Featured Application

The research in this paper will serve as a remarkable guide for the state detection and remaining useful life prediction of water hydraulic high-speed on/off valves and other solenoid valves.

Abstract

Some water hydraulic manipulators used for the remote operation of reactors are controlled by a high-speed on/off valve (HSV). Water hydraulic HSVs operate through a process of high-frequency switching, and since their work environment is poorly lubricated, their components are prone to failure. The present study proposed a hybrid model to detect the state and predict the RUL of water hydraulic HSVs used for manipulators, including (1) an HSV state detection method based on the fuzzy neural network (FNN) algorithm; (2) a remaining useful life (RUL) prediction method based on the integration between the autoregressive integrated moving average (ARIMA) model and the long short-term memory (LSTM) model. Final results showed that the accuracy of state detection based on the FNN method was 93.3%. The relative error of the RUL prediction based on the ARIMA–LSTM was less than 1.6%. The developed method can provide guidance for operation and maintenance personnel to plan maintenance reasonably.

1. Introduction

Nuclear energy is a potential clean energy resource, and its realization will play a key role in energy resource requirements. The water hydraulic manipulator has been used in the operation and maintenance of nuclear power plants because the water has no risk of pollution and is not affected by radiation [1]. In China, the water hydraulic manipulator has been used for blanket module maintenance [2]. Currently, most hydraulic manipulators are controlled by servo valves. However, due to the low viscosity of water, these valves can easily fail due to severe wear [3,4]. Water hydraulic high-speed on/off valves (HSVs) with a cone valve structure have the advantages of reliability and no leakage [5]. Therefore, there is potential for the wide application of HSVs in water hydraulic manipulators. However, the reliability of a water hydraulic HSV is less than that of an oil pressure valve. Long-term operation will degrade the performance of the HSV, and even cause wear, clogging, or other faults [6,7], which will seriously affect the normal operation of the manipulator. Therefore, there is value in developing methods for detecting the degradation state of an HSV that is suitable for a water hydraulic manipulator and predicting its remaining useful life (RUL).

Generally, state detection and RUL prediction methods include physics-based and data-driven approaches [8,9]. Physics-based methods rely on the deviation between the system and the physical model to detect the operating state of the system [10]. Leturiondo et al. [11] established a model of a rolling bearing, which they used to diagnose the fault state of the rolling bearing. They constructed a test system to verify the simulation and conducted many tests. They obtained the accuracy of the model by comparing eigenvalues obtained from the test data with the simulation results. Eker et al. [12] proposed a physics-based model to predict future clogging levels and estimate the RUL of fuel filters. They applied their proposed model to a particulate filter to predict the filter clogging level. El et al. [13] also presented a fault detection method for wind turbines based on the fuzzy sliding mode observer, which was shown to have good performance. Hashemnia et al. [14] adopted a frequency response analysis and a diagnosis method to increase the accuracy of detection of winding faults within a power transformer. Lu et al. [15] presented a physics-based model of a rolling bearing, which uses a wavelet neural network to predict RUL.

The data-driven approach establishes the relationship between system states and system measurements by analyzing previously collected information on the system. The data-driven approach does not rely on a physical model of the system or a-priori knowledge [16]. Deng et al. [17] proposed a gated recurrent unit network that extends particle filters to the case when the measurement equation cannot be established. This method has also been used to predict the RUL of the ball screw. Results have shown that accelerated degradation test systems can accurately predict the degradation performance and RUL of ball screws. Wu et al. [18] used a data-driven fault diagnosis strategy on solid oxide fuel cells to predict their RUL. Their strategy achieved a fault recognition rate of 97% and RUL prediction error of less than 20%. Wang et al. [19] used a data-driven aero-engine performance degradation and RUL prediction strategy. Their strategy was verified using NASA’s aero-engine data. Their method accurately predicted the degradation of aero-engine performance. Jin et al. [20] used a fault identification method based on the Kolmogorov–Smirnov test, a self-organizing diagram, and a Kalman filter. Validation experiment results showed that their method can effectively detect degradation of a bearing and predict its RUL. Wang et al. [21] used an enhanced Kalman filter and an expectation maximization algorithm to predict the RUL of bearings. The advantages of data-driven methods are that sufficient prior knowledge is not necessary and there is no need to establish an accurate physical model; state diagnosis can be realized by analyzing changes in state signals. The accuracy of state prediction can be greatly improved using a data-driven model.

The data-driven method has many sub methods [22,23,24]. The support vector machine (SVM) and relevance vector machine (RVM) models require little training data, but they are not optimal for application to time series problems [25]. Gaussian process regression (GPR) has recently become popular within the prediction of RUL due to its various advantages, including nonparametric modeling, probabilistic prediction, and low computation burden [26]. However, within feature learning, the method requires not only sufficient raw data, but also the optimization of many parameters. The artificial neural network (ANN) is a learning method for complex data composed of neural networks. The ANN model contains one or more hidden processing layers between the input and output layers. This model has a relatively stronger ability to learn compared to other methods. Therefore, the method is suitable for application to classification and regression.

HSVs have complex structures whose operations include electromagnetic, mechanical, and liquid coupling processes. Furthermore, a great deal of experimentation would generally be required to validate such a model. Therefore, the data-driven method is more suitable for HSVs’ state detection and RUL prediction. The objectives of the study were to: (1) construct an HSV test bench and define the HSV degradation state; (2) propose an HSV state detection method based on the FNN algorithm; (3) construct a model to predict the RUL of an HSV based on the integration of the ARIMA model and LSTM model (abbr. ARIMA–LSTM).

2. Methods

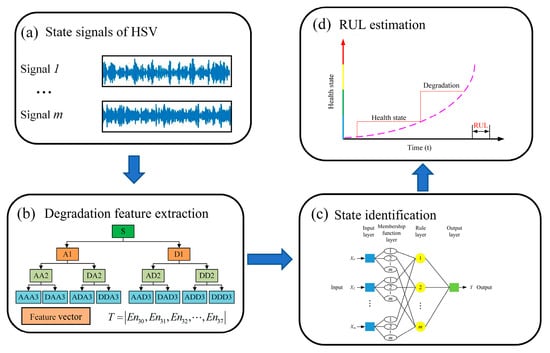

As shown in Figure 1, the degradation prognostic strategy includes signal acquisition, degradation feature extraction, degradation state estimation, and RUL prediction. Figure 1a shows the state signals collected through the whole life cycle of the valve. Figure 1b uses the signal processing method to extract the characteristics of the collected state signals. Figure 1c uses the FNN method to predict the degradation state. Figure 1d predicts the degradation trend and RUL of the valve.

Figure 1.

Scheme of the data-driven prognostic strategy.

2.1. Signal Feature Extraction

The Fourier transform can be used within the field of signal processing to not only analyze a signal in the time domain, but also to analyze signal spectrum, thereby allowing more convenient signal feature extraction. However, these features of the Fourier transform are only suitable for stationary signals over the entire time period. This limitation of the Fourier transform prevents it from being used to analyze a signal with local characteristics [27]. The short-time Fourier transform shows clear advantages over the Fourier transform for processing non-stationary signals. The theoretical premise of the short-time Fourier transform method is the construction of a short-time stationary period for non-stationary signals, similar to the windowing theory. However, since the size of the moving window is fixed, the short-time Fourier transform has a fixed resolution for signal analysis, which presents some challenges. The wavelet transform follows the same concept as the short-time Fourier transform and a moving window. However, there are some shortcomings within the application of wavelet theory multi-resolution analysis to high-frequency signal processing. Wavelet packet theory stipulates the construction of orthogonal wavelets based on multi-resolution analysis, which are further decomposed into low-frequency and then high-frequency wavelets. In addition, wavelet packet decomposition technology can be used to screen the decomposed frequency band according to the characteristics of the signal itself. This allows for the selection of the suitable frequency band or an analysis of the original signal, thereby improving the time–frequency resolution [28,29].

Figure 1b is the decomposed structure of a three-layer wavelet packet. The wavelet packet decomposition technology further simultaneously decomposed the high-frequency and low-frequency signals when decomposing the second and third layers, instead of only decomposing the low-frequency part. In addition, the frequency band suitable for the signal feature extraction is selected. This improves resolutions of the time and frequency domains of the signal. Since the studied fault signal is often non-stationary, wavelet packet decomposition technology is the most appropriate for analyzing the full frequency band to obtain effective fault feature information.

Before performing the wavelet packet decomposition, the Daubechies (db3) wavelet packet basis function is used to decompose the degeneration signal of the HSV. The noise proportion in the HSV current signal is small, and there is no need for too many layers of decomposition. Therefore, choosing the three-layer wavelet packet decomposition of the signal can separate the noise on the premise of ensuring the authenticity of the signal reconstruction.

The total energy of each frequency band signal is extracted and is regarded as a feature vector of state type, as shown in Equations (1) and (2) [30]. After the three-layer decomposition, the state signal is decomposed into eight different frequency bands, and the feature vector is converted, as shown in Equation (2).

where xjk (j = 1:7, k = 1:n) represents the amplitude of the discrete point of the reconstructed signal.

2.2. State Detection Based on FNN

The maintenance activities performed on an HSV typically include corrective and preventive maintenance. Corrective maintenance operations are implemented after failure and usually have high costs associated with maintenance and replacement parts. Traditional preventive maintenance typically involves regular repair of the HSV according to specified standards and is unrelated to the condition of the valve. While these maintenance strategies usually improve the reliability of equipment, they are also significantly costly. Therefore, an approach to balancing the reliability and cost of HSVs is to monitor the condition and assess the health of HSV components, known as predictive maintenance (PdM). PdM is the maintenance policy that predicts the future state of equipment based on current data. The goal of PdM is to use the monitoring data to predict the RUL and potential faults of the equipment, avoid unexpected shutdown, and reduce the maintenance cost by maximizing the residual value of the equipment [31]. Therefore, the present study used neural network technology to detect the state of the HSV, whereas monitoring of the valve degradation performance was the basis for predicting its RUL.

Computer fuzzy reasoning uses fuzzy rules to simulate human fuzzy logic. This method can be used to improve the accuracy of computer simulation. The FNN, formed by a combination of fuzzy reasoning and a neural network, increased the self-learning ability of the system [32,33]. The FNN was based on a traditional neural network which fuzzifies the input and output signals. The topological structure of the FNN is shown in Figure 1c. The FNN is divided into five layers [34]:

- (a)

- Input layer: The input layer node is connected with an input quantity X = (X1, X2, …, Xn), and n is the number of the input variables. The purpose of the input layer is to transfer the input directly to the next layer.

- (b)

- Fuzzification layer: This layer calculates the membership function of each input component. The Gaussian membership function is generally used, represented by Equation (3).where μij, cij and σij are membership function parameters.

- (c)

- Fuzzy inference layer: This layer calculates the applicability of each rule, i.e., activation strength, and can be represented by Equation (4).

- (d)

- De-fuzzification layer: This layer normalizes the input quantity, as shown in Equation (5).

- (e)

- Output layer: The output of this layer is shown in Equation (6).where wj is the connection weight.

The FNN learning process mainly includes structure adjustment and parameter learning. The FNN uses the gradient descent method to learn connection weight wj, the center cij, and the membership function σij. This allows the FNN to obtain an FNN model with improved parameters.

During this process, the objective function is defined as Equation (7).

where yd is the expected output of the system.

Parameter learning is used to minimize expected objective function, and the parameter updating formula is shown in Equation (8).

where η is the learning rate.

2.3. ARIMA–LSTM Method for RUL Prediction

When compared with the traditional ANN method, the LSTM algorithm can fully capture nonlinear trends and correlations within data. However, there are some disadvantages associated with the single LSTM model, including a slow convergence speed, a large influence of outliers, and local minima [35]. The ARIMA model is suitable for extracting the linear trend in a data series [36,37]. The research [38,39,40] shows that the combination of the ARIMA and LSTM models can improve the accuracy of trend prediction. Therefore, the present study used a hybrid ARIMA–LSTM model to predict the RUL of an HSV.

- (1)

- ARIMA

The ARIMA model is the concept of predicting a future time series value according to the historical time series data. This method is valid when the current value within a time series has a linear relationship with a past value of the time series and random interference. The model can be expressed as ARIMA (p, d, q), which is a combination of auto-regression AR(p), moving average MA(q), and the degree of differencing d:

where L is the lag operator, and represent the parameters of the AR and MA parts, respectively, and represents the error terms.

The ARIMA process consists of four steps:

- (a)

- Sequence stabilization processing: A non-stationary data series requires differential processing for stabilization. The difference coefficient d is used to construct a stable data series.

- (b)

- Model order determination: The ARIMA requires the determination of three parameters. Parameter d is determined in step (a), whereas parameters p and q are determined through ACF and PACF diagrams. AIC is used to select a set of optimal model parameters. The expression of the AIC is shown in Equation (10).

- (c)

- Model test: The validity of the model can be verified by assessing whether the model residual is a white noise sequence.

- (d)

- Prediction: A future value of the time series can be predicted according to the historical time series.

- (2)

- LSTM

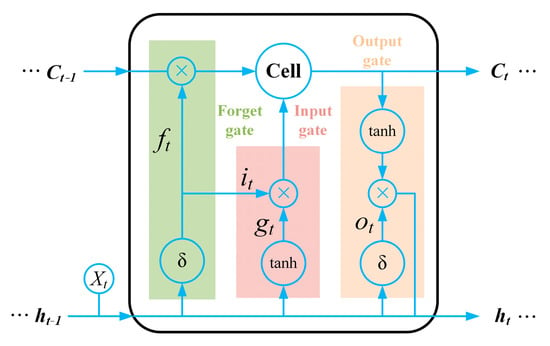

LSTM usually includes three gates: input gate; forgetting gate; output gate. Figure 2 is a structure of the LSTM model [25].

Figure 2.

Dataflow of an LSTM cell.

The LSTM model constructs a relationship from the input sequence to an output sequence using Equations (11)–(15). Within these equations, σ is the activation function, and tanh is the tangent hyperbolic function. Within these two functions, h, c, and t represent hidden states, memory cell state, and time steps, respectively. As such, ht−1 is the previous hidden state, Ct is the current memory cell state, and indicates element-wise multiplication.

- (3)

- Hybrid ARIMA–LSTM

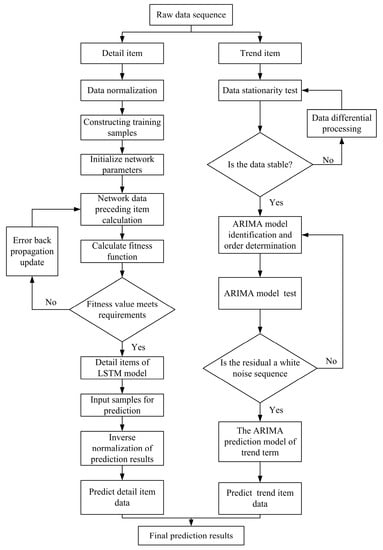

The HSV health index curve contains both linear and nonlinear elements. Therefore, the use of a single model is inadequate for prediction. The present study constructed a hybrid model. Firstly, raw data were filtered using the ARIMA model with the nonlinear law included in the model residuals. The residuals were then input into the LSTM model to extract the nonlinear law. Finally, the predictions based on the ARIMA–LSTM model were superimposed to obtain the final prediction results. Figure 3 shows the workflow of the hybrid models.

Figure 3.

Working flow of ARIMA–LSTM models.

RMSE and MSE error metrics are used to evaluate the performance of the ARIMA–LSTM method in comparison with the actual output:

where ŷ and y are model predictions and actual output, respectively, and m is the number of samples. The values of RMSE and MSE exceed 0 and are inversely related to prediction accuracy [41].

3. Definition of the Degradation Signal and Dataset Acquisition

3.1. Defining the Degradation Signal Based on Driven Current

The health index signal needs to be defined before the state detection and RUL prediction of an HSV can be applied to the water hydraulic manipulator. The health index signal is a mathematical indicator that represents the condition of the HSV and should be easy to monitor in practice. These requirements exclude the electromagnetic force, the dynamic response time, and spool displacement. In contrast, the drive current can be considered as a fault detection signal since variation of the drive current can be easily monitored using a current sensor. In addition, the current signal curve of the HSV contains some of the information that can be used to determine HSV performance [42], as discussed below.

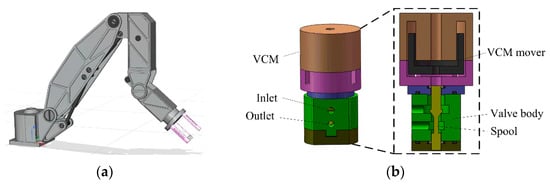

Figure 4 shows the structure of the water hydraulic manipulator and the HSV. The HSV is directly driven by a voice coil motor (VCM). The working state of the HSV is controlled by controlling the state of the VCM.

Figure 4.

Three-dimensional model. (a) Water hydraulic manipulator. (b) Water hydraulic HSV.

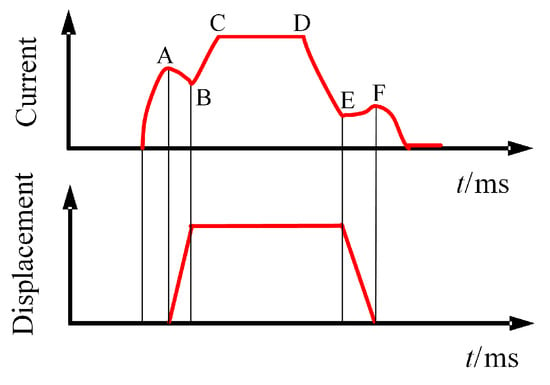

Figure 5 shows the schematic diagram of the HSV current change and spool displacement curve. The working process of the HSV consists of four stages: (1) the actuation process; (2) the movement process; (3) the holding process; and (4) the release process.

Figure 5.

Current variation and spool displacement curves.

- (1)

- Actuation process: A change in the control signal from low to high energizes the coil, causing the coil current to rise. However, the self-inductance does not allow the current to instantaneously stabilize. Electromagnetic force at this point is less than the friction force, the valve spool remains stationary, and there is a continuous increase in current.

- (2)

- Movement process: An increase in the current in the loop beyond a certain threshold, in combination with sufficient generation of electromagnetic force by the coil to overcome the friction force, allows the spool to start moving. During movement of the spool, the coil generates an induced electromotive force due to the action of the eddy current, and the rate of current increase in the loop gradually declines, and may even gradually decrease until the valve is fully open. As shown in Figure 5, when the current value in the loop reaches point A, the spool starts to move and the current decreases, whereas the spool displacement continues to increase. Maximum opening of the valve spool coincides with no changes in the coil air gap, and the current in the loop once again increases until it reaches stabilization.

- (3)

- Maintaining process: The spool is completely open when the current reaches point C, the air gap no longer changes, and the HSV reaches a balanced state while being energized.

- (4)

- Release process: The control signal changes from a high to low level when the current is at point D, the coil loses power, and the coil current begins to decrease. However, the spool remains in an open state. When the current in the circuit decreases to point E, the valve spool starts to move until the valve port is closed.

An analysis of the relationship between the current of the HSV and the movement of the spool implied that the change in current in the loop during the operation of the HSV was different among the different stages. Moreover, degradation of the performance of the HSV was accompanied by a change in driving the current waveform. Therefore, the degradation of the HSV can be assessed by the characteristics of current change during each stage. The present study defined the distortion of the driving current curve as the health index of the HSV. A template current waveform represented by Itemp was defined when the HSV started to work.

where in is the nth sample point of the template current waveform.

The waveform at the kth working cycle is shown as:

where ikn is the nth sample point at the kth operation cycle.

Parameter g [shown as Equation (20)] can be used to define the health index of the HSV.

3.2. Data Acquisition and Analysis

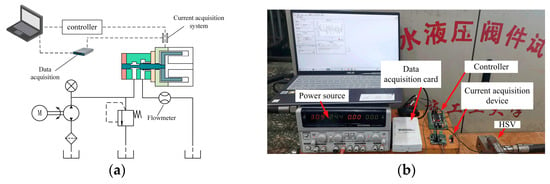

The hydraulic circuit shown in Figure 6 was established to collect the current signal of the HSV. The collected first current waveform signal was set as the template current waveform.

Figure 6.

Experimental system for current detection. (a) Schematic diagram. (b) HSV test bench.

The acquisition card was used to gather the electric current of the HSV. The current acquisition device used was an ACS712 Hall current sensor. This sensor converts the collected current signal into a voltage signal, which it outputs to the acquisition card.

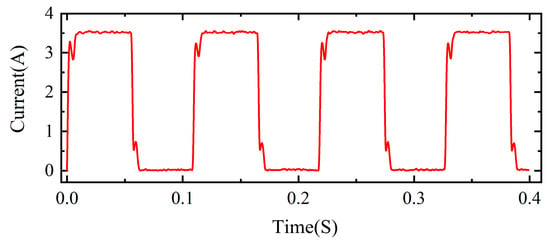

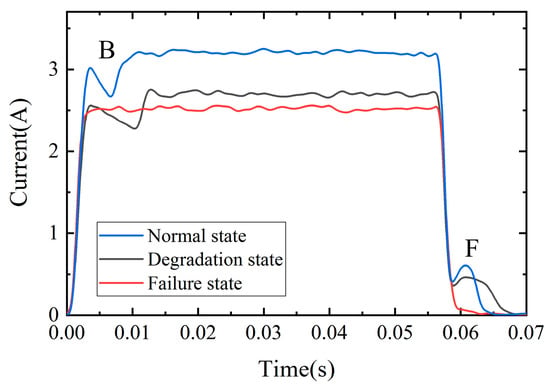

The data collection system contained a water hydraulic piston pump driven by an electric motor, which was used to provide a constant flow rate to the system, as well as a pressure relief valve, which regulated system pressure. The working pressure is set to 10 MPa and the switching frequency of the valve is 10 Hz. When the HSV fails, the valve spool is slightly worn, and the actuator temperature is very high and fails. Therefore, the main reason for the failure of this HSV is the damage to the actuator. Figure 7 is a partial current signal collected from the test. The figure suggests that the current waveform is not a complete rise and fall process, which is consistent with Figure 5. It shows the rationality of the signal acquisition process and results. At the same time, the performance degradation index of the HSV can also be defined according to the change of the current waveform.

Figure 7.

Current signal.

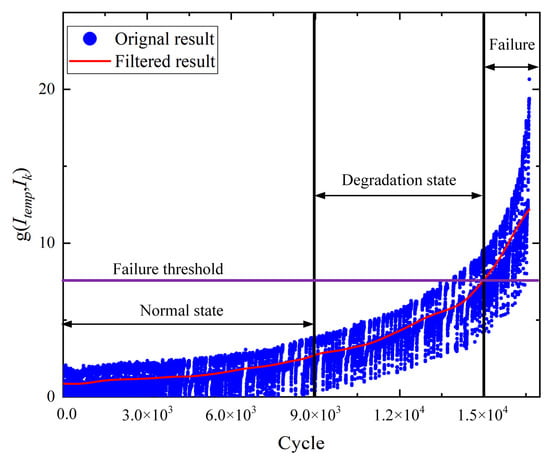

Figure 8 shows the current curve distance versus cycle number of the HSV. The original signal was filtered to obtain a clearer result, and the filtered curve was taken as the trajectory of the final degradation curve. As shown in Figure 8, the entire working state of the HSV could be divided into three stages: (1) a normal state; (2) a degradation state; and (3) a failure state. The state is defined according to the rising degree of the filtered curve and the corresponding g value. During the normal state, the curve is relatively flat, and during the degradation state, the curve has an obvious upward trend. When g continues to increase, the HSV can no longer work reliably, which is defined as the failure state. The number of the working cycles and g value corresponding to each state are shown in Table 1.

Figure 8.

Parameter g versus cycle number.

Table 1.

Working cycles corresponding to degradation states.

Figure 9 is the current signal diagram under three states. The figure suggests that with the performance degradation of the HSV, point B and point F gradually smooth and finally disappear. Figure 5 shows that point B and point F represent the opening response time and closing response time of the HSV, respectively, indicating that with the degradation of HSV performance, the switching response time gradually increases. When the HSV fails, there are no points B and F on the current curve, and the valve spool no longer acts. Moreover, with the performance degradation of the valve, the driving current gradually decreases, indicating that the resistance of the actuator gradually increases.

Figure 9.

Current diagram under three states.

4. Results and Discussion

4.1. State Detection Based on FNN

In Figure 8, each cycle corresponds to a current signal. At each state, 100 (300 in total) current signals are randomly selected to train and test the FNN model, and then 20 (60 in total) current signals are randomly selected from each stage to verify the accuracy of the FNN. The current signals extracted under each state of the HSV were decomposed, and the original signal was decomposed into eight frequency bands. The feature vectors under each state were obtained according to Equations (1) and (2).

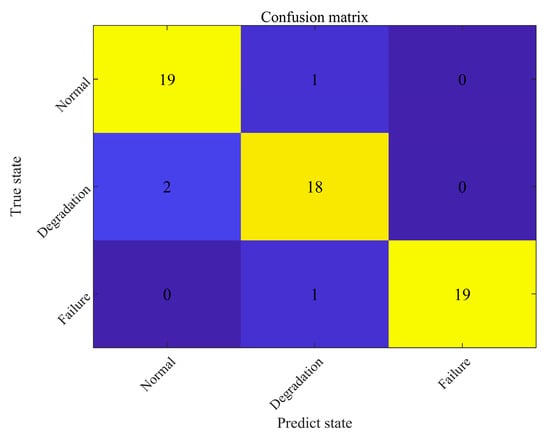

The number of neurons in the input layer of the FNN was equal to the number of eigenvalues in the training sample. Since there were eight eigenvalues for each feature vector, there were an equivalent number of neurons in the input layer. The number of input layer nodes, output layer nodes, and membership functions are 8, 1, and 18, respectively. The corresponding m and n in Figure 1c are 18 and 8, respectively. The training times, expected error, and learning rate η of the neural network were 6000, 0.1, and 0.001, respectively. Figure 10 shows the confusion matrix generated through enumeration of the output results of test sample data. From the figure, the number of correct classifications is displayed on the diagonal of the matrix. The FNN prediction accuracy of the state of the HSV was (19 + 18 + 19)/(19 + 1 + 2 + 18 + 1 + 19) = 93.3%. Therefore, the FNN could meet the requirements of degradation state detection.

Figure 10.

Confusion matrix of prediction and true states.

4.2. RUL Prediction Based on ARIMA–LSTM

The current study used the performance health index g of a water hydraulic HSV to predict the RUL of the valve. The data processing procedure that followed is described below.

- (1)

- Obtaining data: The initial degradation was regarded as the prediction starting cycle. The end prediction cycle was regarded to be the failure state of the HSV.

- (2)

- Data normalization processing: The performance degradation index g data were normalized so that the input value of the ARIMA–LSTM ranged between [0, 1]. This was done to allow faster and more stable convergence of the ARIMA–LSTM model. The normalization formula used was:where X is the original data, Xnorm is the normalized data, and Xmax and Xmin are the maximum and minimum value in the original data, respectively.

- (3)

- Data inverse normalization: Equation (22) was used when evaluating the model after training to restore (inversely normalize) the normalized data. This was done to evaluate the error of the predicted value of the model.

- (4)

- Estimation of prediction accuracy: The absolute error and relative error of RUL prediction of the HSV is used to quantitatively evaluate the prediction accuracy of the ARIMA–LSTM model:where RUL(ae) represents the absolute error of RUL, RUL(re) is the relative error of RUL, EOL is the operation cycle at end of life, EOP is the predicted operation cycle at end of life, and Kp is the operation cycle when the prediction begins.

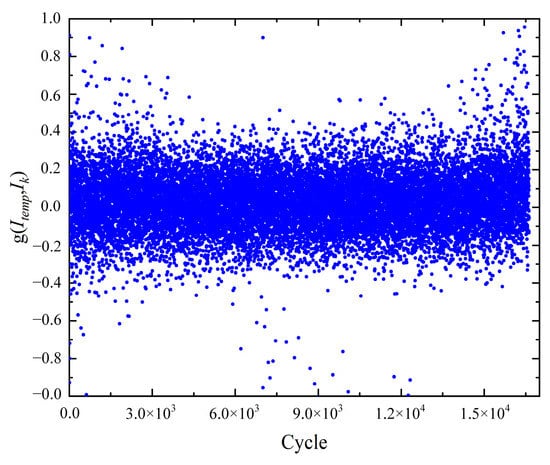

Within the use of the ARIMA model for prediction, the unit root test method is used to assess the stationarity and to determine parameter d for the ARIMA model. Figure 11 shows the sequence diagram of the original data after first-order difference processing. The results showed that the sequence data stabilized, except for individual noise points.

Figure 11.

Sequence diagram after first-order difference processing.

Table 2 shows the unit root test results. The statistical value of −118.8474 was less than the critical statistical value of three confidence levels (1%, 5%, 10%), and the p value was less than 0.05. Therefore, the difference coefficient of the ARIMA model (d) was 1.

Table 2.

Results of unit root test.

The AIC was used to determine p and q for the ARIMA model. The value of the AIC is inversely proportional to the fitting performance. However, the performance of the model is proportional to the model complexity, and the increase in the likelihood may also result in model over-fitting. The values of parameters were limited to [1, 10] to limit the scale of the model and to avoid over-fitting, and the most appropriate value was found through circulation. Table 3 shows the AIC values corresponding to different p and q. As shown in Table 3, a minimum AIC of −2.3043 was obtained under p and q of 8 and 9, respectively. Therefore, the determined model was ARIMA (8, 1, 9).

Table 3.

AIC values corresponding to different p and q.

The model code was written in the Matlab program language. The parameters of the LSTM model were determined and set according to experience and comparison of multiple residual experiments. The hidden layer comprised three layers, containing 30, 300, and 30 neurons, respectively, whereas the number of iteration epochs was 800. Dropout technology was used in model training to further prevent the occurrence of over-fitting. The loss rate of the experimental model was set to 0.2, i.e., 20% of the nodes were discarded in each weight update. The learning rate was set to 0.005.

This study predicted the RUL of an HSV using the ARIMA–LSTM model. When the prediction cycle was set as the start of the degradation state, MSE and RMSE were 0.8421 and 0.9177, respectively.

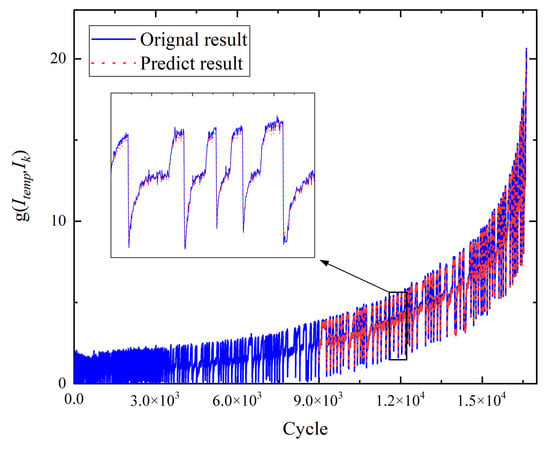

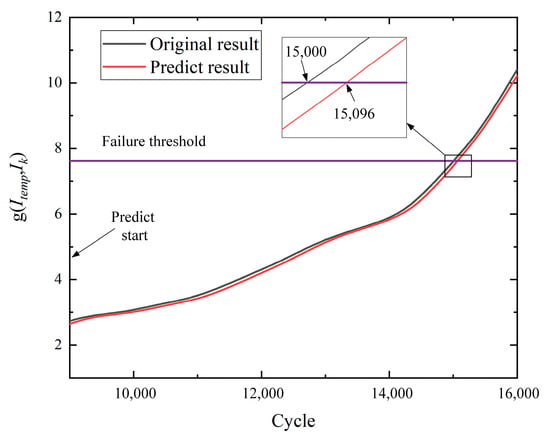

Figure 12 is the predicted and original value of the health index for the HSV. The results showed that the ARIMA–LSTM performed well in predicting the performance degradation trend of the HSV.

Figure 12.

Predicted value and original value.

Figure 13 shows the predicted curve after it was filtered. At HSV failure, the EOL was 15,000. The EOP was 15,096 when Kp was at the start of the degradation state. Therefore, the RUL(Kp), RUL(ae), and RUL(re) were 6096, 96, and 1.6%, respectively. Moreover, the predicted trajectory of the ARIMA–LSTM was consistent with the original trajectory.

Figure 13.

Prediction curve after filtered.

In summary, the relative error of RUL prediction of the hybrid model is less than 1.6%. The model can be used for guiding engineers in RUL forecasting.

4.3. Future Research Work

The present study conducted state detection and RUL prediction of an HSV applied to a water hydraulic manipulator using a data-driven method. The results of the present study can act as a reference for research into the degradation prognosis of HSVs. However, future research work is required to facilitate the full engineering application potential of the HSV. The simulation experiment tests conducted in the present study were in a laboratory environment. Since the HSV examined in the present study operates in a nuclear environment, the conditions of the laboratory may not reflect the complexity of the HSV working environment. This may lead to current waveform distortion and increased uncertainty during current signal acquisition and transmission. Therefore, future studies should collect a corresponding current signal under the actual working environment of a water hydraulic manipulator. In addition, reducing valve clogging or other methods can improve the reliability of the valve, which is also the future research direction of this study.

5. Conclusions

State detection and RUL prediction of an HSV applied to a water hydraulic manipulator present a complex challenge, and there is a non-linear relationship between states and manifestations. The present study proposed a hybrid model to detect the state and predict the RUL of water hydraulic HSVs used for water hydraulic manipulators. The major conclusions of the current study are outlined below:

- (1)

- An HSV current acquisition system was constructed. This system was used to analyze the current characteristics of the HSV under degrading performance. A health index was defined, and the entire life of the HSV can be defined as three states.

- (2)

- The current study proposed a state detection method for an HSV based on the FNN algorithm. A total of 300 groups of current signals were selected for neural network training and 60 groups of current signals were used for verification of the accuracy of the neural network. The state detection results showed the high accuracy of 93.3% based on the FNN algorithm.

- (3)

- A life prediction model of the HSV based on the ARIMA–LSTM model was constructed to predict the RUL of the HSV. The results showed that the ARIMA–LSTM model can accurately predict and track the degradation trend of an HSV, with a relative error of 1.6% for the predicted RUL of the HSV.

The developed method can provide guidance for operation and maintenance personnel to reasonably plan maintenance of water hydraulic HSVs used for water hydraulic manipulators.

Author Contributions

S.N. (Songlin Nie): methodology, supervision. Q.L.: investigation, data curation, writing—original draft preparation. H.J.: conceptualization, software. R.H.: software, data curation. S.N. (Shuang Nie): software, writing—reviewing and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant Nos. 51905011, 51975010, 52005013, 52075007). The authors are very grateful to the editors and the anonymous reviewers for their insightful comments and suggestions.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data included in this study are available upon request by contact with the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nieminen, P.; Esque, S.; Muhammad, A.; Mattila, J.; Väyrynen, J.; Siuko, M.; Vilenius, M. Water hydraulic manipulator for fail safe and fault tolerant remote handling operations at ITER. Fusion Eng. Des. 2009, 84, 1420–1424. [Google Scholar] [CrossRef]

- Zhao, W.; Song, Y.; Wu, H.; Cheng, Y.; Peng, X.; Li, Y.; Wei, J.; Mao, X. Concept design of the CFETR divertor remote handling system. Fusion Eng. Des. 2015, 98–99, 1706–1709. [Google Scholar] [CrossRef]

- Liu, Q.T.; Yin, F.L.; Nie, S.L.; Hong, R.D.; Ji, H. Multi-objective optimization of high-speed on-off valve based on surrogate model for water hydraulic manipulators. Fusion Eng. Des. 2021, 173, 112949. [Google Scholar]

- Watanabe, T.; Inayama, T.; Takeo, O. Design concept of small flow rate servo valve for water hydraulic system. In Proceedings of the International Symposium on System Integration, Tokyo, Japan, 29 January 2009; pp. 1–6. [Google Scholar]

- Linjama, M.; Laamanen, A.; Vilenius, M. Is it time for digital hydraulic? In Proceedings of the Eighth Scandinavian International Conference on Fluid Power, Tampere, Finland, 7–9 May 2003.

- de Camargo, A.P.; Molle, B.; Tomas, S.; Frizzone, J.A. Assessment of clogging effects on lateral hydraulics: Proposing a monitoring and detection protocol. Irrig. Sci. 2014, 32, 181–191. [Google Scholar] [CrossRef]

- Milecki, A.; Myszkowski, A. Modelling of electrohydraulic servo drive used in very low velocity applications. Int. J. Model. Identif. Control 2009, 7, 246–254. [Google Scholar] [CrossRef]

- Vogl, G.W.; Weiss, B.A.; Helu, M. A review of diagnostic and prognostic capabilities and best practices for manufacturing. J. Intell. Manuf. 2019, 30, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Ana, D.B.; Kima, N.H.; Choib, J.H. Practical options for selecting data-driven or physics-based prognostics algorithms with reviews. Reliab. Eng. Syst. Saf. 2015, 133, 223–236. [Google Scholar] [CrossRef]

- Huang, B.; Cohen, K.; Zhao, Q. Active anomaly detection in heterogeneous processes. IEEE Trans. Inf. Theory 2018, 65, 2284–2301. [Google Scholar] [CrossRef]

- Leturiondo, U.; Salgado, O.; Galar, D. Validation of a physics-based model of a rotating machine for synthetic data generation in hybrid diagnosis. Struct. Health Monit. 2017, 164, 458–470. [Google Scholar] [CrossRef]

- Eker, O.F.; Camci, F.; Jennions, I.K. Physics-based prognostic modelling of filter clogging phenomena. Mech. Syst. Signal. PR 2016, 75, 395–412. [Google Scholar] [CrossRef]

- El, B.A.; Boumhidi, I. Fuzzy model-based faults diagnosis of the wind turbine benchmark. Procedia Comput. Sci. 2018, 127, 464–470. [Google Scholar]

- Hashemnia, N.; Abu-Siada, A.; Islam, S. Improved power transformer winding fault detection using FRA diagnostics–Part 1: Axial displacement simulation. IEEE Trans. Dielectr. Electr. Insul. 2015, 221, 556–563. [Google Scholar] [CrossRef]

- Lu, Y.; Li, Q.; Liang, S.Y. Physics-based intelligent prognosis for rolling bearing with fault feature extraction. Int. J. Adv. Manuf. Technol. 2018, 97, 611–620. [Google Scholar] [CrossRef]

- Wang, T.; Lu, G.; Liu, J.; Yan, P. Graph-Based Change Detection for Condition Monitoring of Rotating Machines: Techniques for Graph Similarity. IEEE Trans. Reliab. 2018, 68, 1034–1049. [Google Scholar] [CrossRef]

- Deng, Y.F.; Du, S.C.; Jia, S.Y.; Zhao, C.; Xie, Z. Prognostic study of ball screws by ensemble data-driven particle filters. J. Manuf. Syst. 2020, 56, 359–372. [Google Scholar] [CrossRef]

- Wu, X.; Ye, Q. Fault diagnosis and prognostic of solid oxide fuel cells. J. Power Sources 2016, 321, 47–56. [Google Scholar] [CrossRef]

- Wang, C.; Lu, N.; Cheng, Y.; Jiang, B. A Data-Driven Aero-Engine Degradation Prognostic Strategy. IEEE Trans. Cybern. 2019, 51, 1531–1541. [Google Scholar] [CrossRef]

- Jin, X.; Que, Z.; Sun, Y.; Guo, Y.; Qiao, W. A Data-Driven Approach for Bearing Fault Prognostics. IEEE Trans. Ind. Appl. 2019, 55, 3394–3401. [Google Scholar] [CrossRef]

- Wang, Y.; Peng, Y.; Zi, Y.; Jin, X.; Tsui, K.-L. A Two-Stage Data-Driven-Based Prognostic Approach for Bearing Degradation Problem. IEEE Trans. Ind. Inform. 2016, 12, 924–932. [Google Scholar] [CrossRef]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, B.; Lu, N. Adaptive relevant vector machine based RUL prediction under uncertain conditions. ISA Trans. 2018, 87, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Li, X.Y.; Yuan, C.G.; Wang, Z.P. Multi-time-scale framework for prognostic health condition of lithium battery using modified gaussian process regression and nonlinear regression. J. Power Sources 2020, 467, 228358. [Google Scholar] [CrossRef]

- Li, D.; Yang, L. Remaining Useful Life Prediction of Lithium Battery Based on Sequential CNN–LSTM Method. J. Electrochem. Energy Convers. Storage 2021, 18, 041005. [Google Scholar] [CrossRef]

- Deng, Z.W.; Hu, X.S.; Lin, X.K.; Xu, L.; Che, Y.; Hu, L. General discharge voltage information enabled health evaluation for lithium-ion batteries. IEEE/ASME Trans. Mechatron. 2020, 26, 1295–1306. [Google Scholar] [CrossRef]

- Kalasinsky, V.F.; Johnson, F.B.; Ferwerda, R. Fourier transform infrared and Raman microspectroscopy of materials in tissue. Cell. Mol. Biol. 1998, 44, 141–144. [Google Scholar] [PubMed]

- Wang, C.; Gan, M.; Zhu, C.A. Fault feature extraction of rolling element bearings based on wavelet packet transform and sparse representation theory. J. Intell. Manuf. 2018, 29, 937–951. [Google Scholar] [CrossRef]

- Yang, Y.; Ulrike, D.; Li, J.C.; Ernst, N. Wavelet packet energy–based damage identification of wood utility poles using support vector machine multi-classifier and evidence theory. Struct. Health Monit. 2019, 18, 123–142. [Google Scholar]

- Sun, Y.K.; Cao, Y.; Li, P. Fault diagnosis for train plug door using weighted fractional wavelet packet decomposition energy entropy. Accid. Anal. Prev. 2022, 166, 106549. [Google Scholar] [CrossRef]

- Utah, M.N.; Jung, J.C. Fault state detection and remaining useful life prediction in AC powered solenoid operated valves based on traditional machine learning and deep neural networks. Nucl. Eng. Technol. 2020, 52, 1998–2008. [Google Scholar] [CrossRef]

- Arun, K.; Nikita, K. Fuzzy neural network for pattern classification. Procedia Comput. Sci. 2020, 167, 2606–2616. [Google Scholar]

- Zou, A.J.; Deng, R.; Mei, Q.X.; Zou, L. Fault diagnosis of a transformer based on polynomial neural networks. Clust. Comput. 2019, 22, 9941–9949. [Google Scholar] [CrossRef]

- Wang, X.Y.; Li, Z.L. Research on Fault Prediction of Signal Maintenance Support Subsystem Based on Fuzzy Neural Network. Process Autom. Instrum. 2022, 43, 59–62. (In Chinese) [Google Scholar]

- Fan, D.Y.; Sun, H.; Yao, J.; Zhang, K.; Yan, X.; Sun, Z. Well production forecasting based on ARIMA-LSTM model considering manual operations. Energy 2021, 220, 119708. [Google Scholar] [CrossRef]

- Zhou, Y.; Wei, G.F.; Liu, Y.N.; Zhang, G.X. Research on driving current prediction method based on ARIMA. J. Phys. Conf. Ser. 2021, 1865, 022044. [Google Scholar] [CrossRef]

- Deng, Y.M.; Fan, H.F.; Wu, S.M. A hybrid ARIMA-LSTM model optimized by BP in the forecast of outpatient visits. J. Ambient Intell. Humaniz. Comput. 2020, 1–11. [Google Scholar] [CrossRef]

- Abebe, M.; Noh, Y.; Kang, Y.-J.; Seo, C.; Kim, D.; Seo, J. Ship trajectory planning for collision avoidance using hybrid ARIMA-LSTM models. Ocean Eng. 2022, 256, 111527. [Google Scholar] [CrossRef]

- Mbah, T.J.; Ye, H.W.; Zhang, J.H.; Long, M. Using LSTM and ARIMA to Simulate and Predict Limestone Price Variations. Min. Met. Explor. 2021, 38, 913–926. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.H.; Zhang, Q.; Ding, Y.; Zhang, D. Application of a hybrid ARIMA-LSTM model based on the SPEI for drought forecasting. Environ. Sci. Pollut. Res. 2021, 29, 4128–4144. [Google Scholar] [CrossRef] [PubMed]

- Dave, E.; Leonardo, A.; Jeanice, M.; Hanafiah, N. Forecasting Indonesia Exports using a Hybrid Model ARIMA-LSTM. Procedia Comput. Sci. 2021, 179, 480–487. [Google Scholar] [CrossRef]

- Tang, X.L.; Xiao, M.Q.; Hu, B. Application of Kalman filter to Model-based Prognostics for Solenoid Valve. Soft Comput. 2020, 24, 5741–5753. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).