Dynamic Balance of the Head in a Flexible Legged Robot for Efficient Biped Locomotion

Abstract

1. Introduction

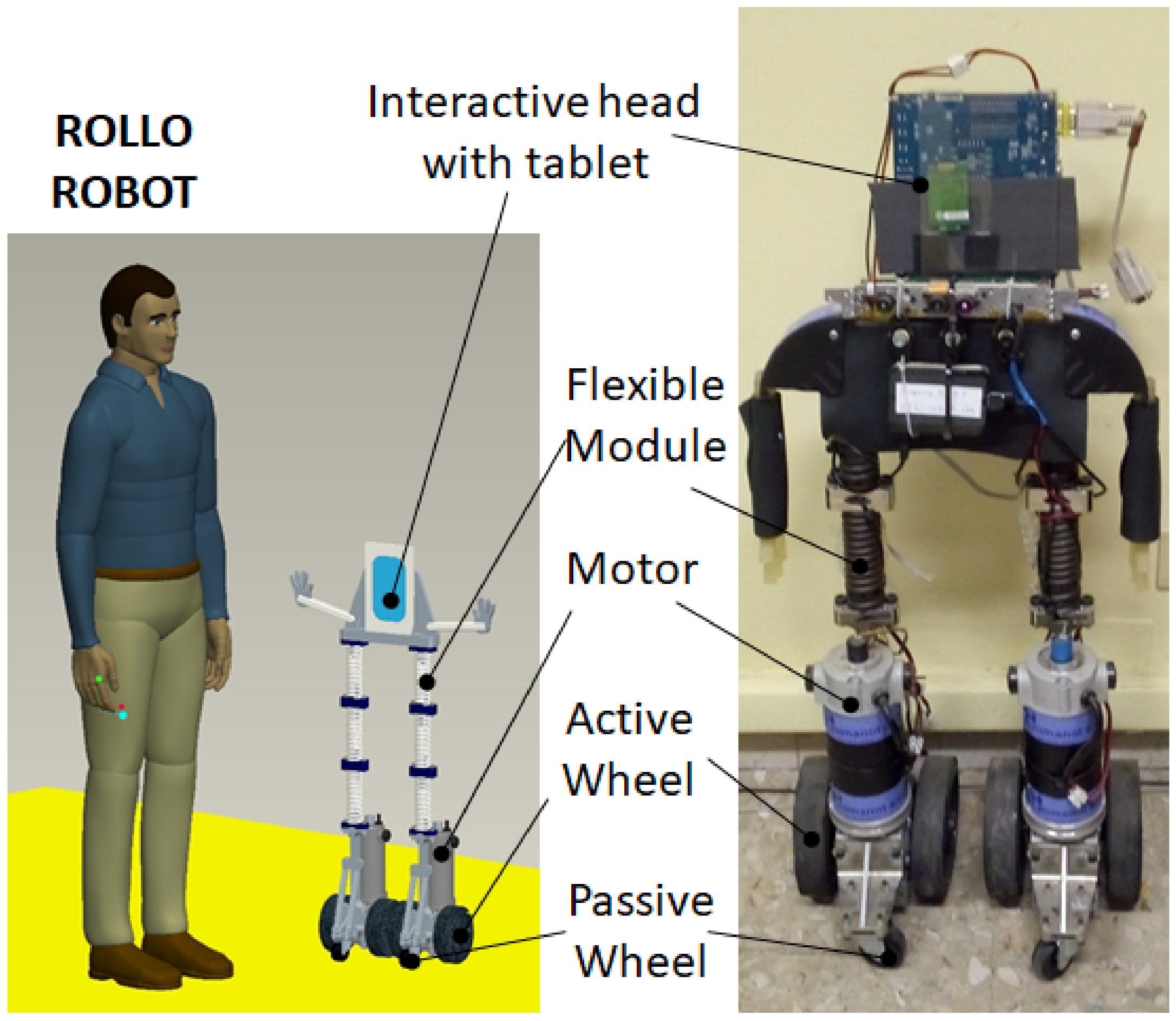

2. Rollo Robot and FE Model

2.1. Rollo in Details

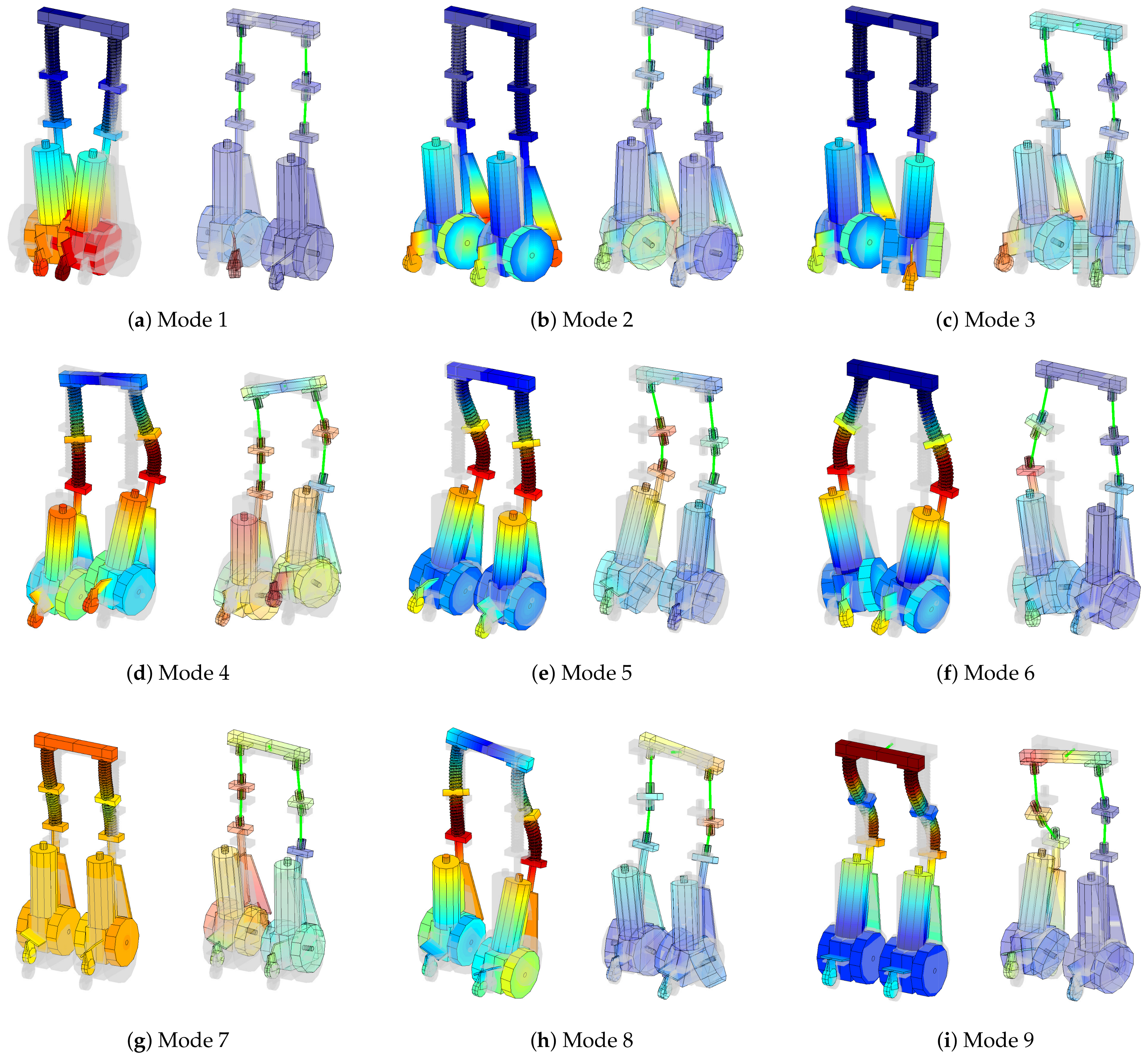

2.2. Rollo Lupos FE Model

3. Design and Validation of the Rollo Model

3.1. Numerical Modal Analysis of the Rollo Robot

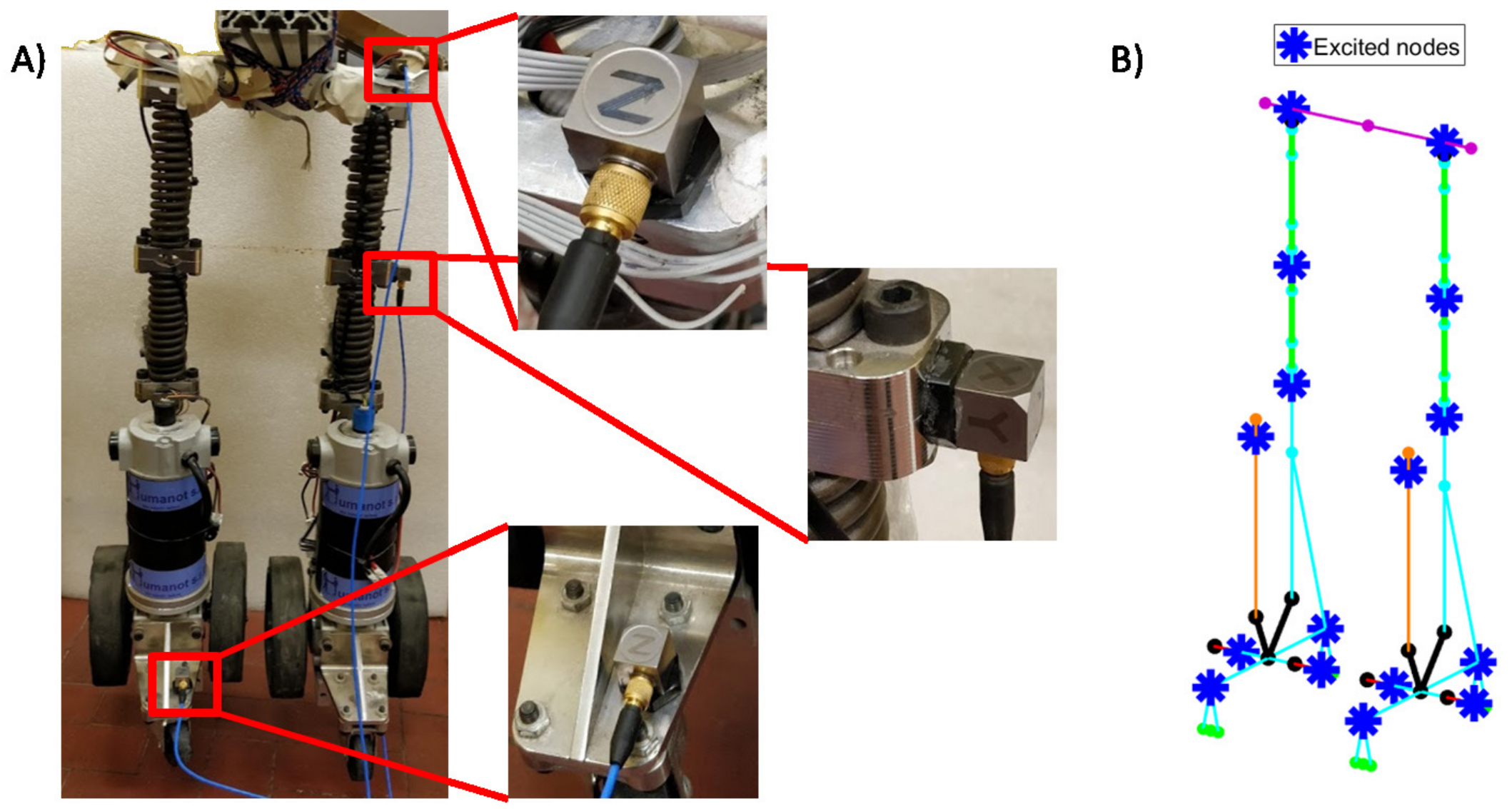

3.2. Experimental Modal Analysis of Rollo Robot

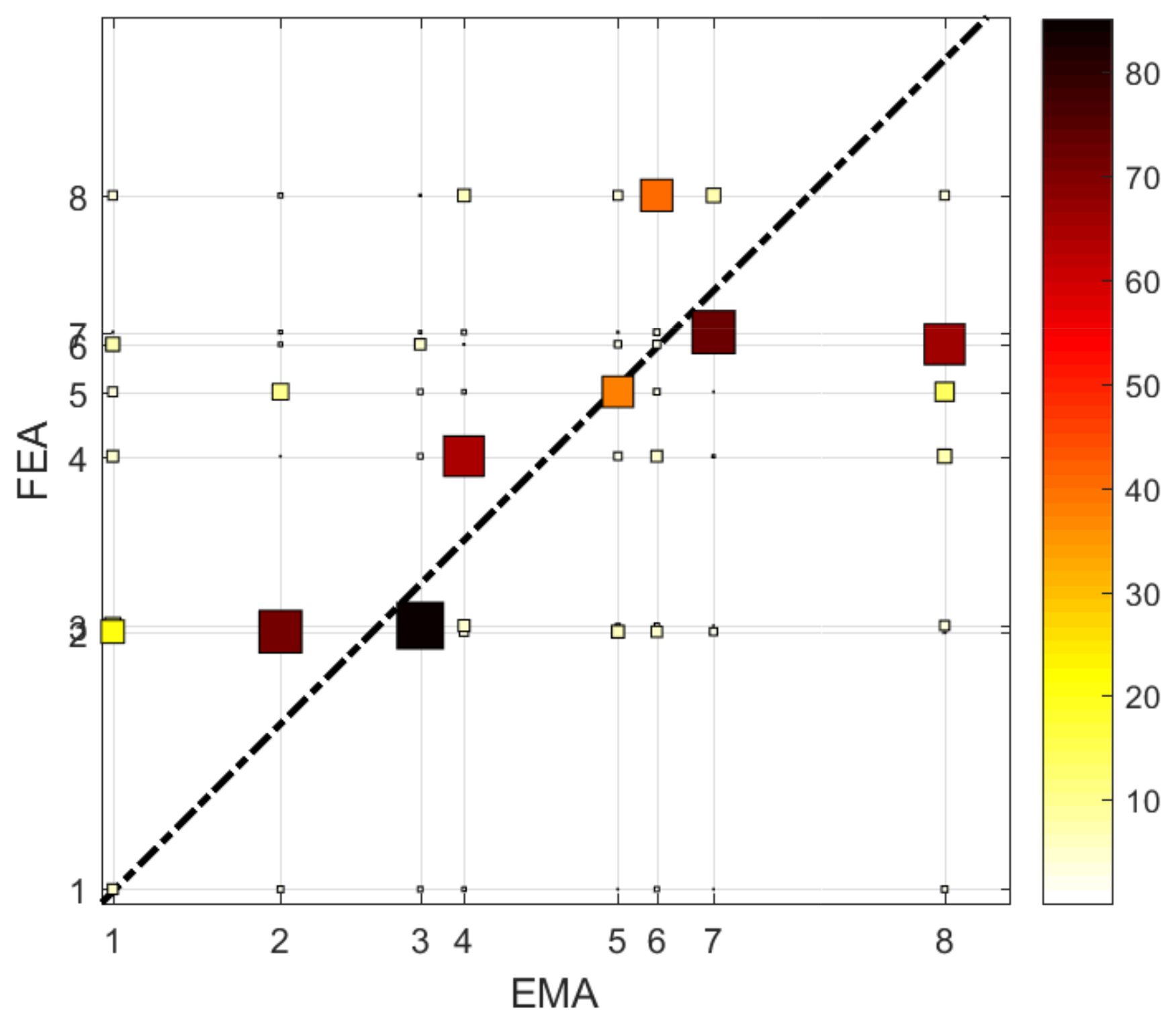

3.3. Model Validation

4. Head Vibration Reduction of the Rollo Model: Results and Discussion

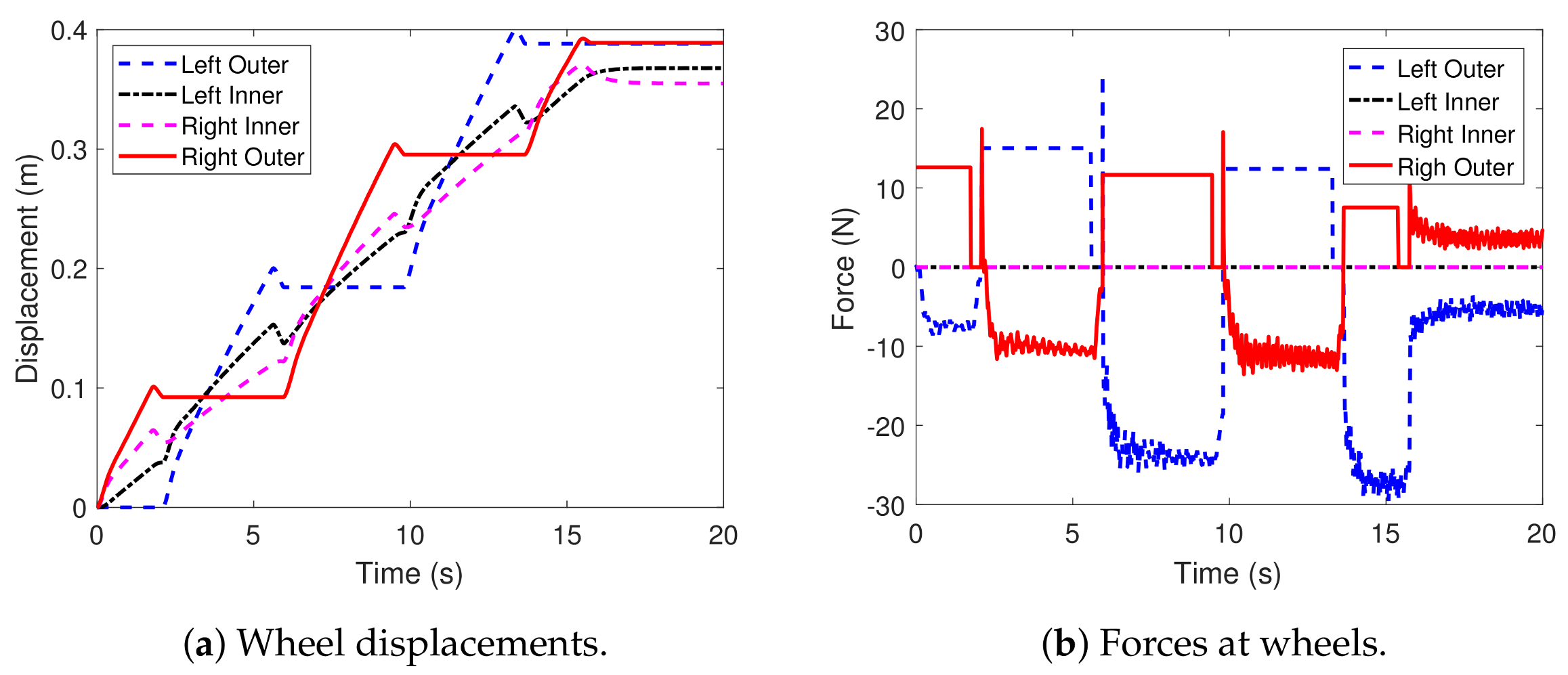

4.1. Numerical Simulation

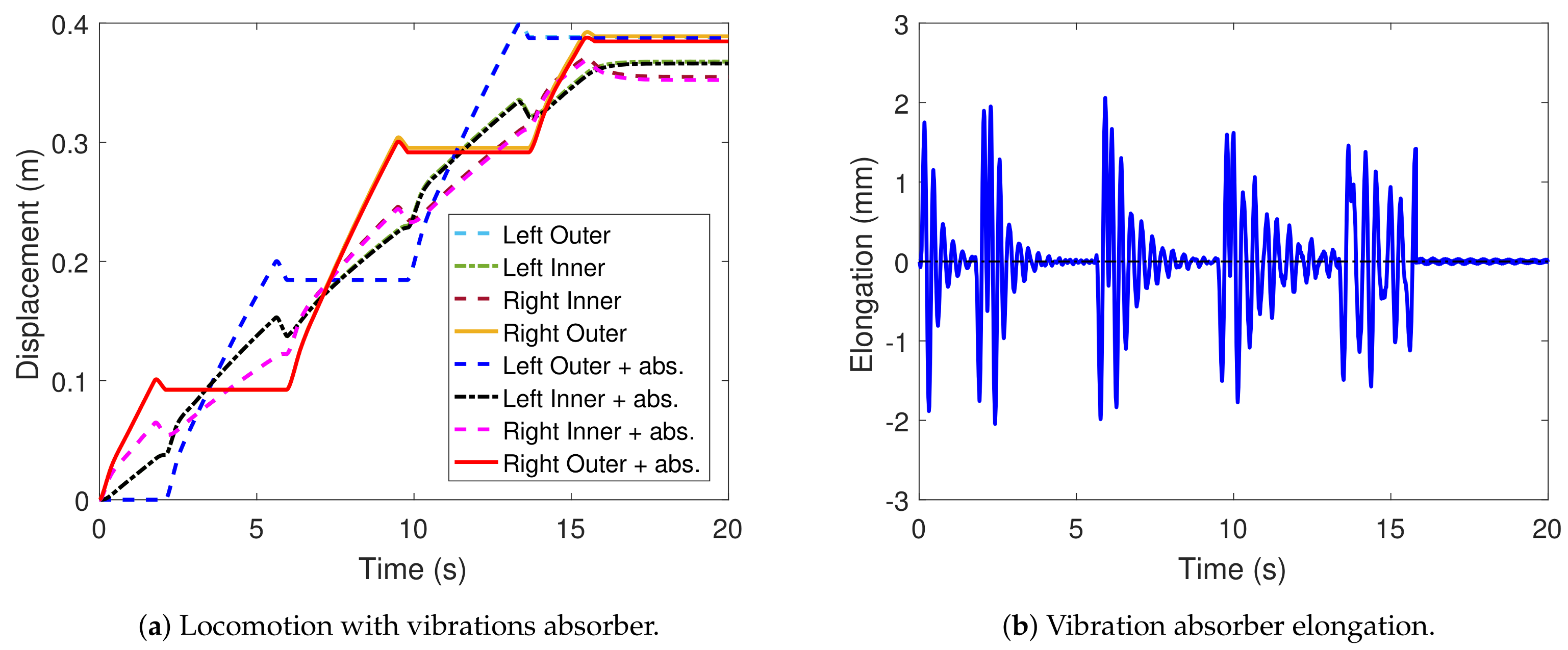

4.2. Head Vibration Reduction

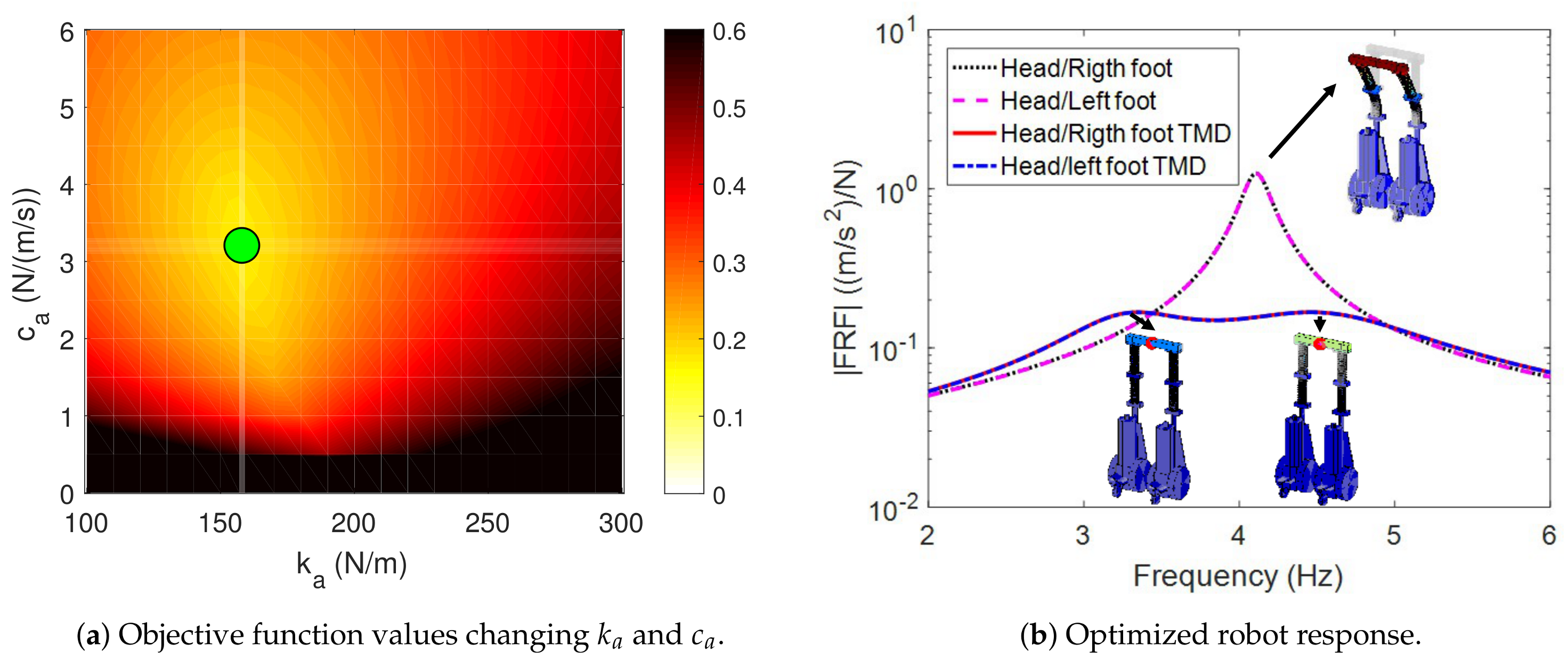

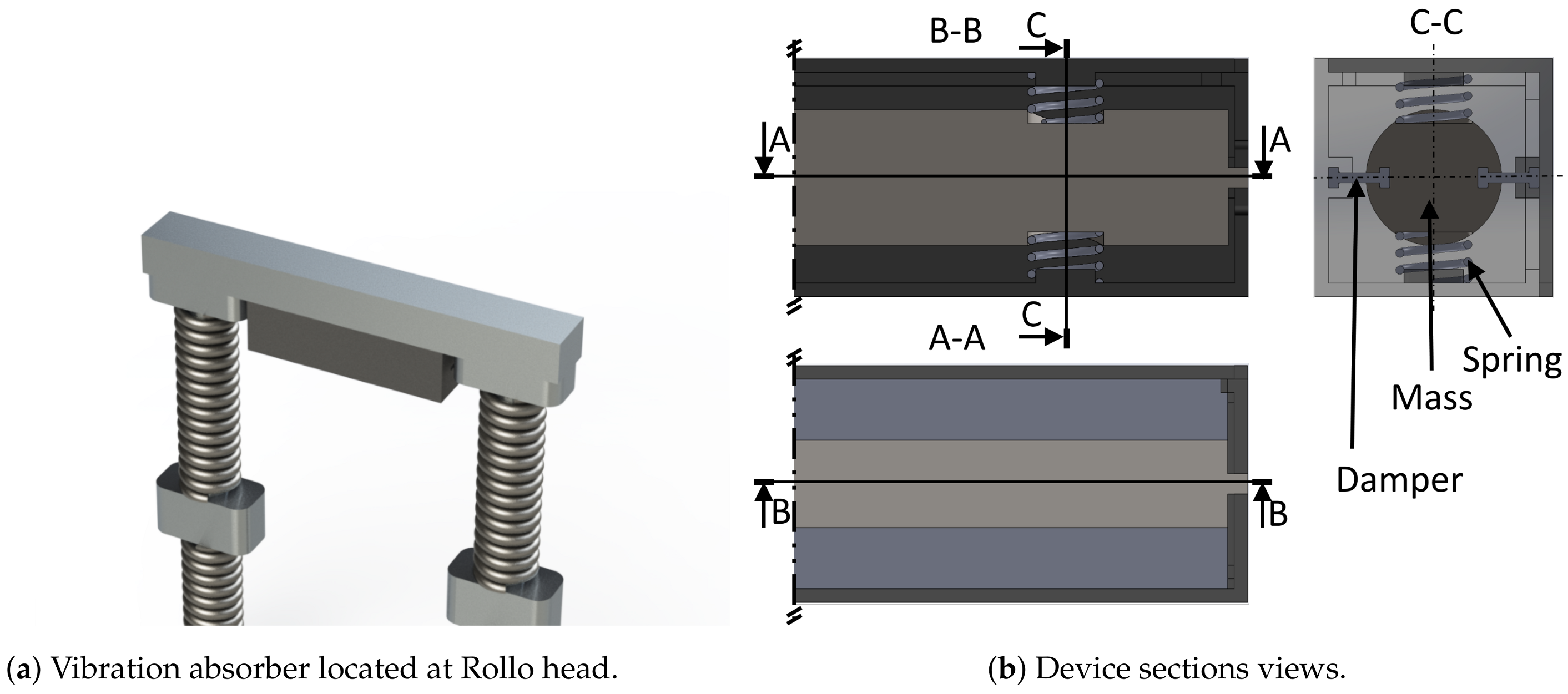

4.3. Dynamic Vibration Absorber Design

5. Conclusions

6. Patents

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ZMP | zero moment point |

| TDM | tuned mass-spring-dumper |

| sdof | single degree of freedom |

| ALS | amyotrophic lateral sclerosis |

| FE | finite element |

| FEM | finite element method |

| FEA | finite element analysis |

| dof | degree of freedom |

| EMA | experimental modal analysis |

| FRFs | frequency response functions |

| MACX | modal assurance criterion for complex modes shapes |

| MLMM | maximum likelihood estimation of a modal model |

| mdof | multi degree of freedom |

| RMS | root mean square |

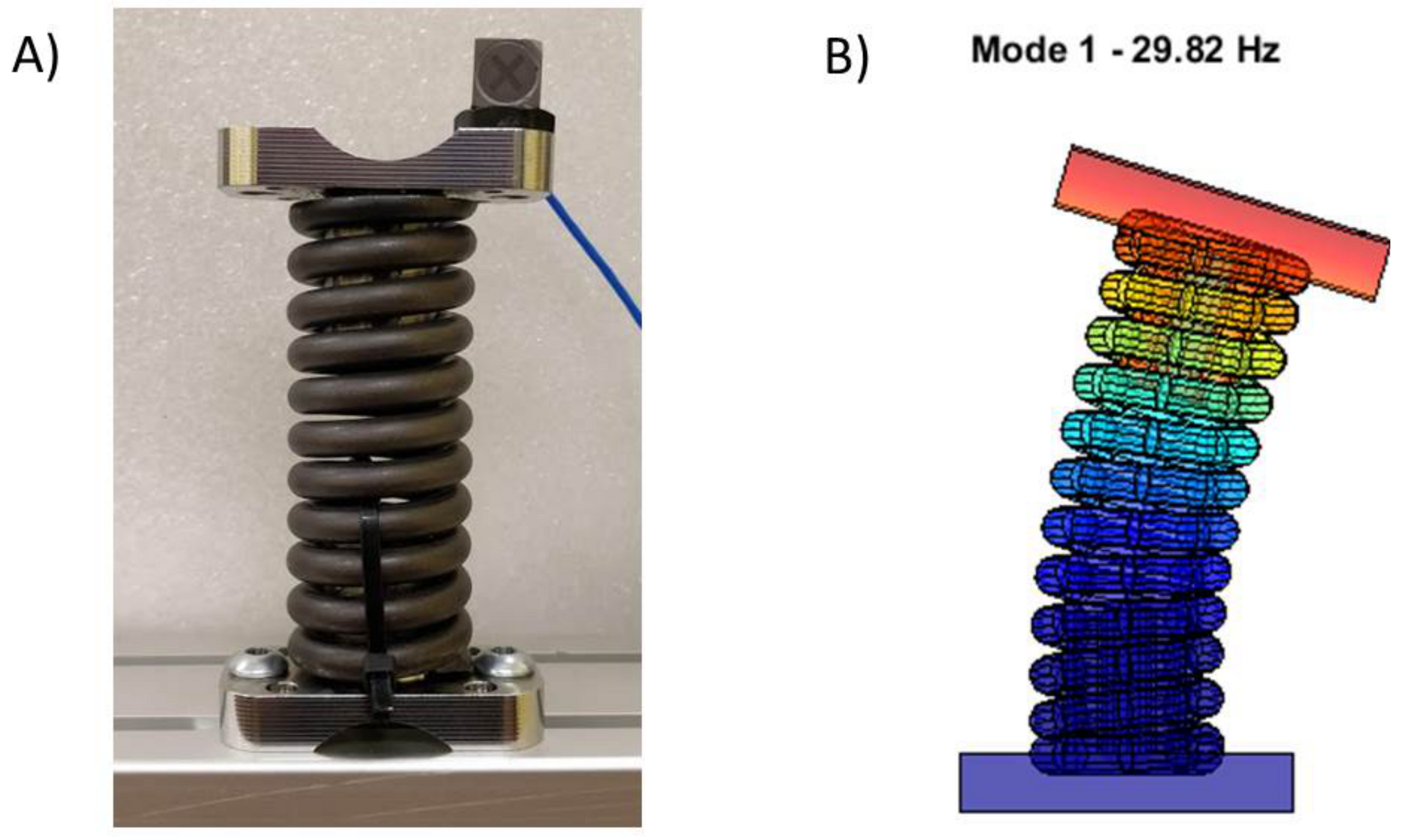

Appendix A. Tuning of the Flexible Module

| Mode | Description | Exp. (Hz) | Num. (Hz) |

|---|---|---|---|

| 1 | 1st bending | 29.6–35.0 | 29.82–30.45 |

| 2 | 1st axial | 95.16 | 93.94 |

| 3 | 1st torsional | 105.98 | 97.08 |

| 4 | 2nd bending | 187.47–210.32 | 185.9–216.7 |

Appendix B. Time Domain Simulations Theory

References

- Hosoda, Y.; Egawa, S.; Tamamoto, J.; Yamamoto, K.; Nakamura, R.; Togami, M. Basic design of human-symbiotic robot EMIEW. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006; pp. 5079–5084. [Google Scholar] [CrossRef]

- Raibert, M.; Blankespoor, K.; Nelson, G.; Playter, R. Bigdog, the rough-terrain quadruped robot. IFAC Proc. Vol. 2008, 41, 10822–10825. [Google Scholar] [CrossRef]

- Muscolo, G.G.; Moretti, G.; Cannata, G. SUAS: A novel soft underwater artificial skin with capacitive transducers and hyperelastic membrane. Robotica 2019, 37, 756–777. [Google Scholar] [CrossRef]

- De Pina Filho, A. Humanoid Robots: New Developments; IntechOpen: London, UK, 2007. [Google Scholar]

- Mombaur, K.; Truong, A.; Laumond, J. From human to humanoid locomotion—An inverse optimal control approach. Auton. Robot. 2010, 28, 369–383. [Google Scholar] [CrossRef]

- Dahiya, R.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing - from humans to humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Alfayad, S.; Tayba, A.M.; Ouezdou, F.B.; Namoun, F. Kinematic synthesis and modeling of a three degrees-of-freedom hybrid mechanism for shoulder and hip modules of humanoid robots. J. Mech. Robot. 2016, 8. [Google Scholar] [CrossRef]

- Alexander, R. The gaits of bipedal and quadrupedal animals. Int. J. Robot. Res. 1984, 3, 49–59. [Google Scholar] [CrossRef]

- Steffan, E.; Pal, S.; Das, T. Bio-inspired locomotion of circular robots with diametrically translating legs. J. Mech. Robot. 2020, 12. [Google Scholar] [CrossRef]

- Alexander, R. Optima for Animals; Princeton University Press: Princeton, NJ, USA, 1996. [Google Scholar]

- McGeer, T. Passive dynamic walking. Int. J. Robot. Res. 1990, 9, 62–82. [Google Scholar] [CrossRef]

- McGeer, T. Passive Dynamic Biped Catalogue; Experimental Robotics II. Lecture Notes in Control and Information Sciences; Springer: Berlin/Heidelberg, Germany, 1993; pp. 463–490. [Google Scholar]

- Pratt, G. Legged robots at MIT: What’s new since Raibert? IEEE Robot. Autom. Mag. 2000, 7, 15–19. [Google Scholar] [CrossRef]

- Righetti, L.; Ijspeert, A. Programmable central pattern generators: An application to biped locomotion control. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, ICRA 2006, Orlando, FL, USA, 15–19 May 2006; pp. 1585–1590. [Google Scholar]

- Ijspeert, A. Central pattern generators for locomotion control in animals and robots: A review. Neural Netw. 2008, 21, 642–653. [Google Scholar] [CrossRef]

- Vukobratović, M.; Borovac, B. Zero-moment point - thirty five years of its life. Int. J. Hum. Robot. 2004, 1, 157–173. [Google Scholar] [CrossRef]

- Ogura, Y.; Aikawa, H.; Shimomura, K.; Kondo, H.; Morishima, A.; Lim, H.; Takanishi, A. Development of a new humanoid robot WABIAN-2. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, ICRA 2006, Orlando, FL, USA, 15–19 May 2006; pp. 76–81. [Google Scholar]

- Muscolo, G.G.; Recchiuto, C.T.; Molfino, R. Dynamic balance optimization in biped robots: Physical modeling, implementation and tests using an innovative formula. Robotica 2015, 33, 2083–2099. [Google Scholar] [CrossRef]

- Muscolo, G.G.; Caldwell, D.; Cannella, F. Calculation of the center of mass position of each link of multibody biped robots. Appl. Sci. 2017, 7, 724. [Google Scholar] [CrossRef]

- EMIEW 2-Hitachi’s Humanoid Robot, Really Cute and Clever. 2010. Available online: https://www.youtube.com/watch?v=6Jb9oJY0Fe8 (accessed on 23 March 2021).

- Dynamics, B. Introducing Handle. 2017. Available online: https://www.youtube.com/watch?v=-7xvqQeoA8c (accessed on 23 March 2021).

- Muscolo, G.G.; Recchiuto, C.T. Flexible structure and wheeled feet to simplify biped locomotion of humanoid robots. Int. J. Humanoid Robot. 2016, 14, 1650030. [Google Scholar] [CrossRef]

- Muscolo, G.G.; Caldwell, D.; Cannella, F. Multibody dynamics of a flexible legged robot with wheeled feet. In Proceedings of the ECCOMAS Thematic Conference on Multibody Dynamics, Prague, Czech Republic, 19–22 June 2017; pp. 19–22. [Google Scholar]

- De Silva, C. Vibration Damping, Control, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Gakkai, D. Earthquake Resistant Design for Civil Engineering Structures, Earth Structures and Foundations in Japan; Japan Society of Civil Engineers: Tokyo, Japan, 1960. [Google Scholar]

- Bachmann, H.; Ammann, W. Vibrations in Structures: Induced by Man and Machines; Structural Engineering Documents, International Association for Bridge and Structural Engineering; IABSE: Zürich, Switzerland, 1987. [Google Scholar]

- Bastow, D.; Howard, G. Car Suspension and Handling; Pentech Press: Budapest, Hungary, 1993. [Google Scholar]

- Fuchs, A.; Nijman, E.; Priebsch, H. Automotive NVH Technology; Springer Briefs in Applied Sciences and Technology; Springer International Publishing: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Ignazio, D.; Ferri, A. Active Control of Aircraft Cabin Noise; Computational and Experimental Methods in Structures; World Scientific Publishing Company: Singapore, 2015. [Google Scholar]

- Lisitano, D.; Bonisoli, E.; Mottershead, J. Experimental direct spatial damping identification by the stabilised layers method. J. Sound Vib. 2018, 437, 325–339. [Google Scholar] [CrossRef]

- Wang, X.; Yang, B. Transient vibration control using nonlinear convergence active vibration absorber for impulse excitation. Mech. Syst. Signal Process. 2019, 117, 425–436. [Google Scholar] [CrossRef]

- Cuvillon, L.; Weber, X.; Gangloff, J. Modal Control for active vibration damping of cable-driven parallel robots. J. Mech. Robot. 2020, 12. [Google Scholar] [CrossRef]

- Johnson, C. Design of passive damping systems. J. Vib. Acoust. Trans. ASME 1995, 117, 171–176. [Google Scholar] [CrossRef]

- Steffen, V.; Rade, D.; Inman, D. Using passive techniques for vibration damping in mechanical systems. J. Braz. Soc. Mech. Sci. 2000, 22, 363–370. [Google Scholar] [CrossRef]

- Maiorino, A.; Muscolo, G.G. Biped robots with compliant joints for walking and running performance Growing. Front. Mech. Eng. 2020, 6, 11. [Google Scholar] [CrossRef]

- Spadaro, F.T.; Muscolo, G.G. Compliant joints influence in four-legged robots. Front. Mech. Eng. 2020, 6, 16. [Google Scholar] [CrossRef]

- Frahm, H. Device for Damping Vibrations of Bodies. U.S. Patent Application No. 989,958, 18 April 1911. [Google Scholar]

- Den Hartog, J. Mechanical Vibrations; Dover Civil and Mechanical Engineering; Dover Publications: Mineola, NY, USA, 2013. [Google Scholar]

- Calabrò, R.; Portaro, S.; Manuli, A.; Leo, A.; Naro, A.; Bramanti, A. Rethinking the robotic rehabilitation pathway for people with amyotrophic lateral sclerosis: A need for clinical trials. Innov. Clin. Neurosci. 2019, 16, 11. [Google Scholar]

- Bonisoli, E. LUPOS—LUmped Parameters Open Source FEM Code, Politecnico di Torino. Tutorial, 16 January 2021. [Google Scholar]

- Maia, N.; Silva, J. Theoretical and Experimental Modal Analysis; Engineering Dynamics Series; Research Studies Press: Somerset, UK, 1997. [Google Scholar]

- Géradin, M.; Rixen, D. Mechanical Vibrations—Theory and Application to Structural Dynamics; John Wiley & Sons: Hoboken, NJ, USA, 2015; p. 616. [Google Scholar]

- Genta, G. Vibration Dynamics and Control; Mechanical Engineering Series; Springer: New York, NY, USA, 2008. [Google Scholar]

- Peeters, B.; Van der Auweraer, H.; Guillaume, P.; Leuridan, J. The PolyMAX frequency-domain method: A new standard for modal parameter estimation? Shock Vib. 2004, 11, 395–409. [Google Scholar] [CrossRef]

- El-Kafafy, M.; Peeters, B.; Guillaume, P.; De Troyer, T. Constrained maximum likelihood modal parameter identification applied to structural dynamics. Mech. Syst. Signal Process. 2016, 72–73, 567–589. [Google Scholar] [CrossRef]

- Vacher, P.; Jacquier, B.; Bucharles, A. Extensions of the MAC criterion to complex modes. In Proceedings of the International Conference on Noise and Vibration Engineering, ISMA, Leuven, Belgium, 20–22 September 2010; pp. 2713–2726. [Google Scholar]

- Ghandchi Tehrani, M.; Mottershead, J.E.; Shenton, A.T.; Ram, Y.M. Robust pole placement in structures by the method of receptances. Mech. Syst. Signal Process. 2011, 25, 112–122. [Google Scholar] [CrossRef]

- Lisitano, D.; Jiffri, S.; Bonisoli, E.; Mottershead, J.E. Experimental feedback linearisation of a non-smooth nonlinear system by the method of receptances. Math. Mech. Solids 2018. [Google Scholar] [CrossRef]

- Jiffri, S.; Fichera, S.; Mottershead, J.E.; Da Ronch, A. Experimental nonlinear control for flutter suppression in a nonlinear aeroelastic system. J. Guid. Control. Dyn. 2017, 40, 1925–1938. [Google Scholar] [CrossRef]

- Dal Borgo, M.; Ghandchi Tehrani, M.; Elliott, S.J. Active nonlinear control of a stroke limited inertial actuator: Theory and experiment. J. Sound Vib. 2020, 465. [Google Scholar] [CrossRef]

- Camperi, S.; Ghandchi Tehrani, M.; Elliott, S.J. Local tuning and power requirements of a multi-input multi-output decentralised velocity feedback with inertial actuators. Mech. Syst. Signal Process. 2019, 117, 689–708. [Google Scholar] [CrossRef]

- Randall, S.; Halsted, D.; Taylor, D. Optimum vibration absorbers for linear damped systems. J. Mech. Des. Trans. ASME 1981, 103, 908–913. [Google Scholar] [CrossRef]

- Cirelli, M.; Valentini, P.; Pennestrì, E. A study of the non-linear dynamic response of spur gear using a multibody contact based model with flexible teeth. J. Sound Vib. 2019, 445, 148–167. [Google Scholar] [CrossRef]

- Richiedei, D.; Trevisani, A. Updating of finite element models for controlled multibody flexible systems through modal analysis. In Computational Methods in Applied Sciences; Springer: Berlin/Heidelberg, Germany, 2020; Volume 53, pp. 264–271. [Google Scholar] [CrossRef]

- Bosmans, J.; Blockmans, B.; Croes, J.; Vermaut, M.; Desmet, W. 1D-3D nesting: Embedding reduced order flexible multibody models. In Conference for Wind Power Drives; CWD Aachen: Aachen, Germany, 2019; pp. 523–537. [Google Scholar]

- Foss, K. Coordinates Which Uncouple the Equations of Motion of Damped Linear Dynamic Systems; Technical Report; Massachusetts Institute of Technology Aeroelastic and Structures Research Laboratory: Cambridge, MA, USA, 1956. [Google Scholar]

- Bonisoli, E.; Lisitano, D.; Conigliaro, C. Experimental-numerical comparison of contact nonlinear dynamics through multi-level linear mode shapes. In Nonlinear Structures and Systems; Springer: Berlin/Heidelberg, Germany, 2019; Volume 1, pp. 263–271. [Google Scholar] [CrossRef]

| Mode | Description | Num. (Hz) | Exp. (Hz) | Exp. (%) |

|---|---|---|---|---|

| 1 | 1st legs bending out of phase lateral direction | 0.527 | 0.492 | 54.92 |

| 2 | 1st legs torsion in phase | 4.063 | 2.796 | 6.78 |

| 3 | 1st legs torsion out of phase | 4.147 | 4.715 | 1.51 |

| 4 | 1st legs axial out of phase | 6.471 | 5.316 | 5.94 |

| 5 | 2nd legs bending in phase | 7.356 | 8.744 | 3.91 |

| 6 | 2nd legs bending out of phase lateral direction | 8.008 | 7.964 | 2.28 |

| 7 | 1st legs axial in phase | 8.175 | 7.431 | 3.62 |

| 8 | 2nd legs bending out of phase motion direction | 10.05 | 11.91 | 5.01 |

| 9 | 2nd legs bending in phase motion direction | 12.64 | 17.95 | 6.38 |

| 10 | 3rd legs bending in phase lateral direction | 23.99 | 28.67 | 5.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisitano, D.; Bonisoli, E.; Recchiuto, C.T.; Muscolo, G.G. Dynamic Balance of the Head in a Flexible Legged Robot for Efficient Biped Locomotion. Appl. Sci. 2021, 11, 2945. https://doi.org/10.3390/app11072945

Lisitano D, Bonisoli E, Recchiuto CT, Muscolo GG. Dynamic Balance of the Head in a Flexible Legged Robot for Efficient Biped Locomotion. Applied Sciences. 2021; 11(7):2945. https://doi.org/10.3390/app11072945

Chicago/Turabian StyleLisitano, Domenico, Elvio Bonisoli, Carmine Tommaso Recchiuto, and Giovanni Gerardo Muscolo. 2021. "Dynamic Balance of the Head in a Flexible Legged Robot for Efficient Biped Locomotion" Applied Sciences 11, no. 7: 2945. https://doi.org/10.3390/app11072945

APA StyleLisitano, D., Bonisoli, E., Recchiuto, C. T., & Muscolo, G. G. (2021). Dynamic Balance of the Head in a Flexible Legged Robot for Efficient Biped Locomotion. Applied Sciences, 11(7), 2945. https://doi.org/10.3390/app11072945