Abstract

This study investigated the effects of the use of low magnetic fields as a potential method for improving the quality of apples after storage. The fruit were exposed to 100 μT magnetic fields for 8 h per day and kept for a period of two weeks in room conditions. The results showed that the samples that were treated with a magnetic field generally had a higher value ratio of total soluble solid and titratable acidity compared to the untreated samples, which indicated their higher quality. Continuous treatment with a magnetic field influenced the mechanical properties of apples, as demonstrated by the greater firmness, lower weight loss and suppressed CO2 production of the apples that were stored in room conditions. After the treatment of the apples, a new product was produced with greater firmness, higher quality potential (the ratio of total soluble solid and titratable acidity) and an extended shelf life/lower respiration rate. Therefore, treatment with a magnetic field can be used to extend the shelf life of apples and needs to be demonstrated by further investigations.

1. Introduction

Apples are an important source of sugars, amino acids, proteins, organic acids, vitamins and minerals in the human diet. This is important because it is recommended that they are eaten fresh. However, they are perishable products with a high metabolism and respiration rate, which are responsible for their limited shelf life [1]. Improvements in the postharvest treatment of fresh fruit are very important for increasing food availability [2] because losses during postharvest handling can reach 25–28% [3].

Apples have varied nutritional qualities that are lost during postharvest processing. Losses that occur during storage depend on external and internal conditions. The temperature and relative humidity during postharvest handling activities have the greatest impact on the storage efficiency of apples and the quality characteristics of fruit and thus, affect their shelf life [4,5]. They affect, for example, fruit firmness, weight loss, titratable acidity and the content of soluble solids [6]. During ripening, there is a process of pectin degradation that plays an important role in cell wall degradation, which also has an effect on the shelf life of fruit [7].

Proper postharvest handling involves altering the natural conditions of the product in order to prolong their postharvest life [8]. Therefore, there is a need to find a new method for reducing the softening and senescence and prolonging the shelf life of fruit that are kept at room temperature after storage. This would provide a much-needed improvement in postharvest technology.

This need can be met using physical methods (high voltage electric field, UV-C light, IR radiation, microwave radiation, etc.).

The use of an alternating magnetic field (AMF) also has the potential to meet this need. AMFs are naturally occurring, easy to use, low on energy consumption and safe for the environment [9]. Magnetic fields have been reported to exert a positive effect on living organisms by influencing metabolic pathways [10,11,12]. Magnetic fields can change the selective permeability of a membrane, the position of the main membrane components (protein and lipid domains) and the molecular position of the electric charge. This can affect turgor pressure variations. The above changes may affect the rate of the physical, biochemical and physiological processes of the tissue of biological material. They also influence the activation of protein synthesis, thus increasing the viability of organisms [13,14,15,16]. Alternating magnetic fields (AMFs) have been used by researchers to treat seedlings, plants, fruit and irrigated water. Numerous scientists have reported the positive effects of AMFs on plant growth. The treatment of plant crops with a magnetic field increases the germination rate, size and dry weight of the plant. After the application of a magnetic field, there can also be improvement in the parameters of fruit growth, such as an increase in the number of leaves, the leaf surface, the macroelement content in the leaves and the number of flowers and fruit per plant. A variable magnetic field can also increase the total fruit yield as well as the average weight of the fruit [17].

High voltage electric fields (HVEFs) can be used to extend the shelf life and improve the quality of fruit and vegetables. The electric field reduces the rate of cellular respiration and ethylene production, thus extending the postharvest shelf life. The electric field increases the action of the SOD, APX and CAT enzymes and increases the concentrations of reduced glutathione, ascorbic acid and polyphenols [17].

UV-C light has direct and indirect inhibitory and damaging effects on living cells; therefore, it is widely used for disinfection purposes. UV-C light stimulates the synthesis and accumulation of health-promoting phytochemicals before and after harvest, extends the shelf life of fruit and vegetables and stimulates the mechanisms of adaptation to biotic and abiotic ranges. This could be related to the stimulation of the production of reactive oxygen species (ROS) and the stimulation of molecules and antioxidant mechanisms. UV-C can also trigger and regulate signalling pathways due to its effect on ROS production [18].

Microwave radiation is a component of the electromagnetic spectrum that ranges from 300 MHz to 300 GHz. Microwave radiation can cause different biological effects depending on the field strength, wave form, modulation and duration of the exposure. The positive effects of microwave radiation on the germination of seeds and tubers have been demonstrated. Microwave radiation modifies the germination process and reduces crop infections. The exposure of seeds to microwave radiation appears to be beneficial for increasing the germination, growth and vigour of emerging seedlings and the accumulation of biomass in various plant species. The susceptibility of plants to microwave radiation depends on environmental conditions. MW radiation in living tissues causes ion movement, dipole rotation and the distortion of the electronic orbit, which results in rapid and selective heating. Non-destructive MW treatments are widely used to disinfect seeds before sowing or storage [18].

IR radiation is a part of the electromagnetic spectrum within the wavelength range of 0.5 to 1000 mm and is mainly used in food processing. Infrared (IR) radiation is used as an effective method for the disinfection and drying of seeds and the postharvest disinfection of fresh fruit and vegetables. Gamma (γ) radiation is a type of infrared radiation that can penetrate and interact with living tissues. Gamma radiation is used to remove microbial contamination or control insect pests and pathogens, thereby preventing plant diseases. Γ radiation is also used to delay fruit ripening and vegetable germination by inhibiting the activation of key enzyme activities, which results in the extended shelf life of crops. Γ rays are used by plant breeders to obtain the desired characteristics of plants or develop new varieties. The biological effects of γ rays are strongly dependent on the intensity, dose and duration of the exposure. Irradiation with lower doses of γ rays has a positive effect on the morphological features of plants and improves seed germination efficiency. Low-dose irradiation also has a beneficial effect on the production characteristics of crops. Low doses of γ radiation have a stimulating effect on enzymatic activity and the synthesis of nucleic acids and proteins in treated seeds [18].

The use of the above-mentioned physical methods can contribute to satisfying consumer demand for healthy fruit and vegetables with extended storage and storage times.

The objective of this research was to study the effects of treatment with a 100 μT MF on the quality and shelf life of apples after storage that were kept at room temperature.

2. Materials and Methods

2.1. Materials

Idared (Idaredest) and Legal (Red Sour) apples that were harvested at commercial maturity were procured from local producers and stored in a cold store at 3 °C until the experiment began. Experiments on apples were performed in February and March, after storage. The basic postharvest characteristics of the fruit that were tested are presented in Table 1.

Table 1.

Characteristics of the studied fruit.

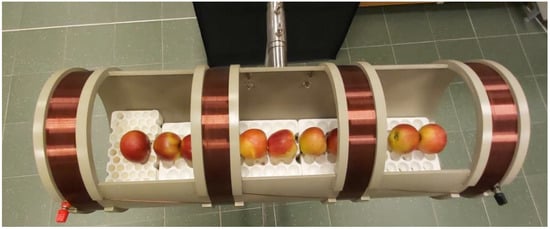

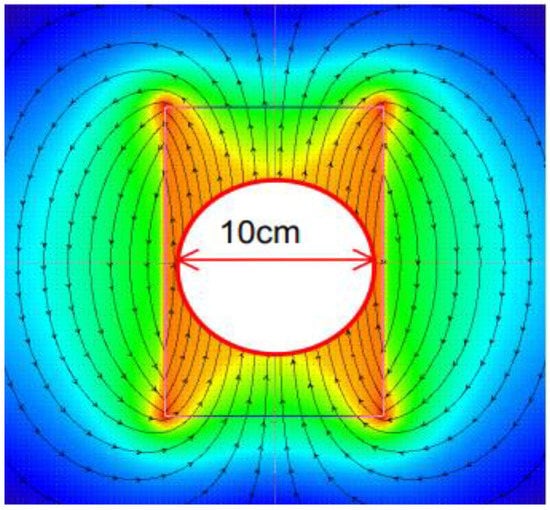

Prior to the trial, fruit were manually selected on the basis of their color, size, uniformity and the lack of physical damage to their surface. Then, they were divided into 2 groups. They were kept for two weeks. The control group was kept in room conditions (at a temperature of 22 °C and relative humidity of 50%). The study group was placed on the base of the central point between the coils as shown in Figure 1 and treated with a magnetic field of 100 μT for 8 h per day in room conditions. Fruit were arranged horizontally with each of their calyxins facing towards the south magnetic field. After connecting the power supply, the passing current produced a magnetic field with homogeneous distribution inside the coil, which had a diameter of 10 cm (Figure 2).

Figure 1.

Coil designed for fruit storage in room conditions.

Figure 2.

Distribution of the magnetic field in the coil.

The quality parameters of the MF and control groups were evaluated after cold storage and after 14 days of storage in room conditions.

The experiment was performed 3–4 times after 120 days of cold storage and at 14-day intervals.

2.2. Magnetic Field Treatment (MF)

The parameters of the above-mentioned magnetic treatment were outlined in a previous study [16].

The magnetic field was generated using cylindrical magnets (length, 100 mm; width, 10 mm). The fruit were exposed to a 100 μT magnetic field during storage at room temperature. The control fruit were not exposed to a magnetic field.

The resulting MFD density was measured using the Kanetec TM801 Tesla. Slow changing fields were produced by means of a 12-layer induction coil with the dimensions of 40 cm × 3.5 cm, which was powered by a 50 Hz AC autotransformer [16].

It consisted of two parallel couples of Helmholtz coils, with the radius of each coil being the same as the distance between them. Two pairs of coils were connected in series and connected to a potential transformer that was capable of converting direct current into alternating current power. The fruit were placed on a substrate at the central point between the coils in an area with a uniform magnetic field. After the treatment, the quality of the apples was assessed on the basis of firmness, TSS, TA, DM and respiration rate.

2.3. Firmness (N)

Tests were performed using an Effigi penetrometer with a diameter of 11.1 mm and a cylindrical tip with a convex face for the penetration of the apple flesh. Penetration tests to a depth of 8 mm were conducted on fruit flesh without a layer of skin. The skin puncture tests were carried out on the two opposite sides of each apple, near the centre, and the average values were reported. The penetration tests were carried out with a 2 mm/s speed of approach of the probe. The peak force (N) indicated the maximum force that was registered during the penetration, which was related to the firmness of the fruit.

2.4. Total Soluble Solid (TSS, °Bx)

The total soluble carbohydrate concentration and acidity were determined using a near-infrared (NIR) fruit selector (F-750 PRODUCE Quality METER, Felix Instruments Inc., Camas, WA, USA), which was calibrated for apples.

To measure the total soluble solids, apple juice was extracted using a home juicer and then filtered through a cotton muslin cloth. The TSS of the filtered juice was measured using a manual refractometer with automatic temperature compensation (DIGITAL REFRRACTOMETER PAL-3, Atago Co.,Ltd., Bellevue, WA, USA), which had at least 0.2% Brix. The following formula was used for the conversion: total soluble solids TSS/acid = titratable acidity.

2.5. Titratable Acidity (TA, %)

The acidity (malic acid mg/5 g fr.wt) was obtained using the Association of Official Analytical Chemists [19] method with slight modifications and the results were presented as percentage of malic acid. Three repetitions were carried out for the determination of TSS and acidity values in the apple juice and the obtained results were recorded. The apple juice was diluted with distilled water (25 mL) and titrated with a 0.1 mol/L NaOH solution with phenolphthalein used as the indicator. The calculation was made using the following formula:

Titratable acidity (malic acid mg/5 g fr.wt) = d × 0.006 (when the NaoH solution is 0.1 N) a × b × c, where a is the weight of the sample, b is the volume of the aliquot being examined, c is the total volume with the distilled water and d is the average burette reading for the sample.

2.6. Dry Matter (DM, %)

The DMC was calculated as the ratio of dry to fresh mass and expressed as a percentage. In the test material, the dry weight was determined in accordance with the methodology [20]. The DMC was determined using samples with a flesh thickness of 10 mm and skin tissues from the cross section that was removed from the equatorial area of each apple. Next, they were oven-dried at 65 °C for 48 h. The dry mass content of each fruit was determined in relation to the fresh mass and the results were expressed as a percentage.

2.7. Respiration Rate (CO2, mg/g fr.wt)

The respiration rate of the apples was calculated according to the method of Zaguła et al., 2020, with some modifications [21]. The respiration rate was expressed as the milligrams of CO2 that was produced per g of fruit per 24 h (mg/g). The increase in carbon dioxide was measured by monitoring the CO2 production of the treated and untreated fruit, which were enclosed in a chamber with a volume of 10 dm3 for 24 h at a room temperature of 20 °C and RH of 55%.

The fruit’s production of CO2 was measured using ULTRAMAT 23 apparatus (Siemens, London, England). The following tests were replicated three times. After 72 h, the measuring sensors of the Siemens apparatus were connected to each container in order to measure the level of oxides (the intensity of respiration).

The sensors were connected to each container, then the stopper at the bottom of the container was removed and the apparatus was able to detect the CO2 that was discharged over 72 h from the cellular respiration process of the apples. The apparatus collected a gas sample at a rate of 1 dcm3/min using a probe. The gas concentrations were measured for 10 min until the chamber was completely empty.

2.8. Statistical Analysis

The results were expressed as mean values and significant differences were marked with different Arabic letters. The data that were obtained from four independent measurements of Idared and three independent measurements of Ligol apples after storage in a cold store and being treated with MF or kept as a control in room conditions were subjected to a one-way analysis of variance (ANOVA) to detect significant differences between the mean parameters by means of Statistica 10, using Tukey’s post-hoc test, at α = 0.05 and the number of repetitions n = 3.

Linear regression analysis was used to determine the trends of change in the total soluble solids of the apples during storage maturity and between the dry matter DM and the TSS/TA ratio.

3. Results and Discussion

3.1. Fruit Firmness

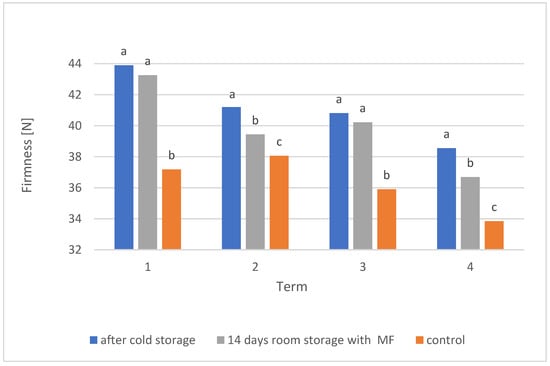

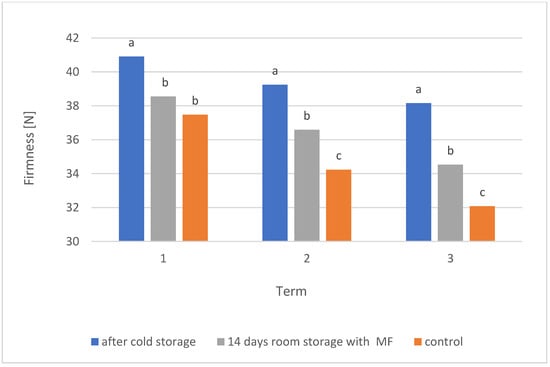

Firmness is an important parameter that is associated with the ripeness, harvest time and quality grade of fruit [22]. The results of the measurements of the firmness parameter for the control and magnetic field-treated fruit of the Idared and Ligol varieties are shown in Figure 3 and Figure 4, respectively. Fruit firmness in both groups decreased continuously over the duration of cold storage and after the 14 days in room conditions for each experiment. After 14 days in room conditions, fruit firmness was higher in the apples that were treated with the magnetic field compared to the control in all cases that were tested. It could be seen that using a magnetic field of 100 μT with a frequency of 50 Hz for both of the studied varieties produced an observed increase in the firmness parameter of up to 10%, depending on the characteristics of the fruit. There were significant differences between the control fruit and those treated with a magnetic field. These could have been influenced by the metabolism of the fruit, which is responsible for the rapid conversion of protopectin into pectin and is related to fruit firmness [23]. The higher firmness values that were found in this study after magnetic field treatment were also likely due to the electroporation that was induced by the electrical impulses, which increases the permeability of cell membranes [24]. In this way, the cell membranes can recover their integrity and structure, which results in firmer tissues. These results showed that the MF treatment retarded the softening of the fruit tissue. Therefore, the application of MF treatment at 100 μT for 8 h per day is the proposed method for maintaining the firmness of apples. The same observations were confirmed by the study of Zaguła et al. [25]. Their results also showed an increase in the postharvest firmness of strawberries of up to 30% using an AMF of 50–150 μT in comparison to a control. MFs penetrate deeper into tissues, which may cause changes in cellular metabolic pathways [11]. Another team of scientists analysed the effects of an electric field on tomatoes and apples. They reported that the electric field permeabilised the cell membrane, which resulted in tissue softening. The pulsating electric field reduced the loss of turgor and the fracture of apple cell membranes [26] and the firmness value of tomatoes [27].

Figure 3.

Effects of MF on the firmness of Idared apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

Figure 4.

Effects of MF on the firmness of Ligol apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

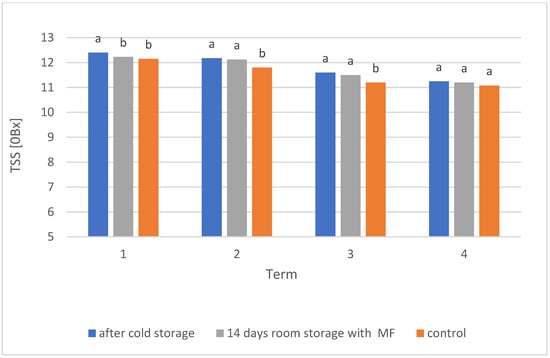

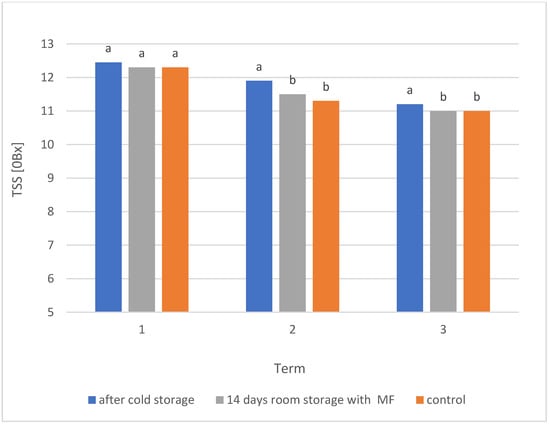

3.2. Total Soluble Solids

The soluble solids percentage values of the fruit that were treated with a magnetic field compared to those of the control samples are shown in Figure 5 and Figure 6. The samples that were treated with a magnetic field had a lower percentage change in soluble sugar concentration than the control samples. After 14 days in room conditions, the TSS values were higher in the apples that were treated with a magnetic field than in the control fruit for each experiment. However, significant differences were only found in the Idared variety between experiments two and three. The MF treatment induced changes in the total soluble solids (TSS) content of the apples. The first TSS measurement for the control group averaged 11.8% and was significantly higher after MF treatment. In this way, TSS values increased by as much as 5% and reached maximum concentrations in the apples that were subjected to MF treatment. Scientists have proved that soluble carbohydrates are cell components of structural and metabolic importance [28]. An increase in TSS may be in response to osmotic stress [29,30]. The application of MF treatment may also the cause of the disorganisation of cell wall polysaccharides and molecular bonds [31], which could lead to a change in the TSS content.

Figure 5.

Effects of MF on the TSS of Idared apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

Figure 6.

Effects of MF on the TSS of Ligol apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

The TSS of the stored apples varied significantly (p < 0.05) in relation to temperature and duration of storage. The total soluble solid content of apples in cold storage (12.2%, on average) was higher than that of apples in room conditions with MF treatment (12.0%, on average) and the control samples (11.7%, on average). The study showed that the storage of apples at room temperature (22 °C) or in cold storage (3 °C) resulted in a decreased TSS content. The TSS value of the Idared variety generally decreased over the course of the four experiments of the study from 12.6 to 11.4% and from 12.2 to 11.3% for apples in room conditions with MF treatment and the control group, respectively. This could have been caused by the use of monosaccharides (glucose, sucrose and fructose) in the cellular respiration process during storage [32]. Similarly, storing apples indoors showed an adverse effect on their TSS content. Extending the shelf life resulted in a significant decrease in TSS content. The variability in TTS content during the storage of apples is illustrated by a linear regression with the coefficient of determination R2 of 0.94–0.97. The slope coefficient with a value of 0.371 was smaller for the MF-treated apples compared to those in cold storage and the control samples, which indicated the less variable dynamic of this parameter during storage. The regression equations are presented in Table 2. The same trend for TSS has been reported in the literature, although described with a third-order polynomial [33,34].

Table 2.

Regression equations describing the variations in TSS between the different storage conditions of the Idared variety.

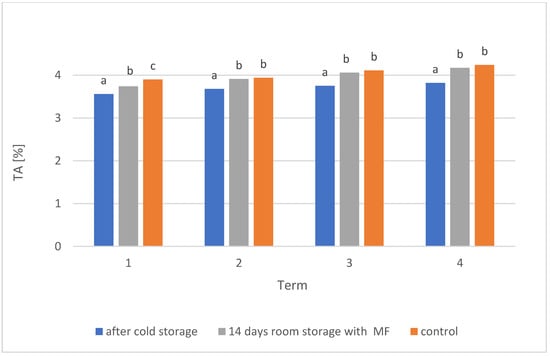

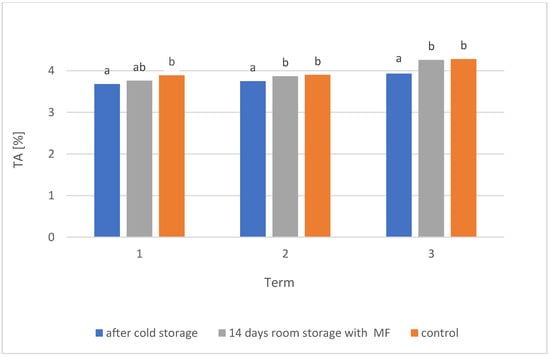

3.3. Titratable Acidity

The test apples were ripened in a cold store and then stored in room conditions. The titratable acidity values of the fruit that were treated with a magnetic field compared to that of the control samples are shown in Figure 7 and Figure 8. In this study, differences in titratable acidity were noted between the test (MF-treated) and control samples. The content of titratable acid affects the taste of apples [35]. Less acidity with minor changes may delay changes in the texture of the apple flavour. In the presented study, the apples that were treated with MF had up to 4.4% less titratable acid than untreated samples. A study by Martiñon et al. [36] reported that titratable acid changed slightly in freshly cut cantaloupes and successfully delayed the postharvest maturation process [36]. These data indicated that treating apples with a magnetic field of 2 mT for 15 min can prolong the life of the proper flavour of apples. The differences between the titratable acidity of the treated and untreated samples were significant and could have been caused by a different metabolic rate, which consumes organic acids and leads to a decrease in acidity [37,38,39,40].

Figure 7.

Effects of MF on the TA of Idared apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

Figure 8.

Effects of MF on the TA of Ligol apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

The difference between the titratable acidity of the studied varieties was not significant. The titratable acidity of the apples did not change much after four months of storage. However, research [41,42,43] has shown a marked difference in the acidity of apples after storage and a decline in the malic acid content of apples after six months of storage.

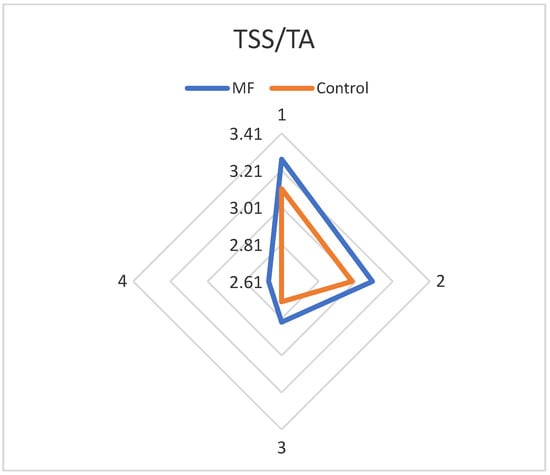

Apple cultivars have been shown to have significant differences in TSS and acidity [33]. The values of the TSS/TA ratio in the studied fruit are presented in Table 3. The TSS/acid ratio is a major quality parameter and is also essential for predicting the maximum shelf life of fruit [44,45]. The average TSS/acid ratio for three experiments was recorded as being 3.06 for the Idared variety and 2.94 for Ligol. The MF treatment increased the value of this ratio by up to 5% compared to the control group. The duration of storage had also a significant effect on the TSS/acid ratio of the apples and caused the value of this parameter to gradually decrease by up to 18%. Ligol apples experienced a decrease in the value of this ratio by 2.58.

Table 3.

Values of the TSS/TA ratio of MF-treated and control apples for each experiment.

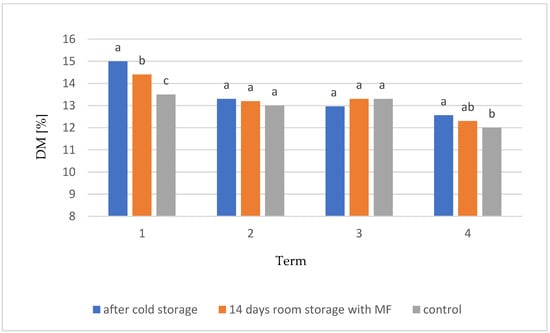

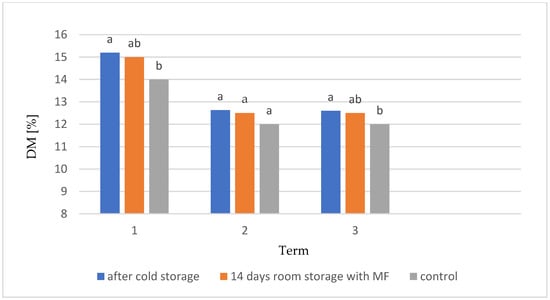

3.4. Dry Mass

Dry matter can be used to determine the potential quality of fruit. It is the result of the accumulation of carbohydrates, starch, sugars, proteins, cell walls, minerals, etc. The DM of the fruit that were subjected to the magnetic field treatment relative to that of the control samples is shown in Figure 9 and Figure 10. The results showed the slower loss of DM for the test samples (those treated with MF) versus the control samples. On the basis of the obtained results, a decrease in DM by up to 6% was observed in the test sample compared to the control samples. The magnetic field treatment reduced the loss of moisture and hardness in the fruit, thus maintaining their structural integrity and fresh appearance for longer during storage. From the conducted research, it could be concluded that the magnetic field treatment can inhibit the action of tissue enzymes [46].

Figure 9.

Effects of MF on the DM of Idared apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

Figure 10.

Effects of MF on the DM of Ligol apples after 120 days of cold storage. For each experiment, apples were stored in room conditions for 14 days. Statistically significant differences are marked by different letters. Differences between average values that are marked with the same letters (a,b) are not statistically significant. The data were analysed separately for each experiment.

Significant differences were observed between the MF-treated samples and the control group of the tested varieties (p < 0.05) during the first two experiments after cold storage. The DM loss for the samples that were treated with an MF of 100 μT was, on average, 1.5% during experiments 3–4 of the study, while it was 4.6% for the control samples. Some research has proved the efficacy of strong electric fields in extending the shelf life of fruit at 20 °C [47,48,49]. Their results showed that the physiological loss of mass during shelf life was lower in the electrical field-treated samples than in the control samples.

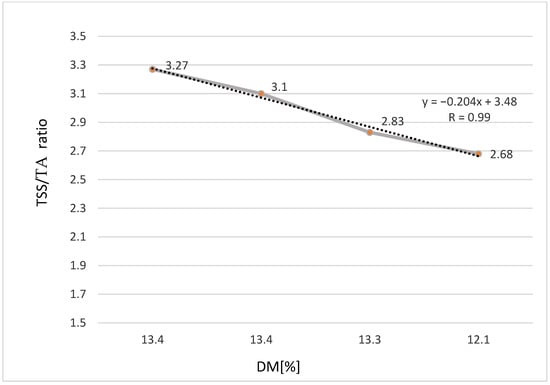

During the first experiment, a DM loss of about 10% was recorded in the Idared variety and about 8% in the Ligol variety. However, the effects of the cultivar on DM loss are not stated. The DM loss percentage of the test apples increased significantly with an incremental increase in storage duration for specimens in cold storage, room conditions with MF treatment and control conditions. The DM content in the fruit decreased linearly with the increase in storage duration due to an increase in the metabolic rate of the fruit [50]. The study showed a linear regression between the dry matter (DM) and TSS/TA ratio of the test apples with an R2 coefficient of 0.99 (Figure 11).

Figure 11.

The dry matter versus TSS/TA ratio of Idared apples.

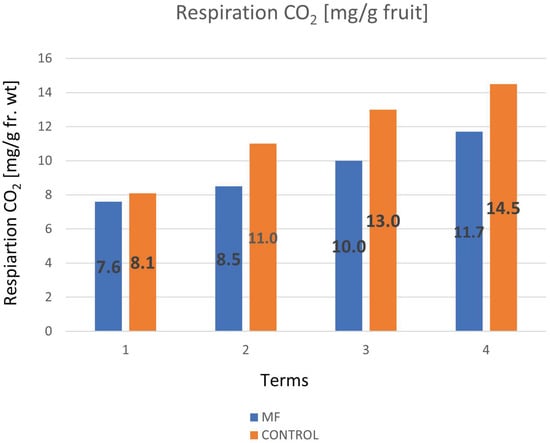

3.5. Respiration Rate

The respiration rate values of the fruit that were exposed to the magnetic field and the fruit in the control group are shown in Figure 12. The respiration rate was expressed as the production of CO2 in the fruit. The production of CO2 was lower in the MF-treated fruit compared to the control apples. The magnetic field that affected the fruit for eight hours a day reduced the production of CO2 compared to the apples that were kept in room conditions. The magnetic and electric fields are elements of plant physiology [51]. The internal electric fields of plants are dependent on those coming from outside impulses, which may cause changes in fruit metabolism that are related to fruit respiration. Many studies [10,21,52] have reported that magnetic and electric fields reduce the respiration rate of various products. Respiration plays an important role in adapting plant metabolism to changing conditions [30,53,54,55,56].

Figure 12.

Effects of MF on the respiration rate of Idared apples.

Generally, the higher the yield of carbon dioxide, the shorter the shelf life of the product [57,58,59]. The level of carbon dioxide in the apples that were exposed to MF treatment was determined using samples that were stored for 14 days at 22 °C and 50% relative humidity. A study by Ko et al. [46] showed that electric fields reduce the activity of enzymes, which is the same feature that inhibits the increase in carbon dioxide yield [46].

The carbon dioxide yields were 7.6 and 8.1 mg of CO2 per gram of fruit and increased to 11.7 and 14.5 mg of CO2 per gram of fruit during storage for treated and untreated samples, respectively. In fact, the MF treatment of fruit reduced the rate of carbon dioxide yield from 6.2% to 23%, depending on the time after storage. This same treatment may have the ability to inhibit metabolism. Generally, the application of MF treatment to apples had an impact on their respiration rate, which led to a decrease in carbon dioxide production. Thus, it contributed to the extension of the shelf life of the apples.

3.6. Summarisation of the Effects of MF on Apples

After the MF treatment of the apples, a new product was produced with a greater firmness and quality potential (ratio of TSS/TA) and an extended shelf life, which was expressed by a lower respiration rate (Figure 13).

Figure 13.

Comparison of quality parameters depending on the development stage of the fruit (1, 2, 3, 4) after storage (parameter values increase from the centre outwards).

4. Conclusions

The authors of the study aimed to investigate the influence of a magnetic field on the shelf life of apples after storage. The parameters of firmness, total soluble solids, titratable acidity, dry weight and CO2 production were used as the indicators of fruit quality. Since the magnetic field method has a low energy consumption, its use would be a cheap and accessible way to improve the shelf life and quality of fruit. Based on this research, it was shown that the magnetic field-treated samples generally had a higher value of SSC/TA ratio compared to untreated samples, which indicated their higher quality and predicted the longer shelf life of the apples. Short periods (8 h per day) of exposure to the magnetic field changed the mechanical properties of the apples, as demonstrated by a greater firmness and lower dry mass loss. It was noticed that apples in the test sample were harder than those in the control group, depending on variety and development stage. Short periods (8 h per day) of exposure to the magnetic field inhibited CO2 production in fruit that were kept in room conditions. The MF treatment of the fruit reduced the rate of carbon dioxide yield from 6.2% to 23%, depending on the time after storage. Magnetic field treatment with 100 μT can be used as a method to extend the freshness and shelf life of apples that are stored in room conditions, but it requires further investigation.

Author Contributions

Conceptualisation, C.P. and B.S.; formal analysis, C.P.; investigation, B.S. and G.Z.; resources, C.P.; data curation, C.P. and E.S.; writing—original draft preparation, C.P. and B.S.; writing—review and editing, A.S. and E.S.; visualisation, B.S. and M.B.; supervision, B.S., G.Z. and M.B.; project administration, B.S. and A.S.; funding acquisition, C.P. All authors have read and agreed to the published version of the manuscript.

Funding

The project was financed by the Minister of Science and Higher Education programme named “Regional Initiative of Excellence” for the years 2019–2022 (project number 026/RID/2018/19; the amount of financing PLN 9 542 500.00).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Seymur, G.B.; Taylor, J.E.; Tucker, G.A. Biochemistry of Fruit Ripening, 1st ed.; Chapman & Hall: London, UK, 1993; pp. 3–51. [Google Scholar]

- Kader, A.A. Fruit maturity, ripening, and quality relationships. Acta Hort. 1999, 485, 203–208. [Google Scholar] [CrossRef]

- Ilyas, M.B.; Ghazanfar, M.U.; Khan, M.A.; Khan, C.A.; Bhatti, M.A.R. Post harvest losses in apple and banana during transport and storage. Pakistan J. Agri. Sci. 2007, 44, 534–539. [Google Scholar]

- LeBlanc, D.; Stark, R.; MacNeil, B.; Goguen, B.; Beraulieu, C. Perishable food temperature in retail stores. In New Development in Refrigeration for Food Safety and Quality; Refrigeration Science and Technology Proceedings of the Meeting of Commission C2, with Commissions B2, D1 and D2-3; International Institute of Refrigeration: Lexington, KY, USA, 1996; Volume 6, pp. 42–57. [Google Scholar]

- Tano, K.; Oulé, M.K.; Doyon, G.; Lencki, R.W.; Arul, J. Comparative evaluation of the effect of storage temperature fluctuation on modified atmosphere packages of selected fruit and vegetables. Postharvest Biol. Technol. 2007, 46, 212–221. [Google Scholar] [CrossRef]

- Tu, K.; Nicolaï, B.; De Baerdemaeker, J. Effects of relative humidity on apple quality under simulated shelf temperature storage. Sci. Hortic. 2000, 85, 217–229. [Google Scholar] [CrossRef]

- Gwanpua, S.G.; Mellidou, I.; Boeckx, J.; Kyomugasho, C.; Bessemans, N.; Verlinden, B.E.; Hertog, M.; Hendrickx, M.E.; Nicolai, B.M.; Geeraerd, A.H. Expression analysis of candidate cell wall-related genes associated with changes in pectin biochemistry during postharvest apple softening. Postharvest Biol. Technol. 2016, 112, 176–185. [Google Scholar] [CrossRef]

- Gonza’lez-Aguilar, G.A.J.F.; Ayala-Zavala, G.I.; Olivas, L.A.; De la Rosa, E. Preserving quality of fresh-cut products using safe technologies. J. Verbr. Lebensm. 2010, 5, 65–72. [Google Scholar] [CrossRef]

- Jia, J.; Wang, X.; Lv, J.; Gao, S.; Wang, G. Alternating Magnetic Field Prior to Cutting Reduces Wound Responses and Maintains Fruit Quality of Cut Cucumis melo L. cv Hetao. Open Biotechnol. J. 2015, 9, 230–235. [Google Scholar] [CrossRef] [Green Version]

- Boe, A.A.; Salunkhe, D.K. Effects of Magnetic Fields on Tomato Ripening. Nature 1963, 199, 91–92. [Google Scholar] [CrossRef]

- Funk, R.H.; Monsees, T.; Özkucur, N. Electromagnetic effects–From cell biology to medicine. Prog. Histochem. Cytochem. 2009, 43, 177–264. [Google Scholar] [CrossRef]

- Markov, M.S. Magnetic Field Therapy: A Review. Electromagn. Biol. Med. 2007, 26, 1–23. [Google Scholar] [CrossRef]

- Hunt, R.W.; Zavalin, A.; Bhatnagar, A.; Chinnasamy, S.; Das, K.C. Electromagnetic Biostimulation of Living Cultures for Biotechnology, Biofuel and Bioenergy Applications. Int J. Mol. Sci. 2009, 10, 4515–4558. [Google Scholar] [CrossRef] [PubMed]

- Nakasono, S.; Saiki, H. Effect of ELF Magnetic Fields on Protein Synthesis inEscherichia coliK12. Radiat. Res. 2000, 154, 208–216. [Google Scholar] [CrossRef]

- Valiron, O.; Peris, L.; Rikken, G.; Bs, A.S.; Bs, Y.S.; Remy, C.; Job, D. Cellular disorders induced by high magnetic fields. J. Magn. Reson. Imaging 2005, 22, 334–340. [Google Scholar] [CrossRef] [PubMed]

- Zaguła, G.; Puchalski, C. Glucose and fructose changes in apple subject to permanent and slow-ranging action magnetic fields. Żywność Nauka Technologia Jakość 2013, 2, 162–172. (In Polish) [Google Scholar]

- Saletnik, B.; Zaguła, G.; Saletnik, A.; Bajcar, M.; Słysz, E.; Puchalski, C. Effect of Magnetic and Electrical Fields on Yield, Shelf Life and Quality of Fruits. Appl. Sci. 2022, 12, 3183. [Google Scholar] [CrossRef]

- De Sousa Araújo, S.; Paparella, S.; Dondi, D.; Bentivoglio, A.; Carbonera, D.; Balestrazzi, A. Physical Methods for Seed Invigoration: Advantages and Challenges in Seed Technology. Front. Plant. Sci. 2016, 7, 646. [Google Scholar] [CrossRef] [Green Version]

- AOAC. Official Methods of Analysis, 15th ed.; Helrich, K., Ed.; Association of Official Analytical Chemists, Inc.: Arlington, VA, USA, 1990. [Google Scholar]

- Regulation of the Minister of Agriculture and Rural Development of 2 December 2004 on the methodology of analytical proceedings in the scope of determining the content of nutrients and feed additives in feed materials, premixes, compound feed and medicated feeds. J. Laws Repub. Poland 2004, 271, 2688.

- Zaguła, G.; Tarapatskyy, M.; Bajcar, M.; Saletnik, B.; Puchalski, C.; Marczuk, A.; Andrejko, D.; Oszmiański, J. Near-Null Geomagnetic Field as an Innovative Method of Fruit Storage. Processes 2020, 8, 262. [Google Scholar] [CrossRef] [Green Version]

- Peng, Y.; Lu, R. Prediction of apple fruit firmness and soluble solids content using characteristics of multispectral scattering images. J. Food Eng. 2007, 82, 142–152. [Google Scholar] [CrossRef]

- Paniagua, C.; Posé, S.; Morris, V.J.; Kirby, A.R.; Quesada, M.A.; Mercado, J.A. Fruit softening and pectin disassembly: An overview of nanostructural pectin modifications assessed by atomic force microscopy. Ann. Bot. 2014, 114, 1375–1383. [Google Scholar] [CrossRef] [Green Version]

- Korohoda, W.; Grys, M.; Madeja, Z. Reversible and irreversible electroporation of cell supensions flowing throught a localized dc electric field. Cell. Mol. Biol. Lett. 2013, 18, 102–119. [Google Scholar] [CrossRef] [PubMed]

- Zaguła, G.; Gorzelany, J.; Puchalski, C. Using a computer video system to examine the impact of magnetic and electromagnetic fields on quality of strawberries. Inż. Rol. 2010, 2, 293–300. [Google Scholar]

- Lebovka, N.I.; Praporscic, I.; Vorobiev, E. Combined treatment of apples by pulsed electric fields and by heating at moderate temperature. J. Food Eng. 2004, 65, 211–221. [Google Scholar] [CrossRef]

- González-Casado, S.; Martín-Belloso, O.; Elez-Martinez, P.; Soliva-Fortuny, R. Enhancing the carotenoid content of tomato fruit with pulsed electric field treatments: Effects on respiratory activity and quality attributes. Postharvest Biol. Technol. 2018, 137, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Rosa, M.; Prado, C.; Podazza, G.; Interdonato, R.; González, J.; Hilal, M.; Prado, F.E. Soluble sugars: Metabolism, sensing and abiotic stress: A complex network in the life of plants. Plant Signal Behav. 2009, 4, 388–393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Atkinson, N.J.; Dew, T.P.; Orfila, C.; Urwin, P.E. Influence of Combined Biotic and Abiotic Stress on Nutritional Quality Parameters in Tomato (Solanum lycopersicum). J. Agric. Food Chem. 2011, 59, 9673–9682. [Google Scholar] [CrossRef]

- Fraire-Velazquez, S.; Balderas-Hernández, V.E. Abiotic stress in plants and metabolic responses. In Abiotic Stress. Plant Responses and Applications in Agriculture, 1st ed.; Vahdati, K., Leslie, C., Eds.; InTech: Rijeka, Croaita, 2013; Volume 2, pp. 25–48. [Google Scholar]

- Cholet, C.; Delsart, C.; Petrel, M.; Gontier, E.; Grimi, N.; L’Hyvernay, A.; Ghidossi, R.; Vorobiev, E.; Mietton-Peuchot, M.; Gény, L. Structural and Biochemical Changes Induced by Pulsed Electric Field Treatments on Cabernet Sauvignon Grape Berry Skins: Impact on Cell Wall Total Tannins and Polysaccharides. J. Agric. Food Chem. 2014, 62, 2925–2934. [Google Scholar] [CrossRef]

- Eskin, N.; Henderson, H.; Townsend, R. Biochemistry of Foods; Elsevier: Amsterdam, The Netherlands, 1971. [Google Scholar] [CrossRef]

- Ali, M.A.; Raza, H.; Khan, M.A.; Hussain, M. Effect of Different Periods of Ambient Storage on Chemical Composition of Apple Fruit. Int. J. Agri. Biol. 2004, 6, 568–571. [Google Scholar]

- Ahmad, F.; Zaidi, S.; Arshad, M. Postharvest quality assessment of apple during storage at ambient temperature. Heliyon 2021, 7, e07714. [Google Scholar] [CrossRef]

- Vallone, S.; Sivertsen, H.; Anthon, G.E.; Barrett, D.M.; Mitcham, E.J.; Ebeler, S.E.; Zakharov, F. An integrated approach for flavour quality evaluation in muskmelon (Cucumis melo L. reticulatus group) during ripening. Food Chem. 2013, 139, 171–183. [Google Scholar] [CrossRef]

- Martiñon, M.E.; Moreira, R.G.; Castell-Perez, M.E.; Gomes, C. Development of a multilayered antimicrobial edible coating for shelf-life extension of fresh-cut cantaloupe (Cucumis melo L.) stored at 4 °C. LWT 2014, 56, 341–350. [Google Scholar] [CrossRef]

- Mahajan, B.V.C. Biochemical and enzymatic changes in apple during cold storage. India. J. Food Sci. Technol. 1994, 31, 142–152. [Google Scholar]

- Clark, C.J.; McGlone, V.A.; Jordan, R.B. Detection of brownheart in ‘Braeburn’ apple by transmission NIR spectroscopy. Postharvest Biol. Technol. 2001, 28, 87–96. [Google Scholar] [CrossRef]

- Riveria, J. Cutting shape and storage temperature affect overall quality of fresh cut papaya cv. Maradol. J. Food Sci. 2005, 70, 488–489. [Google Scholar]

- Ghafir, S.A.M.; Gadalla, S.O.; Murajei, B.N.; El-Nady, M.F. Physiological and anatomical comparison between four different apple cultivars under cold-storage conditions. Afr. J. Plant Sci. 2009, 3, 133–138. [Google Scholar]

- Radenkovs, V.; Juhnevica-Radenkova, K. Effect of storage technology on the chemical composition of apples of the cultivar ‘Auksis’. Zemdirb.-Agric. 2017, 104, 359–368. [Google Scholar] [CrossRef] [Green Version]

- Tahir, I.I.; Ericsson, N.A. Effect of postharvest heating and ca– storage on storability and quality of apple cv. ‘Aroma’. Acta Hort. 2003, 600, 410–415. [Google Scholar] [CrossRef]

- Bilisili, A.A.; Ayanoglu, A.; Baykent, N. Quality changes in stored apples. Teknol. Lab. Yalova 1970, 3, 50–55. [Google Scholar]

- Weibel, F.P.; Treutter, D.; Graf, U.; Haseli, A. Sensory and health-related fruit quality of organic apples: A comparative field study over three years using conventionaland holistic methods to assess fruit quality. In Proceedings of the 11th International Conference on Cultivation Technique and Phytopathological Problems in Organic Fruit Growing, Weinsberg, Germany, 3–5 February 2004. [Google Scholar]

- Peck, G.; Andrews, P.K.; Reganold, J.P.; Fellman, J.K. Apple Orchard Productivity and Fruit Quality under Organic, Conventional, and Integrated Management. HortScience 2006, 41, 99–107. [Google Scholar] [CrossRef] [Green Version]

- Ko, W.C.; Shi, H.Z.; Chang, C.K.; Huang, Y.H.; Chen, Y.A.; Hsieh, C.W. Effect of adjustable parallel high voltage on biochemical indicators and actomyosin Ca2þ-ATPase from tilapia (Orechromis niloticus). LWT-Food Sci. Technol. 2016, 69, 417–423. [Google Scholar] [CrossRef]

- Kharel, G.P.; Hashinaga, F. Effect of High Electric Field on Shelf Life of Strawberries. Food Sci. Technol. Int. Tokyo 1996, 2, 198–202. [Google Scholar] [CrossRef] [Green Version]

- Bajgai, T.R.; Hashinaga, F.; Isobec, S.; Raghavan, G.S.V.; Ngadi, M.O. Application of high electric field (HEF) on the shelf-life extensionof emblic fruit (Phyllanthus emblica L.). J. Food Eng. 2006, 4, 308–313. [Google Scholar] [CrossRef]

- Palanimuthu, V.; Rajkumar, P.; Orsat, V.; Gariepy, Y.; Raghavan, G.S.V. Improving cran-berry shelf life using highvoltage electric field treatment. J. Food Eng. 2009, 90, 365–371. [Google Scholar] [CrossRef]

- Atungulu, G.; Nishiyama, Y.; Koide, S. Respiration and climacteric patterns of apples treated with continuous and intermittent direct current electric field. J. Food Eng. 2004, 63, 1–8. [Google Scholar] [CrossRef]

- Scott, B.I.H. Electric fields in plants. Annu. Rev. Plant Physiol. 1967, 18, 409–418. [Google Scholar] [CrossRef]

- Toda, S. Preservation of foods and vegetables by application of electric field. Shokuhin Rhytsu Gijitsu 1990, 19, 62–64. [Google Scholar]

- Łukaszuk, E.; Ciereszko, I. Plant responses to wounding stress. In Biological Diversity—From Cell to Ecosystem, 1st ed.; Łaska, G., Ed.; Polish Botanical Society: Białystok, Poland, 2012; pp. 73–85. [Google Scholar]

- Rakhmankulova, Z.F.; Fedyaev, V.V.; Podashevka, O.A.; Usmanov, I.Y. Alternative Respiration Pathways and Secondary Metabolism in Plants with Different Adaptive Strategies under Mineral Deficiency. Russ. J. Plant Physiol. 2003, 50, 206–212. [Google Scholar] [CrossRef]

- Sabbagh, E.; Lakzayi, M.; Keshtehgar, A.; Rigi, K. The effect of salt stress on respiration, PSII function, chlorophyll, carbohydrate and nitrogen content in crop plants. Int. J. Farming 2014, 3, 988–993. [Google Scholar]

- Yuan, X.K.; Yang, Z.Q.; Li, Y.X.; Liu, Q.; Han, W. Effects of different levels of water stress on leaf photosynthetic characteristics and antioxidant enzyme activities of greenhouse tomato. Photosynthetica 2016, 54, 28–39. [Google Scholar] [CrossRef]

- Bhande, S.D.; Ravindra, M.R.; Goswami, T.K. Respiration rate of banana fruit under aerobic conditions at different storage temperatures. J. Food Eng. 2008, 87, 116–123. [Google Scholar] [CrossRef]

- Famiani, F.; Farinelli, D.; Palliotti, A.; Moscatello, S.; Battistelli, A.; Walker, R.P. Is stored malate the quantitatively most important substrate utilised by respiration and ethanolic fermentation in grape berry pericarp during ripening? Plant Physiol. Biochem. 2014, 76, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Kan, J.; Wang, H.-M.; Jin, C.-H. Changes of Reactive Oxygen Species and Related Enzymes in Mitochondrial Respiration during Storage of Harvested Peach Fruits. Agric. Sci. China 2011, 10, 149–158. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).