Reliability Assessment of PAUT Technique in Lieu of RT for Tube Welds in Thermal Power Plant Facilities

Abstract

:1. Introduction

2. Reliability Evaluation Technique for NDT

2.1. Mathematical Model for POD

2.2. Evaluation of Sizing Performance for Measurement Accuracy

3. Round Robin Test (RRT) and Reliability Analysis

3.1. Tube Weld Specimens

3.2. PAUT Experimental Setup and Perform RRT

3.3. PAUT Reliability Analysis Results

3.4. Comparison with RT

4. Conclusions

- The results of the POD analysis for the tube specimens indicated 80% POD at 6.93 mm; the 80% POD for high-risk planar flaws such as cracks is about 5.1 mm, and the 80% POD for volumetric flaws, which are generally difficult to detect via ultrasonic technique, corresponded to 6.57 mm, indicating relatively poor detection performance.

- In the POD analysis results for different welding materials, the 80% POD for dissimilar metal welds was approximately 11 mm, which was lower compared with similar metal welds (ferritic and austenitic steel). This is thought to be because the interpretation of signals was more difficult owing to the attenuation and dispersion of ultrasonic waves at the interface of different materials.

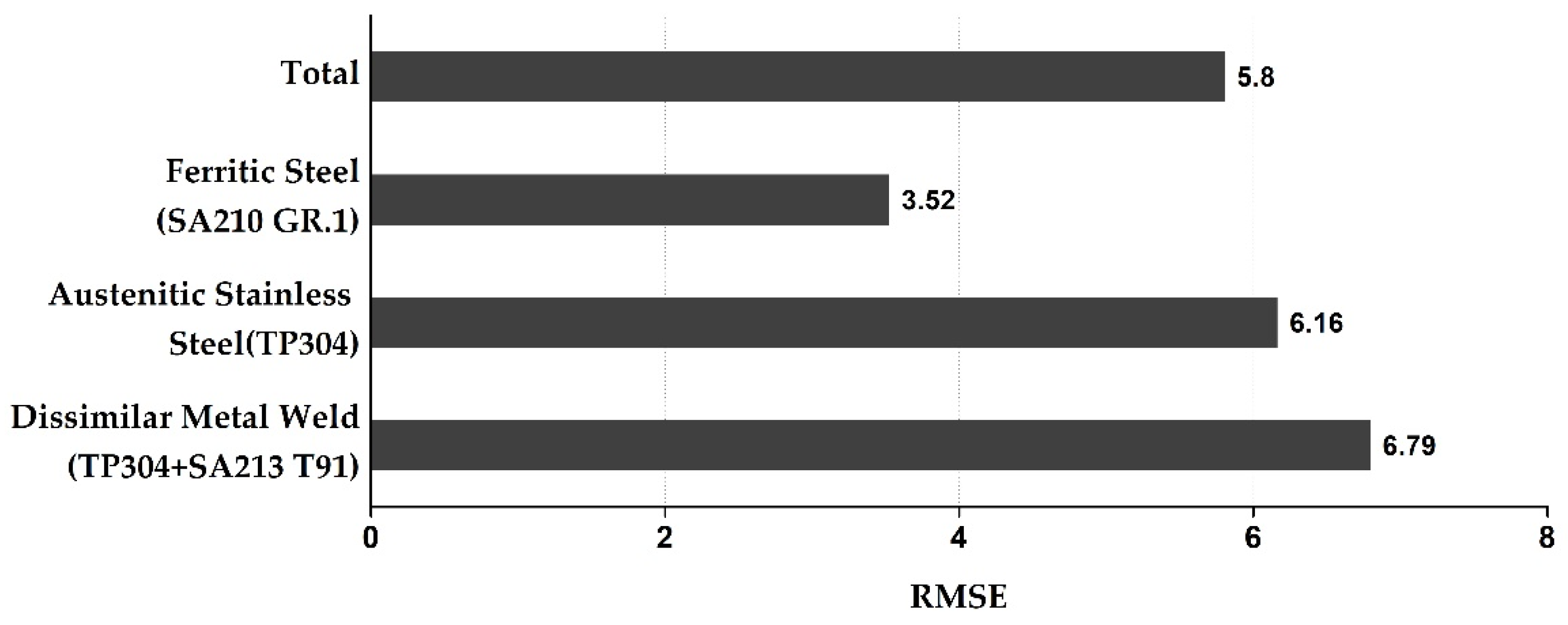

- Overall, there was a tendency for overestimation compared with the actual size of the flaws, and the RMSE for the sizing accuracy was the smallest (3.52 mm) for carbon steel and the largest (6.79 mm) for dissimilar metal welds.

- The flaw detection performance was compared between the PAUT and RT methods. The PAUT method significantly outperformed RT for planar flaws, but in the case of volumetric flaws, it missed a flaw.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Augustyniak, B.; Chmielewski, M.; Sablik, M.J.; Augustyniak, M.; Walker, S. A new eddy current method for nondestructive testing of creep damage in austenitic boiler tubing. Nondestruct. Test. Eval. 2009, 24, 121–141. [Google Scholar] [CrossRef]

- Xueqin, L.; Gang, L.; Shangqing, L. The development of the boiler water wall tube inspection. In Proceedings of the 2008 Third International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 2415–2420. [Google Scholar]

- Malik, A.; Meroufel, A.; Al-Fozan, S. Boiler tubes failures: A compendium of case studies. J. Fail. Anal. Prev. 2015, 15, 246–250. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M.; Soni, A. Advances and researches on non destructive testing: A review. Mater. Today Proc. 2018, 5, 3690–3698. [Google Scholar] [CrossRef]

- Liu, Z.; Kleiner, Y. State of the art review of inspection technologies for condition assessment of water pipes. Measurement 2013, 46, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Feng, Q.; Li, R.; Nie, B.; Liu, S.; Zhao, L.; Zhang, H. Literature review: Theory and application of in-line inspection technologies for oil and gas pipeline girth weld defection. Sensors 2017, 17, 50. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.C.; Kim, J.G.; Kang, S.S.; Jhung, M.J. Korean Round-Robin Tests Result for New International Program to Assess the Reliability of Emerging Nondestructive Techniques. Nucl. Eng. Technol. 2017, 49, 651–661. [Google Scholar] [CrossRef] [Green Version]

- Moran, T.L.; Ramuhalli, P.; Pardini, A.F.; Anderson, M.T.; Doctor, S.R. Replacement of Radiography with Ultrasonics for the Nondestructive Inspection of Welds—Evaluation of Technical Gaps—An Interim Report; US Department of Energy: Washington, DC, USA, 2010.

- Moran, T.L.; Prowant, M.; Nove, C.A.; Pardini, A.F.; Crawford, S.L.; Cinson, A.D.; Anderson, M.T. Applying Ultrasonic Testing in Lieu of Radiography for Volumetric Examination of Carbon Steel Piping; Report No. NUREG/CR-7204, PNNL-24232; U.S. Nuclear Regulatory Commission: Rockville, MD, USA, 2015.

- Azar, L.; Shi, Y.; Wooh, S.C. Beam focusing behavior of linear phased arrays. NDT E Int. 2000, 33, 189–198. [Google Scholar] [CrossRef]

- Song, S.J.; Shin, H.J.; Jang, Y.H. Development of an ultrasonic phased array system for nondestructive tests of nuclear power plant components. Nucl. Eng. Des. 2002, 214, 151–161. [Google Scholar] [CrossRef]

- Caminero, M.A.; García-Moreno, I.; Rodríguez, G.P.; Chacón, J.M. Internal damage evaluation of composite structures using phased array ultrasonic technique: Impact damage assessment in CFRP and 3D printed reinforced composites. Compos. Part B Eng. 2019, 165, 131–142. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M.; Boffa, N.D.; Monaco, E.; Ricci, F. Nondestructive evaluation of carbon fibre reinforced composites with infrared thermography and ultrasonics. Compos. Struct. 2015, 134, 845–853. [Google Scholar] [CrossRef]

- Kim, Y.; Cho, S.; Park, I.K. Analysis of Flaw Detection Sensitivity of Phased Array Ultrasonics in Austenitic Steel Welds According to Inspection Conditions. Sensors 2021, 21, 242. [Google Scholar] [CrossRef] [PubMed]

- Braatz, B.G.; Heasler, P.G.; Meyer, R.M. PARENT Quick Blind Round-Robin Test Report; Report No. PNNL-22677; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2014.

- Annis, C. Statistical Best-Practices for Building Probability of Detection (POD) Models. R Package mh1823 2010, Version 2.5.4.4. Available online: http://StatisticalEngineering.com/mh1823/ (accessed on 3 August 2020).

- Doctor, S.R.; Lemaitre, P.; Crutzen, S. Austenitic steel piping testing exercises in PISC. Nucl. Eng. Des. 1995, 157, 231–244. [Google Scholar] [CrossRef]

- Kurz, J.H.; Jüngert, A.; Dugan, S.; Dobmann, G.; Boller, C. Reliability considerations of NDT by probability of detection (POD) determination using ultrasound phased array. Eng. Fail. Anal. 2013, 35, 609–617. [Google Scholar] [CrossRef]

| No. | Type | Material (ASME Spec.) | OD (mm) | THK (mm) | Qty. (EA) |

|---|---|---|---|---|---|

| T01–T06 | Similar Metal | SA210Gr.A1 | 50.8 | 5.6 | 6 |

| T07–T12 | TP304H | 42.2 | 6 | 6 | |

| T13–T18 | 50.8 | 4 | 6 | ||

| T19–T24 | 63.5 | 4 | 6 | ||

| T25–T30 | Dissimilar Metal | TP304H + SA213-T91 | 42.2 | 6.6 | 6 |

| Type | Material (ASME Spec.) | Lack of Fusion | Crack | Porosity | Slag |

|---|---|---|---|---|---|

| Similar Metal | SA210Gr.A1 | 8 | 6 | 5 | 8 |

| TP304H | 8 | 34 | 5 | 8 | |

| Dissimilar Metal | TP304H + SA213-T91 | 8 | 6 | 5 | 8 |

| PA Device | PA Channels | Software | |||

|---|---|---|---|---|---|

| 1D | DLA | Set-Up | Data Acquisition | Data Analysis | |

| OmniScan MX or MX2 | Above 16/64 | Above 16/64 PR | NDT Setup Builder 1.1 | MXU (MX 2.0/MX2 4.4) | OmniPC 5.8/Tomoview 2.10 |

| TOPAZ 32 or 64 | Above 16/64 | Above 32/128 PR | Ultravision 3.10 | Ultravision 3.10 | Ultravision 3.10 |

| Wave Type | Array Type | Frequency [MHz] | No. of Element | Pitch [mm] | Elevation [mm] | Wedge Angle [°] |

|---|---|---|---|---|---|---|

| Shear | 1D | 7.5 | 16 | 0.5 | 10 | 60 |

| Longitudinal | DLA | 5 | 32 | 0.75 | 5 | 70 |

| Team | All | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|

| Detection Size | 6.93 | 6.89 | 5.50 | 10.77 | 7.02 | 5.59 | 5.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.M.; Kang, D.; Kim, Y.L.; Cho, S.; Park, T.; Park, I.K. Reliability Assessment of PAUT Technique in Lieu of RT for Tube Welds in Thermal Power Plant Facilities. Appl. Sci. 2022, 12, 5867. https://doi.org/10.3390/app12125867

Choi YM, Kang D, Kim YL, Cho S, Park T, Park IK. Reliability Assessment of PAUT Technique in Lieu of RT for Tube Welds in Thermal Power Plant Facilities. Applied Sciences. 2022; 12(12):5867. https://doi.org/10.3390/app12125867

Chicago/Turabian StyleChoi, Yu Min, Dongchan Kang, Young Lae Kim, Sungjong Cho, Taesung Park, and Ik Keun Park. 2022. "Reliability Assessment of PAUT Technique in Lieu of RT for Tube Welds in Thermal Power Plant Facilities" Applied Sciences 12, no. 12: 5867. https://doi.org/10.3390/app12125867

APA StyleChoi, Y. M., Kang, D., Kim, Y. L., Cho, S., Park, T., & Park, I. K. (2022). Reliability Assessment of PAUT Technique in Lieu of RT for Tube Welds in Thermal Power Plant Facilities. Applied Sciences, 12(12), 5867. https://doi.org/10.3390/app12125867