1. Introduction

In recent years, the development and investigation of a large variety of mobile robots used in a wide diverse set of applications have been enhanced by electronics cost reduction, increased microchips computational capabilities, and intelligent and flexible manufacturing [

1]. Mobile robots can be classified by the environment in which they work: land (UGVs), air (UAVs), or underwater (AUVs) [

2].

Land robots can be further classified by their locomotion, which can be wheeled, tracked, or legged. Wheeled robots have the ability to reach high speeds with low power consumption and can be guided by controlling few degrees of freedom, but their ability to overcome obstacles is limited [

3]. For this reason, although wheeled robots are the most prominent, tracked and legged robots offer motion advantages over the former in unstructured environments [

4,

5]. It is important to recall that most parts of the earth and other planet’s surfaces are inaccessible to conventional wheeled robots, due to the uneven terrain and obstacles, and therefore, there is a need to develop new mobile robots with enhanced mobile capacities. These natural terrains, on the other hand, offer a great opportunity for legged robots to demonstrate their terrain adapting capabilities [

6]. The increased obstacle overcoming capabilities of legged robots can be explained by the fact that this type of robot does not require a continuous support surface, but uses a discrete foothold for each foot, enhancing their mobility [

7].

On the other hand, the speeds achieved by legged robots are much lower, and energetically this type of robot is very inefficient. This is an important drawback in modern robotics as the battery energy-storing capabilities, and their heavy weight is a limiting design criterion [

7]. Thus, it is critical for robots to be energy-efficient to maximize battery performance. Moreover, generally speaking, legged, robots have more actuators, making them difficult to build and demand complex control algorithms.

Legged robots are biologically inspired, and their design tries to replicate the walking motion of animals in nature: One leg robots are inspired by kangaroos, two-legged robots by bipeds, four legs on quadrupeds, and more than four legs are inspired by insects. The number of legs might be an evident classification criterion, but it is important to realize that the number of legs will also determine the gait stability, which can be static or dynamic. Robots with static gaits are always balanced as the robot weight vector always remains within the polygon formed by the legs in touch with the ground [

8]. As a general rule, the more legs, the more stable the robot will be, but this will give rise to slow, inefficient, and complex legged robots.

In this paper, a hexapod robot will be considered, more specifically a C-leg shape hexapod robot. Hexapod robots are one of the most statically stable legged robots, and possess great flexibility, while standing or moving [

9]. This stability combined with a simple C-leg design with only one degree of freedom per leg, offers a balanced trade-off between the increased mobility capabilities of legged robots and the robustness and high speeds of conventional wheeled robots [

10].

Figure 1 shows a C-legged hexapod robot designed and manufactured by the Universidad Politécnica de Madrid.

Figure 1.

C-Legged hexapod robot designed and Manufactured by the Centro de Automática y Robótica de la Universidad Politécnica de Madrid, picture taken by one of the article’s authors [

11].

Figure 1.

C-Legged hexapod robot designed and Manufactured by the Centro de Automática y Robótica de la Universidad Politécnica de Madrid, picture taken by one of the article’s authors [

11].

One of the most well-known C-legged hexapod robots is RHex [

12]. This project was funded by the Defense Advanced Research Projects Agency (DARPA) and involved many universities, such as the University of Michigan, McGill University, University of California, amongst others.

The synchronization possibilities of the six individual legs give rise to a variety of different gaits which determine the motion of the robot [

13]. The two most common gaits are the alternating tripod gait mode and the six legs synchronized gait mode [

10].

The alternating tripod gait mode is the standard walking/running gait used by Rhex. This gait groups the front and back leg from one side and the central leg from the opposite side to form two tripods. In this gait mode, one tripod is always in touch with the ground, while the other is moving freely in the air, offering increased speed and efficiency. A video simulation of this gait mode generated by implementing the kinematic model developed in this article in MATLAB can be seen in the

Supplementary Materials.

The six legs synchronized gait mode, offers increased power and is generally used when hill climbing. On the other hand, this gait has reduced speed and reduced energy-efficiency, as at certain periods, the robot will lie on its chassis while the legs continue rotating. Similarly, to the alternating tripod gait, a video simulation of this gait mode can be seen in the

Supplementary Materials.

Enhancing the energy-efficiency of legged robots has been a field of great interest and investigation in recent years [

14]. These investigations have taken different routes, including (a) designing special robot structures that can reduce the energy consumption [

15,

16], (b) optimizing gait modes [

13,

17,

18] (c) optimizing foot contact force [

14], and (d) energy-efficient trajectory planning [

19]. From these four different routes, the majority of the investigations have focused their efforts on optimizing the contact force to increase the robot’s efficiency. This type of optimization is based on the fact that over constraints of hexapod robots produce internal forces between contract points that ultimately lead to energy inefficiency and gait instability [

14,

20]. Implementing force distribution together with position control algorithms, ensures that adequate torque is applied at each joint reducing the energy wasted in each joint. On the other hand, the main objective of gait optimization is to increase the robots’ mobility performance [

21], but it has also been proved that optimizing and switching between the different gait modes can save up to 20% [

22]. Furthermore, switching between different gait modes can be combined with efficient trajectory planning, and information regarding the terrain can then be used to adequately choose between different gait modes [

19].

All of the four optimization techniques have in common the fact that these investigations start with a robot design and their objective is to increase its performance, but it is possible that the design they start with, is inefficient compared to other design possibilities. Therefore, determining and knowing how different design parameters affect the core efficiency of the system is essential to obtain the best design possible, prior to the incorporation of all the different optimizations mentioned above.

Given the fact, that many of these investigations start with a design that needs optimization, the energy models are obtained by analyzing the energy consumption of each motor joint using the torque and the angular velocity [

14]. In this article, the energy model will be obtained from a more macroscopic perspective and will be understood as the gravitational potential energy (GPE) and kinetic energy (KE) of the robot, allowing a generic hexapod robot to be considered. This offers a novel procedure to obtain the consumption of hexapod robots.

The objective of this article is to provide the reader with an understanding of the motion and energy consumption of hexapod robots, together with some design considerations, that will allow energy-efficient C-legged hexapod robots to be developed. To do so, the kinematic model and the energy model of a single C-leg system will be developed to determine the impact of mass, leg radius, and leg’s angular velocity on the energy consumption of the system. Even though a single C-leg system might seem physically far off from the actual robot, the reality is that the models developed in this article can be used to model a complete robot when moving under different gait modes. In fact, the equations obtained in this article for a single C-leg system also model the motion of a C-legged hexapod robot moving with all the legs synchronized. This is because in this gait mode, the six legs can be represented by a unique virtual leg. Moreover, the six legs in alternating tripod gait can be thought of as two virtual legs, and hence the robot’s motion is easily modeled using two individual C-leg models and synchronizing them out of phase. Videos of these two gait modes can be found in the

Supplementary Materials.

The article is structured in the following way, firstly, the kinematic model of a single C-leg system is developed, which will be used to quantify the KE and GPE variations of the system, and therefore, the energy consumption and power demand associated with these variations. Then the kinematic and energy models will be validated experimentally on a custom-made test bench. Finally, the models will be used to investigate the impact of different design parameters on energy consumption, and a set of design guidelines will be drawn.

Finally, it is worthwhile mentioning that the models developed are not only useful to increase the efficiency of the system in terms of physical design, as well as in terms of gait motion. In fact, in continuation to the work presented in this article, the models presented here have been used to perform a gait optimization using an evolutionary algorithm.

3. Model Experimental Validation

3.1. Set-Up

To validate the kinematic and energy model developed in the previous section, it was necessary to design a test bench that matched the model assumptions. This meant to restrict the degrees of freedom of the system to only translation motion in the X- and Y-direction. To do so, the following test bench has been designed in SolidWorks and manufactured using a 3D printer.

The test bench consists of two sets of rail pairs that allow motion in the X- and Y-direction and limit the motion and rotation in the remaining degrees of freedom. To facilitate movement in the X- and Y-direction, IGUS bearings have been fitted in the sliding parts.

The motor used throughout the set of experiments is the JGY-371 motor with the specifications seen in

Table 1:

Due to the motor’s worm gearbox, the minimum distance between the shaft and the edge of the gearbox is 16 mm. This means that the system’s hip will never be at a height lower than 16 mm above the ground, thus the value of is 16 mm. The motor driver used is the MDD10A which controls the motor speed, which has been set either to 30 rpm in the open loop or to 30 rpm with the PID close loop control.

To validate the kinematic model, two distance sensors were used. On the one hand, the distance sensor used to measure the height (y) was an ultrasonic sensor (hc-sr04), placed in the vertical slider, shown in

Figure 12. On the other hand, to measure the displacement in the X-axis, a ToF sensor (cj vl53l0xv2) was placed in between the horizontal rails, and it measures the distance between the slider and the rail’s end. The position of this sensor can be seen in

Figure 12. Both sensors are connected to an Arduino Uno, which sends the data back to MATLAB via serial communication.

The legs diameter used for the kinematic model experiment are r = 20 mm for the space trajectory validation and r = 15 mm, trajectory vs. time validation.

The leg has been designed to fulfill the conditions imposed during the development of the model. As it can be seen from

Figure 13, the motor shaft and the legs end form a semicircle, and to avoid sliding, the legs contact surface has been made rugged. Furthermore, the leg’s end has been designed as thin as possible to ensure the system pivots around one unique point when the values of

belong to the interval

.

To validate the energy model, the leg radius was set to be r = 15 mm (the same as the one used in the kinematic model validation). The INA219 sensor was used to measure the power consumption of the system. This sensor communicates via I2C to the Arduino Uno, which itself sends the data to a MATLAB script in the computer via serial.

It is important to note that the energy model developed predicts the power consumption of the motor, due to the GPE and KE energy changes. This means that if the power consumption is measured directly when the system is moving, then the energy consumption associated with other sources, such as internal frictions, resistances, inertias, etc., will be included in those measurements. To obtain the consumption associated strictly with GPE and KE variations, the following procedure was done.

Firstly, the power consumption of the motor at a constant with no load (i.e., leg rotating elevated from the ground), was measured. In this way, the power consumption associated with overcome the internal frictions, resistance, inertias, etc., is quantified; the results are shown in the left graph of Figure 17. Then the power consumption was measured when moving the whole system at the same constant . The power consumption load-free was deducted from the total consumption to obtain the consumption associated with the energy changes of the system. There will also be other sources of energy consumption included in this final amount, such as friction losses between test-bench bearings and the rails and between the leg and the ground, but those should be negligible compared to the energy variations of the system.

To summarize, the model parameters can be seen in

Table 2.

3.2. Results and Discussion

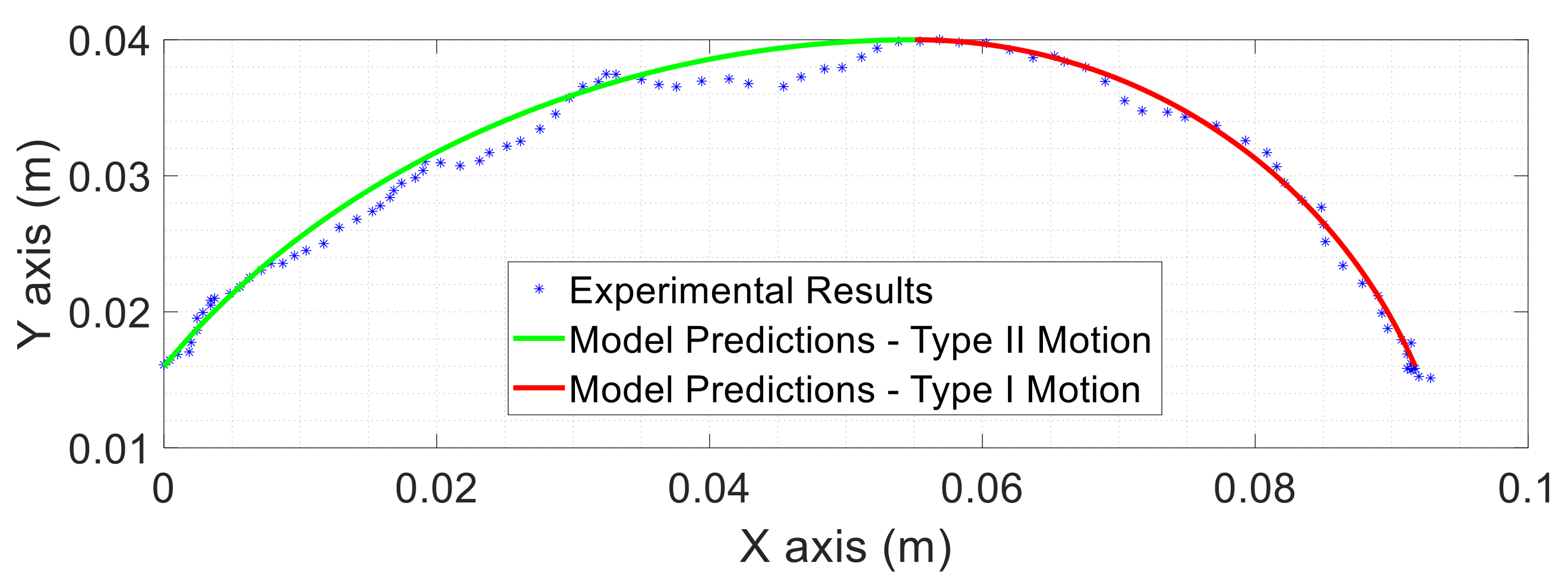

Overall, it can be seen that the experimental results accurately fit the model for both the trajectory in space (

Figure 14) and the evolution of

and

in time (

Figure 15).

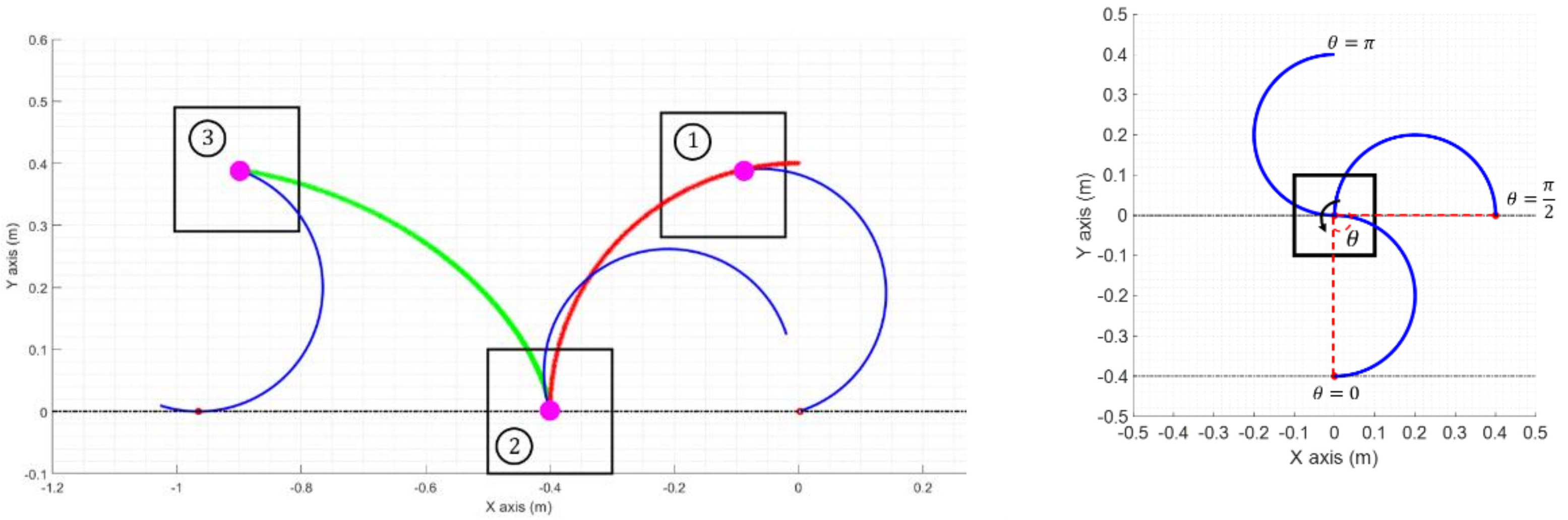

It can be seen that the system power demand to the motor is not constant throughout one entire revolution. Therefore, in an open loop control, the systems starts lagging as it can be seen in

Figure 15. The motor changes from being rotating free of load, to having to rise the weight of system, to finally having to hold the weight of the system and avoiding it from free falling. These torque variation requirements can be accounted for using a close loop control—which, according to the error difference between the desired rpms and the actual rpms, changes the voltage input. Due to the non-linearity of the system, a PID control does not provide a suitable controller, as was noticed in the experiments.

Kinematic Model Validation: Trajectory

Figure 14.

Motion Trajectory Experimental Results obtained with a system of r = 0.02 m throughout one complete revolution compared to the Model Predictions.

Figure 14.

Motion Trajectory Experimental Results obtained with a system of r = 0.02 m throughout one complete revolution compared to the Model Predictions.

Kinematic Model Validation: Displacement evolution with time—2 cycles

Figure 15.

Graphs showing the evolution of (left), and of (right) in time throughout two revolutions at 30 rpm in the open loop and in the close loop control, r = 0.015 m.

Figure 15.

Graphs showing the evolution of (left), and of (right) in time throughout two revolutions at 30 rpm in the open loop and in the close loop control, r = 0.015 m.

In

Figure 16, one can observe how the actual rpms of the system drop for both the open loop and close loop control, but on the close loop control the rpms overshoots straight after this decrease. This overshoot allows the system to catch up, and therefore, making it seem that at the end of the revolution, the system is not lagging

Figure 15. In reality, the controller is not able to cope with the nonlinear load variation and is not capable of maintaining the 30 rpms. A more suitable controller, such as a fuzzy or adaptive controller, would allow for different responses at different rotation angles, which would allow for adequate control. Investigating a nonlinear controller for this application is very important for precise control, but is outside the scope of this article.

The legs dimensions were changed in the two experiments, because during the testing stage, it was noticed that a leg with r = 0.02 m required too much motor torque, which caused the system to lag even more. A reduced leg demands less torque, and therefore, allows the close loop control to be more reactive and meet the reference command sooner. On the other hand, a larger leg implies bigger changes in displacement, and for this reason, this size leg was left for the trajectory validation, shown in

Figure 14.

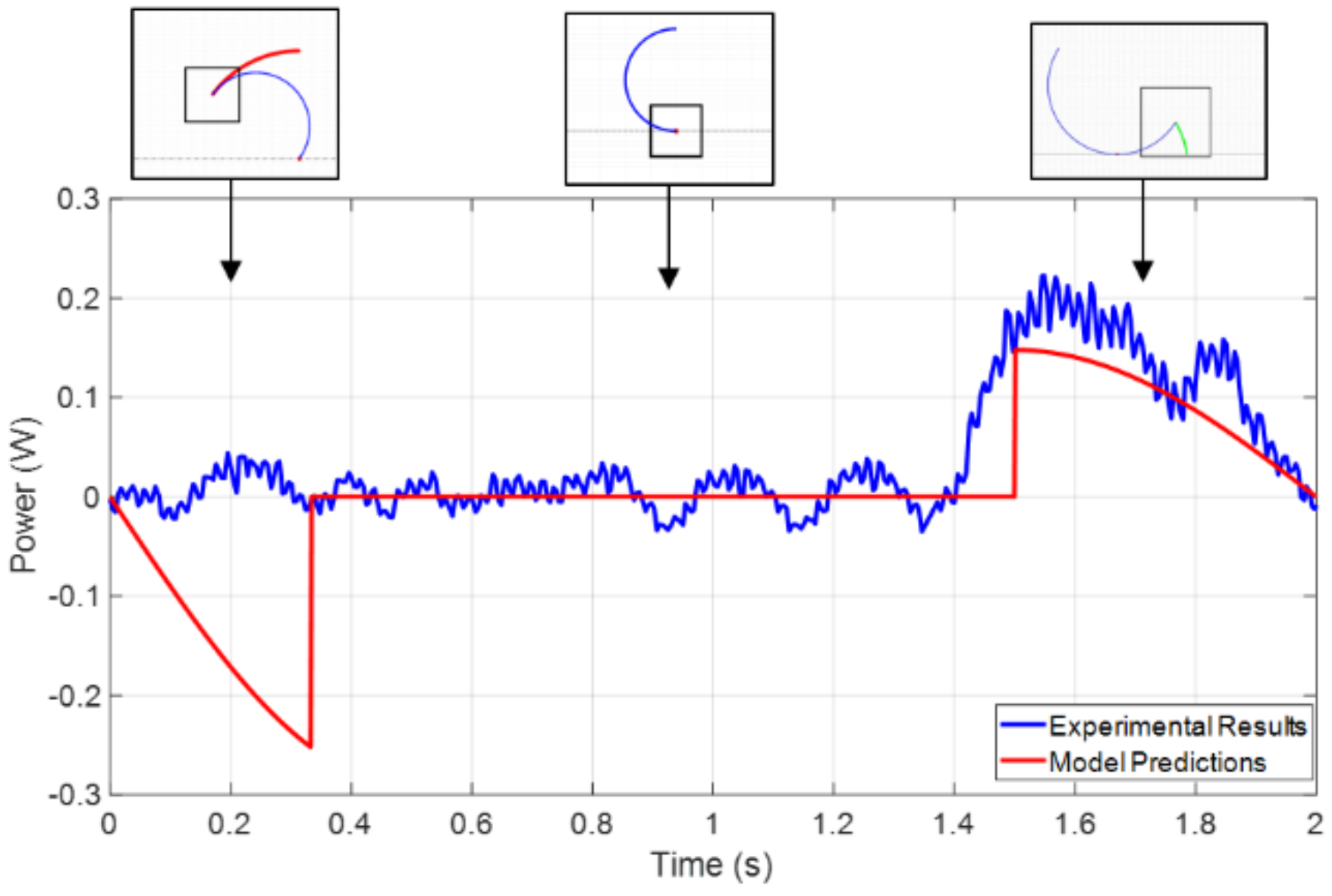

Energy Model Validation:

The image on the left in

Figure 17 shows the power consumption of the motor when no load is applied; this power consumption, as previously said, is due to internal resistance, friction losses, and inertial losses. It can be seen that the signal is noisy, but has a very constant average power consumption of 0.104 W. These oscillations could be due to many factors, such as oscillations in the supplying voltage, sensor errors, defects on the motor hardware, etc. It would be interesting to determine if there are some periodic variations associated with defects in the motor hardware that occur on every cycle. If this is the case, an average power consumption depending on the angular position of the motor, which would provide a more precise solution.

The image on the right in

Figure 17 represents the motor’s power consumption when the system is moving, and therefore, a load is applied to the motor shaft. For most of the time, the motor consumption is constant and has the same value as the average power consumption measured when the motor had no load applied.

If the average power consumption under no load conditions is subtracted from the curve shown on the right image of

Figure 17, the power consumption associated with the energy variations is obtained (

Figure 18). This can be compared to the predictions obtained in the previous section (red line in

Figure 18).

The predictions estimated a negative power demand during Type I motion as the system has to dissipate GPE, but this has not been detected by the sensors. After revisiting the equations and the equipment to explain this phenomenon, it was noticed that the motor used in the experiments contains a worm gearbox that self-locks to avoid the motor being back-driven [

24]. In self-locking worm gears, the torque applied from the load side is blocked and will not drive the worm. This is ideal for applications where loading against the gravitational force is required, but this device will not allow for regenerative braking [

25]. The energy applied is dissipated in heat, friction, and internal deflections. For this reason, the motor will drive, consuming the same power as if it was under no load conditions.

During Type II motion, it can be observed that the model predicts relatively accurately the power demand with an RMSE of 0.043. If the whole set of results are considered (Type I and Type II), then the RMSE increases to 0.077. As expected, the experimental values are higher than the predictions as friction losses between the leg and the ground have been neglected.

4. Design Parameters Impact on Power Demand and Energy Consumption

In this section, the effect , and have on the power demand, and the energy consumption during a complete revolution will be analyzed. Instead of analyzing the energy consumption as a value in Joules, the horizontal distance () covered by the system with one Joule of energy will be considered instead. In this way, the efficiency in transforming energy to horizontal displacement can be determined and compared. No energy recovery will be assumed (similarly to the set-up used throughout the report); hence, negative power demands will be assumed to be 0, thus 0 energy consumed for these periods. Furthermore, the system will be considered dimensionless .

4.1. Mass

The effect of the mass on power demand can be seen to be linear (left image in

Figure 19). Although the relationship between the power demand and the mass is linear, this does not hold for the effect of mass on the distance covered with one joule. More mass implies more KE and more GPE variations, which leads to energy being wasted. From the right image in

Figure 19, one can conclude that the relationship between the mass and the distance covered per joule is inversely proportional.

4.2. Angular Velocity

The effect of the angular velocity on the peak power demand can be seen not to be linear, but in fact, takes an exponential form (

Figure 20). According to

©Matlab’s regression toolbox, the exponential relationship, which has been determined using the nonlinear least squares method, has the following form [

26]:

The confidence value returned by the toolbox for this regression fitting is 95%. Even though the exponential constant term is small (0.02), the impact of angular velocity on peak power demands is so large because of the wide range of possible angular velocities. Increased angular speeds imply that the leg’s rotation cycle time is reduced, meaning the energy variations need to be supplied quicker, leading to high peak power demands.

On the other hand, the angular velocity effect on the distance covered with one joule is not as drastic, as increased angular speeds only lead to higher KE variations (

Figure 20). Whereas in the previous parameter analyzed (mass), increased mass implied increased KE and GPE hence its massive impact on the distance per joule.

4.3. Leg Radius

Larger legs require more instantaneous power demands (

Figure 21), due to the systems increment in GPE and KE variations. The relationship between the leg’s radius and the peak power demand is not linear, but an exponential one. According to

©Matlab’s regression toolbox, the exponential relationship has the following form:

The confidence value returned by the toolbox for this regression fitting is 95%. The exponential factor of this relationship (

Figure 21, [

26]) actually has a bigger value than the exponential growth rate seen between the angular velocity and the peak power demand (

Figure 20, [

25]).

Finally, the distance covered with 1 Joule of energy is inversely proportional to the leg’s radii (

Figure 21).

4.4. Design Parameters Recommendations

The relationship obtained between the parameters analyzed and the peak power demand and the distance covered with one joule are sum up in the

Table 3, the meaning of the different colors and acronyms are shown below this table.

Once again, it is worthwhile noting, that even though a simple C-leg system has been considered throughout the article, the conclusions obtained are the same as they would be for a full C-legged hexapod robot moving with all six legs synchronized. In an alternating tripod gait, the impact of the parameters investigated affects the energy and power consumption according to the synchronization of the two tripods, and can, therefore, be reduced.

With the conclusions obtained in the analysis performed in this section, the following recommendations are suggested to produce an efficient and well dimensioned C-legged hexapod robot. The following recommendations are for generic hexapod robots with no energy recovery, and therefore, no numbers that might be different for particular cases are used:

Energy-Efficiency: To produce a robot efficient in the transformation of joules to distance covered, the mass has to be kept as low as possible. This is because the KE and GPE variations are increased, and that implies a greater loss of energy. For this reason, the mass reduction should be the main objective throughout the design stage.

Motor Selection: Special care has to be taken when selecting the motors; as motors with high revolutions will need to supply really high-power demands. With the results obtained in

Section 4, it is not recommended to have angular speeds over 140 rpms when the leg is in contact with the grounds, as higher rpms will lead to massive peak power demand, requiring the motor to be very powerful and to have high torque. Selecting a motor with so much power might also have the drawback of increased mass, which ultimately leads to a decrease in energy-efficiency. The 140 rpms recommendation when the leg is in contact with the ground does not imply the maximum rpms of the motor should be this. It is beneficial to have a motor with maximum rpms over this, so it can move quicker in rotation angles, where the power demand is low and then slower when the power demand is higher. This will allow for better gait synchronization, which can increase the efficiency of the system.

Increasing Maximum Speed: If the maximum speed of the system wants to be increased, it might be worthwhile to increase the legs radius rather than selecting a motor with higher rpms. The desired maximum speed might be achieved with a larger leg that does not require a motor with so much power. On the other hand, this increase in leg radius will lead to more GPE and KE losses, but these losses will probably be smaller if this increase in leg radius has avoided choosing heavier motors. Moreover, the impact of the leg radius on the GPE and KE can be mitigated with gait synchronization.

As previously said, these recommendations are for hexapod robots with no energy recovery. If energy is recovered when the power demand is negative, then the relationship between the different variables changes slightly. It is important to remember that the negative power demand (during Type I motion) is associated with a decrease in GPE. In this period, energy has to be removed and is proportional to the mass and the height variation of the system. Hence, taking this into account and if energy recovery is implemented, then the impact of the system’s mass and leg radius on the distance covered with one joule, will be less than when there is no energy recovery. The energy-efficiency will be largely dependent on the ability to use the decrease in GPE. This could be by recharging the battery, which requires complex circuits, or using a supercapacitor that charges during those periods and releases the energy back to the motors during peak power demands. If the energy recovery efficiency is 100% then the mass and the leg radius will have no impact on the GPE, increasing the distance covered with one joule considerably. On the other hand, the impact of all the variables analyzed on peak power demand will be the same even if there is energy recovery.

5. Conclusions

The kinematic model of a C-legged robot is the concatenation of two different types of motion, a pivoting and a rolling motion. This can be extended to other types of legs, such as ellipsoids. Based on the motion mechanics, a kinematic model has been developed for a semicircle shape leg. This model has been verified experimentally in a custom-made test bench, proving that the model predictions fit very accurately the motion of the system. During the experimental validation, it was noticed that the system tended to lag, and for this reason, a PID was implemented to maintain the revolution time constant. It would be later on discovered that the reason for this lag was the high-power demand required by the system to gain the GPE and KE in a short period of time. In fact, it was noticed that a PID could not cope with the nonlinearity of the system.

The procedure developed to obtain the kinematic model of the system has been made generic and can be easily extended to any leg form that can be parameterized by an angle . This means that the whole analysis performed in this article could be done for an ellipse or a C-leg shape leg bigger than a semicircle.

Building upon the kinematic model of a single-leg system, the KE and GPE of the system were determined and then used to obtain the power demand associated with this kinetic energy variation. The model predicts high peak power demands when the system has to rise, which caused the system to lag during the kinematic model validation. The energy and power demand was verified using the custom-engineered test bench and by measuring the power consumption of the motor. Due to the mechanics of the worm gearbox of the motor, only the positive power demand was able to be detected. During the periods of predicted negative power demands, the motor had no power consumption associated with the energy variations of the system.

Using the energy and power model, the impact of variables, such as the mass, the angular speed, and the leg radius, were investigated to draw a set of guidelines that help design and select motors for C-legged hexapod robot. It has been concluded that the mass of the system impacts drastically the efficiency of the robot, draining the battery capacity. Thus, the main objective in the design stage is to reduce the weight as much as possible, especially if no energy recovery method is implemented.

The angular speed of the leg has a large impact on the peak power demand as this variable reduces the time interval in which the energy has to be supplied. For this reason, it is recommended to keep the legs’ angular velocity when in contact with the ground to speeds below 140 rpms. Higher rpms require high-power demands, which might not be achieved by the motors. Selecting more powerful motors to achieve this power demand at high rpms, might lead to heavier motors, and therefore, a less efficient robot.

Moreover, the leg radius has an effect on the peak power demand and on the distance traveled with one joule, but its effect on these two evaluation parameters is smaller than the angular speed on the peak power demand and that of the mass on the energy-efficiency. Hence, it might be a good idea to increase the leg radius if the maximum speed of the robot wants to be increased.