Application of FTIR-ATR Spectrometry in Conjunction with Multivariate Regression Methods for Viscosity Prediction of Worn-Out Motor Oils

Abstract

1. Introduction

2. Materials and Methods

2.1. Oil Samples Used for Construction and Verification of the Calibration Model

2.2. Determination of Kinematic Viscosity at 100 °C

2.3. IR Spectrum Acquisition and Data Processing

3. Results and Discussions

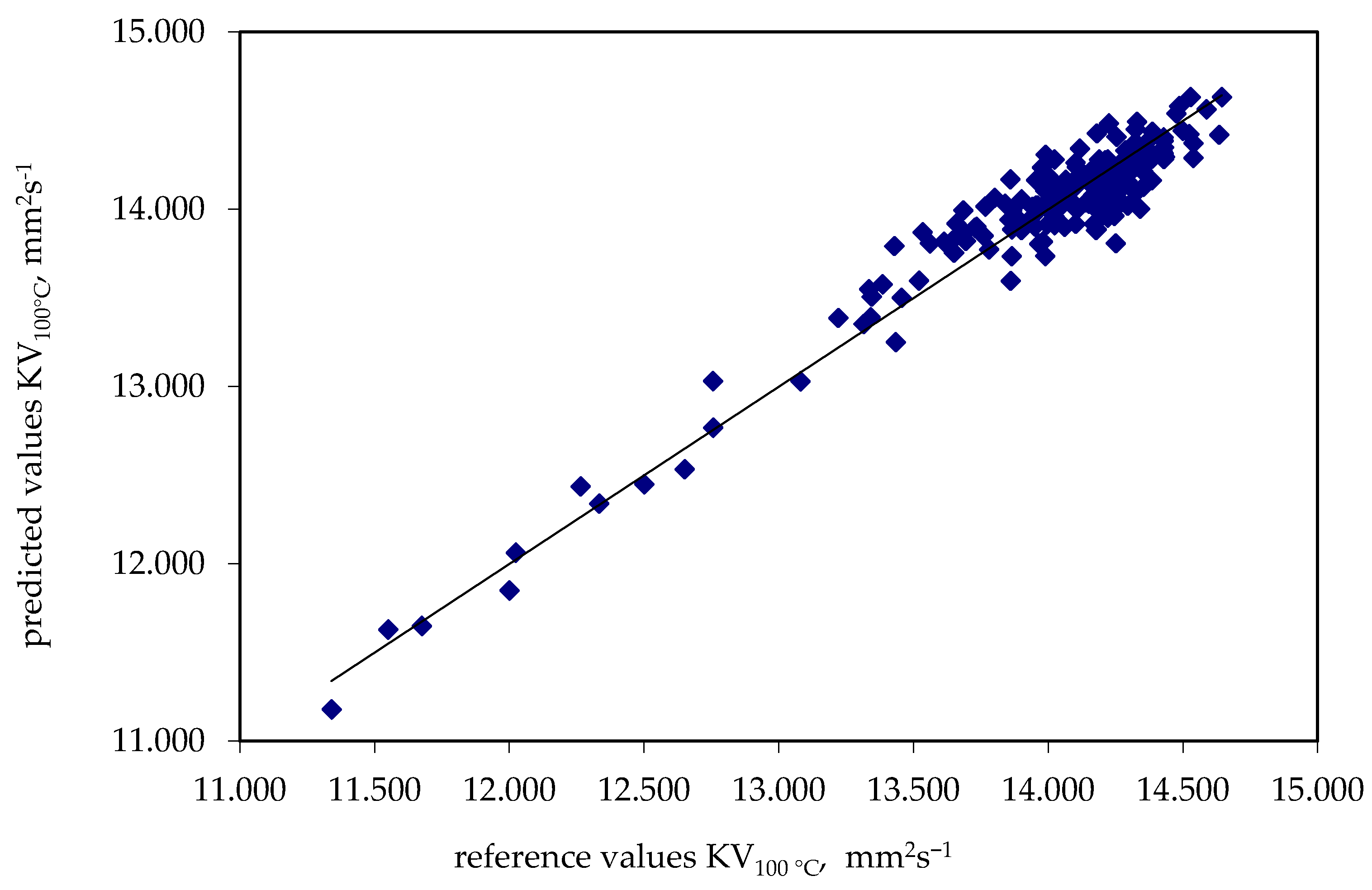

3.1. Development of Calibration FTIR-ATR Model

3.2. Validation of the Calibration Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hujo, Ĺ.; Jablonický, J.; Markovič, J.; Tulík, J.; Simikić, M.; Zastempowski, M.; Janoušková, R. Design of Laboratory Test Equipment for Automotive Oil Filters to Evaluate the Technical Life of Engine Oil. Appl. Sci. 2021, 11, 483. [Google Scholar]

- Šarkan, B.; Stopka, O. Quantification of road vehicle performance parameters under laboratory conditions. Adv. Sci. Technol. Res. J. 2018, 12, 16–23. [Google Scholar] [CrossRef]

- Caban, J.; Droździel, P.; Ignaciuk, P.; Kordos, P. The impact of changing the fuel dose on chosen parameters of the diesel engine start-up process. Transp. Probl. 2019, 14, 51–62. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Stopková, M.; Stopka, O.; Kalašová, A.; Ovčiarik, P. User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions. Open Eng. 2021, 11, 151–160. [Google Scholar] [CrossRef]

- Macián, V.; Tormos, B.; Bastidas, S.; Pérez, T. Improved fleet operation and maintenance through the use of low viscosity engine oils: Fuel economy and oil performance. Maint. Reliab. 2020, 22, 201–211. [Google Scholar] [CrossRef]

- Borucka, A.; Wiśniowski, P.; Mazurkiewicz, D.; Świderski, A. Laboratory measurements of vehicle exhaust emissions in conditions reproducing real traffic. Measurement 2021, 174, 108998. [Google Scholar] [CrossRef]

- Dziubak, T. Operating fluids contaminantions and their effect on the wear of elements of a motor vehicle’s combustion engine. Arch. Motor. 2016, 72, 43–72. [Google Scholar]

- Sejkorová, M. Tribotechnical diagnostics as a tool for effective management of maintenance. Perner’s Contacts 2015, 10, 126–136. Available online: https://pernerscontacts.upce.cz/index.php/perner/article/view/679 (accessed on 10 March 2021).

- Synák, F.; Kalašová, A.; Synák, J. Air Filter and Selected Vehicle Characteristics. Sustainability 2020, 12, 9326. [Google Scholar] [CrossRef]

- Jakóbiec, J.; Budzik, G. Czynniki mające wpływ na stopień degradacji oleju silnikowego w okresie eksploatacji. Arch. Motor. 2007, 3, 209–216. [Google Scholar]

- Ziółkowska, M. Wpływ sadzy na proces żelowania oleju silnikowego. Nafta-Gaz 2019, 3, 178–184. [Google Scholar] [CrossRef]

- Sejkorová, M.; Šarkan, B.; Caban, J.; Marczuk, A. On relationship between infrared spectra of worn out engine oils and their kinematic viscosity. Przem. Chem. 2018, 97, 49–54. [Google Scholar] [CrossRef]

- Kučera, M.; Kopčanová, S.; Sejkorová, M. Lubricant Analysis as the Most Useful Tool in the Proactive Maintenance Philosophies of Machinery and its Components. Manag. Syst. Prod. Eng. 2020, 28, 196–201. [Google Scholar] [CrossRef]

- Šarkan, B.; Caban, J.; Marczuk, A.; Vrabel, J.; Gnap, J. Composition of exhaust gases of spark ignition engines under conditions of periodic inspection of vehicles in Slovakia. Przem. Chem. 2017, 96, 675–680. [Google Scholar] [CrossRef]

- Tormos, B.; Novella, R.; Gomez-Soriano, J.; García-Barberá, A.; Tsuji, N.; Uehara, I.; Alonso, M. Study of the influence of emission control strategies on the soot content and fuel dilution in engine oil. Tribol. Int. 2019, 136, 285–298. [Google Scholar] [CrossRef]

- Macián, V.; Tormos, B.; Gómez, Y.A.; Salavert, J.M. Proposal of an FTIR methodology to monitor oxidation level in used engine oils: Effects of thermal degradation and fuel dilution. Tribol. Trans. 2012, 55, 872–882. [Google Scholar] [CrossRef]

- Gołębiowski, W.; Wolak, A.; Zając, G. The influence of the presence of a diesel particulate filter (DPF) on the physical and chemical properties as well as the degree of concentration of trace elements in used engine oils. Pet. Sci. Technol. 2019, 37, 746–755. [Google Scholar] [CrossRef]

- Hurtová, I.; Sejkorová, M.; Verner, J. A study of diesel particulate filter impact on engine oil quality. In Transport Means: Proceedings of the International Scientific Conference; Kaunas University of Technology: Palanga, Lithuenia, 2019; pp. 691–695. [Google Scholar]

- Nowak, P.; Kucharska, K.; Kamiński, M.A. The New Test Procedure for Group-Type Composition of Base Oils of Lubricating Oils, Especially Emitted into the Environment. Energies 2020, 13, 3772. [Google Scholar] [CrossRef]

- Nowak, P.; Kucharska, K.; Kamiński, M. Ecological and Health Effects of Lubricant Oils Emitted into the Environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef]

- Pan, Y.; Jing, Y.; Wu, T.; Kong, X. An Integrated Data and Knowledge Model Addressing Aleatory and Epistemic Uncertainty for Oil Condition Monitoring. Reliab. Eng. Saf. 2021, 210, 107546. [Google Scholar] [CrossRef]

- Sejkorová, M.; Jilek, P. Possibilities of Detecting Diesel Leaking into Engine Oil with Fuel Sniffer. Acta Univ. Agric. Silvic. Mendel. Brun. 2019, 67, 749–755. [Google Scholar] [CrossRef]

- Yanaseko, T.; Sato, H.; Kuboki, I.; Mossi, K.; Asanuma, H. Vibration Viscosity Sensor for Engine Oil Monitoring Using Metal Matrix Piezoelectric Composite. Materials 2019, 12, 3415. [Google Scholar] [CrossRef]

- Wolak, A.; Zając, G.; Słowik, T. Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices. Sensors 2021, 21, 2530. [Google Scholar] [CrossRef]

- Heredia-Cancino, J.; Carrillo-Torres, R.; Munguía-Aguilar, H.; Álvarez-Ramos, M. An innovative method to reduce oil waste using a sensor made of recycled material to evaluate engine oil life in automotive workshops. Environ. Sci. Pollut. Res. 2020, 27, 28104–28112. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring–A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar]

- Sasic, S.; Yokelson, H.; Kotecki, T.; Austin, S.; Thacker, K.; Moore, R. Multivariate Calibration of Total Acid Number in Crude Oils via Near-Infrared Spectra. Energy Fuels 2020, 34, 6974–6980. [Google Scholar] [CrossRef]

- Liu, C.; Tang, X.; Yu, T.; Wang, T.; Lu, Z.; Yu, W. Measurement of Moisture Content in Lubricating Oils of High-speed Rail Gearbox by Vis-NIR Spectroscopy. Optik 2020, 224, 165694. [Google Scholar] [CrossRef]

- Pinheiro, C.T.; Rendall, R.; Quina, M.J.; Reis, M.S.; Gando-Ferreira, L.M. Assessment and prediction of lubricant oil properties using infrared spectroscopy and advanced predictive analytics. Energy Fuels 2017, 31, 179–187. [Google Scholar] [CrossRef]

- Barra, I.; Kharbach, M.; Qannari, E.M.; Hanafi, M.; Cherrah, Y.; Bouklouze, A. Predicting cetane number in diesel fuels using FTIR spectroscopy and PLS regression. Vib. Spectrosc. 2020, 111, 103157. [Google Scholar] [CrossRef]

- Barra, I.; Kharbach, M.; Bousrabat, M.; Cherrah, Y.; Hanafi, M.; Qannari, E.M.; Bouklouze, A. Discrimination of diesel fuels marketed in Morocco using FTIR, GC-MS analysis and chemometrics methods. Talanta 2020, 209, 120543. [Google Scholar] [CrossRef] [PubMed]

- Siotani, M.; Hayakawa, T.; Fujikoshi, Y. Modern Multivariate Statistical Analysis; A Graduate Course and Handbook; American Science Press: Columbia, NC, USA, 1985. [Google Scholar]

- Haaland, D.M.; Thomas, E.V. Partial least-squares methods for spectral analyses. 1. Relation to other quantitative calibration methods and the extraction of qualitative information. Anal. Chem. 1998, 60, 1193–1202. [Google Scholar] [CrossRef]

- Varmuza, K.; Filzmoser, P. Introduction to Multivariate Statistical Analysis in Chemometrics; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Wolak, A. TBN performance study on a test fleet in real-world driving conditions using present-day engine oils. Measurement 2018, 114, 322–331. [Google Scholar] [CrossRef]

- Wolak, A. Changes in lubricant properties of used synthetic oils based on the total acid number. Meas. Control. 2018, 51, 65–72. [Google Scholar] [CrossRef]

- Li, D.; Sedman, J.; García-González, D.L.; Van De Voort, F.R. Automated acid content determination in lubricants by FTIR spectroscopy as an alternative to acid number determination. J. ASTM Int. 2009, 6, 1–12. [Google Scholar]

- Winterfield, C.; Van De Voort, F.R. Automated acid and base number determination of mineral-based lubricants by Fourier transform infrared spectroscopy: Commercial laboratory evaluation. JALA 2014, 19, 577–586. [Google Scholar] [CrossRef]

- Sejkorová, M.; Šarkan, B.; Veselík, P.; Hurtová, I. FTIR Spectrometry with PLS Regression for Rapid TBN Determination of Worn Mineral Engine Oils. Energies 2020, 13, 6438. [Google Scholar] [CrossRef]

- Macián, V.; Tormos, B.; García-Barberá, A.; Tsolakis, A. Applying chemometric procedures for correlation the FTIR spectroscopy with the new thermometric evaluation of Total Acid Number and Total Basic Number in engine oils. Chemom. Intell. Lab. Syst. 2021, 208, 104215. [Google Scholar] [CrossRef]

- De Rivas, B.L.; Vivancos, J.L.; Ordieres-Meré, J.; Capuz-Rizo, S.F. Determination of the total acid number (TAN) of used mineral oils in aviation engines by FTIR using regression models. Chemom. Intell. Lab. Syst. 2017, 160, 32–39. [Google Scholar] [CrossRef]

- Hirri, A.; Tagourmate, S.; Benamar, A.; Kzaiber, F.; Oussama, A. Prediction of kinematic viscosity in motor oil using ftir coupled with partial least squares regression. Int. J. Chem. Mater. Environ. Res. 2017, 4, 102–107. [Google Scholar]

- Braga, J.W.B.; dos Santos Junior, A.A.; Martins, I.S. Determination of viscosity index in lubricant oils by infrared spectroscopy and PLSR. Fuel 2014, 120, 171–178. [Google Scholar] [CrossRef]

- Caneca, A.R.; Pimentel, M.F.; Galvão, R.K.H.; da Matta, C.E.; de Carvalho, F.R.; Raimundo, I.M.; Rohwedder, J.J. Assessment of infrared spectroscopy and multivariate techniques for monitoring the service condition of diesel-engine lubricating oils. Talanta 2006, 70, 344–352. [Google Scholar] [CrossRef]

- Marinović, S.; Jukić, A.; Doležal, D.; Špehar, B.; Krištović, M. Prediction of used lubricating oils properties by infrared spectroscopy using multivariate analysis. Goriva Maz. 2012, 51, 205–215. [Google Scholar]

- Borin, A.; Poppi, R.J. Application of mid infrared spectroscopy and iPLS for the quantification of contaminants in lubricating oil. Vib. Spectrosc. 2005, 37, 27–32. [Google Scholar] [CrossRef]

- Bassbasi, M.; Hafid, A.; Platikanov, S.; Tauler, R.; Oussama, A. Study of motor oil adulteration by infrared spectroscopy and chemometrics methods. Fuel 2013, 104, 798–804. [Google Scholar] [CrossRef]

- Balabin, R.M.; Safieva, R.Z.; Lomakina, E.I. Near-infrared (NIR) spectroscopy for motor oil classification: From discriminant analysis to support vector machines. Microchem. J. 2011, 98, 121–128. [Google Scholar] [CrossRef]

- ČSN EN ISO 3104 (656216). Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity; Czech Standards Institute: Prague, Czech Republic, 1998. (In Czech) [Google Scholar]

- Godoy, J.L.; Vega, J.R.; Marchetti, J.L. Relationships between PCA and PLS-regression. Chemom. Intell. Lab. Syst. 2014, 130, 182–191. [Google Scholar] [CrossRef]

- Ergon, R.; Granato, D.; Ares, G. Principal component regression (PCR) and partial least squares regression (PLSR). In Mathematical and Statistical Methods in Food Science and Technology; John Wiley and Sons: Chichester, UK, 2014; pp. 121–142. [Google Scholar]

- Spectroscopic Software TQ Analyst—Brief Guide; Internal Document of Nicolet CZ; Nicolet CZ: Prague, Czech Republic, 2007. (In Czech)

- Al-Ghouti, M.A.; Al-Atoum, L. Virgin and recycled engine oil differentiation: A spectroscopic study. J. Environ. Manage. 2009, 90, 187–195. [Google Scholar] [CrossRef] [PubMed]

- Čorňák, Š. Identification of operating fluids with fingerprint method utilization. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; University of Agriculture: Jelgava, Latvia, 2018; pp. 2048–2053. [Google Scholar]

- Sejkorová, M.; Hurtová, I.; Jilek, P.; Novák, M.; Voltr, O. Study of the Effect of Physicochemical Degradation and Contamination of Motor Oils on Their Lubricity. Coatings 2021, 11, 60. [Google Scholar] [CrossRef]

- Simkovic, I. Chemometric Tools for Quantitative FTIR Spectroscopy of Soils. Chem. Listy 2017, 111, 22–34. [Google Scholar]

| Spectral Range 1750–650 cm−1 | PLS | PCR | ||||

|---|---|---|---|---|---|---|

| PCs | R | RMSEC (mm2s−1) | PCs | R | RMSEC (mm2s−1) | |

| not adjusted | 7 | 0.89 | 0.197 | 10 | 0.88 | 0.204 |

| 1st derivation | 5 | 0.88 | 0.197 | 10 | 0.85 | 0.186 |

| 2nd derivation | 10 | 0.95 | 0.148 | 10 | 0.47 | 0.372 |

| Validation Sample | Measured KV100 °C (mm2s−1) | Predicted KV100 °C (mm2s−1) | Standard Deviation (mm2s−1) |

|---|---|---|---|

| 1 | 14.275 | 14.107 | 0.119 |

| 2 | 14.219 | 14.111 | 0.076 |

| 3 | 14.534 | 14.370 | 0.116 |

| 4 | 13.890 | 14.110 | 0.156 |

| 5 | 14.032 | 13.837 | 0.138 |

| 6 | 14.125 | 14.275 | 0.106 |

| 7 | 14.032 | 13.850 | 0.129 |

| 8 | 14.610 | 14.455 | 0.110 |

| 9 | 13.900 | 13.750 | 0.106 |

| 10 | 12.550 | 12.320 | 0.163 |

| 11 | 11.720 | 11.600 | 0.085 |

| 12 | 13.540 | 13.290 | 0.177 |

| 13 | 12.010 | 12.211 | 0.142 |

| 14 | 14.250 | 14.480 | 0.163 |

| 15 | 14.000 | 14.249 | 0.176 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sejkorová, M.; Kučera, M.; Hurtová, I.; Voltr, O. Application of FTIR-ATR Spectrometry in Conjunction with Multivariate Regression Methods for Viscosity Prediction of Worn-Out Motor Oils. Appl. Sci. 2021, 11, 3842. https://doi.org/10.3390/app11093842

Sejkorová M, Kučera M, Hurtová I, Voltr O. Application of FTIR-ATR Spectrometry in Conjunction with Multivariate Regression Methods for Viscosity Prediction of Worn-Out Motor Oils. Applied Sciences. 2021; 11(9):3842. https://doi.org/10.3390/app11093842

Chicago/Turabian StyleSejkorová, Marie, Marián Kučera, Ivana Hurtová, and Ondřej Voltr. 2021. "Application of FTIR-ATR Spectrometry in Conjunction with Multivariate Regression Methods for Viscosity Prediction of Worn-Out Motor Oils" Applied Sciences 11, no. 9: 3842. https://doi.org/10.3390/app11093842

APA StyleSejkorová, M., Kučera, M., Hurtová, I., & Voltr, O. (2021). Application of FTIR-ATR Spectrometry in Conjunction with Multivariate Regression Methods for Viscosity Prediction of Worn-Out Motor Oils. Applied Sciences, 11(9), 3842. https://doi.org/10.3390/app11093842