Centrifugal Modeling of the Relationship between Tunnel Face Support Pressure and Ground Deformation in Water-Rich Sandy Soil

Abstract

:1. Introduction

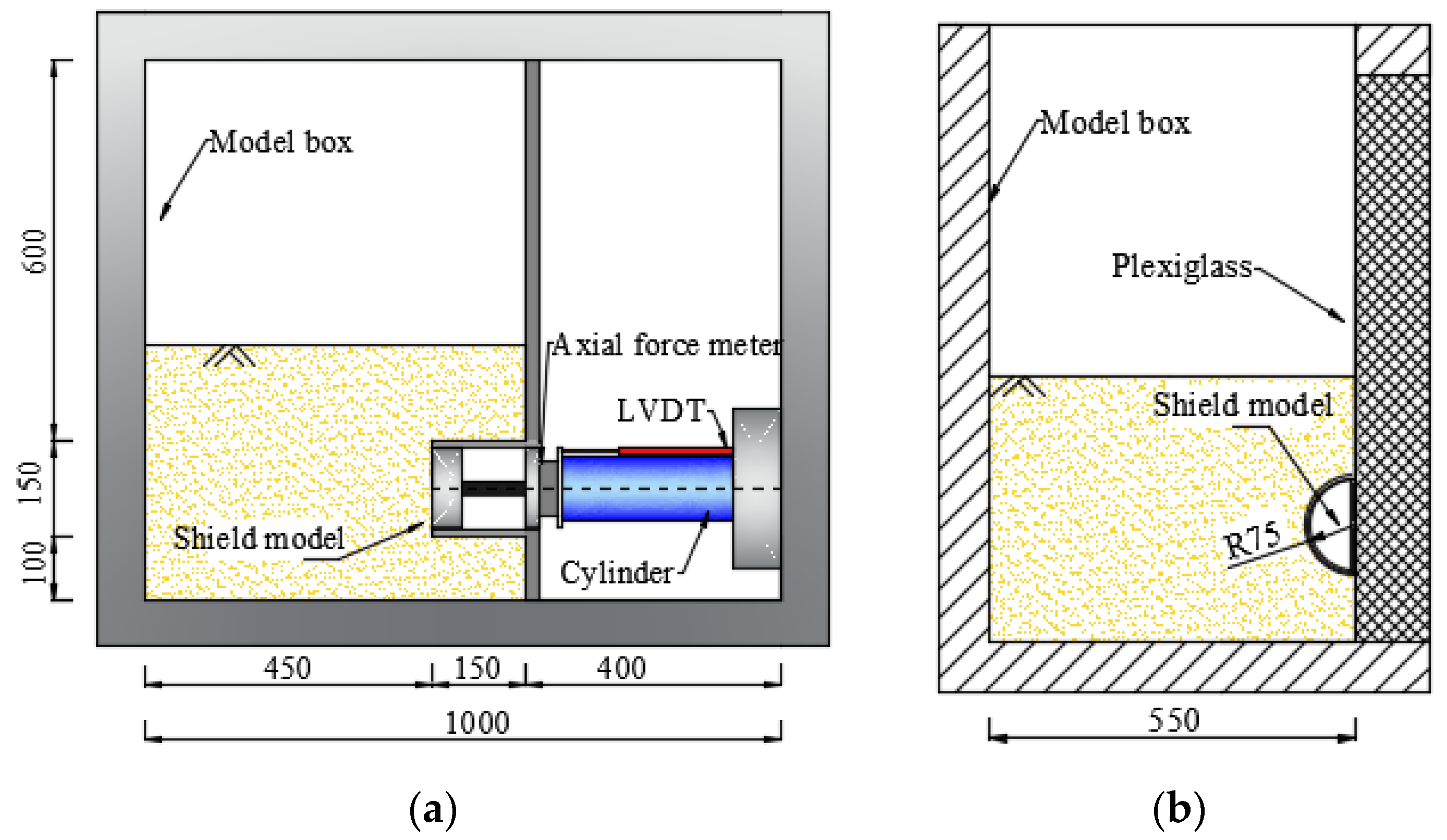

2. Centrifuge Model Test

2.1. Model Setup

2.2. Material Properties

2.3. Monitoring Scheme

2.4. Test Procedure

- (1)

- The test equipment was assembled and the waterproof treatment was conducted. Then, the sand is layered in the model box by the sand rain method, the flow rate is about 1.5 kg/min, and the falling distance is 500 mm. The earth pressure sensors as well as pore pressure sensors were embedded in predetermined positions. The sand spraying is stopped when the predetermined covering thickness C is reached, and the water pipe network at the bottom of the model box is saturated and infiltrated to the design water level.

- (2)

- After completion of model preparation and final check, the model container was transferred to the swinging platform and fixed. Then, install the LED light source and high-definition camera, adjust the LED flood light source position and camera position, focal length, etc. to meet the required photographing conditions. After fixing the camera, calibrate the photographing area to achieve the required accuracy. The prepared model is shown in Figure 5. Finally, close the door and start the machine and data collecting system.

- (3)

- Accelerate slowly and continuously correct the counterweight till reaching equilibrium. Then accelerate to 83.7 g to consolidate the soil. After all the sensor data are stable, the faceplate is pushed forward slowly at a speed of about 0.05 mm/s. The stresses and displacements in the soil mass are monitored. The specific jacking process in the experiment is controlled according to the real-time observation of the soil deformation by the camera and the monitored data during the test.

- (4)

- After finish the process of excess support pressure, slowly back the faceplate at a speed of about 0.1 mm/s and observe the change of the support pressure. When the support pressure drops to the initial level, stop the action and stabilize for 3 min. Then, continues to back the faceplate at a speed of about 0.1 mm/s until active face failure occurs. Similar to the case of excess support pressure, stresses and displacements in the soil mass are monitored.

- (5)

- After finish all the actions, gradually reduce the centrifuge acceleration from 83.7 g to 0 and lift the model device out of the centrifuge basket. Shut down the machine, excavate the soil and sensors, clean the soil box and equipment, wash the sand and dry it for the next set of tests.

3. Test Results

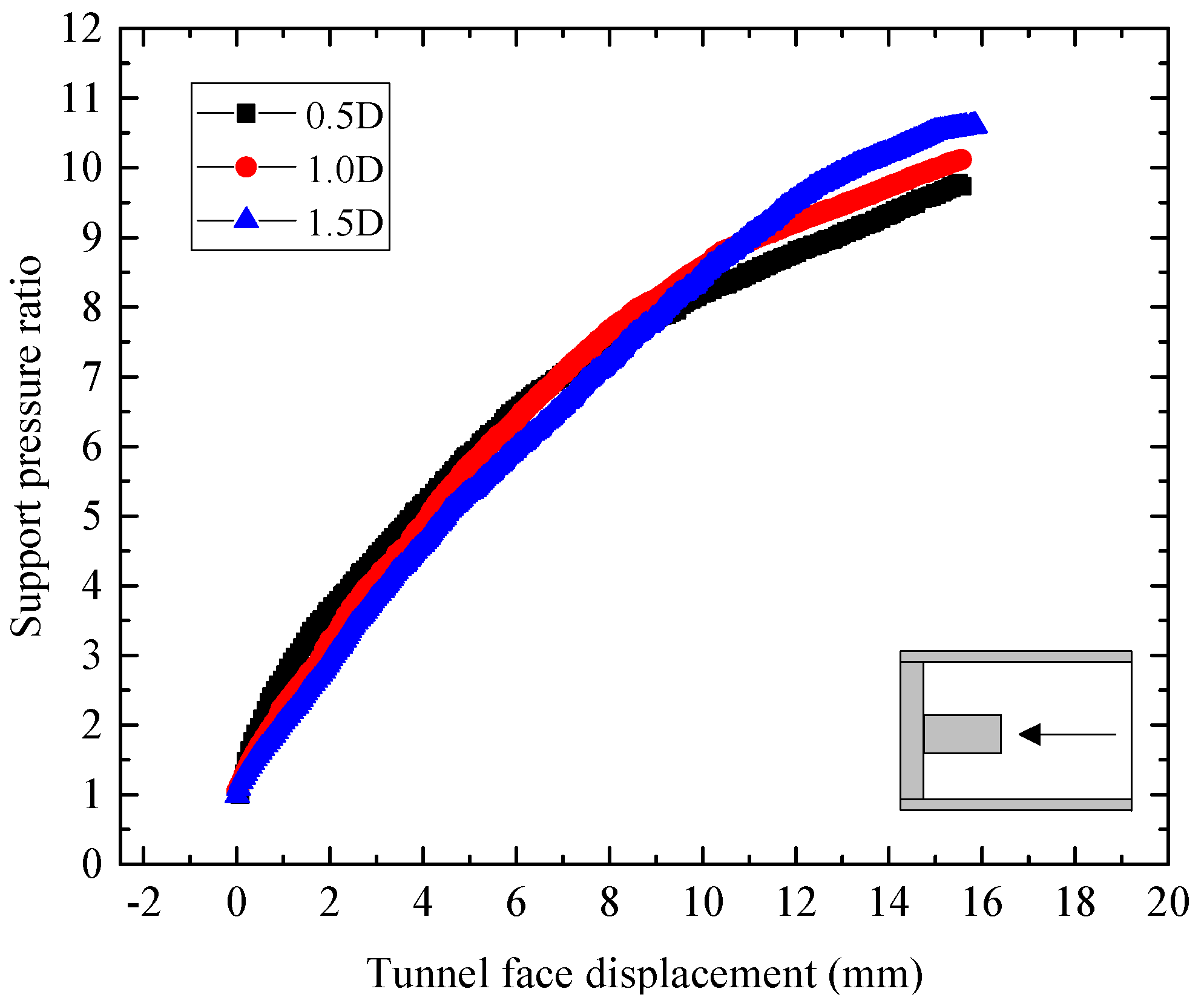

3.1. Excess Support Pressure

3.1.1. Support Pressure Ratio

3.1.2. Soil and Pore Pressure

3.1.3. Maximum Heave

3.1.4. Measurement of Soil Deformation with PIV

3.2. Insufficient Support Pressure

3.2.1. Support Pressure Ratio

3.2.2. Soil and Pore Pressure

3.2.3. Maximum Heave

3.2.4. Measurement of Soil Deformation with PIV

4. Discussion

4.1. Ground Deformation Mechanism

4.2. Surface Displacement

4.2.1. Settlement Trough Width

4.2.2. Relationship between Support Pressure and Maximum Displacement

4.3. Control of Support Pressure Based on the Surface Displacement

5. Conclusions

- (1)

- The ground disturbance range induced by excess support pressure is approximately fishtail-shaped. When the burial depth is shallow (<1.5D), the surface disturbance range can extend horizontally to about twice buried depth beyond the front of the face and the maximum heave occurred at a distance of approximately buried depth beyond the front of the excavation face. However, when the burial depth is large (≥1.5D), the ground deformation caused by the excess support pressure is difficult to extend to the surface, but it will cause great disturbance in the ground.

- (2)

- The ground disturbance range induced by insufficient support pressure is approximately chimney-shaped. The range of ground disturbance area in water-rich sand soil induced by insufficient support pressure was observed to extend horizontally to about buried depth beyond the front of the face which was larger than that in dry sand soil. The shallower the buried depth, the more sensitive the ground deformation as well as the greater the range of ground surface settlement.

- (3)

- A supporting pressure control coefficient which is related to buried depth is proposed to quantitatively describe the relationships between the surface displacement with support pressure and the relationship was found linear before the excavation face reaching the limit state.

- (4)

- The effect of reducing the initial settlement by increasing the support pressure is limited, and may even further cause greater surface settlement directly above the excavation surface. In comparison, the ground deformation is more sensitive in the case of insufficient support pressure. For shallow tunnels, the support pressure needs to be strictly controlled to avoid being insufficient while for deep tunnels, if the supporting pressure is insufficient, it is necessary to pay attention to the discharge amount of soil to avoid further accelerating the ground deformation disturbance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Cai, Y.; Zhu, W. Numerical Study and Field Monitoring of the Ground Deformation Induced by Large Slurry Shield Tunnelling in Sandy Cobble Ground. Adv. Civ. Eng. 2019, 2019, 4145721. [Google Scholar] [CrossRef] [Green Version]

- Yuan, D.J.; Yin, F.; Wang, H.W.; Qingfei, H.; Heng, X. Study of soil disturbance caused by super-large diameter slurry shield tunnelling. Chin. J. Rock Mech. Eng. 2009, 28, 2074–2080. (In Chinese) [Google Scholar]

- Yuan, D.J.; Huang, Q.F.; Wang, Y. Risk Analysis and Countermeasures of Nanjing Yangtze River Tunnel During Large Diameter Slurry Shield Tunneling. In Proceedings of the 2009 International Symposium on Risk Control and Management of Design, Construction and Operation in Underground Engineering, Dalian, China, 20–22 October 2009; pp. 190–193. [Google Scholar]

- Luo, W.; Yuan, D.; Jin, D.; Lu, P.; Chen, J. Optimal Control of Slurry Pressure during Shield Tunnelling Based on Random Forest and Particle Swarm Optimization. Comput. Model. Eng. Sci. 2021, 128, 109–127. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Liu, S.; Li, X.; Luo, W. Performance of Existing Subway Tunnels Undercrossed by Four Closely Spaced Shield Tunnels. J. Perform. Constr. Facil. 2018, 33, 04018099. [Google Scholar] [CrossRef]

- Yuan, D.; Luo, W.; Jin, D.; Lu, P. Hydraulic fracturing pressure of concentric double-layered cylinder in cohesive soil. Front. Struct. Civ. Eng. 2021, 15, 937–947. [Google Scholar] [CrossRef]

- Lu, P.; Yuan, D.; Chen, J.; Jin, D.; Wu, J.; Luo, W. Face Stability Analysis of Slurry Shield Tunnels in Rock-Soil Interface Mixed Ground. KSCE J. Civ. Eng. 2021, 25, 2250–2260. [Google Scholar] [CrossRef]

- Jin, D.; Zhang, Z.; Yuan, D. Effect of dynamic cutterhead on face stability in EPB shield tunneling. Tunn. Undergr. Space Technol. 2021, 110, 103827. [Google Scholar] [CrossRef]

- Mollon, G.; Dias, D.; Soubra, A.-H. Probabilistic analyses of tunneling-induced ground movements. Acta Geotech. 2013, 8, 181–199. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Sayed, G.; Salib, S.R. Minimum depth of soil cover above soil–steel bridges. J. Geotech. Geoenvironmental Eng. 2002, 128, 672–681. [Google Scholar] [CrossRef]

- Yeau, K.Y.; Sezen, H.; Fox, P.J. Simulation of behavior of in-service metal culverts. J. Pipeline Syst. Eng. Pract. 2014, 5, 04013016. [Google Scholar] [CrossRef]

- Brachman, R.W.I.; Elshimi, T.M.; Mak, A.C.; Moore, I.D. Testing and Analysis of a Deep-Corrugated Large-Span Box Culvert prior to Burial. J. Bridg. Eng. 2012, 17, 81–88. [Google Scholar] [CrossRef]

- Lei, H.; Zhang, Y.; Hu, Y.; Liu, Y. Model test and discrete element method simulation of shield tunneling face stability in transparent clay. Front. Struct. Civ. Eng. 2021, 15, 147–166. [Google Scholar] [CrossRef]

- Berthoz, N.; Branque, D.; Subrin, D.; Wong, H.; Humbert, E. Face failure in homogeneous and stratified soft ground: Theoretical and experimental approaches on 1g EPBS reduced scale model. Tunn. Undergr. Space Technol. 2012, 30, 25–37. [Google Scholar] [CrossRef]

- Wong, K.; Sing, W.K.; Chen, Y.; Bian, X. Centrifuge and numerical investigation of passive failure of tunnel face in sand. Tunn. Undergr. Space Technol. 2012, 28, 297–303. [Google Scholar] [CrossRef]

- Ng, C.; Wong, K. Investigation of passive failure and deformation mechanisms due to tunnelling in clay. Can. Geotech. J. 2013, 50, 359–372. [Google Scholar] [CrossRef]

- Kasper, T.; Meschke, G. A numerical study of the effect of soil and grout material properties and cover depth in shield tunnelling. Comput. Geotech. 2006, 33, 234–247. [Google Scholar] [CrossRef]

- Hu, X.; Fu, W.; Ju, J.W.; He, C.; Fang, Y.; Wang, J. Face stability conditions in granular soils during the advancing and stopping of earth-pressure-balanced-shield machine. Tunn. Undergr. Space Technol. 2021, 109, 103755. [Google Scholar] [CrossRef]

- Chen, R.; Yin, X.; Tang, L.; Chen, Y. Centrifugal model tests on face failure of earth pressure balance shield induced by steady state seepage in saturated sandy silt ground. Tunn. Undergr. Space Technol. 2018, 81, 315–325. [Google Scholar] [CrossRef]

- Franza, A.; Marshall, A.M.; Zhou, B. Greenfield tunnelling in sands: The effects of soil density and relative depth. Geotechnique 2019, 69, 297–307. [Google Scholar] [CrossRef] [Green Version]

- Soranzo, E.; Tamagnini, R.; Wu, W. Face stability of shallow tunnels in partially saturated soil: Centrifuge testing and numerical analysis. Geotechnique 2015, 65, 454–467. [Google Scholar] [CrossRef]

- Davis, E.H.; Gunn, M.J.; Mair, R.J.; Seneviratine, H.N. The stability of shallow tunnels and underground openings in cohesive material. Geotechnique 1980, 30, 397–416. [Google Scholar] [CrossRef]

- Anagnostou, G.; Kovári, K. The face stability of slurry-shield-driven tunnels. Tunn. Undergr. Space Technol. 1994, 9, 165–174. [Google Scholar] [CrossRef]

- Mollon, G.; Dias, D.; Soubra, A.-H. Face Stability Analysis of Circular Tunnels Driven by a Pressurized Shield. J. Geotech. Geoenvironmental Eng. 2009, 136, 215–229. [Google Scholar] [CrossRef] [Green Version]

- Idinger, G.; Aklik, P.; Wu, W.; Borja, R.I. Centrifuge model test on the face stability of shallow tunnel. Acta Geotech. 2011, 6, 105–117. [Google Scholar] [CrossRef] [Green Version]

- Verruijt, A.; Booker, J.R. Surface settlements due to deformation of a tunnel in an elastic half plane. Géotechnique 1998, 48, 709–713. [Google Scholar] [CrossRef]

- Peck, R.B. Deep Excavations and Tunneling in Soft Ground. Proc. 7th ICSMFE 1969, 225–290. Available online: https://ci.nii.ac.jp/naid/10012600540/ (accessed on 8 May 2022).

- Zhu, C.; Li, N. Prediction and analysis of surface settlement due to shield tunneling for Xi’an Metro. Can. Geotech. J. 2017, 54, 529–546. [Google Scholar] [CrossRef]

- Jin, D.; Shen, X.; Yuan, D. Theoretical analysis of three-dimensional ground displacements induced by shield tunneling. Appl. Math. Model. 2020, 79, 85–105. [Google Scholar]

- Zhang, Z.; Hu, X.; Scott, K.D. A discrete numerical approach for modeling face stability in slurry shield tunnelling in soft soils. Comput. Geotech. 2011, 38, 94–104. [Google Scholar] [CrossRef]

- Zhang, C.; Han, K.; Zhang, D. Face stability analysis of shallow circular tunnels in cohesive–frictional soils. Tunn. Undergr. Space Technol. 2015, 50, 345–357. [Google Scholar] [CrossRef]

- Pan, Q.; Dias, D. The effect of pore water pressure on tunnel face stability. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 2123–2136. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, R.-P.; Wu, H.-N.; Liu, Y. Ground settlement induced by tunneling crossing interface of water-bearing mixed ground: A lesson from Changsha, China. Tunn. Undergr. Space Technol. 2020, 96, 103224. [Google Scholar] [CrossRef]

- Yin, X.; Chen, R.; Meng, F.; Ding, Z.; Cui, Y.; Hedayat, A.; Mooney, M. Face stability of slurry-driven shield with permeable filter cake. Tunn. Undergr. Space Technol. 2021, 111, 103841. [Google Scholar] [CrossRef]

- Maleska, T.; Beben, D. Numerical analysis of a soil-steel bridge during backfilling using various shell models. Eng. Struct. 2019, 196, 109358. [Google Scholar] [CrossRef]

- Aydingun, O.; Adalier, K. Numerical analysis of seismically induced liquefaction in earth embankment foundations. Part I. Benchmark model. Can. Geotech. J. 2003, 40, 753–765. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, P.; Wu, H.; Wang, Z.; Zhong, Z. Prediction of shield tunneling-induced ground settlement using machine learning techniques. Front. Struct. Civ. Eng. 2019, 13, 1363–1378. [Google Scholar] [CrossRef]

- Garnier, J.; Gaudin, C.; Springman, S.M.; Culligan, P.J.; Goodings, D.; Konig, D.; Kutter, B.; Phillips, R.; Randolph, M.F.; Thorel, L. Catalogue of scaling laws and similitude questions in geotechnical centrifuge modelling. Int. J. Phys. Model. Geotech. 2007, 7, 1–23. [Google Scholar] [CrossRef]

- Chapman, D.N.; Ahn, S.K.; Hunt, D.V. Investigating ground movements caused by the construction of multiple tunnels in soft ground using laboratory model tests. Can. Geotech. J. 2007, 44, 631–643. [Google Scholar] [CrossRef]

- Chen, R.-P.; Li, J.; Kong, L.-G.; Tang, L.-J. Experimental study on face instability of shield tunnel in sand. Tunn. Undergr. Space Technol. 2013, 33, 12–21. [Google Scholar] [CrossRef]

- Subrin, D. Etudes Théoriques sur la Stabilité et le Comportement des Tunnels Renforcés par Boulonnage. Ph.D. Thesis, Institut National des Sciences Appliquées de Lyon, Villeurbanne, France, 2002. [Google Scholar]

- Leca, E.; Dormieux, L. Upper and lower bound solutions for the face stability of shallow circular tunnels in frictional material. Geotechnique 1990, 40, 581–606. [Google Scholar] [CrossRef] [Green Version]

- Chambon, P.; Corté, J. Shallow Tunnels in Cohesionless Soil: Stability of Tunnel Face. J. Geotech. Eng. 1994, 120, 1148–1165. [Google Scholar] [CrossRef]

- Horn, N. Horizontaler erddruck auf senkrechte abschlussflächen von tunnelröhren. Landeskonferenz Der Ung. Tiefbauindustrie 1961, 7, 16. [Google Scholar]

- Zhang, P.; Yin, Z.-Y.; Chen, R.-P. Analytical and Semi-Analytical Solutions for Describing Tunneling-Induced Transverse and Longitudinal Settlement Troughs. Int. J. Géomeéch. 2020, 20, 04020126. [Google Scholar] [CrossRef]

- Zhao, C.; Lavasan, A.A.; Barciaga, T.; Schanz, T. Mechanized tunneling induced ground movement and its dependency on the tunnel volume loss and soil properties. Int. J. Numer. Anal. Methods Géoméch. 2019, 43, 781–800. [Google Scholar] [CrossRef]

- O’Reilly, M.P.; New, B.M. Settlements above Tunnels in the United Kingdom-Their Magnitude and Prediction. 1982. Available online: https://trid.trb.org/view/186714 (accessed on 8 May 2022).

| Quantity | Gravity/(m·s2) | Diameter of Tunnel/m | Deformation/mm | Density/kg/m3 | Stress/kPa | Elastic Modulus/MPa |

|---|---|---|---|---|---|---|

| Similarity ratio | 1:83.7 | 1:83.7 | 1:83.7 | 1:1 | 1:1 | 1:1 |

| Material | Dry Density/ρd (kg/m3) | Elastic Modulus/E (MPa) | Poisson’s Ratio/v | Cohesive/c (kPa) | Frictional Angel/φ (°) | Porosity/n | Average Particle Size /d50 (mm) | Maximum Porosity/emax | Minimum Porosity/emin |

|---|---|---|---|---|---|---|---|---|---|

| Sand | 1460 | 20 | 0.3 | 0 | 30 | 0.46 | 0.2 | 0.97 | 0.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, W.; Yuan, D.; Jin, D.; Lu, P.; Chen, J.; Yang, G. Centrifugal Modeling of the Relationship between Tunnel Face Support Pressure and Ground Deformation in Water-Rich Sandy Soil. Appl. Sci. 2022, 12, 5802. https://doi.org/10.3390/app12125802

Luo W, Yuan D, Jin D, Lu P, Chen J, Yang G. Centrifugal Modeling of the Relationship between Tunnel Face Support Pressure and Ground Deformation in Water-Rich Sandy Soil. Applied Sciences. 2022; 12(12):5802. https://doi.org/10.3390/app12125802

Chicago/Turabian StyleLuo, Weiping, Dajun Yuan, Dalong Jin, Ping Lu, Jian Chen, and Gongbiao Yang. 2022. "Centrifugal Modeling of the Relationship between Tunnel Face Support Pressure and Ground Deformation in Water-Rich Sandy Soil" Applied Sciences 12, no. 12: 5802. https://doi.org/10.3390/app12125802

APA StyleLuo, W., Yuan, D., Jin, D., Lu, P., Chen, J., & Yang, G. (2022). Centrifugal Modeling of the Relationship between Tunnel Face Support Pressure and Ground Deformation in Water-Rich Sandy Soil. Applied Sciences, 12(12), 5802. https://doi.org/10.3390/app12125802