Validation of Seismic Performance of Stainless Press-to-Connect Piping System under Cyclic Loadings

Abstract

:1. Introduction

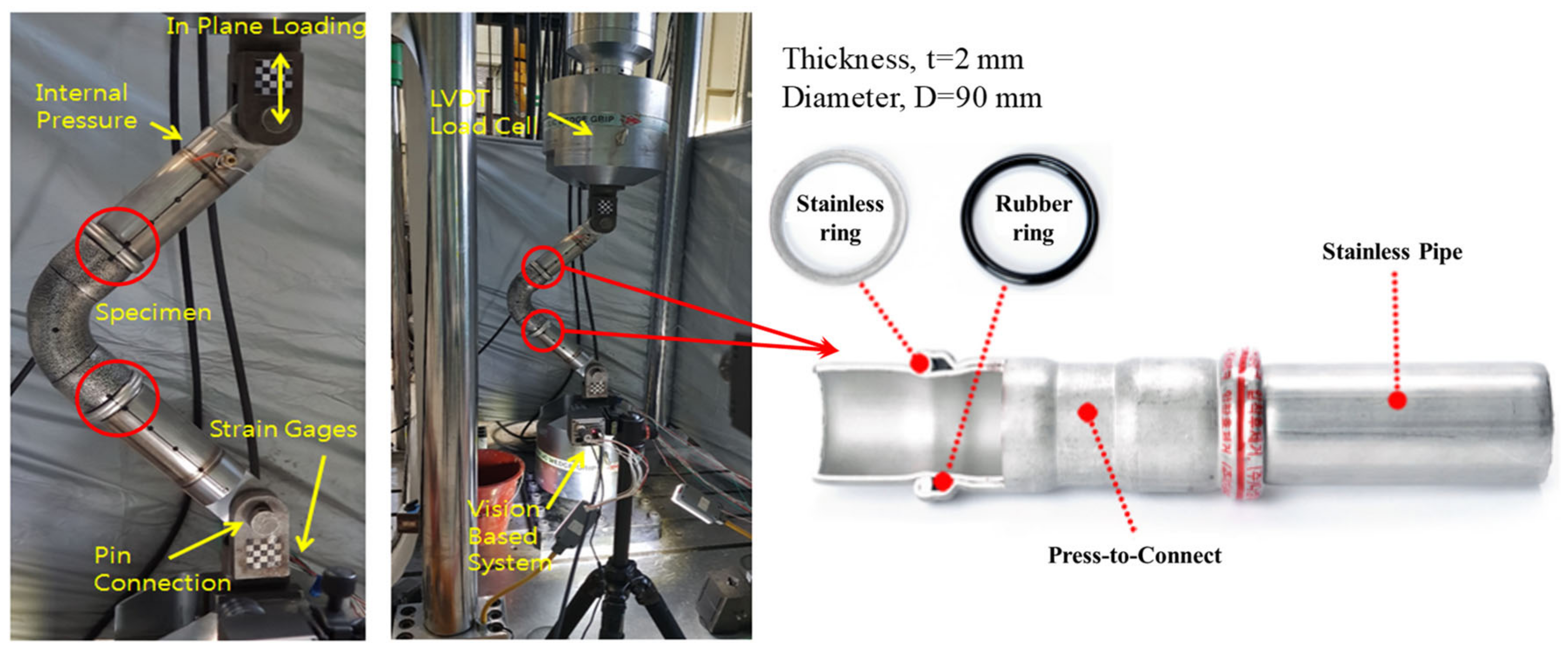

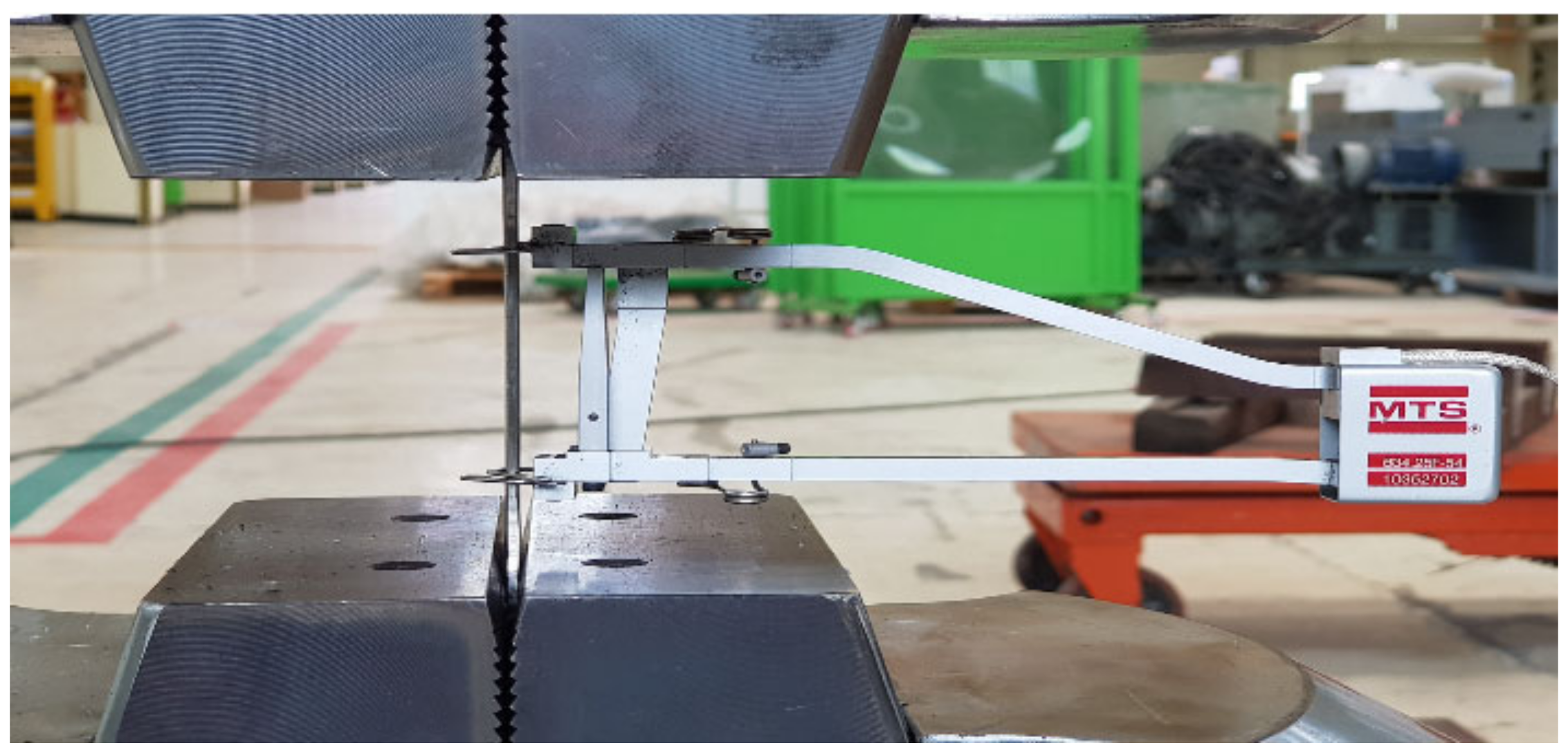

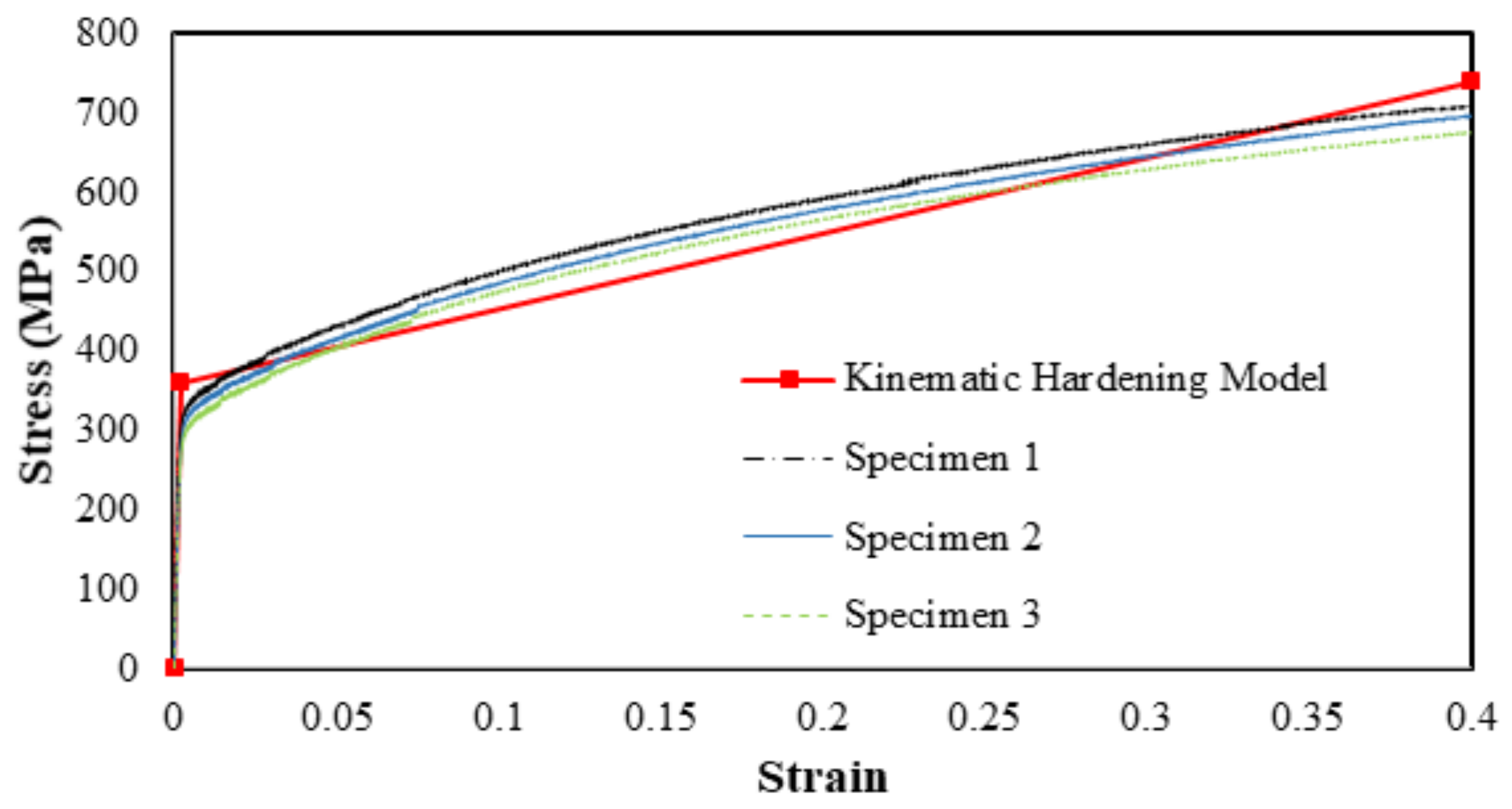

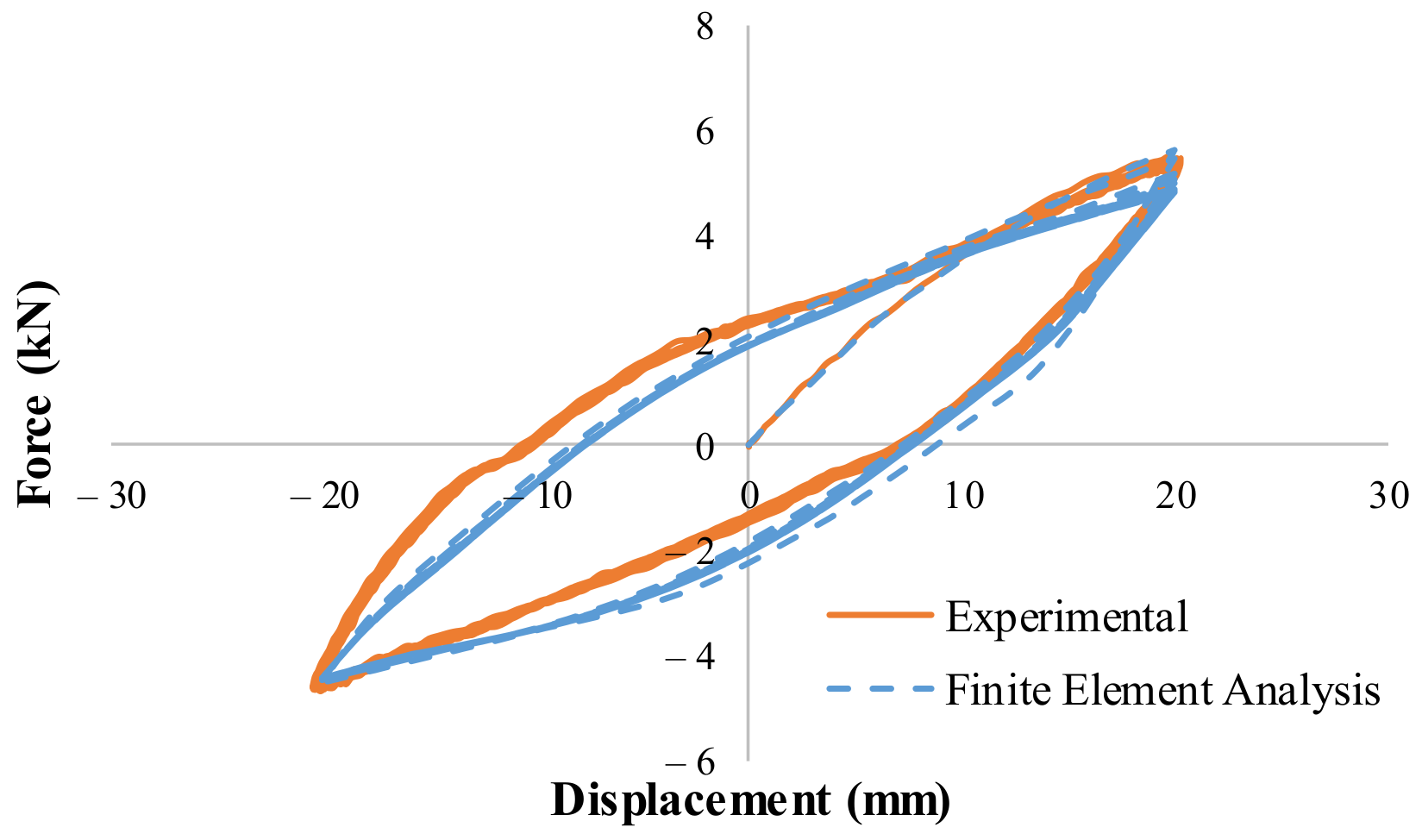

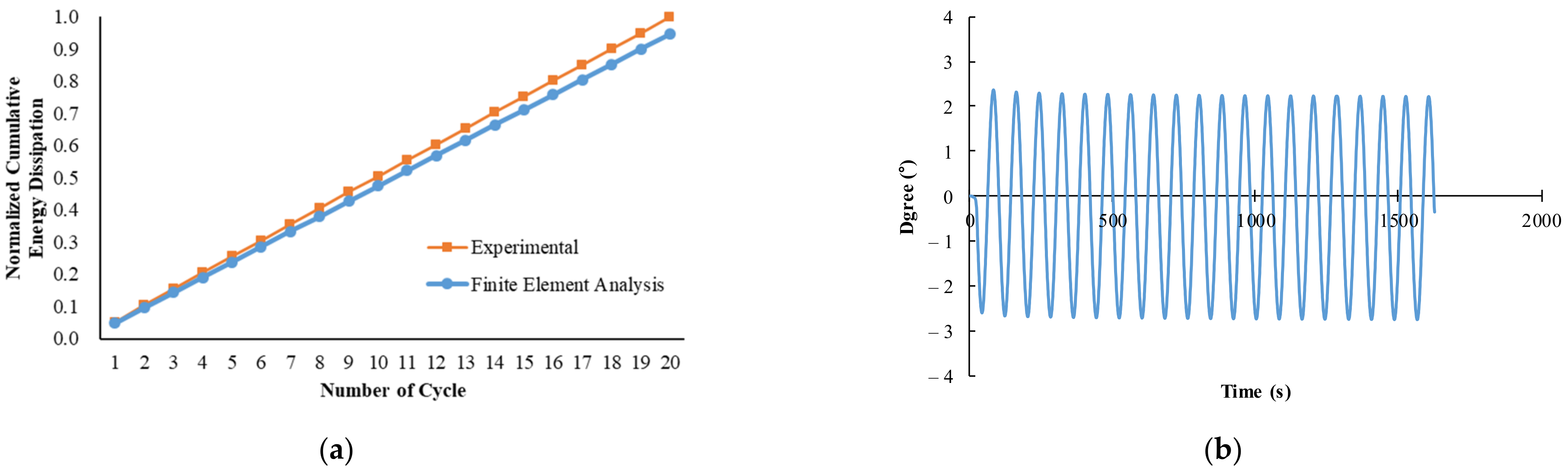

2. Experimental Test of Component Level

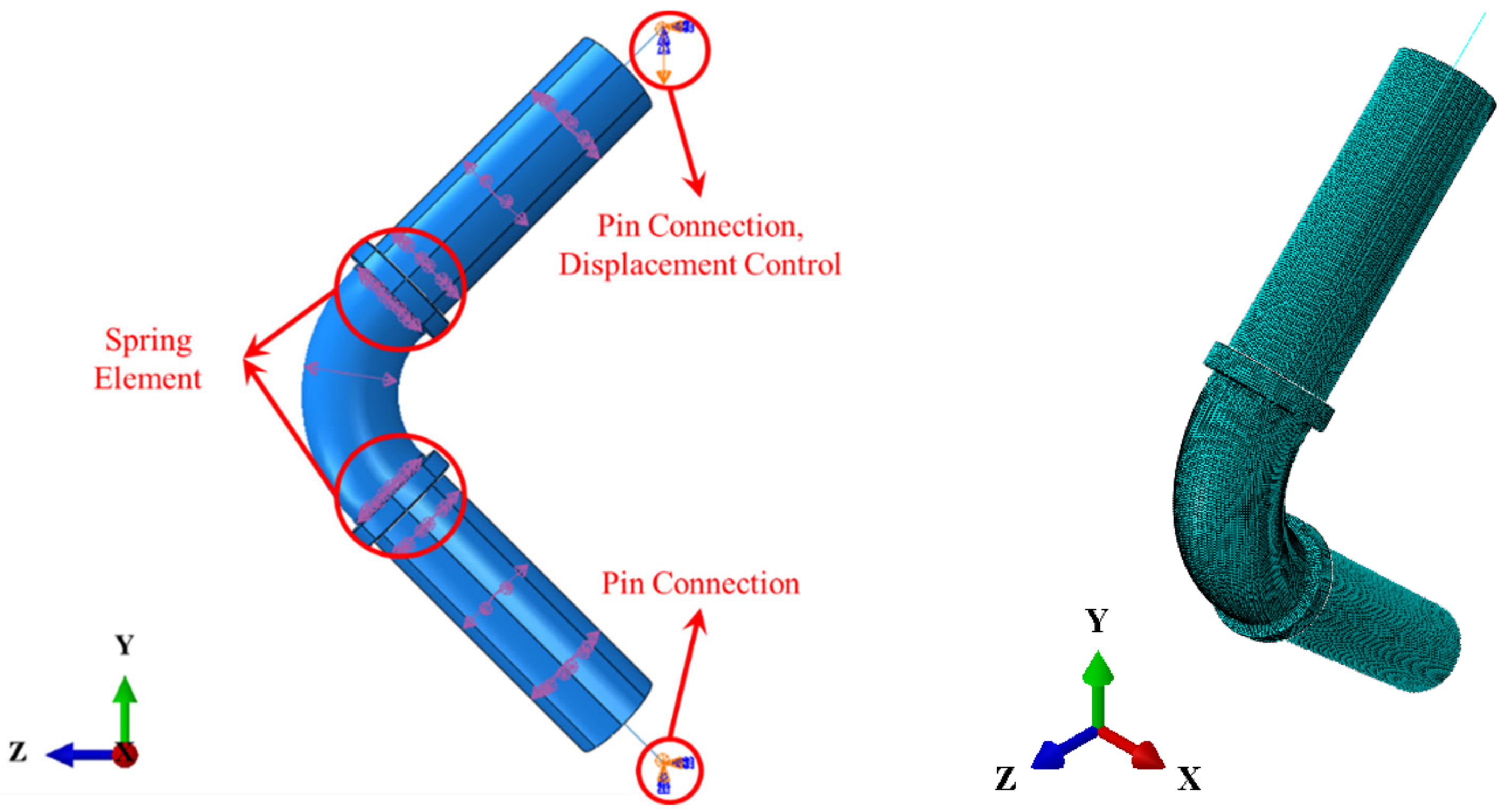

3. Validation of FE Model of Elbow Component

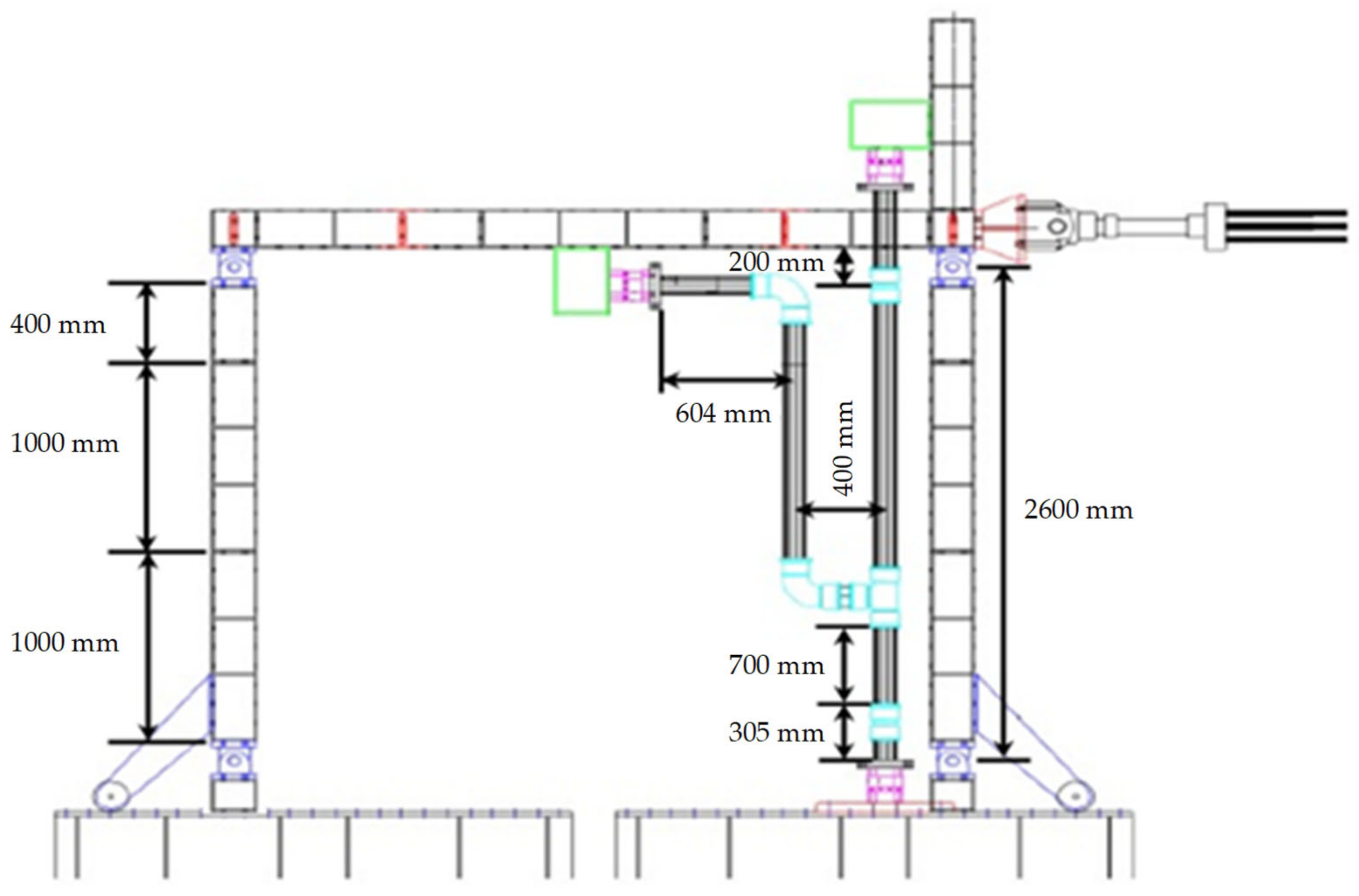

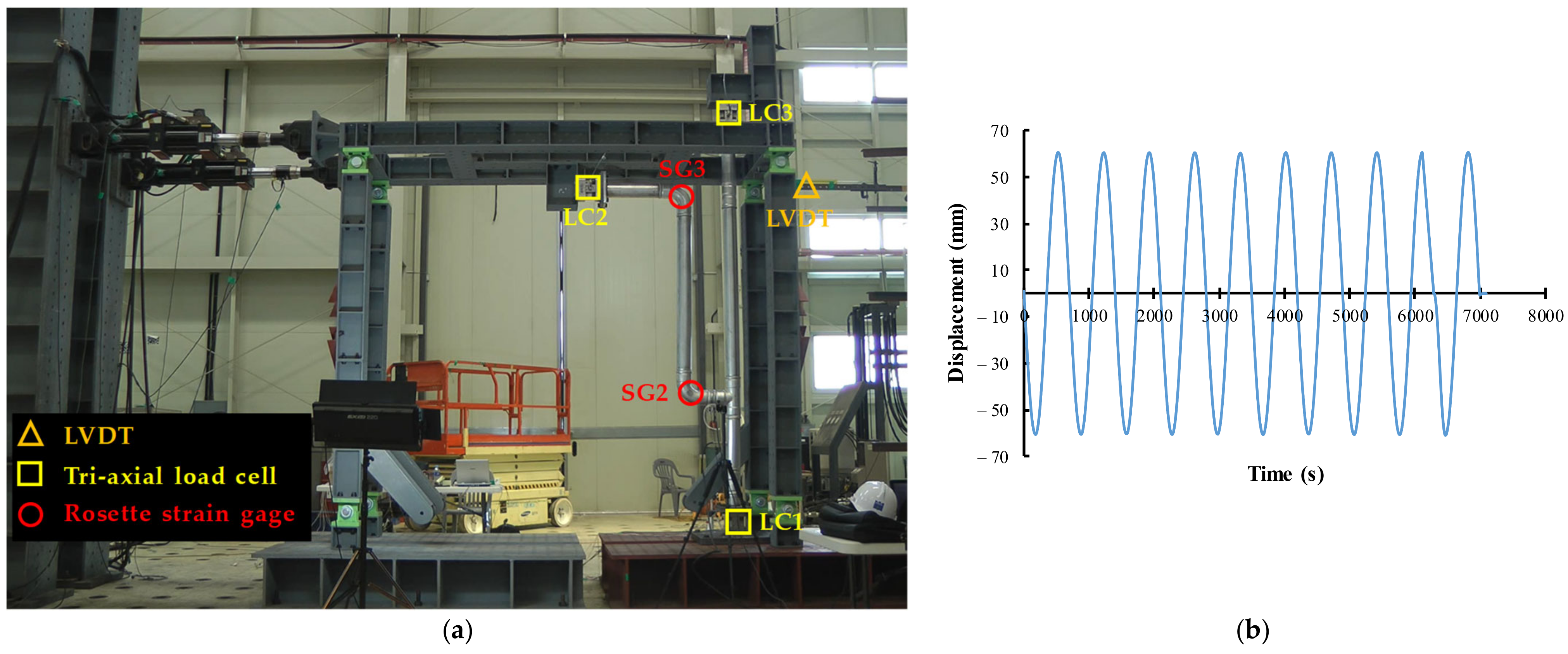

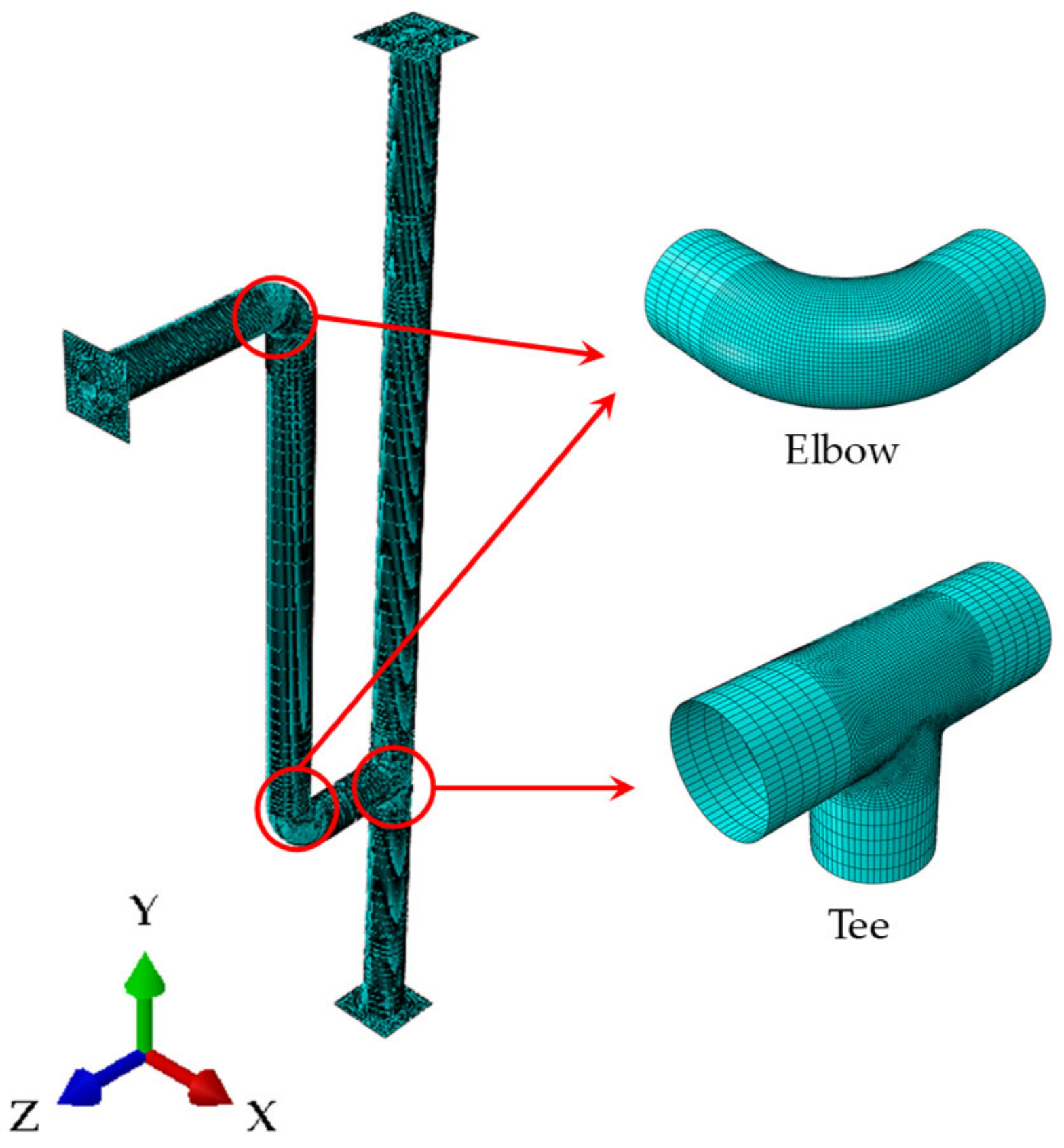

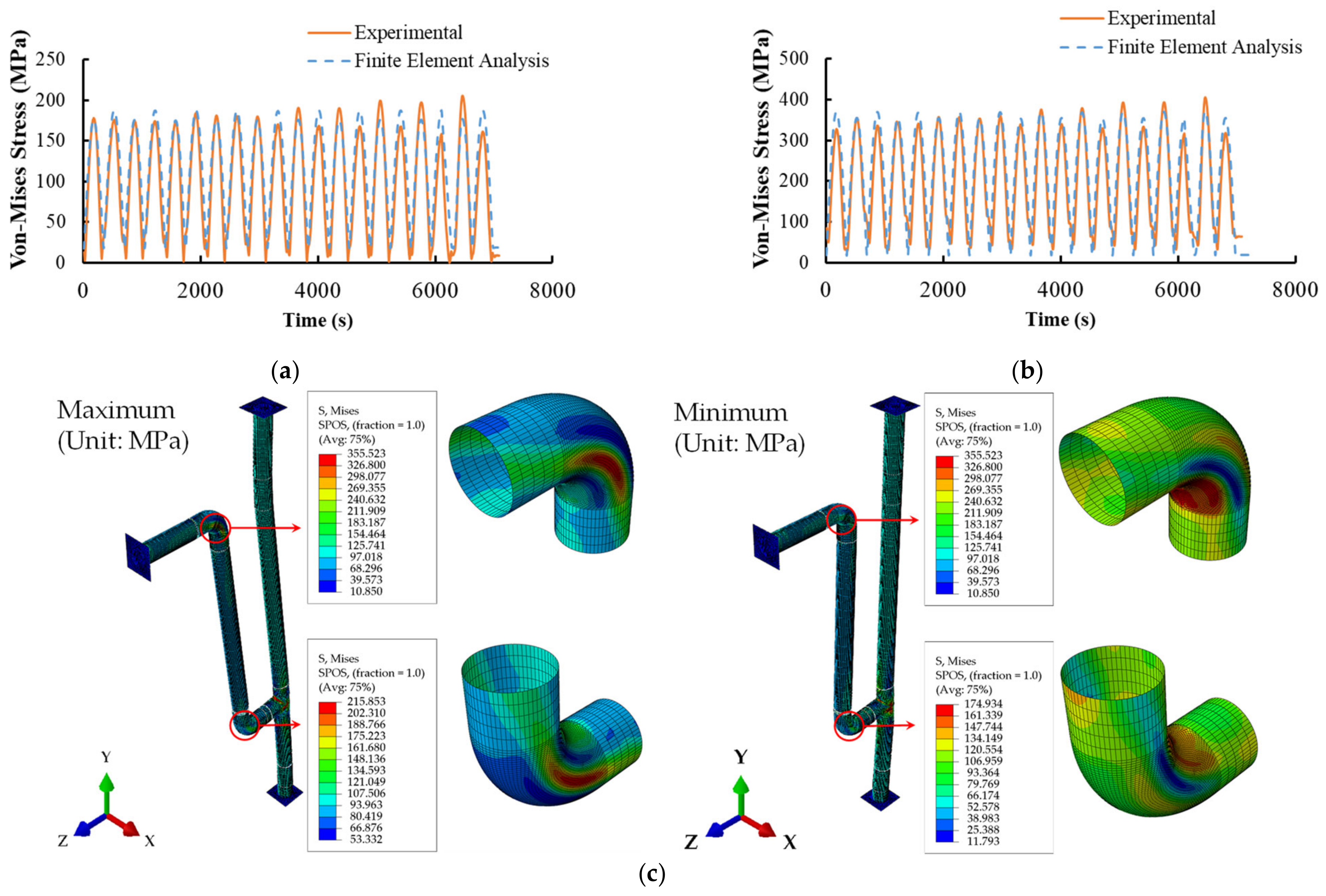

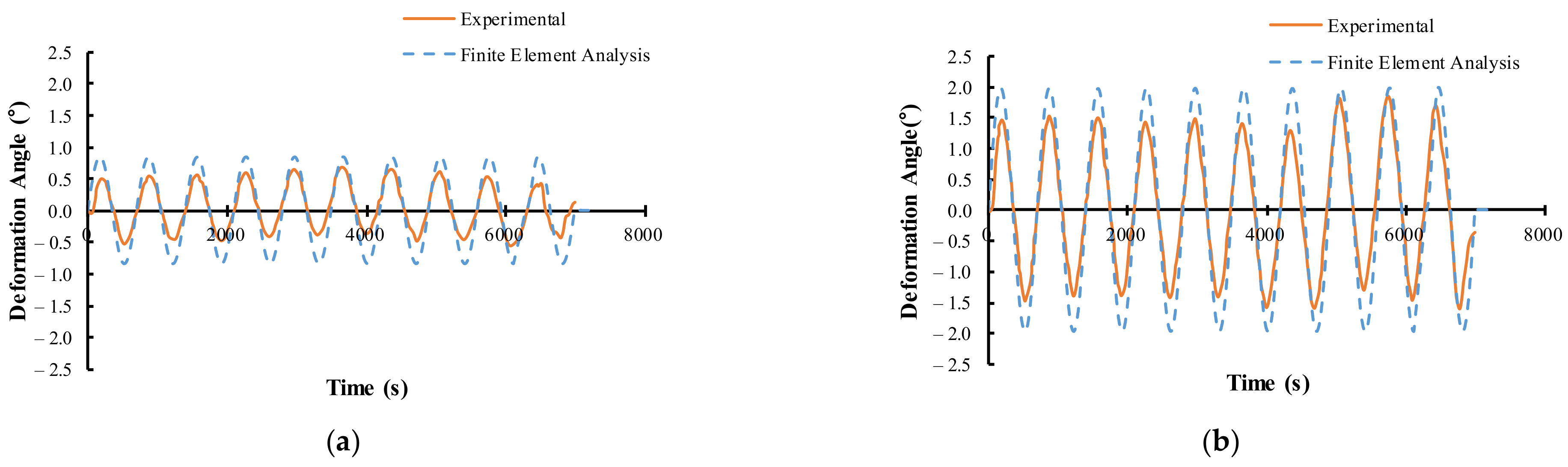

4. Experimental Test of Large-Scale Piping System

5. Validation and Verification of FE Large Scale Piping System Model

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rubeiz, C.G. Performance of Pipes during Earthquakes. In Proceedings of the Pipelines Specialty Conference 200, San Diego, CA, USA, 15–19 August 2009. [Google Scholar] [CrossRef]

- Ryu, Y.; Gupta, A.; Jung, W.; Ju, B.S. A reconciliation of experimental and analytical results for piping systems. Int. J. Steel Struct. 2016, 16, 1043–1055. [Google Scholar] [CrossRef]

- Ju, B.S.; Gupta, A. Seismic fragility of threaded tee-joint connections in piping systems. Int. J. Press. Vessel. Pip. 2015, 132, 106–118. [Google Scholar] [CrossRef]

- Ju, B.S.; Gupta, A.; Ryu, Y.H. Piping fragility evaluation: Interaction with high-rise building performance. J. Press. Vessel. Technol. 2017, 139, 031801. [Google Scholar] [CrossRef]

- Wang, T.; Shang, Q.; Chen, X.; Li, J. Experiments and fragility analysis of piping systems connected by grooved fit joints with large deformability. Front. Built Environ. 2019, 5, 49. [Google Scholar] [CrossRef]

- Soroushian, S.; Maragakis, E.; Zaghi, A.E.; Rahmanishamsi, E.; Itani, A.M.; Pekcan, G. Response of a 2-story test-bed structure for the seismic evaluation of nonstructural systems. Earthq. Eng. Eng. Vib. 2016, 15, 19–29. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, L.; Sun, Y.; Shi, Y.; He, Y.; Zhen, Y. Strength analysis of the interference joint of the oval submarine pipeline to the mechanical connector. Appl. Ocean Res. 2020, 101, 102229. [Google Scholar] [CrossRef]

- Kim, S.W.; Jeon, B.G.; Ahn, S.W.; Wi, S.W. Seismic behavior of riser pipes with pressure and groove joints using an in-plane cyclic loading test. J. Build. Eng. 2021, 34, 101911. [Google Scholar] [CrossRef]

- ASCE/SEI 7-16; Minimum Design Loads for Buildings and other Structures. American Society of Civil Engineers: Alexander Bell Drive Reston, WV, USA, 2017.

- NFPA 13; Standard for the Installation of Sprinkler System. National Fire Protection Association: Quincy, MA, USA, 2013.

- ABAQUS Ver. Dassault System. 2021. Available online: https://www.3ds.com/products-services/simulia/products/abaqus/latest-release/ (accessed on 21 March 2022).

- ABAQUS/CAE User’s Manual, 2021. Dassault System. Available online: http://130.149.89.49:2080/v6.11/pdf_books/CAE.pdf (accessed on 21 March 2022).

- Barkey, M.E.; Lee, Y.L. Chapter 8-strain-based multiaxial fatigue analysis. In Metal Fatigue Analysis Handbook; Elsevier: Amsterdam, The Netherlands, 2012; pp. 299–331. [Google Scholar] [CrossRef]

- Watanabe, K.; Natori, K.; Tanaka, T.; Imaida, Y. Study on the bauschinger effect with increasing of tensile strength in dual phase steel sheet. WIT Trans. Built Environ. 2010, 112, 119–131. [Google Scholar] [CrossRef] [Green Version]

- KBC. Korea Building Code; Architectural Institute of Korea: Seoul, Korea, 2016. [Google Scholar]

- IBC. International Building Code; International Code Council: Washington, DC, USA, 2015. [Google Scholar]

- ASME Boiler and Pressure Vessel Code Section III, Rules for Construction of Nuclear Facility Components, Division 1-Subsectio NB, Class 1 Components; American Society of Mechanical Engineers: New York, NY, USA, 2015.

| Level | |||

|---|---|---|---|

| Special | I | II | |

| Drift ratio | 0.010 h | 0.015 h | 0.020 h |

| Risk Category | |||

|---|---|---|---|

| IV | III | I or II | |

| Drift ratio | 0.010 hxx | 0.015 hxx | 0.020 hxx |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, B.-S.; Jeon, B.-G.; Kim, S.-W.; Son, H.-Y. Validation of Seismic Performance of Stainless Press-to-Connect Piping System under Cyclic Loadings. Appl. Sci. 2022, 12, 3896. https://doi.org/10.3390/app12083896

Ju B-S, Jeon B-G, Kim S-W, Son H-Y. Validation of Seismic Performance of Stainless Press-to-Connect Piping System under Cyclic Loadings. Applied Sciences. 2022; 12(8):3896. https://doi.org/10.3390/app12083896

Chicago/Turabian StyleJu, Bu-Seog, Bub-Gyu Jeon, Sung-Wan Kim, and Ho-Young Son. 2022. "Validation of Seismic Performance of Stainless Press-to-Connect Piping System under Cyclic Loadings" Applied Sciences 12, no. 8: 3896. https://doi.org/10.3390/app12083896

APA StyleJu, B.-S., Jeon, B.-G., Kim, S.-W., & Son, H.-Y. (2022). Validation of Seismic Performance of Stainless Press-to-Connect Piping System under Cyclic Loadings. Applied Sciences, 12(8), 3896. https://doi.org/10.3390/app12083896