Study on Profitability of Combining Wood and CFRP into Composite Based on Mechanical Performance of Bent Beams

Abstract

1. Introduction

2. Materials and Methods

2.1. Models’ Assumptions

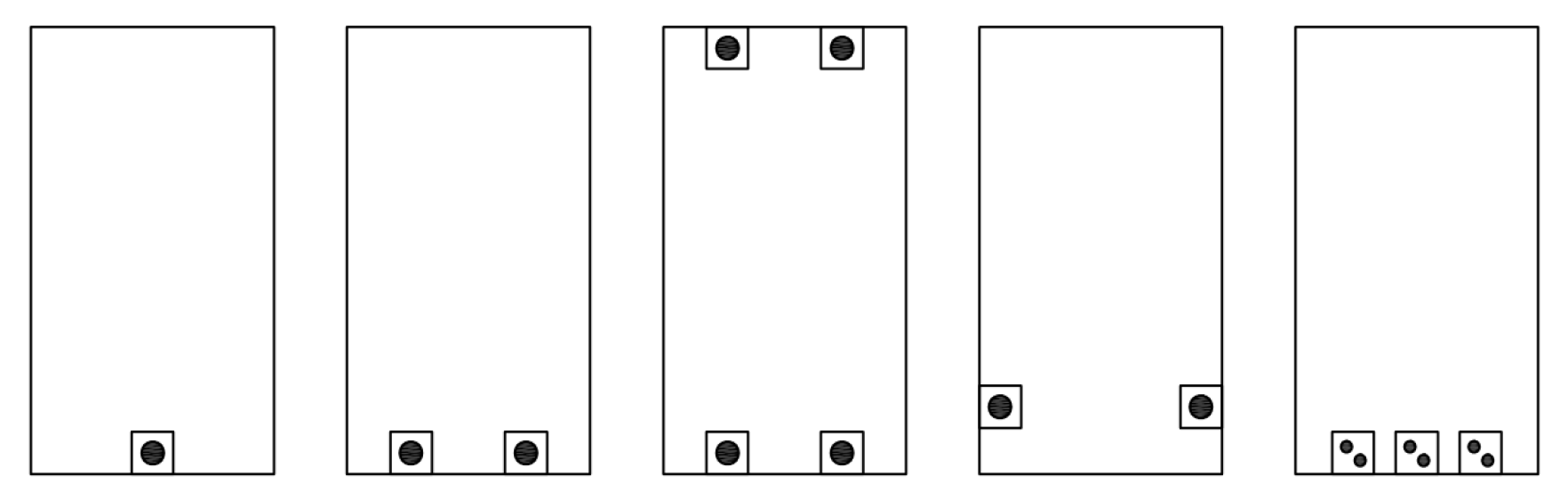

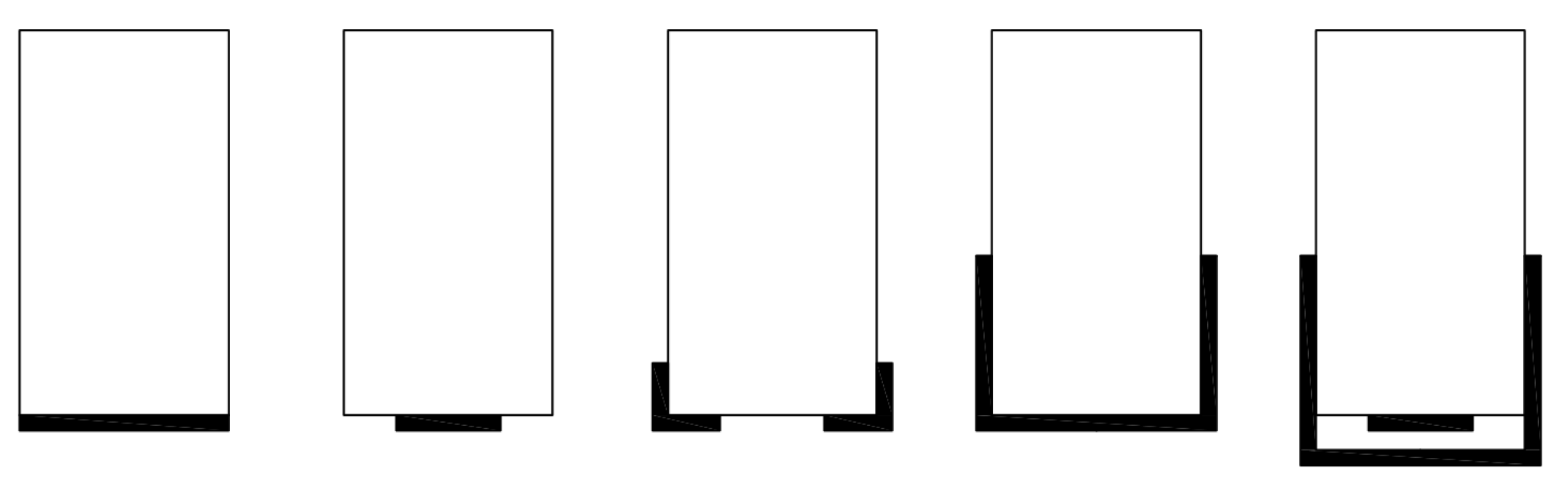

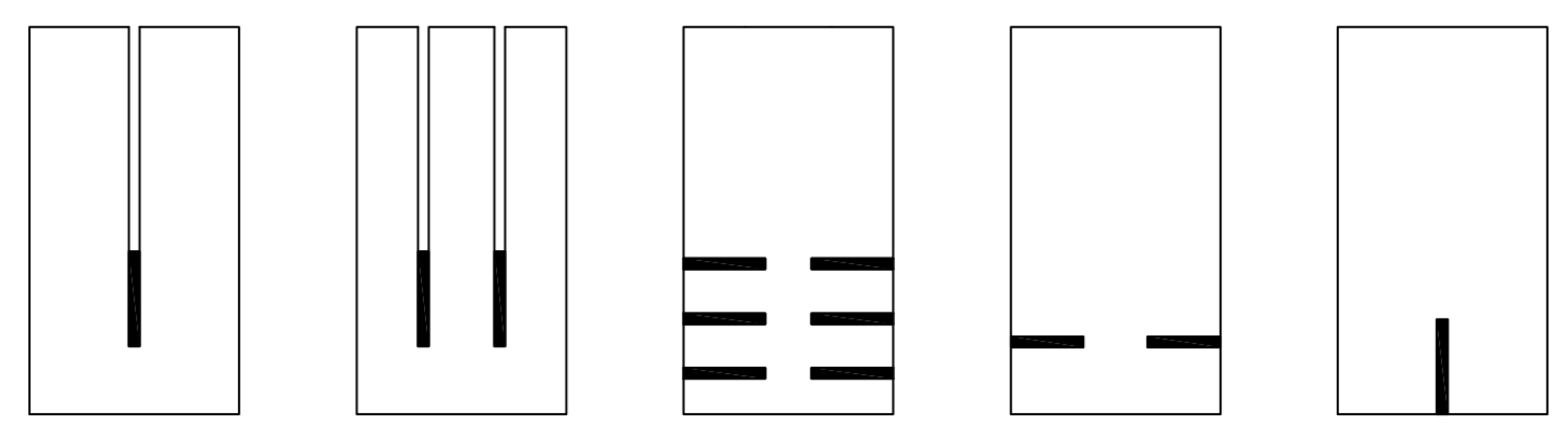

2.2. Analysed Beams’ Cross-Sections

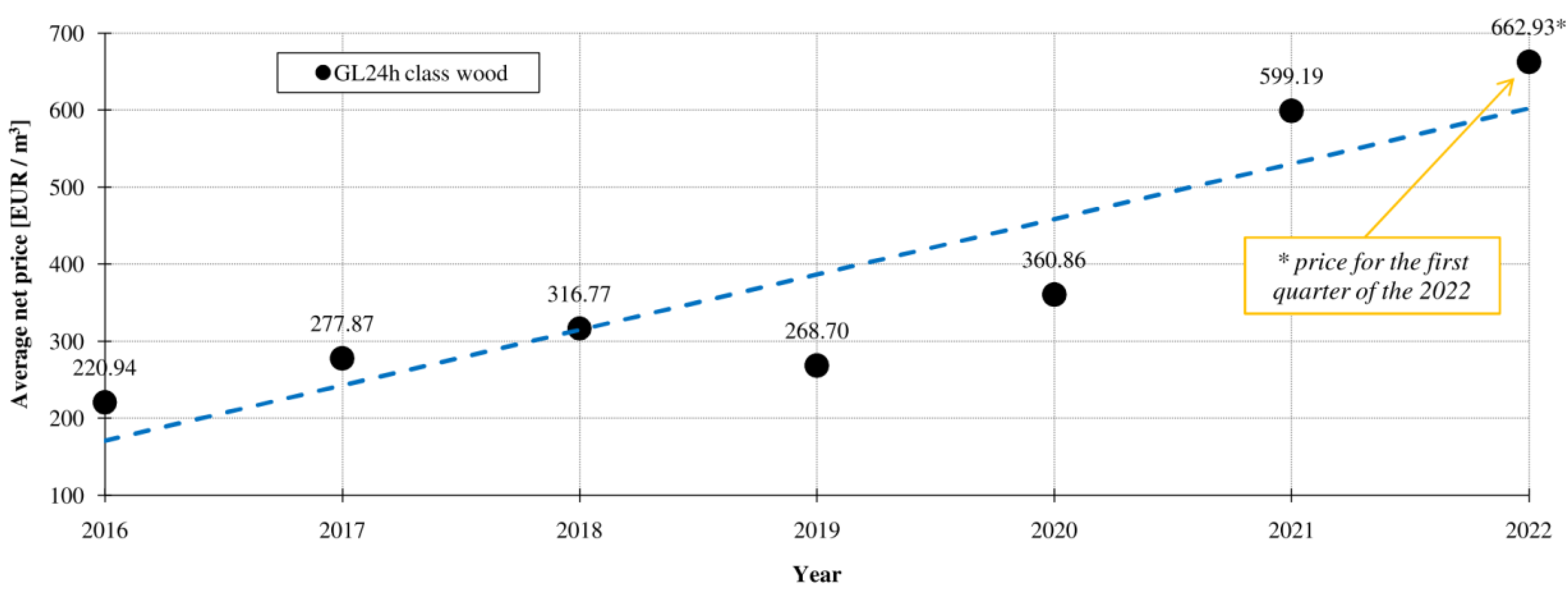

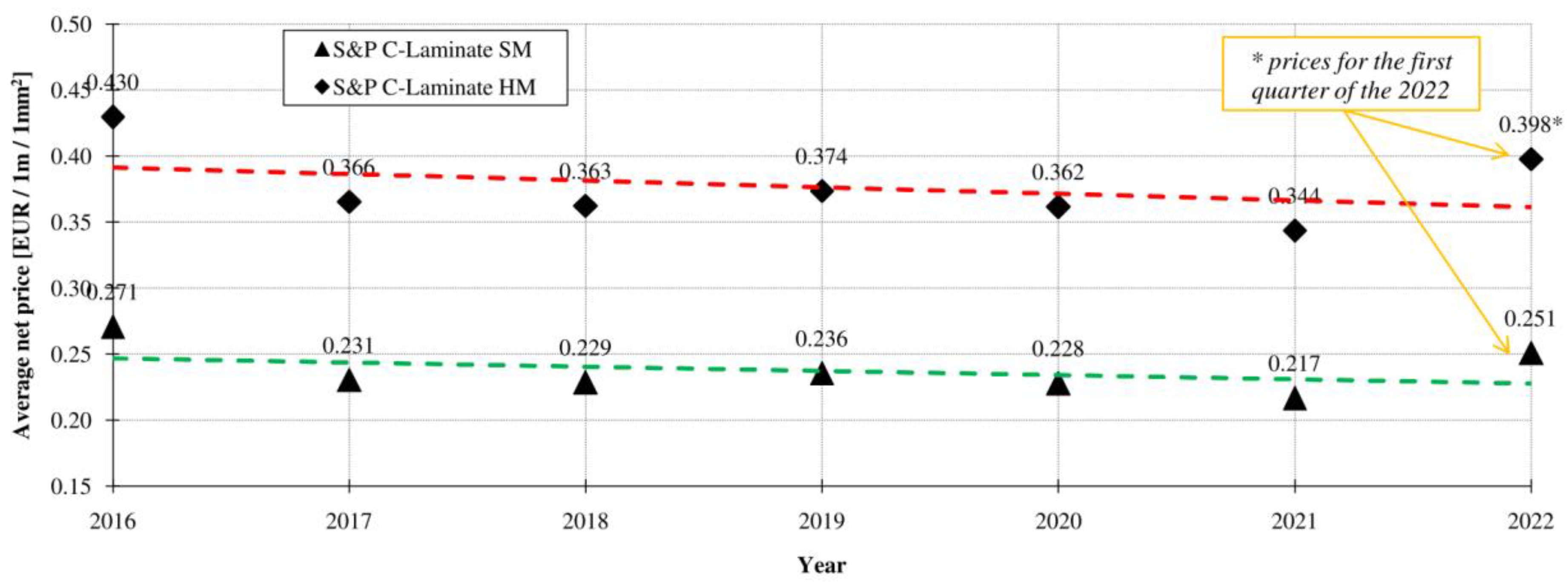

2.3. Materials’ Prices

3. Results and Discussion

3.1. Costs of the Constituent Materials

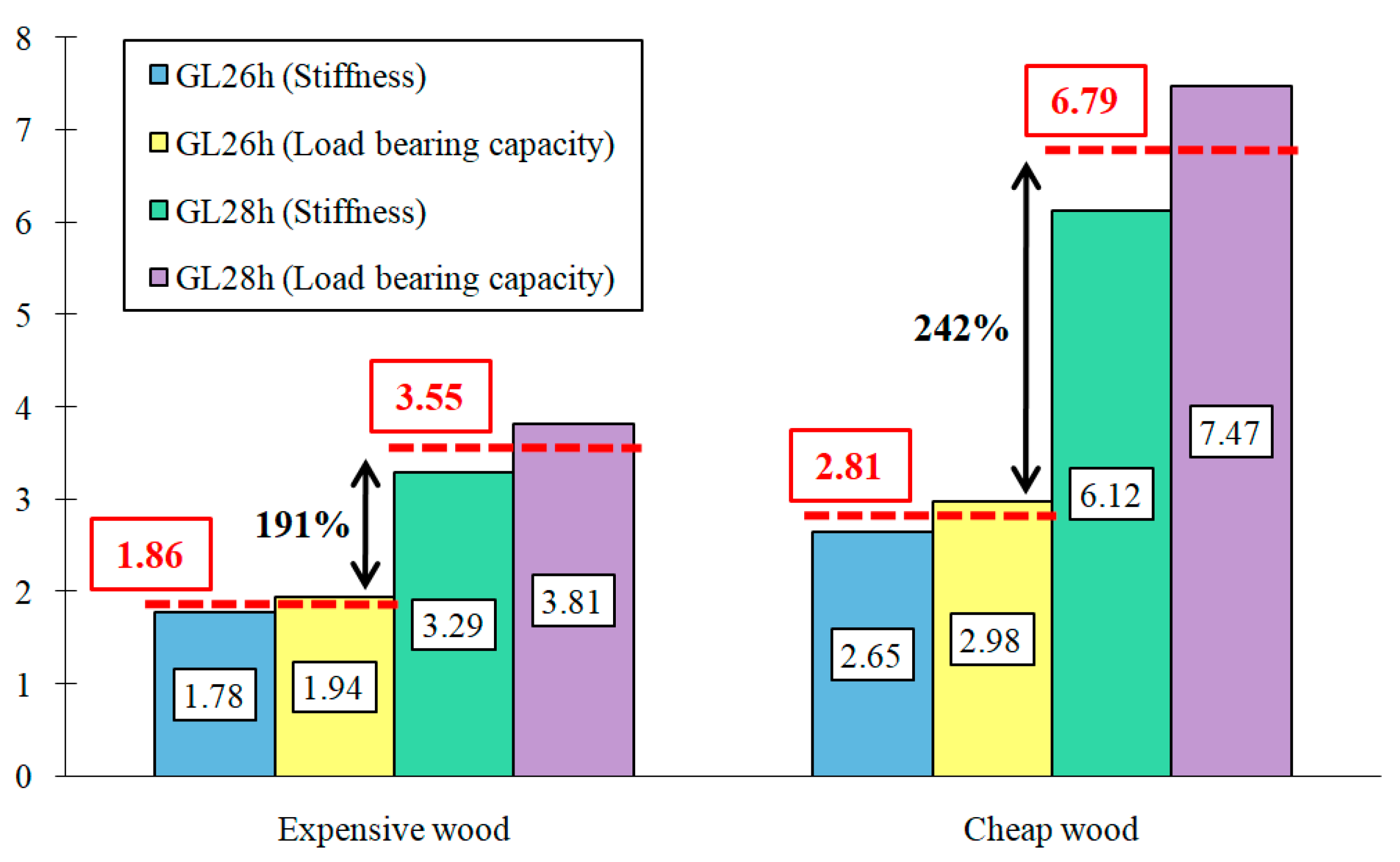

3.2. IncreasesinStiffness and Load-Bearing Capacity

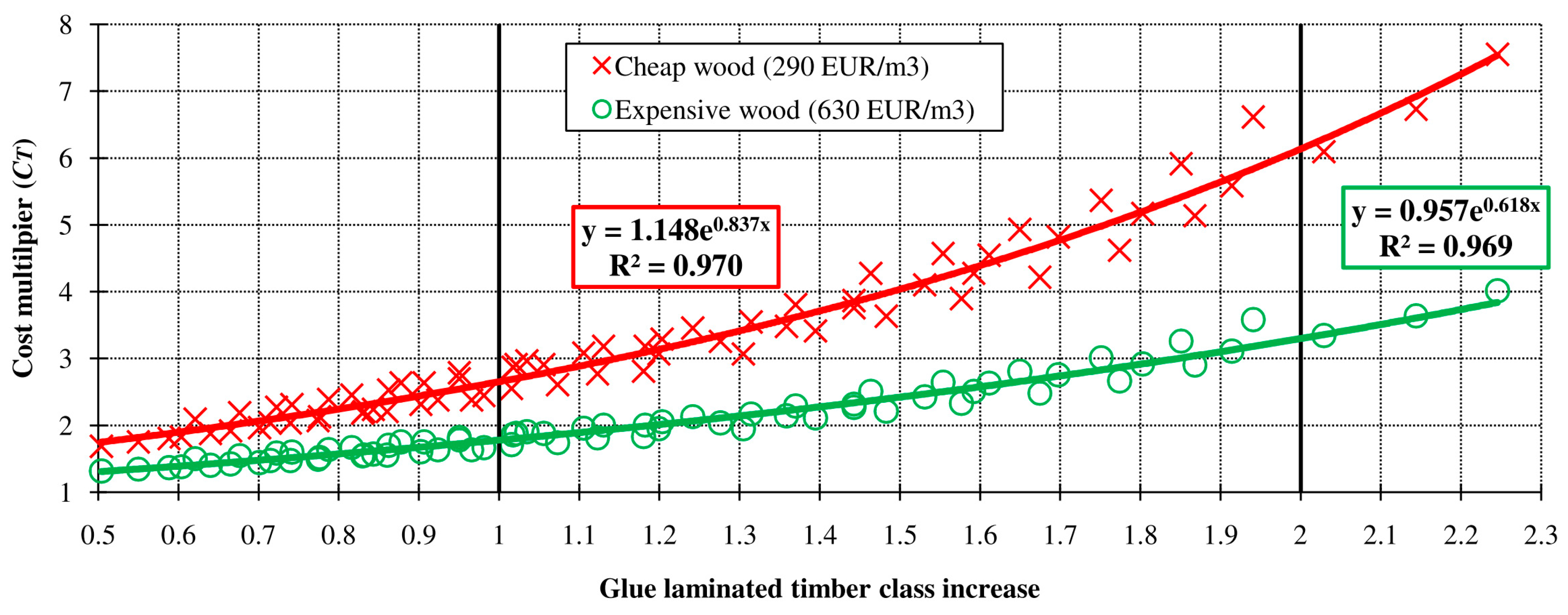

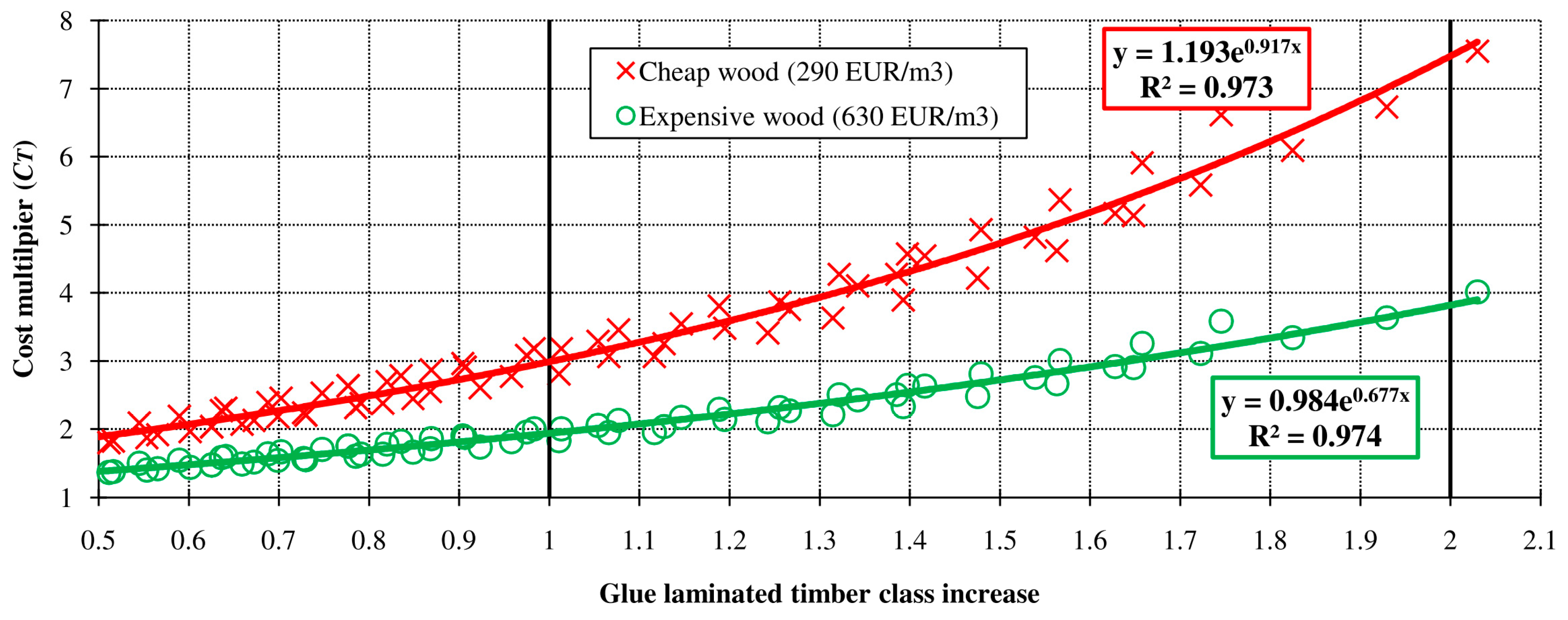

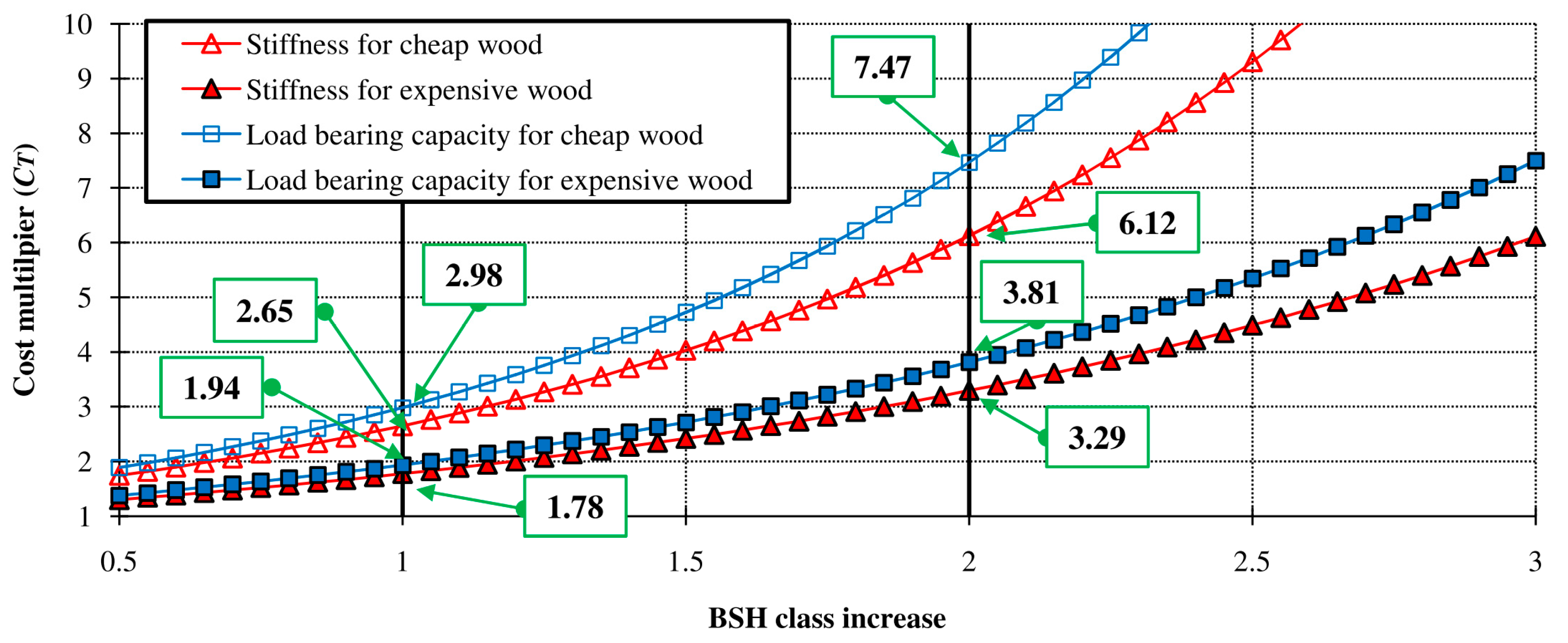

3.3. Study on Cost in Relation to Mechanical Properties of Reinforced and Unreinforced Beams

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schober, K.-U.; Harte, A.M.; Kliger, R.; Jockwer, R.; Xu, Q.; Chen, J.-F. FRP reinforcement of timber structures. Constr. Build. Mater. 2015, 97, 106–118. [Google Scholar] [CrossRef]

- Franke, S.; Franke, B.; Harte, A.M. Failure modes and reinforcement techniques for timber beams—State of the art. Constr. Build. Mater. 2015, 97, 2–13. [Google Scholar] [CrossRef]

- Raftery, G.M.; Whelan, C. Low-grade glued laminated timber beams reinforced using improved arrangements of bonded-in GFRP rods. Constr. Build. Mater. 2014, 52, 209–220. [Google Scholar] [CrossRef]

- Bergner, K.; Tosch, M.; Zauer, M.; Spickenheuer, A.; Wagenführ, A.; Heinrich, G. Process development for the manufacture of fiber reinforced wood composites (FRWC). Constr. Build. Mater. 2018, 180, 275–284. [Google Scholar] [CrossRef]

- Yang, H.; Ju, D.; Liu, W.; Lu, W. Prestressed glulam beams reinforced with CFRP bars. Constr. Build. Mater. 2016, 109, 73–83. [Google Scholar] [CrossRef]

- Andor, K.; Lengyel, A.; Polgár, R.; Fodor, T.; Karácsonyi, Z. Experimental and statistical analysis of spruce timber beams reinforced with CFRP fabric. Constr. Build. Mater. 2015, 99, 200–207. [Google Scholar] [CrossRef]

- de la Rosa García, P.; Cobo Escamilla, A.; González García, M.N. Analysis of the flexural stiffness of timber beams reinforced with carbon and basalt composite materials. Compos. Part B Eng. 2016, 86, 152–159. [Google Scholar] [CrossRef]

- Rescalvo, F.; Valverde-Palacios, I.; Suarez, E.; Gallego, A. Experimental Comparison of Different Carbon Fiber Composites in Reinforcement Layouts for Wooden Beams of Historical Buildings. Materials 2017, 10, 1113. [Google Scholar] [CrossRef]

- Nadir, Y.; Nagarajan, P.; Ameen, M.; Arif, M. Flexural stiffness and strength enhancement of horizontally glued laminated wood beams with GFRP and CFRP composite sheets. Constr. Build. Mater. 2016, 112, 547–555. [Google Scholar] [CrossRef]

- Vahedian, A.; Shrestha, R.; Crews, K. Experimental and analytical investigation on CFRP strengthened glulam laminated timber beams: Full-scale experiments. Compos. Part B Eng. 2019, 164, 377–389. [Google Scholar] [CrossRef]

- Brunetti, M.; Christovasilis, I.P.; Micheloni, M.; Nocetti, M.; Pizzo, B. Production feasibility and performance of carbon fibre reinforced glulam beams manufactured with polyurethane adhesive. Compos. Part B Eng. 2019, 156, 212–219. [Google Scholar] [CrossRef]

- Subhani, M.; Globa, A.; Al-Ameri, R.; Moloney, J. Flexural strengthening of LVL beam using CFRP. Constr. Build. Mater. 2017, 150, 480–489. [Google Scholar] [CrossRef]

- Zhang, C.; Chun, Q.; Wang, H.; Lin, Y.; Shi, J. Experimental study on the flexural behaviour of timber beams strengthened with high ductility and low cost hybrid fibre sheets. Constr. Build. Mater. 2022, 322, 126514. [Google Scholar] [CrossRef]

- Halicka, A.; Ślósarz, S. Strengthening of timber beams with pretensioned CFRP strips. Structures 2021, 34, 2912–2921. [Google Scholar] [CrossRef]

- Halicka, A.; Sl, S. Analysis of behavior and failure modes of timber beams prestressed with CFRP strips. Compos. Struct. 2022, 301, 116171. [Google Scholar] [CrossRef]

- Jankowski, L.J.; Jasieńko, J.; Nowak, T.P. Experimental assessment of CFRP reinforced wooden beams by 4-point bending tests and photoelastic coating technique. Mater. Struct. 2010, 43, 141–150. [Google Scholar] [CrossRef]

- Nowak, T.P.; Jasieńko, J.; Czepiżak, D. Experimental tests and numerical analysis of historic bent timber elements reinforced with CFRP strips. Constr. Build. Mater. 2013, 40, 197–206. [Google Scholar] [CrossRef]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Rubio-de Hita, P. Bending and shear reinforcements for timber beams using GFRP plates. Constr. Build. Mater. 2015, 96, 461–472. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M. Low-grade glued laminated timber reinforced with FRP plate. Compos. Part B Eng. 2011, 42, 724–735. [Google Scholar] [CrossRef]

- Raftery, G.M.; Rodd, P.D. FRP reinforcement of low-grade glulam timber bonded with wood adhesive. Constr. Build. Mater. 2015, 91, 116–125. [Google Scholar] [CrossRef]

- Glišović, I.; Stevanović, B.; Todorović, M. Flexural reinforcement of glulam beams with CFRP plates. Mater. Struct. 2016, 49, 2841–2855. [Google Scholar] [CrossRef]

- Yang, H.; Liu, W.; Lu, W.; Zhu, S.; Geng, Q. Flexural behavior of FRP and steel reinforced glulam beams: Experimental and theoretical evaluation. Constr. Build. Mater. 2016, 106, 550–563. [Google Scholar] [CrossRef]

- He, M.; Wang, Y.; Li, Z.; Zhou, L.; Tong, Y.; Sun, X. An Experimental and Analytical Study on the Bending Performance of CFRP-Reinforced Glulam Beams. Front. Mater. 2022, 8, 607. [Google Scholar] [CrossRef]

- Kawecki, B. Dobór Parametrów Modeli Obliczeniowych Pełnych Dźwigarów z Kompozytów Drewno-Polimerowych Zbrojonych Włóknami (Selection of the Parameters for Numerical Models of Full Girders Made of Wood-Polymer Composites Reinforced with Fibres); Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2021. [Google Scholar]

- Kawecki, B.; Podgórski, J. The Effect of Glue Cohesive Stiffness on the Elastic Performance of Bent Wood–CFRP Beams. Materials 2020, 13, 5075. [Google Scholar] [CrossRef]

- Kawecki, B. Guidelines for FEM modelling of wood-CFRP beams using ABAQUS. Arch. Civ. Eng. 2021, 67, 175–191. [Google Scholar]

- Kawecki, B.; Podgórski, J. 3D ABAQUS simulation of bent softwood elements. Arch. Civ. Eng. 2020, 66, 323–337. [Google Scholar]

- PN-EN 14080:2013; Glued Laminated Timber and Glued Solid Timber—Requirements. Polski Komitet Normalizacyjny: Warsaw, Poland, 2013.

- S&P C-LAMINATE—Technical Information. Available online: https://www.sp-reinforcement.pl/sites/default/files/field_product_col_doc_file/c-laminates_polska_ver012019-low.pdf (accessed on 1 January 2019).

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | 12.50 |

| Length (m) | Height (mm) (Number of Wooden Lamellas) | |||||

| 6 | 280 (7) | 320 (8) | 360 (9) | 400 (10) | 440 (11) | 480 (12) |

| 12 | 650 (14) | 640 (16) | 720 (18) | 800 (20) | 880 (22) | 960 (24) |

| 18 | 840 (21) | 960 (24) | 1080 (27) | 1200 (30) | 1320 (33) | 1440 (36) |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | 12.50 | ||

| Length L(m) | Width (mm) | CFRP Tape Cross-Sectional Area t = 1.2 mm/t = 1.4 mm (mm2) | BSH Volume (m3) | |||||

| 6 | 100 | 120/140 | 0.168 | 0.192 | 0.216 | 0.240 | 0.264 | 0.288 |

| 120 | 144/168 | 0.202 | 0.230 | 0.259 | 0.288 | 0.317 | 0.346 | |

| 150 | 180/210 | 0.252 | 0.288 | 0.324 | 0.360 | 0.396 | 0.432 | |

| 12 | 100 | 120/140 | 0.672 | 0.768 | 0.864 | 0.960 | 1.056 | 1.152 |

| 120 | 144/168 | 0.806 | 0.922 | 1.037 | 1.152 | 1.267 | 1.382 | |

| 150 | 180/210 | 1.008 | 1.152 | 1.296 | 1.440 | 1.584 | 1.728 | |

| 18 | 100 | 120/140 | 1.512 | 1.728 | 1.944 | 2.160 | 2.376 | 2.592 |

| 120 | 144/168 | 1.814 | 2.074 | 2.333 | 2.592 | 2.851 | 3.110 | |

| 150 | 180/210 | 2.268 | 2.592 | 2.916 | 3.240 | 3.564 | 3.888 | |

| Length (m) | Width (mm) | S&P C-Laminate/1.2 mm (EUR) | S&P C-Laminate/1.4 mm (EUR) | ||

|---|---|---|---|---|---|

| 6 | 100 | 173 | 202 | 274 | 319 |

| 120 | 207 | 242 | 328 | 383 | |

| 150 | 259 | 302 | 410 | 479 | |

| 12 | 100 | 346 | 403 | 547 | 638 |

| 120 | 415 | 484 | 657 | 766 | |

| 150 | 518 | 605 | 821 | 958 | |

| 18 | 100 | 518 | 605 | 821 | 958 |

| 120 | 622 | 726 | 985 | 1149 | |

| 150 | 778 | 907 | 1231 | 1436 | |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | ||

| Length (m) | Width (mm) | Cost of “Cheap” BSH (EUR) | |||||

| 6 | 100 | 49 | 56 | 63 | 70 | 77 | 84 |

| 120 | 59 | 67 | 75 | 84 | 92 | 100 | |

| 150 | 73 | 84 | 94 | 104 | 115 | 125 | |

| 12 | 100 | 195 | 223 | 251 | 278 | 306 | 334 |

| 120 | 234 | 267 | 301 | 334 | 367 | 401 | |

| 150 | 292 | 334 | 376 | 418 | 459 | 501 | |

| 18 | 100 | 438 | 501 | 564 | 626 | 689 | 752 |

| 120 | 526 | 601 | 677 | 752 | 827 | 902 | |

| 150 | 658 | 752 | 846 | 940 | 1034 | 1128 | |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | ||

| Length (m) | Width (mm) | Cost of “Expensive” BSH (EUR) | |||||

| 6 | 100 | 106 | 121 | 136 | 151 | 166 | 181 |

| 120 | 127 | 145 | 163 | 181 | 200 | 218 | |

| 150 | 159 | 181 | 204 | 227 | 249 | 272 | |

| 12 | 100 | 423 | 484 | 544 | 605 | 665 | 726 |

| 120 | 508 | 581 | 653 | 726 | 798 | 871 | |

| 150 | 635 | 726 | 816 | 907 | 998 | 1089 | |

| 18 | 100 | 953 | 1089 | 1225 | 1361 | 1497 | 1633 |

| 120 | 1143 | 1307 | 1470 | 1633 | 1796 | 1959 | |

| 150 | 1429 | 1633 | 1837 | 2041 | 2245 | 2449 | |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | ||

| Length (m) | Stiffness /Load-Bearing Capacity | Increases of Stiffness and Load-Bearing Capacity (%) | |||||

| 6 | Kincr | 8.41 | 7.99 | 7.53 | 7.09 | 6.66 | 6.26 |

| Pincr | 11.80 | 11.18 | 10.55 | 9.95 | 9.39 | 8.88 | |

| 12 | Kincr | 5.86 | 5.30 | 4.82 | 4.40 | 4.05 | 3.73 |

| Pincr | 7.98 | 7.23 | 6.59 | 6.06 | 5.60 | 5.21 | |

| 18 | Kincr | 4.33 | 3.86 | 3.47 | 3.15 | 2.87 | 2.63 |

| Pincr | 5.82 | 5.21 | 4.71 | 4.30 | 3.95 | 3.65 | |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | ||

| Length (m) | Stiffness /Load-Bearing Capacity | Increases of Stiffness and Load-Bearing Capacity (%) | |||||

| 6 | Kincr | 9.75 | 9.26 | 8.74 | 8.23 | 7.74 | 7.28 |

| Pincr | 13.73 | 13.02 | 12.29 | 11.60 | 10.95 | 10.35 | |

| 12 | Kincr | 6.81 | 6.16 | 5.60 | 5.12 | 4.71 | 4.34 |

| Pincr | 9.30 | 8.42 | 7.69 | 7.07 | 6.54 | 6.08 | |

| 18 | Kincr | 5.04 | 4.49 | 4.04 | 3.66 | 3.34 | 3.07 |

| Pincr | 6.79 | 6.08 | 5.49 | 5.01 | 4.61 | 4.26 | |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | ||

| Length (m) | Stiffness /Load-Bearing Capacity | Increases of Stiffness and Load-Bearing Capacity (%) | |||||

| 6 | Kincr | 10.13 | 9.66 | 9.14 | 8.61 | 8.11 | 7.64 |

| Pincr | 14.54 | 13.81 | 13.05 | 12.32 | 11.64 | 11.01 | |

| 12 | Kincr | 7.15 | 6.48 | 5.90 | 5.40 | 4.96 | 4.58 |

| Pincr | 9.90 | 8.97 | 8.19 | 7.53 | 6.96 | 6.47 | |

| 18 | Kincr | 5.31 | 4.73 | 4.26 | 3.87 | 3.53 | 3.24 |

| Pincr | 7.24 | 6.47 | 5.85 | 5.34 | 4.91 | 4.54 | |

| L/h | 21.43 | 18.75 | 16.67 | 15.00 | 13.64 | ||

| Length (m) | Stiffness /Load-Bearing Capacity | Increases of Stiffness and Load-Bearing Capacity (%) | |||||

| 6 | Kincr | 11.72 | 11.19 | 10.59 | 9.99 | 9.41 | 8.86 |

| Pincr | 16.91 | 16.07 | 15.20 | 14.35 | 13.56 | 12.82 | |

| 12 | Kincr | 8.31 | 7.53 | 6.86 | 6.28 | 5.77 | 5.33 |

| Pincr | 11.54 | 10.46 | 9.55 | 8.78 | 8.12 | 7.55 | |

| 18 | Kincr | 6.17 | 5.51 | 4.96 | 4.50 | 4.11 | 3.77 |

| Pincr | 8.44 | 7.55 | 6.83 | 6.23 | 5.73 | 5.30 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawecki, B.; Sumorek, A. Study on Profitability of Combining Wood and CFRP into Composite Based on Mechanical Performance of Bent Beams. Appl. Sci. 2022, 12, 10304. https://doi.org/10.3390/app122010304

Kawecki B, Sumorek A. Study on Profitability of Combining Wood and CFRP into Composite Based on Mechanical Performance of Bent Beams. Applied Sciences. 2022; 12(20):10304. https://doi.org/10.3390/app122010304

Chicago/Turabian StyleKawecki, Bartosz, and Andrzej Sumorek. 2022. "Study on Profitability of Combining Wood and CFRP into Composite Based on Mechanical Performance of Bent Beams" Applied Sciences 12, no. 20: 10304. https://doi.org/10.3390/app122010304

APA StyleKawecki, B., & Sumorek, A. (2022). Study on Profitability of Combining Wood and CFRP into Composite Based on Mechanical Performance of Bent Beams. Applied Sciences, 12(20), 10304. https://doi.org/10.3390/app122010304