Patent Analysis of the Development of Technologies Applied to the Combustion Process

Abstract

:1. Introduction

2. Materials and Methods

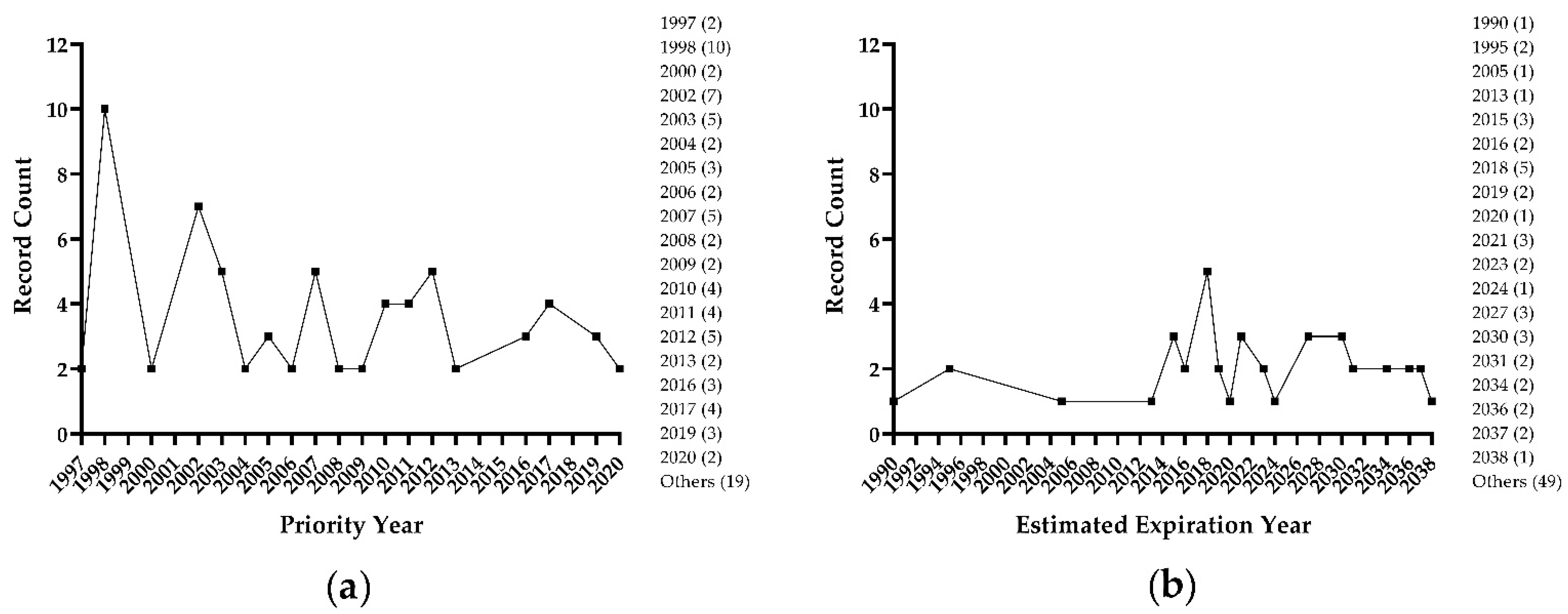

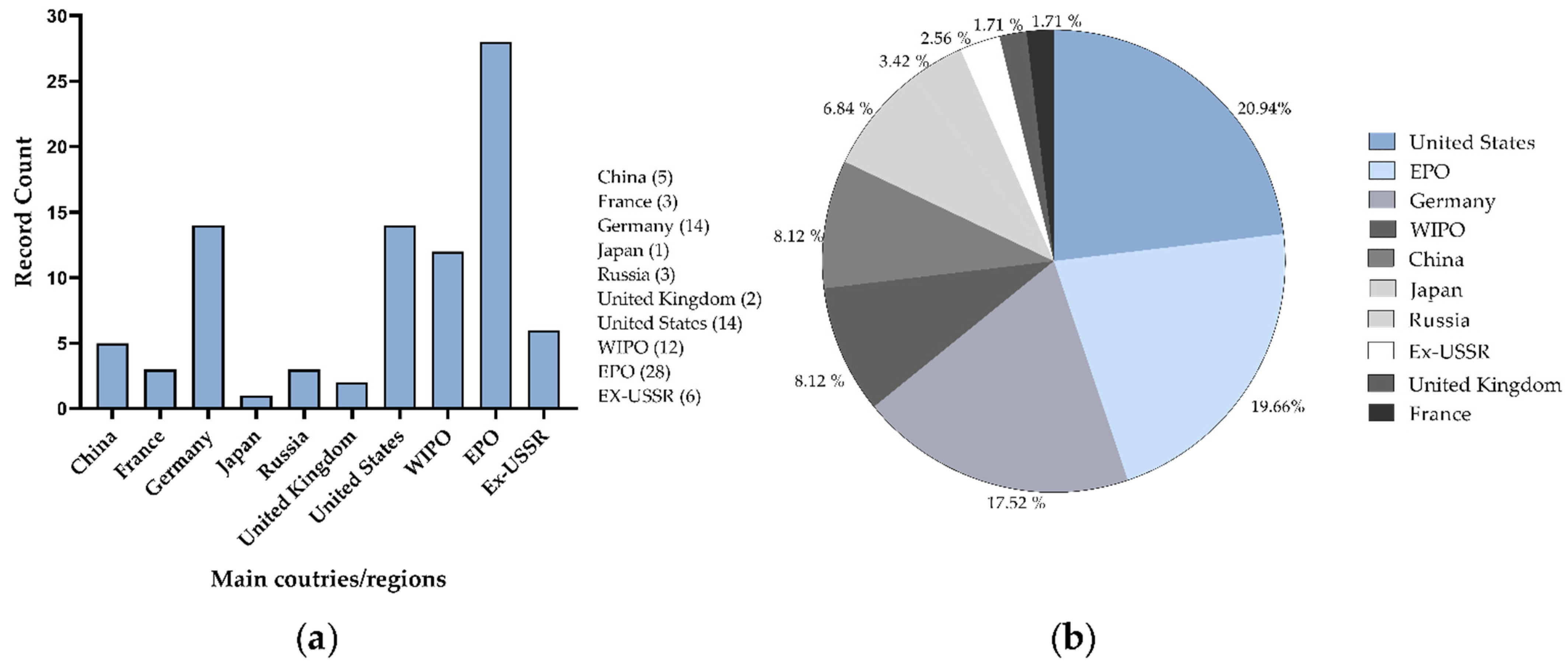

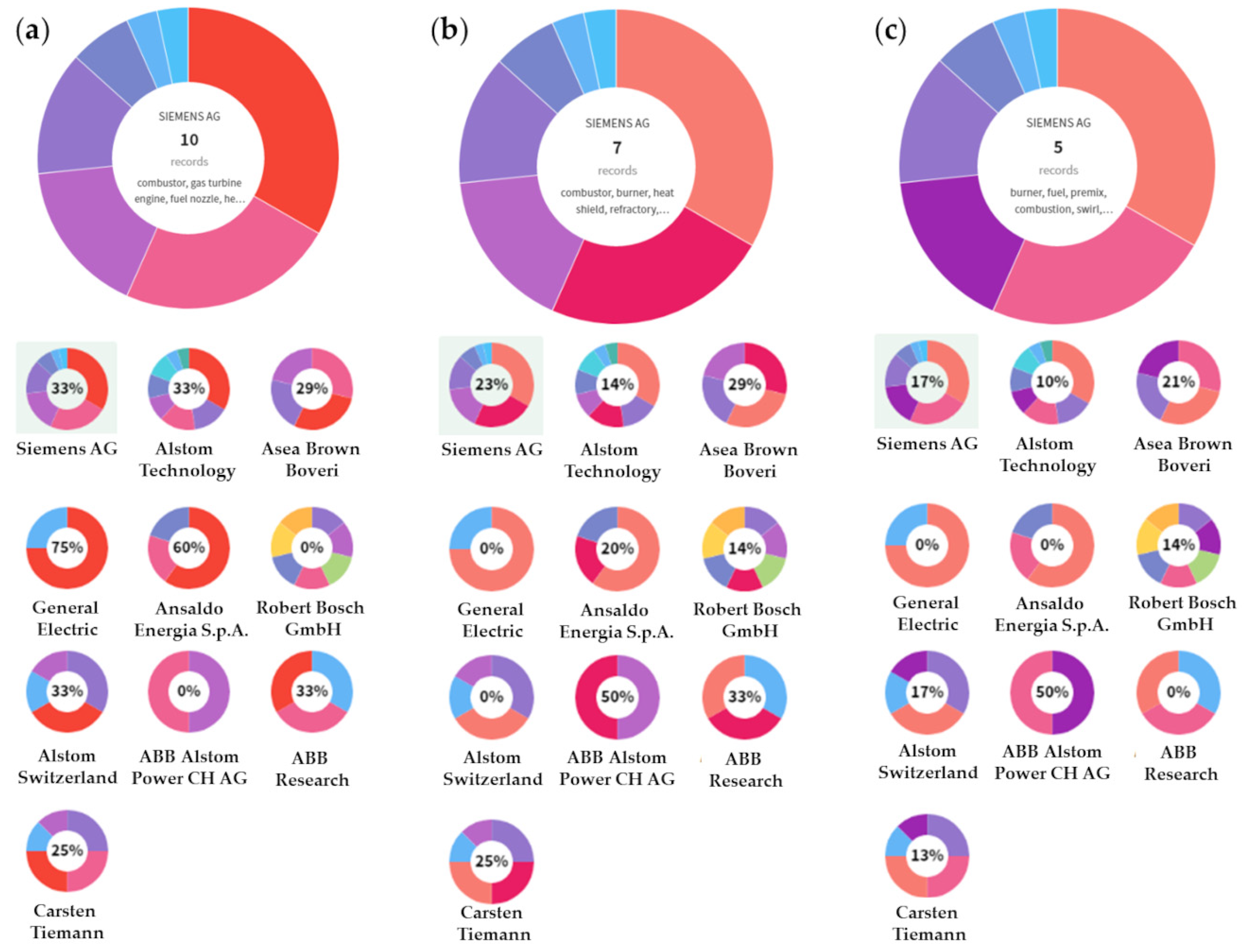

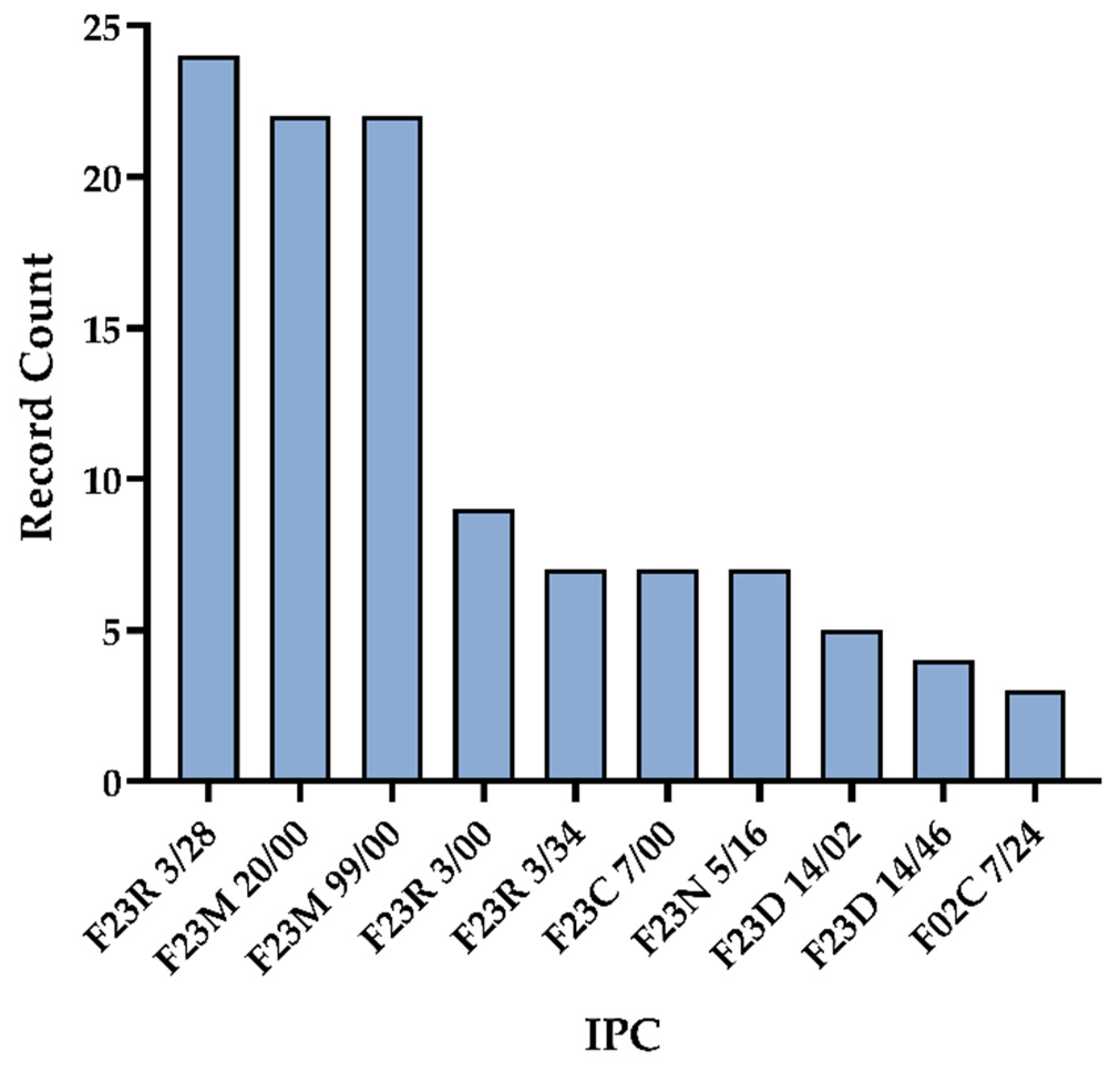

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silva, L.C.; Wilfinger, M.M.; Murari, T.B.; Filho, A.S.N.; Moret, M.A.; Santos, A.A. Experimental evaluation of thermal radiation and soot concentration rates for syngas flames in lean condition and oxygen enhanced combustion. Energy Rep. 2021, 7, 4139–4145. [Google Scholar] [CrossRef]

- Alobaid, F.; Ströhle, J. Special Issue “Thermochemical Conversion Processes for Solid Fuels and Renewable Energies”. Appl. Sci. 2021, 11, 1907. [Google Scholar] [CrossRef]

- Zhang, L.; Li, S.; Yao, M.; Zhou, H.; Ren, Z. Analysis of operating limits and combustion state regulation for low-calorific value gases in industrial burners. Int. J. Hydrogen Energy 2021, 47, 1306–1318. [Google Scholar] [CrossRef]

- Baukal, C.E., Jr. Oxygen-Enhanced Combustion, 2nd ed.; CRC Press: New York, NY, USA, 2013. [Google Scholar]

- Störner, F.; Lind, F.; Rydén, M. Oxygen Carrier Aided Combustion in Fluidized Bed Boilers in Sweden—Review and Future Outlook with Respect to Affordable Bed Materials. Appl. Sci. 2021, 11, 7935. [Google Scholar] [CrossRef]

- Santos, A.A.B.; Torres, E.A.; Pereira, P.A.P. Critical evaluation of the oxygen-enhanced combustion in gas burners for industrial applications and heating systems. J. Braz. Chem. Soc. 2011, 22, 1841–1849. [Google Scholar] [CrossRef] [Green Version]

- Pereira, A.R.B. Evaluation of the Influence of O2-Enriched Combustion Correlation and Acoustic Excitation on Natural Gas Flames. Master’s Thesis, Centro Universitário SENAI CIMATEC, Salvador-BA, Brazil, 30 May 2017. [Google Scholar]

- Shaddix, C.R.; Williams, T.C. The effect of oxygen enrichment on soot formation and thermal radiation in turbulent, non-premixed methane flames. Proc. Combust. Inst. 2016, 36, 4051–4059. [Google Scholar] [CrossRef] [Green Version]

- Jocher, A.; Bonnety, J.; Gomez, T.; Pitsch, H.; Legros, G. Magnetic control of flame stability: Application to oxygen-enriched and carbon dioxide-diluted sooting flames. Proc. Combust. Inst. 2018, 37, 5637–5644. [Google Scholar] [CrossRef]

- Sun, Z.; Dally, B.; Alwahabi, Z.; Nathan, G. The effect of oxygen concentration in the co-flow of laminar ethylene diffusion flames. Combust. Flame 2019, 211, 96–111. [Google Scholar] [CrossRef]

- Pereira, A.R.B.; Santos, A.Á.B.; Guarieiro, L.L.N.; Cavalcante, J.B.H.; dos Anjos, J.P. Experimental evaluation of CO, NOx, formaldehyde and acetaldehyde emission rates in a combustion chamber with OEC under acoustic excitation. Energy Rep. 2019, 5, 1163–1171. [Google Scholar] [CrossRef]

- Foo, K.K.; Sun, Z.; Medwell, P.R.; Alwahabi, Z.T.; Nathan, G.J.; Dally, B.B. Soot evolution and flame response to acoustic forcing of laminar non-premixed jet flames at varying amplitudes. Combust. Flame 2018, 198, 249–259. [Google Scholar] [CrossRef]

- Meng, X.; de Jong, W.; Kudra, T. A state-of-the-art review of pulse combustion: Principles, modeling, applications and R&D issues. Renew. Sustain. Energy Rev. 2016, 55, 73–114. [Google Scholar] [CrossRef]

- Martinez, S.; Merola, S.; Irimescu, A. Flame Front and Burned Gas Characteristics for Different Split Injection Ratios and Phasing in an Optical GDI Engine. Appl. Sci. 2019, 9, 449. [Google Scholar] [CrossRef] [Green Version]

- Martins, C.A.; Carvalho, J.A., Jr.; Veras, C.A.; Ferreira, M.A.; Lacava, P.T. Experimental measurements of the NOx and CO concentrations operating in oscillatory and non-oscillatory burning conditions. Fuel 2006, 85, 84–93. [Google Scholar] [CrossRef]

- Trevisan, B.P.; Dourado, W.M.C. Experimental Investigation of the Acoustic Flame Interactions in a Bunsen Burner. In Proceedings of the 4 Workshop em Engenharia e Tecnologia Espaciais, São José dos Campos, Brazil, January 2013; pp. 1–3. [Google Scholar]

- Sapit, A.; Razali, M.A.; Hushim, M.F.; Khalid, A.; Mohmad, M.N. Effect of Acoustic Excitation toward Jet Flame: An Experimental Design. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 1, 69–74. [Google Scholar]

- WIPO. Obtaining IP Rights: Patents; WIPO: Geneva, Switzerland, 2022. [Google Scholar]

- Correa, S.M. Power generation and aeropropulsion gas turbines: From combustion science to combustion technology. In Proceedings of the Symposium (International) on Combustion, Boulder, CO, USA, 2–7 August 1998; Volume 27, pp. 1793–1807. [Google Scholar] [CrossRef]

- Kamba, N. Environmental Protection and Role of Museums. Conserv. Pract. Mus. 2022, 149–172. [Google Scholar] [CrossRef]

- Sakai, K.; Hassan, M.A.; Vairappan, C.S.; Shirai, Y. Promotion of a green economy with the palm oil industry for biodiversity conservation: A touchstone toward a sustainable bioindustry. J. Biosci. Bioeng. 2022, 133, 414–424. [Google Scholar] [CrossRef] [PubMed]

- Tiemann, C. Combustion Chamber Assembly. WO1999056060A1, 23 April 1998. [Google Scholar]

- Tiemann, C.; Lenze, M.; Lenz, M. Gas-Turbine Burner Assembly with Optical Probe. WO2000012939A1, 31 August 1998. [Google Scholar]

- Biagiolo, F.; Hakim Doisneau, L.; Palys, D.O. System and Method for High Frequency Accoustic Dampers with Caps. EP3742050A1, 21 May 2019. [Google Scholar]

- Leschowski, M.; Lichtenstern, M.; Bäßler, S.; Rabus, P.; Müller, S. Method of Manufacturing a Cooking Appliance Burner System and Cooking Appliance. DE102020106329A1, 9 March 2020. [Google Scholar]

- Beita, J.; Talibi, M.; Sadasivuni, S.; Balachandran, R. Thermoacoustic Instability Considerations for High Hydrogen Combustion in Lean Premixed Gas Turbine Combustors: A Review. Hydrogen 2021, 2, 33–57. [Google Scholar] [CrossRef]

- Liu, T.; Li, J.; Zhu, S.; Yang, L. Determination of the heat conduction transfer function within the thermoacoustic instability limit cycle in a Rijke tube. Appl. Therm. Eng. 2022, 206, 118084. [Google Scholar] [CrossRef]

- Tao, C.; Zhou, H. Effects of different active control strategies on combustion instability decay time, actuator voltage, and damping ratio. J. Appl. Phys. 2020, 128, 054902. [Google Scholar] [CrossRef]

- Zhao, D.; Li, X. A review of acoustic dampers applied to combustion chambers in aerospace industry. Prog. Aerosp. Sci. 2015, 74, 114–130. [Google Scholar] [CrossRef]

- Olivier, C.; Penelet, G.; Poignand, G.; Lotton, P. Active control of thermoacoustic amplification in a thermo-acousto-electric engine. J. Appl. Phys. 2014, 115, 174905. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Li, J.; Cheng, W.; Li, T. Active control of thermoacoustic instability using microsecond plasma discharge. J. Appl. Phys. 2020, 127, 033301. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, L. Electroacoustic control of Rijke tube instability. J. Sound Vib. 2017, 409, 131–144. [Google Scholar] [CrossRef]

- Illingworth, S.; Morgans, A. Advances in feedback control of the Rijke tube thermoacoustic instability. Int. J. Flow Control 2010, 2, 197–218. [Google Scholar] [CrossRef]

- Li, X.; Zhao, D.; Yang, X.; Wen, H.; Jin, X.; Li, S.; Zhao, H.; Xie, C.; Liu, H. Transient growth of acoustical energy associated with mitigating thermoacoustic oscillations. Appl. Energy 2016, 169, 481–490. [Google Scholar] [CrossRef]

- Lovett, J.A.; Turns, S.R. Experiments on axisymmetrically pulsed turbulent jet flames. AIAA J. 1990, 28, 38–46. [Google Scholar] [CrossRef]

- Liu, W.; Xue, R.; Zhang, L.; Yang, Q.; Wang, H. Nonlinear response of a premixed low-swirl flame to acoustic excitation with large amplitude. Combust. Flame 2021, 235, 111733. [Google Scholar] [CrossRef]

- Fujisawa, N.; Iwasaki, K.; Fujisawa, K.; Yamagata, T. Flow visualization study of a diffusion flame under acoustic excitation. Fuel 2019, 251, 506–513. [Google Scholar] [CrossRef]

- Baukal, J. Oxygen-Enhanced Combustion. CRC Press 1998, 15, 354–356. [Google Scholar] [CrossRef]

- Santos, A.A.; Torres, E.A.; Pereira, P.A. Evaluation of the influence of OEC on soot formation and thermal radiation in confined acetylene diffusion flames. Int. Commun. Heat Mass Transf. 2012, 39, 1513–1518. [Google Scholar] [CrossRef]

- Álisson, A.; Santos, B.; Torres, E.A.; Afonso, P.; Pereira, P. Experimental investigation of the natural gas confined flames using the OEC. Energy 2011, 36, 1527–1534. [Google Scholar] [CrossRef]

- Niehoff, T.; Plaschke, H.; Rogge, D.; Rudolph, B. Method for Manufacturing Mineral Wool. EP2284130A1, 16 February 2011. [Google Scholar]

- Andersson, L. Arrangement for Reduction of Acoustinc Vibrations in a Combustion Chamber. WO2000009945A1, 24 February 2000. [Google Scholar]

- Zhu, T.; Hu, Y.; Tang, C.; Wang, L.; Liu, X.; Deng, L.; Che, D. Experimental study on NO formation and burnout characteristics of pulverized coal in oxygen enriched and deep-staging combustion. Fuel 2020, 272, 117639. [Google Scholar] [CrossRef]

- Li, Y.-H.; Kuo, W.-C. The study of optimal parameters of oxygen-enriched combustion in fluidized bed with optimal torrefied woody waste. Int. J. Energy Res. 2020, 44, 7416–7434. [Google Scholar] [CrossRef]

- Skeen, S. Oxygen-Enhanced Combustion: Theory and Applications Recommended Citation; Washington University: St. Louis, MO, USA, 2009. [Google Scholar]

- Merlo, N.; Boushaki, T.; Chauveau, C.; de Persis, S.; Pillier, L.; Sarh, B.; Gökalp, I. Experimental Study of Oxygen Enrichment Effects on Turbulent Non-premixed Swirling Flames. Energy Fuels 2013, 27, 6191–6197. [Google Scholar] [CrossRef]

- Zaidaoui, H.; Boushaki, T.; Koched, A.; Sautet, J.; Sarh, B.; Gökalp, I. Experimental Study of EGR Dilution and O2 Enrichment Effects on Turbulent Non-Premixed Swirling Flames. Combust. Sci. Technol. 2020, 193, 280–289. [Google Scholar] [CrossRef]

- Riahi, Z.; Hraiech, I.; Sautet, J.-C.; Ben Nasrallah, S. Experimental and numerical study of oxidant effect on hythane combustion. Int. J. Hydrogen Energy 2022, 47, 8105–8117. [Google Scholar] [CrossRef]

- Zhen, H.; Liu, H.; Wei, Z.; Liu, Z.; Liu, X.; Huang, Z. A study on acoustically modulated bunsen flame and its impingement heat transfer. Int. J. Hydrogen Energy 2022, 47, 13168–13177. [Google Scholar] [CrossRef]

- Emadi, M.; Karkow, D.; Salameh, T.; Gohil, A.; Ratner, A. Flame structure changes resulting from hydrogen-enrichment and pressurization for low-swirl premixed methane–air flames. Int. J. Hydrogen Energy 2012, 37, 10397–10404. [Google Scholar] [CrossRef]

- Yilmaz, I.; Ratner, A.; Ilbas, M.; Huang, Y. Experimental investigation of thermoacoustic coupling using blended hydrogen–methane fuels in a low swirl burner. Int. J. Hydrogen Energy 2010, 35, 329–336. [Google Scholar] [CrossRef]

- Siemens, A.G. Available online: https://www.siemens.com/global/en.html (accessed on 3 April 2022).

- Alstom. Technology Smart Innovation for Sustainable Mobility. Available online: https://www.alstom.com/company (accessed on 3 April 2022).

- ABB. Asea Brown Boveri. Available online: https://global.abb/group/en (accessed on 3 April 2022).

- Tiemann, C. Method of Operating a Hybrid Burner. US20010018173A1, 20 February 2001. [Google Scholar]

- OEC. Combustion Engines in Germany. Available online: https://oec.world/en/profile/hs92/combustion-engines (accessed on 16 February 2022).

- IEA. Germany 2020: Energy Policy Review; IEA: Paris, France, 2020. [Google Scholar]

- Schürg, F.; Kunze, U. Method for Monitoring a Burner and a Device Therefor. DE102019114788A1, 3 June 2019. [Google Scholar]

- Sigal, I.; Smikhula, A.; Sigal, O. Experience of The Development Of Burners, Chambers, And Technologies For Reducing Emissions of Nitrogen Oxides By Boilers During The Combustion Of Natural Gas. Energy Technol. Resour. Sav. 2019, 70–79. [Google Scholar] [CrossRef]

- Persistence Market Research Rising Adoption of Low Nitrogen Oxide (NOx) Combustion Technology to Surge Industrial Burner Market Value to US$ 9 Bn by 2029, Finds PMR. Available online: https://www.persistencemarketresearch.com/mediarelease/industrial-burner-market.asp (accessed on 16 February 2022).

- EPO. Applying for a Patent; EPO: Munich, Germany, 2022. [Google Scholar]

- WIPO. PCT—The International Patent System. Available online: https://www.wipo.int/pct/en/ (accessed on 16 February 2022).

- Treaty, Patent Cooperation. World Intellectual Property Organization; Treaty, Patent Cooperation: Washington, DC, USA, 2001. [Google Scholar]

- OEC. Combustion Engines in United States. Available online: https://oec.world/en/profile/bilateral-product/combustion-engines/reporter/usa?redirect=true (accessed on 3 April 2022).

- Deng, K.; Zhong, Y.; Wang, M.; Zhong, Y.; Luo, K.H. Effects of Acoustic Excitation on the Combustion Instability of Hydrogen–Methane Lean Premixed Swirling Flames. ACS Omega 2020, 5, 8744–8753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ion, I.V.; Dimofte, E.; Popescu, F.; Akhmetova, I.G. Investigation of flame acoustic excitation of a gas burner. Energy Rep. 2022, 8, 263–269. [Google Scholar] [CrossRef]

- Broatch, A.; Novella, R.; García-Tíscar, J.; Gomez-Soriano, J.; Pal, P. Analysis of combustion acoustic phenomena in compression–ignition engines using large eddy simulation. Phys. Fluids 2020, 32, 085101. [Google Scholar] [CrossRef]

- Dattarajan, S.; Lutomirski, A.; Lobbia, R.; Smith, O.; Karagozian, A. Acoustic excitation of droplet combustion in microgravity and normal gravity. Combust. Flame 2006, 144, 299–317. [Google Scholar] [CrossRef]

- Dang, N.; Zhang, J.; Deguchi, Y. Numerical Study on the Route of Flame-Induced Thermoacoustic Instability in a Rijke Burner. Appl. Sci. 2021, 11, 1590. [Google Scholar] [CrossRef]

- Beinke, S.K.; Hardi, J.S.; Banuti, D.T.; Karl, S.; Dally, B.B.; Oschwald, M. Experimental and numerical study of transcritical oxygen-hydrogen rocket flame response to transverse acoustic excitation. Proc. Combust. Inst. 2020, 38, 5979–5986. [Google Scholar] [CrossRef]

- Križan, G.; Križan, J.; Bajsić, I.; Gaberšček, M. Control of a pulse combustion reactor with thermoacoustic phenomena. Instrum. Sci. Technol. 2017, 46, 43–57. [Google Scholar] [CrossRef]

- Zinn, B.T. Pulse combustion: Recent applications and research issues. Symp. Combust. 1992, 24, 1297–1305. [Google Scholar] [CrossRef]

- INPI. Instituto Nacional da Propriedade Industrial. Available online: https://www.gov.br/inpi/pt-br (accessed on 3 April 2022).

- Pereira, A.; Santos, A.Á.; Neves, P.R. Dispositivo de Combustão de Gás Natural Para o Controle das Correlações Entre Radiação térmica, Formação da Fuligem, CO e NOx Com a Utilização das Técnicas de Combustão Enriquecida Com Oxigênio e Combustão Pulsante. BR1020160229014, 29 November 2016. [Google Scholar]

- Yang, Y.; Wang, G.; Zheng, Y.; Fang, Y.; Zhong, L. A Measuring Acoustic Transmission Relation of Rotational Flow Burner Device. CN207019906U, 4 August 2017. [Google Scholar]

- Tang, G.; Hu, W.; Li, Z.; Wang, X. Pulsation Wire Mesh Catalytic Burning Device and Method. CN103244958A, 14 August 2013. [Google Scholar]

- Schuermans, B.; Güthe, F. A Pulse Metal Wire Net Catalytic Combustion Apparatus and Combustion Method, Particularly Combustion Chamber of Gas Turbine, Involves Forming Transfer Function by Two Partial Transfer Functions. DE102008022117A1, 15 June 2007. [Google Scholar]

- Deegan, T. Acousto Ionic Radio Antenna. US6211617B1, 3 April 2001. [Google Scholar]

- Gutmark, E.; Paschereit, C.O. Method and Device for Affecting Thermoacoustic Oscillations in Combustion Systems. EP1429004A2, 7 December 2002. [Google Scholar]

- WIPO. International Patent Classification (IPC); WIPO: Geneva, Switzerland, 2022. [Google Scholar]

- Zheng, S.; Liu, H.; Sui, R.; Zhou, B.; Lu, Q. Effects of radiation reabsorption on laminar NH3/H2/air flames. Combust. Flame 2021, 235, 111699. [Google Scholar] [CrossRef]

- Markellos, K.; Perdikuri, K.; Markellou, P.; Sirmakessis, S.; Mayritsakis, G.; Tsakalidis, A. Knowledge discovery in patent databases. In Proceedings of the Eleventh International Conference on Information and Kknowledge Management-CIKM’02, Online, 4 November 2002; ACM Press: New York, NY, USA, 2002; pp. 672–674. [Google Scholar]

- Ampornphan, P.; Tongngam, S. Exploring Technology Influencers from Patent Data Using Association Rule Mining and Social Network Analysis. Information 2020, 11, 333. [Google Scholar] [CrossRef]

- Kim, J.; Choi, J.; Park, S.; Jang, D. Patent Keyword Extraction for Sustainable Technology Management. Sustainability 2018, 10, 1287. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Porter, A.L. Analyzing patent topical information to identify technology pathways and potential opportunities. Scientometrics 2015, 102, 811–827. [Google Scholar] [CrossRef]

| IPC Code | Related to |

|---|---|

| F23D 14/32 | Burners for the combustion of a gas, e.g., of a gas stored under pressure as a liquid using a mixture of gaseous fuel and pure oxygen or oxygen-enriched air. |

| G01M 15/04 | Testing the static or dynamic balance of machines or structures; testing of structures or apparatus not otherwise provided for testing internal combustion engines |

| Title | Technology | Main Findings and/or Conclusions | References |

|---|---|---|---|

| A study on acoustically modulated Bunsen flame and its impingement heat transfer | Acoustic | This study experimentally examined the interaction between an acoustic field and a flame by using a low-power loudspeaker to actuate the oscillation of a Bunsen flame. The results showed a 10% increase in total heat-transfer rate when the optimum nozzle-to-plate distance was coupled with the most effective forcing frequency of 50 Hz. | [49] |

| Soot evolution and flame response to acoustic forcing of laminar non-premixed jet flames at varying amplitudes | Acoustic | The authors evaluated the mechanisms that affect soot evolution in time-varying flames of different burner diameters under both steady and forced conditions. The results showed that by increasing the forcing amplitude from low to moderate (from α = 25% to 50%), the soot volume was increased by 50%. However, for the 5.6 mm-diameter burner, a further increase in the forcing amplitude (from α = 50% to 75%) did not increase soot production significantly. They concluded that the spatial correlation between the soot field and the temperature profile is influenced by the burner diameter and forcing conditions. | [12] |

| Flame structure changes resulting from hydrogen-enrichment and pressurization for low-swirl premixed methane–air flames | OEC | This study demonstrated how flame dynamics change in response to the systematic addition of hydrogen in a low-swirl lean premixed methane–air burner. They evaluated 0%, 20%, and 40% hydrogen by volume in fuel mixtures in a low-swirl burner at several chamber pressures. The results indicated that increasing the pressure and hydrogen concentration led to an increase in the maximum density of the flame surface. | [50] |

| Experimental investigation of the natural gas confined flames using the OEC | OEC | This study experimentally evaluated the technique of OEC and its interaction with soot formation and thermal radiation in natural-gas-confined flames. The levels of air enrichment applied were 2% and 4%, and the results suggested that the use of OEC in natural-gas-confined flames produced an increase in thermal radiation coupled with significant reductions in NOx formation. | [40] |

| Experimental investigation of thermoacoustic coupling using blended hydrogen–methane fuels in a low swirl burner | OEC + Acoustic | The aim of this study was to determine the effect of OEC on combustion instability by examining the flame response to a range of three different blends of hydrogen and methane (93% CH4–7% H2, 80% CH4–20% H2, and 70% CH4–30% H2 by volume) employed as fuel with four different acoustic excitation frequencies (85, 125, 222, and 399 Hz). The flame showed increases in flame base coupling and flame compaction with increasing hydrogen concentration for all conditions. | [51] |

| Experimental evaluation of CO, NOx, formaldehyde, and acetaldehyde emission rates in a combustion chamber with OEC under acoustic excitation | OEC + Acoustic | This article experimentally evaluated the interaction of the OEC technique with the pulsating combustion technique by the acoustic excitation of flames and the effects of these techniques on atmospheric emissions of CO, NOx, formaldehyde, and acetaldehyde. The results showed that the application of the OEC and acoustic excitation techniques could reduce pollutant emissions and increase the efficiency of thermal combustion equipment. | [11] |

| Priority Number | Title | Refers to | References |

|---|---|---|---|

| CN207019906U | A measuring acoustic transmission relation of rotational flow burner device. | Rotary flow burner in which an air and fuel premix is fed by means of an acoustically excited sonic vibrator measured by a device for determining the thermoacoustic transfer ratio with the burner. | [75] |

| CN103244958A | A pulse metal wire net catalytic combustion apparatus and combustion method. | Catalytic combustion device that has a pulsating metal wire mesh arranged in an acoustic decoupling chamber connected to a heat radiation duct and a Rijke tube. | [76] |

| CH2007964A | Method for determining thermoacoustic transfer function of burner of combustion system, particularly combustion chamber of gas turbine, involves forming transfer function by two partial transfer functions. | Method that performs and evaluates the application of a thermoacoustic transfer function of a burner of a combustion system, more particularly the combustion chamber of a gas turbine. | [77] |

| US6211617B1 | Acousto ionic radio antenna. | Plasma antenna that uses an acoustic mechanism to accelerate plasma ions, causing them to radiate electromagnetic energy into a fuel/air-based burner. | [78] |

| EP1429004A2 | Method and device for affecting thermoacoustic oscillations in combustion systems. | A burner and a combustion chamber are used to effect modulated fuel injection into a recirculation zone formed in the combustion chamber in order to improve the influence of thermoacoustic vibrations. | [79] |

| IPC Code | Related to |

|---|---|

| F23R 3/28 | Continuous combustion chambers using liquid or gaseous fuel characterized by the fuel supply. |

| F23M 20/00 | Details of combustion chambers not otherwise provided for. |

| F23M 99/00 | Baffles or deflectors for air or combustion products; flame shields. |

| F23R 3/00 | Continuous combustion chambers using liquid or gaseous fuel. |

| F23R 3/34 | Continuous combustion chambers using liquid or gaseous fuel of the fluid-screen type. |

| F23C 7/00 | Combustion apparatus characterized by arrangements for air supply. |

| F23N 5/16 | Systems for controlling combustion using noise-sensitive detectors. |

| F23D 14/02 | Burners for the combustion of a gas, e.g., of a gas stored under pressure as a liquid; premix gas burners, i.e., in which gaseous fuel is mixed with combustion air upstream of the combustion zone. |

| F23D 14/46 | Burners for the combustion of a gas, e.g., of a gas stored under pressure as a liquid; |

| F02C 7/24 | Features, component parts, details, or accessories, not provided for in or of interest apart from air intakes for jet-propulsion plants; heat or noise insulation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, A.Á.B.; Neves, P.R.F.; Oliveira, F.O.; Nunes, D.D.G.; Machado, B.A.S. Patent Analysis of the Development of Technologies Applied to the Combustion Process. Appl. Sci. 2022, 12, 5858. https://doi.org/10.3390/app12125858

Santos AÁB, Neves PRF, Oliveira FO, Nunes DDG, Machado BAS. Patent Analysis of the Development of Technologies Applied to the Combustion Process. Applied Sciences. 2022; 12(12):5858. https://doi.org/10.3390/app12125858

Chicago/Turabian StyleSantos, Alex Álisson Bandeira, Paulo Roberto Freitas Neves, Fabricia Oliveira Oliveira, Danielle Devequi Gomes Nunes, and Bruna Aparecida Souza Machado. 2022. "Patent Analysis of the Development of Technologies Applied to the Combustion Process" Applied Sciences 12, no. 12: 5858. https://doi.org/10.3390/app12125858

APA StyleSantos, A. Á. B., Neves, P. R. F., Oliveira, F. O., Nunes, D. D. G., & Machado, B. A. S. (2022). Patent Analysis of the Development of Technologies Applied to the Combustion Process. Applied Sciences, 12(12), 5858. https://doi.org/10.3390/app12125858