Electric Field Induced Drift of Bacterial Protein Toxins of Foodborne Pathogens Staphylococcus aureus and Escherichia coli from Water

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Bacterial Toxins

2.2. Experimental Procedure and Setting Up Toxin Ion Drift Model

- (1)

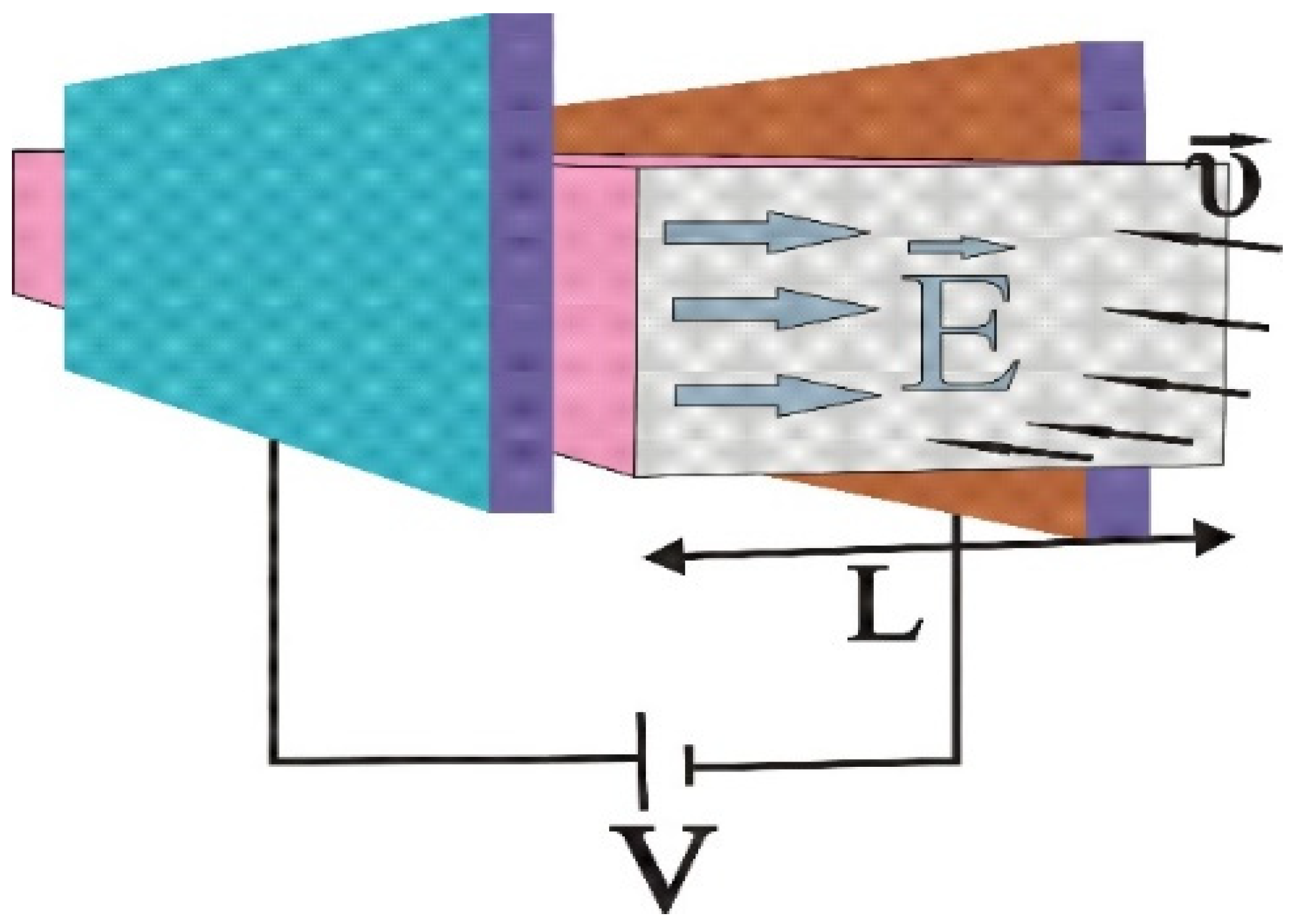

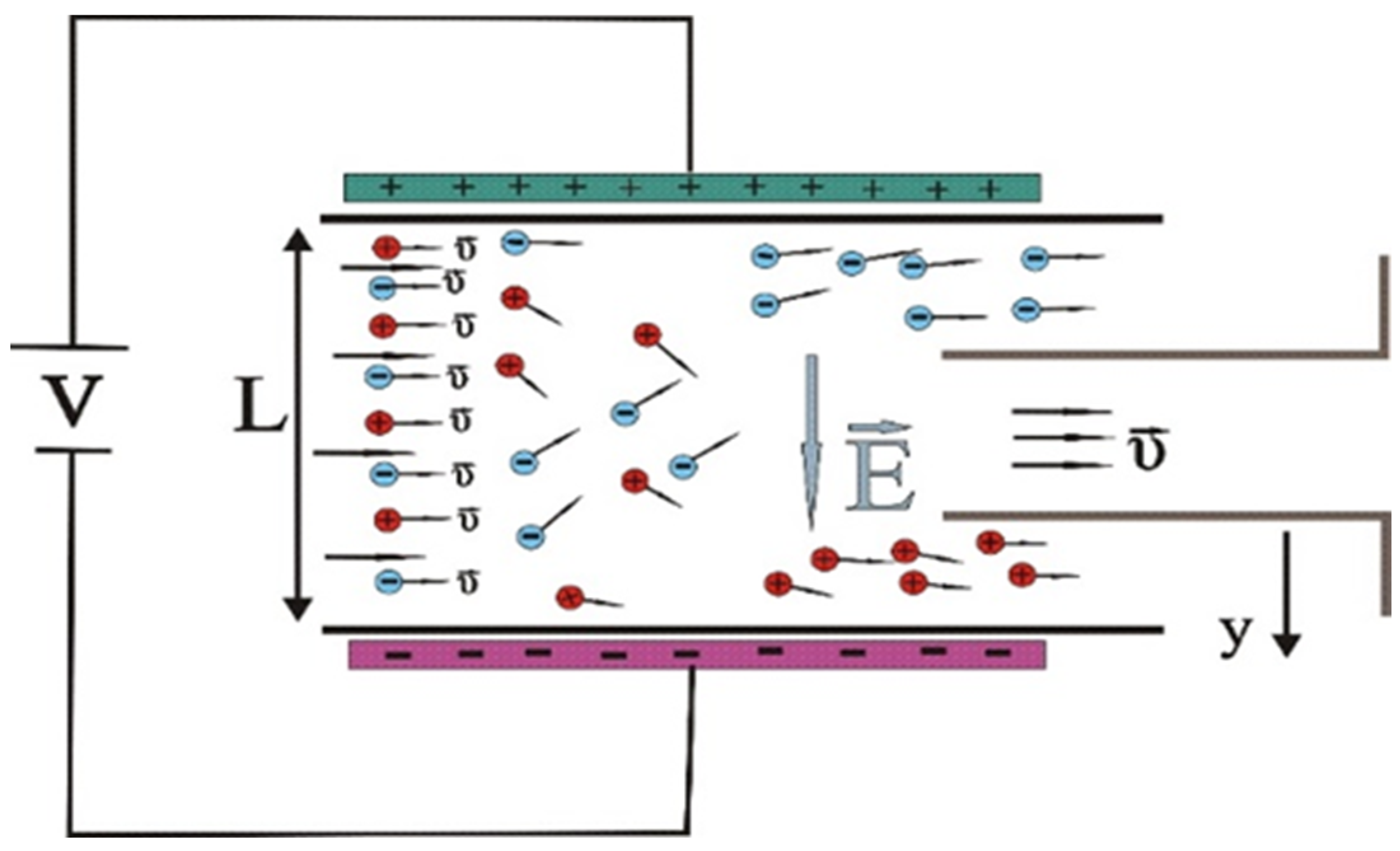

- Two electrodes which are charged by V voltage, and which produce among themselves almost homogeneous electric field intensity with direction from positive to negative electrode.

- (2)

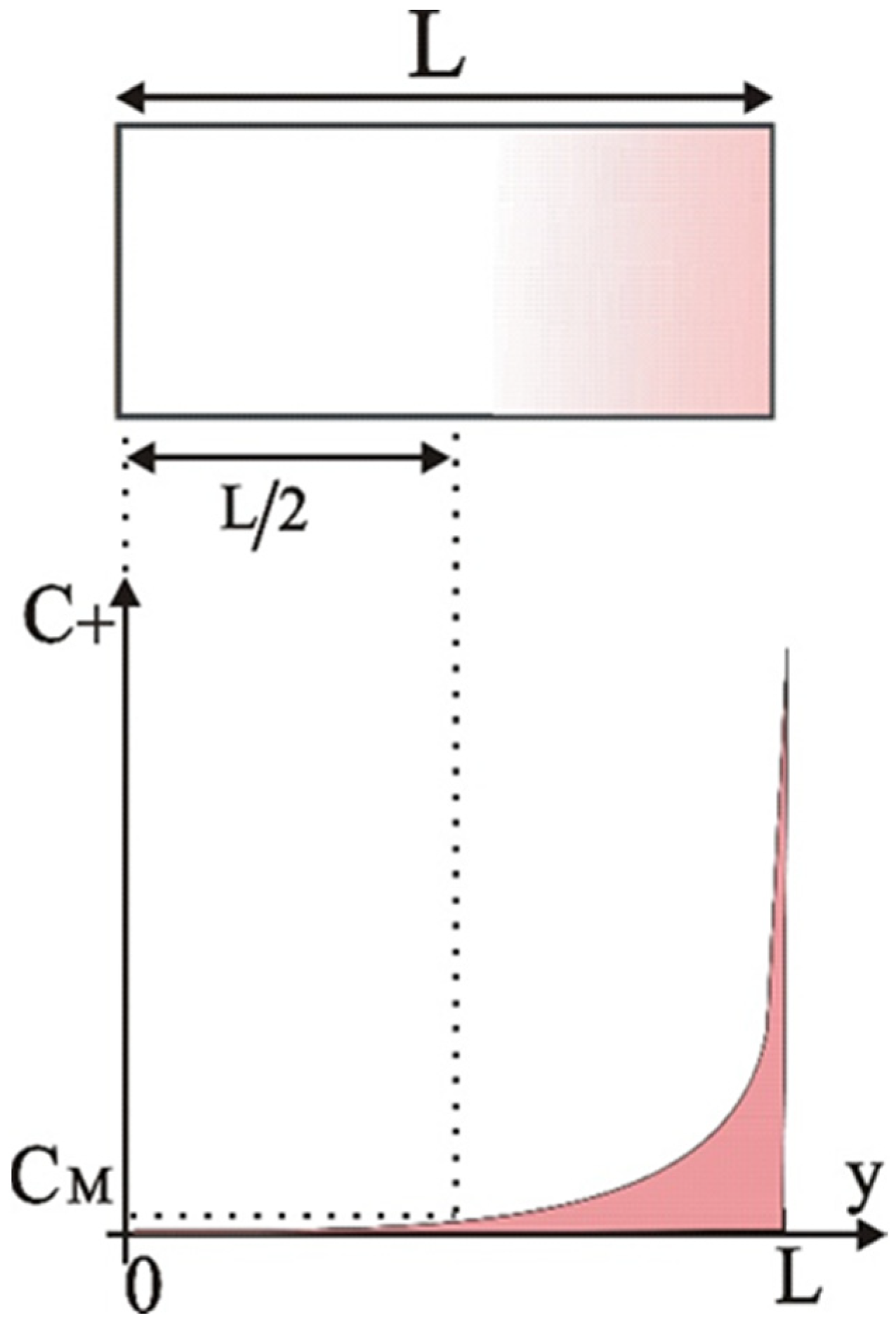

- An insulated duct in which the contaminated water flows through. This is placed along the electrodes and at the minimum distance from them to ensure that the external electric field is almost homogeneous. Therefore, the contaminated water with velocity flows perpendicular to the external electric field intensity, which is considered along the y-axis (Figure 1 and Figure 2), and a change of the toxin ion concentration along the y-axis of the duct is observed (Figure 3).

3. Analysis of the Final Equilibrium State

3.1. Boundary Conditions

- (a)

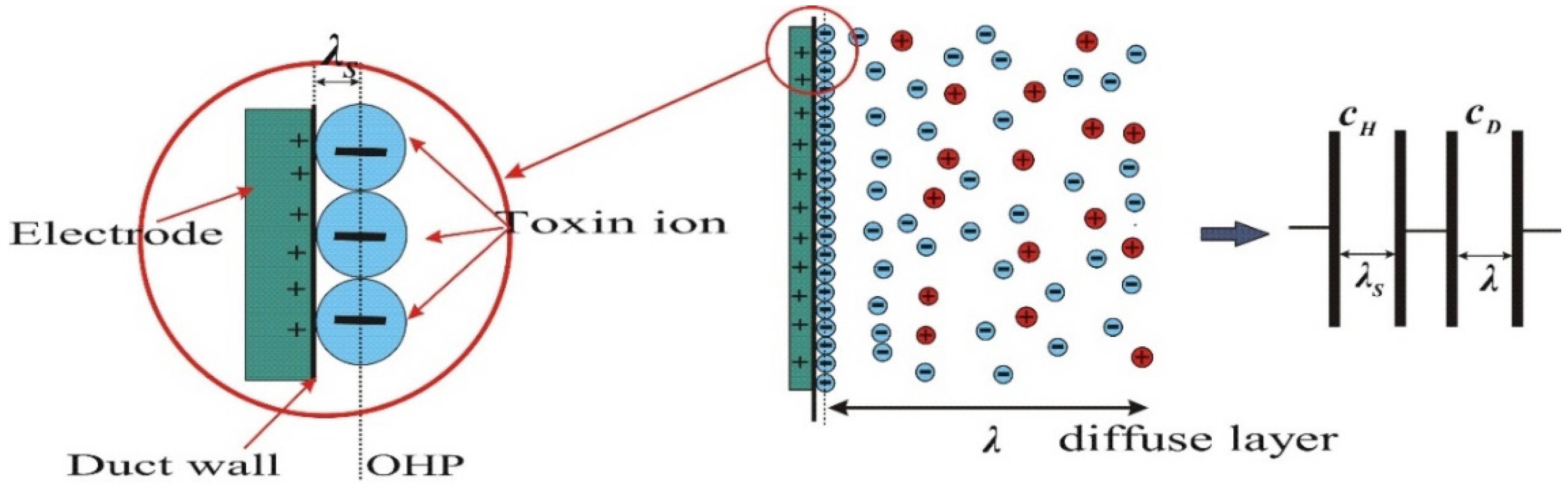

- The compact part (Stern layer), which consists of one layer of ions in direct contact with the walls of the duct. This is simulated with a Helmholtz capacitor, as presented in Figure 4, with effective width approximately equal to the radius of the ion (Table 1). Thus, the capacity of the compact part per unit area is given by

- (b)

- The diffuse layer, which is formed besides the compact part in the inner side of the duct which is simulated with a Gouy–Chapman-type capacitor with effective width (Figure 4) and capacity of the diffuse layer per unit area is given by

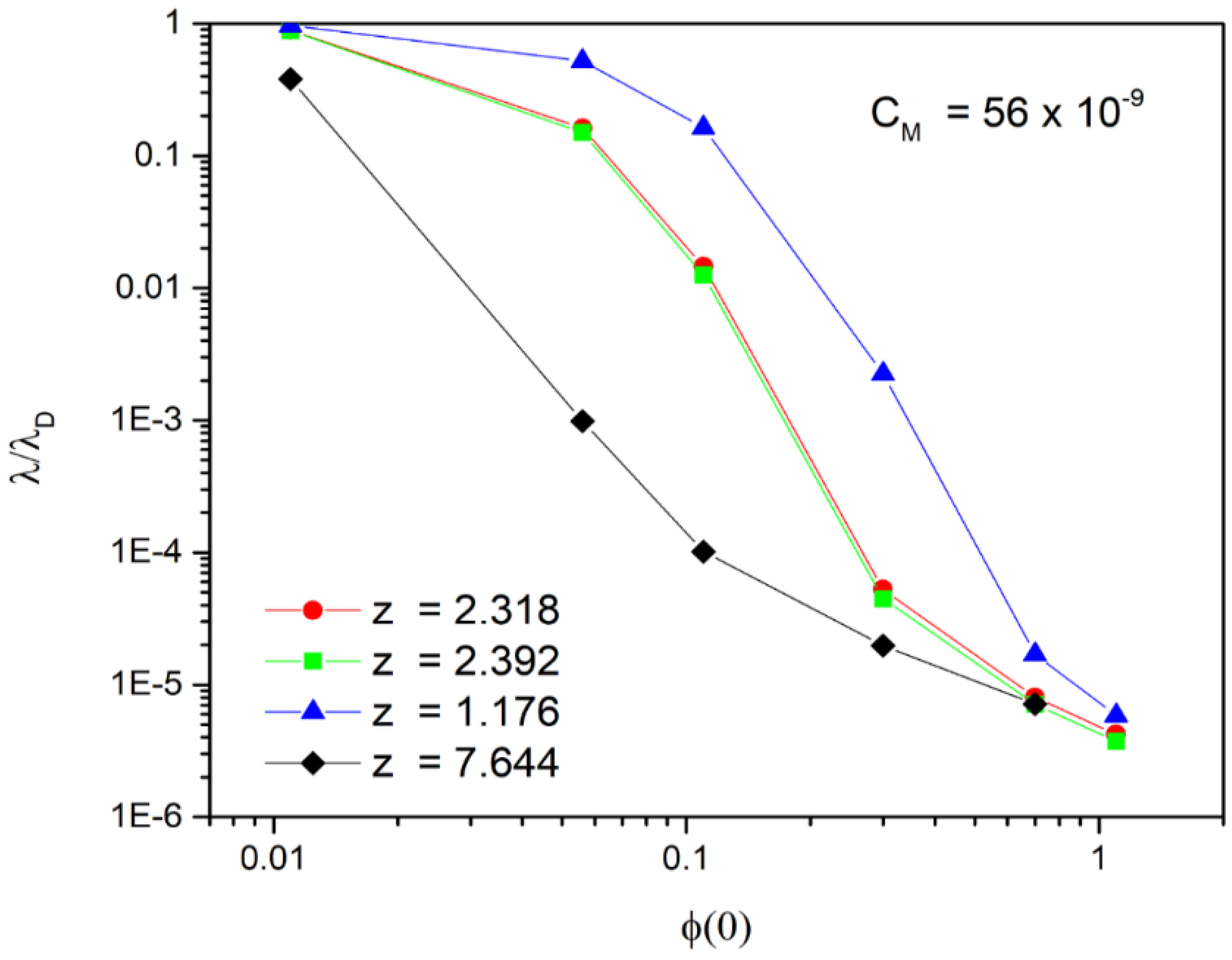

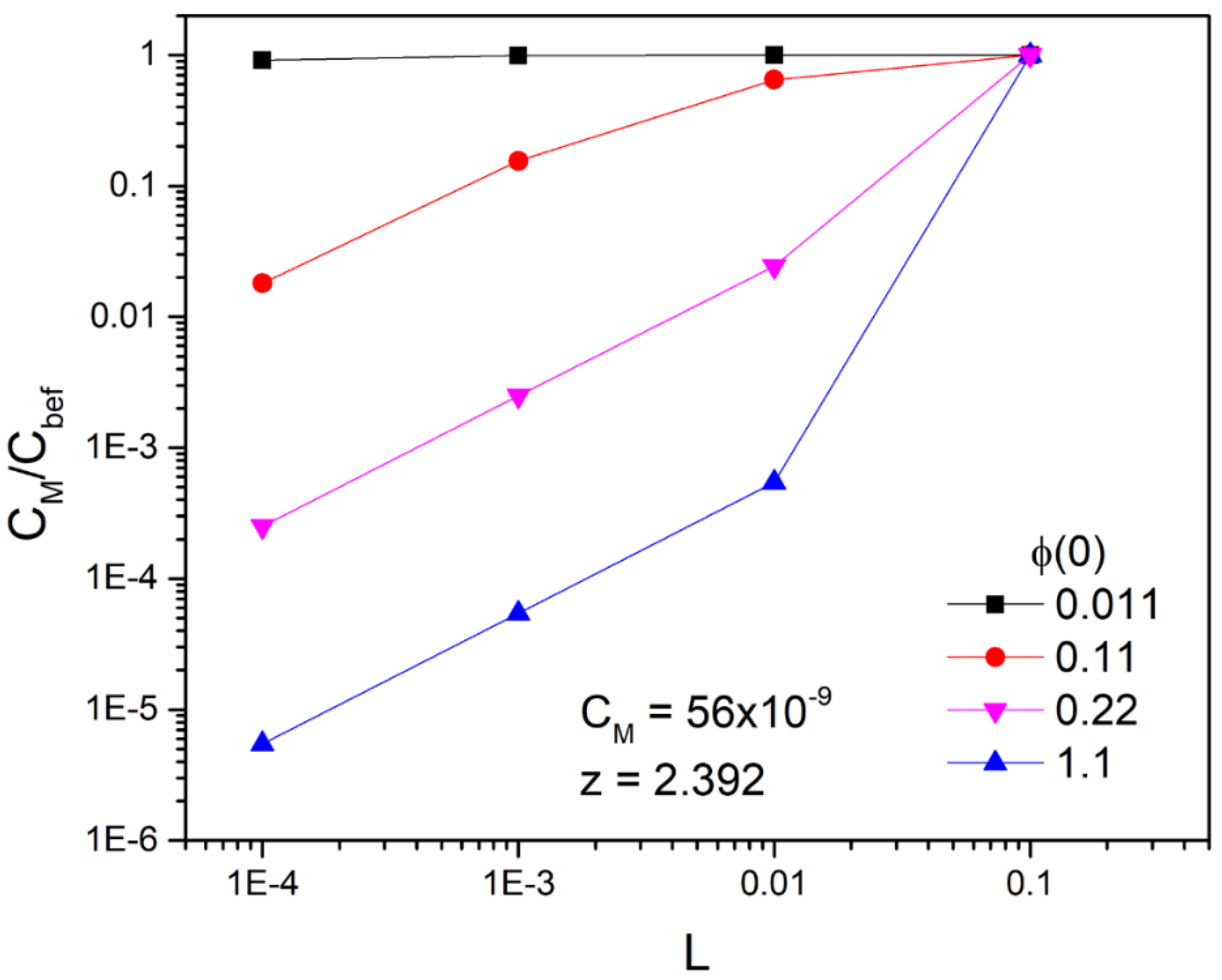

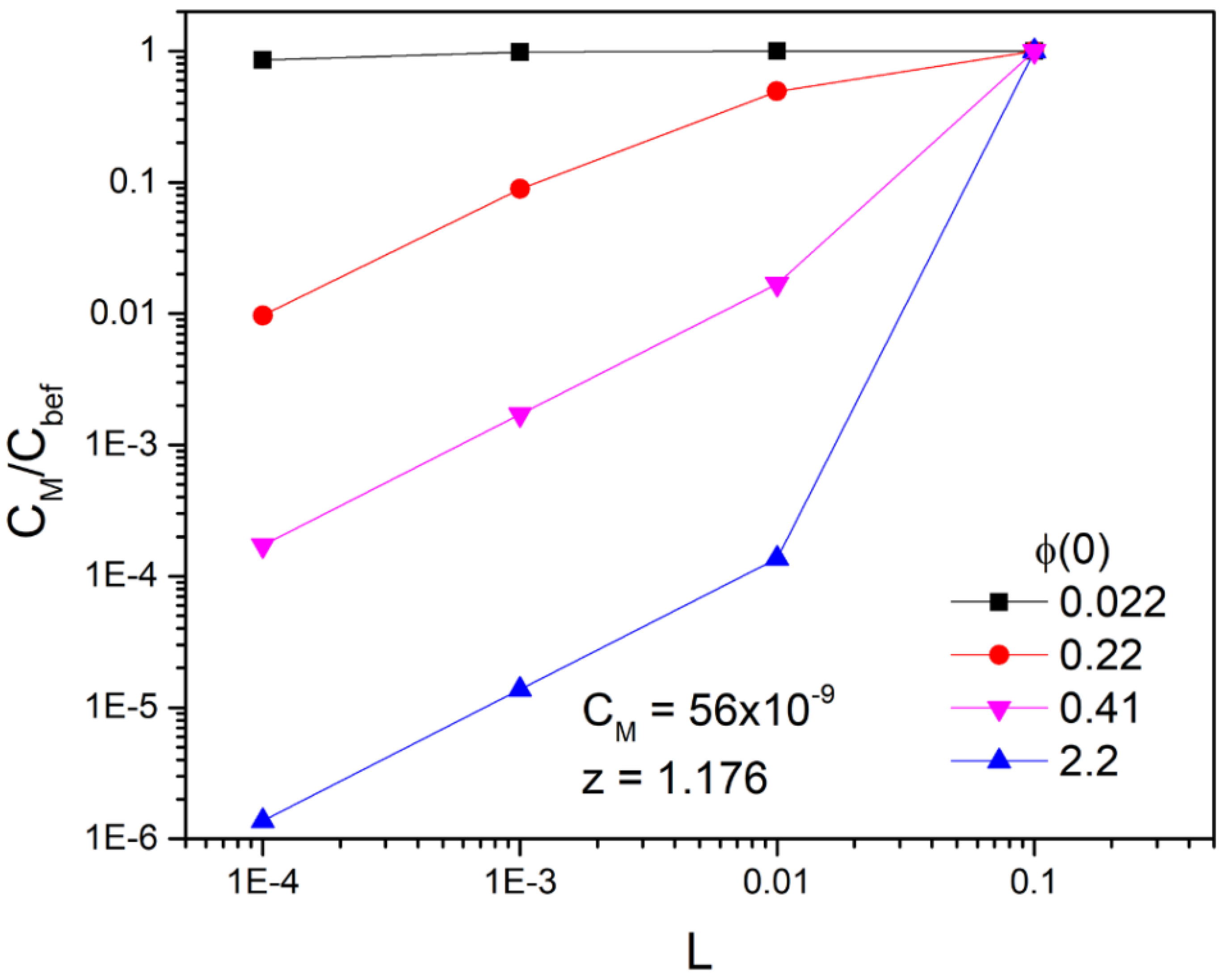

3.2. Calculation of Final Equilibrium State

3.3. Validity of the Model

4. Estimation of Time in the Linear Approximation

- (a)

- The time constant in the linear regime as well as the completion time are proportional to the width of the duct. Therefore, it is useful to calculate the completion time per unit width (s/mm)and the results are represented in Table 4.

- (b)

- The values of the potential with which these times are achieved are extremely small (because only in very low potential the linear approximation can be satisfied)

- (c)

- Although we cannot predict time for higher potentials (as in our case), it is logical to assume that by increasing the external voltage, and consequently the potential φ(0), the time it takes for the bulk solution to reach acceptable concentration values will be drastically reduced.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

Abbreviations

| Concentration, mole/m3 | |

| D | Diffusion coefficient, /s |

| T | Absolute temperature, K |

| z | Number of overflow protons or electrons |

| E | Electric field intensity V/m |

| y | y axis coordinate, m |

| L | Width of the duct, m |

| c | Capacity, F |

| t | Time, s |

| OHP | Outer Helmholtz Plane |

| Greek symbols | |

| electric permittivity, F/m | |

| φ | Electric potential, V |

| σ | Surface charge density, C/m2 |

| μ | Chemical potential, J/mol |

| Electrochemical potential, J/mol | |

| τ | Time constant, s |

| Width of Stern layer, m | |

| λ | Width of the diffuse layer, m |

| diffuse layer width in the linear approximation, m | |

| α | Ion diameter, m |

| Subscripts | |

| y | Along y axis |

| bef | Before |

| l | Linear |

| M | Middle |

| Constants | |

References

- Rajkovic, A.; Jovanovic, J.; Monteiro, S.; Decleer, M.; Andjelkovic, M.; Foubert, A.; Beloglazova, N.; Tsilla, V.; Sas, B.; Madder, A.; et al. Detection of Toxins Involved in Foodborne Diseases Caused by Gram-Positive Bacteria. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1605–1657. [Google Scholar] [CrossRef] [PubMed]

- Abril, A.G.; Villa, T.G.; Barros-Velázquez, J.; Cañas, B.; Sánchez-Pérez, A.; Calo-Mata, P.; Carrera, M. Staphylococcus Aureus Exotoxins and Their Detection in the Dairy Industry and Mastitis. Toxins 2020, 12, 537. [Google Scholar] [CrossRef] [PubMed]

- Amirsoleimani, A.; Brion, G.M.; Diene, S.M.; François, P.; Richard, E.M. Prevalence and Characterization of Staphylococcus Aureus in Wastewater Treatment Plants by Whole Genomic Sequencing. Water Res. 2019, 158, 193–202. [Google Scholar] [CrossRef] [PubMed]

- Silva, V.; Ferreira, E.; Manageiro, V.; Reis, L.; Tejedor-Junco, M.T.; Sampaio, A.; Capelo, J.L.; Caniça, M.; Igrejas, G.; Poeta, P. Distribution and Clonal Diversity of Staphylococcus Aureus and Other Staphylococci in Surface Waters: Detection of ST425-T742 and ST130-T843 MecC-Positive MRSA Strains. Antibiotics 2021, 10, 1416. [Google Scholar] [CrossRef]

- Silva, V.; Caniça, M.; Capelo, J.L.; Igrejas, G.; Poeta, P. Diversity and Genetic Lineages of Environmental Staphylococci: A Surface Water Overview. FEMS Microbiol. Ecol. 2020, 96, fiaa191. [Google Scholar] [CrossRef]

- Vandenesch, F.; Lina, G.; Henry, T. Staphylococcus Aureus Hemolysins, Bi-Component Leukocidins, and Cytolytic Peptides: A Redundant Arsenal of Membrane-Damaging Virulence Factors? Front. Cell. Infect. Microbiol. 2012, 2, 12. [Google Scholar] [CrossRef]

- Oliveira, D.; Borges, A.; Simões, M. Staphylococcus Aureus Toxins and Their Molecular Activity in Infectious Diseases. Toxins 2018, 10, 252. [Google Scholar] [CrossRef]

- Dinges, M.M.; Orwin, P.M.; Schlievert, P.M.; Biology, S.; The, O.F. Exotoxins of Staphylococcus Aureus. Clin. Microbiol. Rev. Jan. 2000, 13, 16–34. [Google Scholar] [CrossRef]

- Sugawara, T.; Yamashita, D.; Kato, K.; Peng, Z.; Ueda, J.; Kaneko, J.; Kamio, Y.; Tanaka, Y.; Yao, M. Structural Basis for Pore-Forming Mechanism of Staphylococcal α-Hemolysin. Toxicon 2015, 108, 226–231. [Google Scholar] [CrossRef]

- Gonzalez, A.G.M.; Cerqueira, A.M.F.; Guth, B.E.C.; Coutinho, C.A.; Liberal, M.H.T.; Souza, R.M.; Andrade, J.R.C. Serotypes, Virulence Markers and Cell Invasion Ability of Shiga Toxin-Producing Escherichia Coli Strains Isolated from Healthy Dairy Cattle. J. Appl. Microbiol. 2016, 121, 1130–1143. [Google Scholar] [CrossRef]

- Joseph, A.; Cointe, A.; Mariani Kurkdjian, P.; Rafat, C.; Hertig, A. Shiga Toxin-Associated Hemolytic Uremic Syndrome: A Narrative Review. Toxins 2020, 12, 67. [Google Scholar] [CrossRef] [PubMed]

- Keir, L.S. Shiga Toxin Associated Hemolytic Uremic Syndrome. Hematol. Oncol. Clin. N. Am. 2015, 29, 525–539. [Google Scholar] [CrossRef] [PubMed]

- Siegler, R.L.; Obrig, T.G.; Pysher, T.J.; Tesh, V.L.; Denkers, N.D.; Taylor, F.B. Response to Shiga Toxin 1 and 2 in a Baboon Model of Hemolytic Uremic Syndrome. Pediatr. Nephrol. 2003, 18, 92–96. [Google Scholar] [CrossRef] [PubMed]

- Touchon, M.; Cury, J.; Yoon, E.J.; Krizova, L.; Cerqueira, G.C.; Murphy, C.; Feldgarden, M.; Wortman, J.; Clermont, D.; Lambert, T.; et al. The Genomic Diversification of the Whole Acinetobacter Genus: Origins, Mechanisms, and Consequences. Genome Biol. Evol. 2014, 6, 2866–2882. [Google Scholar] [CrossRef] [PubMed]

- Conrady, D.G.; Flagler, M.J.; Friedmann, D.R.; Vander Wielen, B.D.; Kovall, R.A.; Weiss, A.A.; Herr, A.B. Molecular Basis of Differential B-Pentamer Stability of Shiga Toxins 1 and 2. PLoS ONE 2010, 5, e15153. [Google Scholar] [CrossRef]

- Bartzis, V.; Sarris, I.E. Time Evolution Study of the Electric Field Distribution and Charge Density Due to Ion Movement in Salty Water. Water 2021, 13, 2185. [Google Scholar] [CrossRef]

- Bartzis, V.; Sarris, I.E. A Theoretical Model for Salt Ion Drift Due to Electric Field Suitable to Seawater Desalination. Desalination 2020, 473, 114163. [Google Scholar] [CrossRef]

- Bartzis, V.; Sarris, I.E. Electric Field Distribution and Diffuse Layer Thickness Study Due to Salt Ion Movement in Water Desalination. Desalination 2020, 490, 114549. [Google Scholar] [CrossRef]

- Sofos, F.; Karakasidis, T.E.; Spetsiotis, D. Molecular Dynamics Simulations of Ion Separation in Nano-Channel Water Flows Using an Electric Field. Mol. Simul. 2019, 45, 1395–1402. [Google Scholar] [CrossRef]

- Sofos, F.; Karakasidis, T.E.; Sarris, I.E. Effects of Channel Size, Wall Wettability, and Electric Field Strength on Ion Removal from Water in Nanochannels. Sci. Rep. 2022, 12, 641. [Google Scholar] [CrossRef]

- Sofos, F. A Water/Ion Separation Device: Theoretical and Numerical Investigation. Appl. Sci. 2021, 11, 8548. [Google Scholar] [CrossRef]

- Fischer, H.; Polikarpov, I.; Craievich, A.F. Average Protein Density Is a Molecular-Weight-Dependent Function. Protein Sci. 2009, 13, 2825–2828. [Google Scholar] [CrossRef] [PubMed]

- Atkins, P.; Paola, J. Atkin’s Physical Chemistry; Oxford University Press: Oxford, UK, 2006. [Google Scholar]

- Mortimer, R.G. Physical Chemistry; John Wiley & Sons: New York, UY, USA, 2008; Volume 8. [Google Scholar]

- Brett, C.M.A.; Brett, A.M.O. Electrochemistry Principles, Methods, and Applications; Oxford University Press: Oxford, UK, 1994. [Google Scholar]

- Debye, P.; Hückel, E. The Theory of Electrolytes. I. Lowering of Freezing Point and Related Phenomena. Phys. Z. 1923, 24, 185–206. [Google Scholar]

- Bonnefont, A.; Argoul, F.; Bazant, M. Analysis of Diffuse Layer on Time-Dependent Interfacial Kinetics. J. Electroanal. Chem. 2001, 500, 52. [Google Scholar] [CrossRef]

- Bazant, M.Z.; Thornton, K.; Ajdari, A. Diffuse-Charge Dynamics in Electrochemical Systems. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip. Top. 2004, 70, 24. [Google Scholar] [CrossRef]

- Wu, S.; Duan, N.; Gu, H.; Hao, L.; Ye, H.; Gong, W.; Wang, Z. A Review of the Methods for Detection of Staphylococcus Aureus Enterotoxins. Toxins 2016, 8, 176. [Google Scholar] [CrossRef]

- Aguilar, J.L.; Varshney, A.K.; Wang, X.; Stanford, L.; Scharff, M.; Fries, B.C. Detection and Measurement of Staphylococcal Enterotoxin-like K (SEl-K) Secretion by Staphylococcus Aureus Clinical Isolates. J. Clin. Microbiol. 2014, 52, 2536–2543. [Google Scholar] [CrossRef]

- Kilic, M.S.; Bazant, M.Z.; Ajdari, A. Steric Effects in the Dynamics of Electrolytes at Large Applied Voltages. I. Double-Layer Charging. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2007, 75, 021502. [Google Scholar] [CrossRef]

- Wellcome Sanger Institute. Toxic Shock Syndrome Toxin-1 [Staphylococcus Aureus]; Wellcome Sanger Institute: Hinxton, UK, 2020. Available online: https://www.ncbi.nlm.nih.gov/protein/CAC5806749.1 (accessed on 1 October 2022).

- Zhang, Y.; Liao, Y.-T.; Salvador, A.; Sun, X.; Wu, V. Complete Genome Sequence of a Shiga Toxin-Converting Bacteriophage, Escherichia Phage Lys12581Vzw, Induced from an Outbreak Shiga Toxin-Producing Escherichia coli. Microbiol. Resour. Announc. 2020, 8, e00793-19. [Google Scholar] [CrossRef]

| Type of Toxin | Toxin 1 Staphylococcus aureus Alpha-Hemolysin | Toxin 2: Staphylococcus aureus Toxic Shock Syndrome Toxin-1 (TSST-1) | Toxin 3: Staphylococcus aureus Enterotoxin Type A | Toxin 4: E. coli Shiga Toxin 2 (One Subunit A and Five Subunits B) |

|---|---|---|---|---|

| Reference | GenBank: QTN48712.1 | GenBank: KIT87450.1 | GenBank: QTN49470.1 | Shiga toxin Stx2 subunit A [Escherichia phage Lyz12581Vzw] NCBI Reference Sequence: YP_009907811.1 Shiga toxin Stx2 subunit B [Escherichia phage Lyz12581Vzw] GenBank: QDF15669.1 |

| Number of amino acids | 319 | 234 | 257 | subunit A: 260 subunit B: 89 |

| Isoelectric point (pI) | 8.511 | 8.615 | 7.938 | 6.282 |

| Net charge (at pH 7.4) z | +2.318 | +2.392 | +1.176 | −7.644 |

| Molecular formula | C1592H2481N433O500S9 | C1196H1885N305O363S4 | C1334H2067N353O404S5 | C3462H5407N925O1068S43 |

| Average mass (Da) | 35,975 | 26,473 | 29,674 | 78,454 |

| Diffusion coefficient D (m2/s) | ||||

| Effective Radius r (m) | ||||

| Diameter α (m) | ||||

| (m) (effective width of the Helmholtz capacitor) |

| Toxin 1 Staphylococcus aureus, Alpha-Hemolysin | Toxin 2 Staphylococcus aureus, Toxic Shock Syndrome Toxin-1 (TSST-1) | Toxin 3 Staphylococcus aureus Enterotoxin Type A | Toxin 4 E. coli Shiga Toxin 2 (One Subunit A and Five Subunits B) | |

|---|---|---|---|---|

| (m) | ||||

| Toxin 1 Staphylococcus aureus Alpha-Hemolysin | Toxin 2 Staphylococcus aureus Toxic Shock Syndrome Toxin-1 (TSST-1) | Toxin 3 Staphylococcus aureus Enterotoxin Type A | Toxin 4 E. coli Shiga Toxin 2 (One Subunit A and Five Subunits B) | |

|---|---|---|---|---|

| () | 10.43 | 14.46 | 13.0 | 4.88 |

| () | ||||

| (V) | 0.21 | 0.22 | 0.41 | 0.062 |

| (V) | 0.24 | 0.26 | 0.41 |

| Toxin 1 Staphylococcus aureus Alpha-Hemolysin | Toxin 2 Staphylococcus aureus Toxic Shock Syndrome Toxin-1 (TSST-1) | Toxin 3 Staphylococcus aureus Enterotoxin Type A | Toxin 4 E. coli Shiga Toxin 2 (One Subunit A and Five Subunits B) | |

|---|---|---|---|---|

| (m−1) | 185,741 | |||

| (m) | ||||

| (V) | 0.003 | |||

| 547 | 470 | 1000 | 210 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartzis, V.; Batrinou, A.; Sarris, I.E.; Konteles, S.J.; Strati, I.F.; Houhoula, D. Electric Field Induced Drift of Bacterial Protein Toxins of Foodborne Pathogens Staphylococcus aureus and Escherichia coli from Water. Appl. Sci. 2022, 12, 12739. https://doi.org/10.3390/app122412739

Bartzis V, Batrinou A, Sarris IE, Konteles SJ, Strati IF, Houhoula D. Electric Field Induced Drift of Bacterial Protein Toxins of Foodborne Pathogens Staphylococcus aureus and Escherichia coli from Water. Applied Sciences. 2022; 12(24):12739. https://doi.org/10.3390/app122412739

Chicago/Turabian StyleBartzis, Vasileios, Anthimia Batrinou, Ioannis E. Sarris, Spyros J. Konteles, Irini F. Strati, and Dimitra Houhoula. 2022. "Electric Field Induced Drift of Bacterial Protein Toxins of Foodborne Pathogens Staphylococcus aureus and Escherichia coli from Water" Applied Sciences 12, no. 24: 12739. https://doi.org/10.3390/app122412739

APA StyleBartzis, V., Batrinou, A., Sarris, I. E., Konteles, S. J., Strati, I. F., & Houhoula, D. (2022). Electric Field Induced Drift of Bacterial Protein Toxins of Foodborne Pathogens Staphylococcus aureus and Escherichia coli from Water. Applied Sciences, 12(24), 12739. https://doi.org/10.3390/app122412739