Investigation of the Heat Transfer and Pressure Drop in Tubes with Transverse Ribs of Zigzag Configurations

Abstract

1. Introduction

2. Numerical Modeling

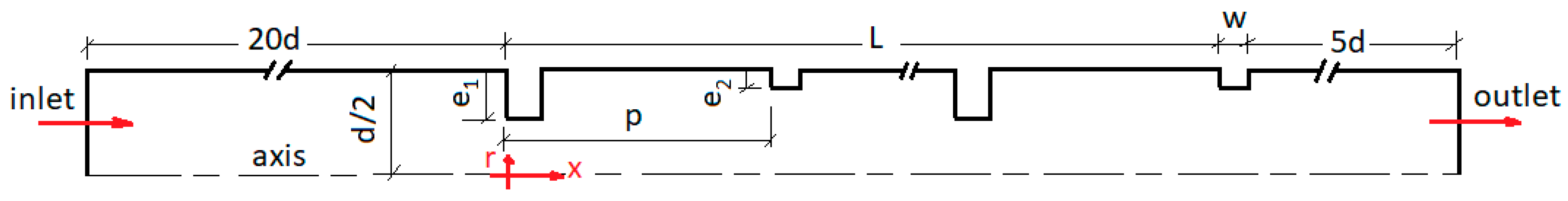

2.1. The Physical Model

2.2. Governing Equations

2.2.1. The Continuity Equation

2.2.2. The Momentum Equation

2.2.3. The Energy Equation

2.3. Data Reduction

2.4. Computational Domain and Boundary Conditions

2.5. Verification of the Numerical Model

2.5.1. Smooth Pipe Verification

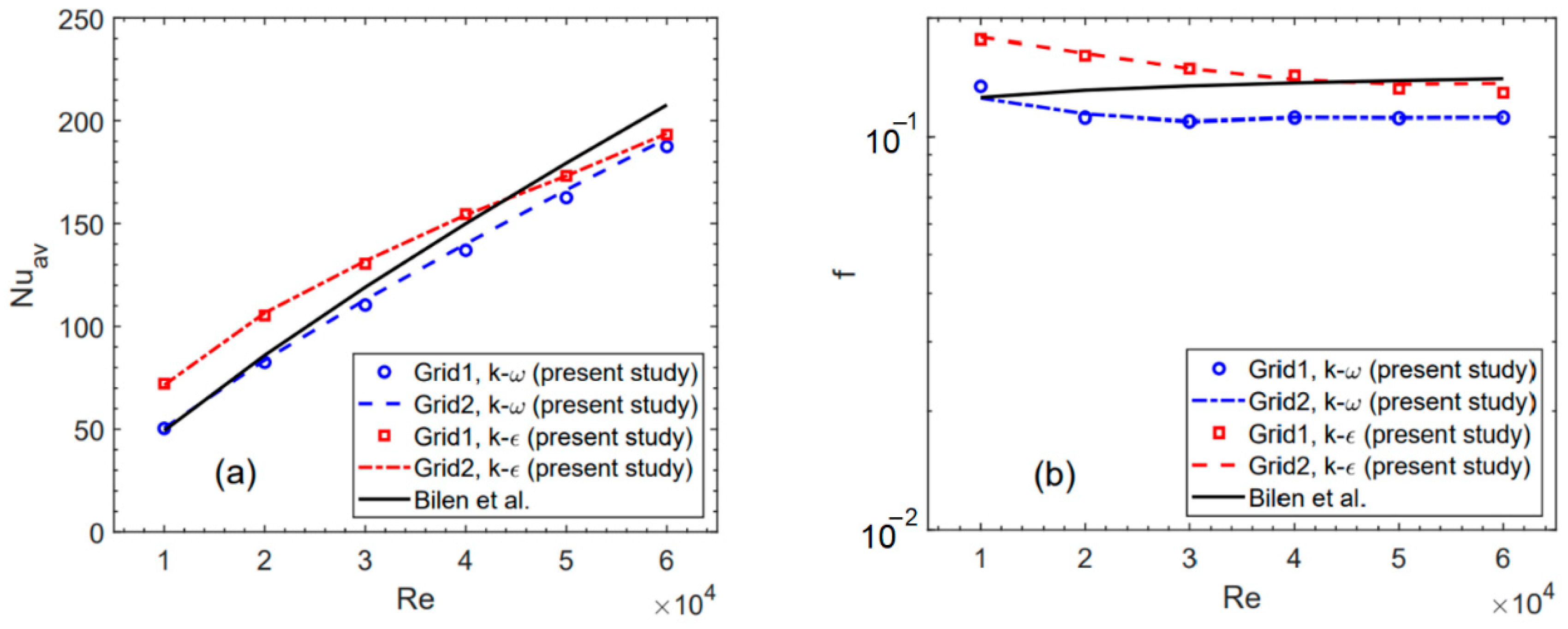

2.5.2. Ribbed Pipe Verification

3. Results and Discussion

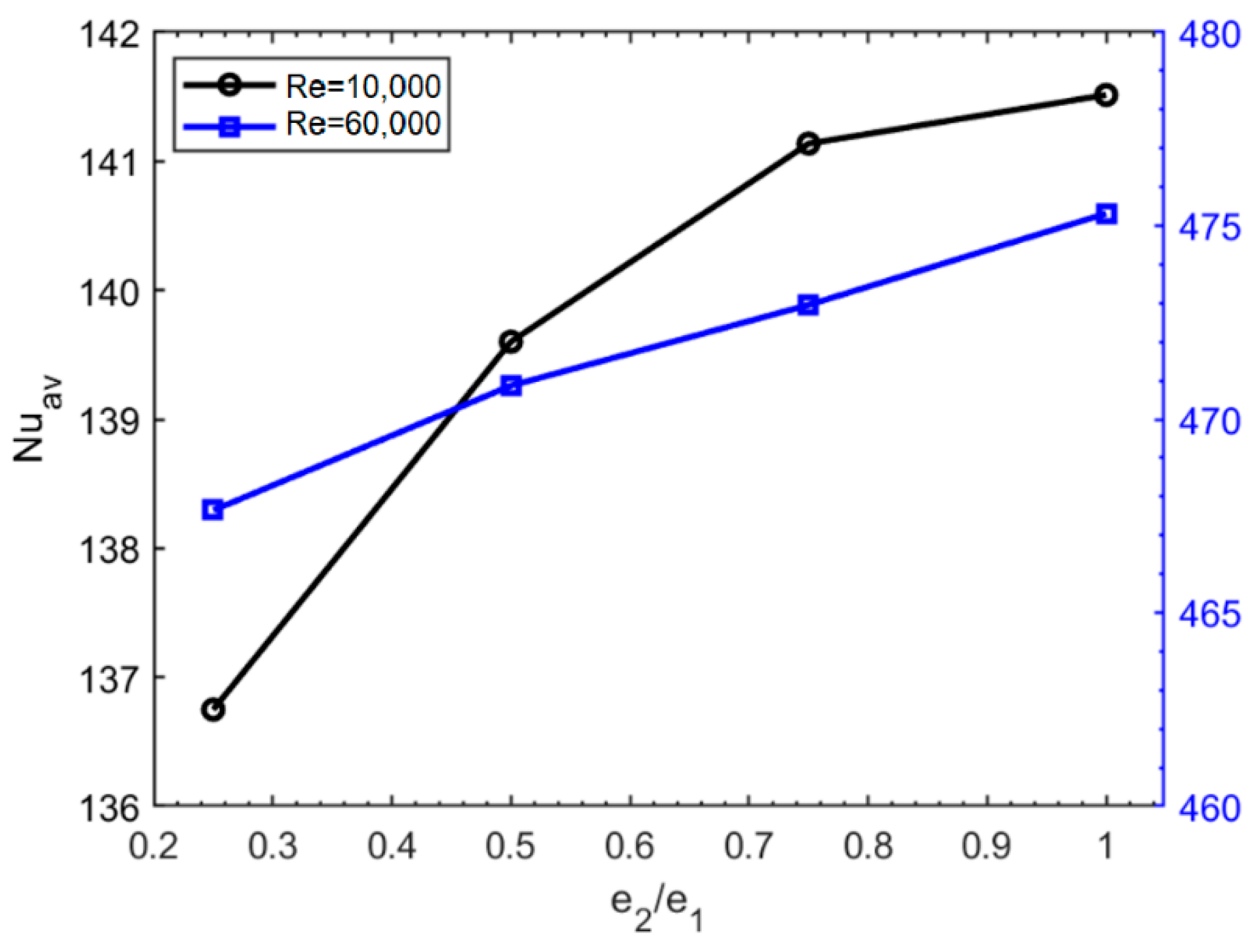

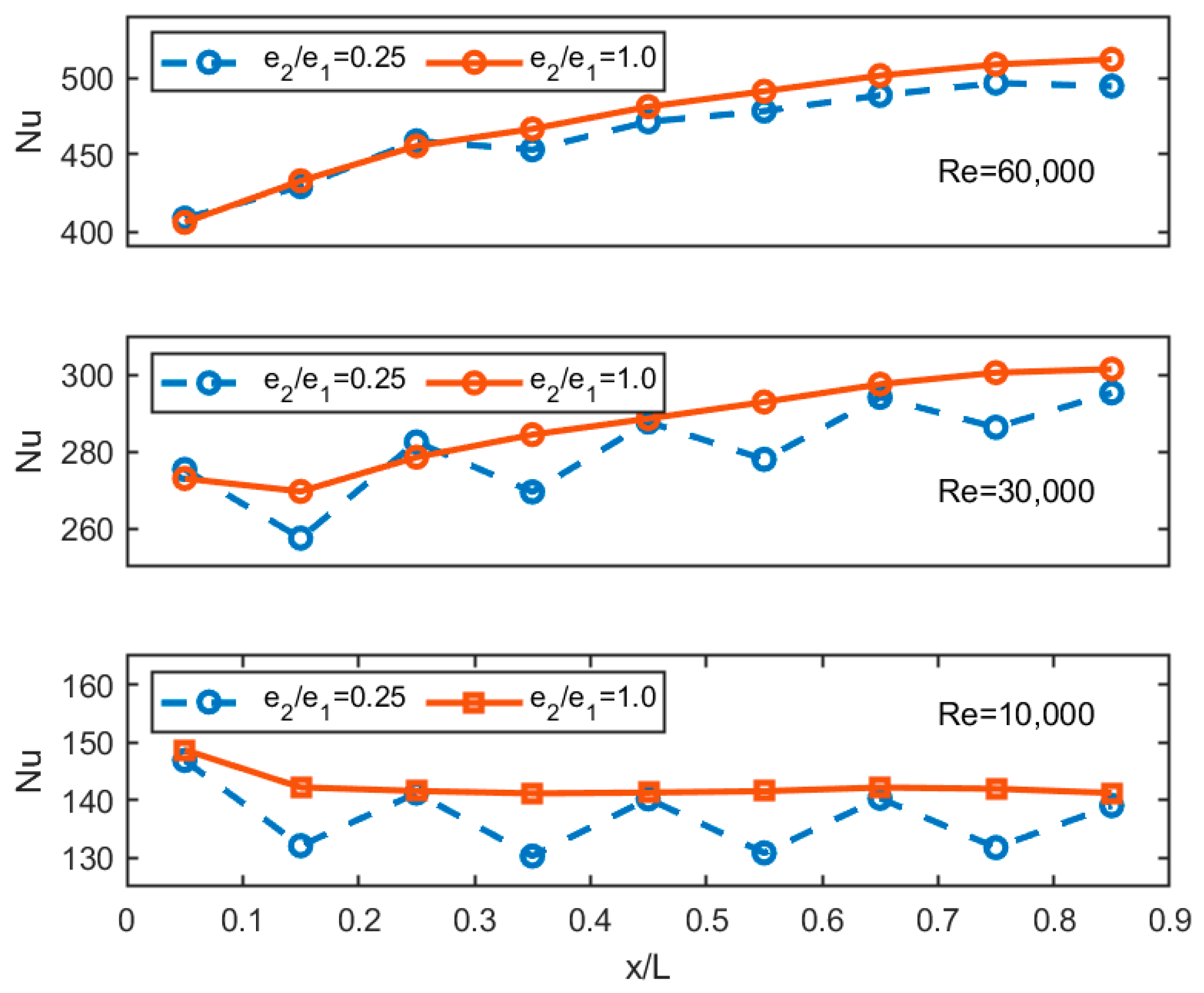

3.1. Effect of the Zigzag Ratio and Pr Number on the Nu Number

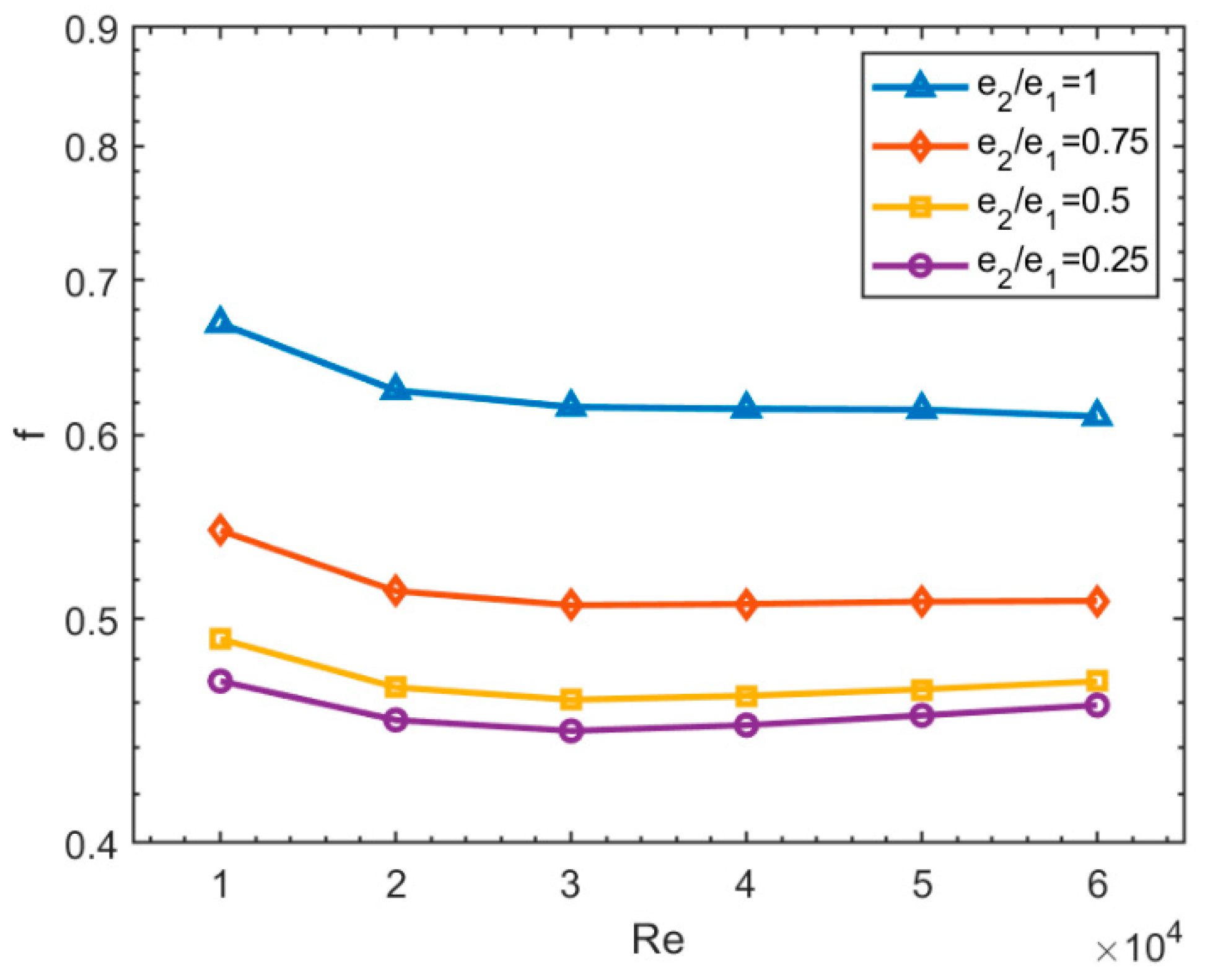

3.2. Effect of the Zigzag Ratio on the Friction Factor

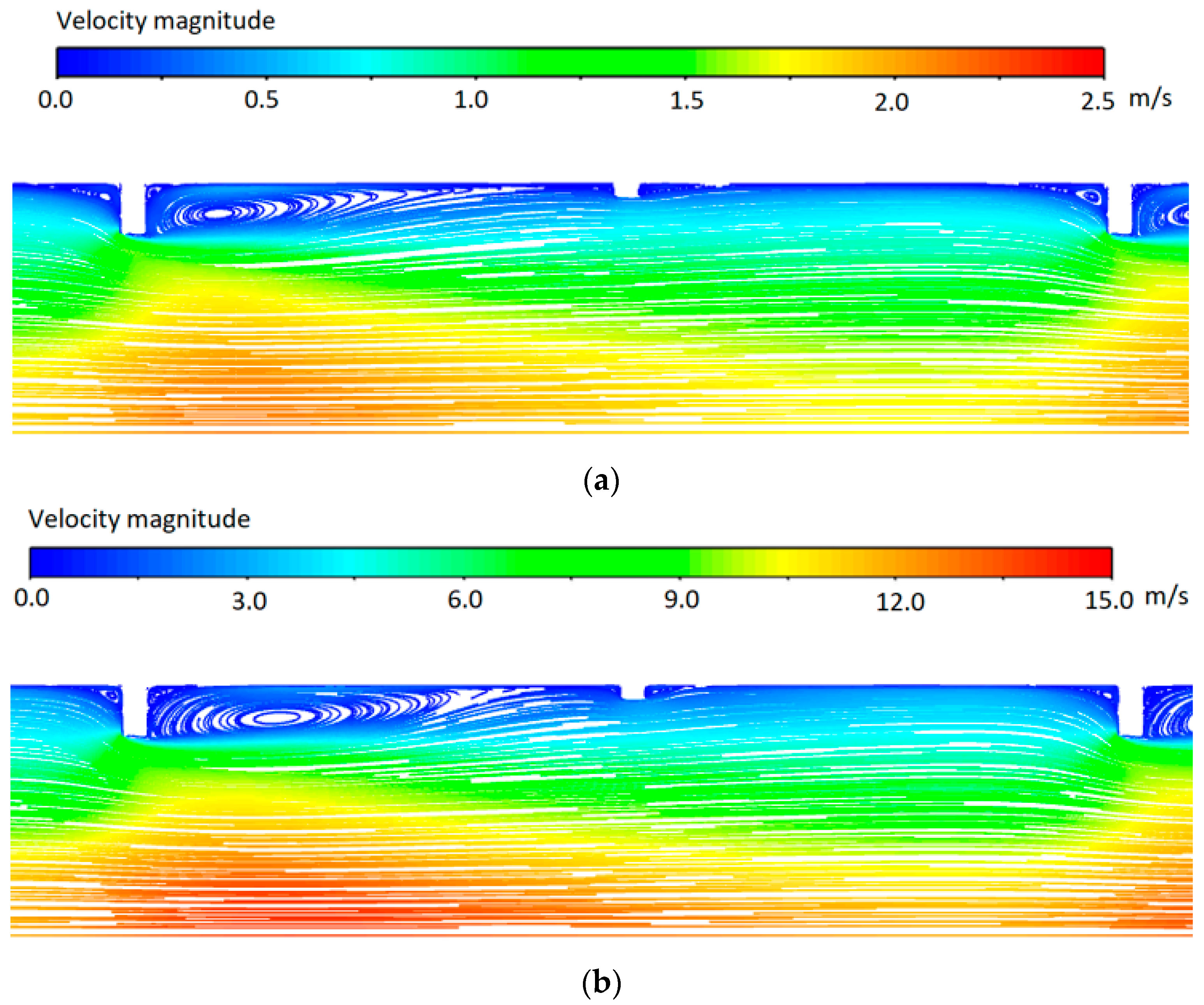

3.3. Streamlines and Velocity Flow Fields

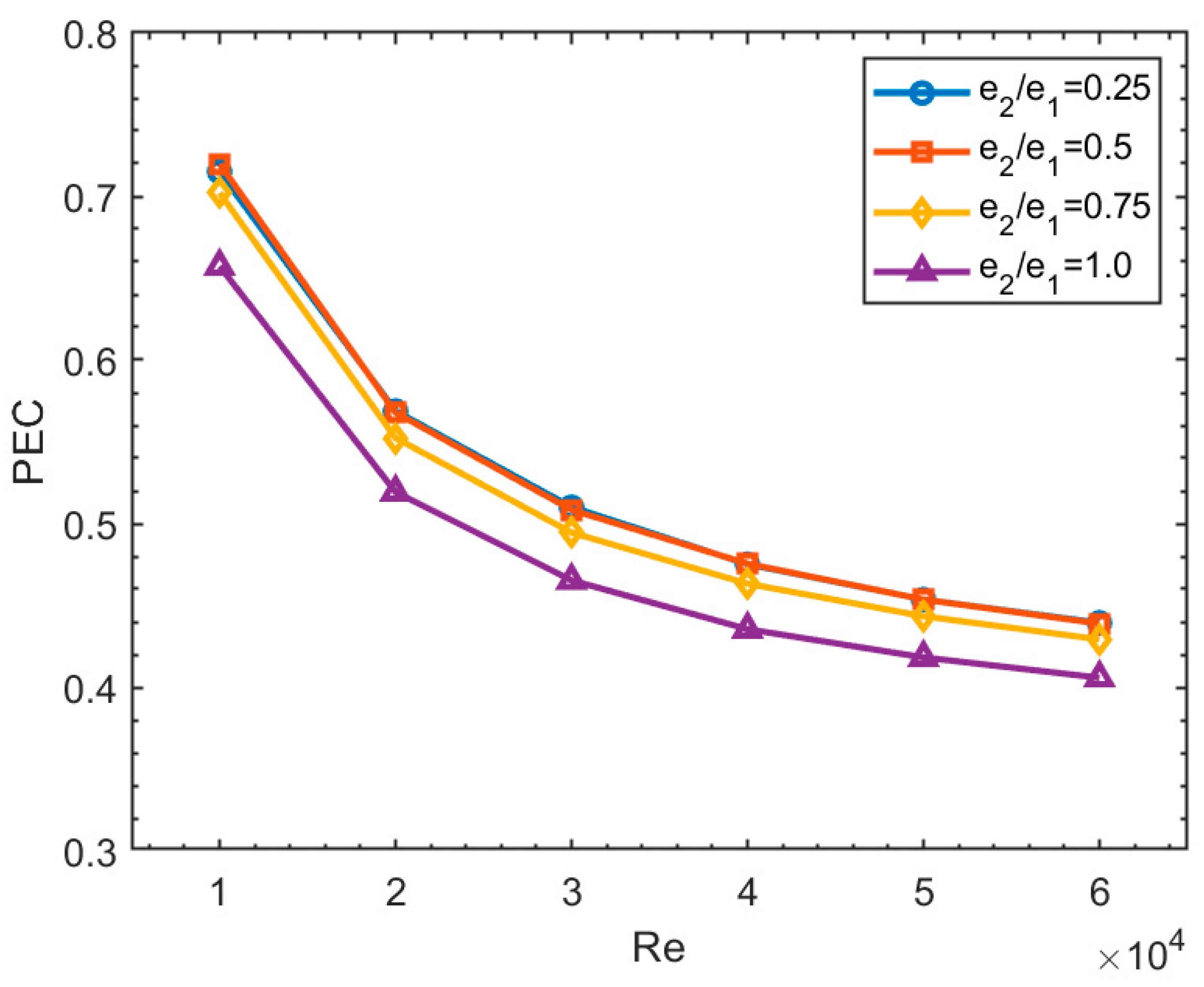

3.4. The Performance Evaluation Criterion, PEC

3.5. Average Nusselt Number and Friction Factor Correlations

4. Conclusions

- For Reynolds number increases in the range of 20,000 up to 60,000, the average Nusselt number increases almost linearly with the Re, but the friction factor shows an almost constant value;

- By increasing the value of e2/e1, the average Nu and f values increase. At low Re values, the growth of Nu is nonlinear, which is different to the behavior of the average Nu at high Re values. The average Nu increases nonlinearly with the Pr number;

- The friction factor varies exponentially with e2/e1;

- The average Nu between the ribs shows a fluctuating behavior at low and high average Re values when the rib height ratios are less than 1.0;

- The circulation zone behind the higher rib dominates the downstream region up to the short rib, which has a smaller downstream circulation zone;

- The performance evaluation criteria index (PEC) values decrease with increases in the Re values and the rib height ratio. PEC values of approximately 8.2% were achieved at rib height ratios of 0.25 and 0.5. A rib height ratio of 0.5 is to be preferred when considering higher values of Nusselt numbers.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Wang, S.; Wen, F.; Zhou, X.; Wang, Z. Effects of continuous wavy ribs on heat transfer and cooling air flow in a square single-pass channel of turbine blade. Int. J. Heat Mass Transf. 2018, 121, 514–533. [Google Scholar] [CrossRef]

- Han, J.C.; Chen, H.C. Turbine blade internal cooling passages with rib tabulators. J. Propuls. Power 2006, 22, 226–248. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Guo, B.; Yu, S.; Zhang, Y.; Chen, T. Investigation of forced convection heat transfer of supercritical pressure water in a vertically upward internally ribbed tube. Nucl. Eng. Des. 2009, 239, 1956–1964. [Google Scholar] [CrossRef]

- Wang, X.; Xu, H.; Wang, J.; Song, W.; Wang, L. High pressure turbine blade internal cooling in a realistic rib roughened two-pass channel. Int. J. Heat Mass Transf. 2021, 170, 121019. [Google Scholar] [CrossRef]

- Chhaparwal, G.K.; Srivastava, A.; Dayal, R. Artificial repeated-rib roughness in a solar air heater—A review. Sol. Energy 2019, 194, 329–359. [Google Scholar] [CrossRef]

- Kumar, B.V.; Manikandan, G.; Kanna, P.R.; Taler, D.; Taler, J.; Nowak-Ocłoń, M.; Mzyk, K.; Toh, H.T. A performance evaluation of a solar air heater using different shaped ribs mounted on the absorber plate-a review. Energies 2018, 11, 3104. [Google Scholar] [CrossRef]

- Alam, T.; Meena, C.S.; Balam, N.B.; Kumar, A.; Cozzolino, R. Thermo-hydraulic performance characteristics and optimization of protrusion rib roughness in solar air heater. Energies 2021, 14, 3159. [Google Scholar] [CrossRef]

- Zheng, N.; Liu, P.; Shan, F.; Liu, Z.; Liu, W. Effects of rib arrangements on the flow pattern and heat transfer in an internally ribbed heat exchanger tube. Int. J. Therm. Sci. 2016, 101, 93–105. [Google Scholar] [CrossRef]

- Bas, H.; Ozceyhan, V. Heat transfer enhancement in a tube with twisted tape inserts placed separately from the tube wall. Exp. Therm. Fluid Sci. 2012, 41, 51–58. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Mashayekhi, R.; Arasteh, H.; Ali, H.M.; Talebizadehsardari, P.; Yaïci, W. Thermo-hydraulic performance analysis on the effects of truncated twisted tape inserts in a tube heat exchanger. Symmetry 2020, 12, 1652. [Google Scholar] [CrossRef]

- Ju, Y.; Zhu, T.; Mashayekhi, R.; Mohammed, H.I.; Khan, A.; Talebizadehsardari, P.; Yaïci, W. Evaluation of multiple semi-twisted tape inserts in a heat exchanger pipe using al2o3 nanofluid. Nanomaterials 2021, 11, 1570. [Google Scholar] [CrossRef] [PubMed]

- Khafaji, H.Q.A.; Wahhab, H.A.A.; Alsaedi, S.S.; Al-maliki, W.A.K.; Alobaid, F.; Epple, B. Thermal Performance Evaluation of a Tubular Heat Exchanger Fitted with Combined Basket—Twisted Tape Inserts. Appl. Sci. 2022, 12, 4807. [Google Scholar] [CrossRef]

- Maradiya, C.; Vadher, J.; Agarwal, R. The heat transfer enhancement techniques and their Thermal Performance Factor. Beni-Suef Univ. J. Basic Appl. Sci. 2018, 7, 1–21. [Google Scholar] [CrossRef]

- Liu, P.; Zheng, N.; Shan, F.; Liu, Z.; Liu, W. Heat transfer enhancement for laminar flow in a tube using bidirectional conical strip inserts. Int. J. Heat Mass Transf. 2018, 127, 1064–1076. [Google Scholar] [CrossRef]

- Xin, F.; Yu, M.; Liu, W.; Liu, Z. Heat transfer characteristics of enhanced cooling tube with a helical wire under oscillatory flow in Stirling engine. Int. J. Therm. Sci. 2021, 168, 107063. [Google Scholar] [CrossRef]

- Gradziel, S.; Majewski, K. Experimental determination of the friction factor in a tube with internal helical ribs. Energies 2019, 12, 257. [Google Scholar] [CrossRef]

- Grądziel, S.; Majewski, K.; Majdak, M.; Mika, Ł.; Sztekler, K.; Kobyłecki, R.; Zarzycki, R.; Pilawska, M. Testing of Heat Transfer Coefficients and Frictional Losses in Internally Ribbed Tubes and Verification of Results through CFD Modelling. Energies 2022, 15, 207. [Google Scholar] [CrossRef]

- Lei, X.; Guo, Z.; Peng, R.; Li, H. Numerical analysis on the heat transfer characteristics of supercritical water in vertically upward internally ribbed tubes. Water 2021, 13, 621. [Google Scholar] [CrossRef]

- Tan, X.H.; Zhu, D.S.; Zhou, G.Y.; Zeng, L.D. Heat transfer and pressure drop performance of twisted oval tube heat exchanger. Appl. Therm. Eng. 2013, 50, 374–383. [Google Scholar] [CrossRef]

- San, J.Y.; Huang, W.C. Heat transfer enhancement of transverse ribs in circular tubes with consideration of entrance effect. Int. J. Heat Mass Transf. 2006, 49, 2965–2971. [Google Scholar] [CrossRef]

- Bilen, K.; Cetin, M.; Gul, H.; Balta, T. The investigation of groove geometry effect on heat transfer for internally grooved tubes. Appl. Therm. Eng. 2009, 29, 753–761. [Google Scholar] [CrossRef]

- Kim, K.M.; Lee, H.; Kim, B.S.; Shin, S.; Lee, D.H.; Cho, H.H. Optimal design of angled rib turbulators in a cooling channel. Heat Mass Transf. 2009, 45, 1617–1625. [Google Scholar] [CrossRef]

- Li, X.W.; Meng, J.A.; Guo, Z.Y. Turbulent flow and heat transfer in discrete double inclined ribs tube. Int. J. Heat Mass Transf. 2009, 52, 962–970. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Abbas, A.K.; Sheriff, J.M. Influence of geometrical parameters and forced convective heat transfer in transversely corrugated circular tubes. Int. Commun. Heat Mass Transf. 2013, 44, 116–126. [Google Scholar] [CrossRef]

- Kim, K.M.; Kim, B.S.; Lee, D.H.; Moon, H.; Cho, H.H. Optimal design of transverse ribs in tubes for thermal performance enhancement. Energy 2010, 35, 2400–2406. [Google Scholar] [CrossRef]

- Ozceyhan, V.; Gunes, S.; Buyukalaca, O.; Altuntop, N. Heat transfer enhancement in a tube using circular cross sectional rings separated from wall. Appl. Energy 2008, 85, 988–1001. [Google Scholar] [CrossRef]

- Akermann, K.; Renze, P.; Dietl, J.; Schröder, W. Large-Eddy Simulation of turbulent heat transfer in a multiple-started helically rib-roughened pipe. Int. J. Heat Mass Transf. 2020, 154, 119667. [Google Scholar] [CrossRef]

- Khdher, A.B.M.; Sidik, N.A.C.; Mamat, R.; Hamzah, W.A.W. Experimental and numerical study of thermo-hydraulic performance of circumferentially ribbed tube with Al2O3 nanofluid. Int. Commun. Heat Mass Transf. 2015, 69, 34–40. [Google Scholar] [CrossRef][Green Version]

- Córcoles-Tendero, J.I.; Belmonte, J.F.; Molina, A.E.; Almendros-Ibáñez, J.A. Numerical simulation of the heat transfer process in a corrugated tube. Int. J. Therm. Sci. 2018, 126, 125–136. [Google Scholar] [CrossRef]

- Wang, D.; Tian, R.; Li, L.; Dai, X.; Shi, L. Heat transfer of R134a in a horizontal internally ribbed tube and in a smooth tube under super critical pressure. Appl. Therm. Eng. 2020, 173, 115208. [Google Scholar] [CrossRef]

- Jordan, S.A. The turbulent character and pressure loss produced by periodic symmetric ribs in a circular duct. Int. J. Heat Fluid Flow 2003, 24, 795–806. [Google Scholar] [CrossRef]

- Aǧra, Ö.; Demir, H.; Özgür, S.A.; Kantaş, F.; Dalklç, A.S. Numerical investigation of heat transfer and pressure drop in enhanced tubes. Int. Commun. Heat Mass Transf. 2011, 38, 1384–1391. [Google Scholar] [CrossRef]

- Xu, W.; Liu, G.; Zhang, Q.; Wang, S.; Lu, H.; Tan, H. Heat transfer and friction factor of Therminol liquid phase heat transfer fluid in a ribbed tube. Chin. J. Chem. Eng. 2017, 25, 1343–1351. [Google Scholar] [CrossRef]

- Ansys. ANSYS Fluent User’s Guide; Release 17; ANSYS: Canonsburg, PA, USA, 2016. [Google Scholar]

- Cengel, Y. Heat and Mass Transfer: Fundamentals and Applications; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- White, F. Fluid Mechanics, 8th ed.; McGraw Hill: New York, NY, USA, 2015. [Google Scholar]

- Webb, R.L.; Eckert, E.R.G. Application of rough surfaces to heat exchanger design. Int. J. Heat Mass Transf. 1972, 15, 1647–1658. [Google Scholar] [CrossRef]

- Webb, R.L. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int. J. Heat Mass Transf. 1981, 24, 715–726. [Google Scholar] [CrossRef]

- Karwa, R.; Sharma, C.; Karwa, N. Performance Evaluation Criterion at Equal Pumping Power for Enhanced Performance Heat Transfer Surfaces. J. Sol. Energy 2013, 2013, 370823. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, S.A.; Incropera, F.P.; Dewitt, D.P. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Qian, X.; Lee, S.W.; Yang, Y. Heat transfer coefficient estimation and performance evaluation of shell and tube heat exchanger using flue gas. Processes 2021, 9, 939. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.H. Investigation of the Heat Transfer and Pressure Drop in Tubes with Transverse Ribs of Zigzag Configurations. Appl. Sci. 2022, 12, 5734. https://doi.org/10.3390/app12115734

Ahmed MH. Investigation of the Heat Transfer and Pressure Drop in Tubes with Transverse Ribs of Zigzag Configurations. Applied Sciences. 2022; 12(11):5734. https://doi.org/10.3390/app12115734

Chicago/Turabian StyleAhmed, Mohamed H. 2022. "Investigation of the Heat Transfer and Pressure Drop in Tubes with Transverse Ribs of Zigzag Configurations" Applied Sciences 12, no. 11: 5734. https://doi.org/10.3390/app12115734

APA StyleAhmed, M. H. (2022). Investigation of the Heat Transfer and Pressure Drop in Tubes with Transverse Ribs of Zigzag Configurations. Applied Sciences, 12(11), 5734. https://doi.org/10.3390/app12115734