Abstract

The aim of this study is to assess the environmental impact of storage systems integrated with energy plants powered by renewable sources. Stationary storage systems proved to be a valid solution for regulating networks, supporting frequency, and managing peaks in electricity supply and demand. Recently, their coupling with renewable energy sources has been considered a strategic means of exploiting their high potential since it permits them to overcome their intrinsic uncertainty. Therefore, the storage systems integration with distributed generation can improve the performance of the networks and decrease the costs associated with energy production. However, a question remains regarding the overall environmental sustainability of the final energy production. Focusing on electrochemical accumulators, the problems mainly concern the use of heavy metals and/or impacting chemical components of storage at the center of environmental hazard debates. In this paper, an environmental assessment from a life-cycle perspective of the hybrid energy systems powered by fossil and renewable sources located on two non-interconnected minor islands is presented. Existing configurations are compared with new ones obtained with the addition of batteries for the exploitation of renewable energy. The results show that, for batteries, the assembly phase, including raw material extraction, transport, and assembly, accounts for about 40% of the total, while the remaining part is related to end-of-life processes. The reuse and recycling of the materials have a positive effect on overall impacts. The results also show that the overall impact is strongly related to the actual energy mix of the place where batteries are installed, even if it is usually lower than that of the solution without the batteries. The importance of a proper definition of the functional unit in the analysis is also emphasized in this work.

1. Introduction

In the recent years, a considerable change in the energy mix took place. The main driver is the penetration of non-predictable renewable energy sources (NPRESs) into the electricity grid pushed by the more and more urgent environmental requirements. Since the Kyoto conference of 1997, when over 160 representatives of different countries established the objectives to shrink greenhouse gas (GHG) emissions, the increase of the use of renewable energy sources (RESs) was considered one of the key mechanisms to reach the overall goals.

In 2010, the European Union (EU) promoted its solution in the field of environment and sustainability, as a natural consequence of the expiration of the 2012 Kyoto protocol. Three environmental objectives were established: a 20% reduction in GHG emissions compared to the 1990 level; a 20% rise in the use of energy from RES; and a 20% increase in energy efficiency. Finally, the EU members with the “2030 Framework for Climate and Energy” [1] established a 40% reduction of the GHG emissions from 1990 levels, a 27% increase of energy saving, and a 27% growth of EU energy consumption produced from RESs by 2030. A second step, the “EU Low-carbon Economy Roadmap” [2] requires a 60% drop of GHG emissions compared to 1990 levels by 2040 and an 80% reduction by 2050.

This important and mandatory growth of RES employment demands strong innovations in the electrical system, mainly due to the intermittent and unpredictable nature of many of these renewable sources. Changes are required on the grid because it must be strengthened in terms of both infrastructure and management points of view. In particular, the distribution network needs to be made capable of managing bidirectional electric flows. From the management viewpoint, there is the need for new grid strategies and more effective operation plans based on optimized tools to forecast electricity demand and supply. The latter is becoming a challenging task, and conventional generators have to bear the burden of providing electrical system security, as production and demand must continually match. Consequently, even the reduction of emissions is lower than the ratio between energy produced from RESs and fossil fuels [3].

In the development of electrical networks, storage systems are an increasingly interesting tool, since they provide flexibility to the electrical network and guarantee higher energy efficiency and better system management [4,5]. They can be used to separate the generation of electricity over time, space, and shape. From an economic point of view, the installation of storage systems allows to stock the energy produced over time at low cost and release it later during a peak of demand to avoid expensive and less efficient forms of purchase or production [6,7]. From the environmental viewpoint, which is the focus of this work, storage systems make possible to entirely exploit the RES production, even if it exceeds the current demand or the grid capacity, and to supply it to the users when their demand overcomes the production. This operation can reduce the use of energy supplied by fossil fuels. But, despite this operating mode clearly decreases the emissions of pollutants during the operation of an energy system, a question remains regarding the overall environmental sustainability of the final energy production, which can be a cornerstone for the widespread use of storage systems.

The International Renewable Energy Agency (IRENA) [8] underlines that the environmental concern can be a constraint when storage is matched to a real energy system and that an improvement of environmental compatibility is a key point for the development of storage technologies. Similarly, the European Energy Research Alliance (EERA) and the European Association for Storage of Energy (EASE) in a joint statement [9] confirm that, among other challenges, improvements of the environmental sustainability are mandatory for the development of energy storage technologies.

In the literature, there are many studies concerning the technical and economic aspects of the storage systems, while their environmental issues have only recently begun to be dealt with. In most cases, only the reduction of carbon emissions during the operational life is analyzed, and the positive contribution to the climate change reduction is reported. Nonetheless, for a clearer understanding of their total environmental impact, it is necessary to consider both the production and the disposal phases of these systems, in addition to their regular life cycle.

Baumann et al. [10] evaluated the CO2 footprint of four types of battery for different grid applications considering production, installation, and operation, while end-of-life is neglected. The life cycle and the energy density are found to be key factors for CO2 emissions as well as the carbon intensity of the electricity used in the battery production process. The results highlight that the most lithium-ion (Li-ion) and NaNiCl batteries show good performance, whereas lead-acid batteries exhibit the worst due to their low life and internal efficiency. Conversely, the environmental performance of redox-flow batteries is strongly dependent on the application. This battery technology is deeply analyzed by Weber et al. [11], and the high recyclability of these batteries is emphasized as an advantage for a life-cycle sustainability. Despite that, the weak points are the vanadium pentoxide production and the low efficiency. A review of life-cycle assessment (LCA) studies on Li-ion batteries, with a focus on the battery production process, has been conducted by Peters et al. [12]. In this case, the results show that research efforts should not only be focused on energy density but also on maximizing cycle life, charge–discharge efficiency, and cycle life.

A study of a hybrid system on an island consisting of wind and photovoltaic (PV) electricity generation and a large-scale lithium titanate battery in place of a diesel engine is presented in Reference [13]. The authors found that the production of the battery accounts only for 6% of the total environmental impact. It has the highest impact on acidification, caused by SO2 emissions from nickel production, and on ozone depletion, due to the use of halogenated hydrocarbon as cooling medium.

A particular use of batteries is studied in Reference [14], which analyzed the environmental benefits and drawbacks of using repurposed batteries from electric vehicles in second-use applications instead of new batteries. As expected, the results show that the highest environmental benefits refer to impact categories dominated by the manufacturing and repurposing stages, such as abiotic depletion potential and mineral resources.

The sustainability of lead-acid, Li-ion, and concentration gradient flow batteries is compared to that of other storage technologies, such as compressed air and pumped hydro energy storage (PHES) systems, by means of a multi-dimensional life-cycle assessment by Stougie et al. [15]. The lithium-ion battery system has the lowest exergy losses, impact on human health, and ecosystem diversity, while PHES is the best for human health, ecosystem diversity, resource availability, and global warming potential. In summary, the impact of the building phase is predominant due to the large infrastructure; depending on the technology, it is about 96–100% for human health and ecosystem, about 85–99% for the resource consumption, and 91–99% for global warming potential (GWP). The highest values refer to Li-ion batteries and the lowest to the blue battery system, which is a concentration gradient flow battery.

Interesting results for the environmental assessment of other storage technologies are reported and discussed in a study performed by Bouman et al. [16]. The focus is on a compressed air energy storage (CAES) system connected with a windfarm. Compared to the configuration without the storage, its presence increases the acidification, the particulate matter, the photochemical oxidant formation, and climate change significantly but decreases the eutrophication, the toxicity, and the mineral resource depletion. Adiabatic CAES moderately increases the environmental impacts across all assessed impact categories, and impacts are sensitive to the required capacity of the thermal energy storage. In comparison with the impacts from the average European electricity mix, both adiabatic and diabatic CAES configurations have lower impacts per kWh of electricity delivered to the grid, except for mineral resource depletion. A study by Kapila et al. [17] reports the results of the calculation of the net energy ratios and life cycle GHG emissions of adiabatic and conventional CAES and PHES. The greenhouse gas emissions associated with construction, operation, and decommissioning life-cycle stages of the energy storage systems are evaluated. The emissions are highly dominated by the operational stage in all the energy storage systems, mainly due to electricity consumption, while the contributions due to the use of material are minimal.

Starting from the above-mentioned published works, some main considerations can be drawn for the environmental assessment of energy storage:

- Greater achievable exploitation of renewable energy does not always guarantee a lower environmental impact.

- Not only the effects on climate change must be evaluated, but a more complete analysis needs to be performed.

- The whole life must be considered, including raw material extraction, materials and products processing, assembly, transport, operation, and decommissioning stages.

- Mainly for the operation stage, the results are greatly affected by the energy sources and the conversion technologies of the system in which the energy storage is integrated. For this reason, a proper analysis must consider the entire system, not only the storage devices. In this regard, an appropriate definition of the functional unit, i.e., the reference to which the results of the analysis refer, is very important.

In this study, the use of electrochemical storage in hybrid energy systems is assessed by means of a life-cycle assessment analysis. Batteries are the most widespread technology in terms of the number of storage devices and do not suffer from geographical limitations, unlike CAES and PHES. They can therefore be adopted in many different places and applications. Lastly, among the other technologies, batteries are the center of public attention regarding the impact of their disposal.

An LCA approach [18,19] from cradle-to-grave is selected, since it represents a standardized methodology, well-known and internationally recognized. It allows the assessment and quantification of environmental impacts and damage related to the development of a product, a procedure, or goods or services in a specific context defined in the analysis. The analysis is integral because all the processes and procedures necessary for the implementation, development, use, and end-of-life phase of the activity are examined. Several examples of application of LCAs to energy systems can be found in the literature [20,21,22,23].

The batteries are supposed to operate on two different small islands not interconnected to the national grid, where, at the time of writing, the energy production system consists of diesel engines and small renewable plants. Despite the small size of RES plants, their production can not be entirely used due to the lack of storage devices. For each case, the analysis regards the overall energy system and compares its current configuration with the one that comprises the storage unit made by the addition of batteries. The possibility to enlarge the size of RES plants with an additional increase of the number of batteries is also studied. An original focus of this study is on the influence on the results of the definition of the functional unit used in the analysis.

2. Battery Model Settings

In the analysis, four different kinds of batteries are studied. These technologies are chosen because they represent technologies at different stages of maturity and are all suitable for stationary applications. Furthermore, they are usually considered to have a low impact on the environment, unlike lead-acid batteries, for example. In the following, the main assumptions made for battery modeling are reported. Note that only the characteristics required for the LCA model are summarized in the work. For a detailed description of the features and operation principles, refer to the literature. For the modeling, secondary data are used. The lack of primary data should not be considered a weak point, since the focus of this work is on the integration of batteries into hybrid systems, not on the production and disposal processes of such technologies.

2.1. The Batteries

2.1.1. Lithium-Iron-Phosphate Battery, LiFePO4 (LFP)

The operation of this type of battery is based on Li-ions and on the cathode made by LiFePO4. The cells are characterized by high auto-discharge ratio, and for this reason they are suitable for stationary applications. They are widely used due to their low cost, non-toxicity, and abundance of ferrous materials. Other distinctive traits are: (i) good electrochemical properties, (ii) high thermal capacity that in turn provide intrinsic stability, (iii) operational safety, and (vi) lack of reactivity at high temperatures.

The properties of this cell allow it to withstand more than 2000 cycles even under high loads thanks to its voltage stability.

The most significant technical limitation is the high electrical resistance, which has been partially solved thanks to the use of cathode coatings with carbonic materials obtained by doping semiconductors; even the electrical and ionic conductivity does not present relevant values. The energy density of this battery is about 90–120 Wh kg−1 [24].

2.1.2. Lithium-Nickel-Manganese-Cobalt Battery, LiNixCoyMnxO2 (NCM)

This type of accumulator is widely used for electric cars thanks to its high acceleration currents. It consists of manganese oxide for the cathode with micro-crystals that form a three-dimensional architecture. This characteristic reduces the electrical resistance and allows a high control of the currents. The union of nickel with manganese provides a high specific energy that makes the battery stable and long lasting. The cell has high thermal stability, and the low internal resistance allows rapid charging and discharging cycles.

The energy density of these accumulators is 140–200 Wh kg−1, and their useful life lasts longer than 2000 cycles. The working temperature of these cells can vary between −20 and +40 °C; therefore, they do not require a very powerful cooling system.

Due to its properties, this technology is suitable also for stationary storage applications as stated in Reference [25].

2.1.3. Vanadium Redox Flow Battery (VRFB)

Vanadium flux batteries are flow batteries based on the redox reaction, which exploits the ability of vanadium to exist in solution in four different oxidation states. The electrolytes, which are stored in tanks and flow into the batteries, are two solutions of vanadium ions in water and sulfuric acid. The main advantage of this cell is that it can obtain an unlimited capacity by using tanks of different sizes. In addition, downtime periods do not cause degradation. Two of the main disadvantages are the low energy density and the rather complex nature of the system. Other peculiarities of this technology are the long durability (over 20 years), the good efficiency, and the low maintenance costs. The battery can undergo overloads of up to 400% for over 10 s, and thanks to its chemical neutrality, there is no risk of fire since the electrolyte solution works autonomously as a refrigerant, limiting overheating issues.

As said, the energy density of the VRFB is rather limited, between 10–75 Wh kg−1. In addition, the costs of electrolytes and membranes significantly affect the final price of the battery, which is therefore relatively high [26].

2.1.4. Sodium Ion Battery (NIB), Na-Ion

Many attempts still need to be made to make this technology competitive with the others in both the field of anodic materials as well as in new electrolytes. However, it is interesting to compare the environmental impact of this type of new accumulator to the existing technologies.

In practice, researchers are starting to focus on this battery type because it can overcome the issue related to lithium resource scarcity, which is a relevant problem considering the expected and very fast growth of the demand in the use of lithium in low emission batteries as well as in hybrid and electric vehicles. Furthermore, lithium reserves are mainly located in remote or politically unstable areas. Therefore, geopolitical aspects can cause an increase of the future cost, extraction times, and the necessity of using lower quality resources.

The distinctive trait of the NIB is the specific energy density per cell; it is up to 136 Wh kg−1, thus comparable or even slightly higher than that of the existing LFP cells.

Estimation of the achievable service life of NIBs is scarce due to the low technical maturity of the technology. The technical sheets for commercial use report at least 300 charge–discharge cycles with an initial conservation capacity of 80%, while 2000 cycles are considered feasible by some research studies [27,28].

2.2. Battery Models

2.2.1. Battery Assembly and Transport

The amounts of material used in the construction of batteries depend on their energy density. In this work, the values are assumed considering lithium cells as mature, while flow batteries are more backward in development. Therefore, it is reasonable to assume a density equal to their technological limit for the former and a lower one in the relevant range for the latter. The values for NIB batteries are derived from Reference [29].

The following values for the battery packs are used:

- 120 Wh kg−1 for LFP;

- 200 Wh kg−1 for NCM;

- 24.3 Wh kg−1 for VRFB;

- 128 Wh kg−1 for NIB.

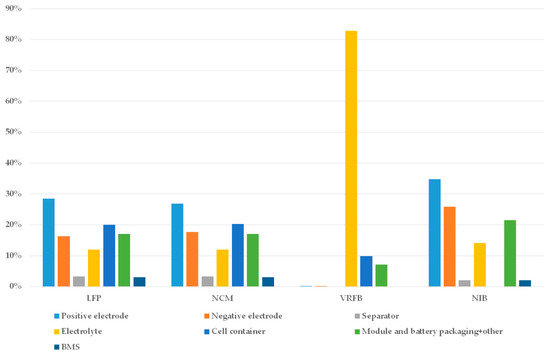

Considering the above-mentioned values and the mass composition of each battery shown in Figure 1, the mass of each element can be derived [11,30,31,32,33].

Figure 1.

Percentage mass composition of the batteries in this study [11,30,31,32,33].

The manufacturing of batteries is carried out in production sites located in Europe. In the manufacturing process, the use of medium voltage electricity is considered, while natural gas is used for the heat production. Road transport is carried out by EURO 5 vehicles with a load capacity from 16 to 32 tons; the rail transport is associated with travel within the EU. The distances among the different processes’ locations are based on typical transport distances according to the Ecoinvent 3 standards [34,35].

2.2.2. Battery Operation

For the operation stage, the assumptions made are summarized in Table 1. They are made in accordance with the results of the experimental campaign for some batteries for operation life and round-trip efficiency given in Reference [36].

Table 1.

Average operating efficiency of the batteries based on the number of life cycles.

The operation of the batteries is strongly related to their operational context as explained in Section 3 for the different scenarios.

In the results presented in this work, for VRFB a life of 13,000 cycles is considered, while for the other batteries it is expected to be equal to 5000 cycles, and the life in years depended on the charge–discharge history of the batteries in each scenario.

2.2.3. Batteries’ End-Of-Life

At the end of the operational life, a recycling scenario is assumed for batteries, considering the state of the art [37,38,39]. Table 2 lists the used percentage of recycling for the different materials.

Table 2.

Percentage of recycling [37,38,39].

The amounts not recycled are disposed or burned, depending on the material, as in the European practice.

The consumption of electricity and heat used in the processes of separation of the different materials, of purification, and of waste transport are considered using the data reported in the Ecoinvent database.

For the NIB, Liu et al. [40] propose a configuration for 100% recyclable sodium-ion technology, while an intermediate disposal scenario is considered in this study among the processes currently existing for lithium-ion battery recycling. Lithium-ion batteries have a composition and structure similar to sodium-ion cells and a hypothesized 100% recyclability that these cells can reach within a few years.

In the scenario of disposal of metal components, it is assumed that components such as the cell casing, Battery Management System (BMS), and cables are recovered. Electronic waste can also be recovered, but landfilling is assumed in this study, as it is today the most common procedure.

3. The Case Study

The hybrid energy systems of two non-interconnected Italian minor islands (Ventotene and Pantelleria), both located in the Mediterranean Sea, are assessed. Firstly, the reference scenario for each island is analyzed, corresponding to the current configuration. For the sake of clarity, Table 3 lists the current energy system of each island as given in Reference [41].

Table 3.

Actual energy mix of the islands.

Then, two alternative scenarios are considered. The first one (named “first scenario”) expects only the addition of batteries. This solution provides a better exploitation of the already existing renewable energy plants and, consequently, an increment of their load factor. In particular, the batteries’ global size, resulting from an in-depth analysis of the islands’ power generation system production, is assumed to be equal to 1 MWh. From a preliminary simulation of the annual system operation, batteries could reduce the diesel consumption by about 2% in Pantelleria and 7% in Ventotene. The simulation is conducted on hourly basis over a year by means of the software HomerPro [42]. The electric load of the islands and wind and solar variability are considered. This simulation is used to find the annual production of each source (RESs and diesel) and the charge–discharge cycles of batteries.

The second scenario (named “alternative scenario”), which can be considered a more advanced one, assumes an increase of the RES penetration in the islands by means of the installation of new wind turbines and PV modules.

The solar and wind potentialities on the two island and the geographic and landscape constraints are considered to properly size the new installations [41], while the size of the batteries is computed by means of an annual simulation by means of HomerPro to avoid the dissipation of energy from RES plants. A preliminary economic assessment guarantees a payback time lower than 10 years but, in this work, the economic optimization is neglected, since it is not the focus of the LCA.

The main results of the annual energy simulation are listed in Table 4. The annual consumption of diesel decreases by about 23% for Pantelleria and 12% for Ventotene with respect to the reference scenario.

Table 4.

Energy mix of the islands in the advanced energy scenario (also named “second scenario”).

4. Results and Discussion

4.1. First Scenario Outcomes

In this section, the results obtained considering only the addition of batteries to the already installed RES power generation system are discussed. As already pointed out, this solution needs to be explored because the addition of batteries can better exploit the installed RES plants.

The “functional unit” of the LCA is 1 MWh of stored energy. This means that it is 1 MWh of electricity produced using renewable energy, when available, stored in the batteries, which is then released when required by the users. In the calculation, battery efficiency is considered. In the reference case, the diesel engine produces this electricity when required by the users.

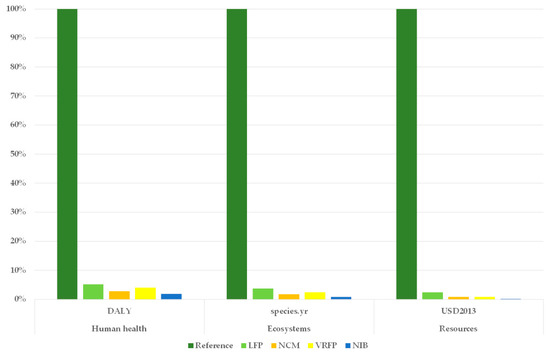

Figure 2 summarizes the damage assessment computed with the ReCiPe 2016 method-Endpoint (H) [43] for Pantelleria. This method summarizes the impact of a process in three areas of protection: human health, ecosystem quality, and resource scarcity.

Figure 2.

Comparison of the impacts for the different batteries and of the reference case (ReCiPe 2016 method-Endpoint (H)).

The results clearly show that the use of the batteries gives a significant reduction of the impacts in overall categories with respect to the reference scenario (actual energy mix as listed in Table 3). In all the categories, the impacts are lower than 6% of the impacts due to production by the diesel engine.

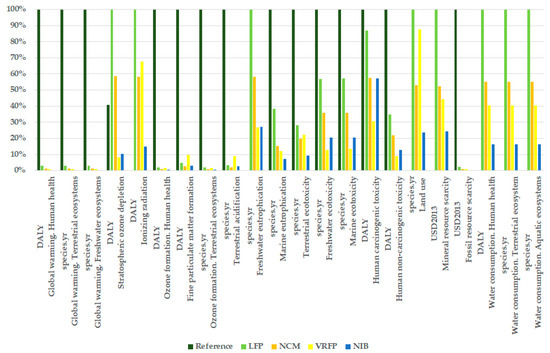

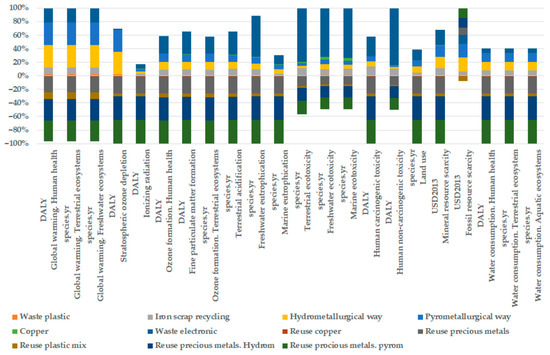

Figure 3 shows in greater detail the impact characterization since the mechanisms affecting the three areas of protection are indicated separately. In this case, it is clear that the use of LFP has the highest impact on stratospheric ozone depletion, ionizing radiation, water consumption and eutrophication, land use, and mineral resource scarcity. The impact is even higher than the use of diesel. Among the batteries, the VRFB presents the highest values for particulate emissions and terrestrial acidification. The NIB presents the lowest value for the mineral resource consumption, about 3 times lower than LFP, confirming the advantage of not using lithium, which has scarce reserves.

Figure 3.

Impact characterization for the different batteries and of the reference case (ReCiPe 2016 method-Endpoint (H)).

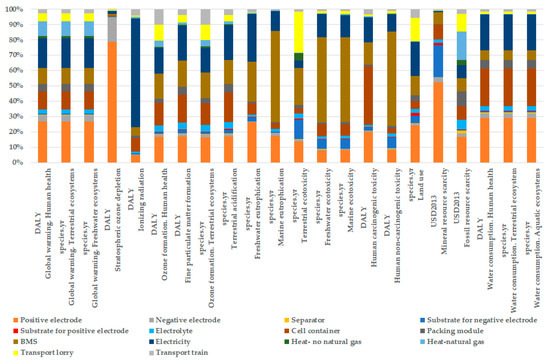

Starting with this final observation, it is interesting to analyze in detail the phases of LFP because it has the worst results among batteries.

Figure 4 shows the characterization of the lone assembly phase and highlights that the main impact is attributable to the positive electrode because it uses lithium and tetrafluoroethylene. In particular, its impact is around 20% of the global impact on human health, ecosystem, and use of resources. BMS greatly affected human health (about 21%) due to the use of electronic components and the liquid crystal display. A great impact is also linked to the use of electricity during the assembly phase. Transport accounts for about 14% in the use of resources.

Figure 4.

Characterization of the assembly phase for LFP (ReCiPe 2016 method-Endpoint (H)).

Figure 5 shows the impact of the end-of-life phase for the LFP battery. It can be noted that the reuse of metals and plastic has a positive effect on overall impact, which for some categories exceeds the impact of the waste treatment. The highest impact on health and environment is caused by the disposal of electronic waste, while for resource use the main impact is due to the pyrometallurgical and hydrometallurgical processes needed to recover lithium, cobalt, and nickel. It corresponds to about 82% of the total impact of this phase and 27% of the total impact of the battery.

Figure 5.

Characterization of the end-of-life phase for LFP (ReCiPe 2016 method-Endpoint (H)).

4.2. Alternative Scenario Outcomes

In this case, the impact linked to the addition of new RES plants is also considered in the LCA analysis besides that of batteries.

The comparison with the results of the previous case (first scenario) in terms of carbon footprint, calculated using the IPCC 100-year characterization factors [44], is listed in Table 5 (Mode 1). The functional unit is still 1 MWh of stored energy. It is clear that, in this case, the results are worse than the previous findings, due to the quota of impact related to the new RES plants. The new values are between 3 (for LFP) and 18 (for NIB) times the previous results. Note that these values are still much lower than those for diesel production.

Table 5.

Carbon footprint of 1 MWh of stored energy in the two scenarios.

The results completely change if a different functional unit is considered. In particular, the annual average impact of 1 MWh of energy supplied to the users by the entire system is considered (Mode 2). Considering the carbon footprint calculation listed for Mode 2 in Table 5, it is clear that the introduction of batteries to exploit entirely the already existing renewable plants (first scenario) gives only a negligible reduction of the islands’ emissions. Contrarily, the increase of the use of renewables and the addition of a greater storage capability provides better results. However, in comparison with the current energy generation systems, there is not a great difference among the different kinds of batteries.

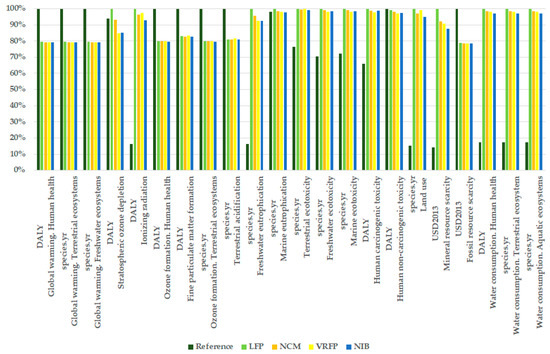

For other impact categories, as shown in Figure 6, different results can be obtained, and, in some cases, the impact of the new system (alternative scenario) is higher than that of the current one. Particularly, water consumption and eutrophication, land use, and mineral resource consumption present higher values due to the addition of PV modules. For the PVs and the wind turbines, the assembly phase and the end-of-life scenario consider the state of the art in Europe.

Figure 6.

Impact characterization for the different batteries in the alternative scenario and for the reference case (ReCiPe 2016 method-Endpoint (H)).

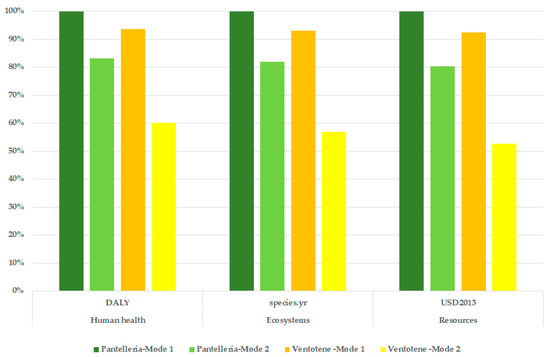

Lastly, to analyze in depth the influence on the results of the location, the damage for Pantelleria and Ventotene is compared for both definitions of the functional unit. For the sake of simplicity, only the results related to the NIB are summarized in Figure 7, but the other batteries present similar outcomes.

Figure 7.

Damage assessment for the energy systems with NIBs in Pantelleria and Ventotene (ReCiPe 2016 Method-Endpoint (H)).

The values have the same trend among the different calculation modes, but even if the batteries are the same, the impacts are quite different between the two islands. This is important because it demonstrates that the environmental benefit of a battery arrangement depends on the energy system where it is inserted, not only on the battery itself.

For example, referring to carbon footprint and excluding the impact caused by the use of diesel, the environmental impacts associated with the battery storage system account for only 13% of total impacts in Pantelleria and 12% in Ventotene. Photovoltaics and wind power plants account for 83% and 3.7%, and 82% and 2%, respectively. Similar results can be found in Reference [13] where a hybrid system combined a large-scale battery energy storage system with renewable electricity generation from wind power and photovoltaics on Graciosa island. In Reference [13], the impact of batteries is about 16% while those of wind power and photovoltaics are 47% and 37%, respectively.

Note that, in some papers and reports, the unit of storage capacity is used as the functional unit. The values of GWP for this functional unit, which excludes the contribution of the operation phase, are summarized in Table 6. They are comparable with the values listed in References [10,12], where the authors found that producing 1 Wh of storage causes 110 gCO2eq of GHG emissions. The relatively low values of this work are mainly related to the highest amounts used for the energy density of batteries.

Table 6.

Global warming potential (GWP) for the different batteries. The functional unit refers to the storage capacity.

Note that these results are far higher than those referring to the energy stored during the lifespan of the batteries and presented in the previous tables. In addition, unlike the previous results, they do not consider the lifespan of the storage and its round-trip efficiency.

5. Conclusions

In this work, the environmental impact of the addition of batteries into a hybrid energy system is evaluated along with their complete life using the LCA approach. As expected, the results show that the overall impact is mainly related to the assembly process and the disposal phase. The reuse process of raw materials can drastically reduce the impacts in all the analyzed endpoint indicators. Sodium ion batteries are promising for all environmental aspects. The potential for improvement for this technology is still significant and refers to the possibility of further reducing the environmental impacts associated with the production of hard carbon for the anode and the nickel content in the active cathode material.

This work also highlights that for a proper evaluation of the environmental benefits of the battery implementation, there is the need to consider (i) the battery operational life and (ii) the complete energy system where the battery works.

The investigation outcomes reveal that the environmental convenience of battery installation is always proved for the analyzed scenarios, except for some impact categories with very low values in this case study. However, the results are different for different installation locations, even if the batteries are the same, depending on the energy mix feeding the battery.

Finally, the analysis also demonstrates that the results are very sensitive to the functional unit. Therefore, it is important to select the proper functional unit and use it in a suitable evaluation of the battery performances.

Future developments of this work will focus on the influence of energy mix and on battery operation strategy on the results of the LCA of energy storage technologies.

Furthermore, even if the economic aspect is not considered in an LCA, the relationship among this aspect and environmental impact will study as a continuation of the work presented in this paper. The goal is to obtain an optimization of the battery size in a specific energy system based on both LCA and economic results.

Author Contributions

Conceptualization, A.S., A.B. and F.D.V.; Data curation, A.S., A.B. and F.D.V.; Formal analysis, A.S., A.B. and F.D.V.; Methodology, A.S., A.B. and F.D.V.; Writing—original draft, A.S. and A.B.; Writing—review and editing, A.S., A.B. and F.D.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| BMS | Battery management system |

| CAES | Compressed air energy storage |

| EASE | European Association for Storage of Energy |

| EERA | European Energy Research Alliance |

| EU | European Union |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| IRENA | International Renewable Energy Agency |

| LCA | Life-cycle assessment |

| LFP or LiFePO4 | Lithium-iron-phosphate |

| Li-ion | Lithium-ion |

| NaNiCl | Sodium–nickel chloride |

| NCM or LiNixCoyMnxO2 | Lithium-nickel-manganese-cobalt |

| NIB | Sodium ion battery |

| NPRSE | Non-predictable renewable energy source |

| PHES | Pumped hydro energy storage |

| PV | Photovoltaic |

| RES | Renewable energy source |

| VRFB | Vanadium redox flow battery |

References

- Commission of the European Communities. Green Paper: A 2030 Framework for Climate and Energy Policies; Publications Office of the European Union: Brussels, Belgium, 2013. [Google Scholar]

- Commission of the European Communities. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Aliprandi, F.; Stoppato, A.; Mirandola, A. Estimating CO2 emissions reduction from renewable energy use in Italy. Renew. Energy 2016, 96, 220–232. [Google Scholar] [CrossRef]

- Stoppato, A.; Benato, A. The Importance of Energy Storage. In Energy Storage; World Scientific: Singapore, 2017; pp. 1–26. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Integrated Thermal Electricity Storage System: Energetic and cost performance. Energy Convers. Manag. 2019, 197, 111833. [Google Scholar] [CrossRef]

- Stoppato, A.; Benato, A.; Destro, N.; Mirandola, A. Design and Operation of a Cogeneration System with Energy Storage opportunity. Energy Build. 2017, 124, 241–247. [Google Scholar] [CrossRef]

- Destro, N.; Benato, A.; Stoppato, A.; Mirandola, A. Components design and daily operation optimization of a hybrid system with energy storages. Energy 2016, 117, 569–577. [Google Scholar] [CrossRef]

- IRENA. Electricity Storage and Renewables: Costs and Markets to 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017. [Google Scholar]

- EASE/EERA. European Energy Storage Technology Development Roadmap towards 2030. 2017. Available online: https://eera-es.eu/wp-content/uploads/2016/03/EASE-EERA-Storage-Technology-Development-Roadmap-2017-HR.pdf (accessed on 18 March 2021).

- Baumann, M.; Peters, J.F.; Weil, M.; Grunwald, A. CO2 Footprint and Life-Cycle Costs of Electrochemical Energy Storage for Stationary Grid Applications. Energy Technol. 2017, 5, 1071–1083. [Google Scholar] [CrossRef]

- Weber, S.; Peters, J.F.; Baumann, M.; Weil, M. Life Cycle Assessment of a Vanadium Redox Flow Battery. Environ. Sci. Technol. 2018, 52, 10864–10873. [Google Scholar] [CrossRef] [PubMed]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Stenzel, P.; Schreiber, A.; Marx, J.; Wulf, C.; Schreieder, M.; Stephan, L. Environmental impacts of electricity generation for Graciosa Island, Azores. J. Energy Storage 2018, 15, 292–303. [Google Scholar] [CrossRef]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life Cycle Assessment of repurposed electric vehicle batteries: An adapted method based on modelling energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Stougie, L.; Del Santo, G.; Innocenti, G.; Goosen, E.; Vermaas, D.; van der Kooi, H.; Lombardi, L. Multi-dimensional life cycle assessment of decentralised energy storage systems. Energy 2019, 182, 535–543. [Google Scholar] [CrossRef]

- Bouman, E.A.; Øberg, M.M.; Hertwich, E.G. Environmental impacts of balancing offshore wind power with compressed air energy storage (CAES). Energy 2016, 95, 91–98. [Google Scholar] [CrossRef]

- Kapila, S.; Oni, A.O.; Gemechu, E.D.; Kumar, A. Development of net energy ratios and life cycle greenhouse gas emissions of large-scale mechanical energy storage systems. Energy 2019, 170, 592–603. [Google Scholar] [CrossRef]

- International Organization for Standardization ISO 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework 2006; ISO: Geneva, Switzerland, 2006.

- ISO International Organization for Standardization ISO 14044:2006 Environmental; ISO: Geneva, Switzerland, 2006.

- Stoppato, A. Life cycle assessment of photovoltaic electricity generation. Energy 2008, 33, 224–232. [Google Scholar] [CrossRef]

- Stoppato, A.; Benato, A. Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler. Energies 2020, 13, 1835. [Google Scholar] [CrossRef]

- Lozano Miralles, J.A.; López García, R.; Palomar Carnicero, J.M.; Martínez, F.J.R. Comparative study of heat pump system and biomass boiler system to a tertiary building using the Life Cycle Assessment (LCA). Renew. Energy 2020, 152, 1439–1450. [Google Scholar] [CrossRef]

- Varun Bhat, I.K.; Prakash, R. LCA of renewable energy for electricity generation systems—A review. Renew. Sustain. Energy Rev. 2009, 13, 1067–1073. [Google Scholar] [CrossRef]

- Web Source. Available online: www.batteryuniversity.com (accessed on 18 March 2021).

- Web Source. Available online: www.eniday.com (accessed on 18 March 2021).

- Alotto, P.; Guarnieri, M.; Moro, F. Redox flow batteries for the storage of renewable energy: A review. Renew. Sustain. Energy Rev. 2014, 29, 325–335. [Google Scholar] [CrossRef]

- Palomares, V.; Serras, P.; Villaluenga, I.; Hueso, K.B.; Carretero-González, J.; Rojo, T. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energy Environ. Sci. 2012, 5, 5884–5901. [Google Scholar] [CrossRef]

- Ong, S.P.; Chevrier, V.L.; Hautier, G.; Jain, A.; Moore, C.; Kim, S.; Ceder, G. Voltage, stability and diffusion barrier differences between sodium-ion and lithium-ion intercalation materials. Energy Environ. Sci. 2011, 4, 3680–3688. [Google Scholar] [CrossRef]

- Peters, J.; Buchholz, D.; Passerini, S.; Weil, M. Life cycle assessment of sodium-ion batteries. Energy Environ. Sci. 2016, 9, 1744–1751. [Google Scholar] [CrossRef]

- Minke, C.; Turek, T. Materials, System Designs and Modelling Approaches in Techno-Economic Assessment of All-Vanadium Redox Flow Batteries—A Review. J. Power Sources 2018, 376, 66–81. [Google Scholar] [CrossRef]

- Web Source. GFE Metalle und Materialien GmbH. Vanadium Electrolyte Solution 1.6 M. 637. Available online: http://www.gfe.com/produktbereiche/vanadium-chemikalien/anwendungen/ 638 energiespeicher/ (accessed on 18 March 2021).

- Adolfsson, M.; Rashid, S. Life Cycle Assessment and Life Cycle Cost of Heat Exchangers. In A Case for Inter Terminals Sweden AB Located in Port of Gothenburg; Chalmers 688, University of Technology: Gothenburg, Sweden, 2016. [Google Scholar]

- Schexnayder, S.M.; Das, S.; Dhingra, R.; Overly, J.G.; Tonn, B.E.; Peretz, J.H.; Waidley, G.; Davis, G.A. Environmental Evaluation of New Generation Vehicles and Vehicle Components; Oak Ridge National Laboratory, US Department of Energy: Washington, DC, WA, USA, 2001.

- Treyer, K.; Bauer, C. Life cycle inventories of electricity generation and power supply in version 3 of the ecoinvent database—Part II: Electricity markets. Int. J. Life Cycle Assess. 2016, 21, 1236–1254. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Weiguang, L.V.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. Application of Life Cycle Assessment to Nanoscale Technology: Lithium-ion Batteries for Electric Vehicles; EPA, United States Environmental Protection Agency: Washington, DC, USA, 2013.

- Web Source. U.S. Environmental Protection Agency (EPA). Application of Life-Cycle Assessment to Nanoscale Technology: Lithium-ion Batteries for Electric Vehicles. 24 April 2013. Available online: https://archive.epa.gov/epa/sites/production/files/2014-01/documents/lithium_batteries_lca.pdf (accessed on 18 March 2021).

- Web Source. Available online: www.vinyloop.com (accessed on 18 March 2021).

- Liu, T.; Zhang, Y.; Chen, C.; Lin, Z.; Zhang, S.; Lu, J. Sustainability-inspired cell design for a fully recyclable sodium ion battery. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Web Source. Legambiente, CNR-IIA. ISOLE SOSTENIBILI: Osservatorio Sulle Isole Minori. 2019. Available online: https://www.isolesostenibili.it/ (accessed on 18 March 2021).

- Web Source. Ricerca Sistema Energetico. Sviluppo delle Fonti Energetiche Rinnovabili nelle Isole Minori non Interconnesse. Rapporto RSE 15000371. Available online: http://rse-web.it/documenti.page?RSE_manipulatePath=yes&RSE_originalURI=/documenti/documento/temi/316137&country=ita (accessed on 18 March 2021).

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower system modeling with HOMER. In Integration of Alternative Sources of Energy; Farret, F.A., Simões, M.G., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 0471712329. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2016, 22, 138–147. [Google Scholar] [CrossRef]

- IPCC. 2013: Climate Change 2013: The Physical Science Basis. In Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; 1535p. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).