Research on Strawberry Cold Chain Transportation Quality Perception Method Based on BP Neural Network

Abstract

:1. Introduction

2. Materials and Methods

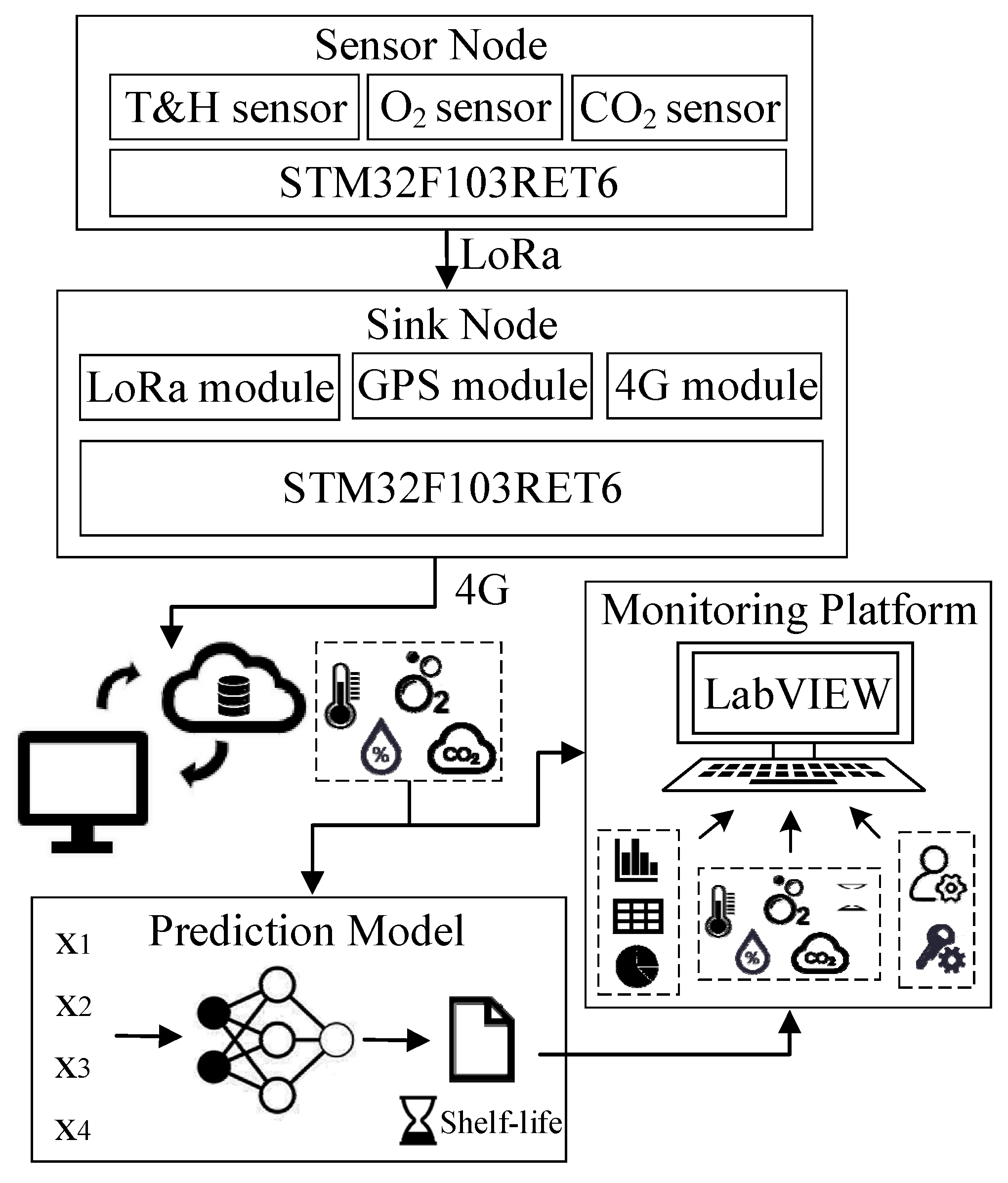

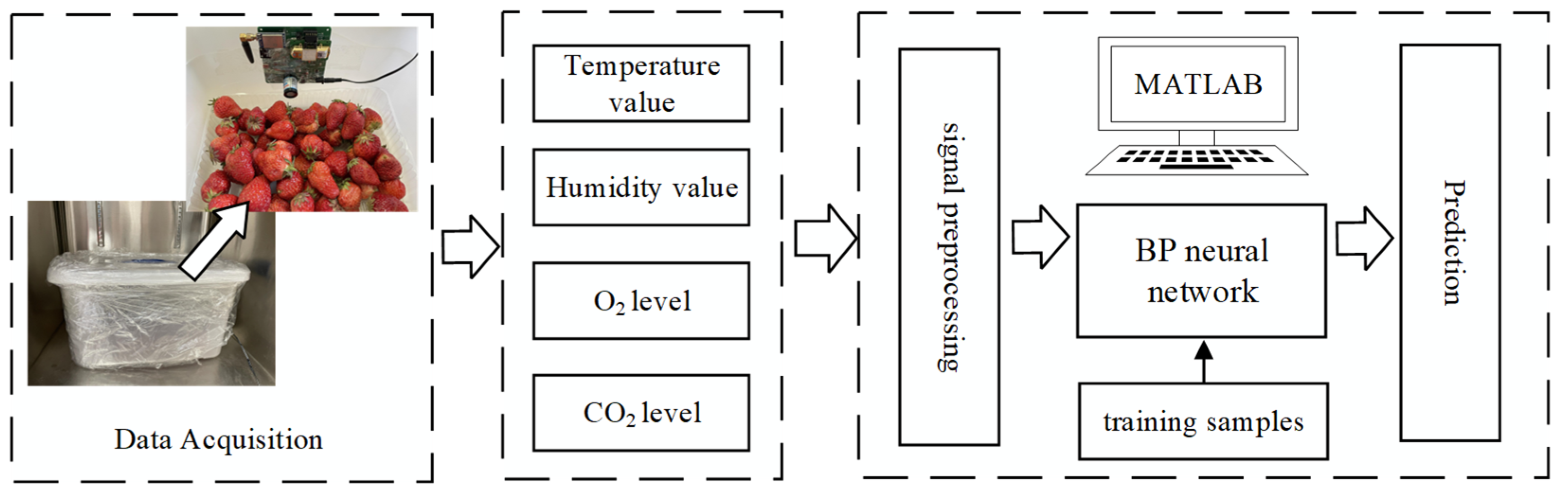

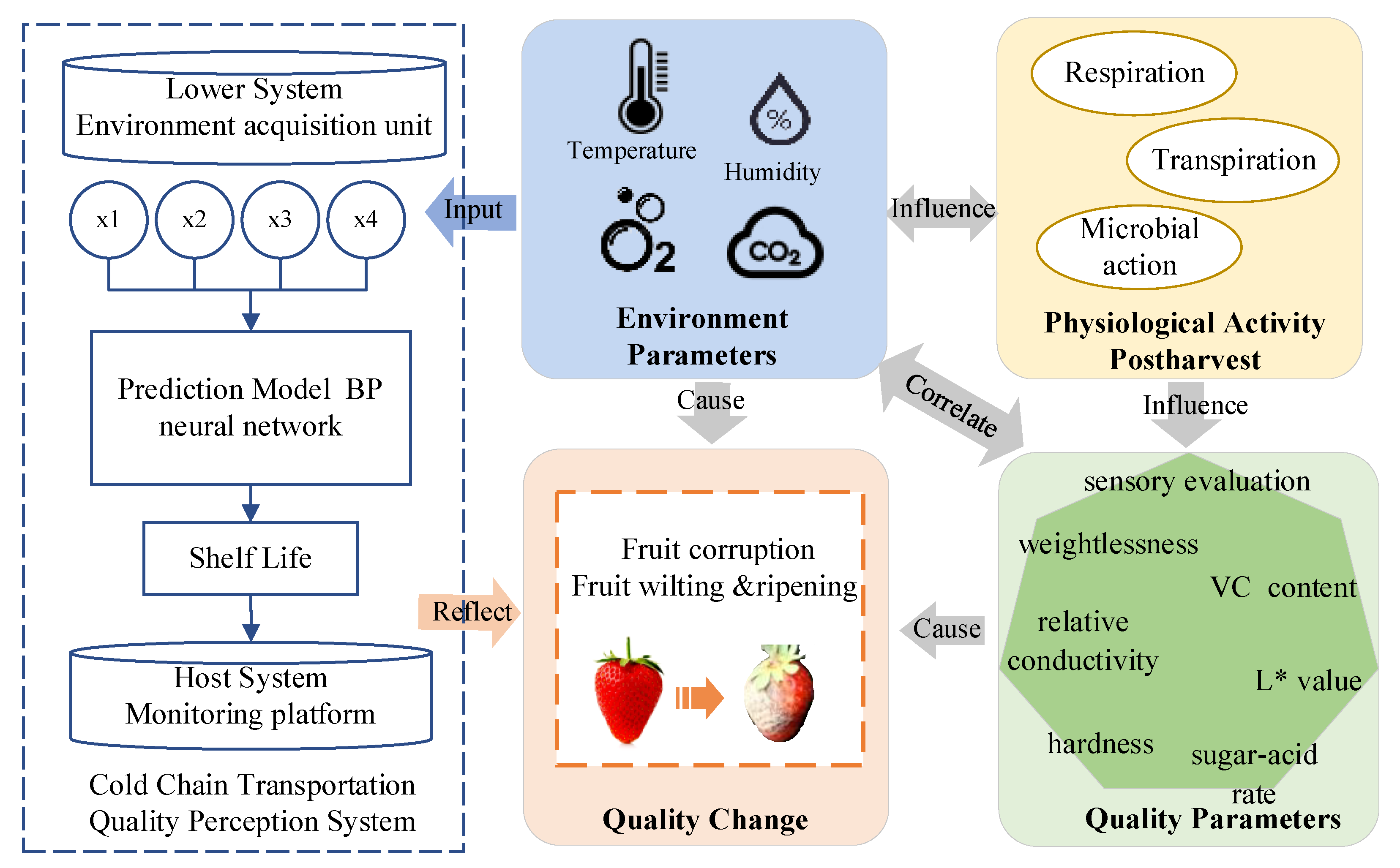

2.1. Architecture Design and Implementation

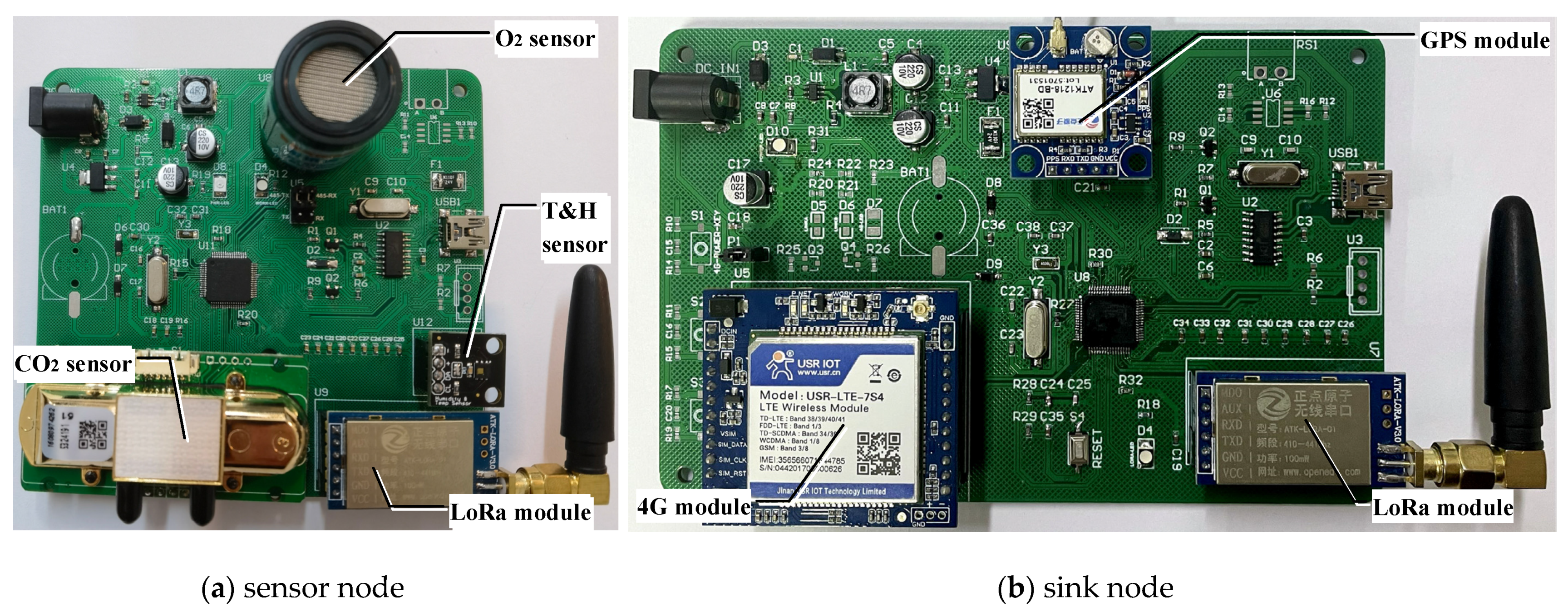

2.1.1. Hardware Design

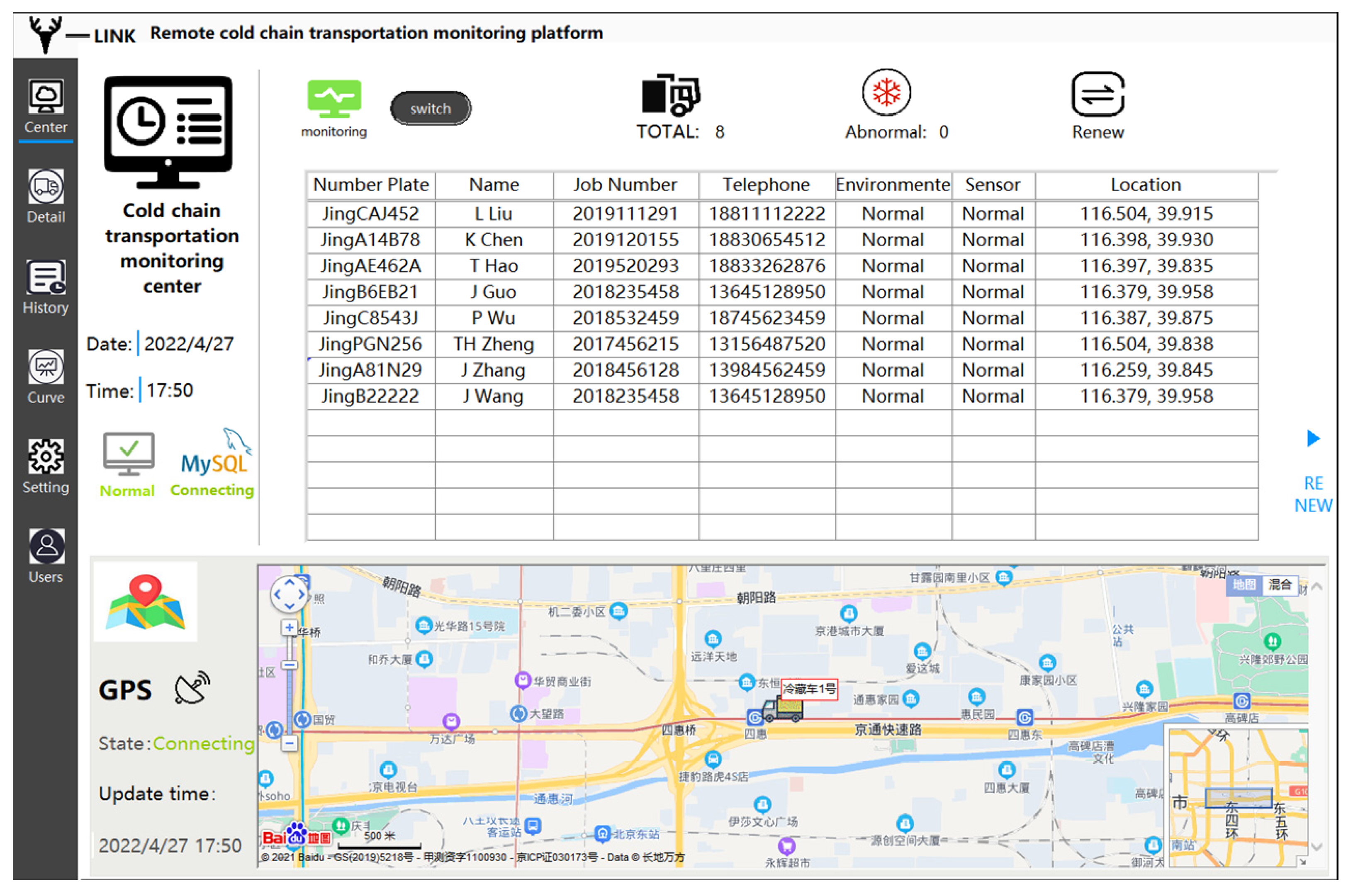

2.1.2. Software Design

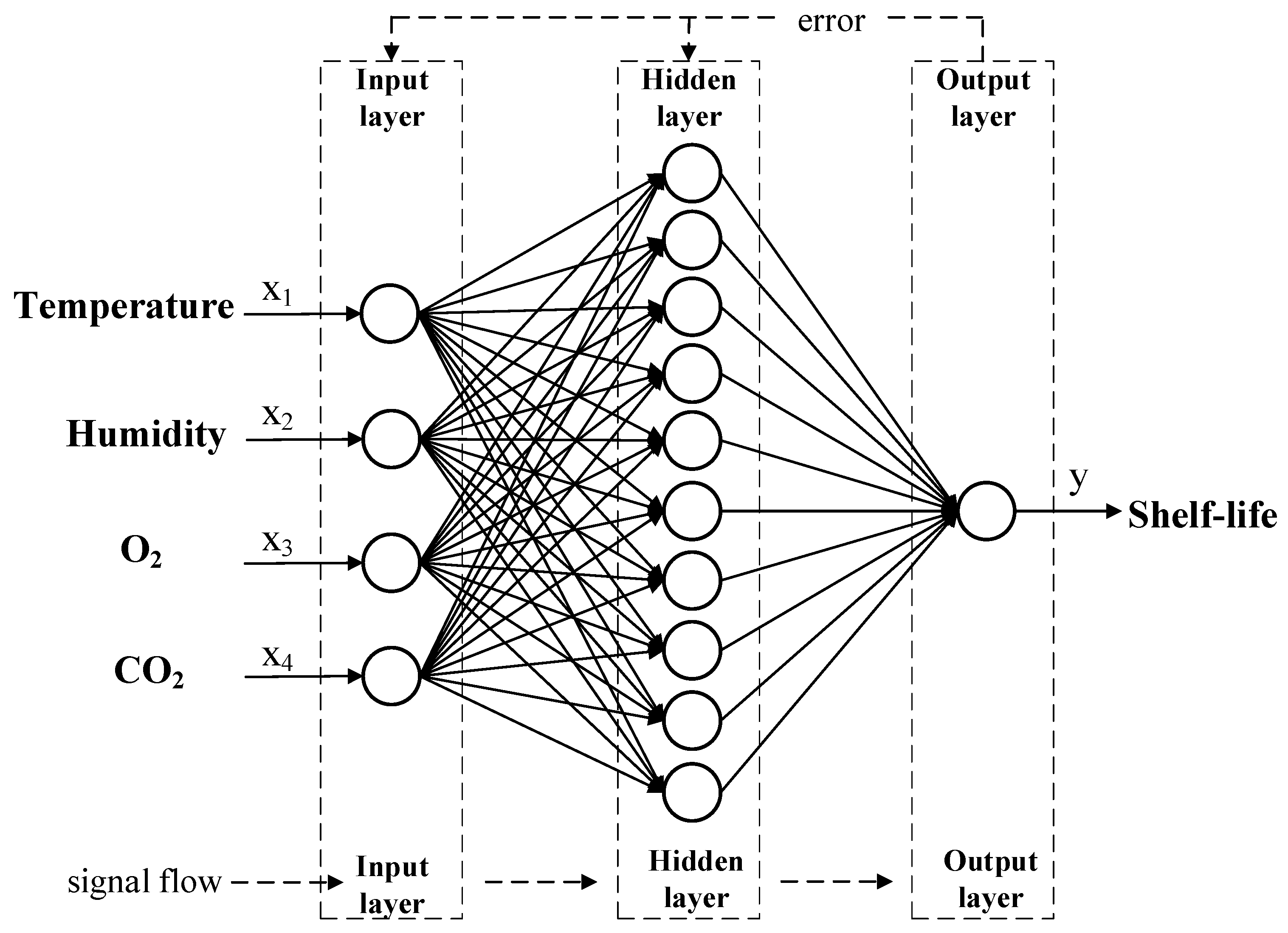

2.1.3. Construction of Shelf-Life Prediction Model

- Flexibility. BP neural network has strong flexibility. It could learn the coupling relationship between different variables by choosing the input and output signals, based on the requirement for different research fields. The BP neural network algorithm has an outstanding advantage in achieving comprehensive analysis with a multi-index. Thus, the algorithm is more applicable in the field of food shelf-life prediction research, compared with the traditional quality modeling methods such as zero-order or first-order reaction kinetic models and the Arrhenius equation.

- Nonlinear mapping capability. BP neural networks can behave similarly to many characteristics of the brain and the information processing of the human nervous system. For this reason, the network can handle huge chunks of data. Moreover, the method’s multi-layer feed-forward network structure can learn complex relationships among variables. Therefore, the BP neural network is suitable for nonlinear problems. In the field of food shelf-life prediction, a BP neural network can explore the full potential relationship between environmental parameters and shelf-life and predict food shelf-life effectively.

- Generalization capability. The BP neural network has a strong self-learning ability to improve the prediction accuracy continuously in the training process. The trained BP neural network can predict non-training samples effectively through learning the non-linear mapping relationship among the limited number of training examples. Moreover, the BP neural network can also improve network performance by changing the type or number of samples, and it is suitable for food shelf-life prediction.

- Construct the neural network structure. The artificial neural network (ANN) is usually made up of an input layer, a hidden layer, and an output layer, and the number of the network layers depends on the number of the hidden layers. When the number of hidden layers is 1, any function that contains the continuous mapping from one finite space to another finite space can be fitted by the network. Theoretically, the more layers, the stronger the fitting ability of the network is. However, with the network being multi-layered, there comes a problem of overfitting [18]. Therefore, this paper constructed a neural network with the structure of one single hidden layer, referring to the models of excellent performance from scholars at home and abroad [19,20].

- Determine the number of nodes in the input, output, and hidden layers. According to the environmental parameters received from the data acquisition unit of CCT-QPS, the number of input layer nodes was four. The number of output layer nodes was one since the output signal was determined to be shelf life. The number of hidden layer nodes was 4–12 according to the empirical Equation (1).where, m—the number of nodes in input layer; n—the number of nodes in output layer; a—a constant between 1–10;

- 3.

2.2. Data Acquisition and Data Fusion

2.2.1. Data Acquisition

2.2.2. Data Fusion

- 1.

- Data Partitioning

- 2.

- Data Preprocessing

- 3.

- Modeling Prediction

2.3. Correlation Analysis Method

3. Results and Discussions

3.1. Influence Mechanism of Environmental Parameters

- 1.

- Temperature

- 2.

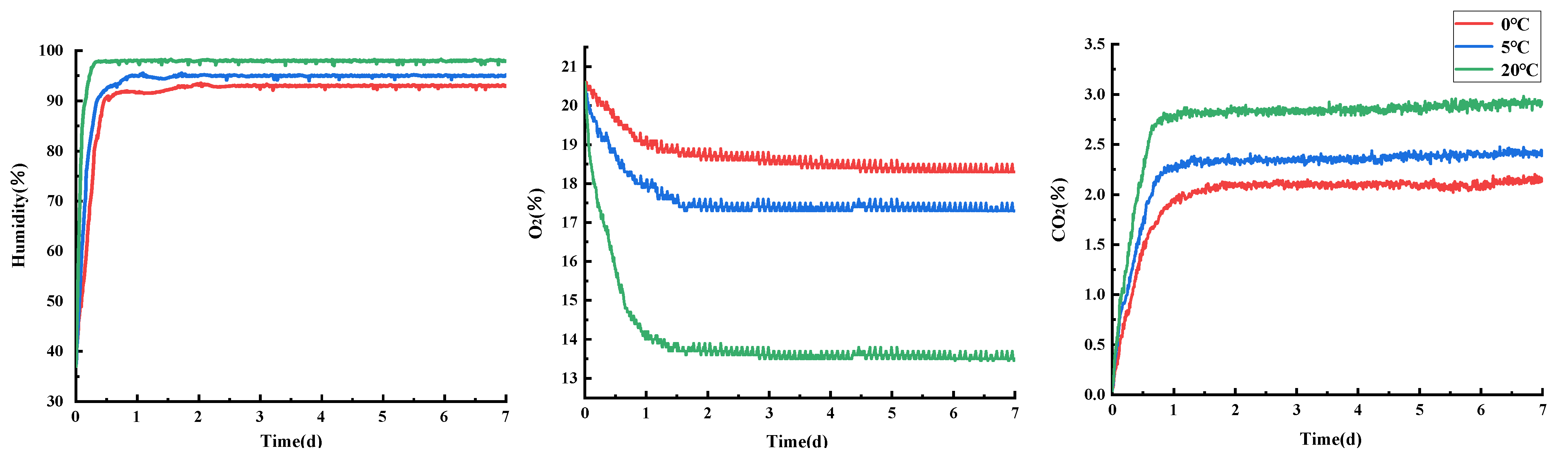

- Relative Humidity

- 3.

- Oxygen level

- 4.

- Carbon dioxide level

3.2. Quality Parameters and Environmental Parameter Analysis

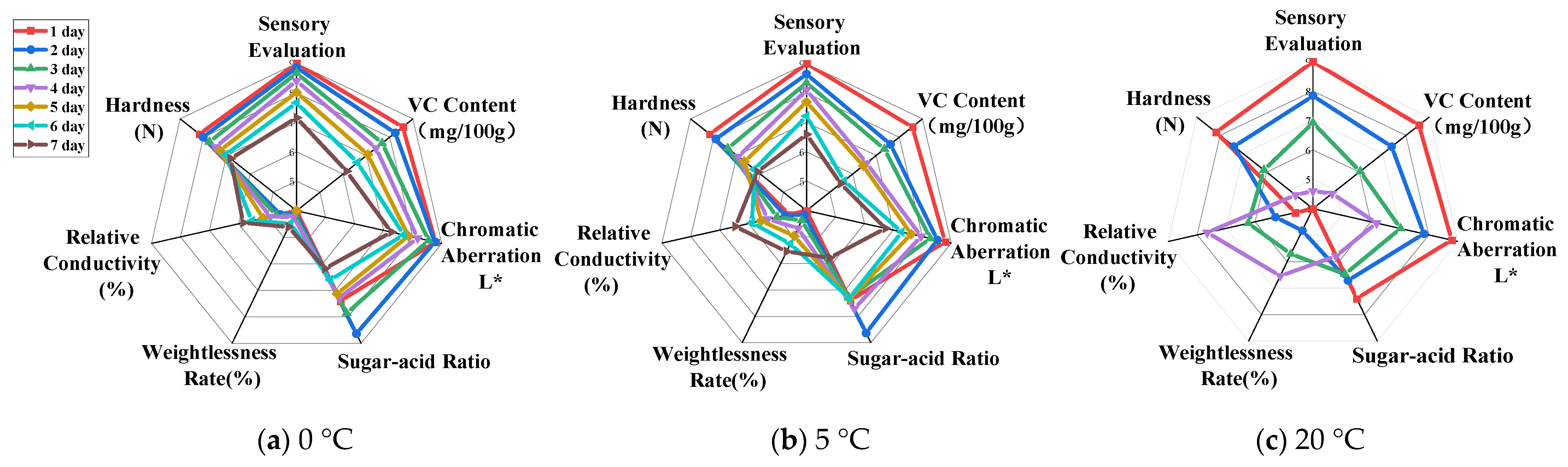

3.2.1. Quality Parameter Results Analysis

3.2.2. Monitoring Data Analysis

3.2.3. Correlation Analysis of Quality Parameters and Environmental Parameters

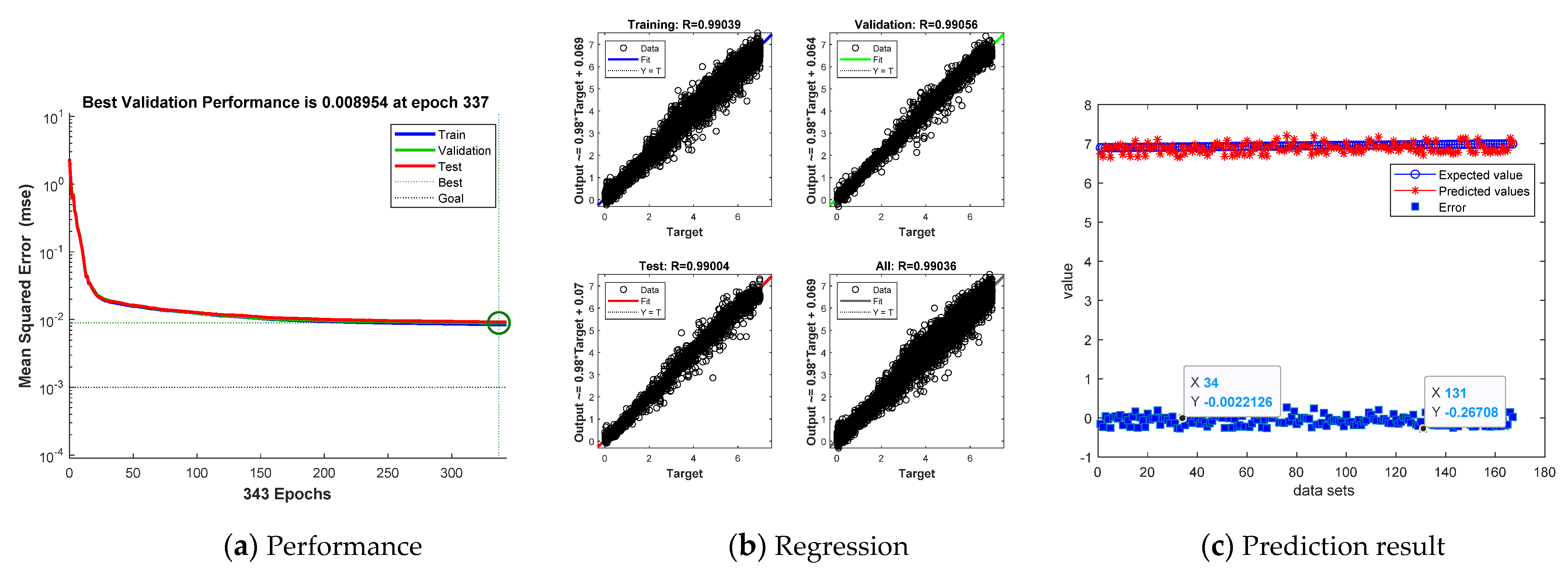

3.3. Evaluation of Shelf-Life Prediction Model

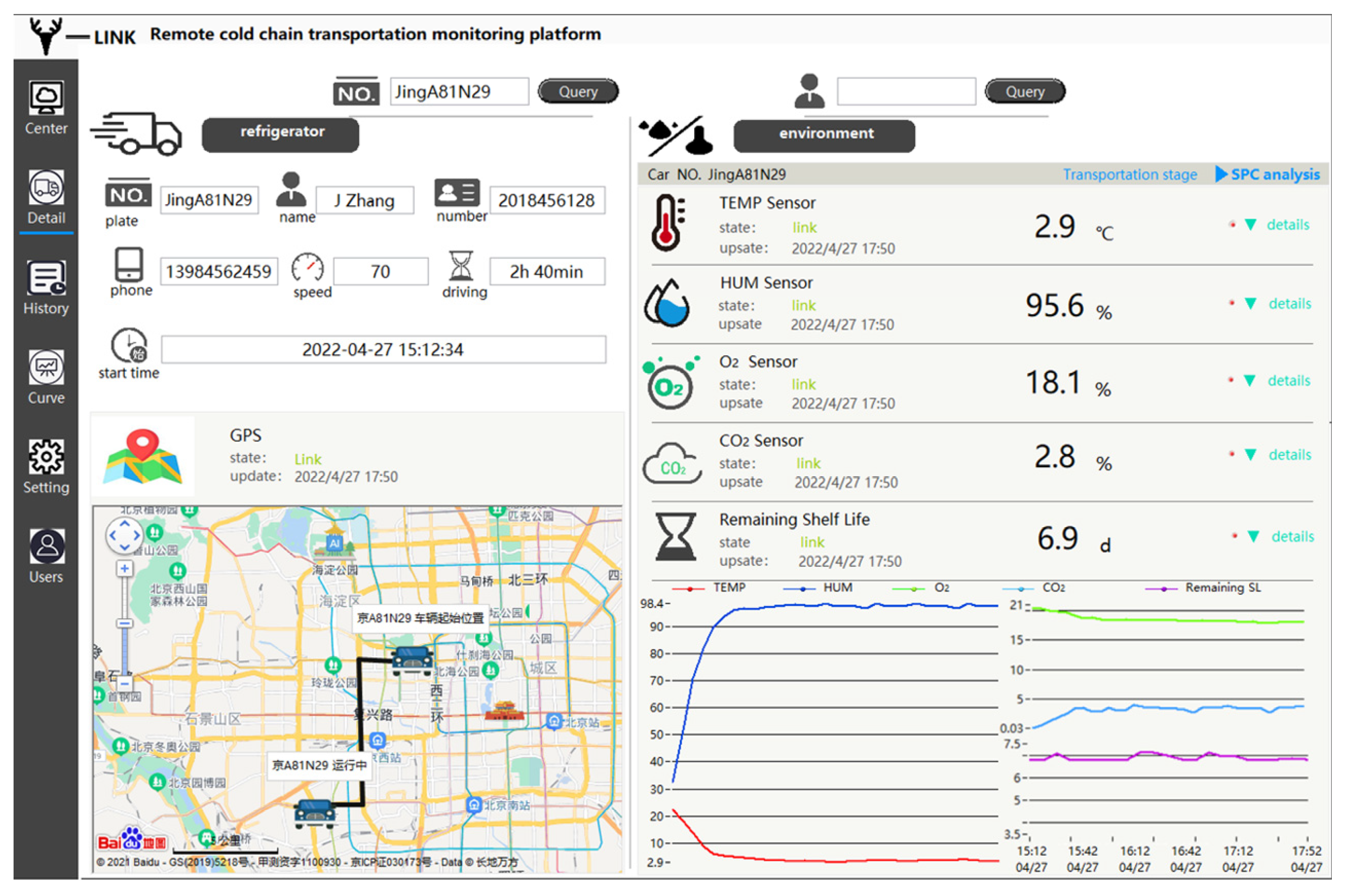

3.4. Evaluation of the System

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tang, T.T.; Xie, X.F.; Ren, X.; Zhang, J.; Wang, Z.D. Research progress of strawberry storage and preservation technology. Food Ind. Sci. Technol. 2020, 41, 332–339. [Google Scholar]

- Katrina, K.; Robert, M.; Jean, P.E.; Maria, C.N.N. A novel approach to determine the impact level of each step along the supply chain on strawberry quality. Postharvest Biol. Technol. 2019, 147, 78–88. [Google Scholar]

- Xiao, X.Q.; He, Q.L.; Li, Z.G.; Arina, O.A.; Zhang, X.S. Improving traceability and transparency of table grapes cold chain logistics by integrating WSN and correlation analysis. Food Control 2017, 73, 1556–1563. [Google Scholar] [CrossRef]

- Dermesonluoglu, E.; Katsaros, G.; Tsevdou, M.; Taoukis, P. Kinetic study of quality indices and shelf life modelling of frozen spinach under dynamic conditions of the cold chain. J. Food Eng. 2015, 148, 13–23. [Google Scholar] [CrossRef]

- Xiao, X.Q. IoT Data Collection and Modeling Method for Cold Chain Logistics Quality Perception. Ph.D. Dissertation, China Agricultural University, Beijing, China, 2017. [Google Scholar]

- Ali, A.; Muhammad, M.T.M.; Sijam, K.; Siddiqui, K. Effect of chitosan coatings on the physicochemical characteristics of Eksotika II papaya (Carica papaya L.) fruit during cold storage. Food Chem. 2011, 124, 620–626. [Google Scholar] [CrossRef]

- Jennifer, R.; DeEll, G.B.; Lum, B.E. Elevated carbon dioxide in storage rooms prior to establishment of controlled atmosphere affects apple fruit quality. Postharvest Biol. Technol. 2016, 118, 11–16. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Ta, B.Q.; Hoivik, N.; Halvorsen, E.; Aasmundtveit, K.E. Carbon Nanotube Based Gas Sensor for Expiration Detection of Perishable Food. In Proceedings of the 13th IEEE Conf. on Nanotechnology (IEEE-NANO), Beijing, China, 5–8 August 2017. [Google Scholar]

- Pratsanee, K.; Danai, B.; Israpong, P.; Pichaya, P. Application of artificial neural networks for predicting parameters of commercial vacuum cooling process of baby cos lettuce. J. Food Process Eng. 2021, 44, e13674. [Google Scholar]

- Cao, M.K.; Wang, D.; Qiu, L.Y.; Ren, X.L.; Ma, H.L. Shelf Life Prediction of ‘Royal Gala’ Apples Based on Quality Attributes and Storage Temperature. Hortic. Sci. Technol. 2021, 39, 343–355. [Google Scholar]

- Pan, Z.L.; Huang, Z.M.; Wang, N.; Zhang, Z.; Xie, X.H.; Suo, B.; Lu, B.G.; Ai, Z.L. BP neural network combined with effective accumulated temperature to predict the shelf life of quick-frozen dumplings in variable temperature refrigeration. Chin. J. Agric. Eng. 2012, 28, 276–281. [Google Scholar]

- Wang, H.B.; Tang, C.D.; Zhang, Y. Indoor environment intelligent monitoring system based on LabVIEW. Internet Things Technol. 2019, 9, 12–15. [Google Scholar]

- Zhang, H.; Zhang, F. A kind of Design of Greenhouse Environment Monitoring System Based on LabVIEW. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 6208–6211. [Google Scholar]

- Li, G.; Yang, L. Neuro-Fuzzy, Predictive Control and MATLAB Implementation; Publishing House of Electronics Industry: Beijing, China, 2013; pp. 17–22. [Google Scholar]

- Afreen, H.; Bajwa, I.S. An IoT-Based Real-Time Intelligent Monitoring and Notification System of Cold Storage. IEEE Access 2021, 9, 38236–38253. [Google Scholar] [CrossRef]

- Yu, F.; Xu, X.Z. A short-term load forecasting model of natural gas based on optimized genetic algorithm and improved BP neural network. Appl. Energy 2014, 134, 102–113. [Google Scholar] [CrossRef]

- Chao, R.; Ning, A.; Jianzhou, W.; Lian, L.; Bin, H.; Duo, S. Optimal parameters selection for BP neural network based on particle swarm optimization: A case study of wind speed forecasting. Knowl.-Based Syst. 2014, 56, 226–239. [Google Scholar]

- LeCun, Y.; Yoshua, B.; Geoffrey, H. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Zhang, X.S.; Wang, W.P.; Xing, S.H.; Ma, Y.F.; Wang, X. Multi-Sensors Enabled Dynamic Monitoring and Quality Assessment System (DMQAS) of Sweet Cherry in Express Logistics. Foods 2020, 9, 602. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.T.; Gao, G.Z.; Li, X.W.; Zhang, X.; Zhang, X.S. Prediction method of blueberry shelf life based on gas sensing information. J. Agric. Mach. 2018, 49, 308–315. [Google Scholar]

- Fu, Z.T.; Zhao, S.; Zhang, X.S.; Martin, P.; Wang, X. Quality Characteristics Analysis and Remaining Shelf Life Prediction of Fresh Tibetan Tricholoma matsutake under Modified Atmosphere Packaging in Cold Chain. Foods 2019, 8, 136. [Google Scholar] [CrossRef] [PubMed]

- Hertog Maarten, L.A.T.M.; Uysal, I.; McCarthy, U.; Verlinden, B.M.; Nicolaï, B.M. Shelf life modelling for first-expired-first-out warehouse management. Philos. Transactions. Ser. A Math. Phys. Eng. Sci. 2014, 372, 20130306. [Google Scholar] [CrossRef]

- Zhang, B.; Xi, W.P.; Wei, W.W.; Shen, J.Y.; Ferguson, I.; Chen, K.S. Changes in aroma-related volatiles and gene expression during low temperature storage and subsequent shelf-life of peach fruit. Postharvest Biol. Technol. 2010, 60, 7–16. [Google Scholar] [CrossRef]

- Wang, J.Y.; Wang, H.; He, J.; Li, L.L.; Shen, M.G.; Tan, X.; Min, H.; Zheng, L.R. Wireless sensor network for real-time perishable food supply chain management. Comput. Electron. Agric. 2015, 110, 196–207. [Google Scholar] [CrossRef]

- Bao, H.Y. Study on the Changes of Active Substances during Storage of Strawberries. Ph.D. Dissertation, Inner Mongolia Agricultural University, Inner Mongolia, China, 2021. [Google Scholar]

- Li, D. Study on the Regulation Mechanism of Anthocyanin Synthesis in Postharvest Strawberry by High Concentration CO2 Treatment. Ph.D. Dissertation, Zhejiang University, Zhejiang, China, 2021. [Google Scholar]

- Adanech, M.T.; Shimeles, T.; Park, D.S.; Seo, M.H.; Cheon, S.J. Effects of Continuous Application of CO2 on Fruit Quality Attributes and Shelf Life during Cold Storage in Cherry Tomato. Korean J. Hortic. Sci. Technol. 2017, 35, 300–313. [Google Scholar]

- Cantwell, M.I.; Thangaiah, A. Acceptable cooling delays for selected warm season vegetables and melons. Acta Hortic. 2012, 934, 77–84. [Google Scholar] [CrossRef]

- Rao, X.J.; Liu, S.; Yan, L.P. Effects of polyethylene bag packaging and 0 °C refrigeration on the quality of head lettuce. Food Mach. 2012, 28, 177–179. [Google Scholar]

- Wei, N. Effects of Pre-Warming Treatment on Postharvest Cell Wall Degradation of Strawberries. Ph.D. Dissertation, Southwest University, Chongqing, China, 2008. [Google Scholar]

- Chen, Y.H.; Lin, H.T.; Shi, J.; Zhang, S.; Lin, Y.F.; Lin, T. Effects of a feasible 1-methylcyclopropene postharvest treatment on senescence and quality maintenance of harvested Huanghua pears during storage at ambient temperature. LWT-Food Sci. Technol. 2015, 64, 6–13. [Google Scholar] [CrossRef]

- Chen, T.; Wang, R.K.; Zhou, L.; Lu, Z.M.; Liu, T. Study on the change law of color difference index during storage of citrus. Agric. Prod. Process. (J.) 2010, 3, 4–7. [Google Scholar]

- Yan, C. Study on Cold Chain Preservation of Postharvest Strawberry. Master’s Dissertation, Shanghai Ocean University, Shanghai, China, 2016. [Google Scholar]

| Hidden Layer Nodes | Epoch | Mean Squared Error (MSE) |

|---|---|---|

| 4 | 164 | 0.0151 |

| 5 | 591 | 0.0129 |

| 6 | 279 | 0.0142 |

| 7 | 237 | 0.0119 |

| 8 | 397 | 0.0112 |

| 9 | 223 | 0.0105 |

| 10 | 343 | 0.00843 |

| 11 | 335 | 0.00933 |

| 12 | 351 | 0.00951 |

| Functions | Results |

|---|---|

| Input and output function | logsig |

| Training function | trainrp |

| Activation function | purelin |

| Parameters | Results |

|---|---|

| Epochs | 1000 |

| lr | 0.01 |

| Goal | 0.001 |

| mc | 0.9 |

| Quality Parameter | Relative Humidity | Oxygen Concentration | Carbon Dioxide Concentration | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 °C | 5 °C | 20 °C | 0 °C | 5 °C | 20 °C | 0 °C | 5 °C | 20 °C | |

| Sensory Evaluation | −0.82 | −0.80 | −0.48 | 0.92 | 0.83 | 0.86 | −0.85 | −0.86 | −0.82 |

| Hardness | −0.91 | −0.84 | −0.39 | 0.99 | 0.87 | 0.86 | −0.80 | 0.85 | −0.83 |

| Weightlessness | 0.85 | 0.80 | 0.46 | −0.95 | −0.82 | −0.84 | 0.80 | −0.90 | 0.90 |

| Relative Conductivity | 0.62 | 0.65 | 0.42 | −0.73 | −0.80 | 0.75 | 0.55 | 0.72 | 0.70 |

| Sugar-acid Ratio | −0.48 | −0.28 | −0.61 | 0.61 | 0.30 | 0.84 | −0.23 | −0.33 | −0.81 |

| VC Content | −0.98 | −0.90 | −0.45 | 0.99 | 0.93 | 0.93 | −0.80 | −0.96 | −0.89 |

| L* Value | −0.71 | −0.78 | −0.51 | 0.82 | 0.82 | 0.86 | −0.74 | −0.85 | −0.83 |

| Shelf-Life Actual Value (d) | BP | SVR | RNN | |||

|---|---|---|---|---|---|---|

| Predictive Value (d) | Error (d) | Predictive Value (d) | Error (d) | Predictive Value (d) | Error (d) | |

| 6.909 | 6.664 | 0.245 | 6.518 | 0.391 | 6.341 | 0.568 |

| 6.919 | 6.661 | 0.258 | 6.453 | 0.466 | 6.467 | 0.452 |

| 6.928 | 7.032 | 0.104 | 6.308 | 0.620 | 7.045 | 0.117 |

| 6.938 | 6.895 | 0.043 | 6.427 | 0.511 | 6.375 | 0.563 |

| 6.947 | 6.794 | 0.153 | 7.338 | 0.391 | 7.171 | 0.224 |

| 6.957 | 6.905 | 0.052 | 6.524 | 0.433 | 6.528 | 0.429 |

| 6.967 | 6.901 | 0.066 | 7.176 | 0.209 | 7.224 | 0.257 |

| 6.976 | 6.709 | 0.267 | 6.544 | 0.432 | 6.260 | 0.716 |

| 6.986 | 6.791 | 0.195 | 6.401 | 0.585 | 6.415 | 0.571 |

| 6.996 | 6.795 | 0.201 | 6.745 | 0.251 | 6.667 | 0.319 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, J.; Guo, M.; Wu, Y.; Gao, J.; Yue, Z. Research on Strawberry Cold Chain Transportation Quality Perception Method Based on BP Neural Network. Appl. Sci. 2022, 12, 8872. https://doi.org/10.3390/app12178872

Qiao J, Guo M, Wu Y, Gao J, Yue Z. Research on Strawberry Cold Chain Transportation Quality Perception Method Based on BP Neural Network. Applied Sciences. 2022; 12(17):8872. https://doi.org/10.3390/app12178872

Chicago/Turabian StyleQiao, Jiping, Meicen Guo, Yuan Wu, Jin Gao, and Zichen Yue. 2022. "Research on Strawberry Cold Chain Transportation Quality Perception Method Based on BP Neural Network" Applied Sciences 12, no. 17: 8872. https://doi.org/10.3390/app12178872

APA StyleQiao, J., Guo, M., Wu, Y., Gao, J., & Yue, Z. (2022). Research on Strawberry Cold Chain Transportation Quality Perception Method Based on BP Neural Network. Applied Sciences, 12(17), 8872. https://doi.org/10.3390/app12178872