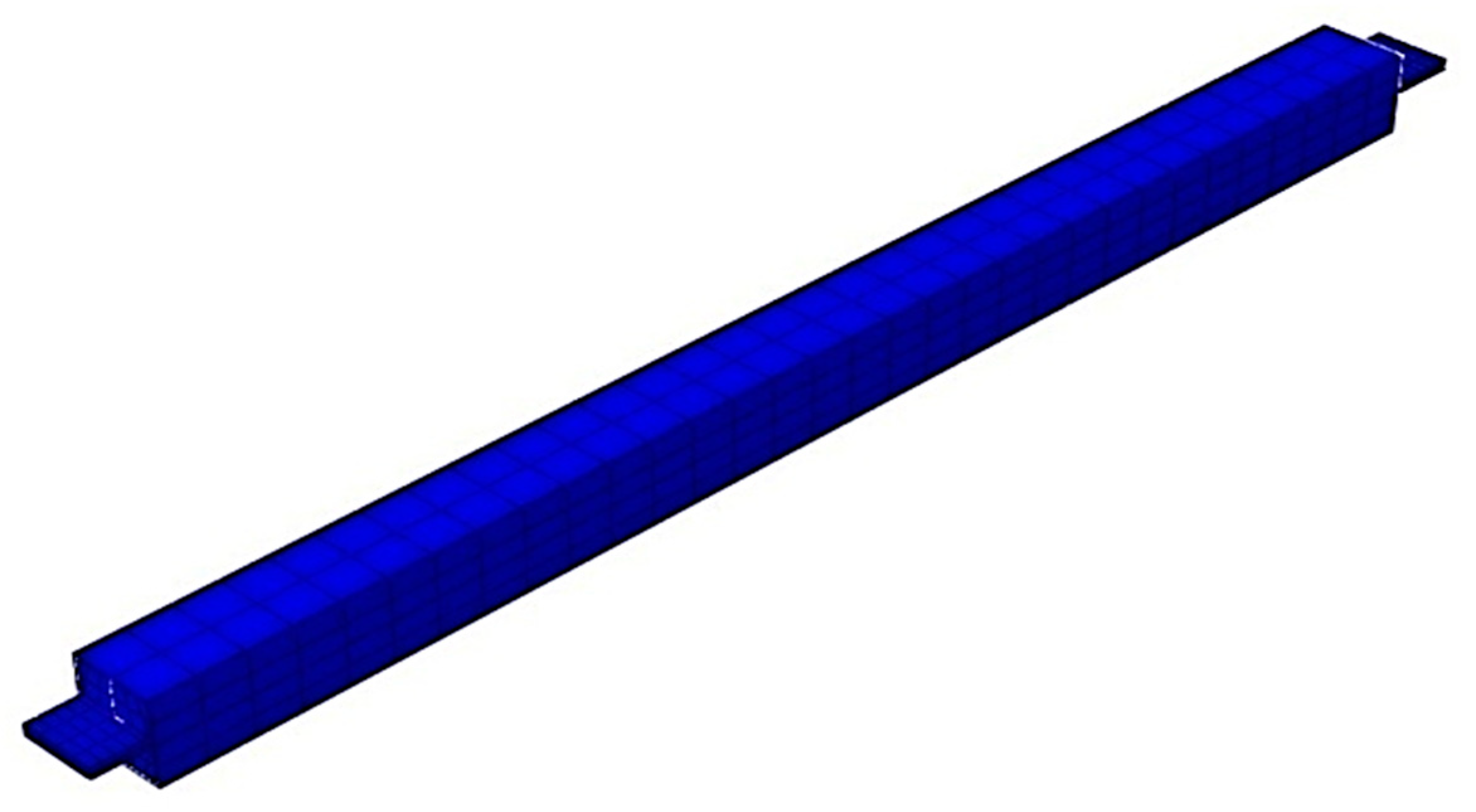

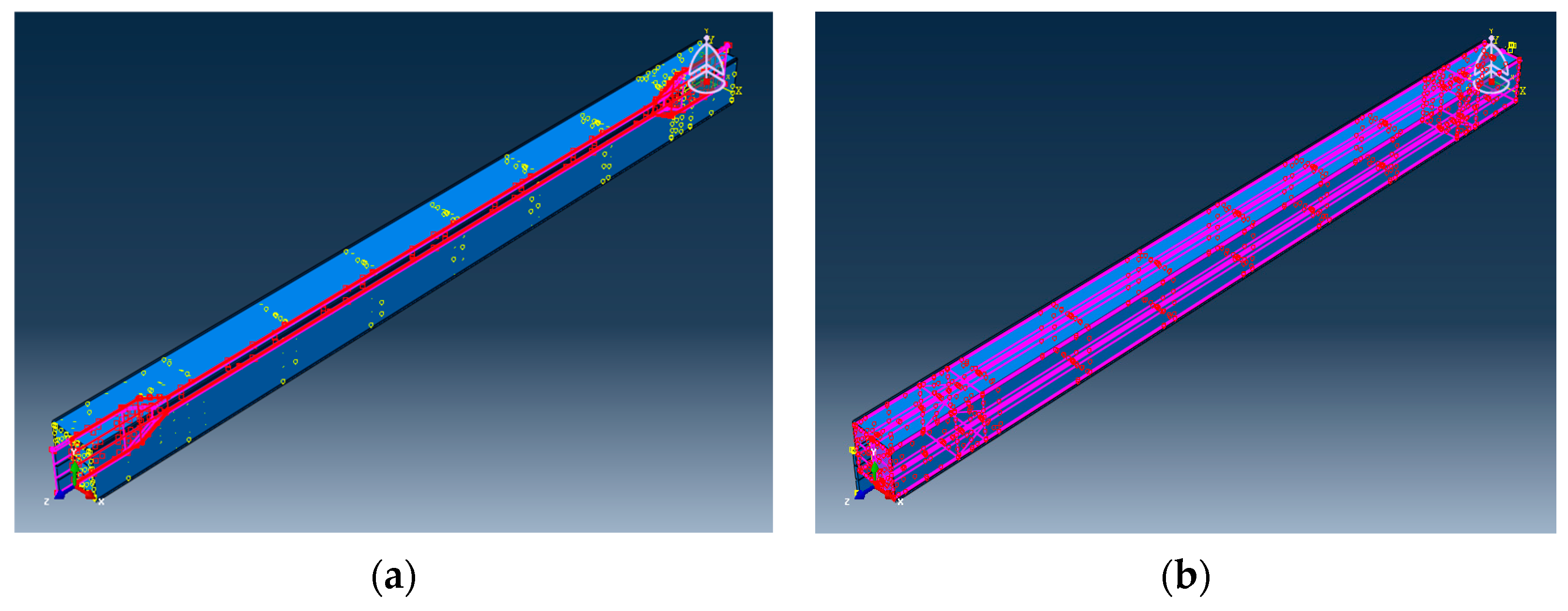

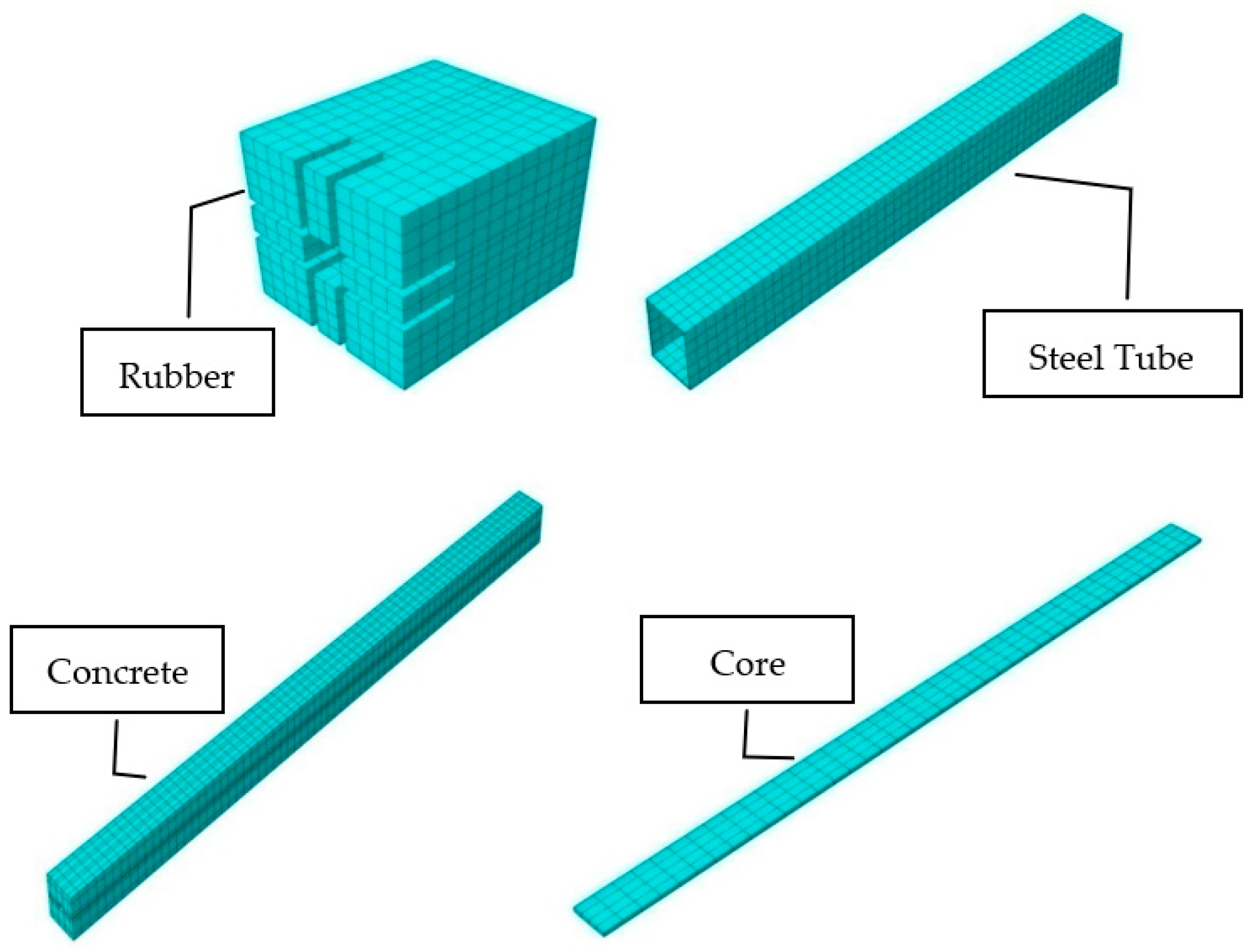

2.3. BRB Meshing Model

2.4. BRB Contact Modeling

2.5. BRB Boundary Condition and Location

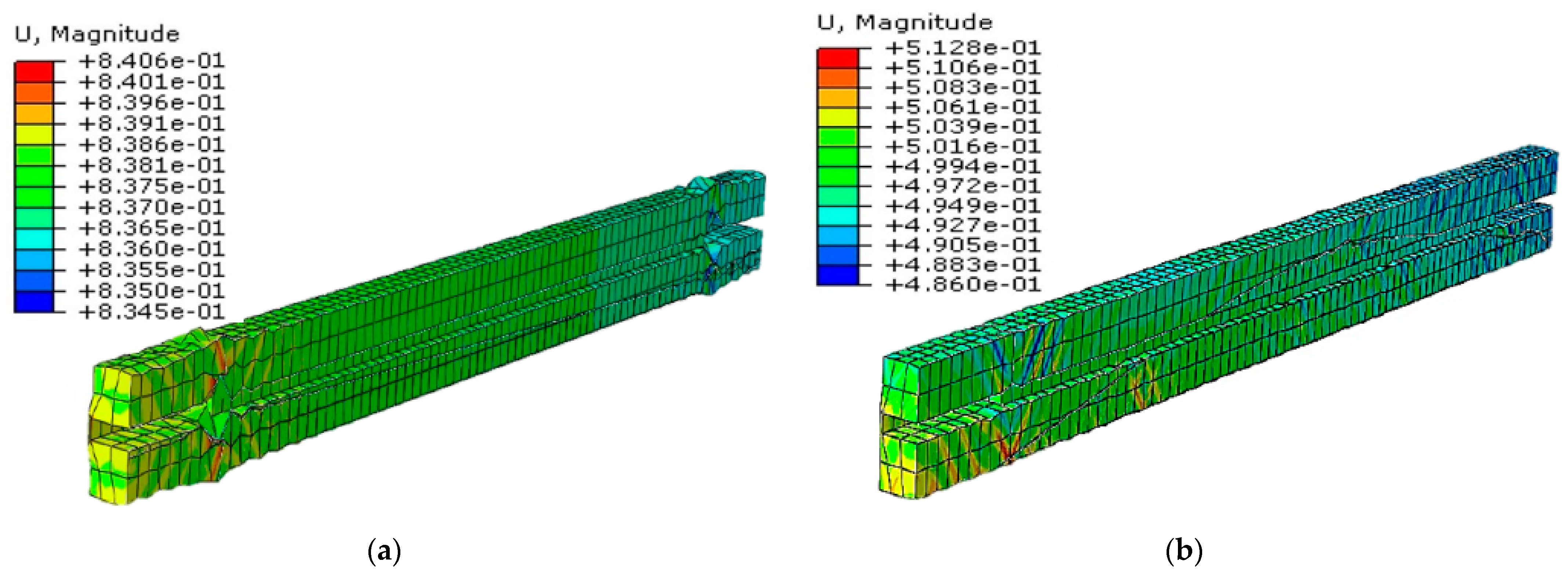

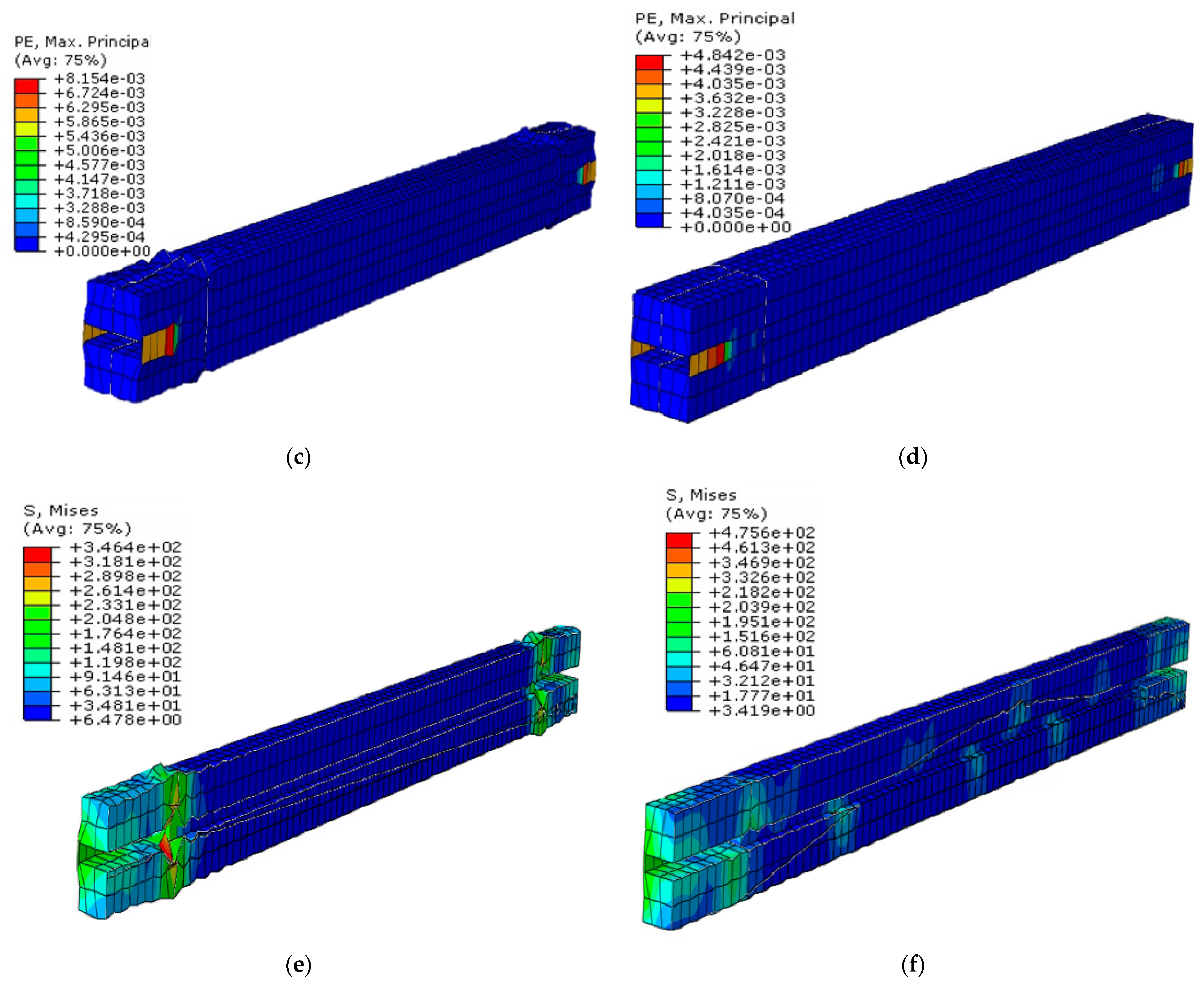

3. Finite Element Analysis Results for UHPFRC and Conventional Concrete Filler

3.1. BRB Hysteretic Response Result for UHPFRC and Conventional Concrete Filler

3.2. Concrete Compressive Strength Effect on BRB Performance

4. Experimental Test of BRB with UHPFRC Concrete

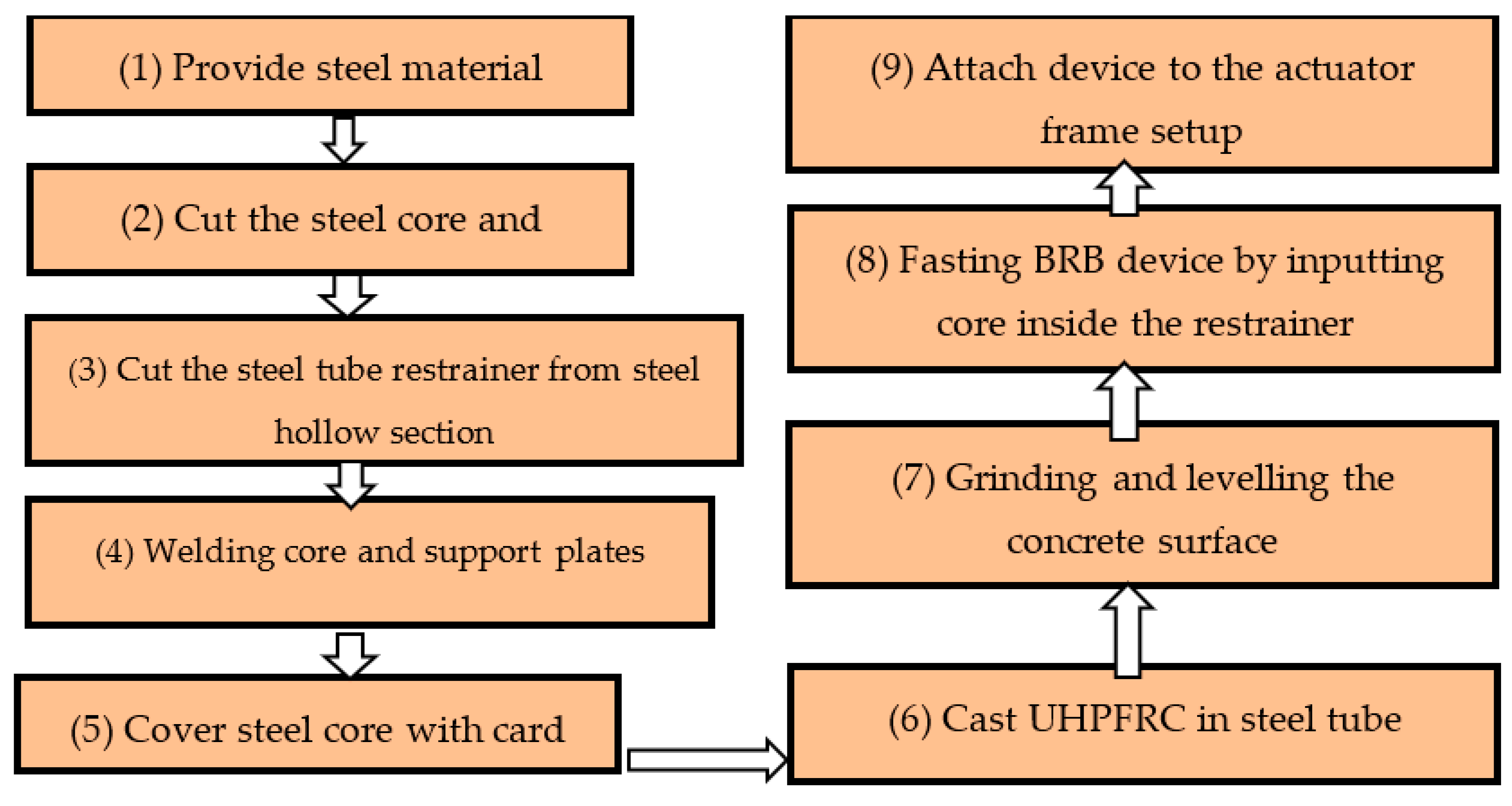

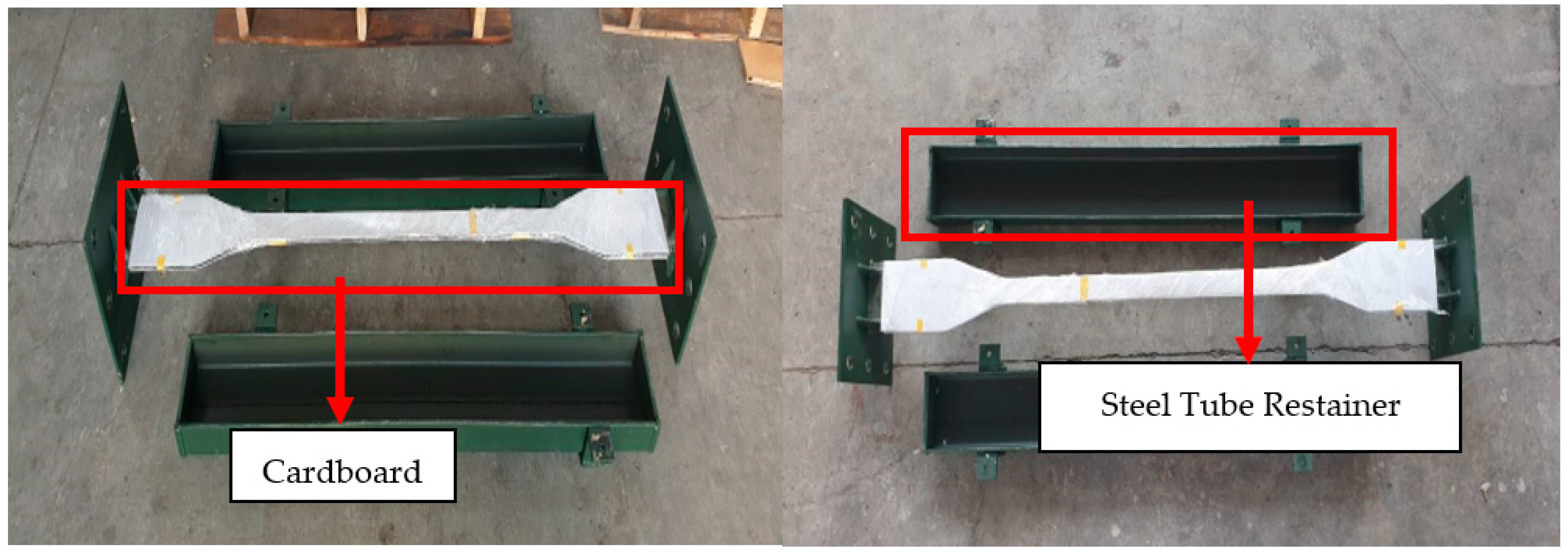

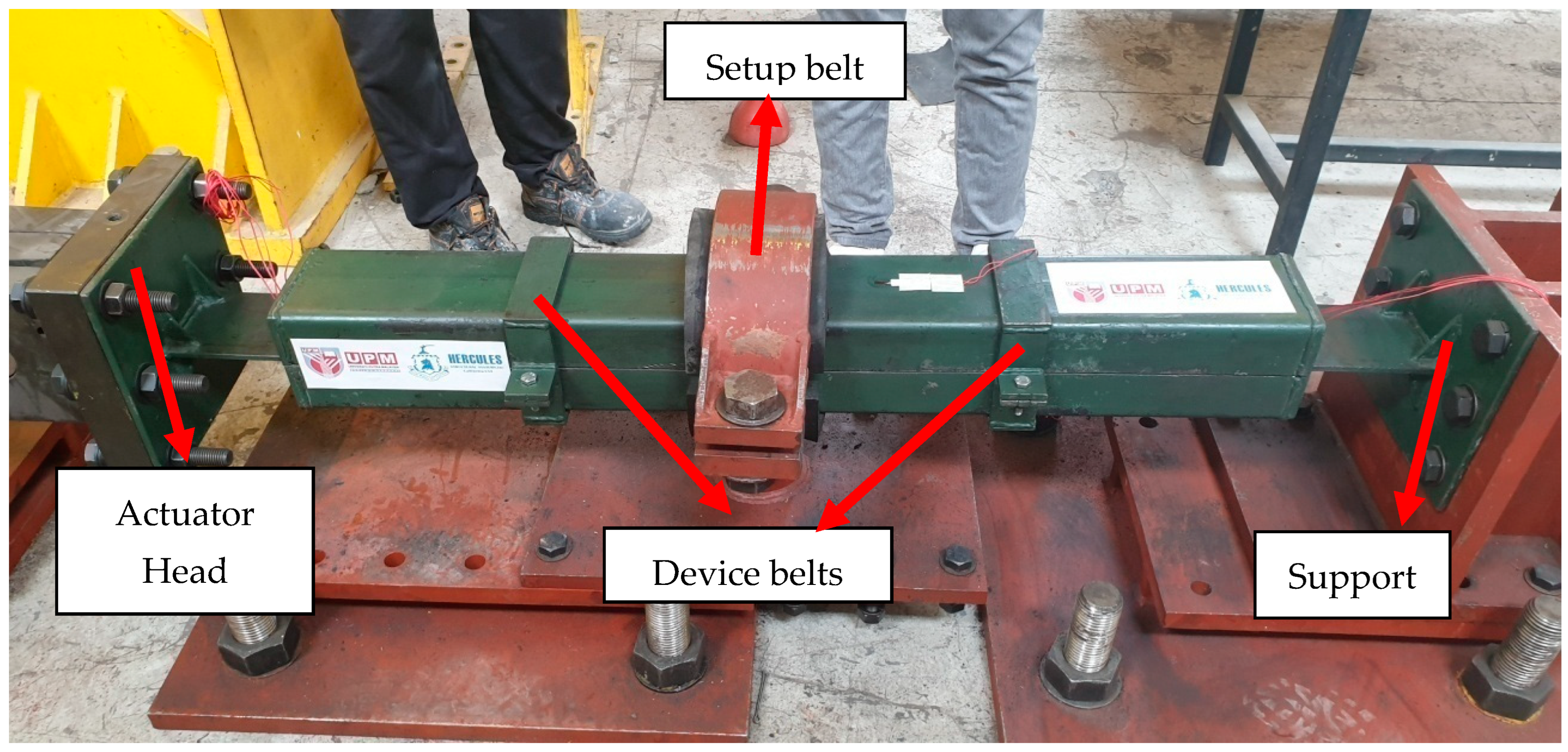

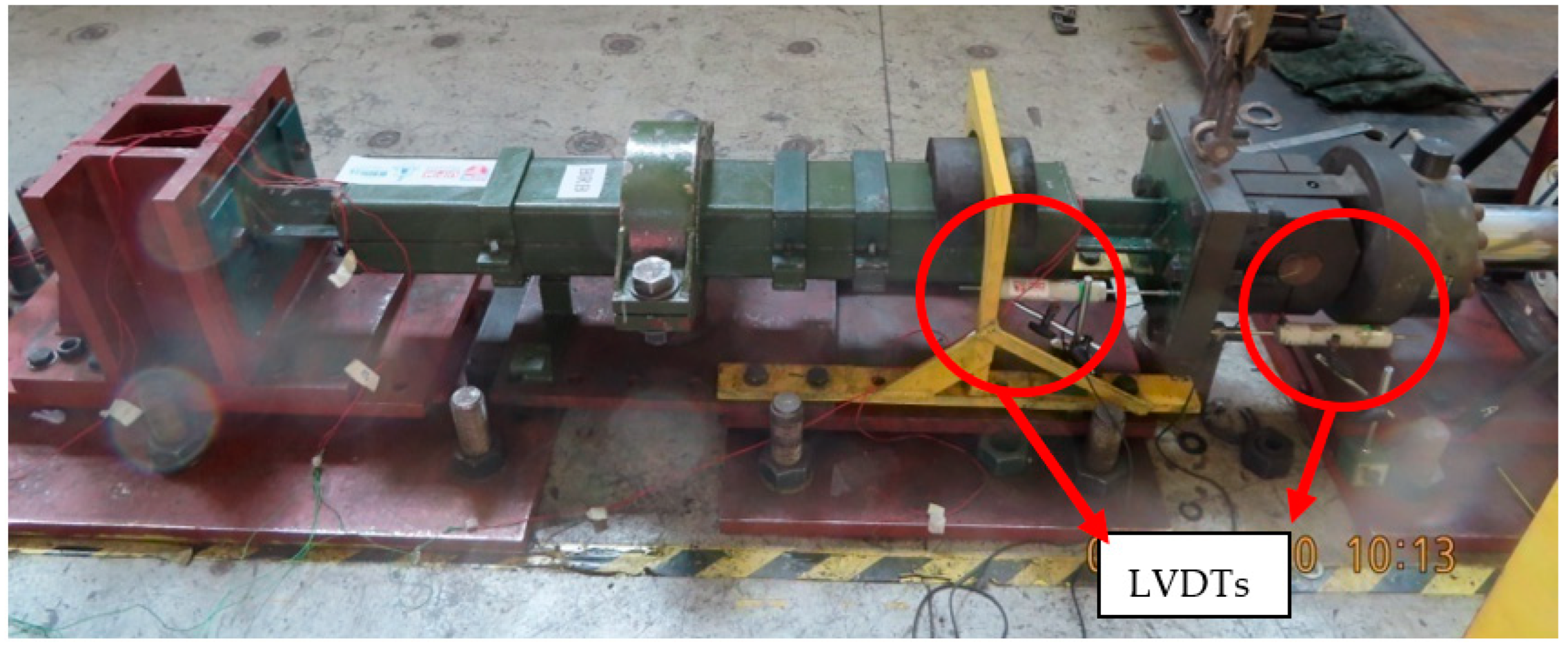

4.1. BRB Fabrication Procedure

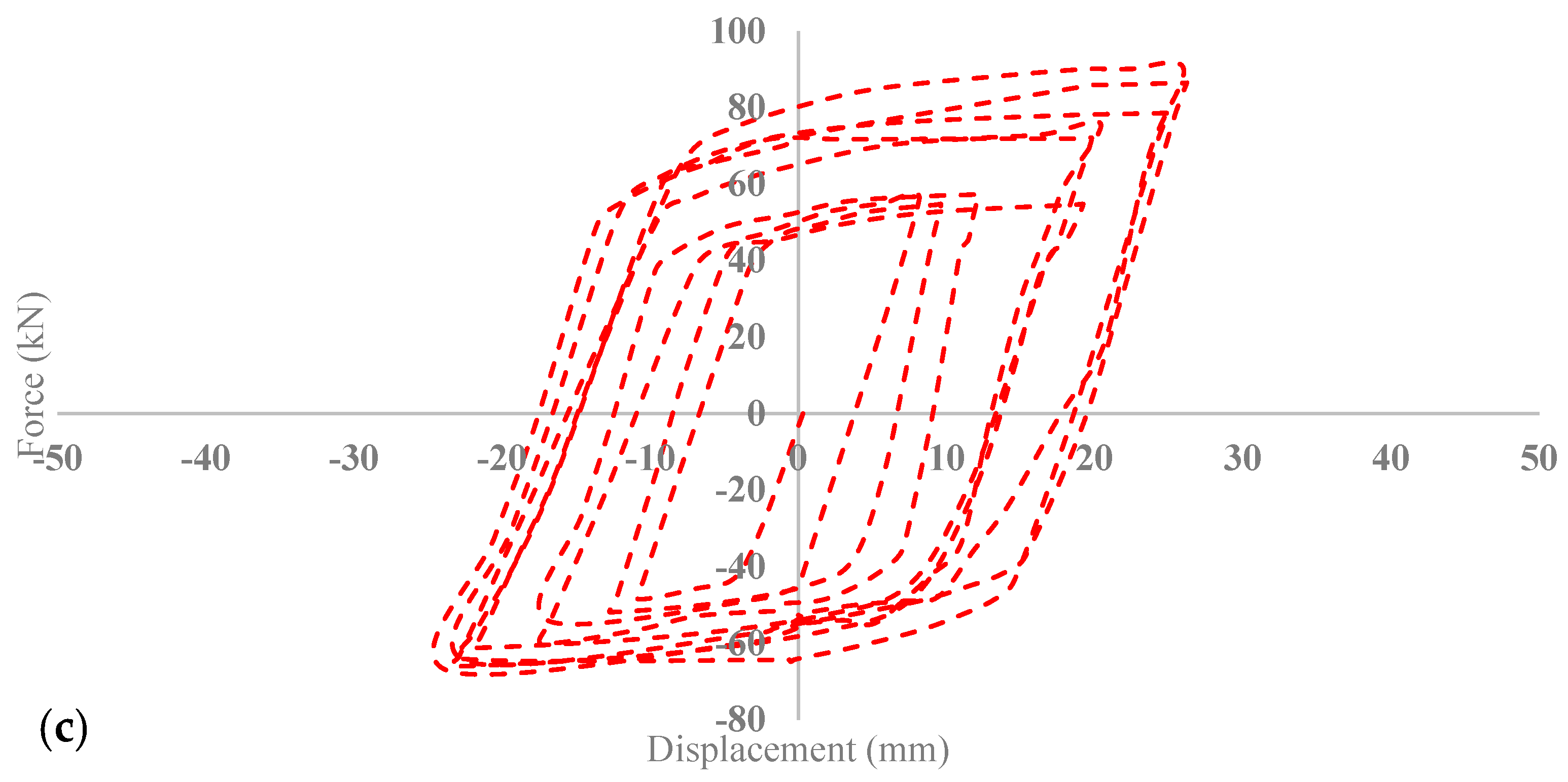

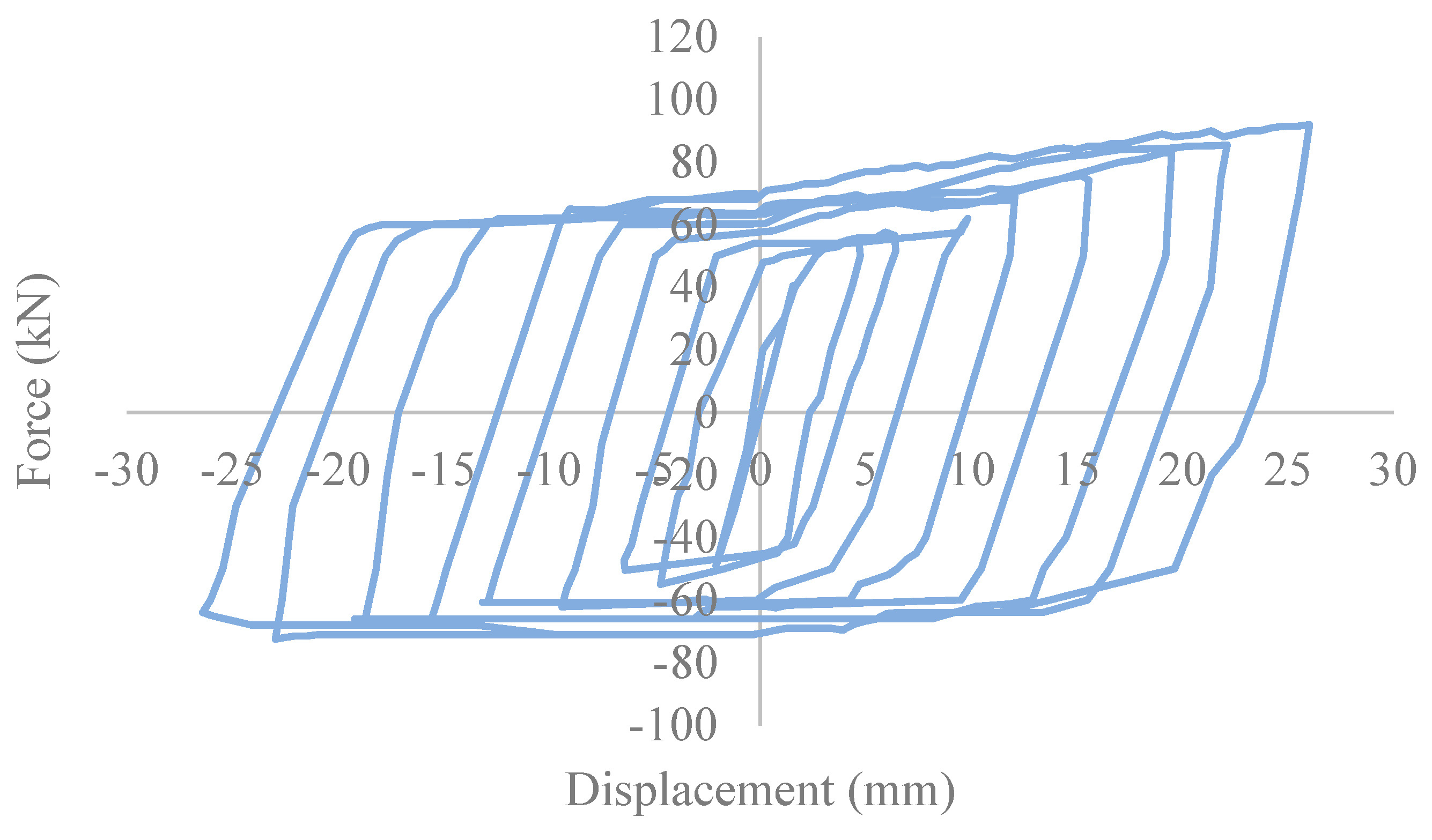

4.2. BRB Experimental Testing Results

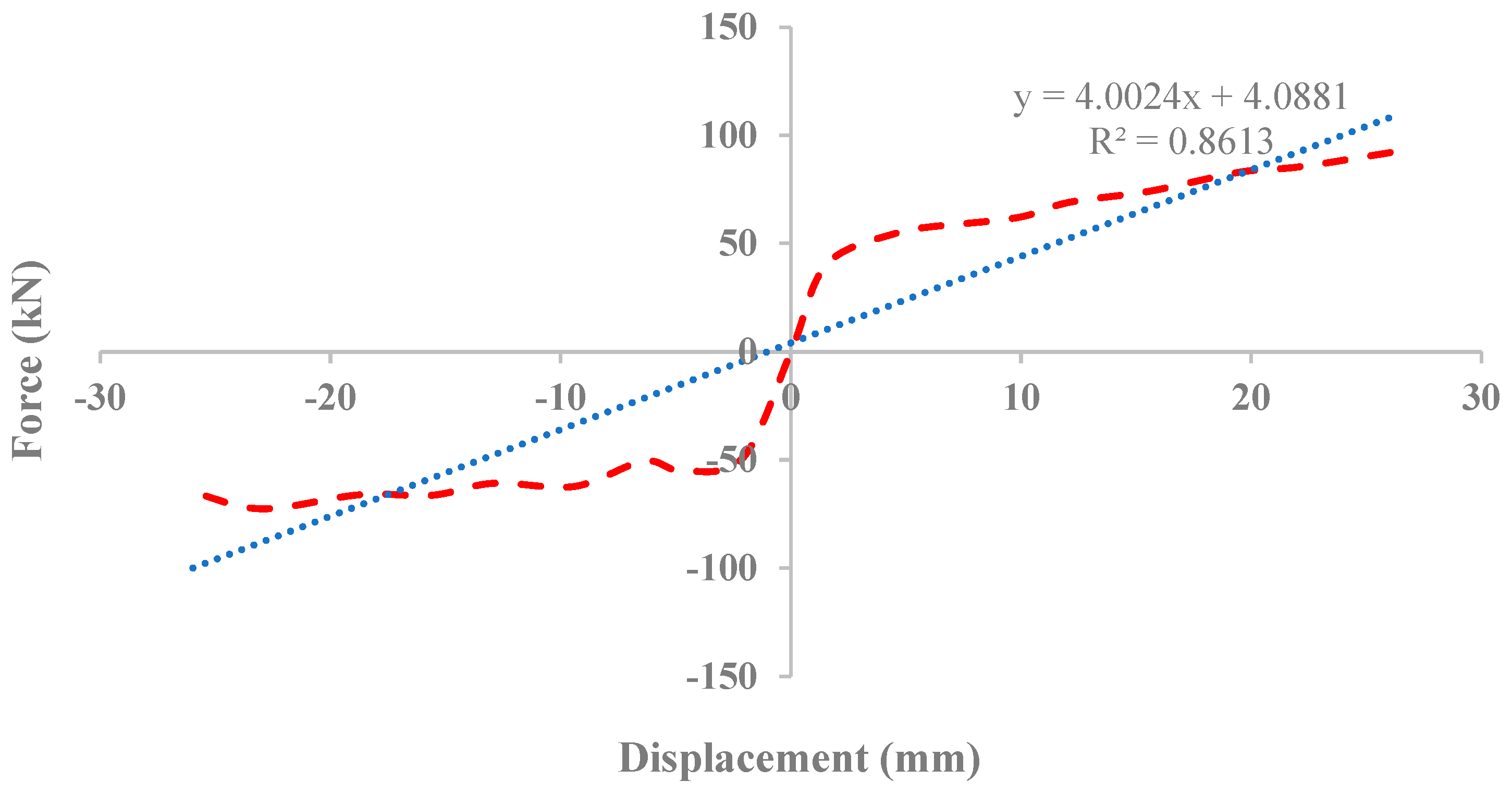

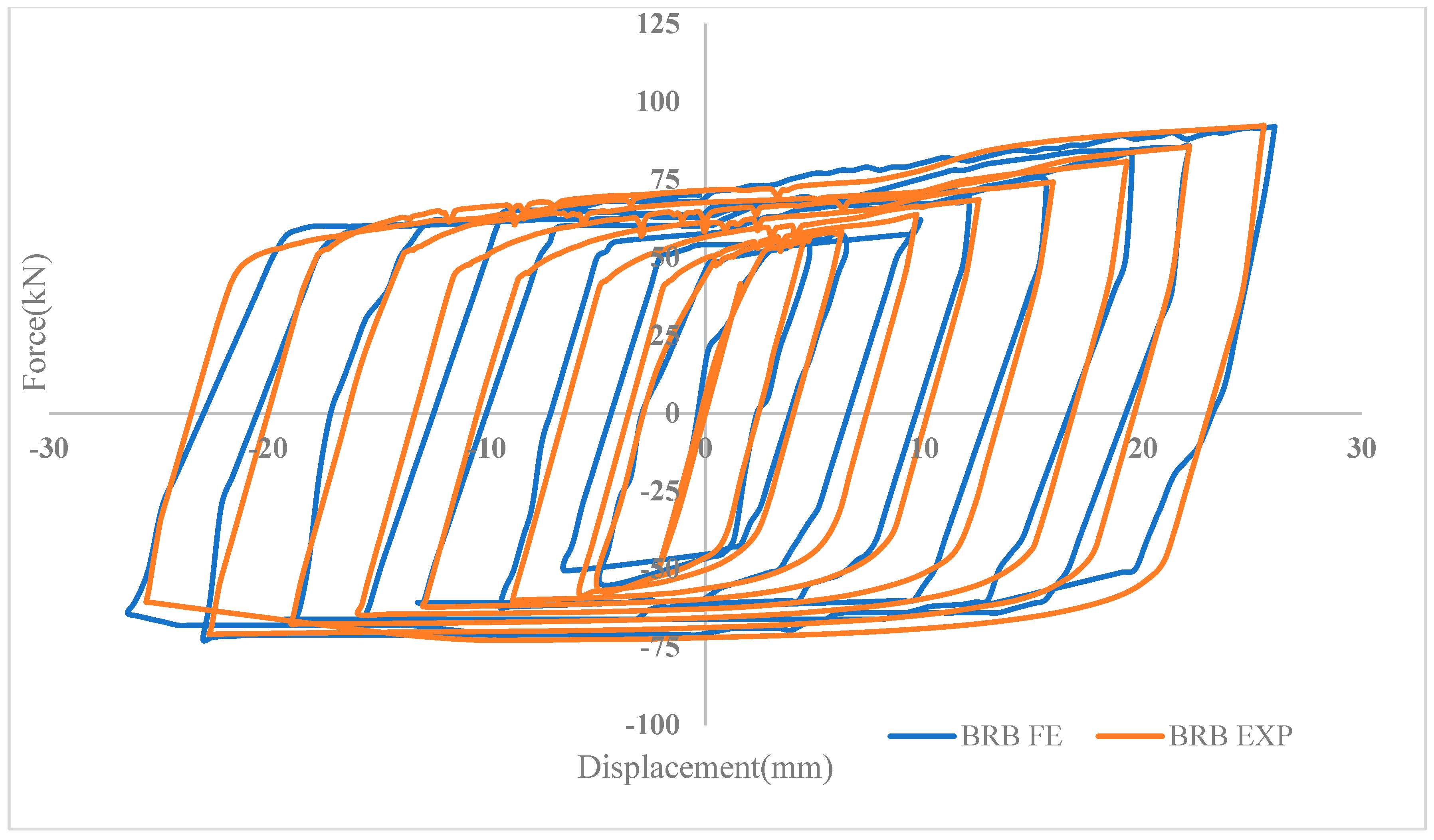

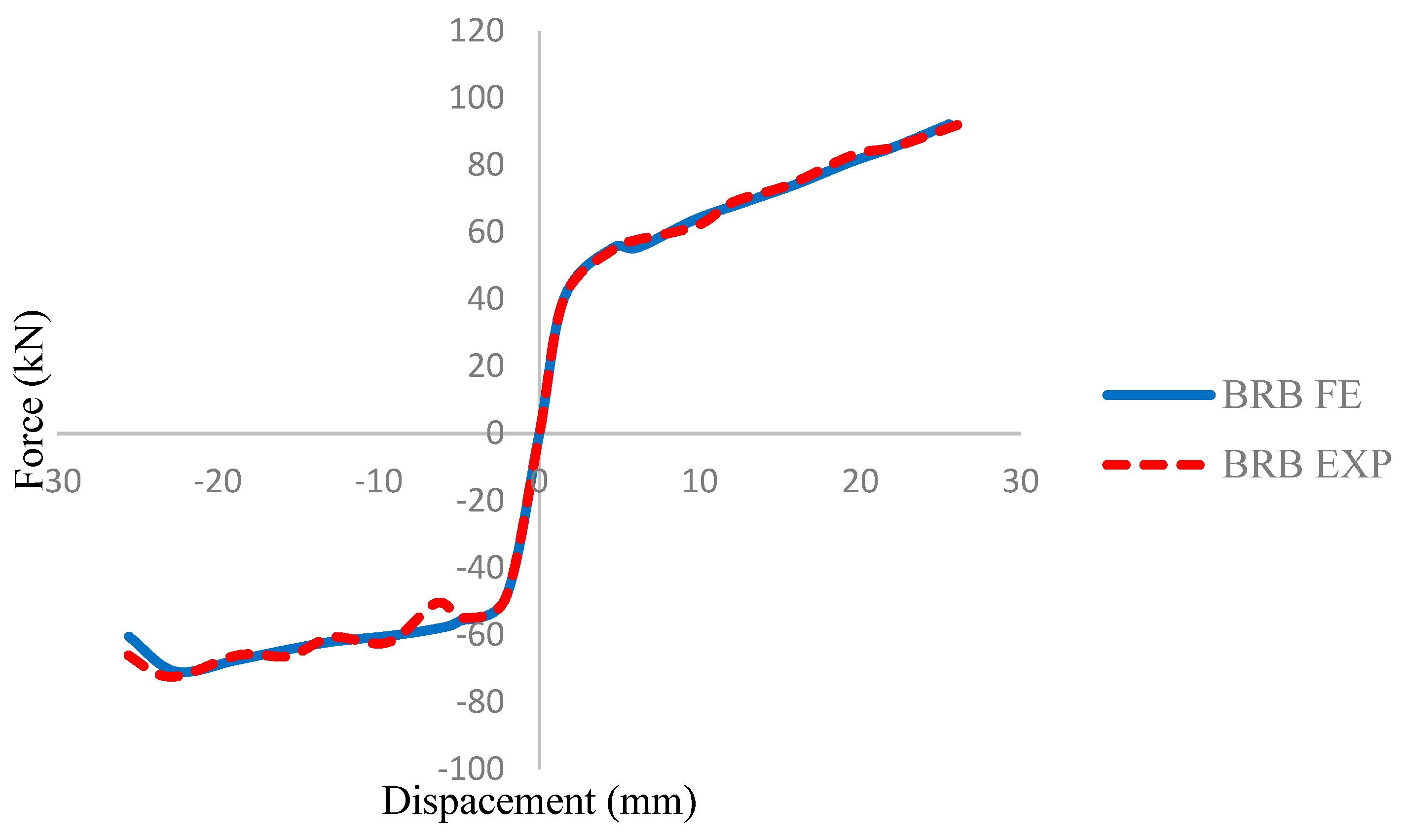

5. Validation of Experimental and FEA Result for BRB

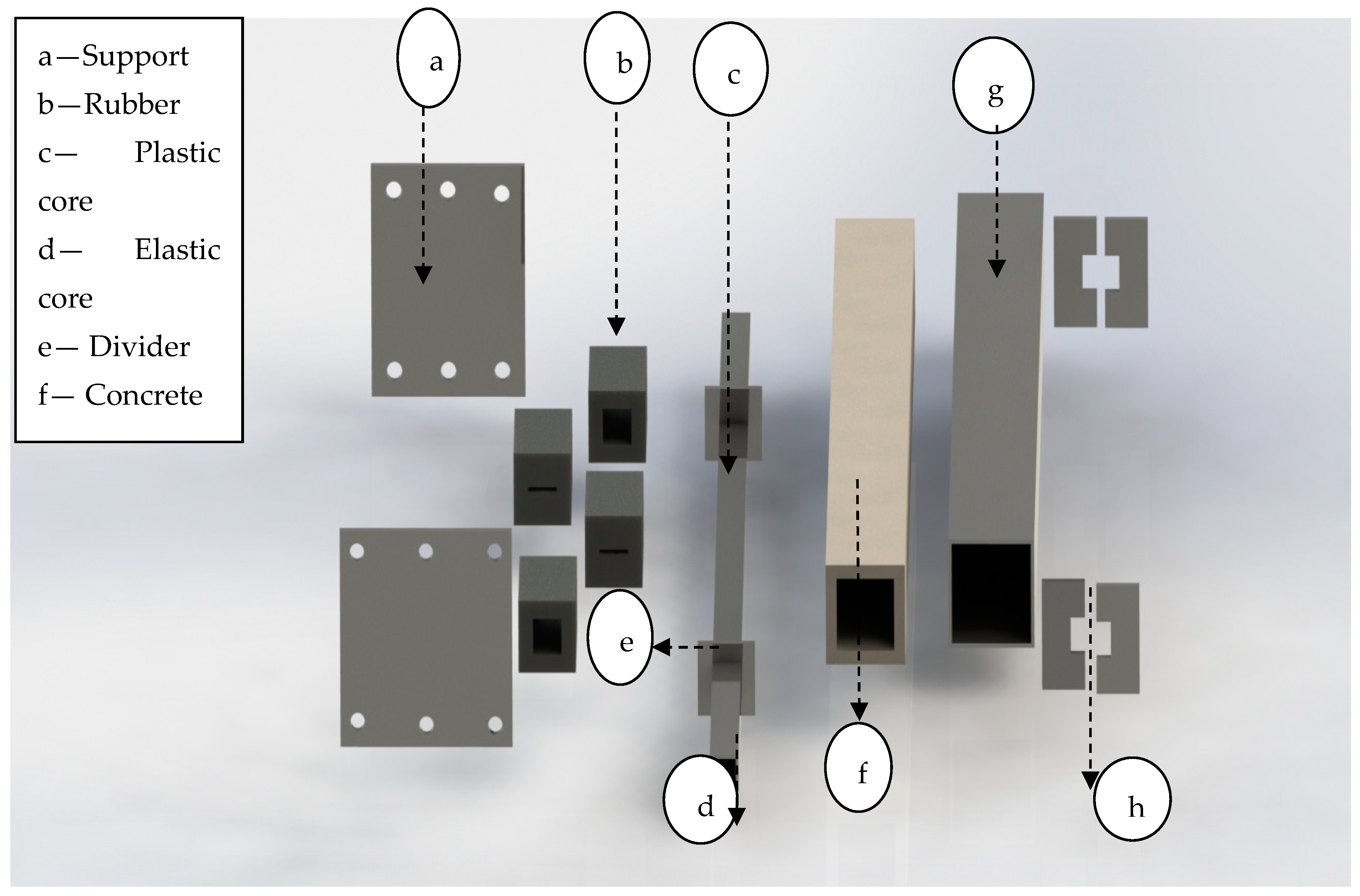

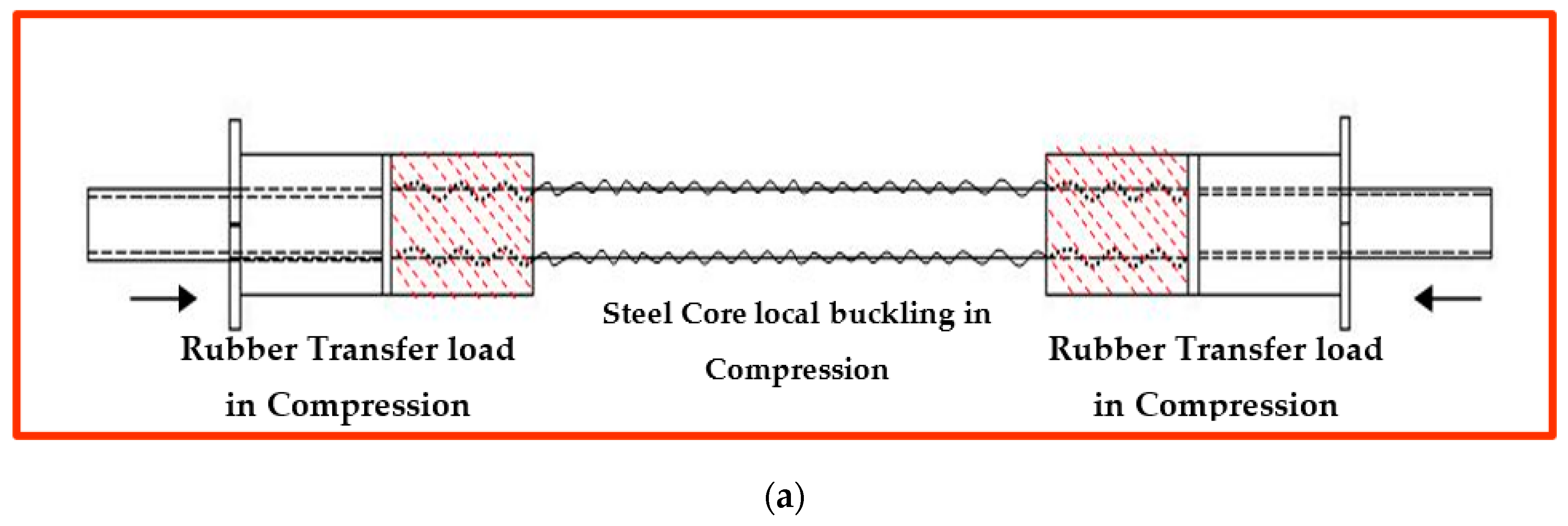

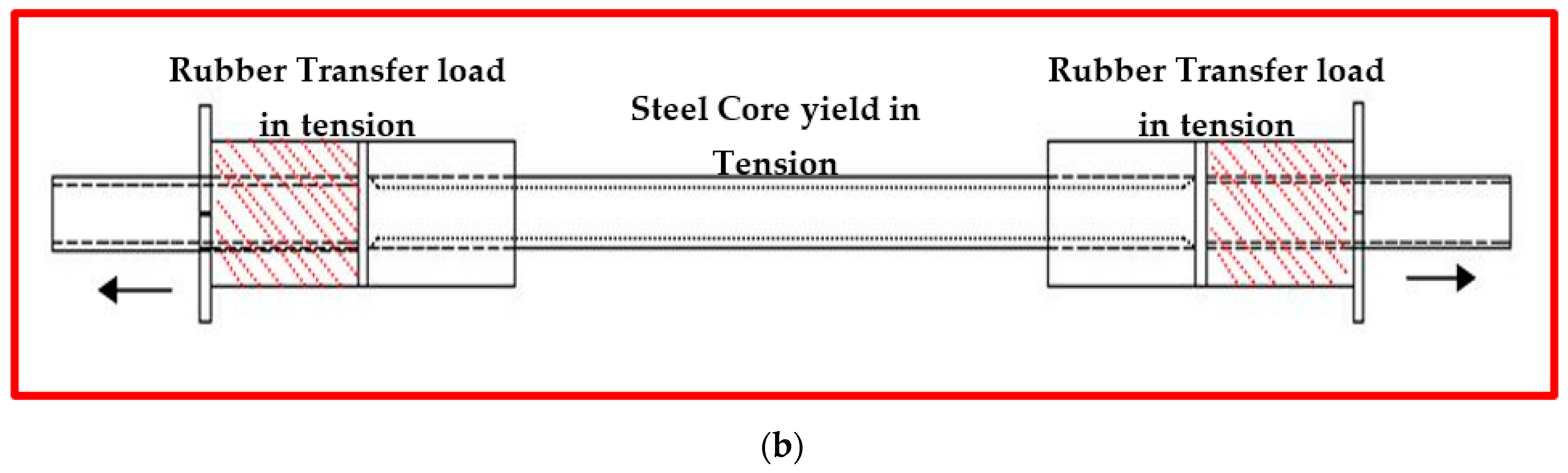

6. Proposed Design of Rubber Buckling Restrained Brace (RBRB)

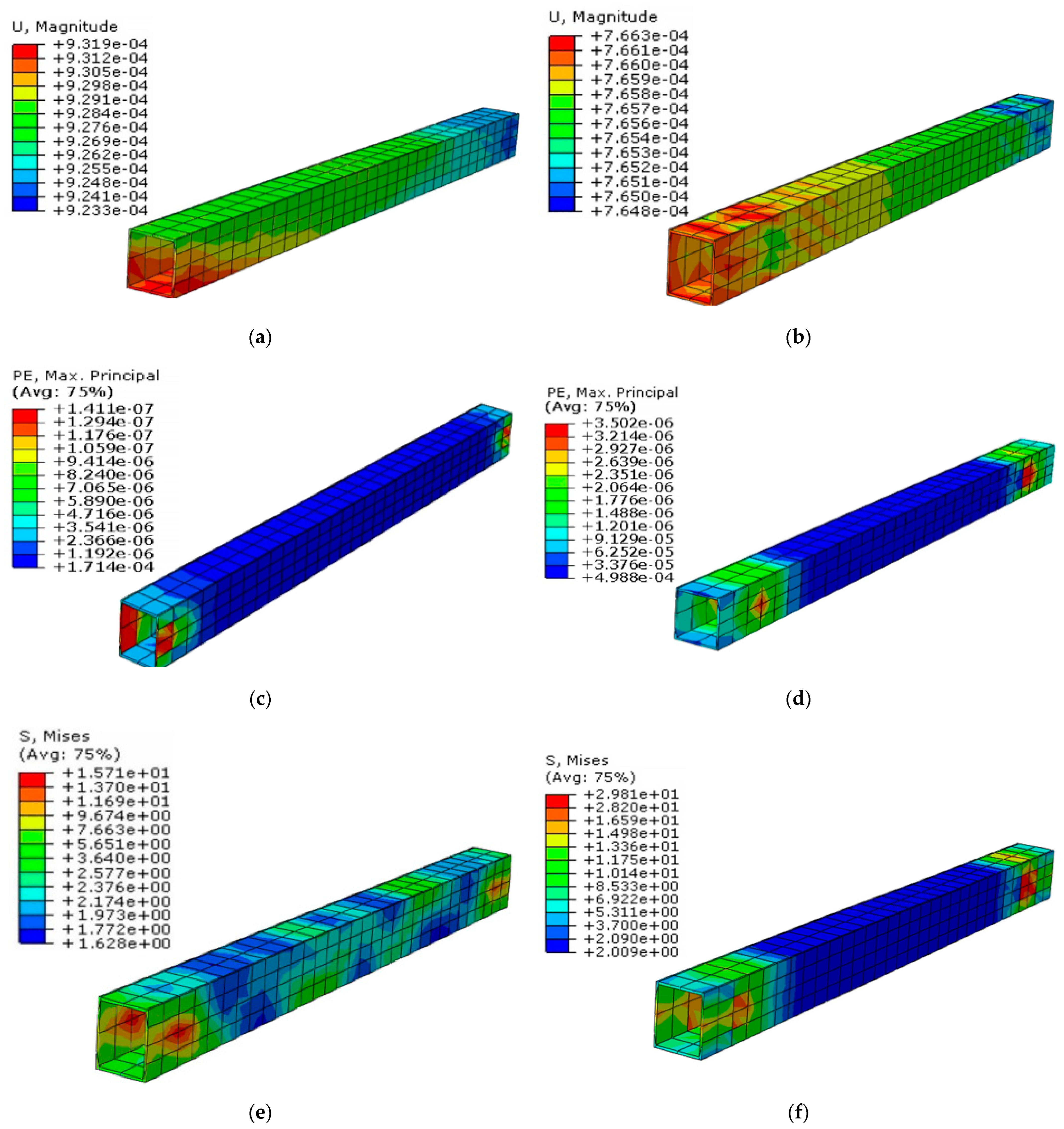

6.1. Investigation of RBRB by Performing FE Simulation

6.1.1. RBRB Material Properties

6.1.2. RBRB Meshing Model

6.1.3. RBRB Contact Modeling

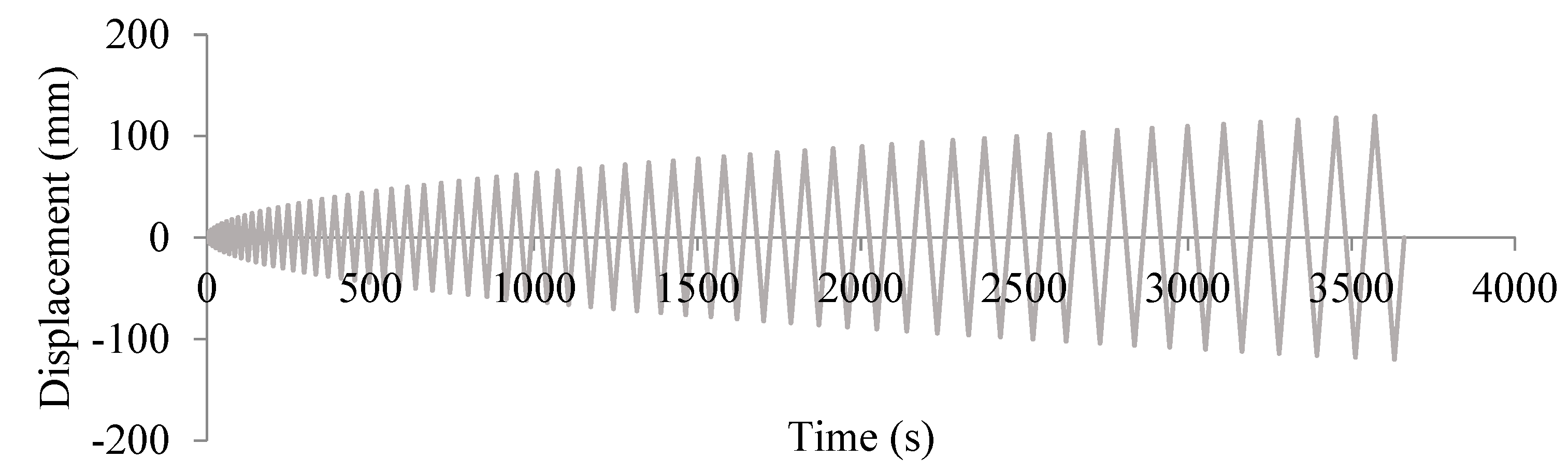

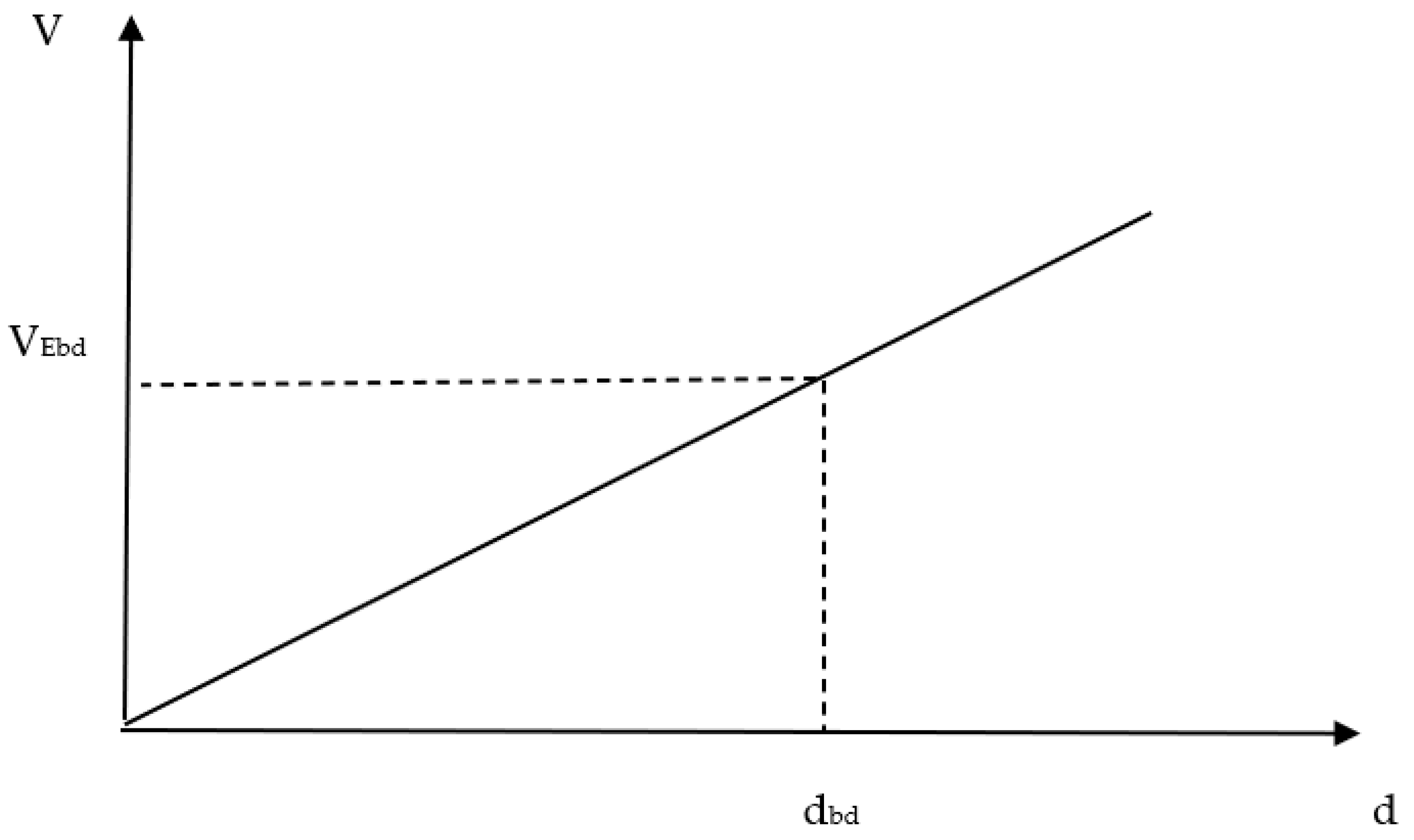

6.1.4. RBRB Boundary Condition and Loading

7. BRB and RBRB Numerical Analysis Results Comparison

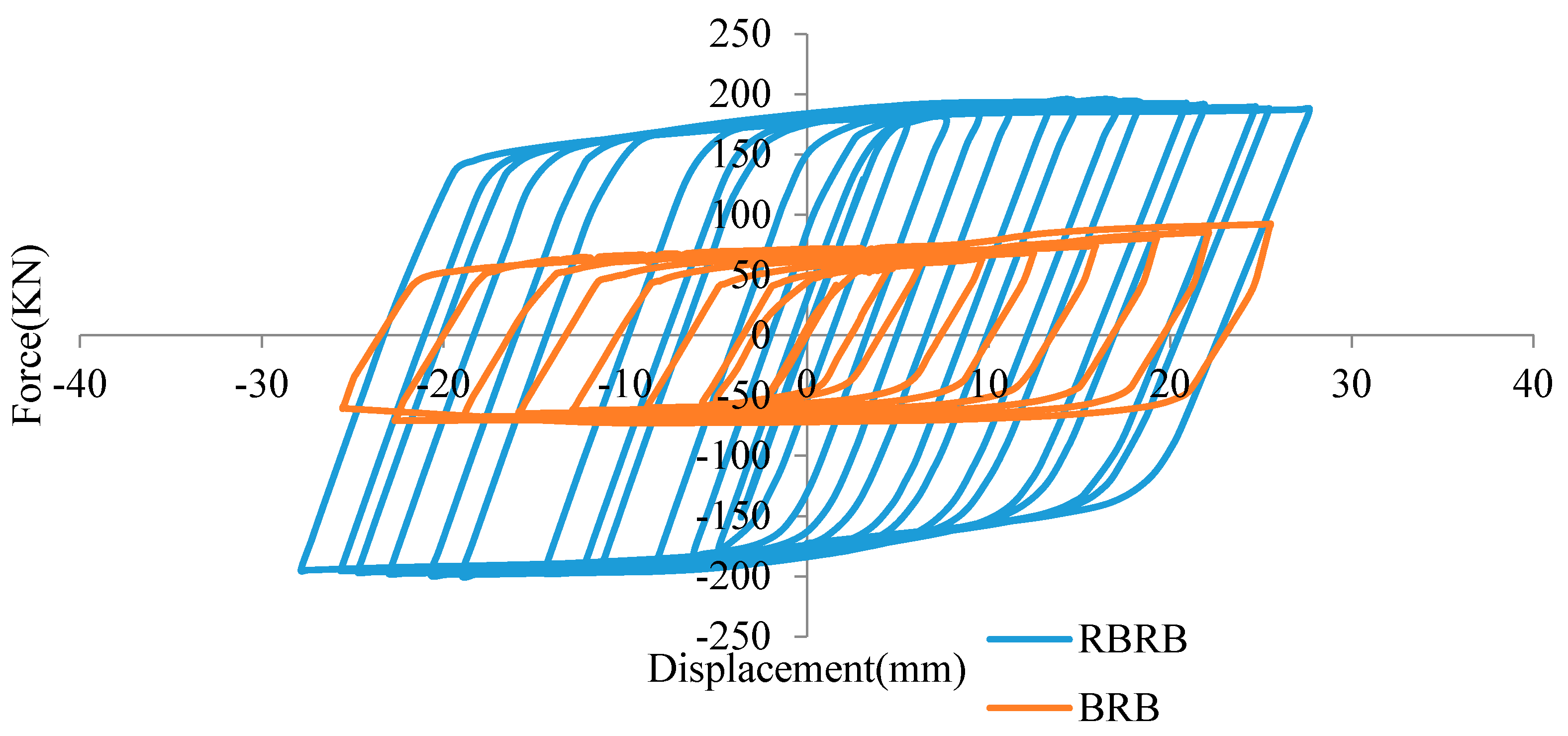

BRB and RBRB Performance Comparison

8. Recommendations for Future Works

- Impose other types of sustainable concrete such as fly ash, PVA fiber, MgO and shrinkage-reducing admixture in a BRB system and checking their effect on the performance.

- Determine the influences of MgO and PVA fiber on the abrasion and cracking resistance.

- Constitutive models can be carried out on the RBRB device to make a comprehensive formulation for utilization in FE software.

- Change the performance of the RBRB by imposing different rubber materials with various hardness.

- Determine the effect of implementing the RBRB device on structural elements such as connections, joints and gusset plates.

9. Conclusions

- The numerical comparison between a BRB filled with conventional concrete and one filled with UHPFRC concrete shows the advantages of using UHPFRC to increase stress and resistance force. Moreover, the finite element results indicated significant agreement with the experimental test.

- It is revealed that using concrete with higher compressive strength results in an increase in resistance force and improves the confinement.

- The results of the parametric study indicate that the effect of the concrete compressive strength exceeding 50 MPa on the BRB performance is negligible, and it may not justify the use of concrete with very high compressive strengths due to the associated costs.

- The results of the study indicate that the proposed RBRB has the ability to enhance the conventional BRB performance by increasing the resistance force caused through the addition of rubber components.

- Based on numerical results, the proposed RBRB is capable of dissipating more energy due to the greater hysteresis curve resulting from the added resistance of rubber component inserted inside the RBRB device.

- The results demonstrate that the RBRB has the capability to overcome the drawbacks of conventional BRB systems and improve the structure’s resistance against the adverse effects of seismic hazards.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skinner, R.I.; Kelly, J.M.; Heine, A.J. Hysteretic dampers for earthquake-resistant structures. Earthq. Eng. Struct. Dyn. 1974, 3, 287–296. [Google Scholar] [CrossRef]

- Nabid, N.; Hajirasouliha, I.; Petkovski, M. Performance-based optimisation of RC frames with friction wall dampers using a low-cost optimisation method. Bull. Earthq. Eng. 2018, 16, 5017–5040. [Google Scholar] [CrossRef]

- Hajirasouliha, I.; Pilakoutas, K. General Seismic Load Distribution for Optimum Performance-Based Design of Shear-Buildings. J. Earthq. Eng. 2012, 16, 443–462. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Bozkurt, M.B.; Topkaya, C. Evaluation of seismic response factors for BRBFs using FEMA P695 methodology. J. Constr. Steel Res. 2018, 151, 41–57. [Google Scholar] [CrossRef]

- Naghavi, M.; Rahnavard, R.; Thomas, R.J.; Malekinejad, M. Numerical evaluation of the hysteretic behavior of concentrically braced frames and buckling restrained brace frame systems. J. Build. Eng. 2019, 22, 415–428. [Google Scholar] [CrossRef]

- Hajirasouliha, I.; Doostan, A. A simplified model for seismic response prediction of concentrically braced frames. Adv. Eng. Softw. 2010, 41, 497–505. [Google Scholar] [CrossRef]

- Moghaddam, H.; Hajirasouliha, I. Optimum strength distribution for seismic design of tall buildings. Struct. Des. Tall Spéc. Build. 2008, 17, 331–349. [Google Scholar] [CrossRef]

- Moghaddam, H.; Hajirasouliha, I. Toward more rational criteria for determination of design earthquake forces. Int. J. Solids Struct. 2006, 43, 2631–2645. [Google Scholar] [CrossRef] [Green Version]

- Özkılıç, Y.O.; Zeybek, Ö.; Topkaya, C. Stability of laterally unsupported shear links in eccentrically braced frames. Earthq. Eng. Struct. Dyn. 2022, 51, 832–852. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Bozkurt, M.B.; Topkaya, C. Mid-spliced end-plated replaceable links for eccentrically braced frames. Eng. Struct. 2021, 237, 112225. [Google Scholar] [CrossRef]

- Özkılıç, Y.; Topkaya, C. Extended end-plate connections for replaceable shear links. Eng. Struct. 2021, 240, 112385. [Google Scholar] [CrossRef]

- Palazzo, G.; López-Almansa, F.; Cahís, X.; Crisafulli, F. A low-tech dissipative buckling restrained brace. Design, analysis, production and testing. Eng. Struct. 2009, 31, 2152–2161. [Google Scholar] [CrossRef]

- Hikino, T.; Okazaki, T.; Kajiwara, K.; Nakashima, M. Out-of-Plane Stability of Buckling-Restrained Braces. In Proceedings of the Structures Congress, Las Vegas, NV, USA, 14–16 April 2011. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, B.; Ou, J. Effect of brace end rotation on the global buckling behavior of pin-connected buckling-restrained braces with end collars. Eng. Struct. 2012, 40, 240–253. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, B.; Li, W.; Ou, J. Local buckling behavior of steel angle core members in buckling-restrained braces: Cyclic tests, theoretical analysis, and design recommendations. Eng. Struct. 2014, 66, 129–145. [Google Scholar] [CrossRef]

- Budaházy, V.; Dunai, L. Numerical analysis of concrete filled Buckling Restrained Braces. J. Constr. Steel Res. 2015, 115, 92–105. [Google Scholar] [CrossRef]

- Takeuchi, T.; Hajjar, J.F.; Matsui, R.; Nishimoto, K.; Aiken, I.D. Local buckling restraint condition for core plates in buckling restrained braces. J. Constr. Steel Res. 2010, 66, 139–149. [Google Scholar] [CrossRef]

- Chou, C.C.; Chen, S.Y. Subassemblage tests and finite element analyses of sandwiched buckling-restrained braces. Eng. Struct. 2010, 32, 2108–2121. [Google Scholar] [CrossRef]

- Hoveidae, N.; Rafezy, B. Overall buckling behavior of all-steel buckling restrained braces. J. Constr. Steel Res. 2012, 79, 151–158. [Google Scholar] [CrossRef]

- Razavi, S.A.; Mirghaderi, S.R.; Hosseini, A.; Shemshadian, M.E. Reduced length buckling restrained brace using steel plates as restraining segment. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Sabelli, R.; Mahin, S.; Chang, C. Seismic demands on steel braced frame buildings with buckling-restrained braces. Eng. Struct. 2003, 25, 655–666. [Google Scholar] [CrossRef]

- Kim, J.; Choi, H. Behavior and design of structures with buckling-restrained braces. Eng. Struct. 2004, 26, 693–706. [Google Scholar] [CrossRef]

- Fahnestock, L.A.; Sause, R.; Ricles, J.M. Seismic Response and Performance of Buckling-Restrained Braced Frames. J. Struct. Eng. 2007, 133, 1195–1204. [Google Scholar] [CrossRef]

- Makris, N.; Aiken, I.D. Component Testing, Seismic Evaluation and Characterization of Buckling-Restrained Braces. J. Struct. Eng. 2004, 130, 880–894. [Google Scholar] [CrossRef]

- Tremblay, R.; Lacerte, M.; Christopoulos, C. Seismic Response of Multistory Buildings with Self-Centering Energy Dissipative Steel Braces. J. Struct. Eng. 2008, 134, 108–120. [Google Scholar] [CrossRef]

- Ragni, L.; Zona, A.; Dall’asta, A. Analytical expressions for preliminary design of dissipative bracing systems in steel frames. J. Constr. Steel Res. 2011, 67, 102–113. [Google Scholar] [CrossRef]

- Esfandiari, J.; Heidari, O.; Esfandiari, S. Experimental behavior of buckling restrained braces by adding diferent admixtures concrete and using the steel core under cyclic loads. Case Stud. Constr. Mater. 2023, 18, e01876. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Essam, A.; Tayeh, B.A.; Elrahman, M.A. Enhancing sustainability of ultra-high performance concrete utilizing high-volume waste glass powder. Case Stud. Constr. Mater. 2022, 17, e01648. [Google Scholar] [CrossRef]

- Sitler, B.; Takeuchi, T.; Matsui, R.; Terashima, M.; Terazawa, Y. Experimental investigation of a multistage buckling-restrained brace. Eng. Struct. 2020, 213, 110482. [Google Scholar] [CrossRef]

- Sitler, B.; Takeuchi, T.; Terazawa, Y.; Terashima, M. Experimental Investigation of Friction at Buckling-Restrained Brace Debonding Interfaces. J. Struct. Eng. 2021, 148, 04021251. [Google Scholar] [CrossRef]

- Gheidi, A.; Mirtaheri, M.; Zandi, A.P.; Alanjari, P. Effect of filler material on local and global behaviour of buckling-restrained braces. Struct. Des. Tall Spéc. Build. 2011, 20, 700–710. [Google Scholar] [CrossRef]

- Faleschini, F.; Bragolusi, P.; Zanini, M.A.; Zampieri, P.; Pellegrino, C. Experimental and numerical investigation on the cyclic behavior of RC beam column joints with EAF slag concrete. Eng. Struct. 2017, 152, 335–347. [Google Scholar] [CrossRef]

| Brace Type | Steel Restrainer Tube (mm) | Core Dimension (mm2) | Gap (mm) | Concrete Type | Steel Tube Restrainer Length (mm) | Total Device Length (mm) |

|---|---|---|---|---|---|---|

| BRB | 150 × 150 × 6 | 300 | 2 | UHPFRC | 1140 | 1500 |

| Material | UHPFRC with Steel Fibers (T1) (kg/m3) |

|---|---|

| Cement | 850 |

| Densified Silica Fume (SF90) | 200 |

| Dry Silica Fine Sand 30/100 PB | 695 |

| Dry Silica Coarse Sand 16/30 PB | 295 |

| Silica VC2644 | 40 |

| Steel Fiber | 22.5 |

| Free Water | 140 |

| 3% moisture | 30.93 |

| Total air voids | - |

| Total | 2408.93 |

| Dilation Angle | Eccentricity | fbo/fco | K | Viscosity Parameter |

|---|---|---|---|---|

| 35 | 0.1 | 1.16 | 0.667 | 0.0001 |

| Dilation Angle | Eccentricity | fbo/fco | K | Viscosity Parameter |

|---|---|---|---|---|

| 35 | 0.1 | 1.12 | 0.667 | 0.005 |

| Material | G40 Concrete |

|---|---|

| Cement | OPC 43 grade |

| Density (kg/m3) | 2439 |

| Wight Per Unit Volume (N) | 24,000 |

| Modulus of Elasticity | 35 |

| Poisson Ratio | 0.2 |

| Coefficient of Thermal Expansion (Millionths/°C) | 10 × 10−6 |

| Steel Core | Displacement (mm) | Strain | Stress (MPa) |

|---|---|---|---|

| BRB (G40) | 37.8 | 0.0023 | 200 |

| BRB (UHPFRC) | 22.2 | 0.0017 | 348 |

| Steel Core | Displacement (mm) | Strain | Stress (MPa) |

|---|---|---|---|

| BRB (G40) | 0.84 | 0.0081 | 345 |

| BRB (UHPFRC) | 0.51 | 0.0044 | 475 |

| Steel Core | Displacement (mm) | Strain | Stress (MPa) |

|---|---|---|---|

| BRB (G40) | 0.00093 | 1.4 × 10−7 | 15.7 |

| BRB (UHPFRC) | 0.00076 | 3.5 × 10−6 | 29.8 |

| BRB (Conventional Concrete) | Max Force (kN) | Maximum Dis (mm) | Stress at Maximum Load (MPa) | Strain at Maximum Load (%) |

|---|---|---|---|---|

| Tension | 90.8 | 25.8 | 213 | 2.3 |

| Compression | 58 | 33.6 | ||

| BRB (UHPFRC concrete) | Max Force (kN) | Maximum Dis (mm) | Stress at maximum load (MPa) | Strain at maximum load (%) |

| Tension | 92.2 | 25.5 | 307 | 1.93 |

| Compression | 70 | 25.6 |

| Maximum Force (kN) | Maximum Displacement (mm) | Maximum Stress in Compression (MPa) | Maximum Strain (%) | ||

|---|---|---|---|---|---|

| BRB (Low Grade) | Tension | 89 | 26 | 186 | 3 |

| Compression | 56 | 45 | |||

| BRB (Medium Grade) | Tension | 86 | 27 | 218 | 2.06 |

| Compression | 64 | 31 | |||

| BRB (High Grade) | Tension | 90 | 26 | 226 | 1.7 |

| Compression | 68 | 23 | |||

| Specimen | Displacement (mm) | Percentage Difference (%) | Ultimate Load (kN) | Percentage Difference (%) | |

|---|---|---|---|---|---|

| BRB | Numerical results | 25 | 3.84 | 92 | 9.8 |

| Experimental results | 26 | 102 |

| Brace Type | Steel Restrainer Tube (mm) | Core Dimension (mm2) | Gap (mm) | Concrete Type | Steel Tube Restrainer Length (mm) | Total Device Length (mm) | Rubber Element (mm) |

|---|---|---|---|---|---|---|---|

| RBRB | 150 × 150 × 6 | 300 | 2 | UHPFRC | 1140 | 1500 | 100 × 100 × 150 |

| Nominal Stress | 0.08 | 0.16 | 0.24 | 0.32 | 0.4 | 0.48 | 0.56 | 0.64 | 0.72 |

| Nominal Strain | 0.014 | 0.033 | 0.053 | 0.08 | 0.12 | 0.16 | 0.20 | 0.25 | 0.29 |

| Nominal Stress | −0.05 | −0.1 | −0.15 | −0.2 | −0.25 | −0.3 | −0.35 | −0.4 |

| Nominal Strain | −0.02 | −0.03 | −0.03 | −0.04 | −0.04 | −0.04 | −0.05 | −0.05 |

| Nominal Stress | −0.45 | −0.5 | −0.55 | −0.6 | −0.65 | −0.7 | −0.75 | −0.8 |

| Nominal Strain | −0.06 | −0.06 | −0.07 | −0.09 | −0.10 | −0.14 | −0.19 | −0.28 |

| BRB | RBRB | Difference Percentage | |

|---|---|---|---|

| Max Force (kN) | Max Force (kN) | ||

| Tension | 92.2 | 193.8 | 110.2% |

| Compression | 70 | 198.72 | 183.89% |

| Specimens | Effective Stiffness | Effective Damping | Dissipated Energy |

|---|---|---|---|

| BRB | 12.76 | 0.518 | 8021 |

| RBRB | 27.2 | 0.530 | 11.806 |

| Effectiveness | 46.9% | 3% | 47.19% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostovar, N.; Hejazi, F. Buckling-Restrained Bracing System with Ultra-High-Performance Fiber Concrete. Appl. Sci. 2023, 13, 8250. https://doi.org/10.3390/app13148250

Ostovar N, Hejazi F. Buckling-Restrained Bracing System with Ultra-High-Performance Fiber Concrete. Applied Sciences. 2023; 13(14):8250. https://doi.org/10.3390/app13148250

Chicago/Turabian StyleOstovar, Nima, and Farzad Hejazi. 2023. "Buckling-Restrained Bracing System with Ultra-High-Performance Fiber Concrete" Applied Sciences 13, no. 14: 8250. https://doi.org/10.3390/app13148250

APA StyleOstovar, N., & Hejazi, F. (2023). Buckling-Restrained Bracing System with Ultra-High-Performance Fiber Concrete. Applied Sciences, 13(14), 8250. https://doi.org/10.3390/app13148250