Impacts of Micro-Deviations of Aperture on the Characteristics of Collision Atomization Field

Abstract

:1. Introduction

2. Theoretical Background

3. Principle and Methods

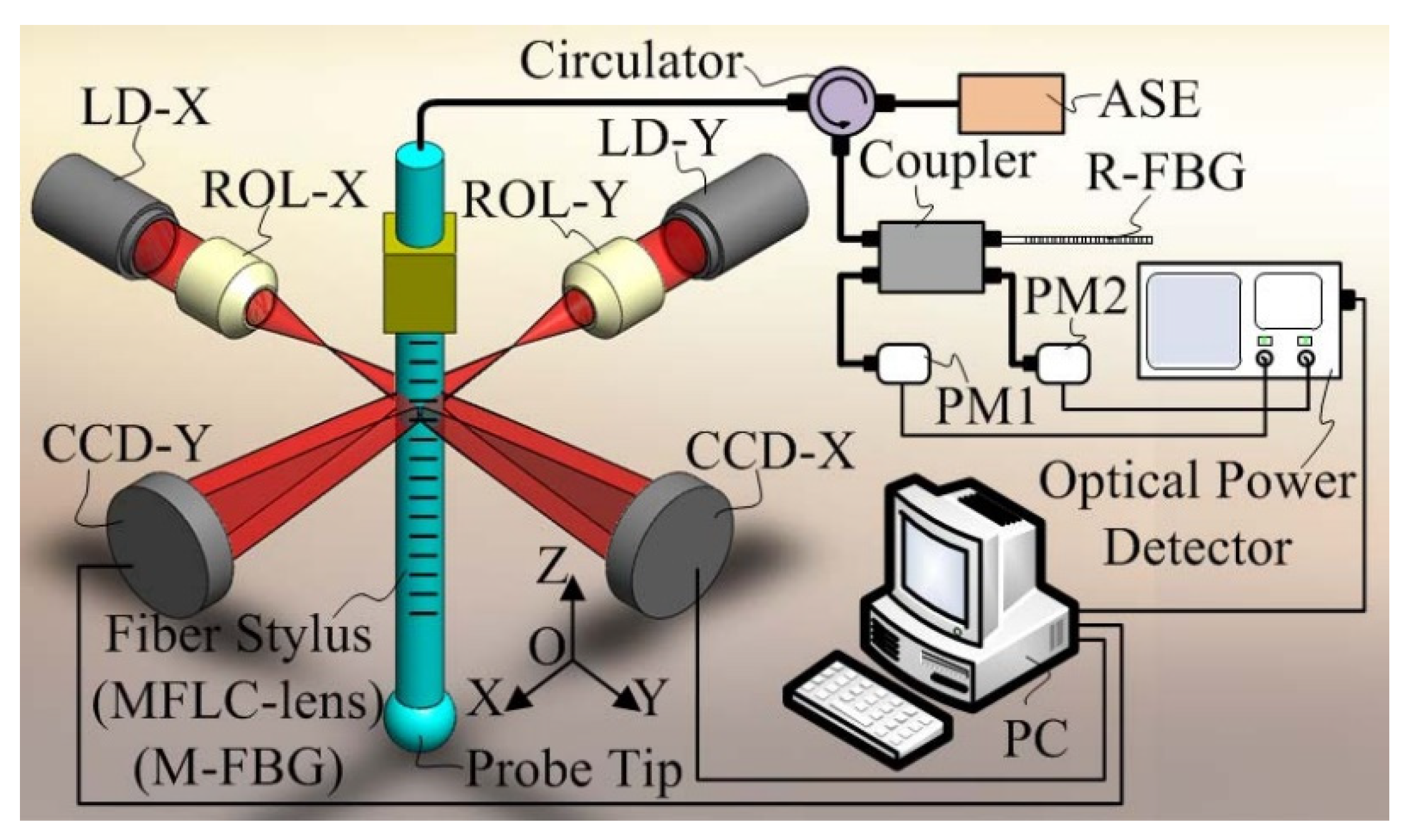

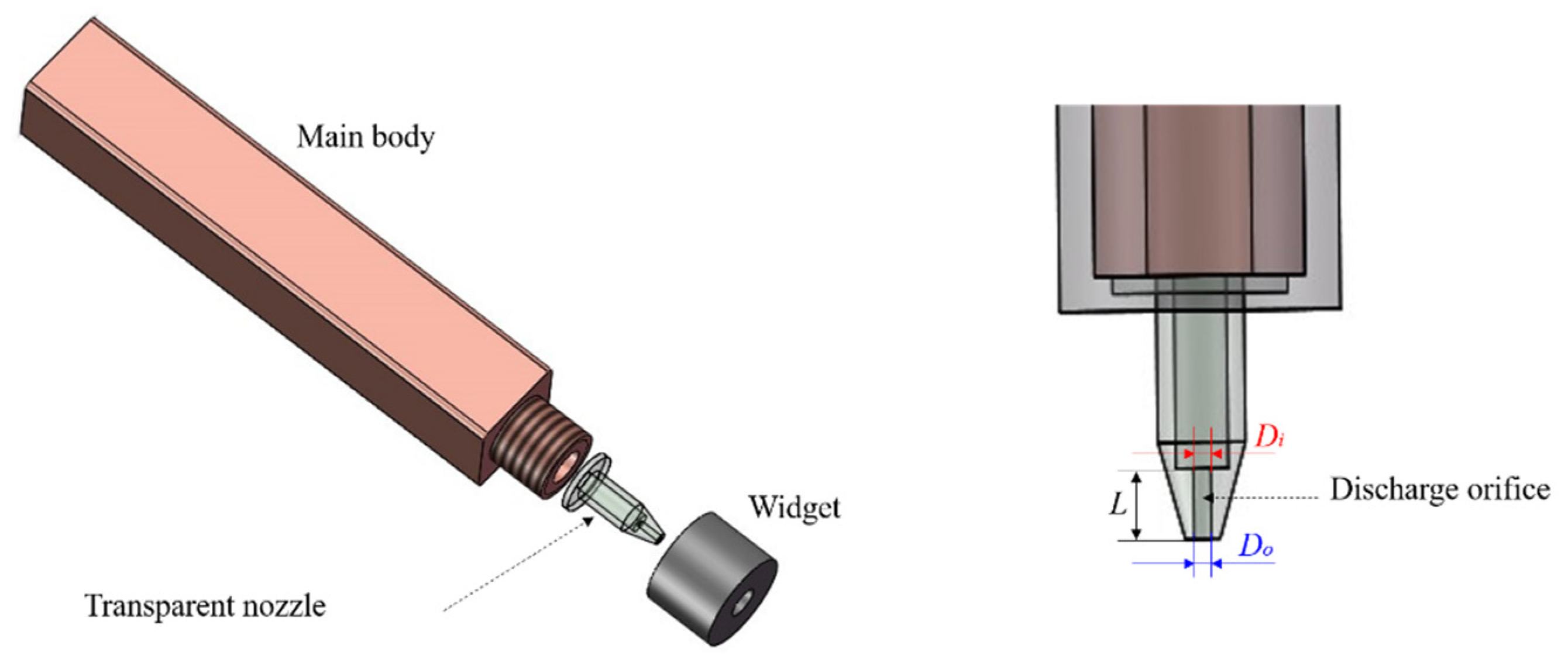

3.1. Measurement Method of Nozzle Diameter

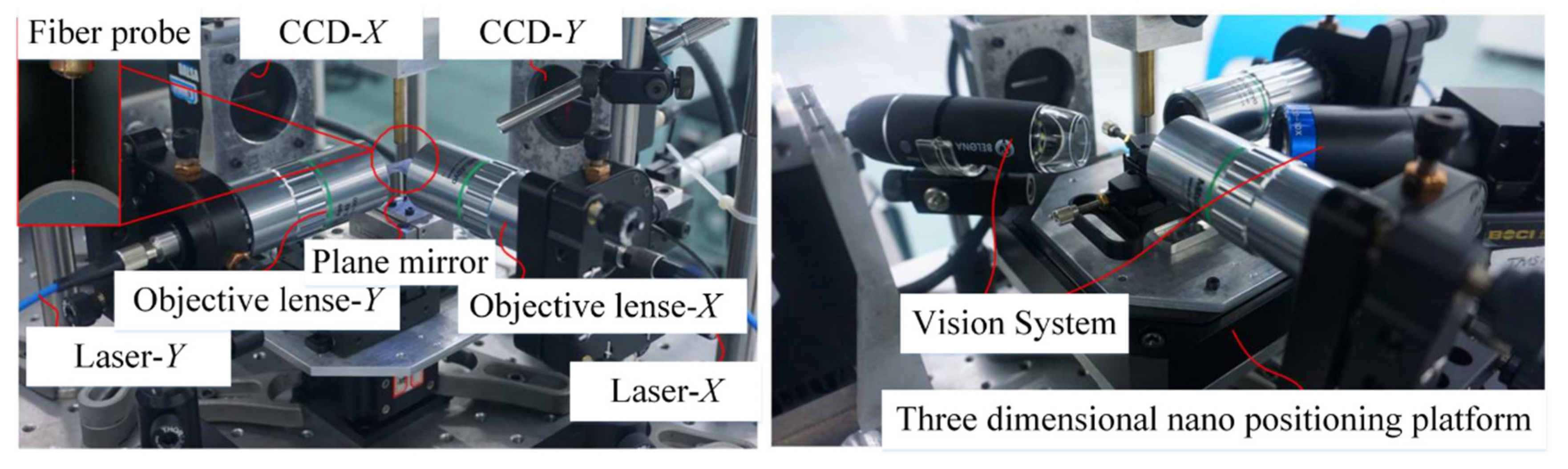

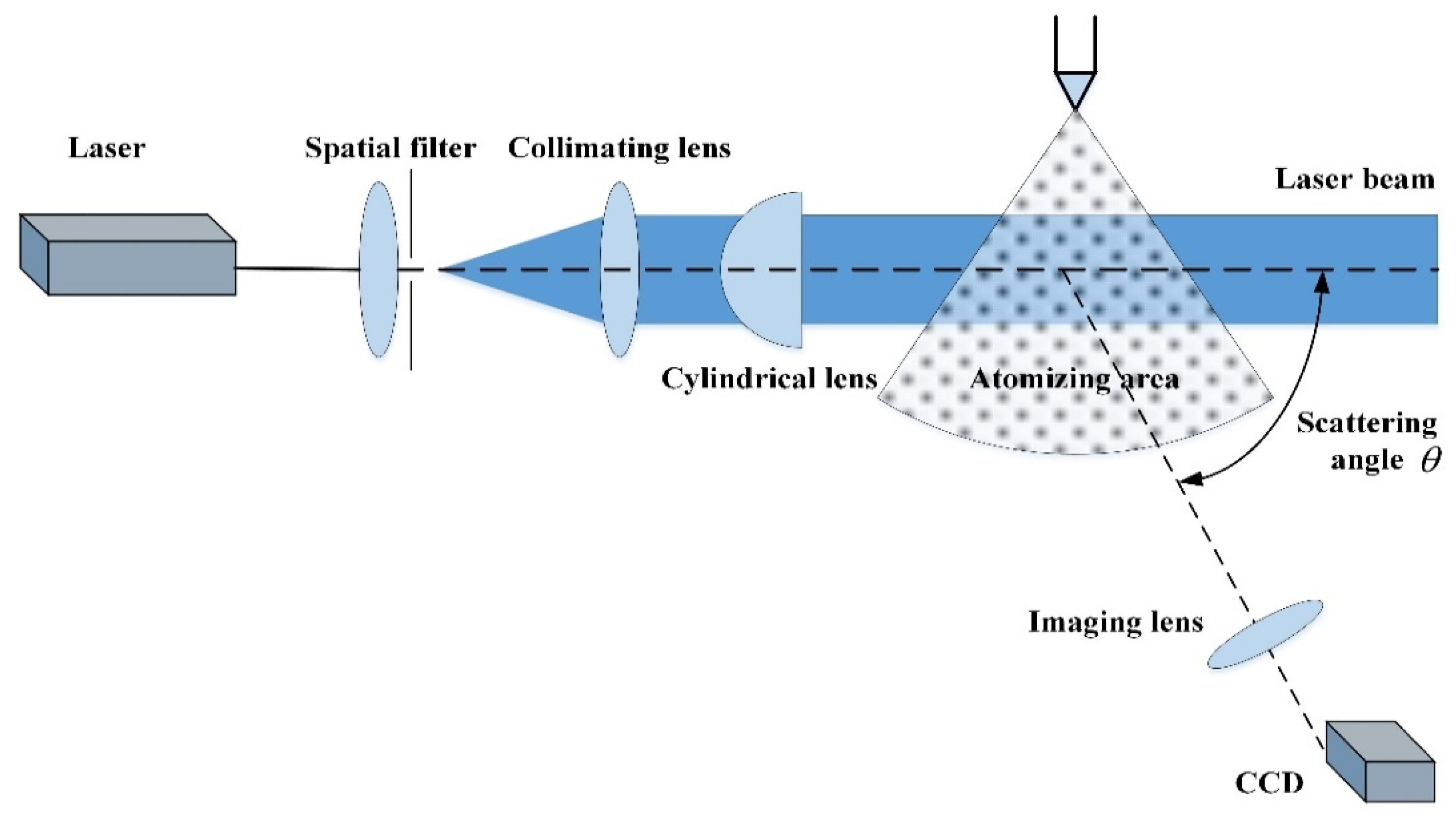

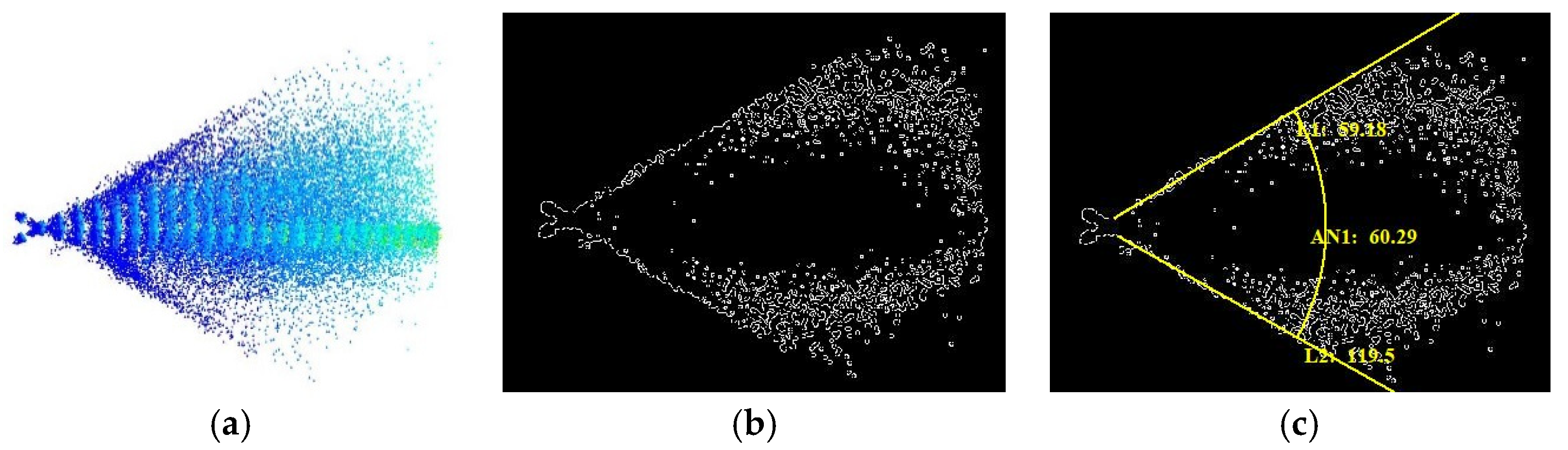

3.2. The Extraction Method of Atomized Particle Information

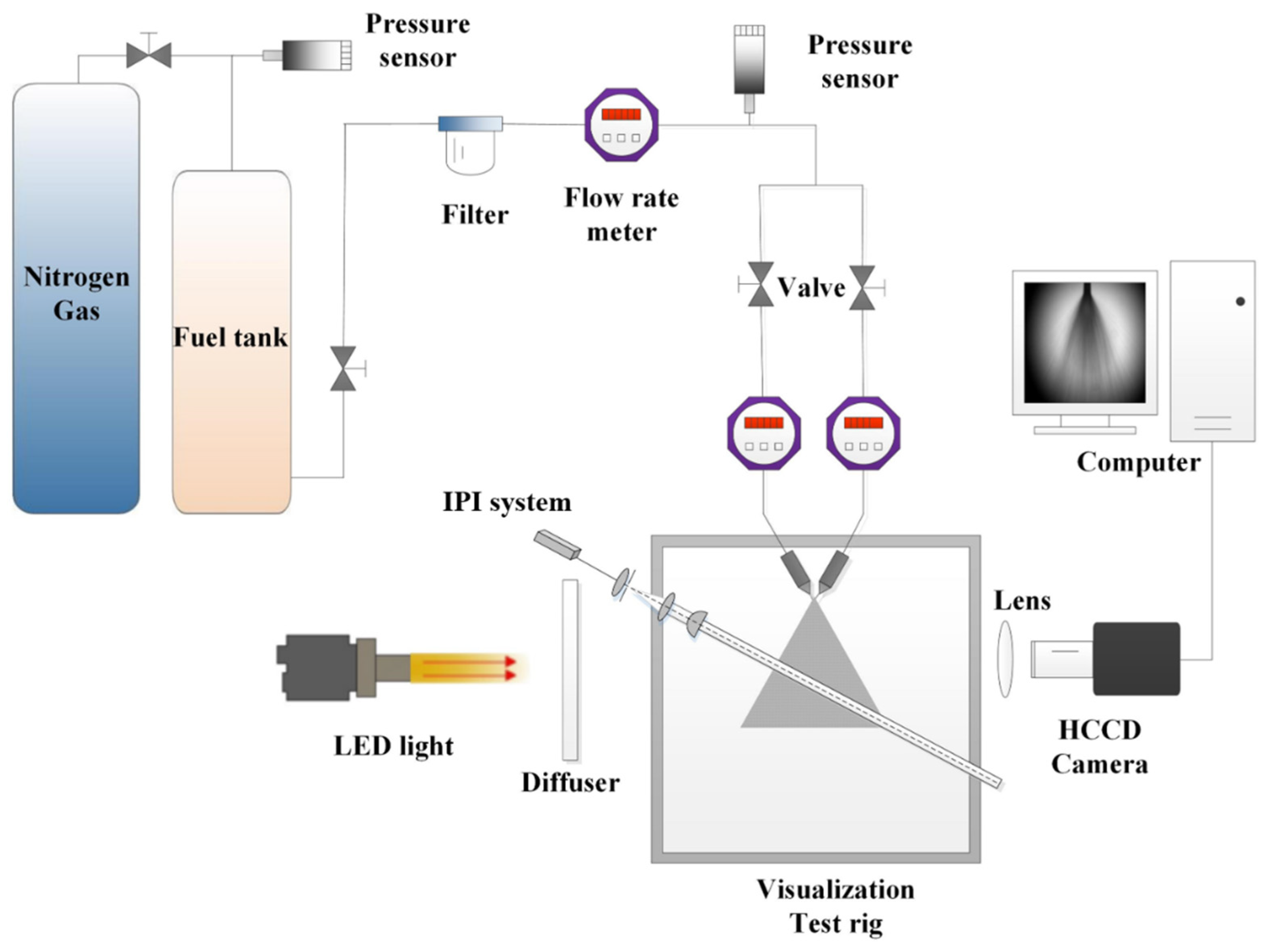

4. Experimental Setup

5. Results and Discussion

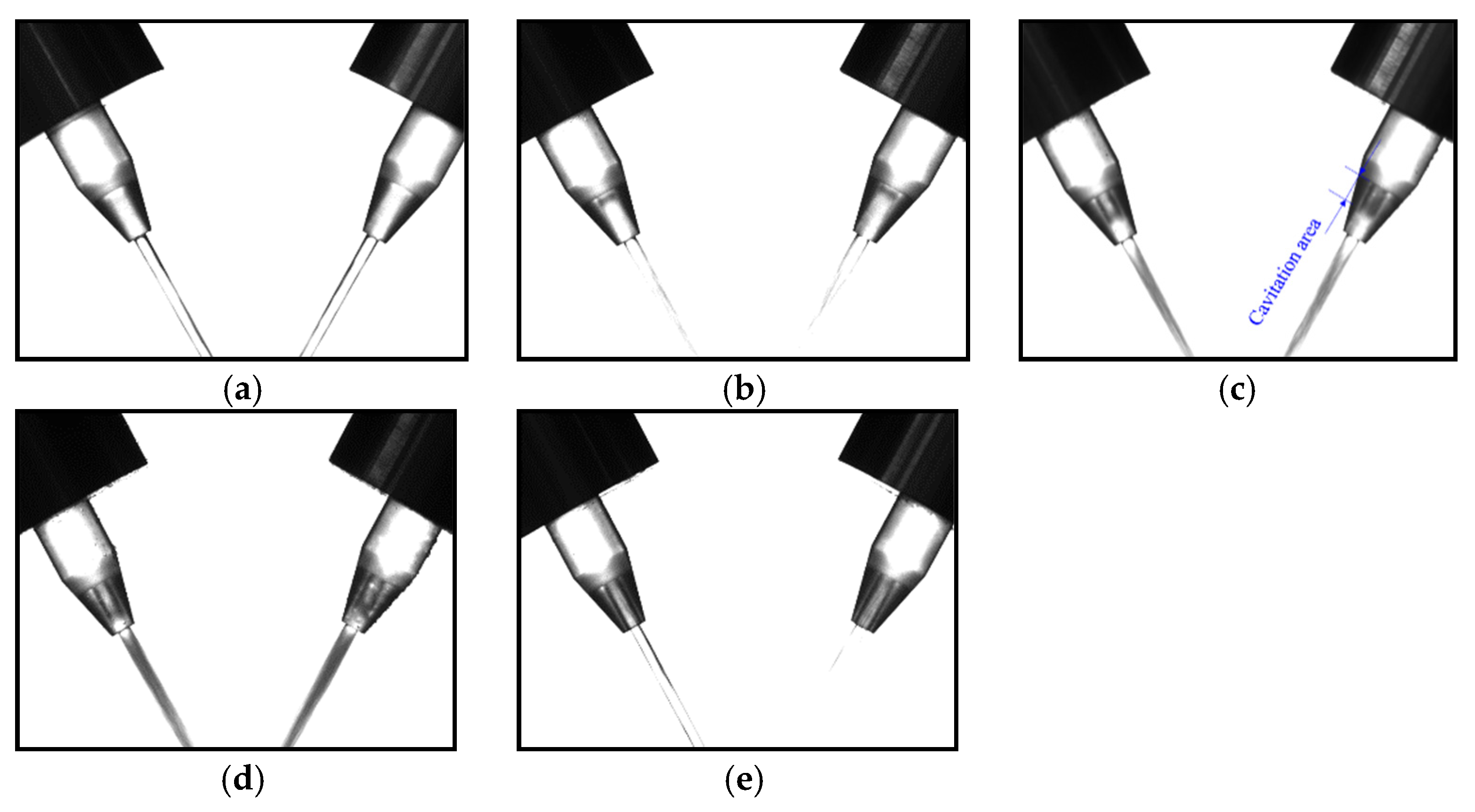

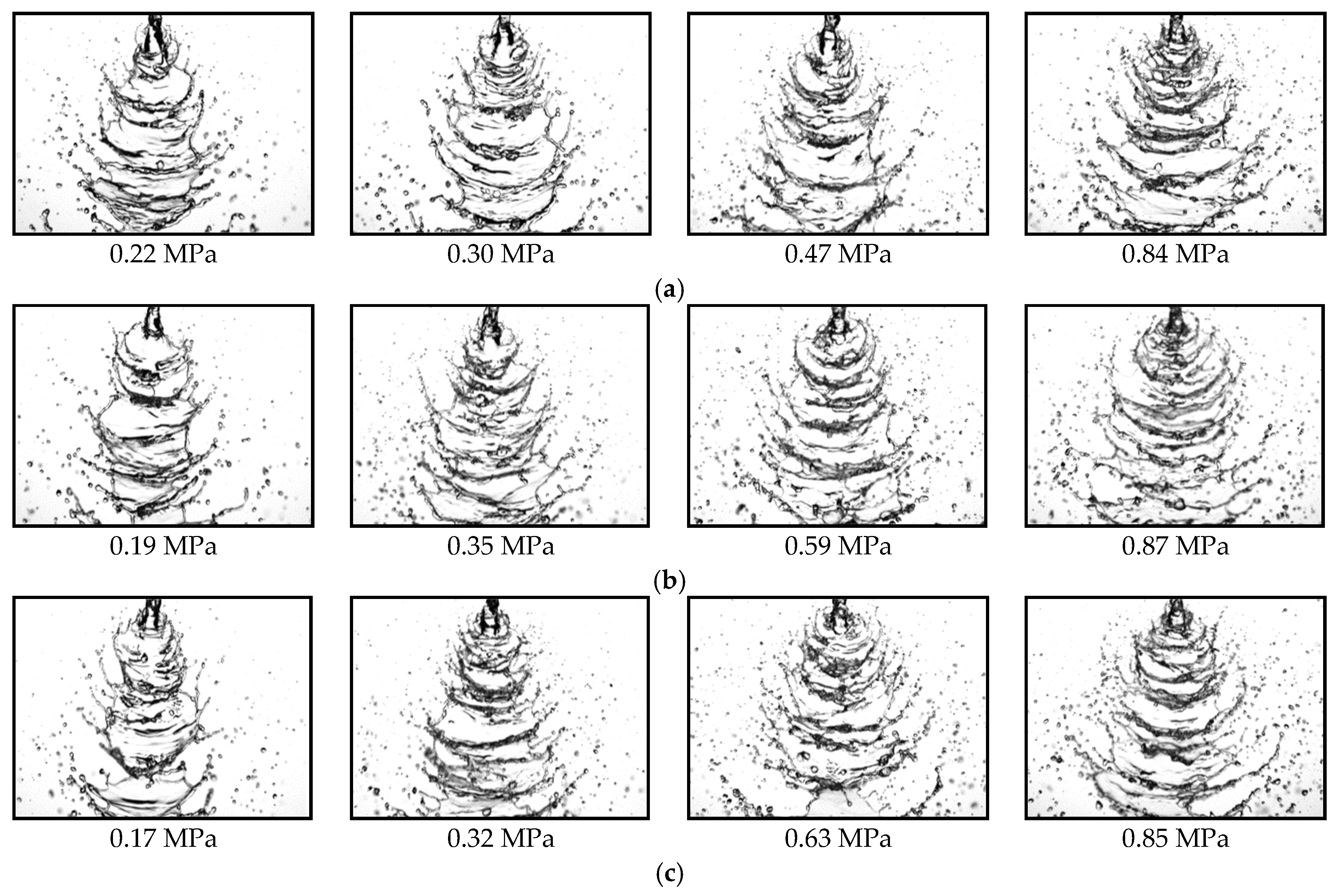

5.1. Cavitation Experiment of Internal Flow Field

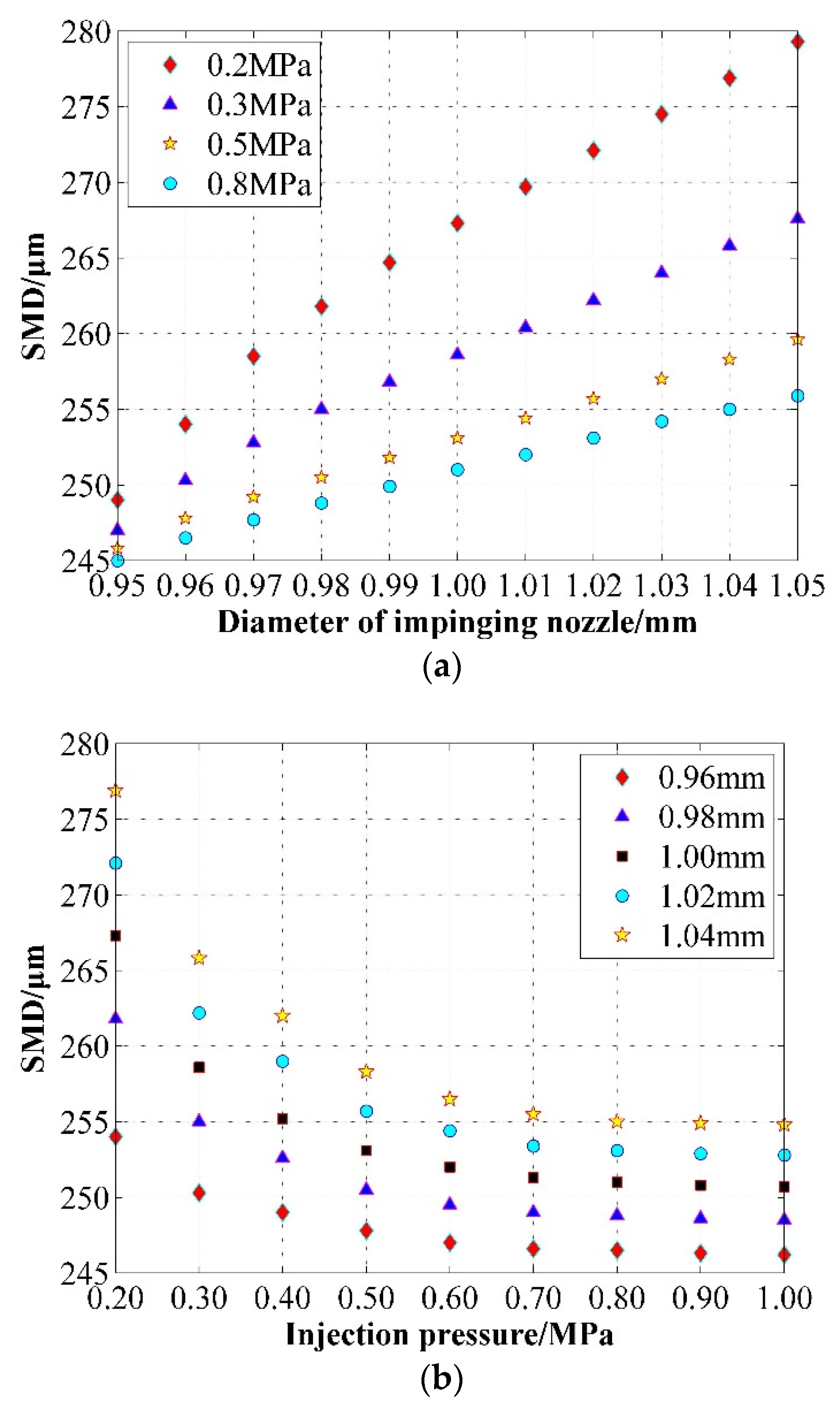

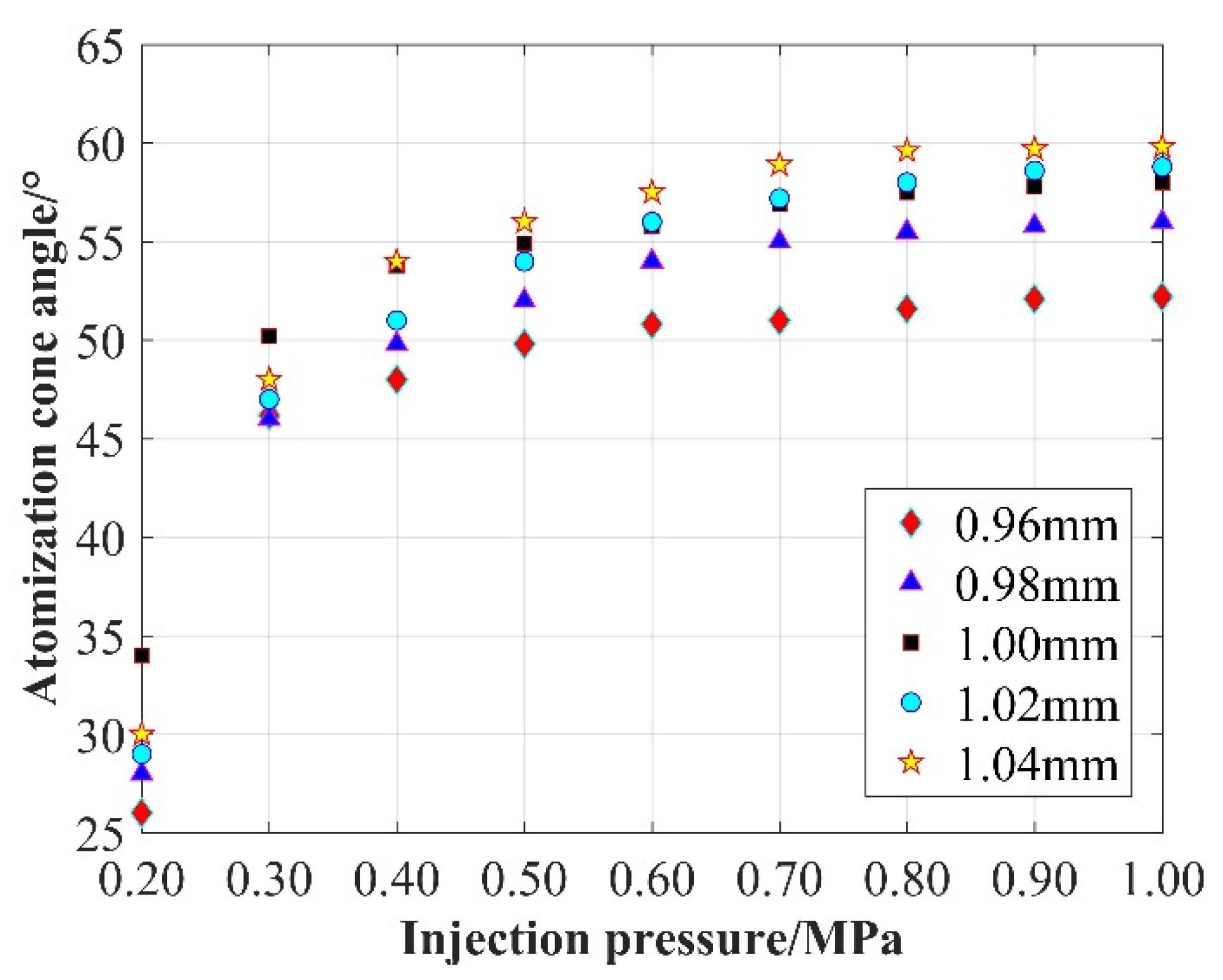

5.2. Influence of Colliding Aperture Deviation on Atomization Effect

6. Conclusions

- (1)

- For the impinging nozzle with a diameter of 1 mm and a length diameter ratio of 4, the injection pressures corresponding to the initial cavitation and flip states are 0.3 MPa and 0.8 MPa.

- (2)

- In the initial stage of cavitation, the changes in the SMD and cone angle are especially obvious. When the nozzle with the diameter of 1 mm has a 5% deviation, the maximum changes in the SMD and atomization cone angle can reach 30 μm and 18°. With increasing injection pressure, the decrease in SMD and the increase in the atomization cone angle reach the maximum 23 μm and 30°. The change in the two tends to be smooth, where SMD tends to 245~255 μm and the atomization cone angle tends to 52~60°.

- (3)

- When the injection pressure is high enough (0.8 MPa) and the air core reaches a certain length, a narrow flow will be formed in the orifice. In this state, the state of the flow field in the impinging nozzle, the SMD of the atomization field and the change in the atomization angle will become very small and almost reach the steady state. For the impinging nozzle with a diameter of 1 mm, the SMD is stable at 251 μm and the atomization cone angle is stable at 58°.

- (4)

- In addition, the increase in injection pressure will also increase the corresponding atomization cone angle of the same pair of nozzles, and finally the atomization cone angle tends to be stable, gradually approaching and not exceeding the collision angle of the two nozzles. When the impingement angle is 60°, the atomization angle of the nozzle with 1 mm aperture is close to 60°, and the nozzle with a 5% diameter deviation has a maximum stable atomization cone angle of 59.5° and a minimum of 52.3°.

- (5)

- The diameter deviation of the orifice is studied in this paper. In subsequent work, the influence of other orifice structure deviations or liquid properties on the performance of the atomization field can be considered. Additionally, related findings can be extended beyond the range of experiments to give the mathematical approximation of obtained data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhuang, F.; Nie, W.; Zhao, W.; Liu, W. Liquid rocket combustion instability analysis methodology-Methods and representative examples. In Proceedings of the 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cleveland, OH, USA, 13–15 July 1998. [Google Scholar]

- Cui, J.; Feng, K.; Li, J.; Tan, J. Development of a double fiber probe with a single fiber Bragg grating for dimensional measurement of microholes with high aspect ratios. Opt. Lett. 2014, 39, 2868–2871. [Google Scholar] [CrossRef] [PubMed]

- Macian, V.; Bermudez, V.; Payri, R.; Gimeno, J. New technique for determination of internal geometry of a diesel nozzle with the use of silicone methodology. Exp. Tech. 2003, 27, 39–43. [Google Scholar] [CrossRef]

- Pfeifer, T.; Schmitt, R.; Konig, N. Interferometric measurement of injection nozzles using ultra-small fiber-optical probes. Chin. Opt. Lett. 2011, 9, 37–40. [Google Scholar]

- Cui, J.; Li, J.; Feng, K.; Tan, J. Three-dimensional fiber probe based on orthogonal micro focal-length collimation for the measurement of micro parts. Opt. Express 2015, 23, 26386–26398. [Google Scholar] [CrossRef] [PubMed]

- Feng, K.; Cui, J.; Zhao, S.; Li, J.; Tan, J. A twin FBG probe and integration with a microhole-measuring machine for the measurement of microholes of high aspect ratios. IEEE/ASME Trans. Mechatron. 2016, 21, 1242–1251. [Google Scholar] [CrossRef]

- Cui, J.; Lai, H.; Li, J.; Ma, Y. Visualization of internal flow and the effect of orifice geometry on the characteristics of spray and flow field in pressure-swirl atomizers. Appl. Therm. Eng. 2017, 127, 812–822. [Google Scholar] [CrossRef]

- Jung, S.; Hoath, S.D.; Martin, G.D.; Hutchings, I.M. Atomization patterns produced by the oblique collision of two Newtonian liquid jets. Phys. Fluids 2010, 22, 042101. [Google Scholar]

- Lefebvre, A. Combustion. In Atomization and Sprays; Hemisphere Publishing Corporation: London, UK; Taylor & Francis: Boca Raton, FL, USA, 1988. [Google Scholar]

- Negeed, E.S.R.; Hidaka, S.; Kohno, M.; Takata, Y. Experimental and analytical investigation of liquid sheet breakup characteristics. Int. J. Heat Fluid Flow 2011, 32, 95–106. [Google Scholar] [CrossRef]

- Chen, X.; Ma, D.-J.; Yang, V.; Popinet, S. High-fidelity simulations of impinging jet atomization. At. Sprays 2013, 23, 1079–1101. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.C.P. The break-up of axisymmetric liquid sheets. J. Fluid Mech. 1970, 43, 305–319. [Google Scholar] [CrossRef]

- Zhao, L.; Torelli, R.; Zhu, X.; Scarcelli, R.; Som, S.; Schmidt, H.; Naber, J.; Lee, S.Y. An Experimental and Numerical Study of Diesel Spray Impingement on a Flat Plate. SAE Int. J. Fuels Lubr. 2017, 10, 407–422. [Google Scholar] [CrossRef]

- Rodrigues, C.; Barata, J.; Silva, A. Modeling of Droplet Deformation and Breakup. J. Propuls. Power 2016, 32, 698–706. [Google Scholar] [CrossRef]

- Yao, C.; Geng, P.; Yin, Z.; Hu, J.; Chen, D.; Ju, Y. Impacts of nozzle geometry on spray combustion of high pressure common rail injectors in a constant volume combustion chamber. Fuel 2016, 179, 235–245. [Google Scholar] [CrossRef]

- Ma, D.J.; Chen, X.D.; Khare, P.; Yang, V. Atomization patterns and breakup characteristics of liquid sheets formed by two impinging jets. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; pp. 1–14. [Google Scholar]

- Fu, Q.F.; Duan, R.Z.; Yang, L.J. Spray of gelled propellants from an impinging-jet injector under different temperatures. Aerosp. Sci. Technol. 2014, 39, 552–558. [Google Scholar] [CrossRef]

- Zheng, G.; Nie, W.; Feng, S.; Wu, G. Numerical Simulation of the Atomization Process of a Like-doublet Impinging Rocket Injector. Procedia Eng. 2015, 99, 930–938. [Google Scholar] [CrossRef] [Green Version]

- Salvador, F.J.; Romero, J.V.; Roselló, M.D.; Jaramillo, D. Numerical simulation of primary atomization in diesel spray at low injection pressure. J. Comput. Appl. Math. 2016, 291, 94–102. [Google Scholar] [CrossRef]

- Lee, I.; Koo, J. Break-up characteristics of gelled propellant simulants with various gelling agent contents. J. Therm. Sci. 2010, 19, 545–552. [Google Scholar] [CrossRef]

- Yang, L.J.; Fu, Q.F.; Qu, Y.Y.; Zhang, W.; Du, M.L.; Xu, B.R. Spray characteristics of gelled propellants in swirl injectors. Fuel 2012, 97, 253–261. [Google Scholar] [CrossRef]

- Baek, G.; Kim, S.; Han, J.; Kim, C. Atomization characteristics of impinging jets of gel material containing nanoparticles. J. Non-Newton. Fluid Mech. 2011, 166, 1272–1285. [Google Scholar] [CrossRef]

- Ren, N.; Marshall, A.W. Characterizing the initial spray from large Weber number impinging jets. Int. J. Multiph. Flow 2014, 58, 205–213. [Google Scholar] [CrossRef]

- Ma, Y.C.; Bai, F.Q.; Chang, Q.; Yi, J.M.; Jiao, K.; Du, Q. An experimental study on the atomization characteristics of impinging jets of power law fluid. J. Non-Newton. Fluid Mech. 2015, 217, 49–57. [Google Scholar] [CrossRef]

- Nurick, W.H. Orifice cavitation and its effect on spray mixing. J. Fluids Eng. 1976, 98, 681–687. [Google Scholar] [CrossRef]

- Sou, A.; Hosokawa, S.; Tomiyama, A. Effects of cavitation in a nozzle on liquid jet atomization. Int. J. Heat Mass Tran. 2007, 50, 3575–3582. [Google Scholar] [CrossRef] [Green Version]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Venegas, O. Study of cavitation phenomenon using different fuels in a transparent nozzle by hydraulic characterization and vi-sualization. Exp. Therm. Fluid Sci. 2013, 44, 235–244. [Google Scholar] [CrossRef] [Green Version]

- Payri, R.; Salvador, F.; Gimeno, J.; de la Morena, J. Study of cavitation phenomena based on a technique for visualizing bubbles in a liquid pressurized chamber. Int. J. Heat Fluid Flow 2009, 30, 768–777. [Google Scholar] [CrossRef]

- Cui, J.; Li, J.; Feng, K.; Tan, J. Three-dimensional fiber probe based on micro focal-length collimation and a fiber Bragg grating for the measurement of micro parts. Opt. Lett. 2015, 40, 3348–3351. [Google Scholar] [CrossRef]

- Cui, J.; Li, J.; Feng, K.; Tan, J.; Zhang, J. A 3D fiber probe based on orthogonal micro focal-length collimation and fiber Bragg grating. Meas. Sci. Technol. 2016, 27, 074005. [Google Scholar] [CrossRef]

- Li, J.; Cui, J.; Tan, J. Design of Three-dimensional Isotropic Microprobe Based on Three-Flexible-Hinge Suspension for Measurement of Microstructures. IEEE/ASME Trans. Mechatron. 2020, 25, 2123–2133. [Google Scholar] [CrossRef]

- Knig, G.; Anders, K.; Frohn, A. A new light-scattering technique to measure the diameter of periodically generated moving droplets-ScienceDirect. J. Aerosol Sci. 1986, 17, 157–167. [Google Scholar] [CrossRef]

- Shen, H.; Coetmellec, S.; Brunel, M. Simultaneous 3D location and size measurement of spherical bubbles using cylindrical interferometric out-of-focus imaging. J. Quant. Spectrosc. Radiat. Transf. 2013, 131, 153–159. [Google Scholar] [CrossRef]

- Dunker, C.; Roloff, C.; Grassmann, A. Interferometric laser imaging for in-flight cloud droplet sizing. Meas. Sci. Technol. 2016, 27, 124004. [Google Scholar] [CrossRef]

- Cui, J.; Lai, H.; Li, J.; Ma, Y. Quantitative analysis of the minor deviations in nozzle internal geometry effect on the cavitating flow. Exp. Therm. Fluid Sci. 2018, 94, 89–98. [Google Scholar] [CrossRef]

- Lai, H. Research on The Influence of Nozzle Geometrical Deviations on The Atomization Characteristics of Fuel Injectors. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Heidmann, M.F.; Priem, R.J.; Humphrey, J.C. A Study of Sprays Formed by Two Impinging Jets; National Advisory Committee for Aeronautics: Moffett Field, CA, USA, 1957. [Google Scholar]

| Nozzle ID | Designed Value (mm) | Inlet Di (mm) | Outlet Do (mm) | Mean Error (%) |

|---|---|---|---|---|

| N1 | 0.95 | 0.94736 | 0.95152 | −0.059 |

| N2 | 0.96 | 0.96273 | 0.96084 | 0.186 |

| N3 | 0.97 | 0.96933 | 0.97216 | 0.077 |

| N4 | 0.98 | 0.97879 | 0.97753 | −0.188 |

| N5 | 0.99 | 0.98785 | 0.99219 | 0.002 |

| N6 | 1.00 | 1.00085 | 1.00337 | 0.211 |

| N7 | 1.01 | 1.00978 | 1.01198 | 0.087 |

| N8 | 1.02 | 1.02327 | 1.02423 | 0.368 |

| N9 | 1.03 | 1.02892 | 1.02826 | −0.137 |

| N10 | 1.04 | 1.04204 | 1.03775 | −0.010 |

| N11 | 1.05 | 1.04502 | 1.05174 | −0.154 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Cui, J.; Wang, H.; Tan, J. Impacts of Micro-Deviations of Aperture on the Characteristics of Collision Atomization Field. Appl. Sci. 2022, 12, 4685. https://doi.org/10.3390/app12094685

Ma Y, Cui J, Wang H, Tan J. Impacts of Micro-Deviations of Aperture on the Characteristics of Collision Atomization Field. Applied Sciences. 2022; 12(9):4685. https://doi.org/10.3390/app12094685

Chicago/Turabian StyleMa, Yarui, Jiwen Cui, Hui Wang, and Jiubin Tan. 2022. "Impacts of Micro-Deviations of Aperture on the Characteristics of Collision Atomization Field" Applied Sciences 12, no. 9: 4685. https://doi.org/10.3390/app12094685

APA StyleMa, Y., Cui, J., Wang, H., & Tan, J. (2022). Impacts of Micro-Deviations of Aperture on the Characteristics of Collision Atomization Field. Applied Sciences, 12(9), 4685. https://doi.org/10.3390/app12094685