Geometric Design of a Face Gear Drive with Low Sliding Ratio

Abstract

:1. Introduction

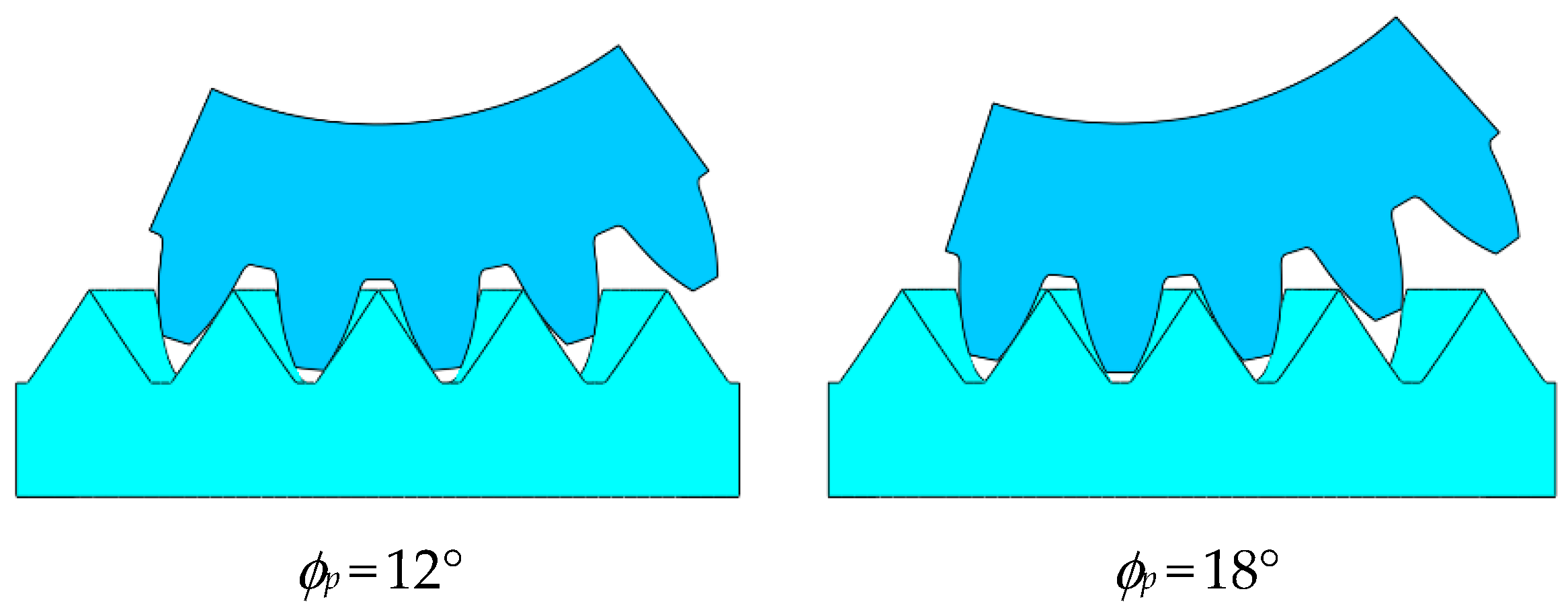

2. Mathematical Models of the Face Gear Pair with Low Sliding Ratio

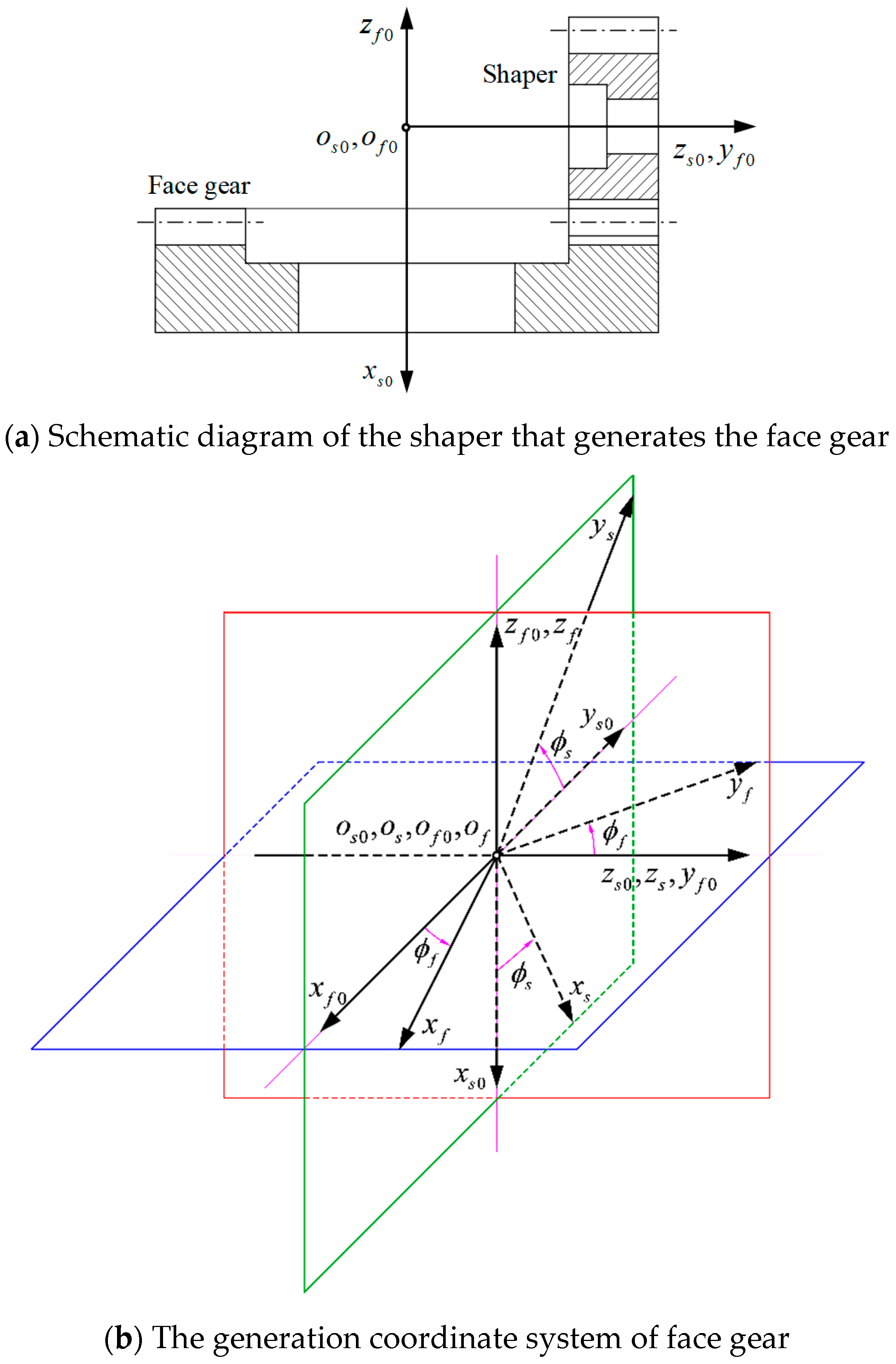

2.1. Construction of Shaper

2.2. Construction of Face Gear Tooth Surface

3. Tooth Width Characteristics

3.1. Undercutting

3.2. Pointing

3.3. Analysis of Tooth Width

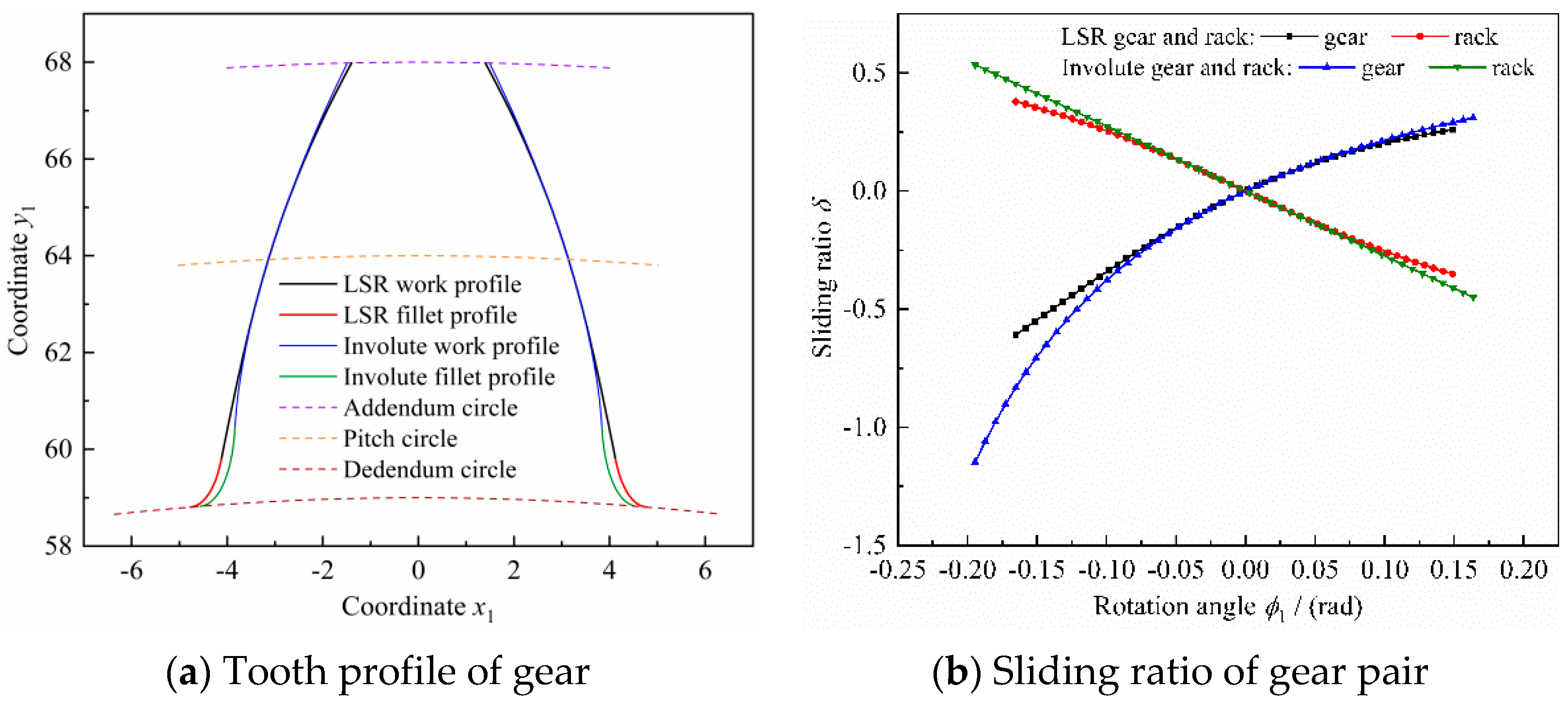

4. Sliding Ratio Characteristics

4.1. Explicit Solution for Meshing Point

4.2. Solution of Sliding Ratio

4.3. Analysis of Sliding Ratio

5. Model Validation

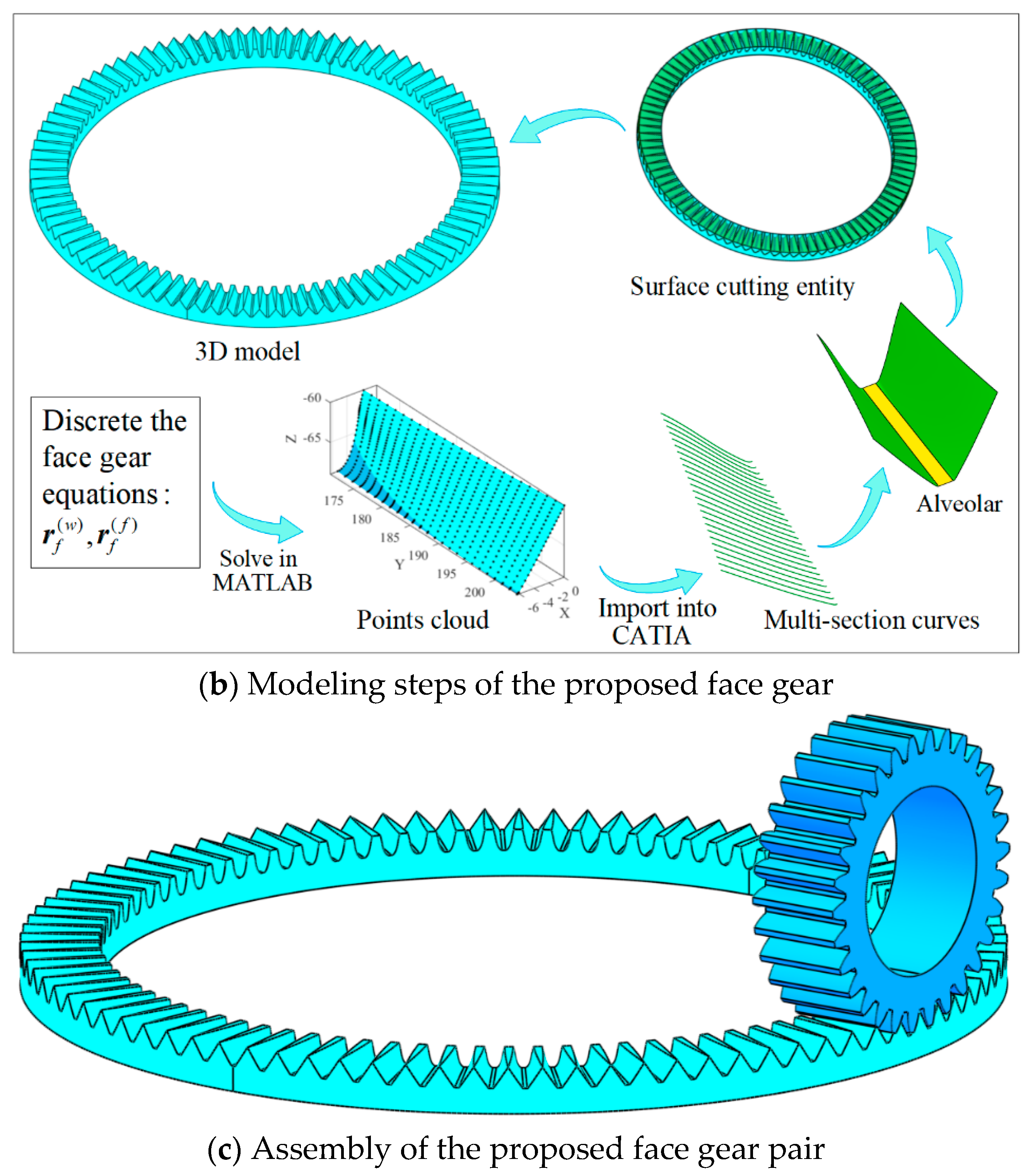

5.1. Modeling of Face Gear Pair

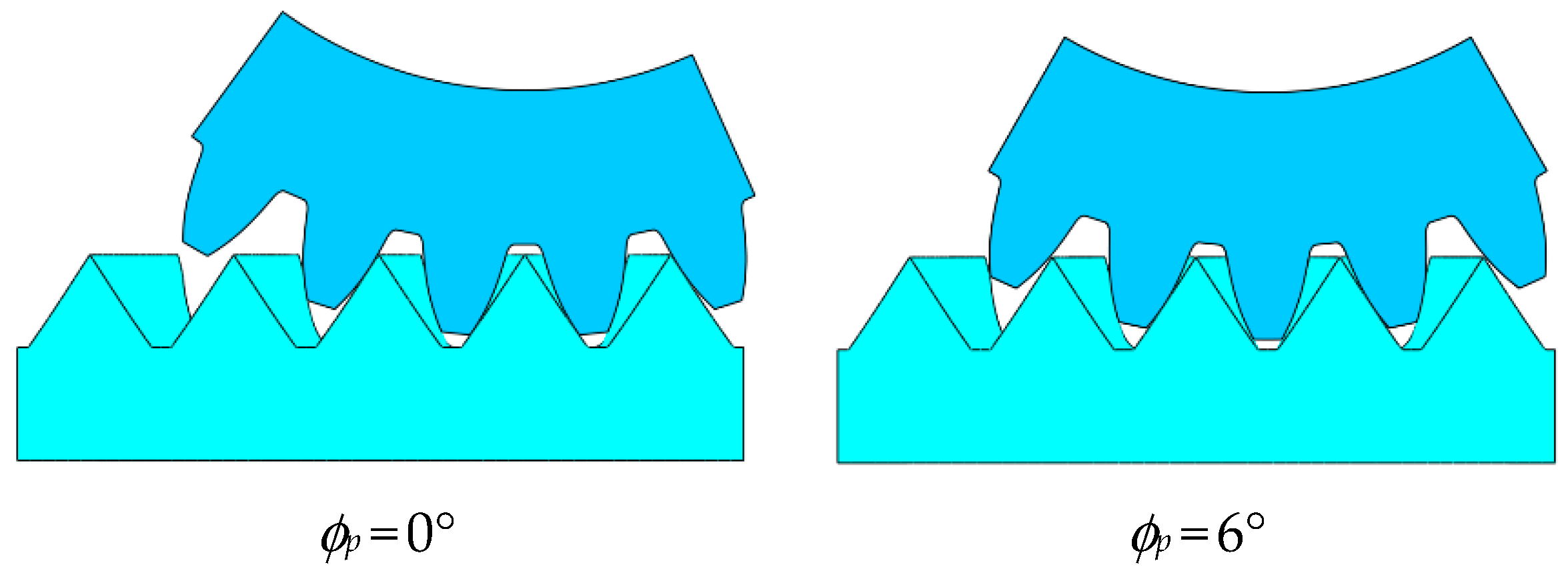

5.2. Motion Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory, 2nd ed.; Cambridge University Press: Cambridge, UK, 2004; ISBN 9780521815178. [Google Scholar]

- Litvin, F.L.; Wang, J.-C.; Bossler, R.B.; Chen, Y.-J.D.; Heath, G.F.; Lewicki, D.G. Application of face-gear drives in helicopter transmissions. J. Mech. Des. 1994, 116, 672–676. [Google Scholar] [CrossRef]

- Heath, G.; Slaughter, S.C.; Fisher, D.J.; Lewicki, D.G.; Fetty, J. Helical face gear development under the enhanced rotorcraft drive system program. In Proceedings of the 67th Annual Forum and Technology Display, Virginia Beach, VA, USA, 3–5 May 2011; Volume 3, pp. 2422–2433, NASA/TM-2011–217125. [Google Scholar]

- Benz, A. Cylkro® face gears: Dutch design and Swiss ingenuity cause transmission breakthrough. In Proceedings of the International Gear Conference 2014, Lyon, France, 26–28 August 2014; pp. 1184–1187. [Google Scholar]

- Choy, F.K.; Polyshchuk, V.; Zakrajsek, J.; Handschuh, R.F.; Townsend, D.P. Analysis of the effects of surface pitting and wear on the vibrations of a gear transmission system. Tribol. Int. 1994, 29, 77–83. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Rycerz, P.; Kadiric, A. Prediction of micropitting damage in gear teeth contacts considering the concurrent effects of surface fatigue and mild wear. Wear 2018, 398, 99–115. [Google Scholar] [CrossRef]

- Litvin, F.L.; Gonzalez-Perez, I.; Fuentes, A.; Vecchiato, D.; Hansen, B.D.; Binney, D. Design, generation and stress analysis of face-gear drive with helical pinion. Comput. Methods Appl. Mech. Eng. 2005, 194, 3870–3901. [Google Scholar] [CrossRef]

- Litvin, F.L.; Nava, A.; Fan, Q.; Fuentes, A. New geometry of face worm gear drives with conical and cylindrical worms: Generation, simulation of meshing, and stress analysis. Comput. Methods Appl. Mech. Eng. 2002, 191, 3035–3054. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A.; Howkins, M. Design, generation and TCA of new type of asymmetric face-gear drive with modified geometry. Comput. Methods Appl. Mech. Eng. 2001, 190, 5837–5865. [Google Scholar] [CrossRef]

- Zschippang, H.A.; Weikert, S.; Küük, K.A.; Wegener, K. Face-gear drive: Geometry generation and tooth contact analysis. Mech. Mach. Theory 2019, 142, 103576. [Google Scholar] [CrossRef]

- Lin, C.; He, C.; Hu, Y. Analysis on the kinematical characteristics of compound motion curve-face gear pair. Mech. Mach. Theory 2018, 128, 298–313. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, C.; Li, S.; Yu, Y.; He, C.; Cai, Z. The Mathematical Model of Curve-Face Gear and Time-Varying Meshing Characteristics of Compound Transmission. Appl. Sci. 2021, 11, 8706. [Google Scholar] [CrossRef]

- Liu, D.; Wang, G.; Ren, T. Transmission principle and geometrical model of eccentric face gear. Mech. Mach. Theory 2017, 109, 51–64. [Google Scholar] [CrossRef]

- Cui, Y.; Fang, Z.; Su, J.; Feng, X. Precise modeling of arc tooth face-gear with transition curve. Chin. J. Aeronaut. 2013, 26, 1346–1351. [Google Scholar]

- Tan, J. Face gearing with a conical involute pinion: Part 2—The face gear: Meshing with the pinion, tooth geometry and generation. In Proceedings of the ASME 2003 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, IL, USA, 2–6 September 2003; pp. 297–306. [Google Scholar]

- Zhang, Y.; Wu, Z. Offset Face Gear Drives: Tooth geometry and contact analysis. J. Mech. Des. 1997, 119, 114–119. [Google Scholar] [CrossRef]

- Chang, H.L.; Tsai, Y.C. A mathematical model of parametric tooth profiles for spur gears. J. Mech. Des. 1992, 114, 8–16. [Google Scholar] [CrossRef]

- Kapelevich, A. Geometry and design of involute spur gears with asymmetric teeth. Mech. Mach. Theory 2000, 35, 117–130. [Google Scholar] [CrossRef]

- Xu, L.; Li, S.; Wang, W. Sliding ratio for novel cycloidal gear drive. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 3954–3963. [Google Scholar] [CrossRef]

- Liu, L.; Meng, F.; Ni, J. A novel non-involute gear designed based on control of relative curvature. Mech. Mach. Theory 2019, 140, 144–158. [Google Scholar] [CrossRef]

- Chen, Z.; Zeng, M.; Fuentes, A. Computerized design, simulation of meshing and stress analysis of pure rolling cylindrical helical gear drives with variable helix angle. Mech. Mach. Theory 2020, 153, 103962. [Google Scholar] [CrossRef]

- Yeh, T.; Yang, D.C.H.; Tong, S.-H. Design of new tooth profiles for high-load capacity gears. Mech. Mach. Theory 2001, 36, 1105–1120. [Google Scholar] [CrossRef]

- Fong, Z.-H.; Chiang, T.-W.; Tsay, C.-W. Mathematical model for parametric tooth profile of spur gear using line of action. Math. Comput. Model. 2002, 36, 603–614. [Google Scholar]

- Wang, Y.; Ren, S.; Li, Y. Design and manufacturing of a novel high contact ratio internal gear with a circular arc contact path. Int. J. Mech. Sci. 2019, 153, 143–153. [Google Scholar] [CrossRef]

- Wang, J.; Luo, S.; Wu, R. A method for the preliminary geometric design of gear tooth profiles with small sliding coefficients. J. Mech. Des. 2010, 132, 054501. [Google Scholar] [CrossRef]

- Wang, J.; Liang, H.; Luo, S.; Wu, R. Active design of tooth profiles using parabolic curve as the line of action. Mech. Mach. Theory 2013, 67, 47–63. [Google Scholar] [CrossRef]

- Buckingham, E. Analytical Mechanics of Gears; McGraw-Hill: New York, NY, USA, 1949. [Google Scholar]

- Litvin, F.L.; Zhang, Y.; Wang, J.-C.; Bossler, R.B.; Chen, Y.-J.D. design and geometry of face-gear drives. J. Mech. Des. 1992, 114, 642–647. [Google Scholar] [CrossRef]

- Chang, S.-H.; Chung, T.-D.; Lu, S.-S. Tooth contact analysis of face-gear drives. Int. J. Mech. Sci. 2000, 42, 487–502. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y.; Zhou, Z.; Tang, J.; Ouyang, H. An advanced CAD/CAE integration method for the generative design of face gears. Adv. Eng. Softw. 2018, 126, 90–99. [Google Scholar] [CrossRef]

- Sheng, W.; Li, Z.; Zhang, H.; Zhu, R. Geometry and design of spur gear drive associated with low sliding ratio. Adv. Mech. Eng. 2021, 13, 16878140211012547. [Google Scholar] [CrossRef]

| Design Parameters | Value |

|---|---|

| Module m (mm) | 4 |

| Tooth number of pinion Np | 30 |

| Tooth number of shaper Ns | 32 |

| Tooth number of face gear Nf | 90 |

| Addendum coefficient ha* | 1.0 |

| Head clearance coefficient c* | 0.25 |

| Design Parameters | Coefficient a1 | Coefficient a2 |

|---|---|---|

| D-1 | −tan 18° | −0.001 |

| D-2 | −tan 19° | −0.001 |

| D-3 | −tan 20° | −0.001 |

| D-4 | −tan 21° | −0.001 |

| D-5 | −tan 22° | −0.001 |

| D-6 | −tan 20° | 0 |

| D-7 | −tan 20° | −0.0005 |

| D-8 | −tan 20° | −0.0015 |

| D-9 | −tan 20° | −0.002 |

| Tooth Width Parameters | The Proposed Face Gear (D-3) | The General face Gear (D-6) |

|---|---|---|

| Inner radius (mm) | 170.490 | 173.059 |

| Outer radius (mm) | 203.135 | 203.231 |

| Tooth width (mm) | 32.645 | 30.172 |

| Sliding Ratio | The Proposed Face Gear Drive (D-3) | The General Face Gear Drive (D-6) | ||

|---|---|---|---|---|

| Pinion | Face Gear | Pinion | Face Gear | |

| Root of tooth | −0.6041 | −0.3931 | −0.9285 | −0.5455 |

| Top of tooth | 0.2822 | 0.3766 | 0.3530 | 0.4815 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, W.; Zhao, J.; Li, Z.; Zhang, H.; Zhu, R. Geometric Design of a Face Gear Drive with Low Sliding Ratio. Appl. Sci. 2022, 12, 2936. https://doi.org/10.3390/app12062936

Sheng W, Zhao J, Li Z, Zhang H, Zhu R. Geometric Design of a Face Gear Drive with Low Sliding Ratio. Applied Sciences. 2022; 12(6):2936. https://doi.org/10.3390/app12062936

Chicago/Turabian StyleSheng, Wei, Jiang Zhao, Zhengminqing Li, Hong Zhang, and Rupeng Zhu. 2022. "Geometric Design of a Face Gear Drive with Low Sliding Ratio" Applied Sciences 12, no. 6: 2936. https://doi.org/10.3390/app12062936

APA StyleSheng, W., Zhao, J., Li, Z., Zhang, H., & Zhu, R. (2022). Geometric Design of a Face Gear Drive with Low Sliding Ratio. Applied Sciences, 12(6), 2936. https://doi.org/10.3390/app12062936