A Semantic Model in the Context of Maintenance: A Predictive Maintenance Case Study

Abstract

:1. Introduction

Scope of the Paper

2. Motivation for Implementing Semantic Technologies toward Industry 4.0

- The documents and guidelines depicting the use of datasets may be corrupted or lost.

- Often, a data description disaccords with its field name.

- It is hard to manage tabular datasets or update their data schemas.

3. State of the Art on Ontologies

3.1. Ontology-Based Knowledge Representation and Relevant Efforts for Maintenance

3.2. Semantic Interoperability in Smart Manufacturing

3.3. Semantic Technologies and Ontologies for Predictive Maintenance

3.4. Research Gap

4. Two-Cycle Methodology to Build a Semantic Model

4.1. The Vocabulary Cycle

- In each use case, which machines are considered?

- For each use case, what stakeholders and/or actors are considered?

- For each machine, what is the bill of materials (represented as a hierarchy diagram)?

- In a specific use case, which component is critical for the management of assets?

- For each critical component, what are the failure modes?

- For each failure mode, what are the effects?

- For each failure mode, what is the criticality?

- Before the failure, what actions are needed?

- After the failure, what actions are needed?

- Which sensors are required for each critical component?

- Which critical components are associated with a sensor?

- For any sensor, what signals are collected?

- Each System as a maintainable item plays its own Role, and the Role of the System inheres in Maintenance_Proccess_Definition

- Each System consists of the System_part and the Embedded Data-Source_Component

- The Embedded Data-Source_Component generates the Source_Data

- Each System_part has a Quality, a Failure_Mode, and an Indicator showing performance

- Each Failure_Mode has a Failure_Symptom and an Indicator presenting its risk, probability, and so on

- Depending on the condition, the System requires Maintenance

- The Product_Provider provides the System

- The Maintenance_Service_Provider provides the Maintenance_Process_Definition

- The Business_Customer owns the System

4.2. The Context Cycle

- Single nouns should be used (except “data”).

- Acronyms should be avoided.

- Univocity of terms and relational expression should be ensured.

- General should be distinguished from particular.

- All non-root terms should be provided with their definitions.

- Key features should be used to define terms and avoid circularity.

- The most generic terms of the domain should be defined first.

- Simpler terms should be used in comparison to the term being defined (to ensure intelligibility).

- Creating terms for universals through logical combinations should be avoided.

- The ontology should be structured around an “is_a” hierarchy, and completeness of “is_a” must be ensured.

- Single inheritance should be ensured.

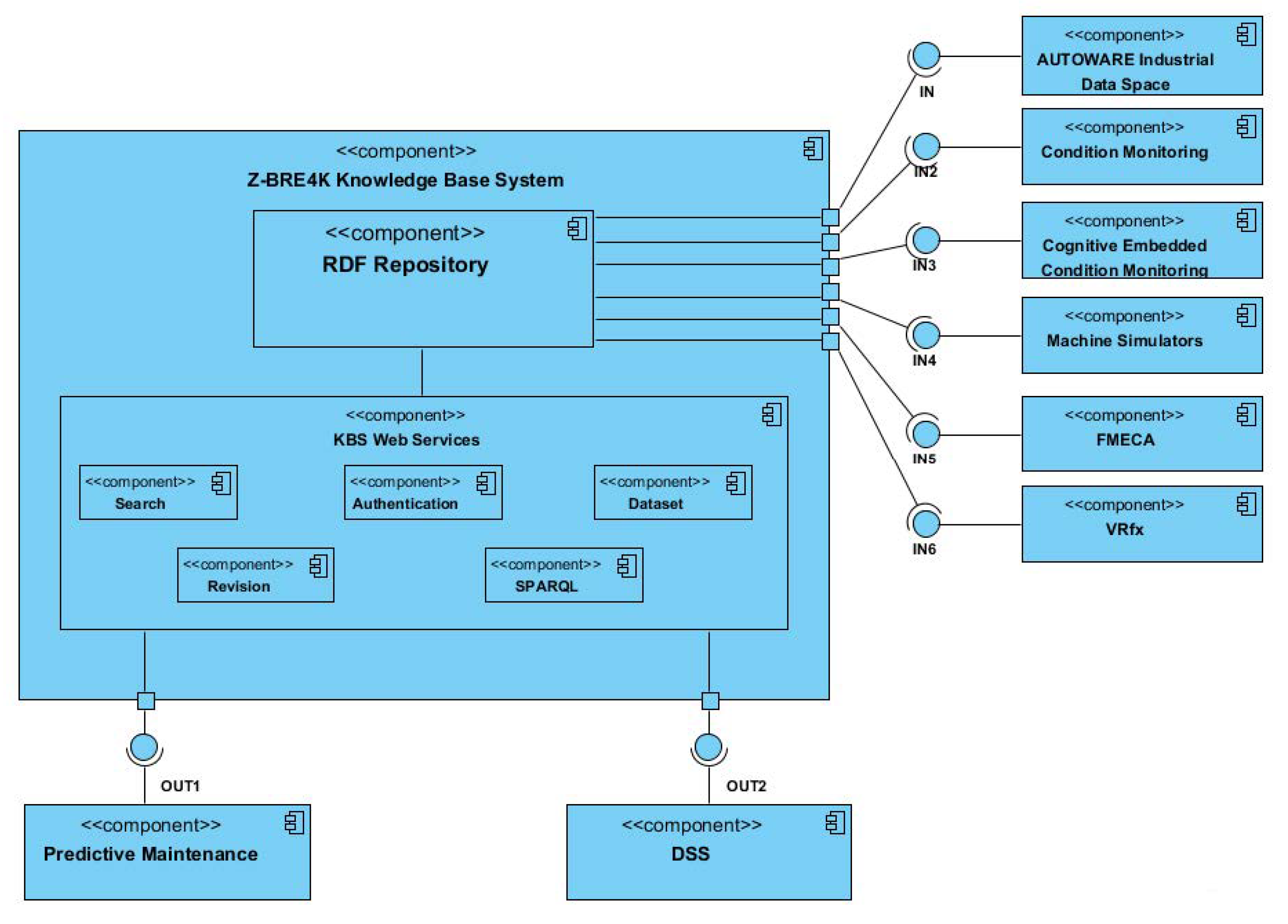

5. Maintenance Ontology and Implementation

5.1. Entities of the Maintenance Ontology

- System breakdown to major subsystems that include functional relationships

- Properly tagged inputs and outputs and identification numbers to consistently reference each subsystem

- Redundancies, alternative signal paths, and key engineering features that facilitate protection against system failures

5.2. Implementation of the Maintenance Ontology

- The competency question methodology proved to be a useful tool for meeting the requirements of stakeholders in the domain field. Future efforts to develop ontologies for smart manufacturing applications should consider this method to standardize the ontology design and development process.

- The BFO framework was successfully implemented to create ontologies in the maintenance engineering domain, and other domains should follow (e.g., zero-defect manufacturing, product-service systems, energy-efficient manufacturing).

- Ontology engineering requires iterative processes. Hence, updates to the classes and their relationships from iterative feedback from end-users and technical providers in different use cases may help developers consolidate the ontology for application to further scenarios.

6. Discussion and Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Class Name | Definition |

|---|---|

| Independent_Continuant | Independent_Continuant (see BFO) |

| Material_Entity | Material_Entity (see BFO) |

| System | The System is a Material_Entity which is a universal set of the target system |

| System_Component | Product Component is a Material Entity which is a part of the System. |

| System_Part | The System_Part is a System_Component which are a modularity subset of the system |

| Embedded_Data-Source_Component | Embedded Data-Source Component is a Product Component that refers to product-embedded information devices/parts (e.g., sensors), which allows for (additional) services to be offered for the product. |

| Stakeholder | Stakeholder/Actor is an entity that describes the humans (or beings) involved in a business scenario (development, deployment, use etc.). |

| Individual_Person | Individual Person is a Stakeholder indicating a separate person who is not a legal entity (i.e., not legally considered a corporate group, as for example a company). |

| Individual_Customer | Individual Customer is an Individual Person that buys or consumes (consumer) any product/maintenance service. |

| Employee | An employee is an Individual Person that works in a Company in the domain. |

| Company | Company is a Stakeholder that can be one or more individuals forming a legal entity (corporate body). |

| Business_Customer | Business Customer is a Company that buys and uses the products, and maintenance services. It is the (group/company) customer of the system, using the system for their own business. |

| Product_Provider | Product Provider is a Supplier/provider/vendor that both produces and sells a product or only sells it. |

| Maintneance_Service_Provider | Service_Provider is a Supplier/provider/vendor that offers a maintenance service. |

| Generally_Dependent_Continuant | Generally Dependent Continuant (see BFO) |

| Resource_Entity | Resource_Entity is a mean (source) that can be used for the design, development, offer and delivery of a PSS, from which benefit can be produced. |

| Source_Data | Source-Data is a Resource_Entity that refers to the digitalised information coming as input from the product or the service, specifically for the scope of Project. |

| Product_Data | Product Data are Source_Data used in the scope of the product and refer specifically to the system part. |

| Embedded_Data | Embedded Data is Product Data generated from embedded data-source components. |

| Digital_Log_Data | Digital Log Data is Product Data generated from a software element, part of the product. |

| Information_Entity | Information_Entity is a Resource, immaterial, describing aspects affecting Project, and referring to all the (processed) data that one can acquire knowledge from, or further process. |

| Indicator | The Indicator is an Information_Entity which is an observed value indicating the state or level of something |

| Key_Performance_Parameter | The Key_Performance_Parameter is an indicator to measure the performance of each mode at time t |

| Key_Risk_Indicator | The Key_Risk_Indicator is an indicator of risk exposures to address potential warning events |

| Risk_Probability_Indicator | The Risk Probability Indicator is an indicator which is a frequency of occurrence of Failure_Effect |

| Severity_Indicator | The Severity Indicator is an indicator of how serious and destructive a failure mode is |

| Detection_Indicator | The Detection_Indicator is a numerical subjective estimation of the effectiveness of the controls to prevent or detect the cause or failure mode before the failure (Threshold?) |

| Risk_Indicator | The Risk is an indicator multiplying Probability Indicator by Severity Indicator of the failure |

| Risk_Priority_Number | The Risk Priority Number is an indicator multiplying Risk Indicator by Detection Indicator of the failure |

| Failure_Symptom | The Failure_Symptom is a Failure_Mechanism_Entity which is a physical feature that is regarded as indicating a condition of the failure |

| System_Failure_Symptom | The System_Failure_Symptom is a Failure_Symptom described in the level of System |

| System_Part_Failure_Symptom | The Subystem_Failure_Symptom is a Failure_Symptom described in the level of System_Part |

| Process_Definition | Process Definition is a structured set of activities designed to accomplish a specific objective. For example, the Process Definition can be the manufacturing process where the equipment is manufactured, or the process where the equipment is used, or the development process where products and maintenance services are being developed etc. |

| Maintenance_Process_Definition | Maintenance Process Definition is a Process Definition referring to a set of non-tangible entities (activities, software modules etc.), related to the maintenance service part, which aims to satisfy a need of the end-users. |

| Predictive_Maintenance_Process_Definition | The Predictive_Maintenance_Process_Definition is a Maintenance_Process_Definition to prevent failures by monitoring |

| Correntive_Maintenance_Process_Definition | The Correntive_Maintenance_Process_Definition is a Maintenance_Process_Definition to correct failures after break down or malfunction |

| Specifically_Dependent_Countinuant | Specifically Dependent Continuant (See BFO) |

| Realisable_Entity | Realisable Entity (See BFO) |

| Failure_Mechanism_Entity | Failure_Mechanism_Entity |

| Failure_Cause | The Failure_Cause is a Failure_Mechanism_Entity which is a defect in design, process, quality, or part application, which are the underlying cause of a failure or which initiate a process which leads to failure. |

| System_Failure_Cause | The System_Failure_Cause is a Failure_Cause described in the level of System |

| System_Part_Failure_Mode | The System_Part_Failure_Mode is a Failure_Cause described in the level of System_Part |

| Quality | Quality (See BFO) |

| Current_Quality | The Current_Quality is a Quality at time t. If they inhere in an entity at all, they are fully exhibited or manifested or realized in that entity. |

| Current_System_Quality | The Current_Quality is a Quality of a System entity at time t. |

| Current_System_Part_Quality | The Current_System_Part_Quality is a Quality of a System_Part entity at time t. |

| Predicted_Quality | The Predicted_Quality is a predicted Quality at future time t. |

| Predictied_System_Quality | The Predictied_System_Quality is a Quality of a System entity at future time t. |

| Predictied_System_Part_Quality | The Predictied_System_Part_Quality is a Quality of a System_Part entity at future time t. |

| Role | (See BFO) |

| System_Role | borne by a group of one or more System(s) by Maintenance_Process_Definition |

| System_Part_Role | borne by a group of one or more System_Part(s) by Maintenance_Process_Definition |

| Embedded_Data-Source_Component_Role | borne by a group of one or more Embedded_Data-Source_Component(s) by Maintenance_Process_Definition |

| Processual_Entity | See BFO |

| Maintenance | Maintenance is a Process made for, and driven by customers, with economic value, and refers to the maintenance Offer entity in conjunction with time t. |

| System Components | Description of Failure Mode | Failure Symptom |

|---|---|---|

| Plastic extruder screw motor | motor is worn | stop the machines (no polymer provided in machine) |

| motor bearing is damaged | local abnormal heating local abnormal noise/vibrations | |

| Pump motor | motor is worn | stop the machines (no polymer provided in machine) |

| motor bearing is damaged | local abnormal heating local abnormal noise/vibrations | |

| Screw gearbox | Wear | local abnormal noise/vibration |

| broken | stop the machines (no polymer provided in machine) | |

| Pump gearbox | Wear | local abnormal noise/vibration |

| broken | stop the machines (no polymer provided in machine) | |

| Pump | wear (teeth and bearing) | abnormal flow rate and pressure local abnormal noise/vibration |

| broken | stop the machines (no polymer provided in machine) | |

| Polymer | wrong composition | abnormal process conditions (flow rate, temperatures, pressures) |

| presence of humidity within the polymer | abnormal process conditions (flow rate, temperatures, pressures) | |

| Bypass valve | Block | stop the machines (no polymer provided in machine) |

| starts sticking | increase in the switching time incomplete switching of the valve increase in the pump outbound pressure | |

| Cooling_fans | motor is worn | abnormal temperature regulations (no airflow provided) |

| motor bearing is damaged | abnormal temperature regulations (different amount of airflow provided) | |

| Mixer | broken | thermal drift of the melted polymer irregular color mixing |

| Heaters | burns itself | abnormal temperature regulations (different heating provided) |

| Screw | Wear | increase in the screw speed abnormal melt pressure fluctuation abnormal flow rate fluctuation abnormal melt temperature abnormal temperature regulations |

| Cylinder | wear | increase in the screw speed; abnormal melt pressure fluctuation; abnormal flow rate fluctuation; abnormal melt temperature; abnormal temperature regulations |

| Object Property | Domain | Range |

|---|---|---|

| has_System_Part | System | System_Part |

| has_System_Failure_Cause | System_Role | System_Failure_Cause |

| has_System_Part_Failure_Mode | System_Part_Role | System_Part_Failure_Mode |

| effects_System_Failure_Cause | System_Part_Failure_Mode | System_Failure_Cause |

| has_System_Failure_Symptom | System_Failure_Cause | System_Failure_Symptom |

| has_System_Part_Failure_Symptom | System_Part_Failure_Mode | System_Part_Failure_Symptom |

| has_Embedded_Data-Source_Component_of_System_Part | System_Part | Embedded_Data-Source_Component |

| generates_Embedded_Data | Embedded_Data-Source_Component | Embedded_Data |

| inheres_in_System_of_Current_System_Quality | Current_System_Quality | System |

| inheres_in_System_Part_of_Current_System_Part_Quality | Current_System_Part_Quality | System_Part |

| inheres_in_System_of_Predictied_System_Quality | Predictied_System_Quality | System |

| inheres_in_System_Part_of_Predictied_System_Part_Quality | Predictied_System_Part_Quality | System_Part |

| has_System_Failure_Cause_of_Current_System_Quality | Current_System_Quality | System_Failure_Cause |

| has_System_Part_Failure_Mode_of_Current_System_Part_Quality | Current_System_Part_Quality | System_Part_Failure_Mode |

| has_System_Failure_Cause_of_Predictied_System_Quality | Predictied_System_Quality | System_Failure_Cause |

| has_System_Part_Failure_Mode_of_Predictied_System_Part_Quality | Predictied_System_Part_Quality | System_Part_Failure_Mode |

| has_Detection_Indicator_of_System_Failure_Cause | System_Failure_Cause | Detection_Indicator |

| has_Detection_Indicator_of_System_Part_Failure_Mode | System_Part_Failure_Mode | Detection_Indicator |

| has_Key_Performance_Parameter_of_System | System | Key_Performance_Parameter |

| has_Key_Performance_Parameter_of_System_Part | System_Part | Key_Performance_Parameter |

| has_Key_Risk_Indicator_of_System_Failure_Cause | System_Failure_Cause | Key_Risk_Indicator |

| has_Key_Risk_Indicator_of_System_Part_Failure_Mode | System_Part_Failure_Mode | Key_Risk_Indicator |

| has_Risk_Probability_Indicator_of_System_Failure_Cause | System_Failure_Cause | Risk_Probability_Indicator |

| has_Risk_Probability_Indicator_of_System_Part_Failure_Mode | System_Part_Failure_Mode | Risk_Probability_Indicator |

| has_Severity_Indicator_of_System_Failure_Cause | System_Failure_Cause | Severity_Indicator |

| has_Severity_Indicator_of_System_Part_Failure_Mode | System_Part_Failure_Mode | Severity_Indicator |

| inheres_in_Risk_Probability_Indicator | Risk_Indicator | Risk_Probability_Indicator |

| inheres_in_Severity_Indicator | Risk_Indicator | Severity_Indicator |

| inheres_in_Risk_Indicator | Risk_Priority_Number | Risk_Indicator |

| inheres_in_Detection_Indicator | Risk_Priority_Number | Detection_Indicator |

| requires_Maintenance_of_System | System | Maintenance |

| requires_Maintenance_of_System_Part | System_Part | Maintenance |

| requires_Predictive_Maintenance_Process_Definition_of_System_Failure_Symptom | System_Failure_Symptom | Predictive_Maintenance_Process_Definition |

| requires_Predictive_Maintenance_Process_Definition_of_System_Part_Failure_Symptom | System_Part_Failure_Symptom | Predictive_Maintenance_Process_Definition |

| requires_Correntive_Maintenance_Process_Definition_of_System_Failure_Symptom | System_Failure_Symptom | Correntive_Maintenance_Process_Definition |

| requires_Correntive_Maintenance_Process_Definition_of_System_Part_Failure_Symptom | System_Part_Failure_Symptom | Correntive_Maintenance_Process_Definition |

| provides_Predictive_Maintenance_Process_Definition | Maintneance_Service_Provider | Predictive_Maintenance_Process_Definition |

| provides_Correntive_Maintenance_Process_Definition | Maintneance_Service_Provider | Correntive_Maintenance_Process_Definition |

| provides_System | Product_Provider | System |

| owns_System | Business_Customer | System |

| owns_System | Individual_Customer | System |

| works_in_Product_Provider | Employee | Product_Provider |

| works_in_Maintneance_Service_Provider | Employee | Maintneance_Service_Provider |

| has_System_Role | System | System_Role |

| has_System_Part_Role | System_Part | System_Part_Role |

| has_Embedded_Data-Source_Component_Role_of_Embedded_Data-Source_Component | Embedded_Data-Source_Component | Embedded_Data-Source_Component_Role |

| inheres_in_Predictive_Maintenance_Process_Definition_of_System_Role | System_Role | Predictive_Maintenance_Process_Definition |

| inheres_in_Predictive_Maintenance_Process_Definition_of_System_Part_Role | System_Part_Role | Predictive_Maintenance_Process_Definition |

| inheres_in_Predictive_Maintenance_Process_Definition_of_Embedded_Data-Source_Component_Role | Embedded_Data-Source_Component_Role | Predictive_Maintenance_Process_Definition |

| inheres_in_Correntive_Maintenance_Process_Definition_of_System_Role | System_Role | Correntive_Maintenance_Process_Definition |

| inheres_in_Correntive_Maintenance_Process_Definition_of_System_Part_Role | System_Part_Role | Correntive_Maintenance_Process_Definition |

| consists_of_System_Part_Role_of_System_Role | System_Role | System_Part_Role |

| consists_of_Embedded_Data-Source_Component_Role_of_System_Role | System_Role | Embedded_Data-Source_Component_Role |

| realized_in_Embedded_Data-Source_Component_Role_of_System_Part_Failure_Mode | System_Part_Failure_Mode | Embedded_Data-Source_Component_Role |

References

- May, G.; Stahl, B.; Taisch, M. Energy management in manufacturing: Toward eco-factories of the future—A focus group study. Appl. Energy 2016, 164, 628–638. [Google Scholar] [CrossRef]

- Selcuk, S. Predictive maintenance, its implementation and latest trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Mobley, R.K. An Introduction to Predictive Maintenance, 2nd ed.; Butterworth-Heinemann: Amsterdam, The Netherlands; New York, NY, USA, 2002. [Google Scholar]

- Zonta, T.; da Costa, C.A.; Righi, R.D.R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.D.P.; Basto, J.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Ayvaz, S.; Alpay, K. Predictive maintenance system for production lines in manufacturing: A machine learning approach using IoT data in real-time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Roda, I.; Macchi, M. Maintenance concepts evolution: A comparative review towards Advanced Maintenance conceptualization. Comput. Ind. 2021, 133, 103531. [Google Scholar] [CrossRef]

- Cheng, J.C.; Chen, W.; Chen, K.; Wang, Q. Data-driven predictive maintenance planning framework for MEP components based on BIM and IoT using machine learning algorithms. Autom. Constr. 2020, 112, 103087. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Li, D.; Wang, S.; Liu, C.; Abbas, H.; Vasilakos, A.V. A Manufacturing Big Data Solution for Active Preventive Maintenance. IEEE Trans. Ind. Inform. 2017, 13, 2039–2047. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E. A cloud-based cyber-physical system for adaptive shop-floor scheduling and condition-based maintenance. J. Manuf. Syst. 2018, 47, 179–198. [Google Scholar] [CrossRef]

- Cho, S.; May, G.; Kiritsis, D. A Predictive Maintenance Approach Toward Industry 4.0 Machines. In Engineering Assets and Public Infrastructures in the Age of Digitalization, Lecture Notes in Mechanical Engineering; Liyanage, J.P., Amadi-Echendu, J., Mathew, J., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 646–652. [Google Scholar] [CrossRef]

- May, G.; Kyriakoulis, N.; Apostolou, K.; Cho, S.; Grevenitis, K.; Kokkorikos, S.; Milenkovic, J.; Kiritsis, D. Predictive Maintenance Platform Based on Integrated Strategies for Increased Operating Life of Factories. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0, IFIP Advances in Information and Communication Technology; Moon, I., Lee, G.M., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 279–287. [Google Scholar] [CrossRef]

- Van Staden, H.E.; Deprez, L.; Boute, R.N. A dynamic “predict, then optimize” preventive maintenance approach using operational intervention data. Eur. J. Oper. Res. 2022, 302, 1079–1096. [Google Scholar] [CrossRef]

- Cao, Q.; Zanni-Merk, C.; Samet, A.; Reich, C.; Beuvron, F.D.B.D.; Beckmann, A.; Giannetti, C. KSPMI: A Knowledge-based System for Predictive Maintenance in Industry 4.0. Robot. Comput. Manuf. 2022, 74, 102281. [Google Scholar] [CrossRef]

- Cho, S.; May, G.; Tourkogiorgis, I.; Perez, R.; Lazaro, O.; de la Maza, B.; Kiritsis, D. A Hybrid Machine Learning Approach for Predictive Maintenance in Smart Factories of the Future. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0, IFIP Advances in Information and Communication Technology; Moon, I., Lee, G.M., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 311–317. [Google Scholar] [CrossRef]

- Reina, A.; Cho, S.-J.; May, G.; Coscia, E.; Cassina, J.; Kiritsis, D. Maintenance Planning Support Tool Based on Condition Monitoring with Semantic Modeling of Systems. In Enterprise Interoperability; Zelm, M., Jaekel, F.-W., Doumeingts, G., Wollschlaeger, M., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 271–276. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput.-Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Montero Jimenez, J.J.; Schwartz, S.; Vingerhoeds, R.; Grabot, B.; Salaün, M. Towards multi-model approaches to predictive maintenance: A systematic literature survey on diagnostics and prognostics. J. Manuf. Syst. 2020, 56, 539–557. [Google Scholar] [CrossRef]

- Cho, S.; May, G.; Kiritsis, D. A Semantic-driven Approach for Industry 4.0. In Proceedings of the IEEE 2019 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini Island, Greece, 29–31 May 2019; pp. 347–354. [Google Scholar] [CrossRef]

- Cho, S.; Hildebrand-Ehrhardt, M.; May, G.; Kiritsis, D. Ontology for Strategies and Predictive Maintenance models. IFAC-PapersOnLine 2020, 53, 257–264. [Google Scholar] [CrossRef]

- Bloch, T.; Sacks, R. Comparing machine learning and rule-based inferencing for semantic enrichment of BIM models. Autom. Constr. 2018, 91, 256–272. [Google Scholar] [CrossRef]

- Nilsson, J.; Sandin, F. Semantic Interoperability in Industry 4.0: Survey of Recent Developments and Outlook. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 127–132. [Google Scholar] [CrossRef]

- Madugula, L. Applications of IoT in Manufacturing: Issues and Challenges. J. Adv. Res. Embed. Syst. 2021, 8, 3–7. [Google Scholar] [CrossRef]

- Dogan, A.; Birant, D. Machine learning and data mining in manufacturing. Expert Syst. Appl. 2021, 166, 114060. [Google Scholar] [CrossRef]

- Mami, M.N.; Grangel-González, I.; Graux, D.; Elezi, E.; Lösch, F. Semantic data integration for the SMT manufacturing process using SANSA stack. In European Semantic Web Conference; Springer: Cham, Switzerland, 2020; pp. 307–311. [Google Scholar]

- Ahmadi, A.; Moradi, M.; Cherifi, C.; Cheutet, V.; Ouzrout, Y. Wireless connectivity of CPS for smart manufacturing: A survey. In Proceedings of the IEEE 2018 12th International Conference on Software, Knowledge, Information Management & Applications (SKIMA), Phnom Penh, Cambodia, 3–5 December 2018; pp. 1–8. [Google Scholar]

- Wang, J.; Xu, C.; Zhang, J.; Zhong, R. Big data analytics for intelligent manufacturing systems: A review. J. Manuf. Syst. 2021, 62, 738–752. [Google Scholar] [CrossRef]

- Kendall, E.F.; McGuinness, D.L. Ontology Engineering; Synthesis Lectures on the Semantic Web: Theory and Technology; Morgan & Claypool: San Rafael, CA, USA, 2019; pp. 1–136. [Google Scholar]

- Tudorache, T. Ontology engineering: Current state, challenges, and future directions. Semant. Web 2020, 11, 125–138. [Google Scholar] [CrossRef]

- Hashemi, P.; Khadivar, A.; Shamizanjani, M. Developing a domain ontology for knowledge management technologies. Online Inf. Rev. 2018, 42, 28–44. [Google Scholar] [CrossRef]

- James, A.T.; Gandhi, O.; Deshmukh, S. Knowledge management of automobile system failures through development of failure knowledge ontology from maintenance experience. J. Adv. Manag. Res. 2017, 14, 425–445. [Google Scholar] [CrossRef]

- Wan, S.; Li, D.; Gao, J.; Roy, R.; Tong, Y. Process and knowledge management in a collaborative maintenance planning system for high value machine tools. Comput. Ind. 2017, 84, 14–24. [Google Scholar] [CrossRef]

- Liang, J.S. A process-based automotive troubleshooting service and knowledge management system in collaborative environment. Robot. Comput.-Integr. Manuf. 2020, 61, 101836. [Google Scholar] [CrossRef]

- Polenghi, A.; Roda, I.; Macchi, M.; Pozzetti, A. Ontology-augmented Prognostics and Health Management for shopfloor-synchronised joint maintenance and production management decisions. J. Ind. Inf. Integr. 2021, 27, 100286. [Google Scholar] [CrossRef]

- Ullah, F.; Habib, M.A.; Farhan, M.; Khalid, S.; Durrani, M.Y.; Jabbar, S. Semantic interoperability for big-data in heterogeneous IoT infrastructure for healthcare. Sustain. Cities Soc. 2017, 34, 90–96. [Google Scholar] [CrossRef]

- Adamczyk, B.S.; Szejka, A.L.; Canciglieri, O. Knowledge-based expert system to support semantic interoperability in smart manufacturing. Comput. Ind. 2020, 115, 103161. [Google Scholar] [CrossRef]

- Weichhart, G.; Panetto, H.; Molina, A. Interoperability in the cyber-physical manufacturing enterprise. Annu. Rev. Control. 2021, 51, 346–356. [Google Scholar] [CrossRef]

- Margaria, T.; Steffen, B. (Eds.) The interoperability challenge: Building a model-driven digital thread platform for CPS. Lecture Notes in Computer Science. In Leveraging Applications of Formal Methods, Verification and Validation, Proceedings of the 10th International Symposium on Leveraging Applications of Formal Methods, ISoLA 2021, Rhodes, Greece, 17–29 October 2021; Springer International Publishing: Cham, Switzerland, 2021; pp. 393–413. [Google Scholar] [CrossRef]

- Canito, A.; Corchado, J.; Marreiros, G. Bridging the Gap between Domain Ontologies for Predictive Maintenance with Machine Learning. In Trends and Applications in Information Systems and Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 533–543. [Google Scholar] [CrossRef]

- Cao, Q.; Giustozzi, F.; Zanni-Merk, C.; Beuvron, F.D.B.D.; Reich, C. Smart Condition Monitoring for Industry 4.0 Manufacturing Processes: An Ontology-Based Approach. Cybern. Syst. 2019, 50, 82–96. [Google Scholar] [CrossRef]

- Cao, Q.; Samet, A.; Zanni-Merk, C.; Beuvron, F.D.B.D.; Reich, C. Combining chronicle mining and semantics for predictive maintenance in manufacturing processes. Semant. Web 2020, 11, 927–948. [Google Scholar] [CrossRef]

- Grüninger, M.; Fox, M.S. (Eds.) The role of competency questions in enterprise engineering. IFIP Advances in Information and Communication Technology. In Benchmarking—Theory and Practice; Springer: Boston, MA, USA, 1995; pp. 22–31. [Google Scholar] [CrossRef]

- Noy, N.F.; McGuinness, D.L. Ontology Development 101: A Guide to Creating Your First Ontology. 2001. Available online: https://corais.org/sites/default/files/ontology_development_101_aguide_to_creating_your_first_ontology.pdf (accessed on 14 June 2022).

- Arp, R.; Smith, B.; Spear, A.D. Building Ontologies with Basic Formal Ontology; Massachusetts Institute of Technology: Cambridge, MA, USA, 2015. [Google Scholar]

- IOF PSS Ontology. Available online: https://www.industrialontologies.org/product-service-system-wg/ (accessed on 14 June 2022).

- Carmignani, G. An integrated structural framework to cost-based FMECA: The priority-cost FMECA. Reliab. Eng. Syst. Saf. 2009, 94, 861–871. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Analysis Techniques for System Reliability: Procedure for Failure Mode and Effects Analysis (FMEA); International Electrotechnical Commission: Geneva, Switzerland, 2006. [Google Scholar]

- Z-BRE4K Project. Available online: https://www.z-bre4k.eu/ (accessed on 14 June 2022).

- ISO 14224; Petroleum, Petrochemical and Natural Gas Industries—Collection and Exchange of Reliability and Maintenance Data for Equipment, 2nd ed. ISO (International Organization for Standardization): Geneva, Switzerland, 2006.

- Rousopoulou, V.; Vafeiadis, T.; Nizamis, A.; Iakovidis, I.; Samaras, L.; Kirtsoglou, A.; Georgiadis, K.; Ioannidis, D.; Tzovaras, D. Cognitive analytics platform with AI solutions for anomaly detection. Comput. Ind. 2022, 134, 103555. [Google Scholar] [CrossRef]

- Cao, Q.; Beden, S.; Beckmann, A. A core reference ontology for steelmaking process knowledge modelling and information management. Comput. Ind. 2022, 135, 103574. [Google Scholar] [CrossRef]

- Montero-Jiménez, J.J.; Vingerhoeds, R.; Grabot, B. Enhancing predictive maintenance architecture process by using ontology-enabled Case-Based Reasoning. In Proceedings of the 2021 IEEE International Symposium on Systems Engineering (ISSE), virtual, 13 September–13 October 2021; pp. 1–8. [Google Scholar]

- Emmanouilidis, C.; Gregori, M.; Al-Shdifat, A. Context Ontology Development for Connected Maintenance Services. IFAC-PapersOnLine 2020, 53, 10923–10928. [Google Scholar] [CrossRef]

- Karray, M.H.; Ameri, F.; Hodkiewicz, M.; Louge, T. ROMAIN: Towards a BFO compliant reference ontology for industrial maintenance. Appl. Ontol. 2019, 14, 155–177. [Google Scholar] [CrossRef]

| Publication | Focus on Maintenance | Is Any Formal Method Used during the Ontology Development Process? | Is the Ontology Tested in an Industrial Case or Used for the Development of a Platform? | Is Any Specific Method Developed by the Authors for the Semantic Model Design? |

|---|---|---|---|---|

| This manuscript (May et al., 2022) | + | Basic Formal Ontology | + | + Two-cycle methodology to build semantic model |

| Cao et al. (2022) [51] | + | Reused previously developed ontologies | + | + Core Reference Ontology (CROS) |

| Montero-Jimenez et al. (2021) [52] | + | Noy and McGuinness (2001) | - | - |

| Polenghi et al. (2021) [34] | + | Reused previously developed ontologies | + | - |

| Emmanouilidis et al. (2020) [53] | + | - | + | - |

| Karray et al. (2019) [54] | + | Basic Formal Ontology | + | - |

| Cao et al. (2019) [40] | + | Noy and McGuinness (2001) | + | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

May, G.; Cho, S.; Majidirad, A.; Kiritsis, D. A Semantic Model in the Context of Maintenance: A Predictive Maintenance Case Study. Appl. Sci. 2022, 12, 6065. https://doi.org/10.3390/app12126065

May G, Cho S, Majidirad A, Kiritsis D. A Semantic Model in the Context of Maintenance: A Predictive Maintenance Case Study. Applied Sciences. 2022; 12(12):6065. https://doi.org/10.3390/app12126065

Chicago/Turabian StyleMay, Gokan, Sangje Cho, AmirHossein Majidirad, and Dimitris Kiritsis. 2022. "A Semantic Model in the Context of Maintenance: A Predictive Maintenance Case Study" Applied Sciences 12, no. 12: 6065. https://doi.org/10.3390/app12126065

APA StyleMay, G., Cho, S., Majidirad, A., & Kiritsis, D. (2022). A Semantic Model in the Context of Maintenance: A Predictive Maintenance Case Study. Applied Sciences, 12(12), 6065. https://doi.org/10.3390/app12126065