Design and Development of a I4.0 Engineering Education Laboratory with Virtual and Digital Technologies Based on ISO/IEC TR 23842-1 Standard Guidelines

Abstract

:1. Introduction

2. Review and Analysis of Industry 4.0 Aspects

2.1. Automotive Industry

2.2. Digital Technologies for Education

2.3. VR/AR Technologies for Education

- Discomfort (i.e., dizziness, headache, nausea) caused when actual physical movement does not occur with respect to the visual stimulus generated in the virtual environment. This is also known as VR/simulator/motion sickness or “cyber-nuisance”.

- Eyesight problems (i.e., visual fatigue, blurred vision, mechanical near-sightedness) due to the proximity of the VR hardware to the user’s eyes.

- Photosensitivity syndrome, where seizures (epilepsy) occur due to rapid flashing light stimuli.

- Musculoskeletal disorders (i.e., pain or fatigue of the musculoskeletal system) due to performing repetitive tasks over long periods of time while using VR hardware.

- Hygiene problems (skin and/or eye infection/irritation) due to poor disinfection or cleaning of the VR hardware, which is used by many people.

- Accidents (i.e., collisions, falling) caused by the limitation of the user’s field of view when using VR devices. These accidents may also occur when the user confuses reality with the virtual world (e.g., when users try to sit or lean against a virtual-world chair or wall that does not exist in real life).

3. Development of the Virtual and Digital Laboratory

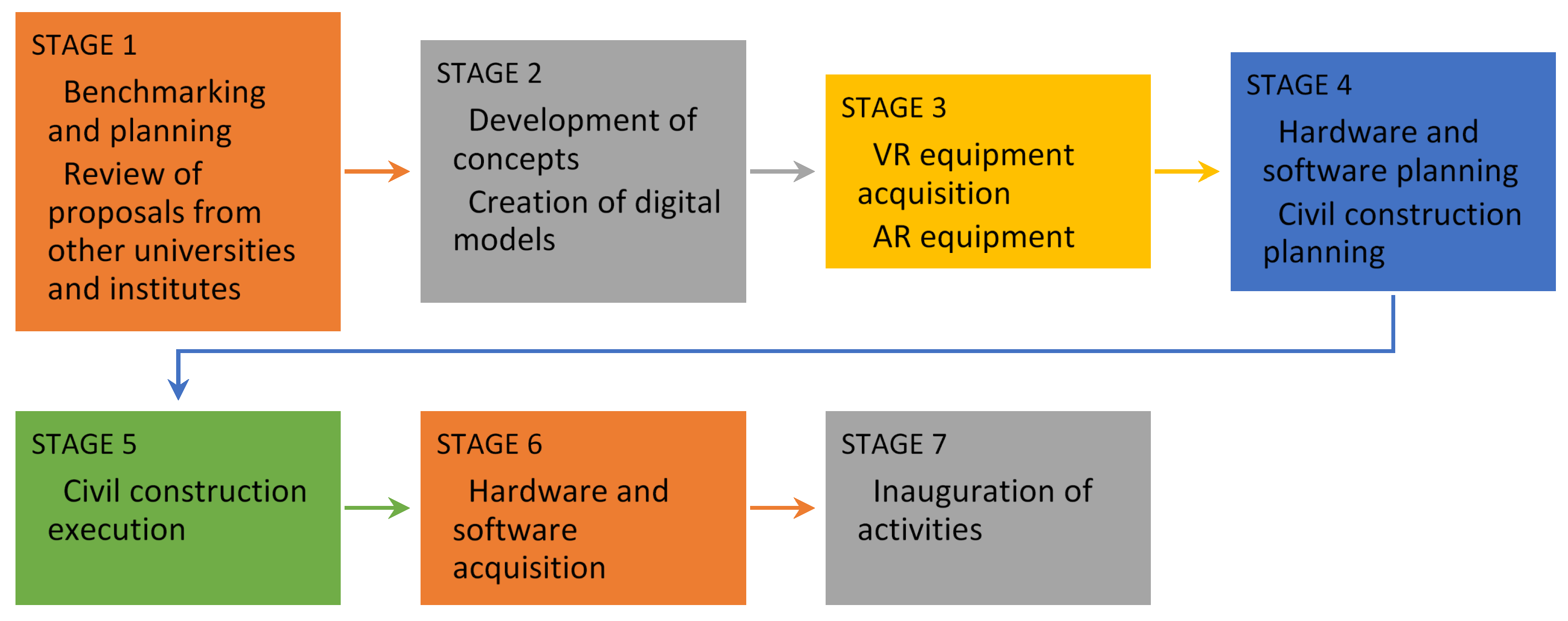

3.1. Planning Process

3.2. Space and Equipment

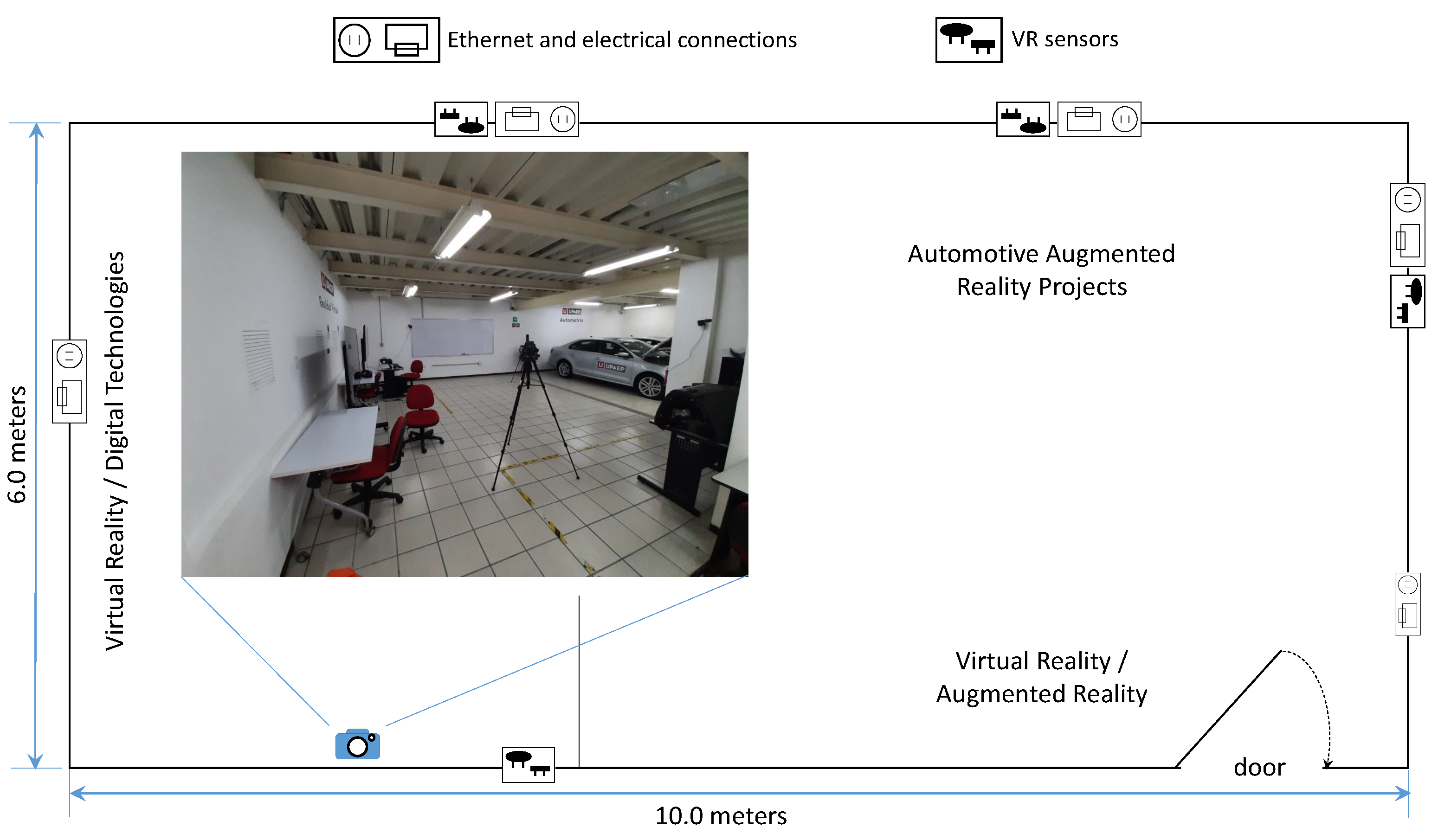

- A: This space was equipped with adequate lighting, Ethernet connection points, and VR sensors. Its main purpose is to provide support for collaborative VR/AR projects, including digital design and manufacturing of automotive parts and simulation. The space is distributed in accordance with the safety guidelines of the ISO/IEC TR 23842-1 standard. Figure 2 presents the general layout of space A, and Table 1 presents the details of the planned VR/AR equipment.

- B: This space is located in a building shared with other engineering laboratories. It features an industrial KUKA robot, which was adapted for testing automotive designs. It also provides support for collaborative VR/AR projects in mechatronics and industrial engineering. Figure 3 presents the general equipment installed in this room.

4. Results and Experiences on Automotive Design and Training

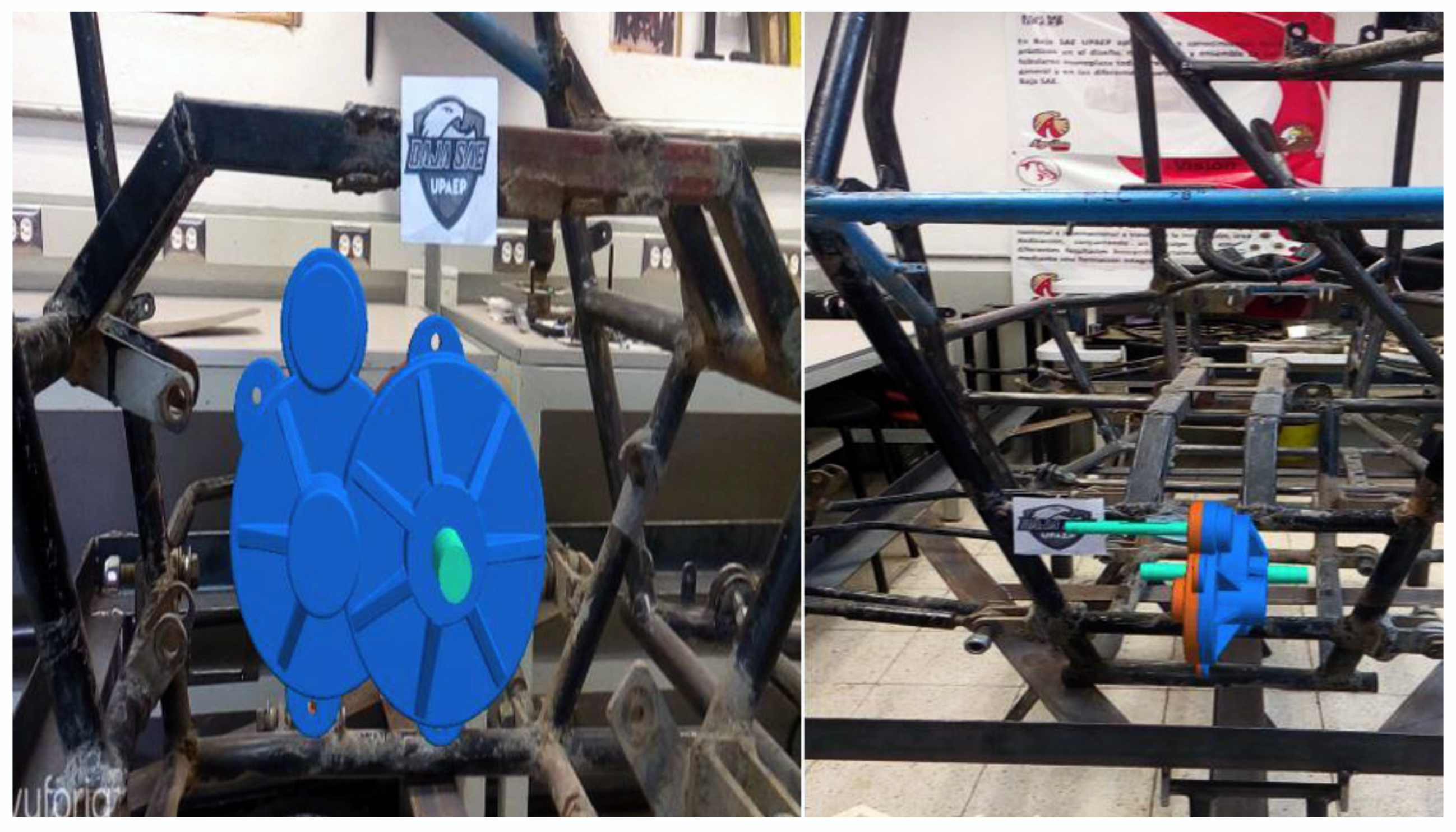

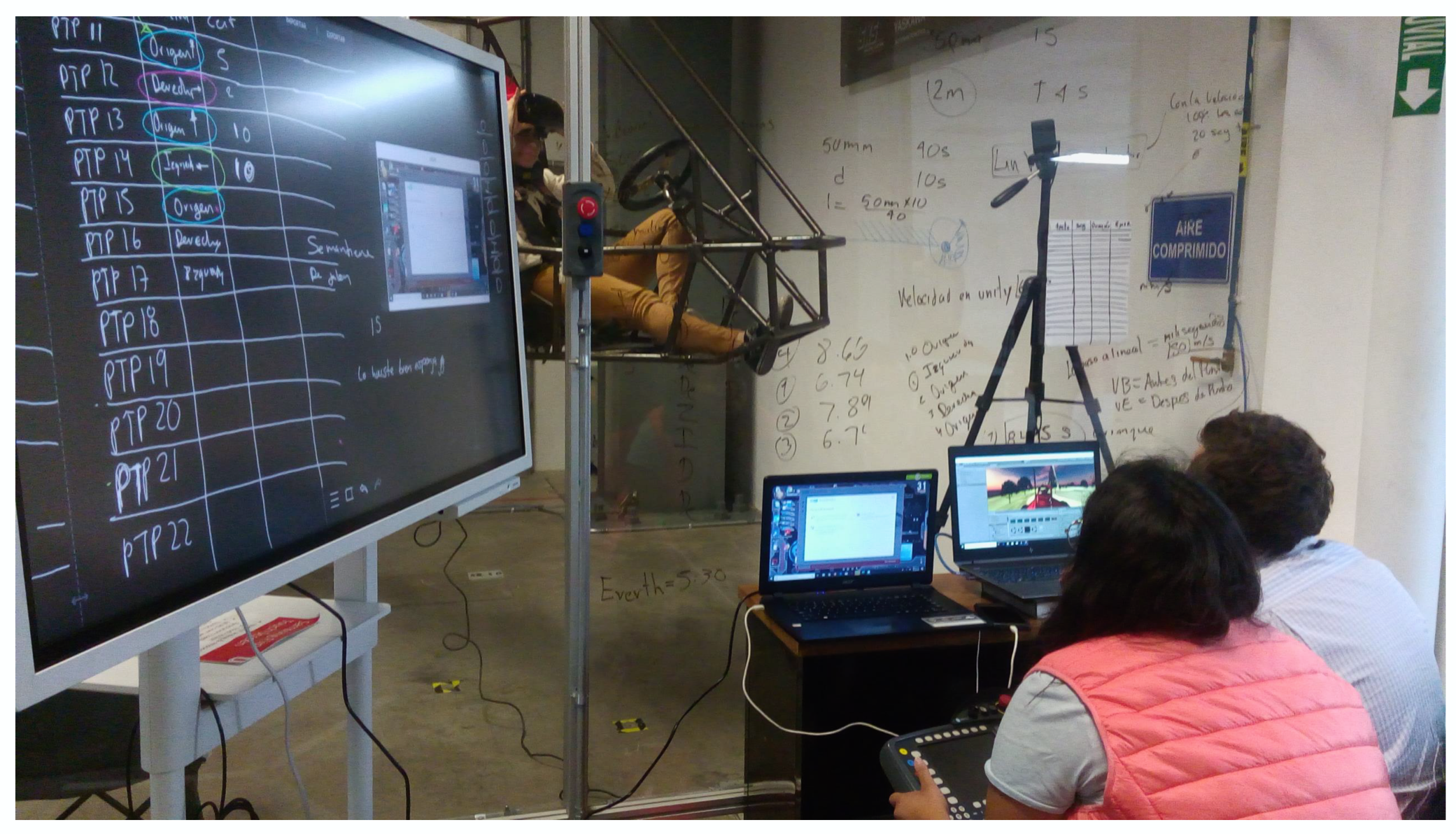

4.1. Automotive Projects

4.2. Assessment of User Experience

5. Conclusions

- Lack of guidance regarding how the technologies work;

- Limited budget for financing larger facilities and technological resources;

- Scheduling and pedagogical conflicts when introducing new content and skills into the educational programs;

- Reluctance to change from the traditional pedagogical practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chryssolouris, G.; Mavrikios, D.; Rentzos, L. The Teaching Factory: A Manufacturing Education Paradigm. Procedia CIRP 2016, 57, 44–48. [Google Scholar] [CrossRef]

- Rekh, S.; Chandy, A. Implementation of academia 4.0 for engineering college education. Procedia Comput. Sci. 2020, 172, 673–678. [Google Scholar] [CrossRef]

- Fauzi, M.A. E-learning in higher education institutions during COVID-19 pandemic: Current and future trends through bibliometric analysis. Heliyon 2022, 8, e09433. [Google Scholar] [CrossRef]

- Engineering.com. Whitepaper: Industry 4.0 and the Future of Engineering Education; University of Cincinnati Online. 2020. Available online: https://www.engineering.com/ResourceMain.aspx?resid=1123&e_src=relres-ecom (accessed on 10 April 2022).

- Hernández-Muñoz, G.M.; Habib-Mireles, L.; García-Castillo, F.A.; Montemayor-Ibarra, F. Industry 4.0 and engineering education: An analysis of nine technological pillars inclusion in higher educational curriculum. In Best Practices in Manufacturing Processes; Springer: Cham, Swizterland, 2019; pp. 525–543. [Google Scholar]

- Elbestawi, M.; Centea, D.; Singh, I.; Wanyama, T. SEPT learning factory for industry 4.0 education and applied research. Procedia Manuf. 2018, 23, 249–254. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital twin service towards smart manufacturing. Procedia CIRP 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Ray, A. E-learning: The new normal in the post-covid world. Int. Res. J. Mod. Eng. Technol. Sci. 2020, 2, 866–876. [Google Scholar]

- Chong, S.; Pan, G.T.; Chin, J.; Show, P.L.; Yang, T.C.K.; Huang, C.M. Integration of 3D printing and Industry 4.0 into engineering teaching. Sustainability 2018, 10, 3960. [Google Scholar] [CrossRef] [Green Version]

- Cuautle-Gutierrez, L.; Cordero-Guridi, J.D.J. Reducción de transmisión para vehículo todo terreno con realidad aumentada e ingeniería asistida por computadora. Rev. Politec. 2020, 15, 32–40. [Google Scholar] [CrossRef] [Green Version]

- Pratap-Singh, R.; Javaid, M.; Kataria, R.; Tyagi, M.; Haleem, A.; Suman, R. Significant applications of virtual reality for COVID-19 pandemic. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 661–664. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, P. Virtual Reality Aided Design. A survey of the use of VR in automotive industry. In Product Engineering; Talaba, D., Amditis, A., Eds.; Springer: Cham, Swizterland, 2008; pp. 277–296. [Google Scholar]

- Standard ISO/IEC TR 23842 1:2020; Information Technology for Learning, Education and Training Human Factor Guidelines for Virtual Reality Content; Part 1: Considerations when Using VR Content. International Organization for Standardization: Geneva, Switzerland, 2020.

- Plotnikova, D.; Volosiuk, A.; Tikhonov, G.; Tsynchenko, A.; Luneva, A.; Smolin, A. VR Application for Vestibular System Training (Pilot Study). In Proceedings of the 21st Congress of the International Ergonomics Association (IEA 2021), Online, 13–18 June 2021; Springer: Cham, Switzerland, 2022; pp. 552–558. [Google Scholar]

- Barreto-Junior, C.D.L.; Cardoso, A.; Lamounier-Junior, E.A.; Silva, P.C.; Silva, A.C. Designing Virtual Reality Environments through an Authoring System Based on CAD Floor Plans: A Methodology and Case Study Applied to Electric Power Substations for Supervision. Energies 2021, 14, 7435. [Google Scholar] [CrossRef]

- Yoon, H. Opportunities and Challenges of Smartglass-Assisted Interactive Telementoring. Appl. Syst. Innov. 2021, 4, 56. [Google Scholar] [CrossRef]

- Pirker, J.; Lesjak, I.; Parger, M.; Gütl, C. An educational physics laboratory in mobile versus room scale virtual reality—A comparative study. Int. J. Online Biomed. Eng. 2017, 13, 106–120. [Google Scholar] [CrossRef] [Green Version]

- Hod, Y. Future learning spaces in schools: Concepts and designs from the learning sciences. J. Form. Des. Learn. 2017, 1, 99–109. [Google Scholar] [CrossRef] [Green Version]

- Pregowska, A.; Masztalerz, K.; Garlinska, M.; Osial, M. A Worldwide Journey through Distance Education—From the Post Office to Virtual, Augmented and Mixed Realities, and Education during the COVID-19 Pandemic. Educ. Sci. 2021, 11, 118. [Google Scholar] [CrossRef]

- Cuautle-Gutierrez, L.; Cordero-Guridi, J.D.J.; Carrillo-Aguilar, J.; Lebano-Perez, E. Simulation of an All-Terrain Vehicle Driving Experience Using Virtual Reality. In Smart Trends in Computing and Communications; Springer: Singapore, 2022; pp. 51–60. [Google Scholar]

| Equipment | Description |

|---|---|

| VR | VR Headset HTC VIVE Pro (×3) |

| AR | AR Headset Moverio BT-300 Developer Edition |

| Digital Technologies | HP Z6 G4 Workstation |

| (CAD/CAM/CAE/Additive Manufacturing) | HP ZBook 15 G5 |

| 3D Printer Markforged | |

| 3D Printer Formlabs High Resolution | |

| Collaborative Activities and Projects | Samsung Flip 55” Touch Screen |

| Samsung 65 "Smart TV Ultra HD 4K (×2) | |

| Kanto MTM65PL Mobile support for TV (×2) | |

| Blackboard ALFRA 3213 Pintarron Star (×4) | |

| Neewer Portable Aluminum Alloy Camera Tripod Monopod | |

| Pepper Sacks Armchair Puff Drop Red (×6) | |

| Globa AL-1085 mobile table (×3) | |

| COSMO AL-430 VERSA chair |

| Question | Totally Agree | Agree | Neutral | Disagree | Totally Disagree |

|---|---|---|---|---|---|

| The use of the VR/AR device was easy and the laboratory space adequate for my practice | 47.4 | 42.1 | 8.0 | 2.5 | 0.0 |

| The virtual reality models allow learning to be extended to users of CAD technologies and conventional computer laboratories | 52.6 | 31.6 | 12.2 | 3.6 | 0.0 |

| The scope of VR technologies and the VR/AR laboratory tools allow knowledge to be extended in the different areas of engineering. | 60.5 | 23.7 | 13.2 | 2.6 | 0.0 |

| VR/AR technologies facilitate learning in courses compared to technologies used in traditional laboratories. | 60.5 | 26.3 | 10.5 | 2.1 | 0.6 |

| VR content allows a more comprehensive understanding of a mechanical design in relation to the traditional CAD model, through the tools of the VR/AR laboratory. | 47.4 | 31.6 | 15.8 | 3.6 | 1.6 |

| The manipulation of the digital model in the virtual and laboratory environment extends the manipulation tools in relation to those allowed in a conventional computer laboratory. | 54.1 | 37.8 | 2.8 | 3.1 | 2.2 |

| VR models and VR/AR lab tools present better engineering development opportunities versus conventional CAD laboratories. | 50.0 | 36.8 | 10.5 | 0.6 | 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cordero-Guridi, J.-d.-J.; Cuautle-Gutiérrez, L.; Alvarez-Tamayo, R.-I.; Caballero-Morales, S.-O. Design and Development of a I4.0 Engineering Education Laboratory with Virtual and Digital Technologies Based on ISO/IEC TR 23842-1 Standard Guidelines. Appl. Sci. 2022, 12, 5993. https://doi.org/10.3390/app12125993

Cordero-Guridi J-d-J, Cuautle-Gutiérrez L, Alvarez-Tamayo R-I, Caballero-Morales S-O. Design and Development of a I4.0 Engineering Education Laboratory with Virtual and Digital Technologies Based on ISO/IEC TR 23842-1 Standard Guidelines. Applied Sciences. 2022; 12(12):5993. https://doi.org/10.3390/app12125993

Chicago/Turabian StyleCordero-Guridi, José-de-Jesús, Luis Cuautle-Gutiérrez, Ricardo-Iván Alvarez-Tamayo, and Santiago-Omar Caballero-Morales. 2022. "Design and Development of a I4.0 Engineering Education Laboratory with Virtual and Digital Technologies Based on ISO/IEC TR 23842-1 Standard Guidelines" Applied Sciences 12, no. 12: 5993. https://doi.org/10.3390/app12125993

APA StyleCordero-Guridi, J.-d.-J., Cuautle-Gutiérrez, L., Alvarez-Tamayo, R.-I., & Caballero-Morales, S.-O. (2022). Design and Development of a I4.0 Engineering Education Laboratory with Virtual and Digital Technologies Based on ISO/IEC TR 23842-1 Standard Guidelines. Applied Sciences, 12(12), 5993. https://doi.org/10.3390/app12125993