Mechanistic Study on the Influence of Stratigraphy on the Initiation and Expansion Pattern of Hydraulic Fractures in Shale Reservoirs

Abstract

:1. Introduction

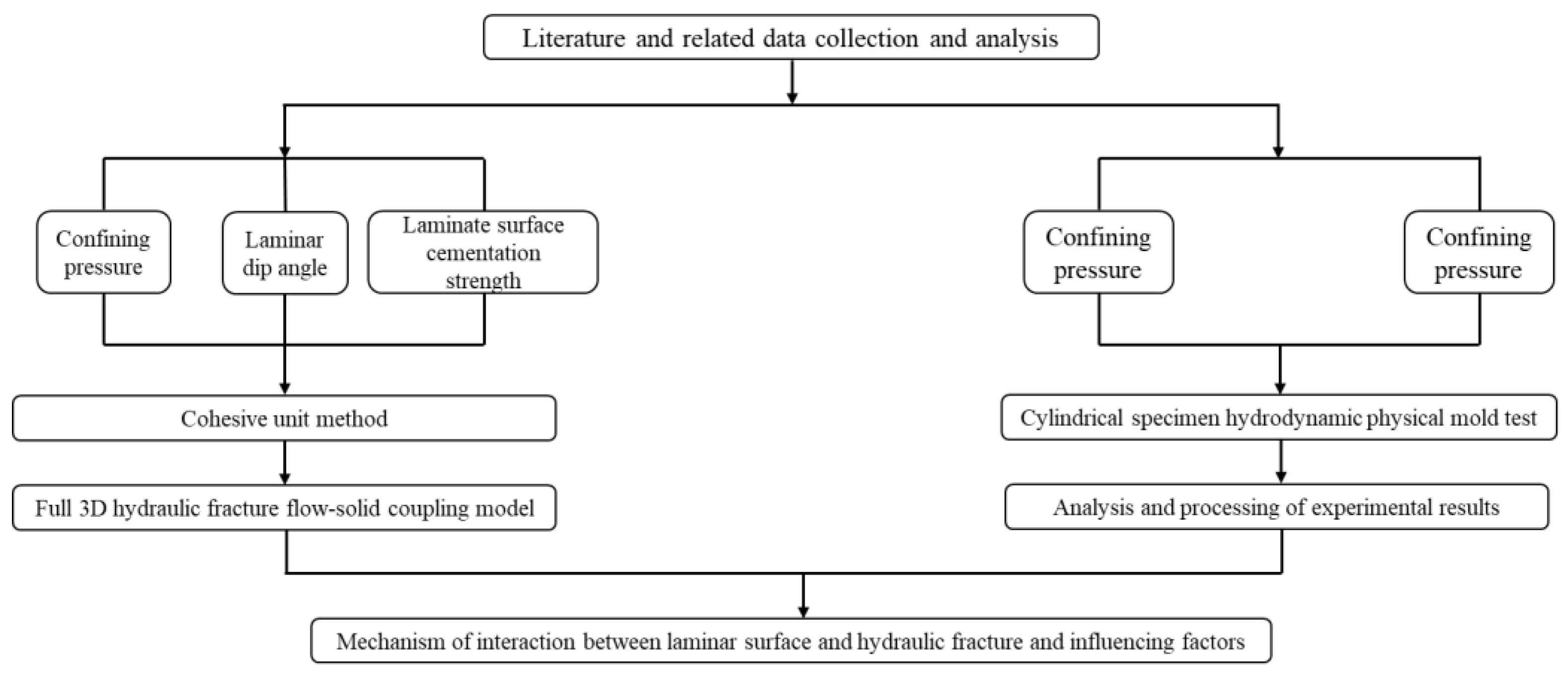

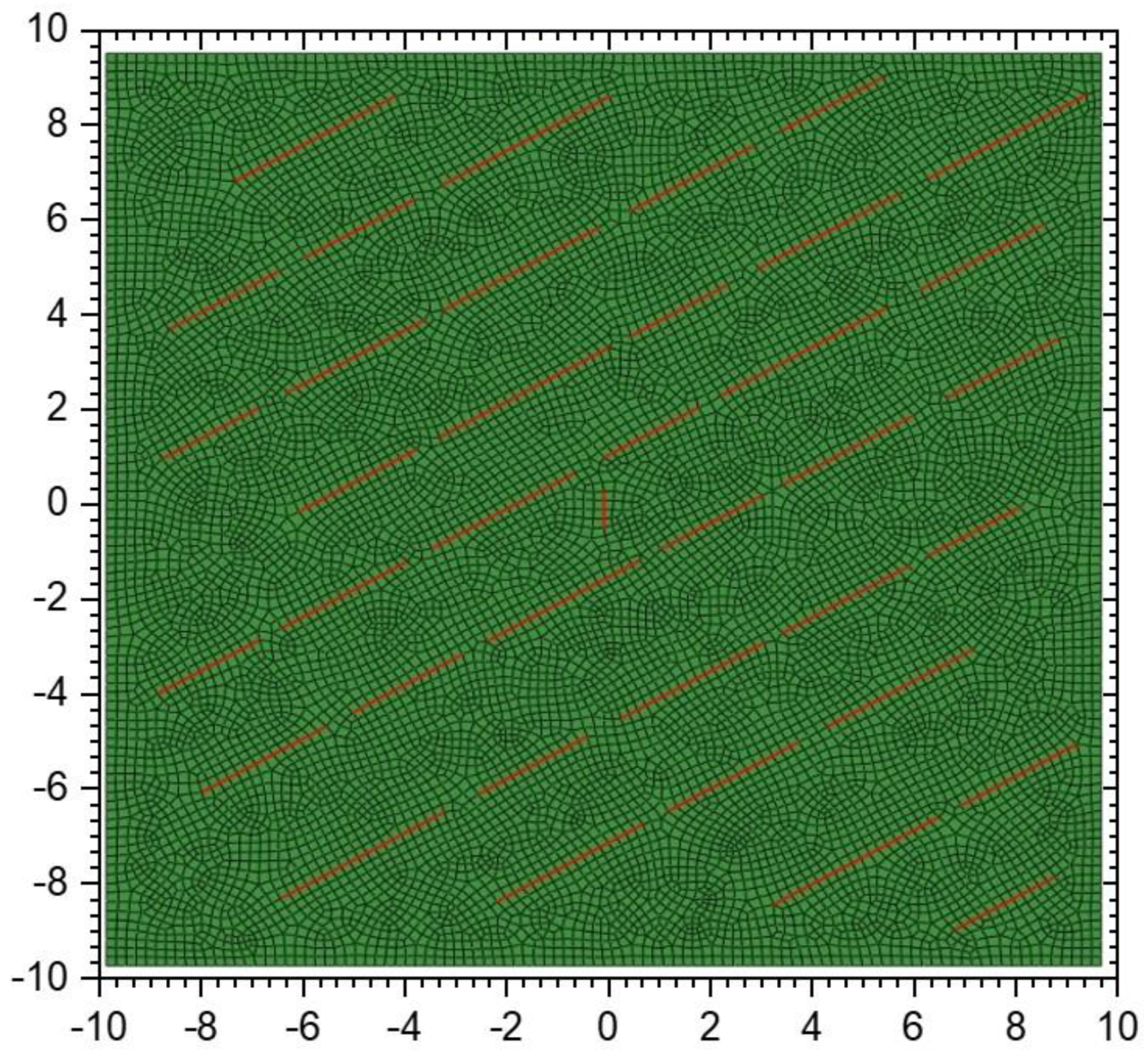

2. Numerical Simulation Calculation Model

2.1. Model Control Equations

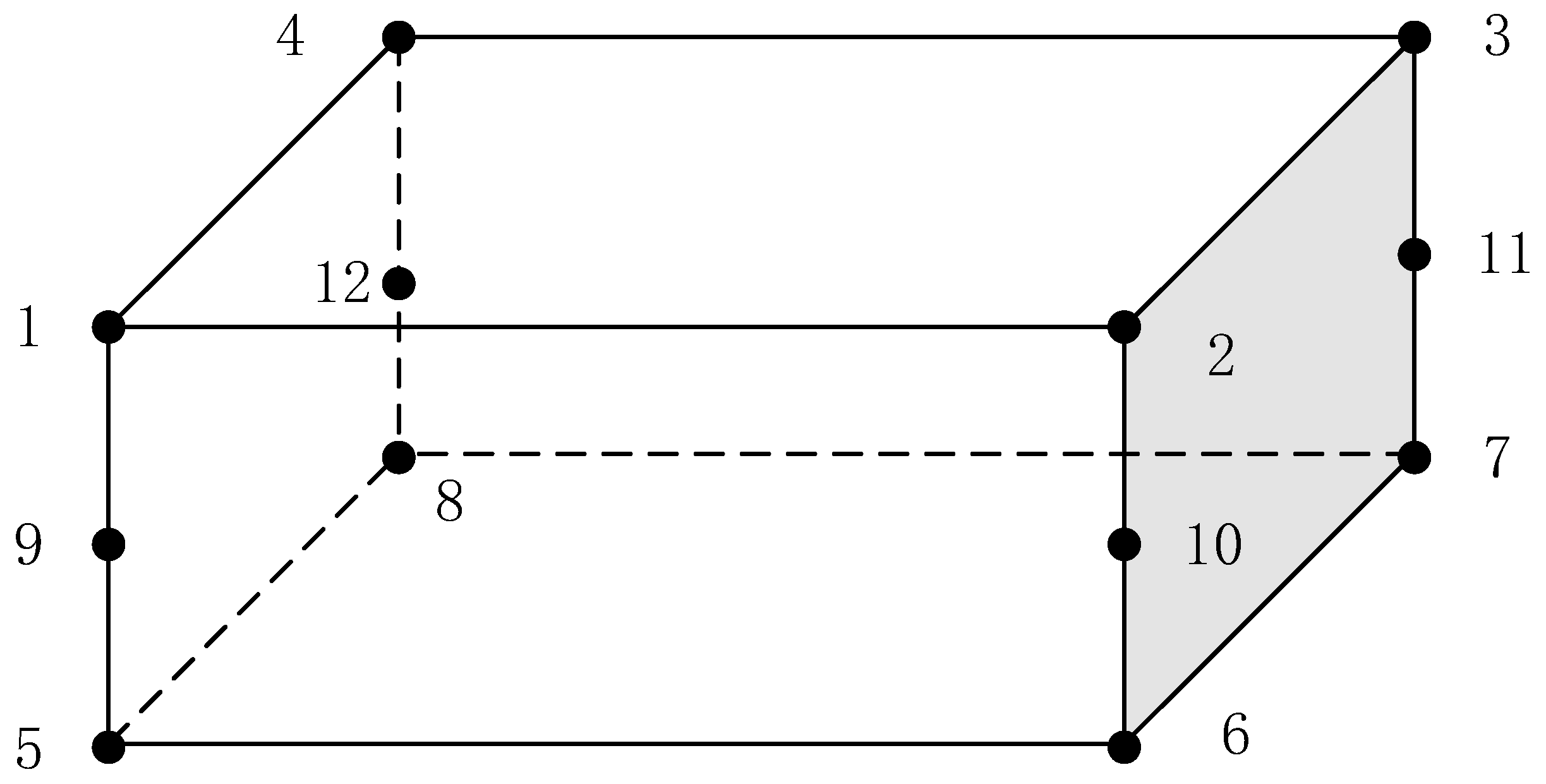

2.1.1. Cohesive Pore Pressure Unit

- (1)

- Cohesive pore pressure unit introduction

- ①

- To simulate hydraulic fracture initiation and extension based on the traction–separation criterion;

- ②

- To describe the tangential flow of the fluid within the fracture and the normal flow perpendicular to the wall.

- (2)

- Unit damage model

- (3)

- Initial cracking guidelines of the unit

- ①

- Maximum stress criterion

- ②

- Secondary stress criterion

- ③

- Maximum stress criterion

- ④

- Secondary strain guidelines

- ⑤

- Hybrid mode based on the stress mode ratio

- ⑥

- Hybrid mode based on energy mode

- (4)

- Cohesive cell expansion guidelines

- (5)

- Fluid flow equation in the unitary damage zone

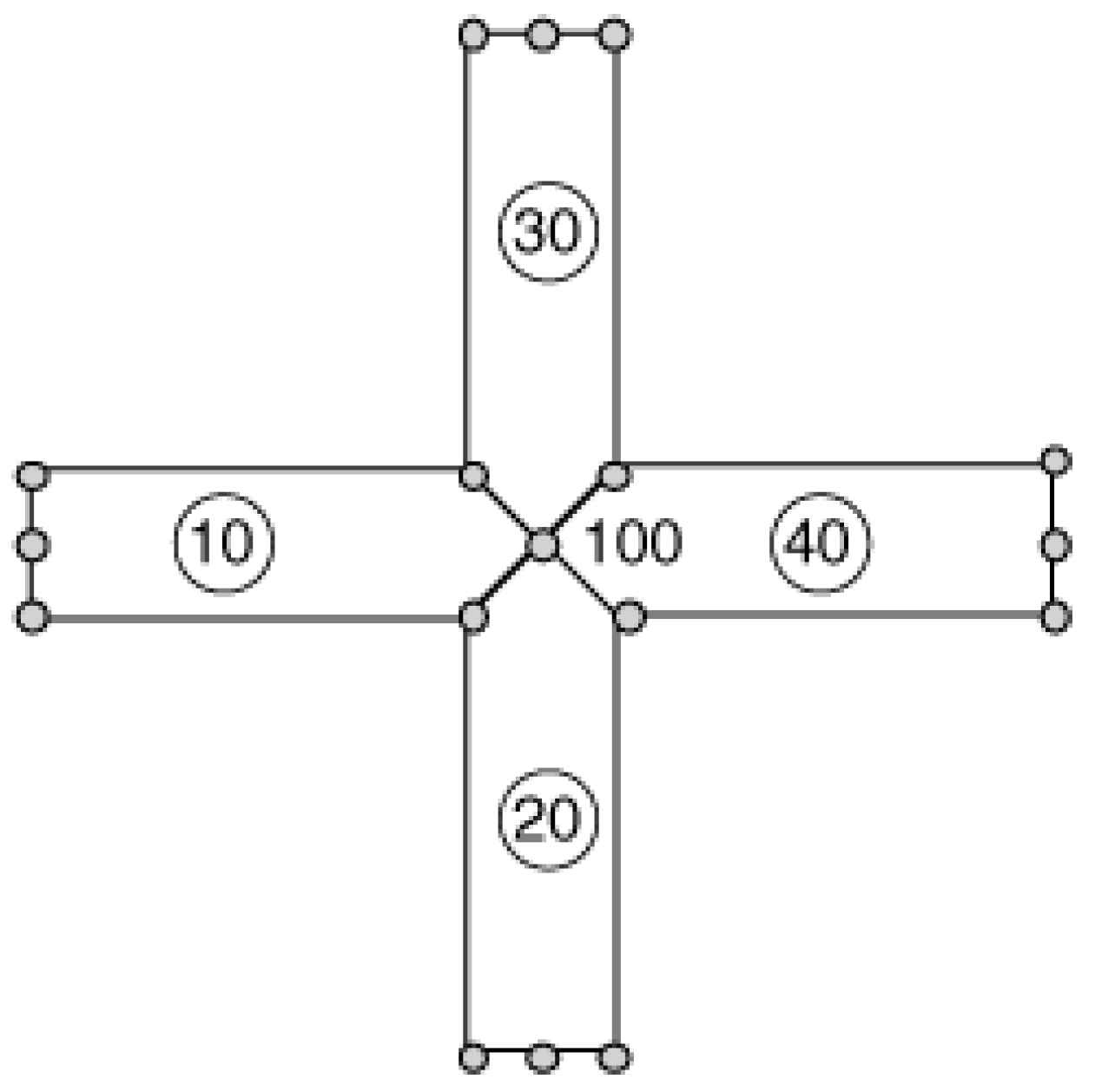

2.1.2. Hole Pressure Unit Embedding Method

2.2. Benchmarking Example

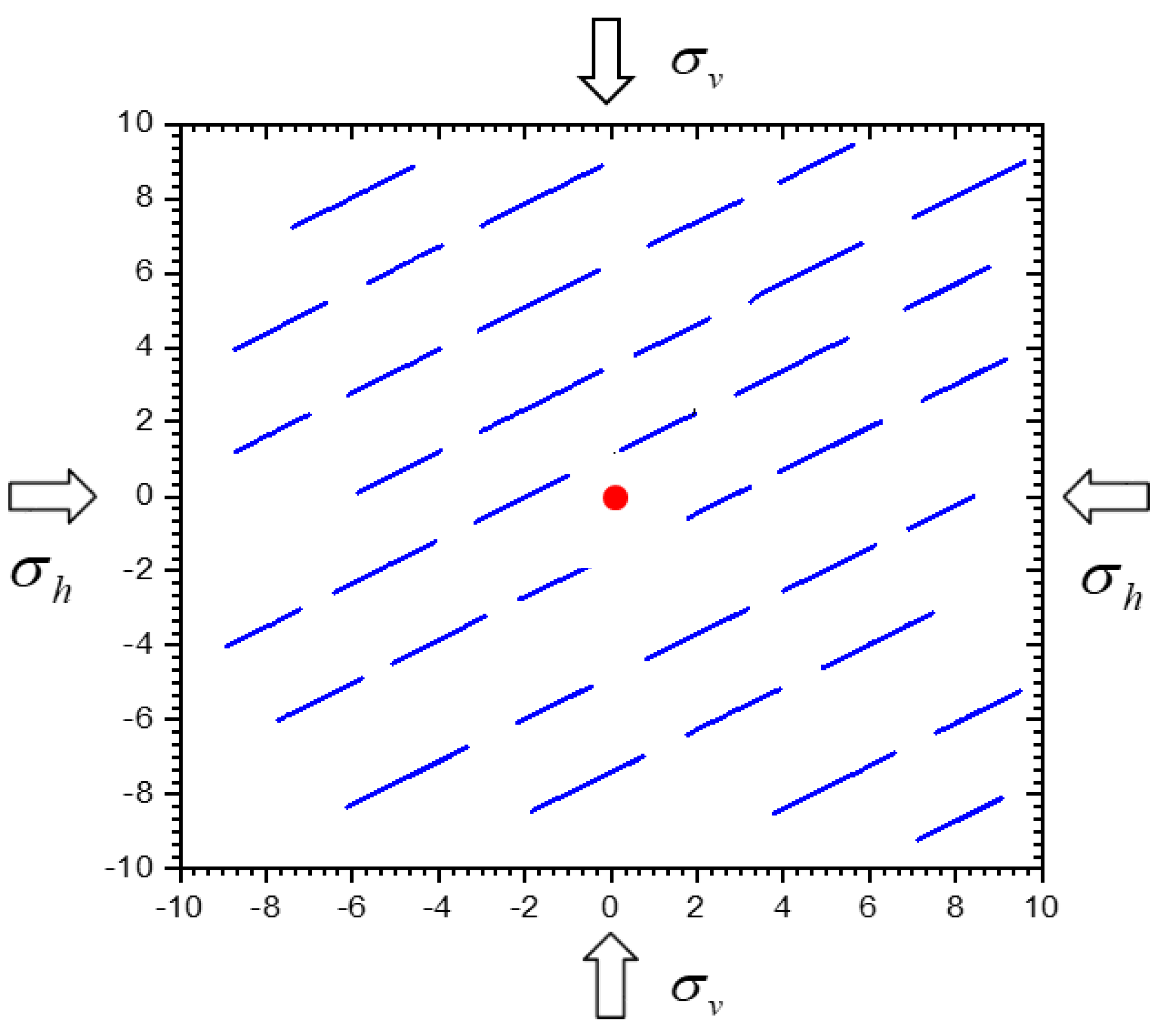

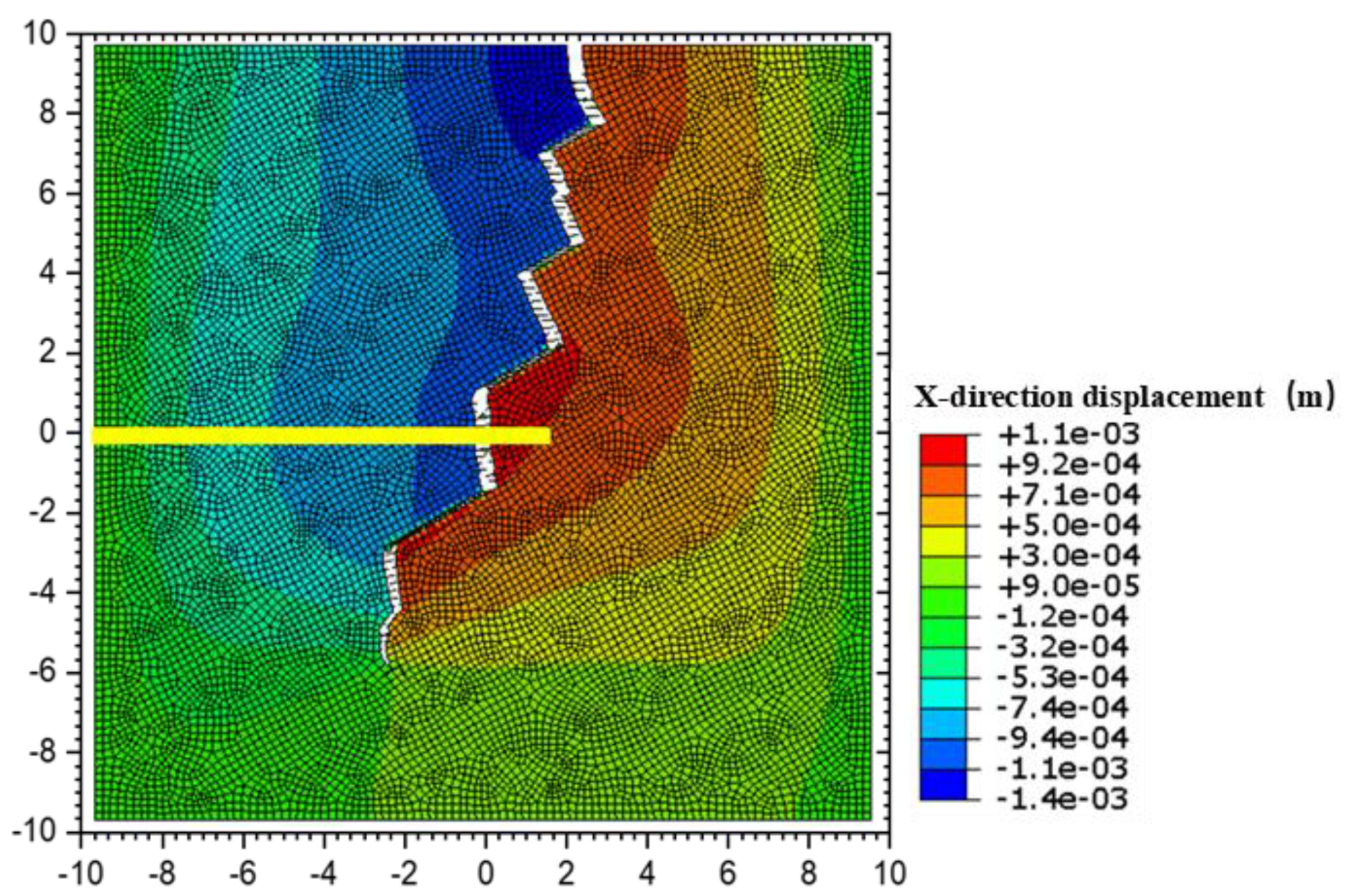

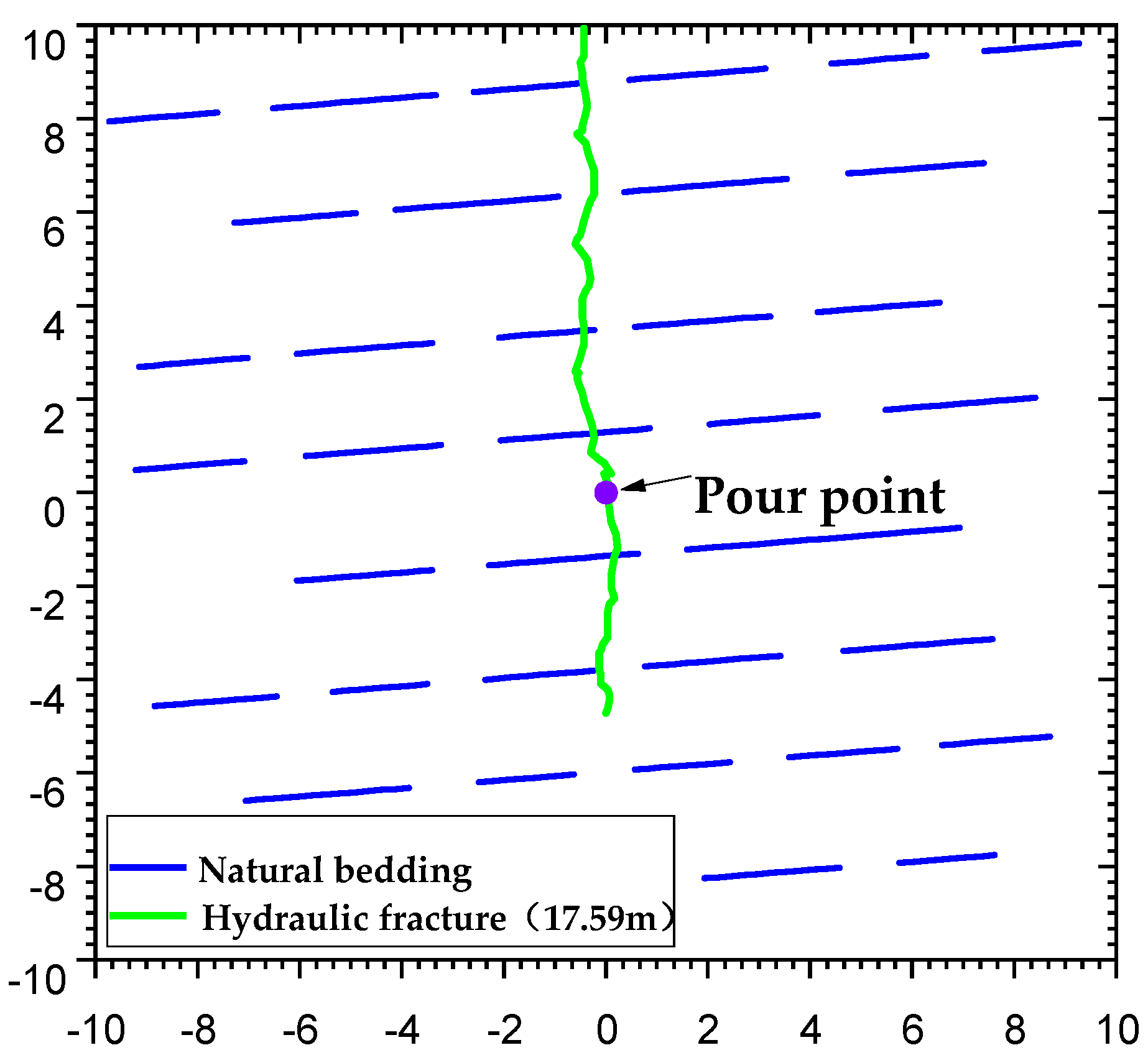

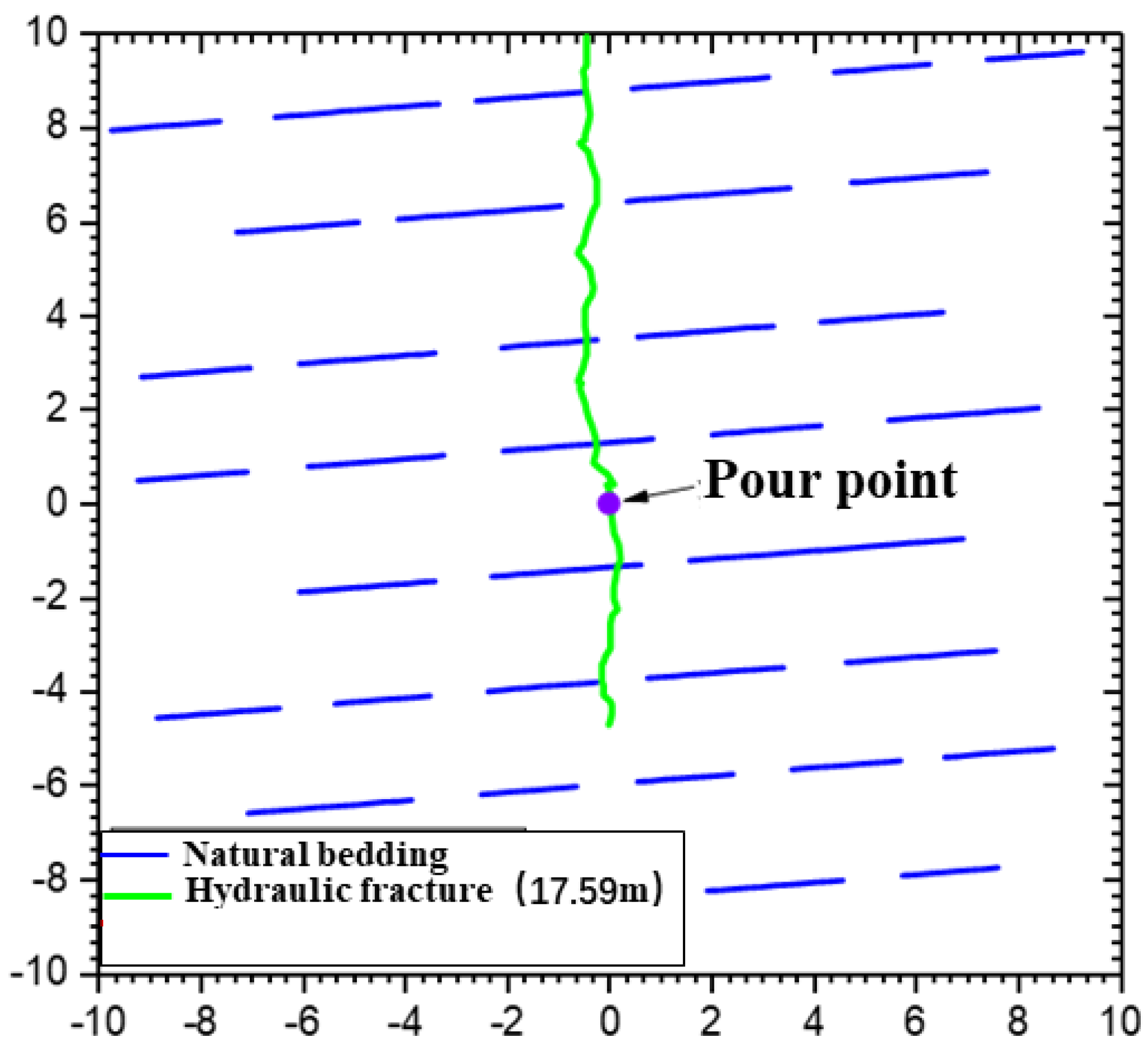

2.3. The Effect of Differential Ground Stress

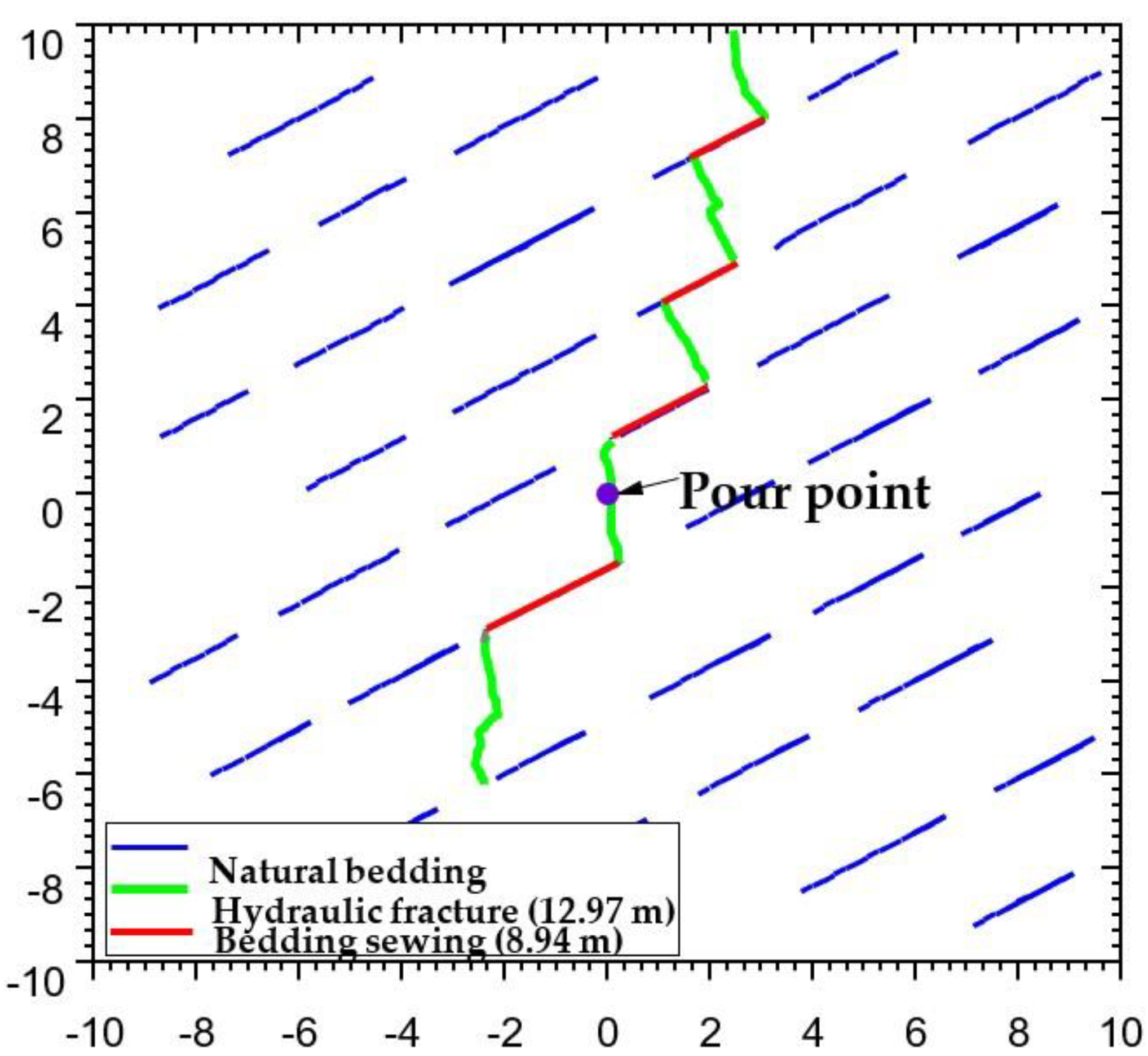

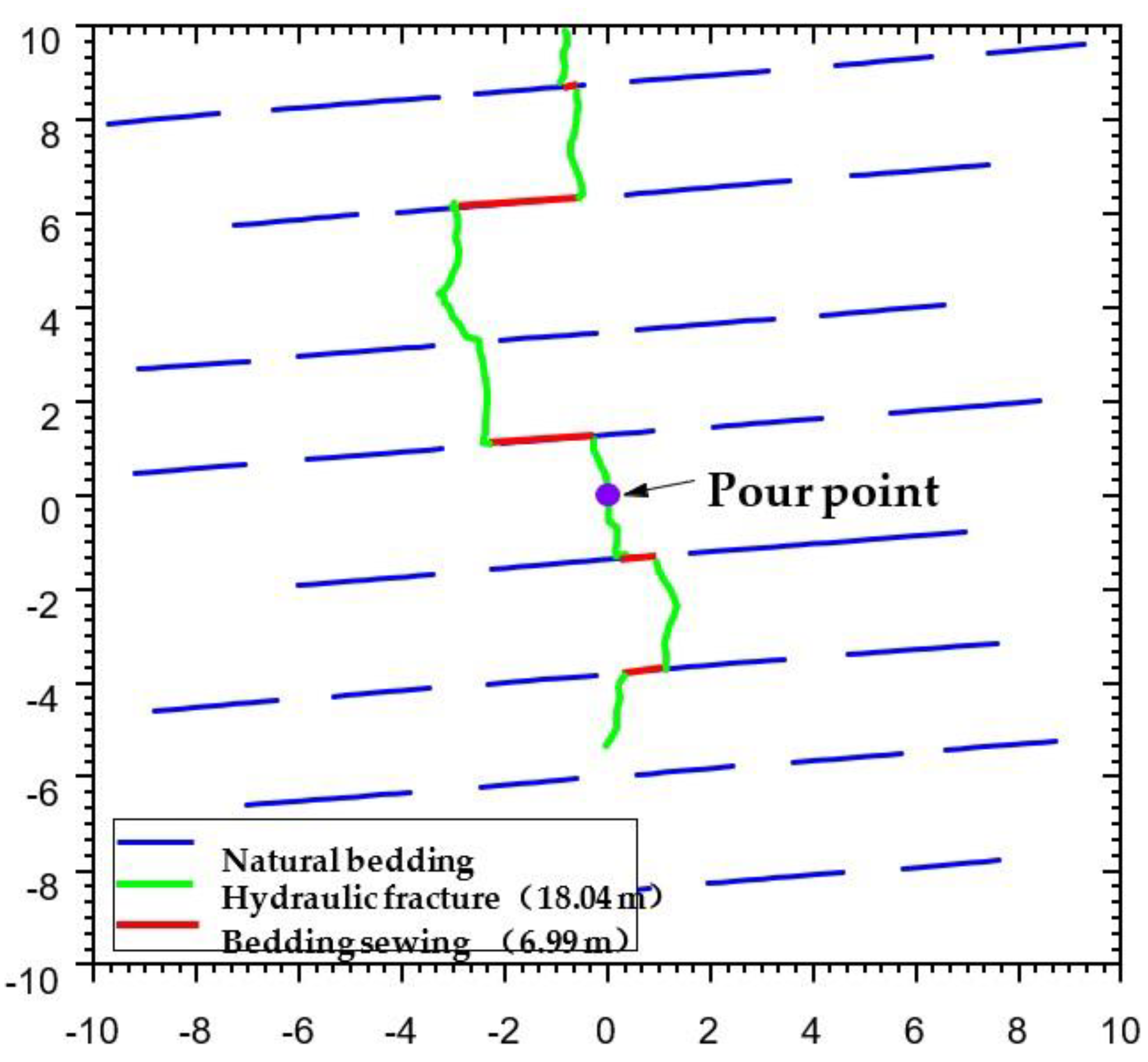

2.4. Effect of Laminar Dip Angle

2.5. Effect of Laminar Cementation Strength

3. Hydraulic Fracturing Experiment

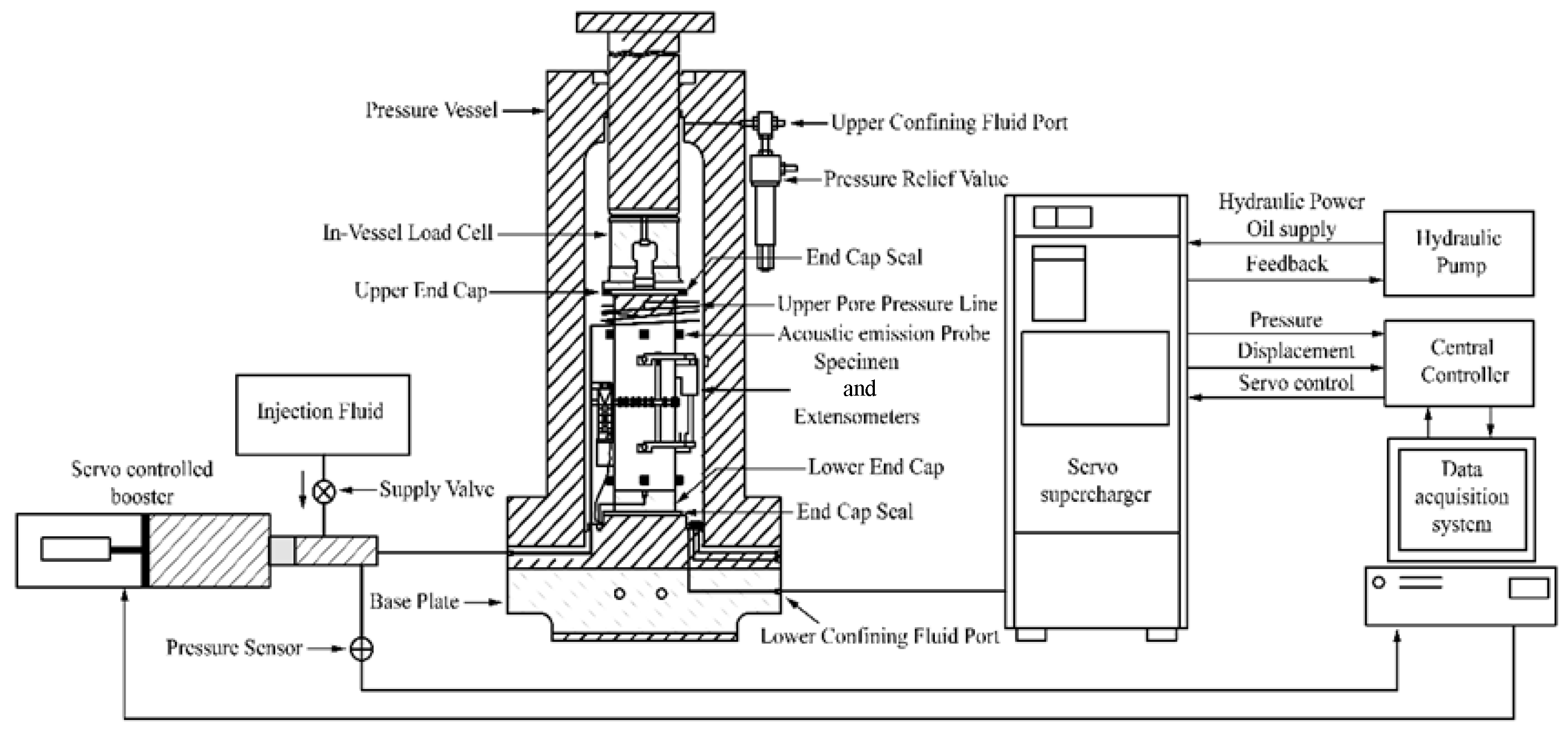

3.1. Experimental Setup

- (1)

- Rock stress servo loading system

- (2)

- Fracturing fluid pumping system

- (3)

- Acoustic emission detection system

- (4)

- Industrial CT scanning system

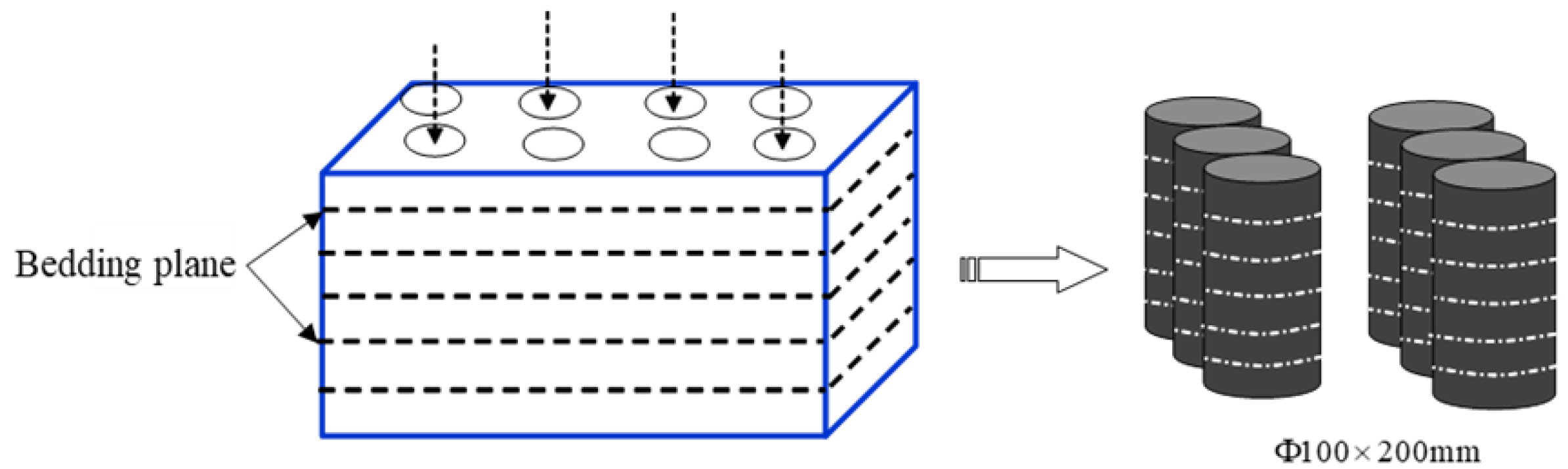

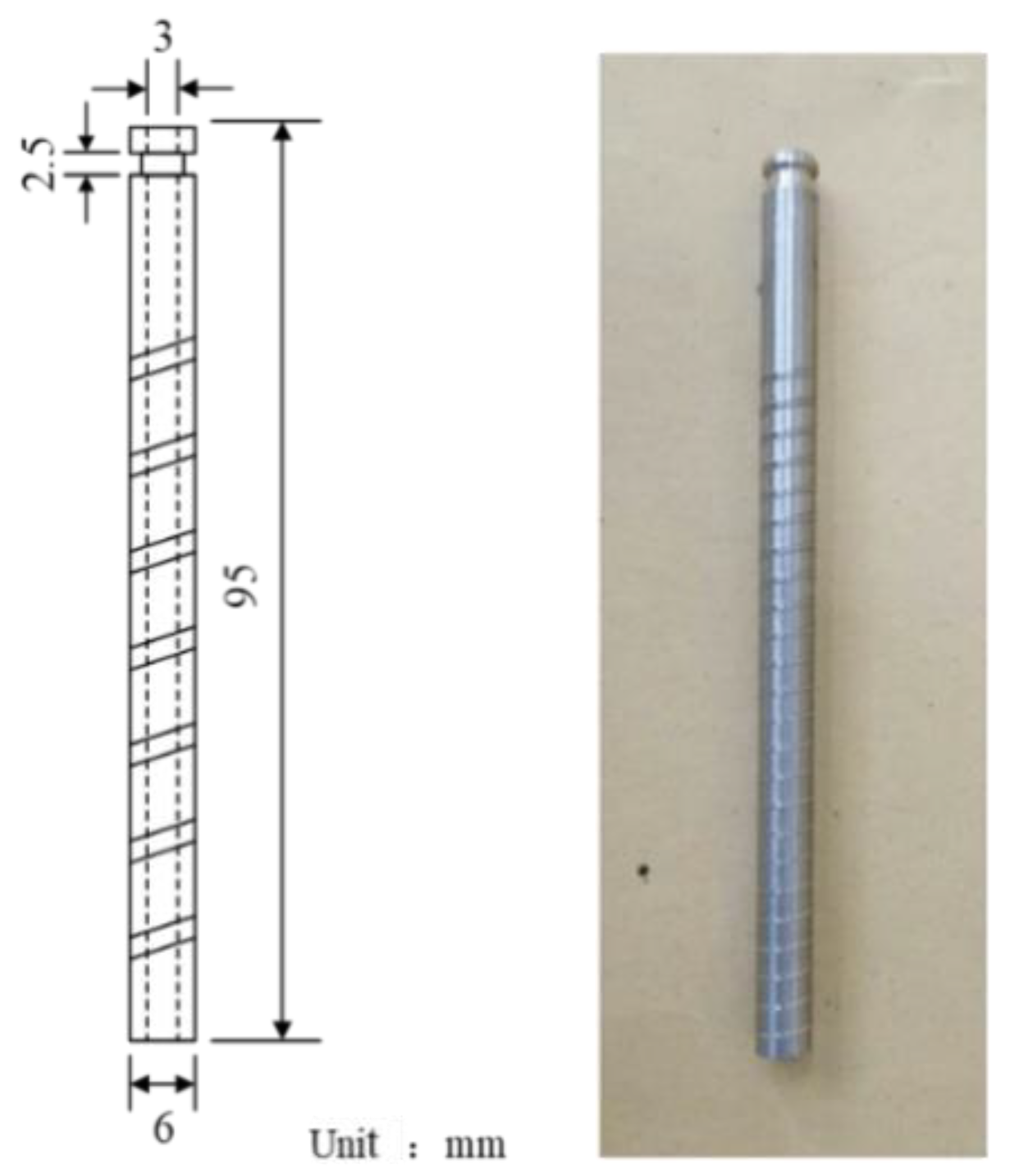

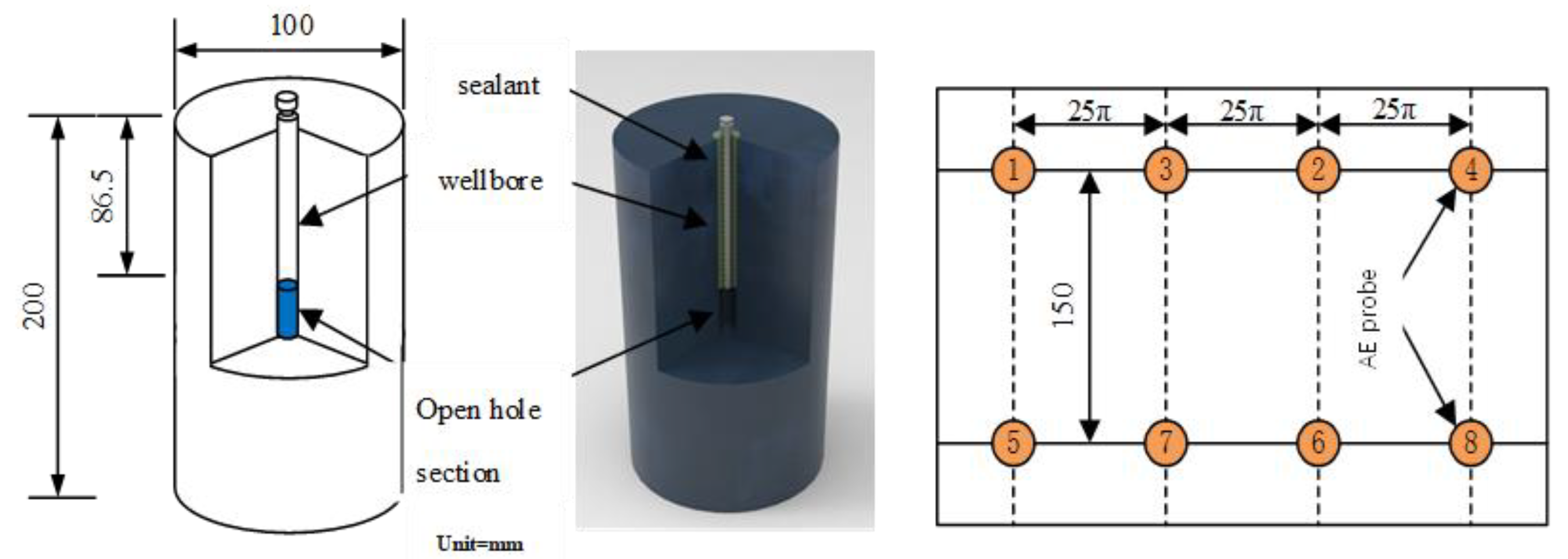

3.2. Specimen Preparation

3.3. Experimental Parameter Design

3.4. Experimental Procedure

- Prepressure description: The specimen laminae and natural fracture development are observed by the naked eye, and the location of the distribution of the weak surface of the primary structure is marked with a chalk or a marker.

- Gas tightness check: Since the shale laminae are more developed, shear misalignment is very likely to occur during specimen preparation, causing damage to the wellbore seal. Therefore, a certain amount of fluid is first pumped into the wellbore before the experiment, the pressure is maintained at approximately 0.5 MPa for 3–5 min, and the outer surface of the specimen is observed for the fracturing fluid oozing out.

- Acoustic emission probe installation: Eight acoustic emission probes are installed on the surface of the specimen, and a coupling agent is used to adhere the probes closely to the specimen while gently tapping each probe to ensure that each probe is working properly.

- Stress loading: The specimen is placed in the triaxial high-pressure chamber. The circumferential and axial pressures are loaded to the specified values in turn, and they are maintained for 10–20 min to ensure uniform stresses inside the specimen.

- Fracturing fluid injection: The Isco plunger pump is started, fracturing fluid is injected into the specimen according to the set displacement, acoustic emission detection is carried out simultaneously, the plunger pump and acoustic emission detection system are turned off when there is a significant drop in the pump pressure, and the axial pressure and circumferential pressure are unloaded in turn.

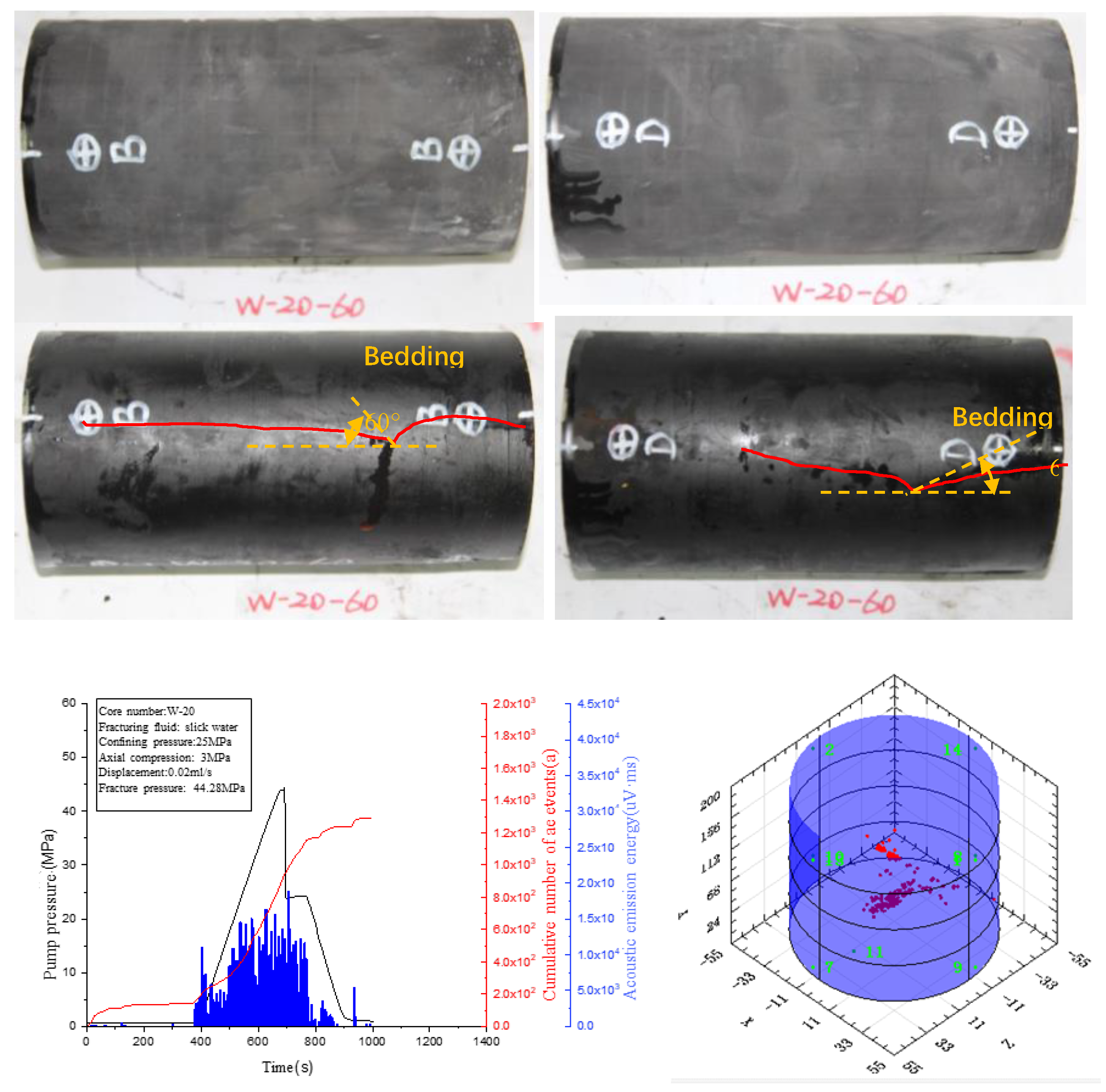

- Postpressure description: After the test, the surface of the specimen is first photographed by a digital camera to record the cracks on the surface of the specimen. Then, some specimens are selected to carry out a postpressure CT sweep to quantitatively characterize the spatial distribution of the hydraulic cracks. Finally, the post-test sample is cut to trace the hydraulic crack direction by a tracer display to summarize the hydraulic crack expansion law.

3.5. Experimental Results

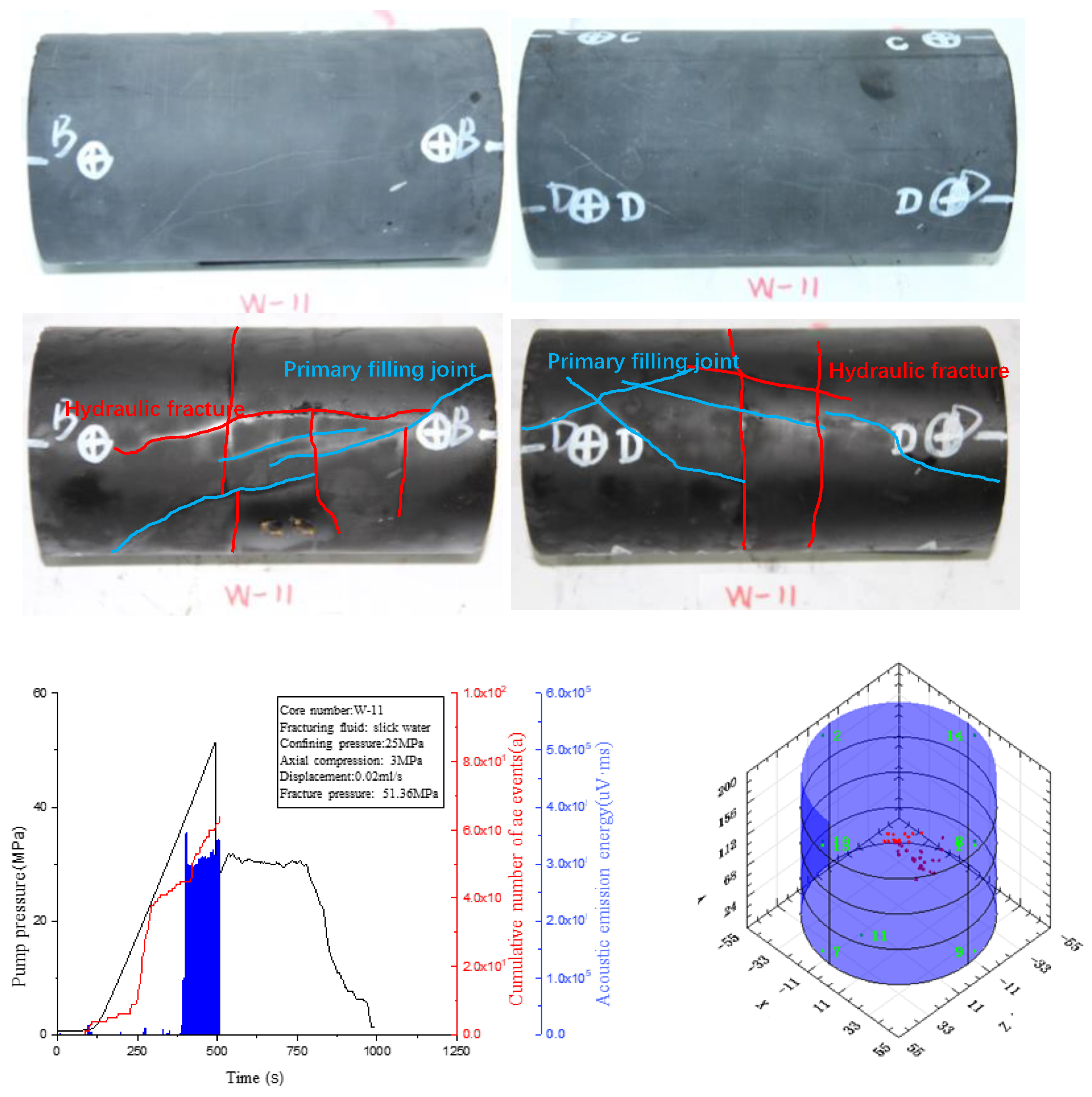

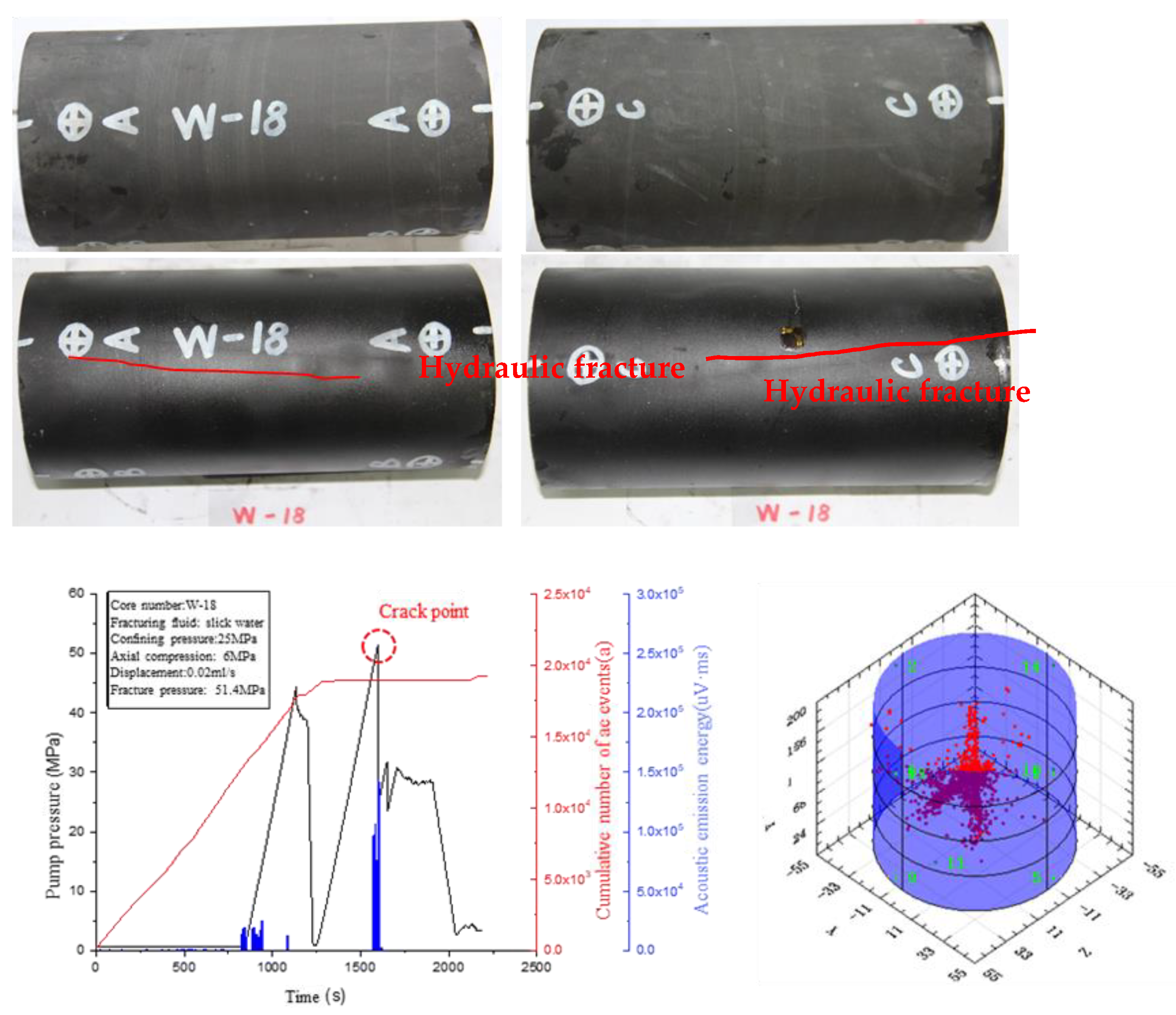

3.5.1. Horizontal Ground Stress Difference

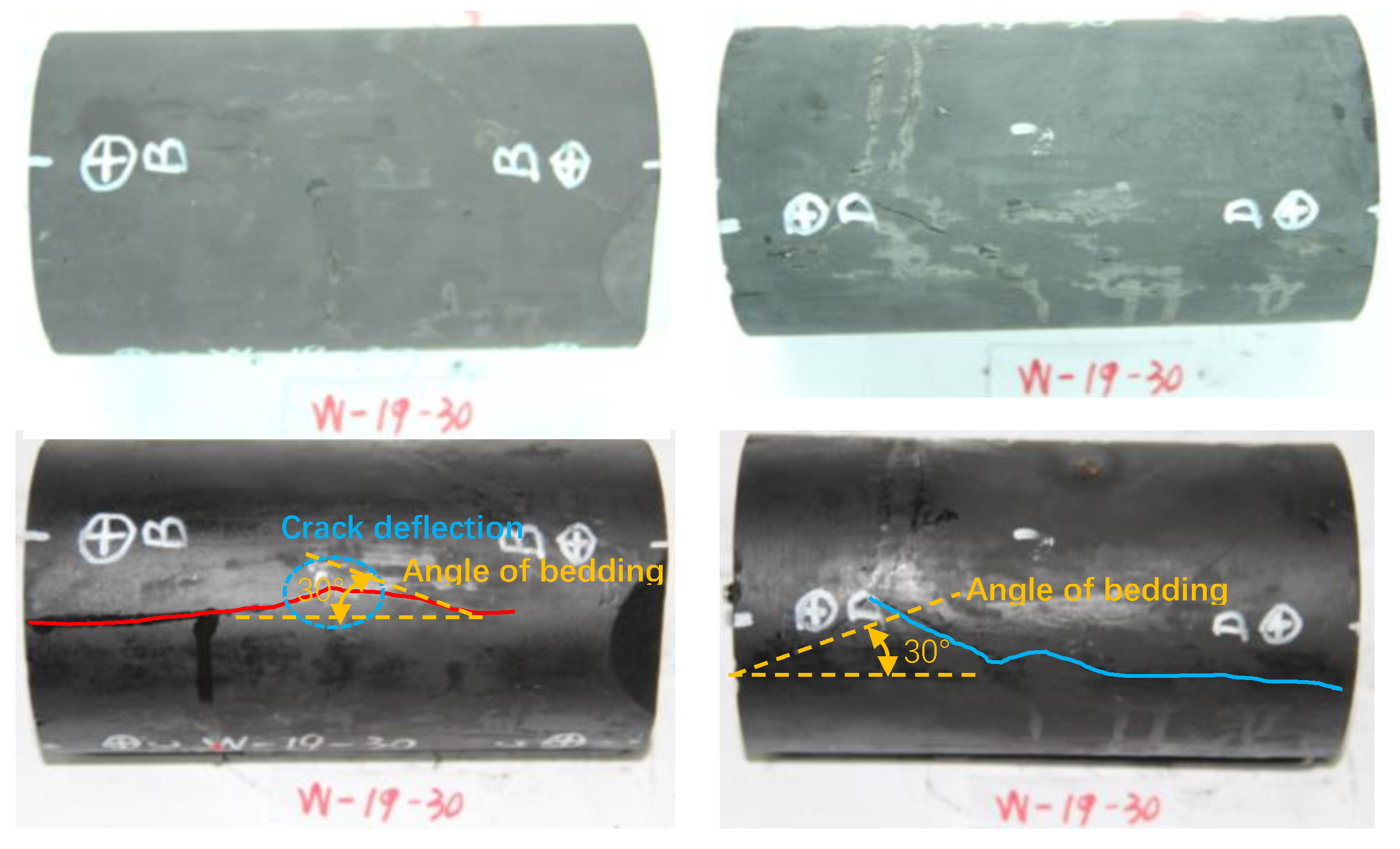

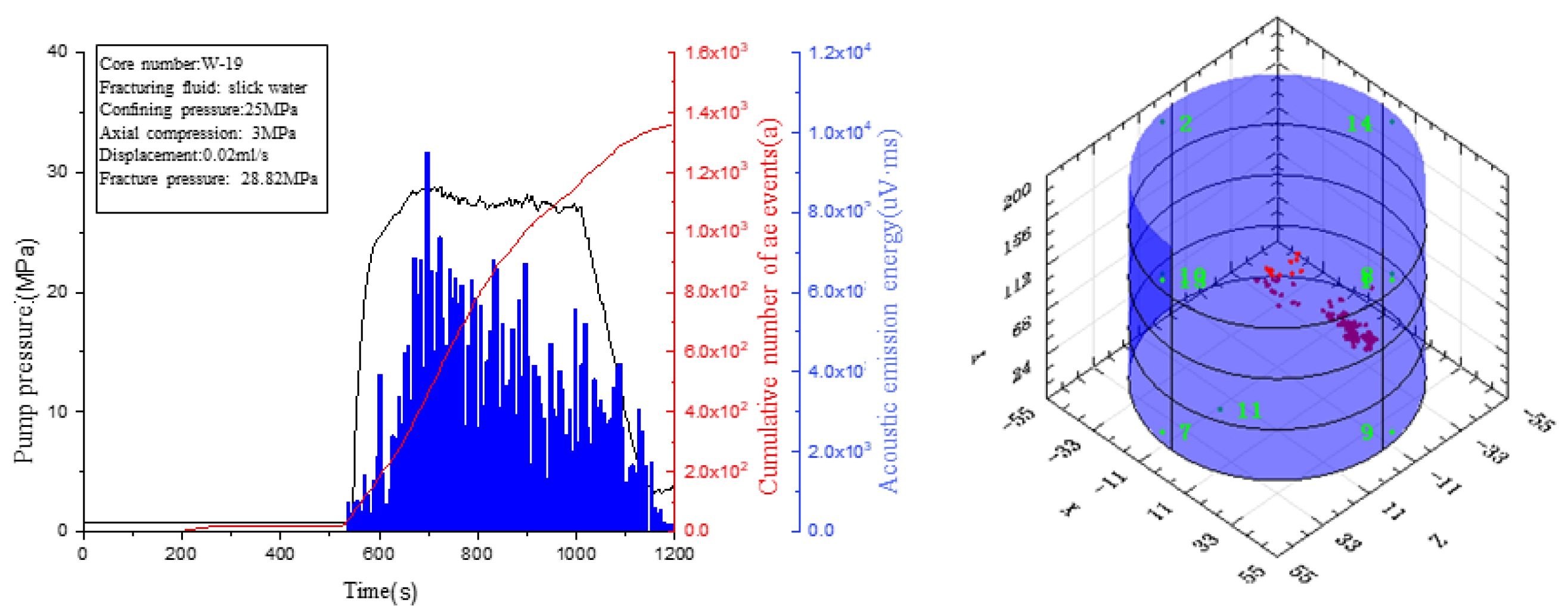

3.5.2. Laminar Dip Angle

4. Conclusions

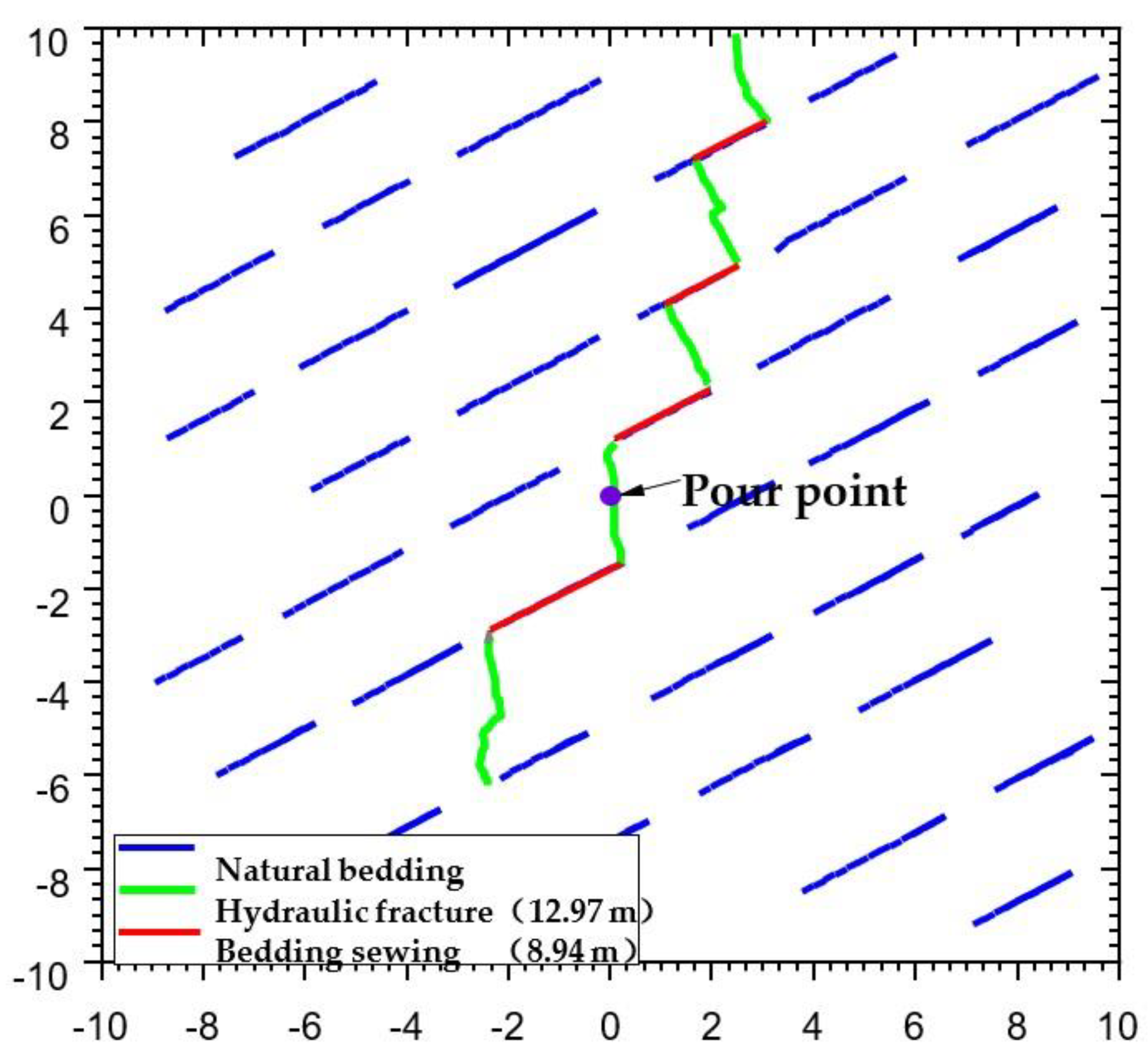

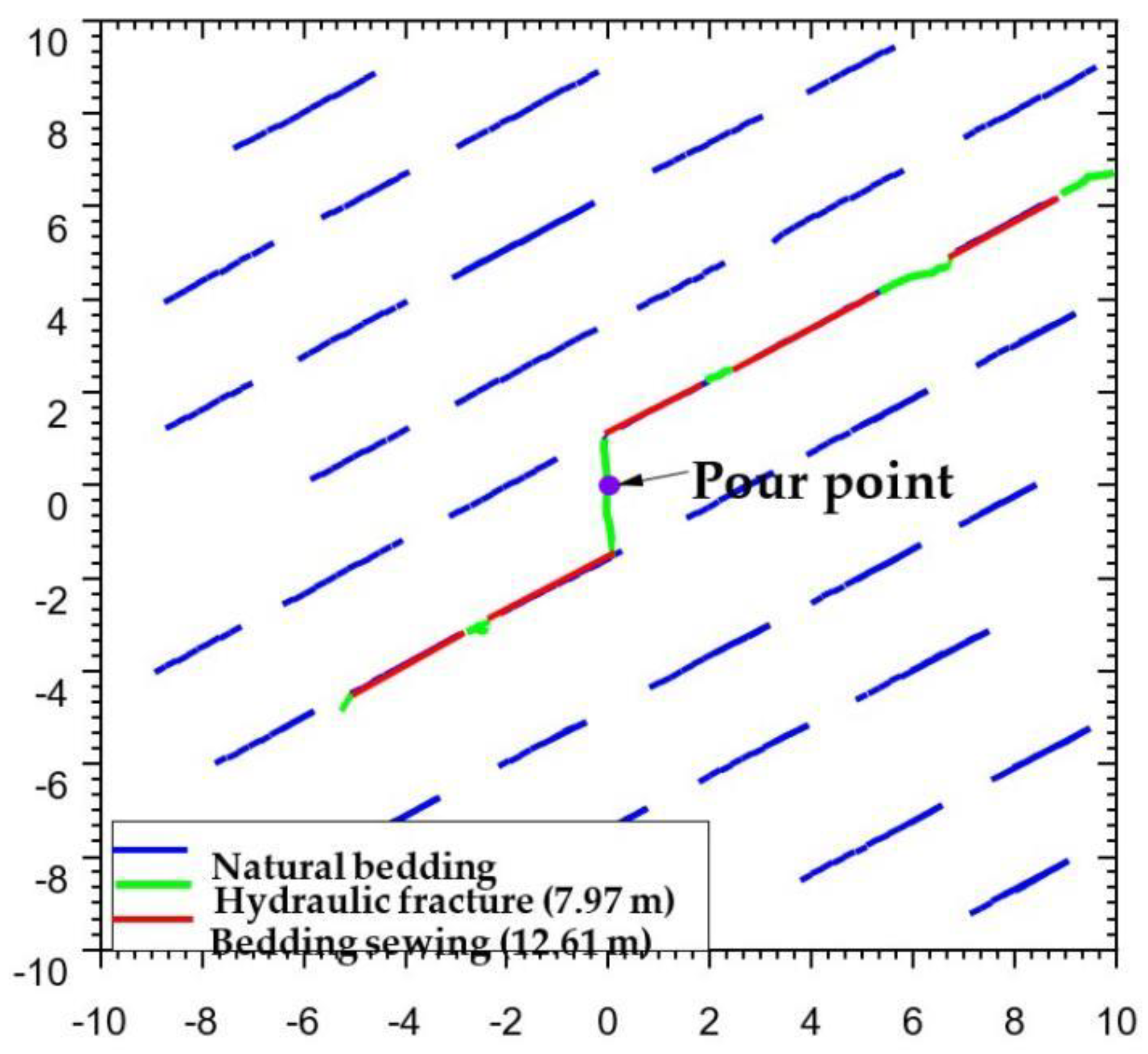

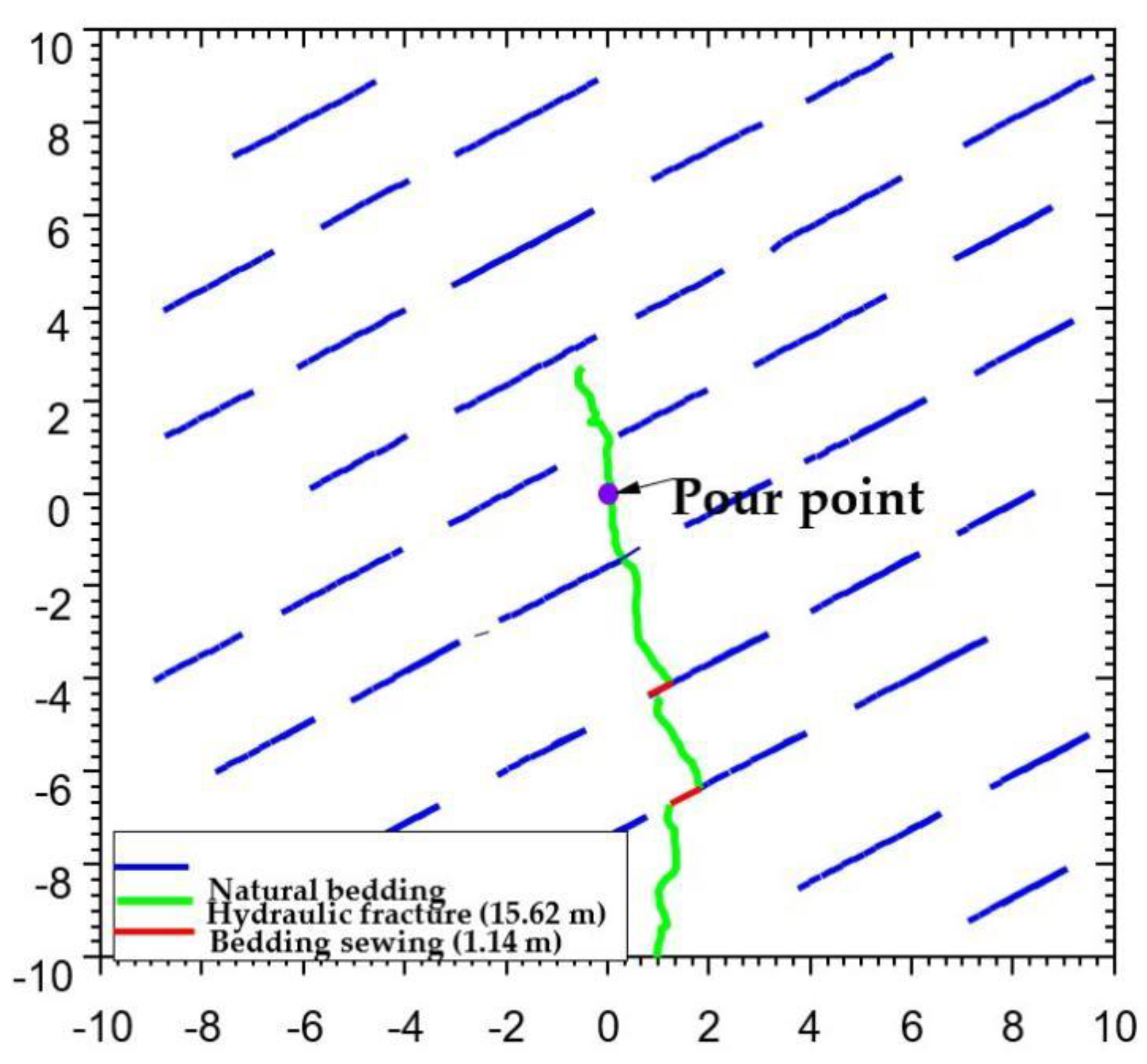

- The influence of laminae on the expansion pattern of artificial cracks is mainly affected by various factors, such as the original ground stress state, the cementation strength of laminae joints, and the approach angle of artificial cracks. The numerical calculation results show that the hydraulic fracture first expands in the direction perpendicular to the minimum horizontal principal stress after starting from the injection point, and after encountering the laminated joints, the hydraulic fracture turns and expands along the side of the laminated surface.

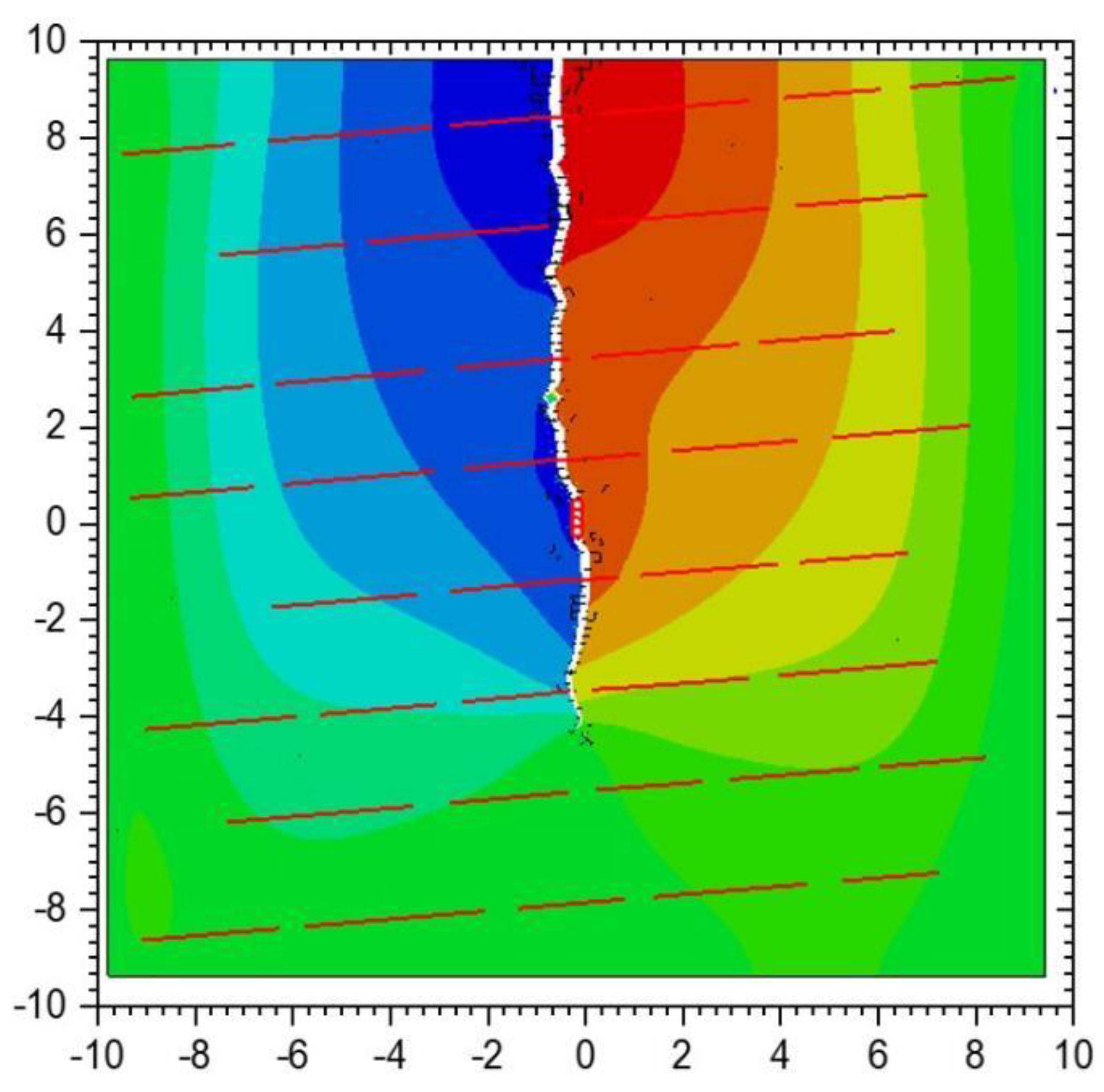

- The expansion process of hydraulic fracture under different horizontal ground stress conditions is simulated by using the global embedding cohesive unit method, and under the same conditions, a certain horizontal ground stress difference can induce hydraulic fracture to form a more complex seam network. However, with the further increase in the horizontal ground stress difference, the vertical stress difference coefficient increases, the probability of hydraulic fracture penetration along the longitudinal direction of the maximum principal stress increases, the horizontal laminar surface of communication decreases, and the complexity of the fracture network decreases.

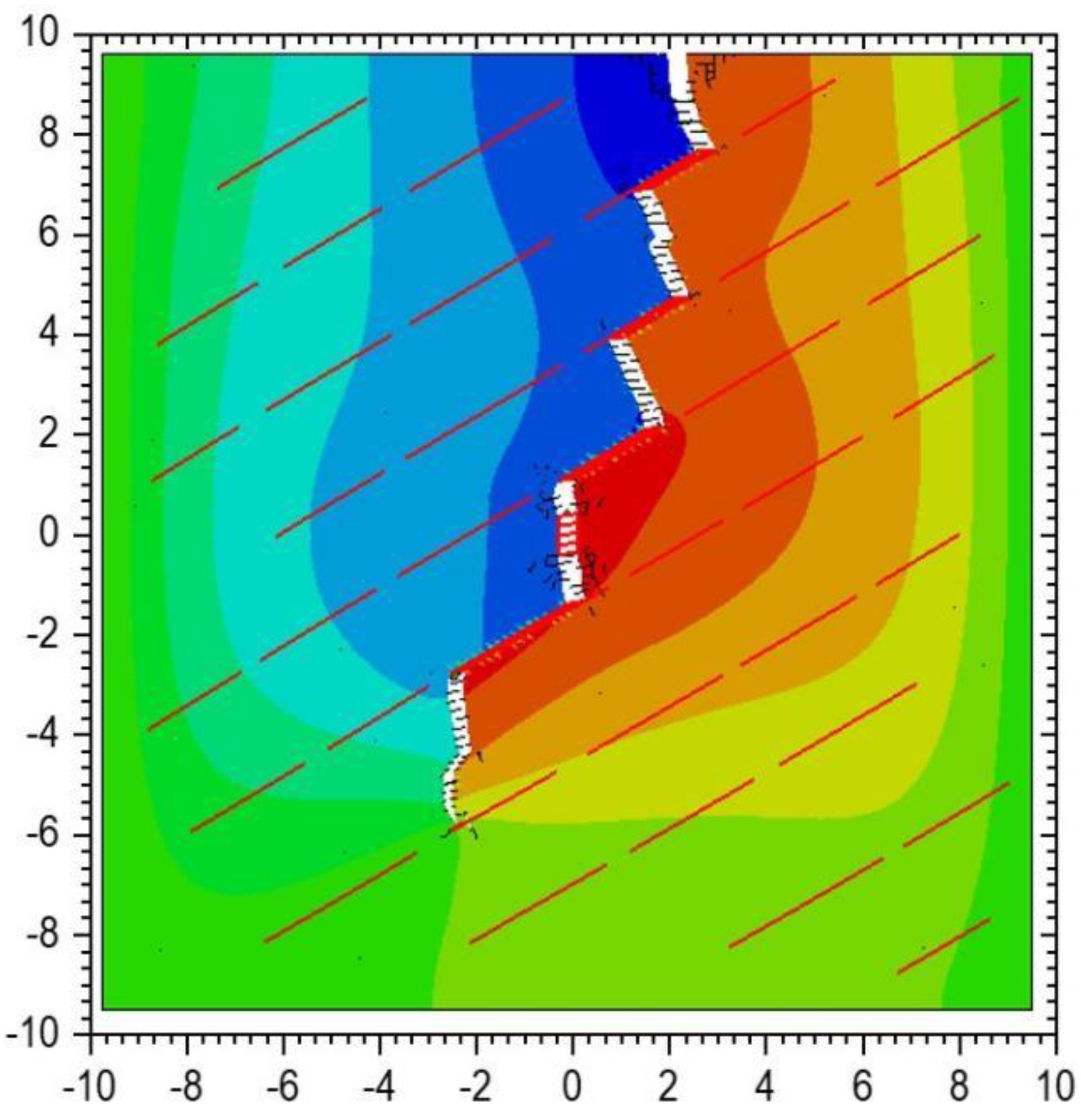

- It can be seen from the numerical simulation and physical model experiments that with the increase in the laminar dip angle (angle between the lamina and horizontal direction), the positive stress acting on the laminated joints decreases, the frictional resistance between the laminated surfaces decreases, and shear damage along the laminated surfaces is more likely to occur, so the distance between the communicating laminated joints and the complexity of the joint network increase.

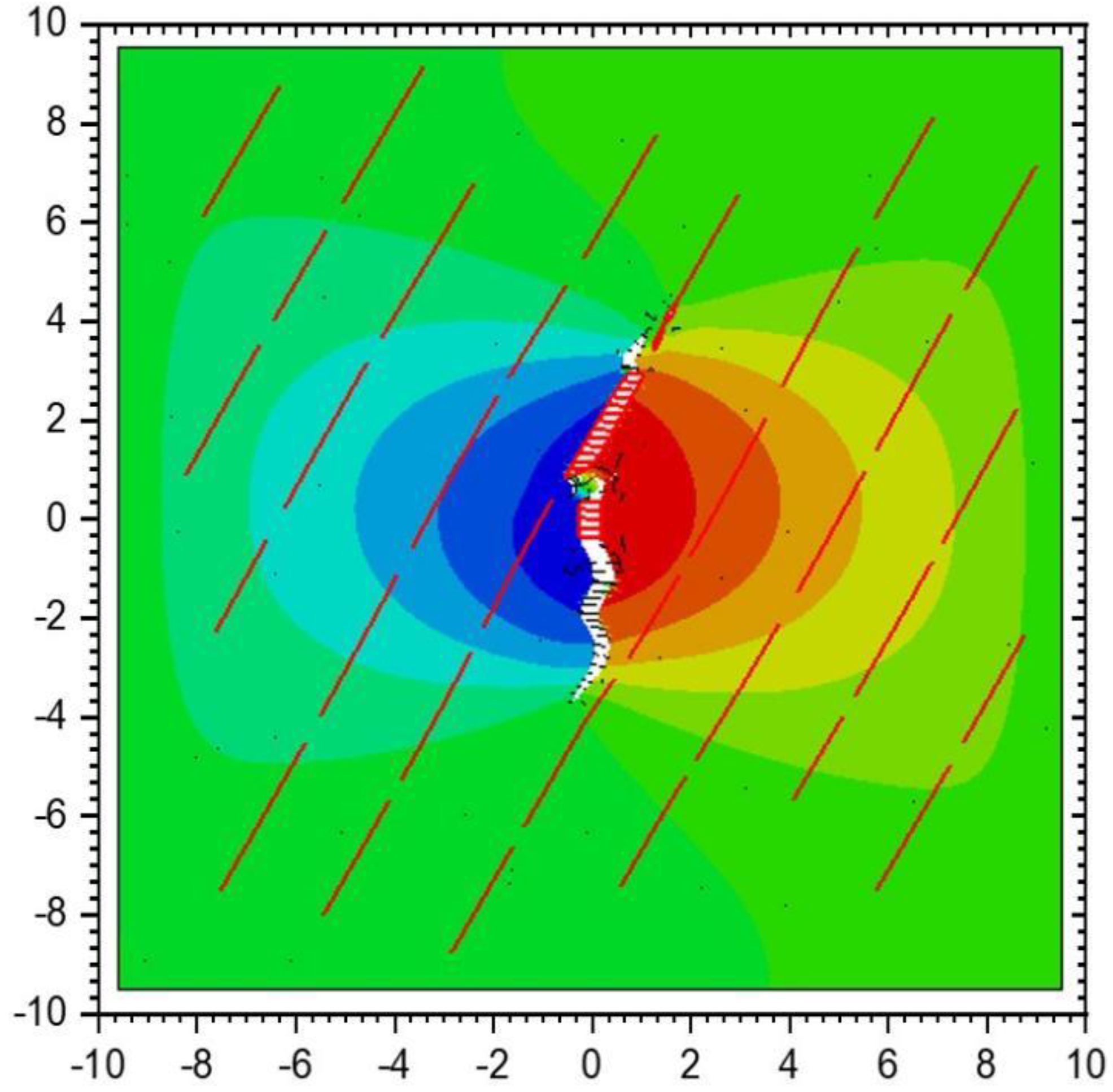

- By simulating the hydraulic fracture expansion process of rocks under different cementation surface strength conditions, it is found that as the cementation strength of laminated surfaces decreases, the tensile strength of laminated surfaces decreases, the hydraulic fracture is more likely to induce shear slip of the laminated surfaces, and the fracture complexity increases significantly.

- In this study, the interaction mechanism and influencing factors between laminae and hydraulic fracture extension were studied from the two perspectives of numerical simulation and physical model testing, but there were biases in the specimen itself because the cylindrical specimens used were outcrops. In future work, we will combine manual sample making and downhole cores to exclude the interference of the specimen itself and conduct a more systematic and comprehensive study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zou, C.; Zhai, G.; Zhang, Y.; Wang, H.; Zhang, G.; Li, J.; Wang, Z.; Wen, Z.; Ma, F.; Liang, Y.; et al. Global conventional−unconventional oil and gas formation distribution, resource potential and trend forecast. Oil Explor. Dev. 2015, 42, 13–25. [Google Scholar]

- Jiang, Z.; Zhang, W.; Liang, C.; Wang, Y.; Liu, H.; Chen, X. Basic characteristics of shale oil reservoirs and evaluation elements. J. Pet. 2014, 35, 184–196. [Google Scholar]

- Zhang, J.; Lin, L.; Li, Y. Shale oil classification and evaluation. Geosci. Antecedents 2012, 19, 322–331. [Google Scholar]

- Lu, S.; Xue, H.; Wang, M.; Xiao, D.; Huang, W.; Li, J.; Xie, L.; Tian, S.; Wang, S. Exploring the evaluation criteria of shale oil and gas resources classification. J. Pet. 2016, 37, 1309–1322. [Google Scholar]

- Lu, S.; Xue, H.; Wang, M.; Chen, F.; Huang, W.; Li, J.; Wang, W.; Cai, X. Exploring the evaluation criteria of shale oil and gas resources classification. Oil Explor. Dev. 2012, 39, 249–256. [Google Scholar]

- Zou, C.; Zhu, R.; Bai, B.; Yang, Z.; Hou, L.; Zha, M.; Fu, J.; Shao, Y.; Liu, K.; Cao, H.; et al. Meaning, Characteristics, Potential and Challenges of Tight Oil and Shale Oil. Bull. Miner. Rock Geochem. 2015, 34, 3–17. [Google Scholar]

- Lin, S.; Zou, C.; Yuan, X.; Yang, Z. Current status of tight oil development in the U.S. and insights. Rocky Reserv. 2011, 23, 25–30, 64. [Google Scholar]

- Pramod, K. Woodford growing revenues by farming to oil shale. World Oil 2012, 233, 32. [Google Scholar]

- Zhao, J.; Fang, C.; Zhang, J.; Wang, L.; Zhang, X. Evaluation of Shale Gas Selection Areas in China from North American Shale Gas Exploration and Development. J. Xi’an Univ. Pet. 2011, 26, 1–7. [Google Scholar]

- Guan, W. Study on the evaluation criteria of the “sweet spot” of inter−salt shale oil in Qianjiang Depression. J. Jianghan Pet. Staff. Univ. 2020, 33, 15–17. [Google Scholar]

- Fan, S. Pore Structure Characteristics and Influencing Factors of the Inter−Salt Shale Oil Reservoir in Qianjiang Depression, Qianjiang Section 3; China University of Petroleum: Beijing, China, 2020. [Google Scholar]

- Zhang, C. Oil−Bearing and Movability Analysis of Inter−Salt Shales of Qianjiang Formation in Qianjiang Depression, Jianghan Basin; China University of Petroleum: Beijing, China, 2020. [Google Scholar]

- Xu, E.; Tao, G.; Li, Z.; Wu, S.; Zhang, W.; Rao, D. Microscopic reservoir characteristics of different petrographic phases of inter−salt shale oil reservoirs in Qianjiang Depression, Jianghan Basin—Example of 4 subsections of 10 rhymes in three sections of the Paleoproterozoic Qianjiang Formation. Pet. Exp. Geol. 2020, 42, 193–201. [Google Scholar]

- Hu, G. Analysis of the influence of mechanical parameters of stratified shale on fracture morphology of hydraulic fracturing. Drill. Eng. 2022, 49, 97–103. [Google Scholar]

- Wang, Y.; Han, D.; Zhao, L.; Mitra, A.; Aldin, S. An experimental investigation of the anisotropic dynamic and static properties of eagle ford shales. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 20–22 July 2019; p. 304. [Google Scholar]

- Du, M.; Pan, P.; Ji, W.; Zhang, Z.; Gao, Y. Spatial and temporal characteristics of the damage process in carbonaceous shale Brazil under cleavage load. Geotechnics 2016, 37, 3437–3446. [Google Scholar]

- Ma, X.; Li, C.; Bai, J.; Ma, Z. Analysis of physical characteristics of shale rock based on ultrasonic testing. Oil Geophys. Prospect. 2021, 56, 801–808. [Google Scholar]

- Chen, X.; Liu, R.; Xie, B.; Pan, Y.; He, X. Capacity model for fractured horizontal wells in shale reservoirs considering laminar seams. Xinjiang Oil Gas 2022, 18, 73–79. [Google Scholar]

- Heng, S.; Yang, C.; Guo, Y.; Wang, C.; Wang, L. Study on the influence of laminae on shale hydraulic fracture extension. J. Rock Mech. Eng. 2015, 34, 228–237. [Google Scholar]

- Liu, Z.; Feng, Q.; Wang, Y.; Wang, H.; Zou, L.; Tang, J. Fracture height prediction model and construction optimization method for fracturing Weiyuan shale gas reservoirs considering the influence of stratigraphy. Logging Technol. 2022, 1, 114–121. [Google Scholar]

| Input Parameters | Numerical Value |

|---|---|

| Rocks | |

| Young’s modulus (GPa) | 14 |

| Poisson’s ratio | 0.2 |

| Density (kg/m3) | 2600 |

| Tensile strength (MPa) | 6 |

| Permeability coefficient (m/s) | 1 × 10−7 |

| Porosity | 0.1 |

| Layer theory | |

| Tensile strength (MPa) | 2 |

| Critical damage displacement (m) | 0.001 |

| Fracturing fluids | |

| Injection rate (m2/s) | 0.002 |

| Viscosity (Pa·s) | 0.001 |

| Sensor Coordinates (mm) | Sensor Space Location | |||

|---|---|---|---|---|

| Passage | X | Y | Z | |

| 1 | 55.00 | 175.00 | 0.00 |  |

| 2 | −55.00 | 175.00 | 0.00 | |

| 3 | 0.00 | 175.00 | 55.00 | |

| 4 | 0.00 | 175.00 | −55.00 | |

| 5 | 55.00 | 25.00 | 0.00 | |

| 6 | −55.00 | 25.00 | 0.00 | |

| 7 | 0.00 | 25.00 | 55.00 | |

| 8 | 0.00 | 25.00 | −55.00 | |

| Specimen Number | Test Parameters | Rupture Pressure (MPa) | Crack Type | |||

|---|---|---|---|---|---|---|

| Surrounding Pressure (MPa) | Shaft Pressure (MPa) | Displacement (mL/min) | Viscosity (MPa·s) | |||

| W–11 | 25 | 3 | 1.2 | 3.0 | 51.36 | Complex seam network |

| W–18 | 25 | 6 | 1.2 | 3.0 | 51.40 | Vertical seam |

| W–19 | 25 | 3 | 1.2 | 3.0 | 28.82 | Complex seam network |

| W–20 | 25 | 3 | 1.2 | 3.0 | 44.28 | Complex seam network |

| Specimen Number | Fracturing Fluids | Displacement (mL/s) | Shaft Pressure (MPa) | Surrounding Pressure (MPa) | Rupture Pressure (MPa) |

|---|---|---|---|---|---|

| W–11 | Slick water | 0.02 | 28 | 25 | 51.36 |

| W–18 | Slick water | 0.02 | 31 | 25 | 51.40 |

| Specimen Number | Fracturing Fluids | Laminar Perspective | Displacement (mL/s) | Shaft Pressure (MPa) | Surrounding Pressure (MPa) | Rupture Pressure (MPa) |

|---|---|---|---|---|---|---|

| W–19 | Slippery water | 30 | 0.02 | 3 | 25 | 28.82 |

| W–20 | Slippery water | 60 | 0.02 | 3 | 25 | 44.28 |

| W–11 | Slippery water | 90 | 0.02 | 3 | 25 | 51.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Hu, Z.; Chang, X. Mechanistic Study on the Influence of Stratigraphy on the Initiation and Expansion Pattern of Hydraulic Fractures in Shale Reservoirs. Appl. Sci. 2022, 12, 8082. https://doi.org/10.3390/app12168082

Li S, Hu Z, Chang X. Mechanistic Study on the Influence of Stratigraphy on the Initiation and Expansion Pattern of Hydraulic Fractures in Shale Reservoirs. Applied Sciences. 2022; 12(16):8082. https://doi.org/10.3390/app12168082

Chicago/Turabian StyleLi, Shuangming, Zhiwen Hu, and Xin Chang. 2022. "Mechanistic Study on the Influence of Stratigraphy on the Initiation and Expansion Pattern of Hydraulic Fractures in Shale Reservoirs" Applied Sciences 12, no. 16: 8082. https://doi.org/10.3390/app12168082

APA StyleLi, S., Hu, Z., & Chang, X. (2022). Mechanistic Study on the Influence of Stratigraphy on the Initiation and Expansion Pattern of Hydraulic Fractures in Shale Reservoirs. Applied Sciences, 12(16), 8082. https://doi.org/10.3390/app12168082