Performance of Polymer Composites Lubricated with Glycerol and Water as Green Lubricants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Lubricants

2.3. Tribological Tests

2.4. Wear Evaluation and Characterisation of Worn Surfaces

3. Results

3.1. Hardness

3.2. Tribological Results

3.2.1. Running in Time for Different Polymers

3.2.2. Coefficient of Friction for Different Polymers

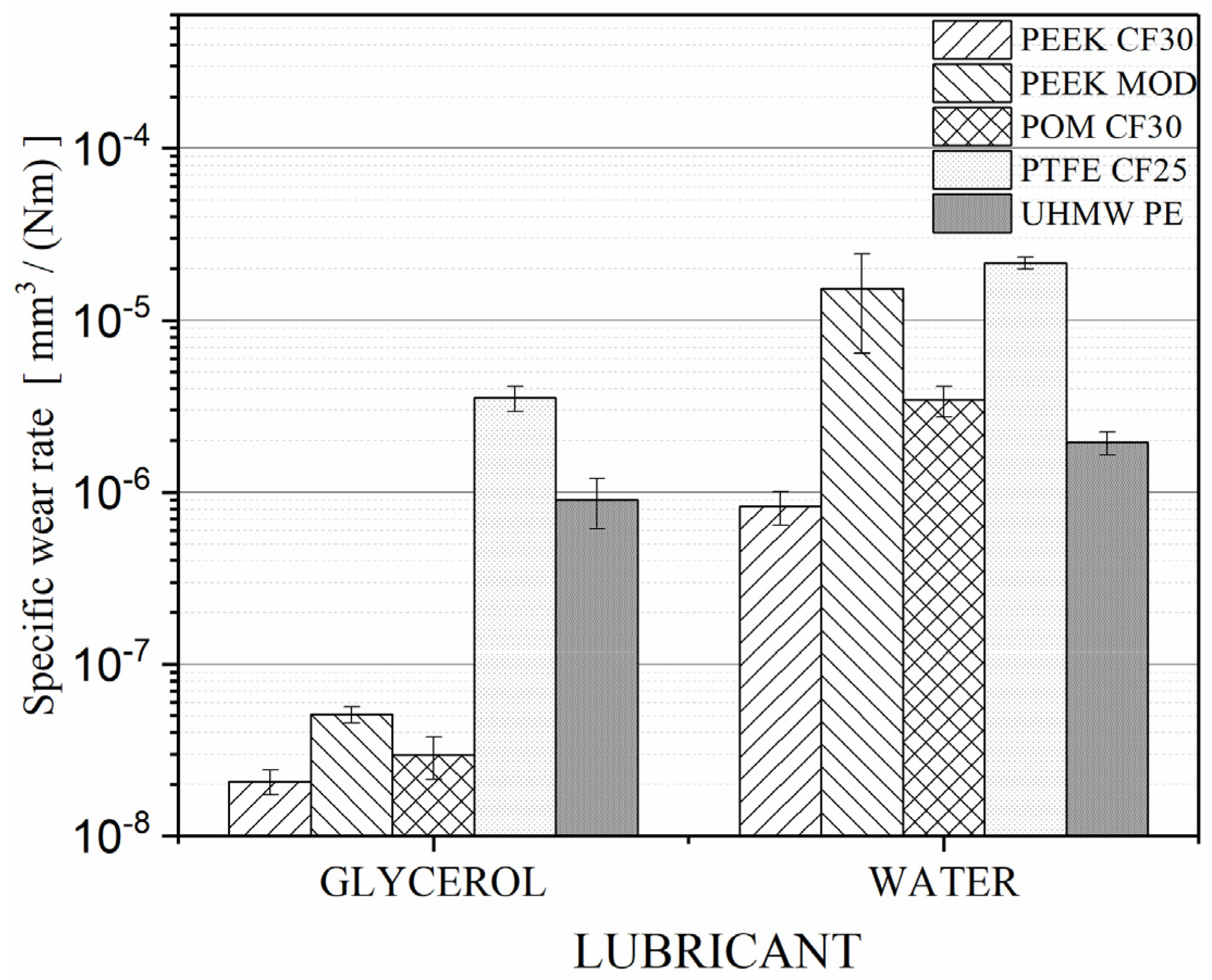

3.2.3. Specific Wear Rate for Different Polymers

3.3. Digital Microscopy and SEM

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deuster, S.; Schmitz, K.; Widomski, K.; Barnat-Hunek, D.; Musz-Pomorska, A. Bio-Based Hydraulic Fluids and the Influence of Hydraulic Oil Viscosity on the Efficiency of Mobile Machinery. Sustainability 2021, 13, 7570. [Google Scholar] [CrossRef]

- Somberg, J.; Saravanan, P.; Vadivel, H.S.; Berglund, K.; Shi, Y.; Ukonsaari, J.; Emami, N. Tribological characterisation of polymer composites for hydropower bearings: Experimentally developed versus commercial materials. Tribol. Int. 2021, 162, 107101. [Google Scholar] [CrossRef]

- Theivendran, K.; Arshad, F.; Hanif, U.K.; Reito, A.; Griffin, X.; Foote, C.J. Carbon fibre reinforced PEEK versus traditional metallic implants for orthopaedic trauma surgery: A systematic review. J. Clin. Orthop. Trauma. 2021, 23, 101674. [Google Scholar] [CrossRef] [PubMed]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef] [Green Version]

- Golchin, A.; Simmons, G.F.; Glavatskih, S.; Prakash, B. Tribological behaviour of polymeric materials in water-lubricated contacts. Proc. Inst. Mech. Eng. Part. J. J. Eng. Tribol. 2013, 227, 811–825. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, L.; Xie, G.; Li, Z.; Chen, H.; Gong, H.; Xu, W.; Guo, D.; Luo, J. A review on tribology of polymer composite coatings. Friction 2021, 9, 429–470. [Google Scholar] [CrossRef]

- Panin, S.V.; Alexenko, V.O.; Buslovich, D.G. High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review†. Polymers 2022, 14, 975. [Google Scholar] [CrossRef] [PubMed]

- Doumeng, M.; Ferry, F.; Delbé, K.; Mérian, T.; Chabert, F.; Berthet, F.; Marsan, O.; Nassiet, V.; Denape, J. Evolution of crystallinity of PEEK and glass-fibre reinforced PEEK under tribological conditions using Raman spectroscopy. Wear 2019, 426–427, 1040–1046. [Google Scholar] [CrossRef] [Green Version]

- Yaragalla, S.; Zahid, M.; Panda, J.K.; Tsagarakis, N.; Cingolani, R.; Athanassiou, A. Comprehensive enhancement in thermomechanical performance of melt-extruded peek filaments by graphene incorporation. Polymers 2021, 13, 1425. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Wang, J.; Yan, F. Comparative investigation on the tribological behaviors of CF/PEEK composites under sea water lubrication. Tribol. Int. 2012, 52, 170–177. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D. Friction and wear properties of stainless steel sliding against polyetheretherketone and carbon-fiber-reinforced polyetheretherketone under natural seawater lubrication. Mater. Des. 2014, 53, 881–887. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J.; Liu, N.; Yan, F. Synergetic Effect of Lubricant Additive and Reinforcement Additive on the Tribological Behaviors of PEEK-Based Composites under Seawater Lubrication. Tribol. Trans. 2013, 56, 672–680. [Google Scholar] [CrossRef]

- Jia, J.; Chen, J.; Zhou, H.; Hu, L.; Chen, L. Comparative investigation on the wear and transfer behaviors of carbon fiber reinforced polymer composites under dry sliding and water lubrication. Compos. Sci. Technol. 2005, 65, 1139–1147. [Google Scholar] [CrossRef]

- Guan, Z.; Wu, D.; Cheng, Q.; Wang, Z.; Tang, M.; Liu, Y. Friction and Wear characteristics of CF/PEEK against 431 stainless steel under high hydrostatic pressure water lubrication. Mater. Des. 2020, 196, 109057. [Google Scholar] [CrossRef]

- Li, D.; Liu, Y.; Deng, Y.; Fang, M.; Wu, D. The Effect of Different Temperatures on Friction and Wear Properties of CFRPEEK against AISI 431 Steel under Water Lubrication. Tribol. Trans. 2017, 61, 357–366. [Google Scholar] [CrossRef]

- Campbell, K.L.; Sidebottom, M.A.; Atkinson, C.C.; Babuska, T.F.; Kolanovic, C.A.; Boulden, B.J.; Junk, C.P.; Krick, B.A. Ultralow Wear PTFE-Based Polymer Composites—The Role of Water and Tribochemistry. Macromolecules 2019, 52, 5268–5277. [Google Scholar] [CrossRef]

- Wang, J.; Yan, F.; Xue, Q. Tribological behavior of PTFE sliding against steel in sea water. Wear 2009, 267, 1634–1641. [Google Scholar] [CrossRef]

- Wang, J.; Chen, B.; Liu, N.; Han, G.; Yan, F. Combined effects of fiber/matrix interface and water absorption on the tribological behaviors of water-lubricated polytetrafluoroethylene-based composites reinforced with carbon and basalt fibers. Compos. Part. A Appl. Sci. Manuf. 2014, 59, 85–92. [Google Scholar] [CrossRef]

- Bin Ali, A.; Samad, M.A.; Merah, N. UHMWPE Hybrid Nanocomposites for Improved Tribological Performance Under Dry and Water-Lubricated Sliding Conditions. Tribol. Lett. 2017, 65, 1–10. [Google Scholar] [CrossRef]

- Vadivel, H.S.; Golchin, A.; Emami, N. Tribological behaviour of carbon filled hybrid UHMWPE composites in water. Tribol. Int. 2018, 124, 169–177. [Google Scholar] [CrossRef]

- Golchin, A.; Villain, A.; Emami, N. Tribological behaviour of nanodiamond reinforced UHMWPE in water-lubricated contacts. Tribol. Int. 2017, 110, 195–200. [Google Scholar] [CrossRef]

- Suñer, S.; Joffe, R.; Tipper, J.L.; Emami, N. Ultra high molecular weight polyethylene/graphene oxide nanocomposites: Thermal, mechanical and wettability characterisation. Compos. B Eng. 2015, 78, 185–191. [Google Scholar] [CrossRef]

- Belotti, L.P.; Vadivel, H.S.; Emami, N. Tribological performance of hygrothermally aged UHMWPE hybrid composites. Tribol. Int. 2019, 138, 150–156. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Wei, L.; Cheng, B.; Shi, Z.; Ding, Y.; Zhang, X.; Duan, H. Effects of thermal-oxidative aging processes on tribological properties of polyformaldehyde and ultra-high molecular weight polyethylene: A comparative study. J. Appl. Polym. Sci. 2022, 139, 51632. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Liang, M.; Wu, H.; Zou, H.; Chen, Y.; Zhou, S. Comparative study on the mechanical, tribological, and thermal properties of POM composites filled with different PTFE. J. Thermoplast. Compos. Mater. 2020, 35, 1319–1341. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, S.; He, Y.; Wang, X.; Wu, D. Effect of poly(ethylene oxide) on tribological performance and impact fracture behavior of polyoxymethylene/polytetrafluoroethylene fiber composites. Compos. Part B Eng. 2011, 42, 1945–1955. [Google Scholar] [CrossRef]

- Rodionov, L.; Rekadze, P. Experimental Vibroacoustic Research of a Gear Pump Made of different Materials. Procedia Eng. 2017, 176, 636–644. [Google Scholar] [CrossRef]

- Skowró, J.; Kosucki, A.; Stawí, Ł. materials Overview of Materials Used for the Basic Elements of Hydraulic Actuators and Sealing Systems and Their Surfaces Modification Methods. Materials 2021, 14, 1422. [Google Scholar] [CrossRef]

- Matkovič, S.; Pogačnik, A.; Kalin, M. Wear-coefficient analyses for polymer-gear life-time predictions: A critical appraisal of methodologies. Wear 2021, 480–481, 203944. [Google Scholar] [CrossRef]

- Strmčnik, E.; Majdič, F. Comparison of leakage level in water and oil hydraulics. Res. Artic. Adv. Mech. Eng. 2017, 9, 2017. [Google Scholar] [CrossRef]

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Tomala, A.; Karpinska, A.; Werner, W.S.M.; Olver, A.; Störi, H. Tribological properties of additives for water-based lubricants. Wear 2010, 269, 804–810. [Google Scholar] [CrossRef]

- Hernández-Sierra, M.T.; Bravo-Sánchez, M.G.; Báez, J.E.; Aguilera-Camacho, L.D.; Santos García-Miranda, J.; Moreno, K.J. Improvement Effect of Green Lubricants on the Tribological and Mechanical Performance of 4140 Steel. Appl. Sci. 2019, 9, 4896. [Google Scholar] [CrossRef] [Green Version]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Zhang, S.; Luo, J. Controllable superlubricity of glycerol solution via environment humidity. Langmuir 2013, 29, 11924–11930. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, C.; Gu, Y.; Jérôme, F. Green Chemistry CRITICAL REVIEW Glycerol in energy transportation: A state-of-the-art review. Green Chem. 2021, 23, 7865–7889. [Google Scholar] [CrossRef]

- Ma, Q.; He, T.; Khan, A.M.; Wang, Q.; Chung, Y.W. Achieving macroscale liquid superlubricity using glycerol aqueous solutions. Tribol. Int. 2021, 160, 107006. [Google Scholar] [CrossRef]

- Trejo González, J.A.; Longinotti, M.P.; Corti, H.R. The Viscosity of Glycerol−Water Mixtures Including the Supercooled Region. J. Chem. Eng. Data 2011, 56, 1397–1406. [Google Scholar] [CrossRef]

- Liu, C.; Qiao, Y.; Lv, B.; Zhang, T.; Rao, Z. Glycerol based binary solvent: Thermal properties study and its application in nanofluids. Int. Commun. Heat. Mass. Transf. 2020, 112, 104491. [Google Scholar] [CrossRef]

- Shi, Y.; Minami, I.; Grahn, M.; Björling, M.; Larsson, R. Boundary and elastohydrodynamic lubrication studies of glycerol aqueous solutions as green lubricants. Tribol. Int. 2014, 69, 39–45. [Google Scholar] [CrossRef]

- Björling, M.; Shi, Y. DLC and Glycerol: Superlubricity in Rolling/Sliding Elastohydrodynamic Lubrication. Tribol. Lett. 2019, 67, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Lin, B.; Yan, S.; Wang, A.; Zhang, X.; Ge, S. Influence of temperature and concentration on tribological properties of silicon nitride in glycerol aqueous solution. Ceram. Int. 2016, 42, 3786–3796. [Google Scholar] [CrossRef]

- Tamayo, J.G.Z.; Björling, M.; Shi, Y.; Prakash, B.; Larsson, R. Micropitting performance of glycerol-based lubricants under rolling-sliding contact conditions. Tribol. Int. 2022, 167, 107348. [Google Scholar] [CrossRef]

- Ayerdi, J.J.; Aginagalde, A.; Llavori, I.; Bonse, J.; Spaltmann, D.; Zabala, A. Ball-on-flat linear reciprocating tests: Critical assessment of wear volume determination methods and suggested improvements for ASTM D7755 standard. Wear 2021, 470–471, 203620. [Google Scholar] [CrossRef]

- Bijwe, J.; Sen, S.; Ghosh, A. Influence of PTFE content in PEEK–PTFE blends on mechanical properties and tribo-performance in various wear modes. Wear 2005, 258, 1536–1542. [Google Scholar] [CrossRef]

- Lin, Z.; Yue, H.; Gao, B. Enhancing tribological characteristics of PEEK by using PTFE composite as a sacrificial tribofilm-generating part in a novel dual-pins-on-disk tribometer. Wear 2020, 460–461, 203472. [Google Scholar] [CrossRef]

- Nadeem, I.; Malok, M.; Kovač, J.; Bin Yaqub, T.; Cavaleiro, A.; Kalin, M. Superior macro-scale tribological performance of steel contacts based on graphene quantum dots in aqueous glycerol. Tribol. Int. 2023, 181, 108328. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Guo, Y.; Bian, D.; Zhao, Y. Tribological Behavior of PEEK/PTFE Composites Reinforced with Carbon Fibers and Graphite. Materials 2022, 15, 7078. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Wang, H.; Fan, N.; Wang, M.; Liu, H.; Yan, F. Comparative study of the effects of nano-sized and micro-sized CF and PTFE on the thermal and tribological properties of PEEK composites. Polym. Adv. Technol. 2018, 29, 896–905. [Google Scholar] [CrossRef]

- Guo, L.; Pei, X.; Zhao, F.; Zhang, L.; Li, G.; Zhang, G. Tribofilm growth at sliding interfaces of PEEK composites and steel at low velocities. Tribol. Int. 2020, 151, 106456. [Google Scholar] [CrossRef]

- Dhakal, N.; Shi, Y.; Emami, N. Tribological behaviour of UHMWPE composites lubricated by polyvinylpyrrolidone-modified water. Lubr. Sci. 2021, 34, 42–53. [Google Scholar] [CrossRef]

- Kurdi, A.; Chang, L. Recent Advances in High Performance Polymers—Tribological Aspects. Lubricants 2019, 7, 2. [Google Scholar] [CrossRef] [Green Version]

| Name | Raw Material | Filler [wt%] | Modulus of Elasticity at 25 °C [GPa] | Poisson Coefficient ν | Water Absorption ISO 62 [%] |

|---|---|---|---|---|---|

| Polymer—plate | |||||

| PEEK CF30 | PEEK | 30% Carbon Fibres | 6.8 | 0.38–0.44 | 0.02 |

| PEEK MOD | PEEK | 10% Carbon Fibres, 10% Graphite and 10% PTFE Fibres | 5.92 | 0.38–0.44 | 0.3 |

| POM CF30 | POM | 30% Carbon Fibres | 3 | 0.35–0.49 | 0.01 |

| PTFE CF25 | PTFE | 25% Carbon Fibres | 1.1 | 0.46 | 0.05 |

| UHMW PE | UHMW PE | / | 0.76 | 0.4–0.42 | 0.01 |

| Counterpart—ball | |||||

| AISI 440-C stainless steel | Carbon | 16–18% Cr, max 1% Mn, Si, S, Mo | 200 | 0.285 | / |

| Density [g/cm3] | Kinematic Viscosity [mm2/s] | |||||

|---|---|---|---|---|---|---|

| Lubricant | 25 °C | 40 °C | 80 °C | 25 °C | 40 °C | 80 °C |

| Glycerol | 1.26 | 1.25 | 1.22 | 728.2 | 228.78 | 26.11 |

| Water | 0.99 | 0.99 | 0.97 | 0.89 | 0.66 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trajkovski, A.; Novak, N.; Pustavrh, J.; Kalin, M.; Majdič, F. Performance of Polymer Composites Lubricated with Glycerol and Water as Green Lubricants. Appl. Sci. 2023, 13, 7413. https://doi.org/10.3390/app13137413

Trajkovski A, Novak N, Pustavrh J, Kalin M, Majdič F. Performance of Polymer Composites Lubricated with Glycerol and Water as Green Lubricants. Applied Sciences. 2023; 13(13):7413. https://doi.org/10.3390/app13137413

Chicago/Turabian StyleTrajkovski, Ana, Nejc Novak, Jan Pustavrh, Mitjan Kalin, and Franc Majdič. 2023. "Performance of Polymer Composites Lubricated with Glycerol and Water as Green Lubricants" Applied Sciences 13, no. 13: 7413. https://doi.org/10.3390/app13137413

APA StyleTrajkovski, A., Novak, N., Pustavrh, J., Kalin, M., & Majdič, F. (2023). Performance of Polymer Composites Lubricated with Glycerol and Water as Green Lubricants. Applied Sciences, 13(13), 7413. https://doi.org/10.3390/app13137413