Development and Application of a Microsurfacing Mix Design Method to Assess the Influence of the Emulsion Type

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

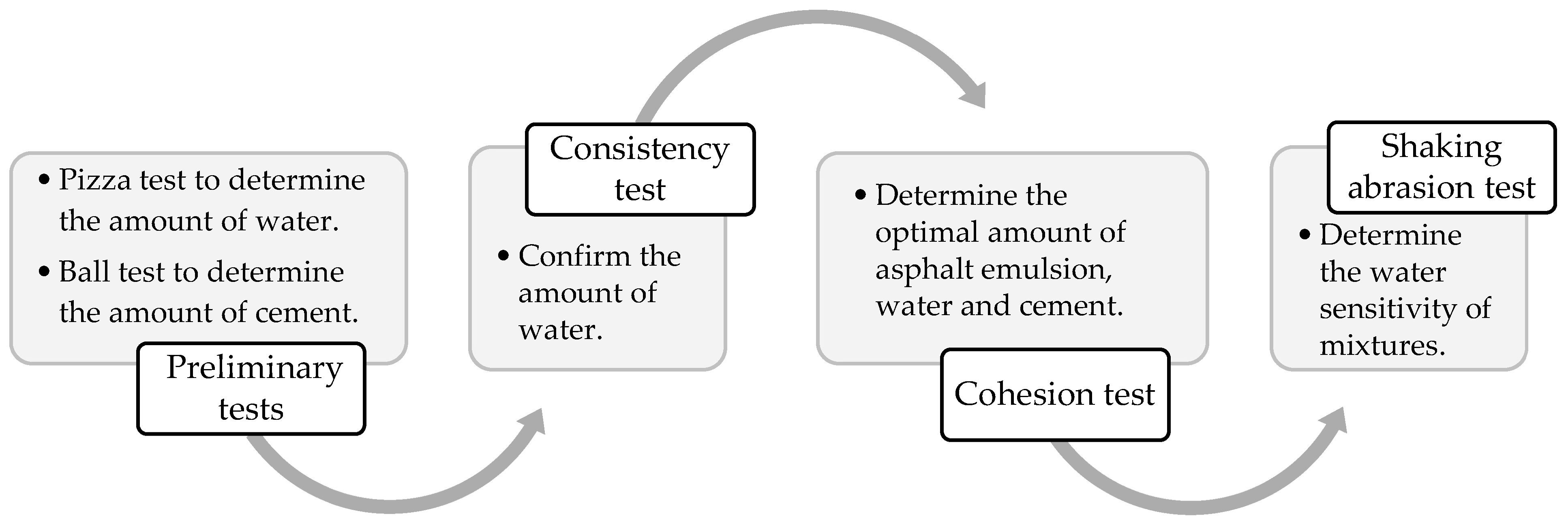

2.2. Structure of the Microsurfacing Mix Design Method Proposed in This Work

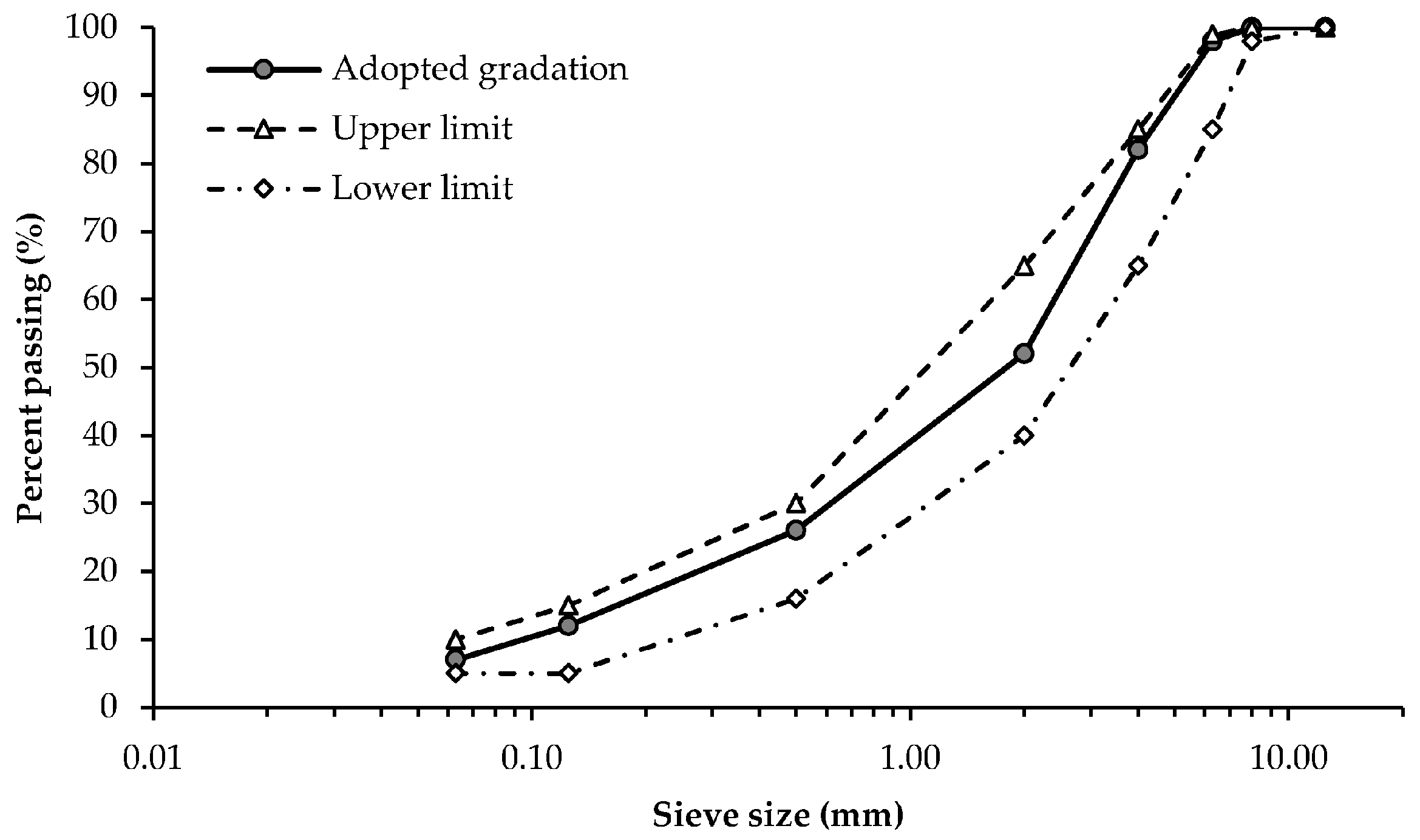

2.3. Characterization of Aggregates Used in Microsurfacing Mixtures

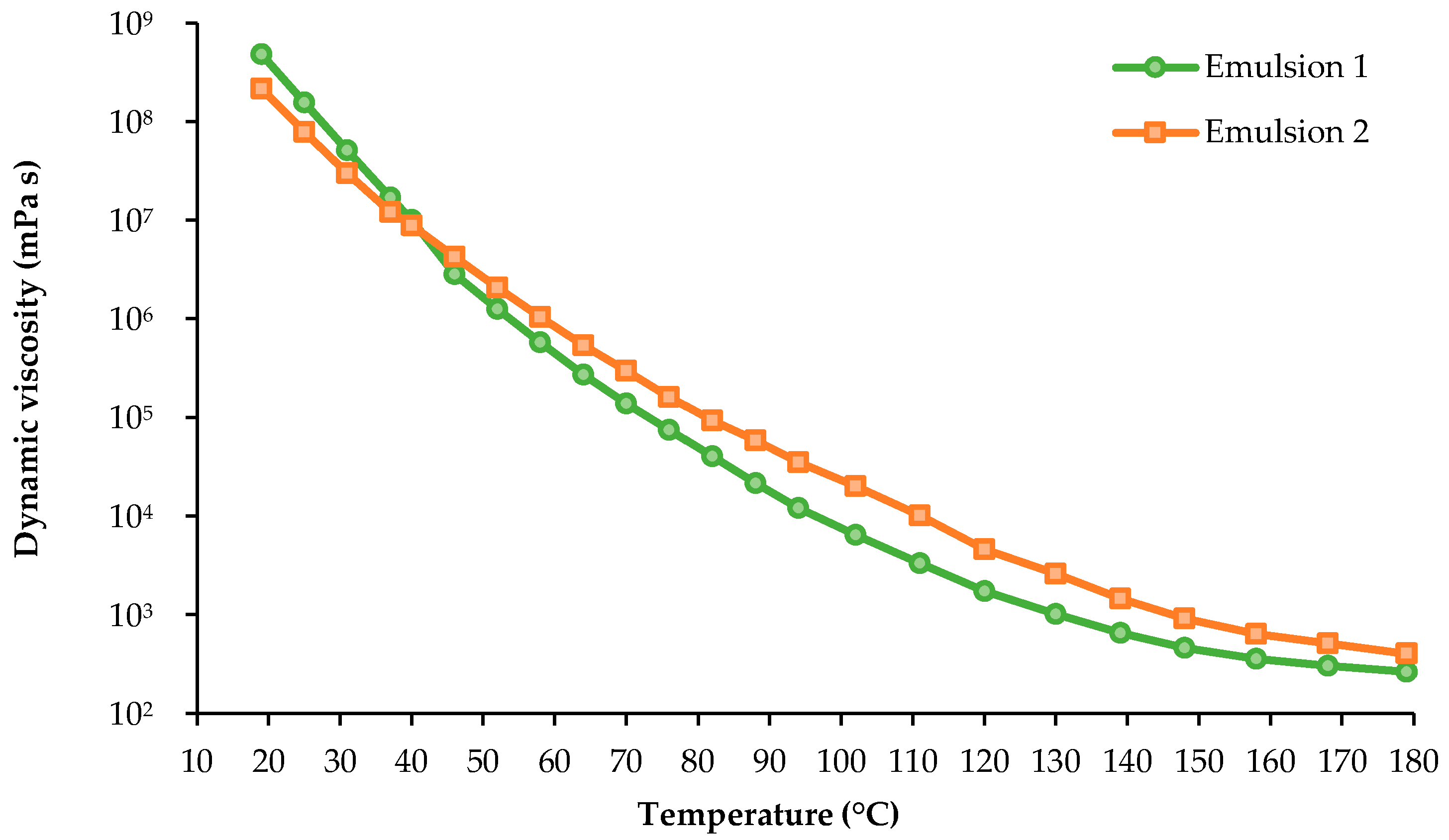

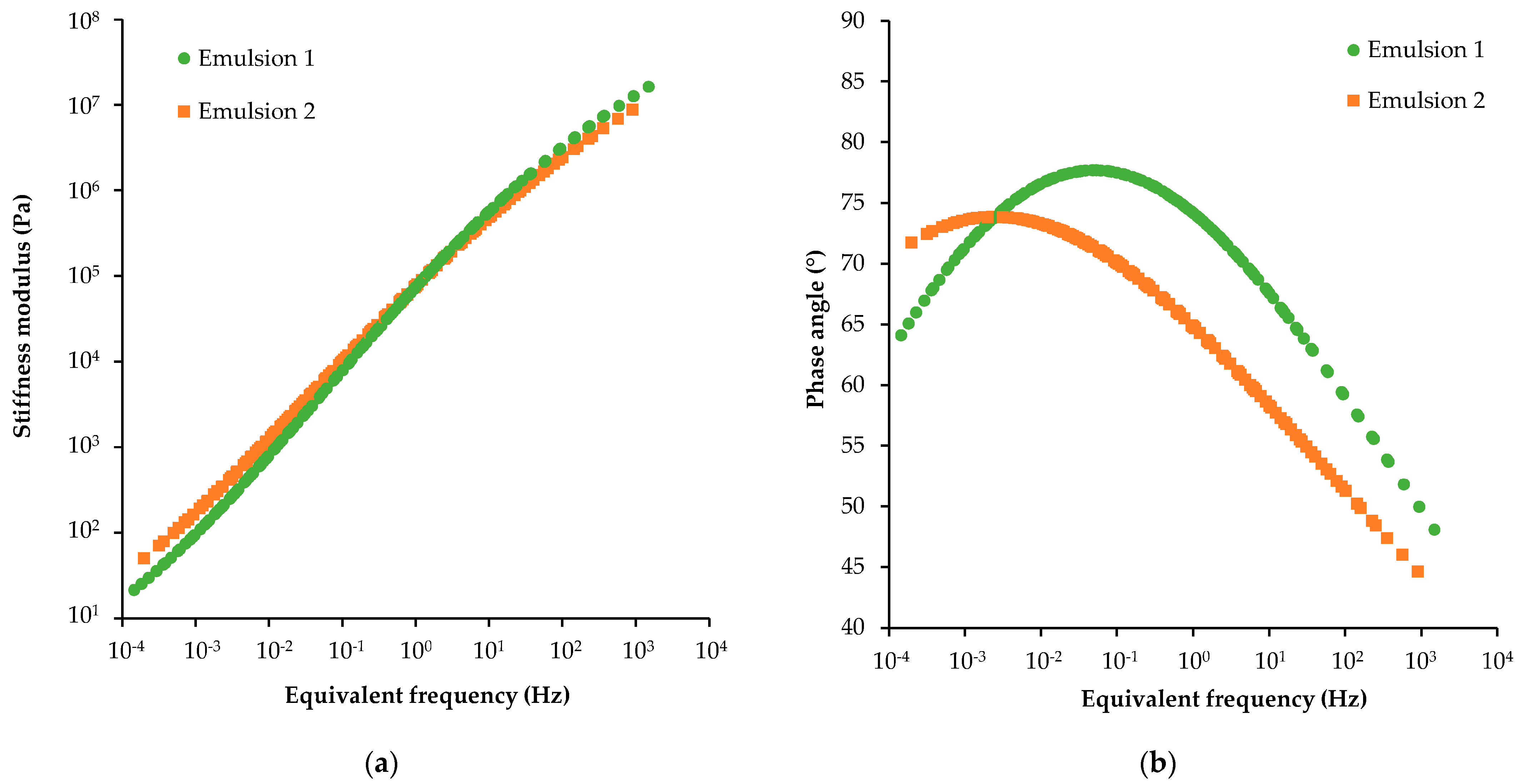

2.4. Characterization of Asphalt Emulsions Used in Microsurfacing Mixtures

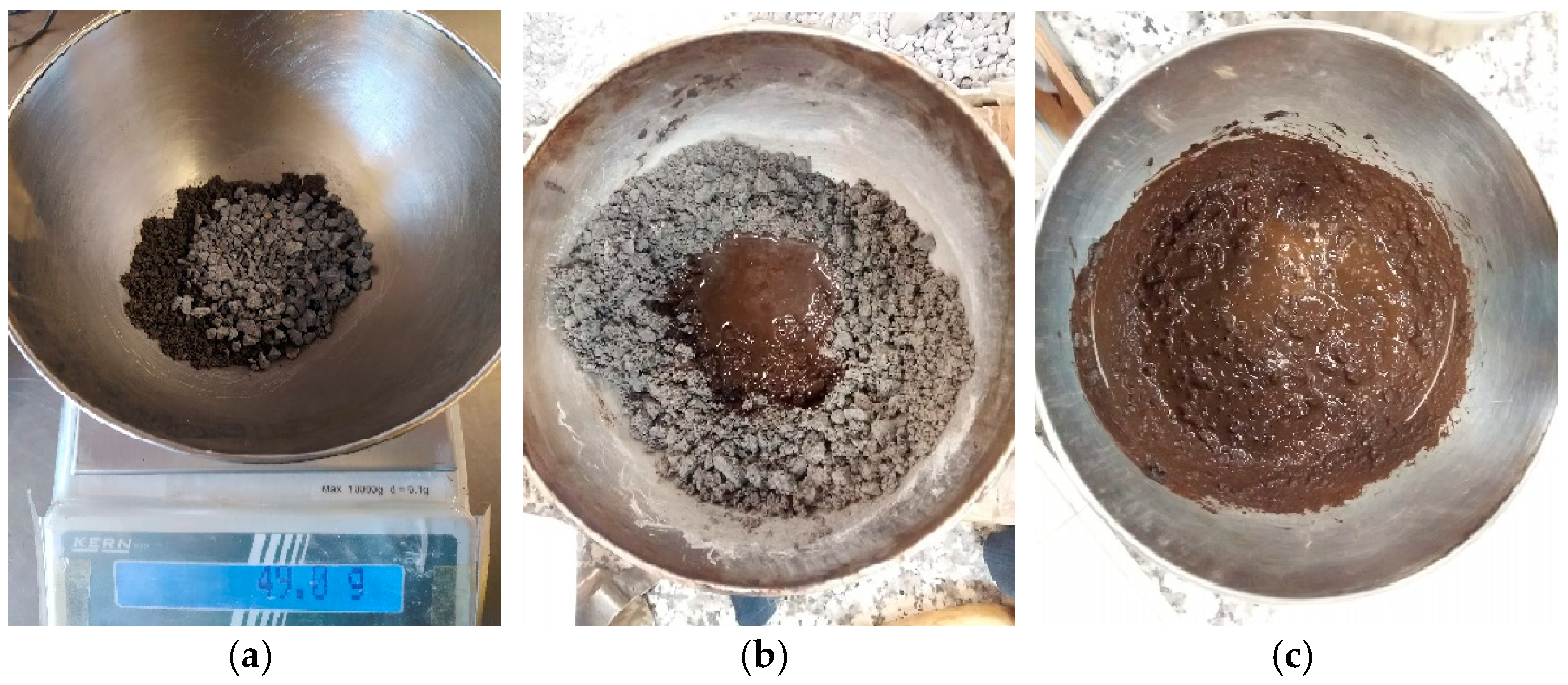

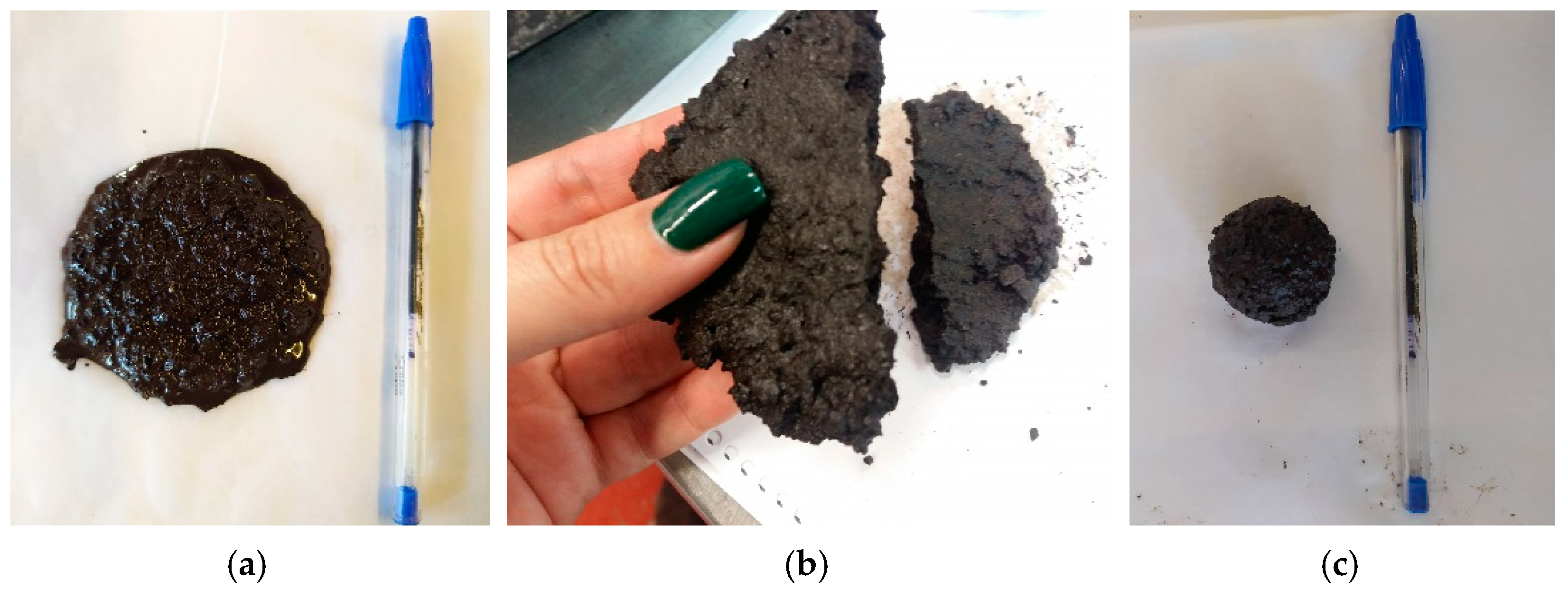

2.5. Preparation of Microsurfacing Mixtures

2.6. Microsurfacing Mix Design Method

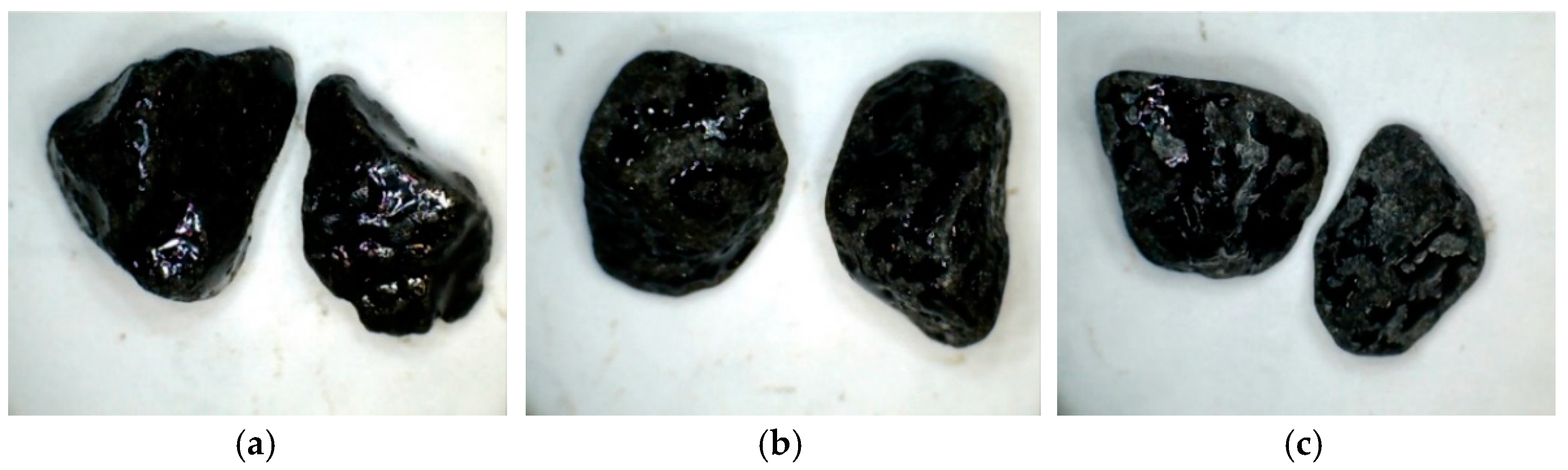

2.6.1. Preliminary Mix Design Tests

2.6.2. Consistency Test

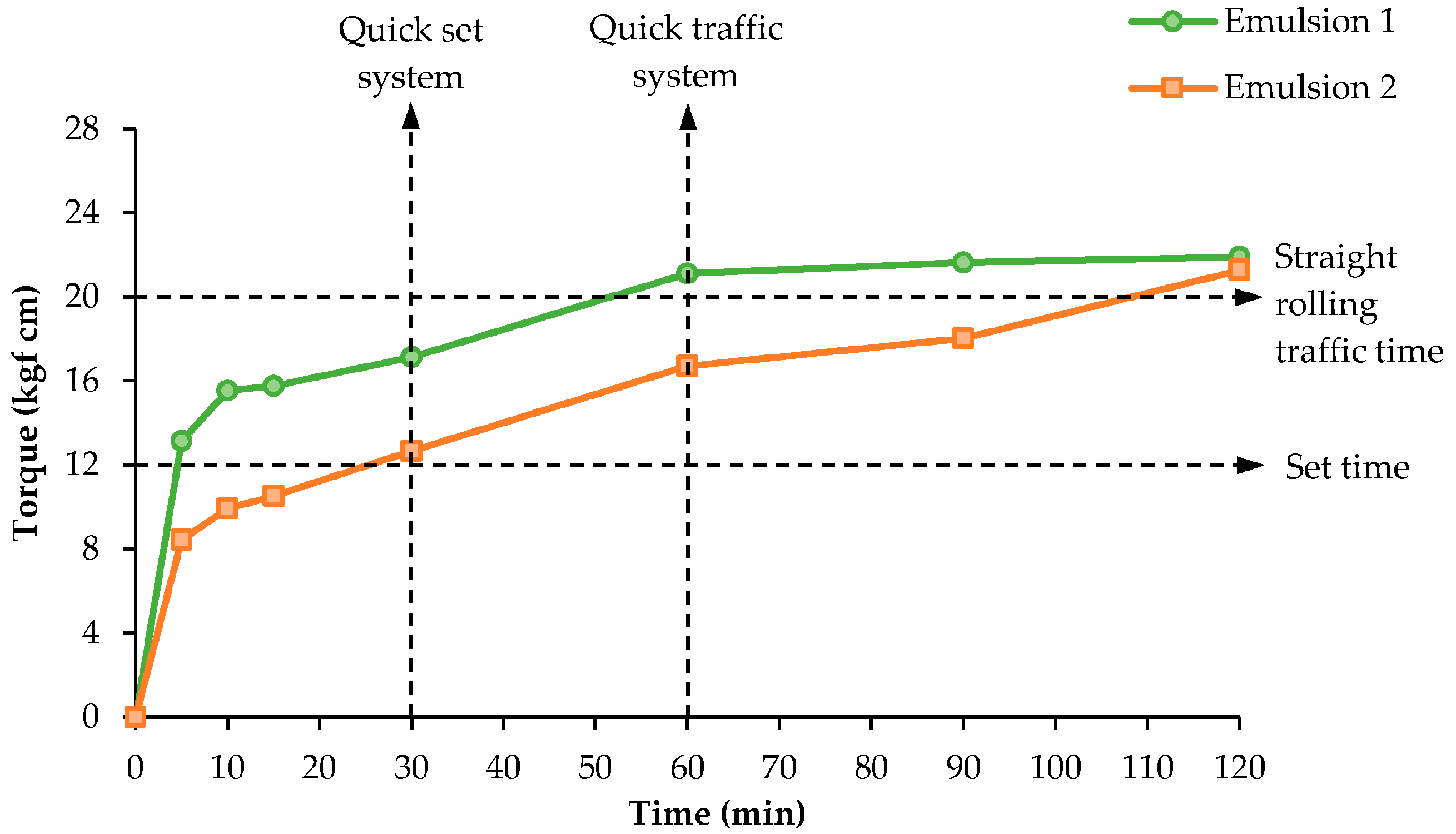

2.6.3. Cohesion Test

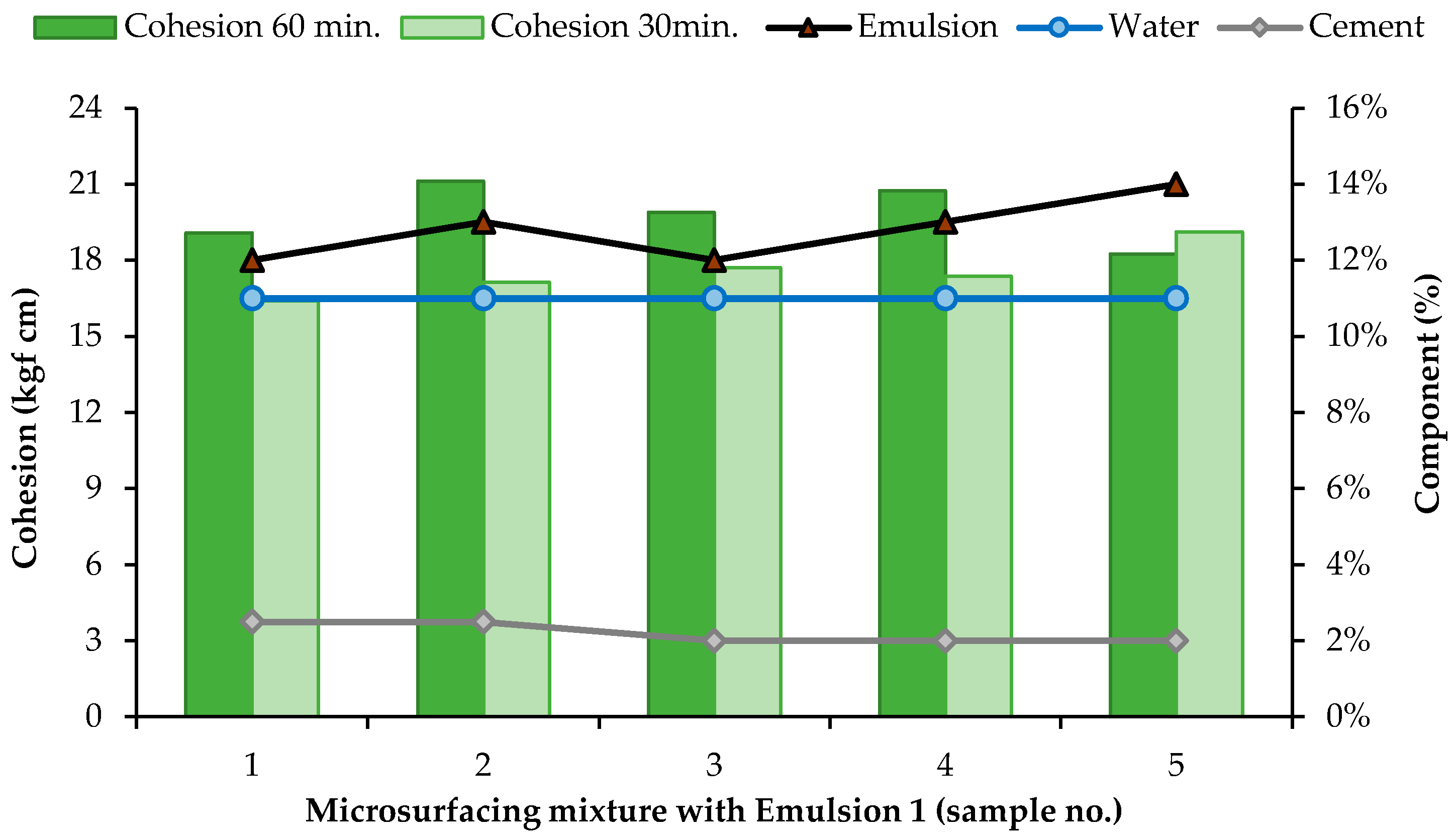

2.6.4. Shaking Abrasion Test

3. Results

3.1. Aggregate Characteristics

3.2. Asphalt Emulsions’ Characteristics

3.3. Microsurfacing Test Results

3.3.1. Preliminary Design of Microsurfacing Mixtures

3.3.2. Consistency Test Results

3.3.3. Cohesion Test Results

3.3.4. Shaking Abrasion Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shanbara, H.K.; Dulaimi, A.; Al-Mansoori, T.; Al-Busaltan, S.; Herez, M.; Sadique, M.; Abdel-Wahed, T. The future of eco-friendly cold mix asphalt. Renew. Sustain. Energy Rev. 2021, 149, 111318. [Google Scholar] [CrossRef]

- Wulandari, P.S.; Tjandra, D. The effect of crumb rubber in dense graded and open graded cold mixture asphalt. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Surabaya, Indonesia, 20 August 2021. [Google Scholar]

- Dash, S.S.; Panda, M. Influence of mix parameters on design of cold bituminous mix. Constr. Build. Mater. 2018, 191, 376–385. [Google Scholar] [CrossRef]

- Xiao, F.P.; Yao, S.L.; Wang, J.G.; Li, X.H.; Amirkhanian, S. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Bhargava, N.; Siddagangaiah, A.K.; Ryntathiang, T.L. State of the art review on design and performance of microsurfacing. Road Mater. Pavement Des. 2020, 21, 2091–2125. [Google Scholar] [CrossRef]

- Zalnezhad, M.; Hesami, E. Effect of steel slag aggregate and bitumen emulsion types on the performance of microsurfacing mixture. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 215–226. [Google Scholar] [CrossRef]

- Bae, A.; Stoffels, S.M. Economic effects of microsurfacing on thermally-cracked pavements. KSCE J. Civ. Eng. 2008, 12, 177–185. [Google Scholar] [CrossRef]

- Madane, A.; Taye, S.; Mamidwar, S.; Chavan, S. A laboratory investigation on type III micro-surfacing with different fillers. Int. Res. J. Eng. Technol. (IRJET) 2019, 6, 3321–3324. [Google Scholar]

- Broughton, B.; Lee, S.-J. Microsurfacing in Texas; Texas State University: San Marcos, TX, USA, 2012. [Google Scholar]

- Freeman, T.; Pinchett, D.; Haobo, R.; Spiegelman, C. Analysis and Treatment Recommendations from the Supplemental Maintenance Effectiveness Research Program (SMERP); Texas Transportation Institute: College Station, TX, USA, 2002. [Google Scholar]

- Callai, S.C.; Sangiorgi, C. A review on acoustic and skid resistance solutions for road pavements. Infrastructures 2021, 6, 41. [Google Scholar] [CrossRef]

- Keymanesh, M.R.; Ziari, H.; Zalnezhad, H.; Zalnezhad, M. Mix design and performance evaluation of microsurfacing containing electric arc furnace (EAF) steel slag filler. Constr. Build. Mater. 2021, 269, 121336. [Google Scholar] [CrossRef]

- Grilli, A.; Graziani, A.; Carter, A.; Sangiorgi, C.; Pivoto Specht, L.; Copetti Callai, S. Slurry surfacing: A review of definitions, descriptions and current practices. RILEM Tech. Lett. 2019, 4, 103–109. [Google Scholar] [CrossRef]

- Broughton, B.; Lee, S.-J.; Kim, Y.-J. 30 Years of Microsurfacing: A Review. ISRN Civ. Eng. 2012, 2012, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.F.; Jia, J.; Chen, Q. Road Performance Comprehensive Evaluation of Polymer Modified Emulsified Asphalt Fiber Microsurfacing. Adv. Mater. Sci. Eng. 2022, 2022, 8179137. [Google Scholar] [CrossRef]

- Destrée, A.; Vansteenkiste, S.; Tanghe, T.; De Visscher, J.; Grilli, A. Reliable Laboratory Tests: A Prerequisite for the Design of High-Quality Slurry Surfacing Mixtures. Adv. Mater. Sci. Eng. 2022, 2022, 1–20. [Google Scholar] [CrossRef]

- Lonbar, M.S.; Nazirizad, M. Laboratory Investigation of Materials Type Effects on the Microsurfacing Mixture. Civ. Eng. J. 2016, 2, 86–94. [Google Scholar] [CrossRef]

- Gransberg, D.D. Microsurfacing: A Synthesis of Highway Practices. NCHRP Synthesis 411; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

- Robati, M.; Carter, A.; Perraton, D. Evaluation of a modification of current microsurfacing mix design procedures. Can. J. Civ. Eng. 2015, 42, 319–328. [Google Scholar] [CrossRef] [Green Version]

- Robati, M.; Carter, A.; Perraton, D. Repeatability and reproducibility of micro-surfacing mixture design tests and effect of aggregates surface areas on test results. Aust. J. Civ. Eng. 2013, 11, 41–55. [Google Scholar] [CrossRef]

- Bhargava, N.; Siddagangaiah, A.K.; Ryntathiang, T.L. Systematic approach to address challenges in microsurfacing mix design. Constr. Build. Mater. 2021, 270, 121759. [Google Scholar] [CrossRef]

- Poursoltani, M.; Hesami, S. Performance evaluation of microsurfacing mixture containing reclaimed asphalt pavement. Int. J. Pavement Eng. 2020, 21, 1491–1504. [Google Scholar] [CrossRef]

- Robati, M. Evaluation and Improvement of Micro-Surfacing Mix Design Method and Modelling of Asphalt Emulsion Mastic in Terms of Filler-Emulsion Interaction. Ph.D. Thesis, École de Technologie Supérieure, Université du Québec, Montreal, QC, Canada, 2014. [Google Scholar]

- Robati, M.; Carter, A.; Perraton, D. Evaluation of test methods and selection of aggregate grading for type III application of micro-surfacing. Int. J. Pavemnet Eng. Asph. Technol. 2013, 14, 11–66. [Google Scholar] [CrossRef]

- Kumar, R.; Ryntathiang, T.L. New Laboratory Mix Methodology of Microsurfacing and Mix Design. Transp. Res. Procedia 2016, 17, 488–497. [Google Scholar] [CrossRef]

- European Standard EN 12274-3; CEN. Slurry Surfacing—Test Methods—Part 3: Consistency. European Committee for Standardization: Brussels, Belgium, 2018.

- European Standard EN 12274-4; CEN. Slurry Surfacing—Test Methods—Part 4: Determination of Cohesion of the Mix. European Committee for Standardization: Brussels, Belgium, 2018.

- European Standard EN 12274-7; CEN. Slurry Surfacing—Test Methods—Part 7: Shaking Abrasion Test. European Committee for Standardization: Brussels, Belgium, 2005.

- Infraestruturas de Portugal. Caderno de Encargos Tipo Obra. 14.03—Pavimentação. Características dos Materiais; Infraestruturas de Portugal: Almada, Portugal, 2014. [Google Scholar]

- Austroads Test Method AGPT-T270-18; Determination of Optimum Amount of Added Water for Bituminous Slurry (Consistency Test). Austroads: Sydney, Australia, 2018.

- Peralta, J.; Hilliou, L.; Silva, H.M.R.D.; Machado, A.V.; Pais, J.C.; Oliveira, J.R.M. Rheological Quantification of Bitumen Aging: Definition of a New Sensitive Parameter. Appl. Rheol. 2010, 20, 63293. [Google Scholar] [CrossRef]

- Technical Bulletin No. 139; Test Method to Determine Set and Cure Development of Slurry Surfacing Systems by Cohesion Tester. International Slurry Surfacing Association: Glen Ellyn, IL, USA, 2017.

- ASTM D6372-15; Standard Practice for Design, Testing, and Construction of Micro-Surfacing. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

| Time | Emulsion 1 | Emulsion 2 |

|---|---|---|

| After 6 h | 95% | 90% |

| After 24 h | 70% | 50% |

| After 48 h | 50% | 30% |

| Mixture | Design of the Microsurfacing Mixture | Cohesion (kgf cm) | |||

|---|---|---|---|---|---|

| Water (%) | Cement (%) | Emulsion (%) | After 30 min | After 60 min | |

| 1 | 11% | 2.5% | 12% | 16.40 | 19.06 |

| 2 | 11% | 2.5% | 13% | 17.12 | 21.11 |

| 3 | 11% | 2.0% | 12% | 17.70 | 19.89 |

| 4 | 11% | 2.0% | 13% | 17.36 | 20.74 |

| 5 | 11% | 2.0% | 14% | 19.12 | 18.22 |

| Mixture | Design of the Microsurfacing Mixture | Cohesion (kgf cm) | |||

|---|---|---|---|---|---|

| Water (%) | Cement (%) | Emulsion (%) | After 30 min | After 60 min | |

| 1 | 9 | 2.5 | 12 | 8.09 | 11.34 |

| 2 | 9 | 2.5 | 13 | 8.74 | 13.99 |

| 3 | 9 | 3.0 | 13 | 13.49 | 16.04 |

| 4 | 10 | 3.0 | 13 | 12.68 | 16.71 |

| 5 | 11 | 3.0 | 13 | 10.62 | 13.63 |

| 6 | 10 | 3.0 | 14 | 10.35 | 14.88 |

| 7 | 10 | 3.0 | 12 | 10.02 | 13.50 |

| Emulsion | Sample | Vv (cm3) | Water Absorption (%) | Abrasion (%) |

|---|---|---|---|---|

| Emulsion 1 | 1 | 18.2 | 13.59 | 1.95 |

| 2 | 18.0 | 13.26 | 1.97 | |

| 3 | 18.0 | 12.71 | 2.21 | |

| 4 | 17.8 | 13.48 | 2.49 | |

| Mean | 18.0 | 13.26 | 2.15 | |

| Emulsion 2 | 1 | 17.9 | 12.22 | 0.74 |

| 2 | 17.3 | 12.07 | 0.51 | |

| 3 | 17.9 | 11.11 | 0.49 | |

| 4 | 17.9 | 11.73 | 0.74 | |

| Mean | 17.8 | 11.78 | 0.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moura, C.F.N.; Oliveira, J.R.M.; Silva, H.M.R.D.; Palha, C.A.O.F.; Sangiorgi, C. Development and Application of a Microsurfacing Mix Design Method to Assess the Influence of the Emulsion Type. Appl. Sci. 2023, 13, 7925. https://doi.org/10.3390/app13137925

Moura CFN, Oliveira JRM, Silva HMRD, Palha CAOF, Sangiorgi C. Development and Application of a Microsurfacing Mix Design Method to Assess the Influence of the Emulsion Type. Applied Sciences. 2023; 13(13):7925. https://doi.org/10.3390/app13137925

Chicago/Turabian StyleMoura, Caroline F. N., Joel R. M. Oliveira, Hugo M. R. D. Silva, Carlos A. O. F. Palha, and Cesare Sangiorgi. 2023. "Development and Application of a Microsurfacing Mix Design Method to Assess the Influence of the Emulsion Type" Applied Sciences 13, no. 13: 7925. https://doi.org/10.3390/app13137925

APA StyleMoura, C. F. N., Oliveira, J. R. M., Silva, H. M. R. D., Palha, C. A. O. F., & Sangiorgi, C. (2023). Development and Application of a Microsurfacing Mix Design Method to Assess the Influence of the Emulsion Type. Applied Sciences, 13(13), 7925. https://doi.org/10.3390/app13137925