Health-Monitoring Methodology for High-Temperature Steam Pipes of Power Plants Using Real-Time Displacement Data

Abstract

1. Introduction

2. Stress-Calculation Methodologies for High-Temperature Steam Pipes

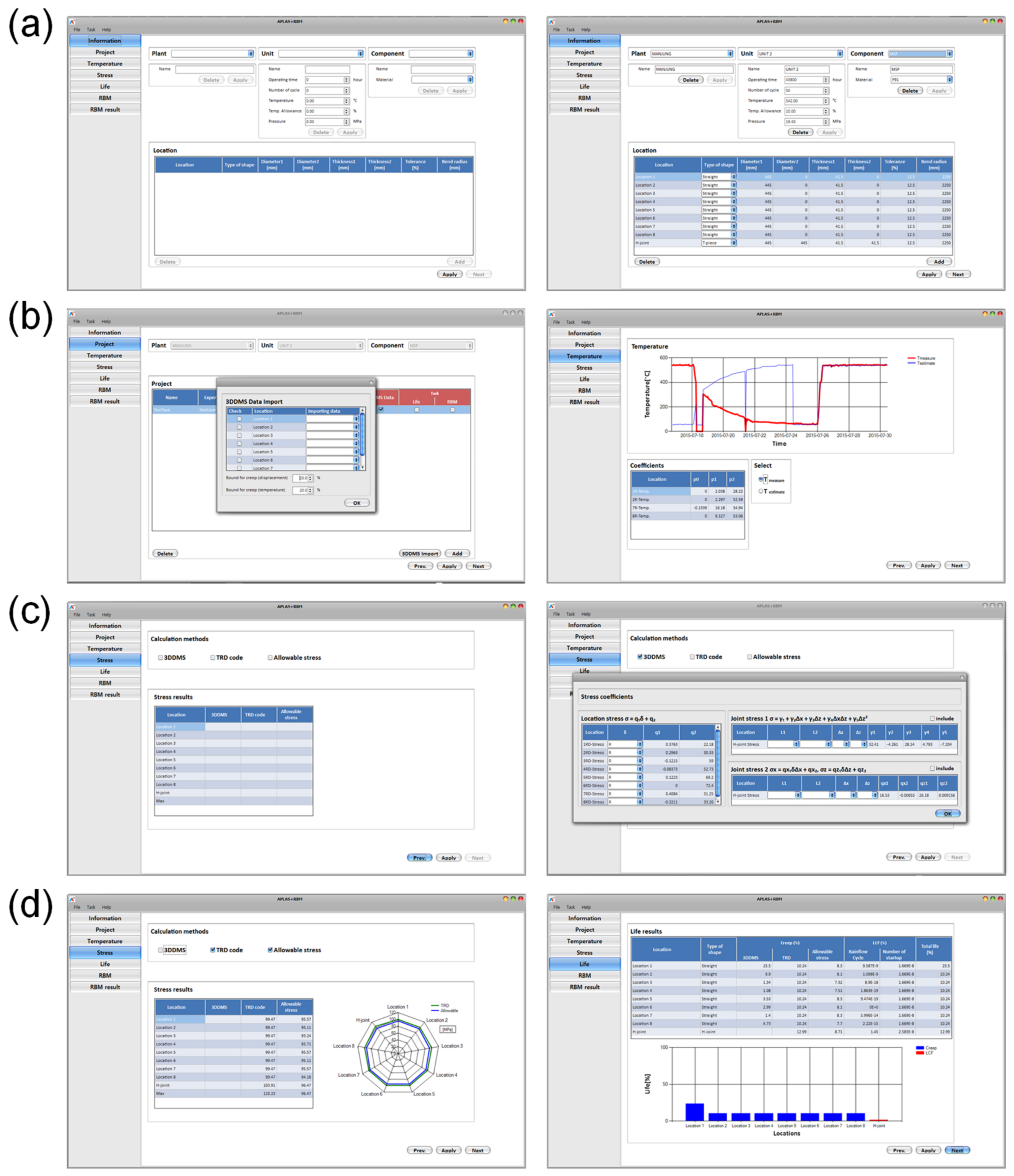

2.1. TRD-Code-Based Method

2.2. Design-Stress-Based Method (Allowable Stress)

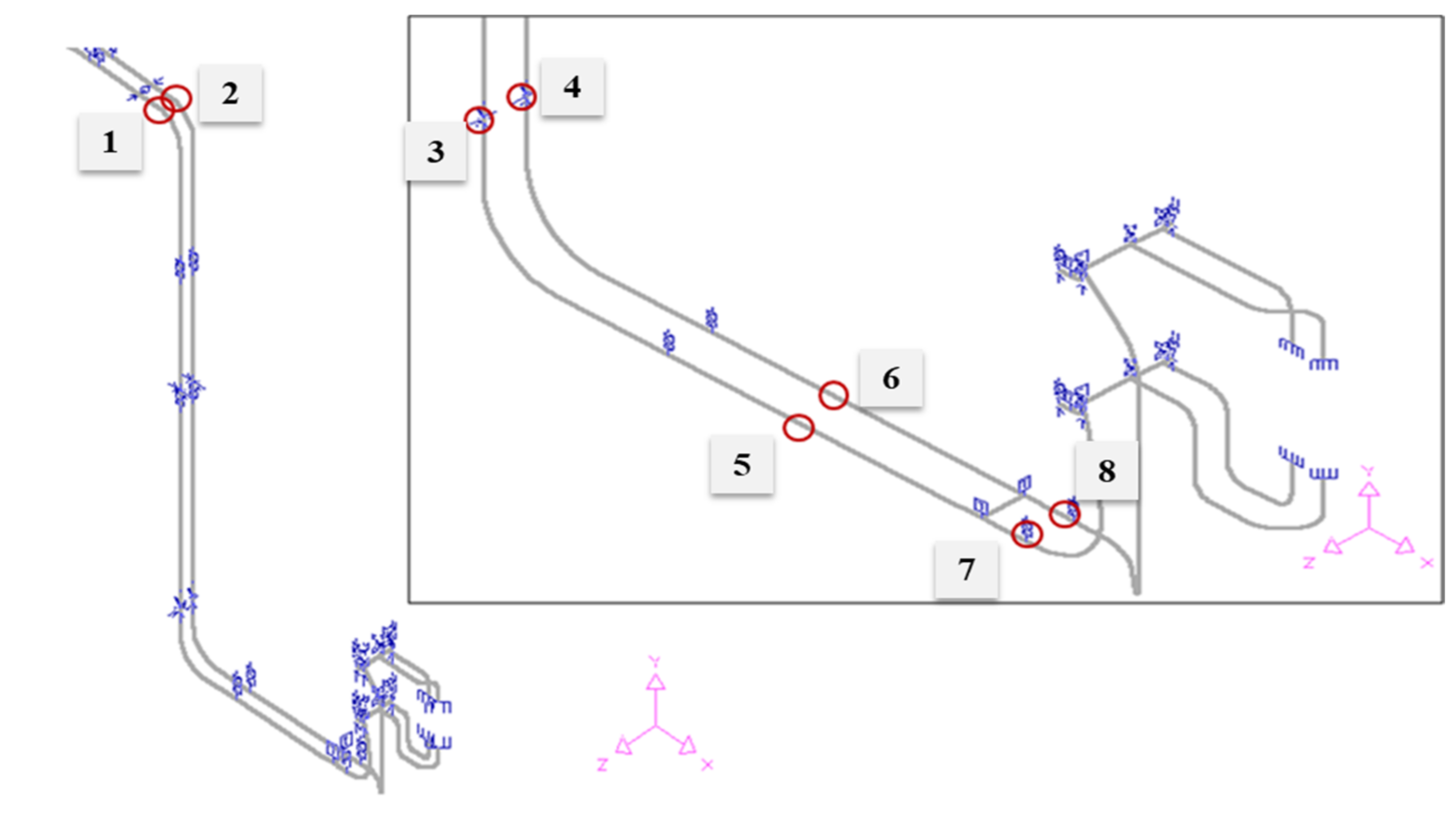

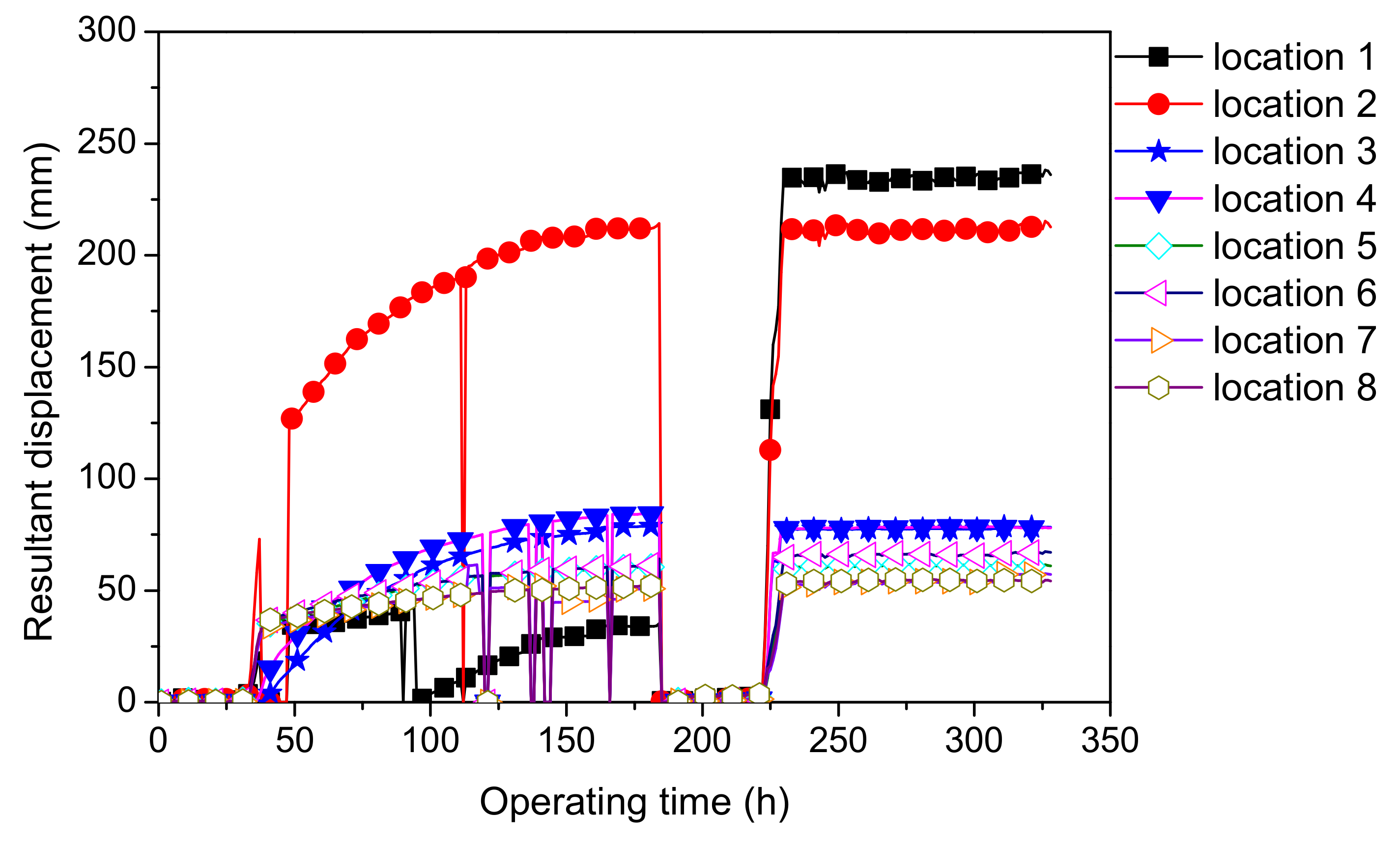

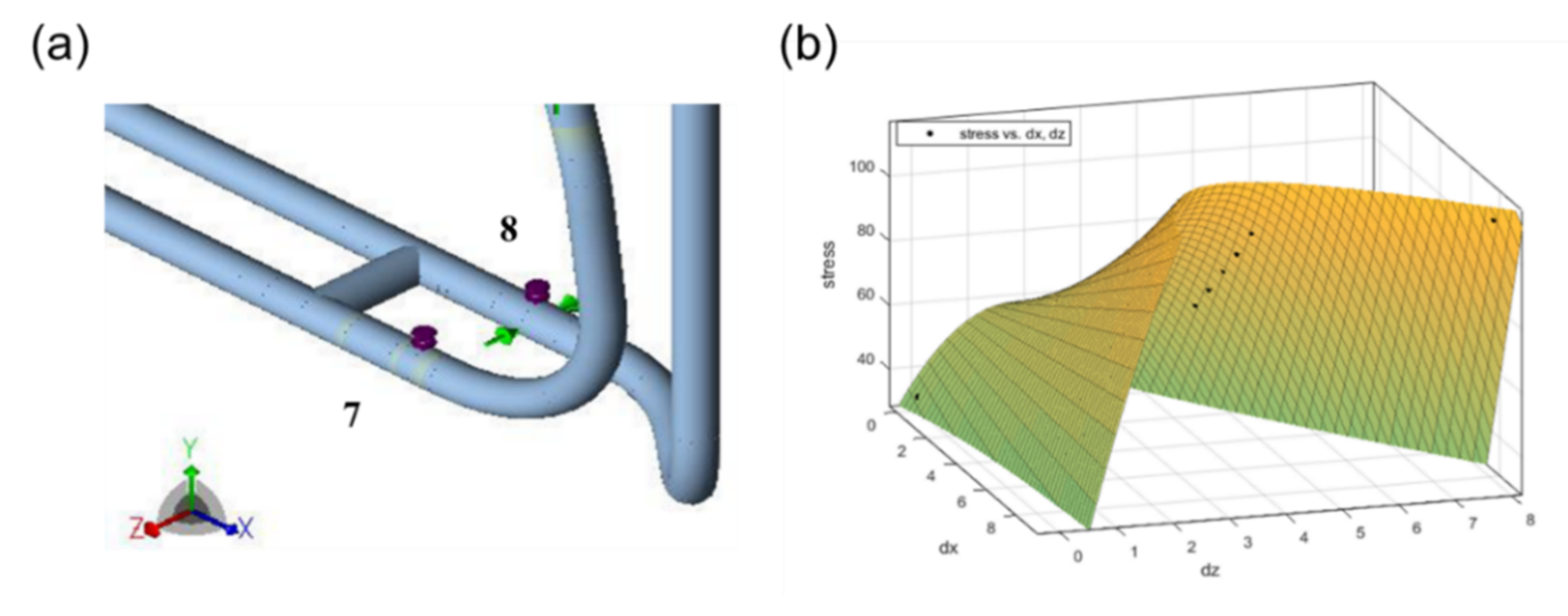

2.3. DDMS-Data-Based Method

3. Life Evaluation for High-Temperature Steam Pipes

3.1. Creep Life Prediction

3.2. Low-Cycle Fatigue Life Prediction

3.3. Lifetime Prediction

4. Development of the Health-Monitoring Program for the High-Temperature Steam Pipes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spera, D.A. A Linear Creep Damage Theory for Thermal Fatigue of Materials. Ph.D. Thesis, University of Wisconsin-Madison, Madison, WI, USA, 1968. [Google Scholar]

- Taira, S. Lifetime of Structures Subjected to Varying Load and Temperature. In Creep in Structures. IUTAM Symposia (International Union of Theoretical and Applied Mechanics); Hoff, N.J., Ed.; Springer: Berlin/Heidelberg, Germany, 1962. [Google Scholar]

- Miner, M.A. Cumulative Damage in Fatigue. J. Appl. Mech. 1945, 12, A159–A164. [Google Scholar]

- Robinson, E.L. Effect of Temperature Variation on the Long-Time Rupture Strength of Steels. Trans. ASME 1952, 74, 777–780. [Google Scholar]

- Polhemus, J.F.; Spaeth, C.E.; Vogel, W.H. Ductility Exhaustion Model for Prediction of Thermal Fatigue and Creep Interaction. In Fatigue at Elevated Temperatures; Carden, A.E., McEvily, A.J., Wells, C.H., Eds.; ASTM International: West Conshohocken, PA, USA, 1973; pp. 625–636. [Google Scholar]

- Priest, R.H.; Ellison, E.G. A Combined Deformation Map-Ductility Exhaustion Approach to Creep-Fatigue Analysis. Mater. Sci. Eng. 1981, 49, 7–17. [Google Scholar] [CrossRef]

- Goswami, T. Low Cycle Fatigue Life Prediction—A New Model. Int. J. Fatigue 1997, 19, 109–115. [Google Scholar] [CrossRef]

- Manson, S.S.; Halford, G.R.; Hirschberg, M.H. Creep-Fatigue Analysis by Strain-Range Partitioning. In First Symposia on Design for Elevated Temperature Environment; ASME: San Francisco, CA, USA, 1971; pp. 12–28. [Google Scholar]

- Ostergren, W.J. A Damage Function and Associated Failure Equations for Predicting Hold Time and Frequency Effects in Elevated Temperature, Low Cycle Fatigue. J. Test. Eval. 1976, 4, 327–339. [Google Scholar]

- Halford, G.R. Energy Required for Fatigue. J. Mater. 1966, 1, 3–18. [Google Scholar]

- Chiou, Y.C.; Yip, M.C. An Energy-Based Damage Parameter for the Life Prediction of AISI 304 Stainless Steel Subjected to Mean Strain. J. Chin. Inst. Eng. 2006, 29, 507–517. [Google Scholar] [CrossRef]

- Fan, Z.; Chen, X.; Chen, L.; Jiang, J. Fatigue–Creep Behavior of 1.25Cr0.5Mo Steel at High Temperature and its Life Prediction. Int. J. Fatigue 2007, 29, 1174–1183. [Google Scholar] [CrossRef]

- Lee, K.-O.; Hong, S.-G.; Lee, S.-B. A New Energy-Based Fatigue Damage Parameter in Life Prediction of High-Temperature Structural Materials. Mater. Sci. Eng. A Struct. 2008, 496, 471–477. [Google Scholar] [CrossRef]

- ASME. Standard Heat Treatments for Fabrication Processes: ASME Code for Pressure Piping, B31 ASME B31.1-2017; ASME: New York, NY, USA, 2017. [Google Scholar]

- Wang, Q.; Chen, J.; Chen, X.; Gao, Z.; Li, Y. Fatigue Life Prediction of Steam Generator Tubes by Tube Specimens with Circular Holes. Metals 2019, 9, 322. [Google Scholar] [CrossRef]

- Nilsson, K.-F.; Dolci, F.; Seldis, T.; Ripplinger, S.; Grah, A.; Simonovski, I. Assessment of thermal fatigue life for 316L and P91 pipe components at elevated temperatures. Eng. Fract. Mech. 2016, 168, 73–91. [Google Scholar] [CrossRef]

- He, X.; Chen, J.; Tian, W.; Li, Y.; Jin, W. Low Cycle Fatigue Behavior of Steam Generator Tubes under Axial Loading. Materials 2018, 11, 1944. [Google Scholar] [CrossRef] [PubMed]

- Arora, P.; Gupta, S.K.; Bhasin, V.; Singh, R.K.; Sivaprasad, S.; Tarafder, S. Testing and assessment of fatigue life prediction models for Indian PHWRs piping material under multi-axial load cycling. Int. J. Fatigue 2016, 85, 98–113. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.D.; Berto, F.; Antunes, F.V. Fatigue life assessment of notched round bars under multiaxial loading based on the total strain energy density approach. Theor. Appl. Fract. Mech. 2018, 97, 340–348. [Google Scholar] [CrossRef]

- Bertini, L.; Frendo, F.; Marulo, G. Fatigue life assessment of welded joints by two local stress approaches: The notch stress approach and the peak stress method. Int. J. Fatigue 2018, 110, 246–253. [Google Scholar] [CrossRef]

- Salifu, S.; Desai, D.; Kok, S. Numerical simulation and creep-life prediction of X20 steam piping. Mater. Today Proc. 2021, 38, 893–898. [Google Scholar] [CrossRef]

- Jing, H.; Su, D.; Xu, L.; Zhao, L.; Han, Y.; Sun, R. Finite element simulation of creep-fatigue crack growth behavior for P91 steel at 625 °C considering creep-fatigue interaction. Int. J. Fatigue 2017, 98, 41–52. [Google Scholar] [CrossRef]

- Xu, Q.; Yang, X.; Lu, Z. On the development of creep damage constitutive equations: A modified hyperbolic sine law for minimum creep strain rate and stress and creep fracture criteria based on cavity area fraction along grain boundaries. Mater. High Temp. 2017, 34, 323–332. [Google Scholar] [CrossRef]

- Salifu, S.; Desai, D.; Kok, S. Prediction and Comparison of Creep Behavior of X20 Steam Plant Piping Network with Different Phenomenological Creep Models. J. Mater. Eng. Perform. 2020, 29, 7382–7395. [Google Scholar] [CrossRef]

- Ghaffar, M.H.A.; Husin, S.; Baek, J.E. Application of displacement monitoring system on high temperature steam pipe. IOP Conf. Ser. Mater. Sci. Eng. 2017, 257, 012026. [Google Scholar] [CrossRef]

- Hong, H.; Cai, Z.; Wang, W.; Liu., Y. An online monitoring method for creep-fatigue life consumption with real-time damage accumulation. Int. J. Damage Mech. 2021. [Google Scholar] [CrossRef]

- Zhang, H.; Jia, J.; Wang, N.; Hu, X.; Tu, S.-T.; Zhou, S.; Wang, Z. Development of On-Line Monitoring Systems for High Temperature Components in Power Plants. Sensors 2013, 13, 15504–15512. [Google Scholar] [CrossRef]

- Hussain, M.F.; Barton, R.R.; Joshi, S.B. Metamodeling: Radial basis functions versus polynomials. Eur. J. Oper. Res. 2002, 138, 142–154. [Google Scholar] [CrossRef]

- Kourakos, G.; Mantoglou, A. Pumping optimization of coastal aquifers based on evolutionary algorithms and surrogate modular neural network models. Adv. Water Resour. 2009, 32, 507–521. [Google Scholar] [CrossRef]

- Kennedy, M.C.; O’Hagan, A. Bayesian calibration of computer models. J. R. Stat. Soc. Ser. B 2001, 63, 425–464. [Google Scholar] [CrossRef]

- Yoon, H.; Jun, S.-C.; Hyun, Y.; Bae, G.-O.; Lee, K.-K. A comparative study of artificial neural networks and support vector machines for predicting groundwater levels in a coastal aquifer. J. Hydrol. 2011, 396, 128–138. [Google Scholar] [CrossRef]

- Laloy, E.; Rogiers, B.; Vrugt, J.A.; Mallants, D.; Jacques, D. Efficient posterior exploration of a high-dimensional groundwater model from two-stage Markov chain Monte Carlo simulation and polynomial chaos expansion. Water Resour. Res. 2013, 49, 2664–2682. [Google Scholar] [CrossRef]

- Becht, C. Power Piping: The Complete Guide to ASME B31.1; ASME Press: New York, NY, USA, 2013. [Google Scholar]

- CAESAR II Design Manuals; ASME Standards, B 31.3, BS 7159; ASME Press: New York, NY, USA, 2019.

- Lu, H.; Wu, X.; Huang, K. Study on the Effect of Reciprocating Pump Pipeline System Vibration on Oil Transportation Stations. Energies 2018, 11, 132. [Google Scholar] [CrossRef]

- Chu, Q.; Zhang, M.; Li, J.; Chen, Y.; Luo, H.; Wang, Q. Failure Analysis of a Steam Pipe Weld Used in Power Generation Plant. Eng. Fail. Anal. 2014, 44, 363–370. [Google Scholar] [CrossRef]

- Sawada, K.; Kimura, K.; Abe, F.; Taniuchi, Y.; Sekido, K.; Nojima, T.; Ohba, T.; Kushima, H.; Miyazaki, H.; Hongo, H.; et al. Catalog of NIMS Creep Data Sheets. Sci. Technol. Adv. Mater. 2019, 20, 1131–1149. [Google Scholar] [CrossRef] [PubMed]

- Junak, G. Low-cycle fatigue of P91 and P92 Steels Used in the Power Engineering Industry. Arch. Mater. Sci. Eng. 2011, 48, 19–24. [Google Scholar]

- Choi, W.; Yoon, H.; Youn, B.D. Operation-Adaptive Damage Assessment of Steam Turbines Using a Nonlinear Creep-Fatigue Interaction Model. IEEE Access 2020, 8, 126776–126783. [Google Scholar] [CrossRef]

- Rusin, A.M. Technical Risk Involved in Long-Term Operation of Steam Turbines. Reliab. Eng. Syst. Saf. 2007, 92, 1242–1249. [Google Scholar] [CrossRef]

- Pohja, R.; Holmström, S.; Nilsson, K-F.; Payten, W.; Lee, H.-Y.; Aktaa, J. Creep-Fatigue Interaction Rules for P91: MATTER—Deliverable D4.5; European Commission EC: Rome, Italy, 2014; p. 64. [Google Scholar]

- Rytter, A. Vibration Based Inspection of Civil Engineering Structures. Ph.D. Thesis, University of Aalborg, Aalborg, Denmark, 1993. [Google Scholar]

| Geometry | Dominant Formula |

|---|---|

| Straight | |

| Bent | |

| T/Y piece |

| Location | Max. Magnitude of Displacement (mm) | Von-Mises Stress (MPa) | |

|---|---|---|---|

| 1 | 238.042 | 112.35 | |

| 2 | 215.21 | 94.76 | |

| 3 | 79.046 | 49.39 | |

| 4 | 84.65 | 45.64 | |

| 5 | 61.92 | 76.96 | |

| 6 | 67.46 | 72.40 | |

| 7 | 61.44 | 58.84 | |

| 8 | 54.98 | 13.69 | |

| H-joint | Difference in displacement between locations 7 and 8 (mm) | 113.76 | |

| = 7.65 | = 6.6 | ||

| Coefficients | Goodness of Fit | ||||||

|---|---|---|---|---|---|---|---|

| SSE | R-square | RMSE | |||||

| 32.41 | −4.261 | 28.14 | 4.793 | −7.204 | 2.389 | 0.999 | 0.7728 |

| Von-Mises Stress (MPa) | ||

|---|---|---|

| 1.0 | 0.0 | 28.149 |

| 2.0 | 1.0 | 54.41 |

| 3.0 | 2.0 | 75.84 |

| 4.0 | 2.0 | 81.17 |

| 4.0 | 3.0 | 92.46 |

| 6.0 | 4.0 | 111.23 |

| 7.65 | 6.6 | 113.76 |

| Location | Types | 3DDMS (MPa) | TRD (MPa) | Allowable (MPa) | Maximum Stress (MPa) |

|---|---|---|---|---|---|

| 1 | Straight | 112.35 | 99.47 | 95.57 | 112.35 |

| 2 | 94.76 | 95.11 | 99.47 | ||

| 3 | 49.39 | 93.24 | 99.47 | ||

| 4 | 45.64 | 93.71 | 99.47 | ||

| 5 | 76.96 | 95.57 | 99.47 | ||

| 6 | 72.40 | 95.11 | 99.47 | ||

| 7 | 58.84 | 95.57 | 99.47 | ||

| 8 | 13.69 | 94.18 | 99.47 | ||

| H-joint | T-piece | 113.76 | 103.91 | 96.47 | 113.76 |

| 280 | 11.834 | 13.67 | −4.51161 |

| 0.009 | −0.1 | 1.205 | −0.78 |

| Location | Creep Life Consumption Rate (%) | LCF Life Consumption Rate (%) | Total Life Consumption Rate (%) | |||

|---|---|---|---|---|---|---|

| 3DDMS | TRD | Allowable | Rainflow Cycle | Number of Cycles | ||

| 1 | 23.5 | 10.24 | 8.3 | 3.34 × 10−9 | 5.82 × 10−8 | 23.5 |

| 2 | 9.9 | 8.1 | 3.82 × 10−10 | 5.82 × 10−8 | 10.24 | |

| 3 | 1.39 | 7.32 | 3.18 × 10−18 | 5.82 × 10−8 | 10.24 | |

| 4 | 1.05 | 7.51 | 6.49 × 10−20 | 5.82 × 10−8 | 10.24 | |

| 5 | 3.53 | 8.3 | 3.09 × 10−19 | 5.82 × 10−8 | 10.24 | |

| 6 | 2.99 | 8.1 | 0 | 5.82 × 10−8 | 10.24 | |

| 7 | 1.4 | 8.3 | 2.09 × 10−14 | 5.82 × 10−8 | 10.24 | |

| 8 | 0.17 | 7.7 | 7.74 × 10−16 | 5.82 × 10−8 | 10.24 | |

| H-joint | 36.62 | 12.99 | 8.71 | 0.1 | 5.82 × 10−8 | 36.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, W.; Han, J. Health-Monitoring Methodology for High-Temperature Steam Pipes of Power Plants Using Real-Time Displacement Data. Appl. Sci. 2021, 11, 2256. https://doi.org/10.3390/app11052256

Choi W, Han J. Health-Monitoring Methodology for High-Temperature Steam Pipes of Power Plants Using Real-Time Displacement Data. Applied Sciences. 2021; 11(5):2256. https://doi.org/10.3390/app11052256

Chicago/Turabian StyleChoi, Woosung, and Jihoon Han. 2021. "Health-Monitoring Methodology for High-Temperature Steam Pipes of Power Plants Using Real-Time Displacement Data" Applied Sciences 11, no. 5: 2256. https://doi.org/10.3390/app11052256

APA StyleChoi, W., & Han, J. (2021). Health-Monitoring Methodology for High-Temperature Steam Pipes of Power Plants Using Real-Time Displacement Data. Applied Sciences, 11(5), 2256. https://doi.org/10.3390/app11052256