Featured Application

Granular ferromagnetic MnAl incorporated into polymeric matrix can be implemented in 3D-printing of rare-earth-free magnets without forming into filaments.

Abstract

Process parameters leading to magnetic polymer composites, an essential ingredient in the additive manufacturing of rare-earth-free magnets, are investigated. The induction melting of manganese (Mn) and aluminum (Al), and subsequent annealing at 450, 500, or 550 °C for 20 min, gave rise to ferromagnetic τ–MnAl phase, as well as other phases. The nonmagnetic Al4C3 and oxide phases were then removed by the magnetic separation. Magnetic powders from the magnetic separation were incorporated in polylactic acid (PLA) matrix via a solution route. The remanent magnetization as high as 4.3 emu/g in the powder form was reduced to 2.3–2.6 emu/g in the composites. The reduction in coercivity was minimal, and the largest value of 814 Oe was obtained when the powder annealed at 450 °C was loaded in the composite. The phase composition and hence magnetic properties were even more sensitive to the carbon (C) doping. Interestingly, the addition of 3% C led to coercivity as high as 1445 Oe in MnAl–C powders without further annealing. The enhanced coercivity was attributed to the domain wall pinning by the AlMn3C phase, and magnetizations are likely increased by this phase.

1. Introduction

Permanent magnets are commonly produced by powder compactions. The dimensions of magnets are therefore limited by the compaction mold. Additive manufacturing currently opens up opportunities for unconventional designs of rare-earth magnets [1,2,3,4,5], hard ferrites [5,6], and iron oxides [7,8], as well as recycled magnets [9]. Novel magnets of varying shapes and sizes can be printed out. To this end, magnetic materials are produced in a printable form by mixing with polymeric materials and then drawing into fibers [4,5]. In addition, recent advents of three-dimensional (3D) printers enable the use of magnetic polymer composites in the form of granules.

Manganese–aluminum (MnAl) in the L10 structure exhibits ferromagnetism at room temperature. Such a phase, referred to as τ–MnAl, is commonly transformed from the high temperature ε phase. The metastable τ phase tends to decompose into nonmagnetic Mn-rich β and γ2 (Al8Mn5) phases. The stability of the τ–MnAl phase is improved with the moderate addition of carbon (C). Differential Scanning Calorimetry (DSC) indicates that the doping of 1 at% C prevents the decomposition of τ phase into nonmagnetic phases [10,11]. MnAl–C certainly exhibits lower maximum energy products than those of rare-earth magnets, but it has still received much attention as a rare-earth-free magnet [12]. MnAl-based magnets have been proposed as a “gap magnet” between the high-performance rare-earth magnets and low-cost ferrites.

In addition to MnAl–C powders, bulk MnAl-based magnets consolidated by a variety of techniques have been investigated. The extrusion process was employed by Chaturvedi et al. and Thielsch et al. at elevated temperatures [13,14]. Alternatively, high-pressure compactions enhanced the coercivity of bulk magnets compared to MnAl–C powders from the solid-state reaction [15] and gas atomization [16]. Si et al. also prepared bulk magnets from high-pressure compactions of melt-spun ribbons [17]. Tyrman et al. demonstrated a similar enhancement of magnetic properties by high-pressure spark plasma sintering [18]. Madugundo et al. reported the different magnetic properties of MnAl–C magnets produced by microwave sintering, hot compaction, and hot deformation [19]. Pressure applied in the hot deformation promoted a textured structure, leading to the highest coercivity.

For MnAl to be compatible with 3D printing, Palmero et al. produced MnAl–C/polyethylene (PE) composites in the forms of fibers [20]. In this article, MnAl-based granules for 3D printing are produced. Magnetic properties of MnAl–C powders are examined to assess the effects of C doping, as well as annealing temperature, and are compared to those after the incorporation in polylactic acid (PLA) matrix.

2. Materials and Methods

(Mn55Al45)100-xCx powders, where x = 0 (MnAl–C0), 1 (MnAl–C1), 2 (MnAl–C2), and 3 (MnAl–C3), were firstly prepared according to the procedure described in a previous work [21]. In summary, an induction heating tube with argon flow of 5 L/min was used to heat Mn flakes (purity 99.9%), Al granules (purity 99.995%), and C (purity 99.09%) at 1450 °C. After 3 minutes, the power supplied to the heating coils was switched off, allowing the gradual cooling to room temperature. The obtained alloys were ground into powders and subsequently annealed in a tube furnace (Carbolite GHA12/300) under argon atmosphere. In this work, three different annealing temperatures of 450, 500, and 550 °C were investigated in order to increase the τ–MnAl, whereas the annealing time was kept constant at only 20 min to minimize decomposition of τ–MnAl, as suggested by Qian et al. [15].

The ferromagnetic τ phase in annealed MnAl–C powders was separated from other nonmagnetic phases by using a magnetic field. A sheet of hard ferrite was slowly dragged to attract the magnetic portion from the annealed powders distributed on a sheet of paper. This process was repeated several times until the magnetic and nonmagnetic portions were thoroughly discriminated. Both portions were then examined by field-emission scanning electron microscope (FESEM: Zeiss Merlin Compact, Carl Zeiss Microscopy GmbH, Germany) with the energy-dispersive X-ray spectroscopy (EDS: Oxford Aztec, Oxford Instruments, UK). The phases in MnAl–C powders before and after the magnetic separation were characterized by a single crystal X-ray diffractometer (XRD, Rigaku SuperNova diffractometer with a HyPix 3000 detector, Rigaku Corporation, Poland) using Cuα radiation (λ = 1.54184 Å). Data reduction, scaling and absorption corrections were performed using CrysAlisPro software in the micro powder mode. Crystalline phases present in the XRD patterns were quantified by Rietveld refinement via XPowder12 software. This software indexed the set of diffraction peaks by searching and matching with the Predicted Powder Diffraction Database (P2D2). The phase components were calculated using the least squares statistical method and the pattern intensity ratio (PIR) scale factor. The quantitative analysis is based on database records with increased accuracy by the addition of background subtraction and inclusion/exclusion elements selected from the periodic table. The quality of data related to the 2 θ correction fitting was assessed by the value of the R-factor. In addition, the full width of the intensity distribution at half of the maximum intensity (β) of the major τ-MnAl peak was used to determine the crystallite size (d) according to the Scherrer formula [22]:

where λ is the wavelength of Kα.

Composites were prepared by loading PLA with MnAl–C powders collected from the magnetic separation. From the preliminary assessment of mechanical characteristics, the MnAl–C0/PLA composition of 60/40 wt% was selected. Firstly, PLA powders were dissolved in 20 mL toluene (6% w/w) at 120 °C. The solution was stirred by using a 500 rpm rotating magnetic bar for 1 h. MnAl–C0 powders were then added before heating and stirring continued for another 1 h in order to achieve homogeneous dispersion in the polymeric matrix. Once heating and stirring were terminated, the temperature was cooled down to room temperature. The residual toluene was removed by allowing evaporation for 24 h, and pieces of bulk MnAl–C0/PLA composites were finally obtained. Magnetic properties of MnAl–C powders and MnAl–C/PLA composites were measured at room temperature using a vibrating sample magnetometer (VSM). Loose powders and small granules were loaded in specially designed capsules, which locked the sample in place with a built-in screw. Each sample holder was mounted at the end of a rod and placed between the pole faces of an electromagnet. The coercivity and remanent magnetization were respectively determined from the x- and y-intercepts of the magnetization plots against the magnetic field from −15 to 15 kOe.

3. Results

To understand the influence of process parameters leading to magnetic polymer composites, MnAl–C powders are firstly characterized and discussed in Section 3.1. In the following section, results from the separation between ferromagnetic τ–MnAl and nonmagnetic powders are presented. Finally, the magnetic properties of MnAl–C/PLA composites are analyzed in Section 3.3.

3.1. MnAl–C Powders after Annealing

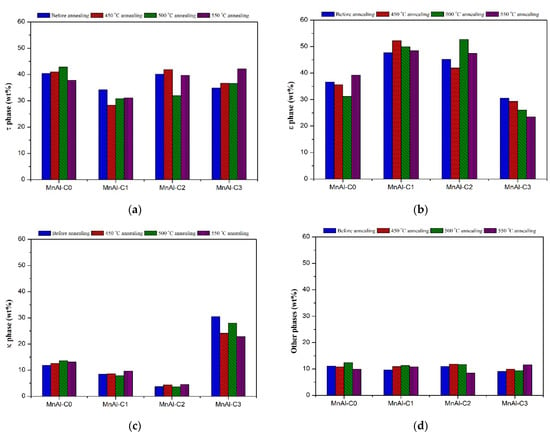

XRD patterns (not shown here) of (Mn55Al45)100-xCx powders before and after annealing reveal the mixed phases of β, γ2, C, Al4C3, AlMn3, κ(AlMn3C), and ε–MnAl, as well as τ–MnAl. The ferromagnetic τ phase is indexed by the diffraction 2θ angles at 24.6°, 41.1°, 46.5°, 53.3°, and 89.2°, respectively, from: (0,0,1); (1,0,1); (1,1,0); (1,1,1); and (2,0,2) planes (JCPDS 01-078-2655 and 00-048-1831). The c/a ratio of τ–MnAl is around 1.3, whereas the nonmagnetic ε–MnAl has a higher value of 1.6. From the Rietveld refinement, the variations in τ, ε, κ phase compositions with C doping and annealing are plotted in Figure 1. From every condition, the τ–MnAl in Figure 1a of less than 45% is much lower than those obtained in previous reports [12,13,14,15,16,17,18,19,20]. The induction heating without re-melting may yield a lower ε phase to begin with, and the ε → τ phase transformation can only be moderately increased by extending the annealing time to 2 h [21].

Figure 1.

Weight ratio of (a) τ phase; (b) ε phase; (c) κ phase; (d) other remaining phases in (Mn55Al45)100-xCx powders computed from XRD spectra by the Rietveld refinement. After melting in the induction heating tube, MnAl–C0 (x = 0), MnAl–C1 (x = 1), MnAl–C2 (x = 2), and MnAl–C3 (x = 3) samples were annealed at 450, 500, and 550 °C for 20 min under argon atmosphere.

Figure 1 may not exhibit a clear phase variation with C doping, but some trends are observed. First of all, other crystalline and amorphous phases around 10% are present in every sample, as shown in Figure 1d. A total of 90% composition of τ, ε, and κ is varied depending on the level of C doping. In Figure 1c, the maximum phase over 20% in MnAl–C3 indicates that the largest C doping promotes the formation of AlMn3C. By contrast, the phase is less than 10% when the C doping is lowered and becomes minimal in the case of MnAl–C2.

The remaining phase compositions show the trade-off between τ–MnAl in Figure 1a and the decrease in ε–MnAl in Figure 1b. The trend is consistent with the ε → τ phase transformation upon annealing at around 450–550 °C [10,11,23,24,25]. In the case of the MnAl–C3, the intensity of the major τ–MnAl peak is significantly reduced, but the minor peak at 53.3° is increased. The effect of annealing temperature is observable. Without C doping (MnAl–C0), the highest amount of τ phase and the lowest amount of ε phase are clearly observed after the annealing at 500 °C. In contrast, the amounts of ε–MnAl are still higher than τ–MnAl compositions in MnAl–C1 and MnAl–C2 after the annealing. For the highest C doping (MnAl–C3), the ε phase is at the lowest in Figure 1b and monotonically decreases with increasing annealing temperature. On the other hand, the τ phase reaches the maximum by annealing at 550 °C. Hence, the C doping not only shifts the ε → τ phase transformation to a higher temperature, but also inhibits the decomposition of τ phase [10,11,25].

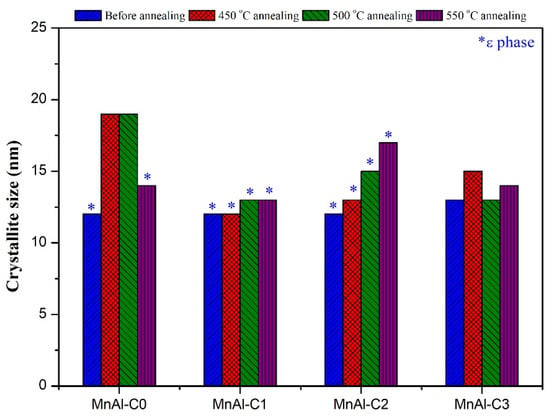

The annealing clearly influences the crystallite size, as shown in Figure 2. For all C doping, crystallite sizes of the main MnAl phase are comparable, and the growths are clearly observed after annealing at 550 °C. However, the largest crystallite in MnAl–C3 is obtained from the annealing at 450 °C because of the different phase compositions in the as-melted alloys.

Figure 2.

Crystallite size of the main τ or ε phase in (Mn55Al45)100-xCx powders before and after annealing for 20 min at 450, 500, 550 °C under argon atmosphere.

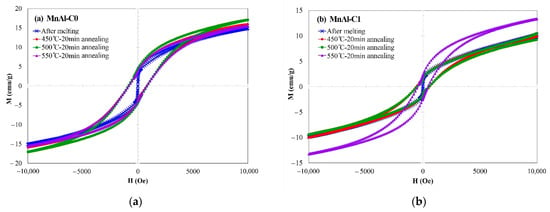

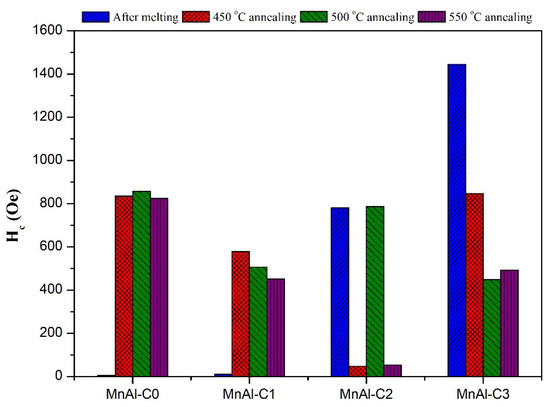

Magnetic properties of MnAl–C after annealing at 450, 500, and 550 °C are compared to those of powders after melting in Figure 3. Both doping and subsequent heat treatments have been implemented to modify the properties of rare-earth-free magnets. However, the finding in this MnAl suggests that the effect of doping is more pronounced. Ferromagnetic properties could be obtained by melting MnAl with 3% C, and no further heat treatment is required. Higher C doping levels result in substantial coercivity in as-melted MnAl–C2 and MnAl–C3. On the other hand, the hysteresis loops for as-melted MnAl–C0 and MnAl–C1 are very narrow, and the corresponding coercivities are modest. In these cases, annealing is important as it greatly widens the hysteresis loop, and enhances the coercivity.

Figure 3.

Hysteresis loops of (Mn55Al45)100-xCx powders; (a) MnAl–C0 (x = 0), (b) MnAl–C1 (x = 1), (c) MnAl–C2 (x = 2), and (d) MnAl–C3 (x = 3) after melting and annealing at 450, 500, and 550 °C for 20 min under argon atmosphere.

The coercivity is typically influenced by several parameters. Magnetocrystalline anisotropy is not affected by the annealing temperature in this work, because the c/a ratio of τ–MnAl remains rather constant. Instead, the coercivity is much more sensitive to the C doping, as shown in Figure 4. The enhanced coercivity, in MnAl–C3 for instance, is likely due to the domain wall pinning by the AlMn3C phase [26]. The increase in the AlMn3C phase suppresses the growth of τ–MnAl, resulting in a crystallite size of 13–15 nm, which is insensitive to the annealing.

Figure 4.

Coercivity (Hc) of (Mn55Al45)100-xCx powders before and after annealing for 20 min at 450, 500, and 550 °C under argon atmosphere.

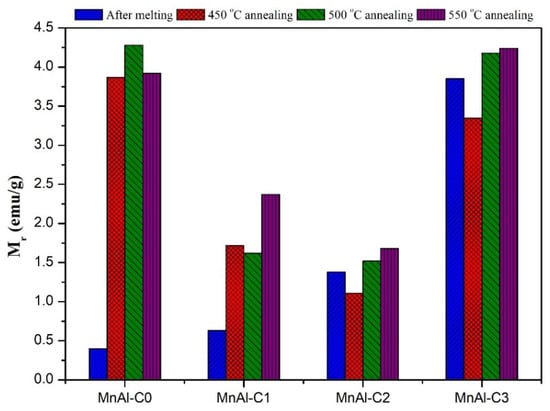

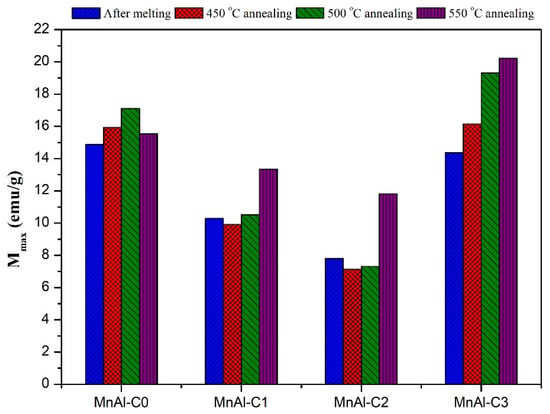

Remanent and maximum magnetizations from hysteresis loops are respectively shown in Figure 5 and Figure 6. The annealing greatly increases the remanent magnetizations of MnAl–C0, and the magnetizations reach the maximum by annealing at 450 °C. With C doping, the magnetizations are largest in the case of annealing at 550 °C. The magnetization is increased mostly at the expense of the coercivity. The magnetizations are mainly attributed to the τ–MnAl. However, the high τ phase composition in Figure 1a does not always lead to the largest magnetization in Figure 6. This discrepancy suggests that substantial magnetization is originated from another phase. The likely source is the κ phase, which exhibits ferromagnetism near room temperature [27,28]. This is also consistent with the finding of the largest magnetization in MnAl–C3, with the highest κ phase composition.

Figure 5.

Remanent magnetization (Mr) of (Mn55Al45)100-xCx powders before and after annealing for 20 min at 450, 500, and 550 °C under argon atmosphere.

Figure 6.

Maximum magnetization (Mmax) of (Mn55Al45)100-xCx powders before and after annealing for 20 min at 450, 500, and 550 °C under argon atmosphere.

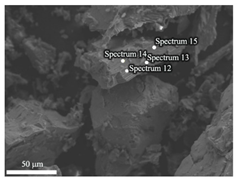

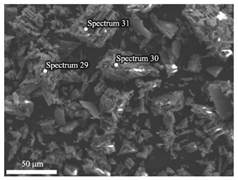

3.2. MnAl–C Powders after Magnetic Separation

Results from magnetic separation are exemplified in Table 1. Two portions from MnAl–C0 powders are clearly discriminated by their colors. Dark gray powders, attracted to a sheet of ferrite, exhibit high compositions of both Mn and Al. This EDS result is consistent with the MnAl with remaining Mn-rich β and κ phases. Substantial oxygen and carbon from the melting in crucibles are also detected. These elemental compositions are partly accounted for in amorphous phases which are not observed from XRD peaks. The FESEM micrograph in Table 1 reveals that the powder consists of bulky clusters with flat facets, similar to MnAl observed by Qian et al. [15]. In contrast, the nonmagnetic powders have a much lighter color. From EDS spectra, the elemental compositions are predominantly O, C, and Al, corresponding to Al4C3 and oxide phases. The Mn composition is notably minimal, and the FESEM micrograph in Table 1 reveals smaller microplates.

Table 1.

Comparison between magnetic and nonmagnetic powders separated by magnetic field. MnAl–C0 was annealed at 550 °C for 20 min under argon atmosphere.

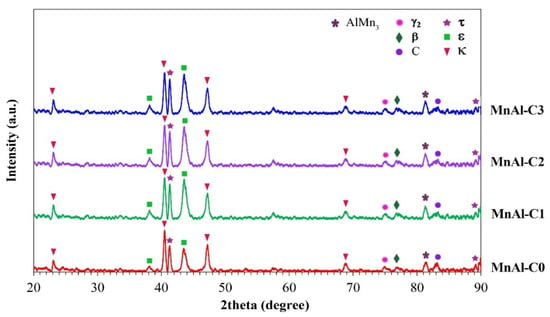

After the magnetic separation, XRD is used to reexamine the phase of dark gray powders. The XRD patterns shown in Figure 7 differ greatly from those before the magnetic separation in Figure 1. In all four spectra, the peaks of nonmagnetic Al4C3 phase are eliminated, and the relative intensity of τ–MnAl is therefore increased. However, other phases including ε, κ, β, γ2, AlMn3 and C remain. Low intensities of β and γ2 peaks suggest that the decomposition of τ–MnAl is suppressed but high intensities of ε–MnAl indicate incomplete ε → τ phase transformation.

Figure 7.

XRD patterns of (Mn55Al45)100-xCx powders after the removal of nonmagnetic portion by magnetic separation. MnAl–C0 (x = 0), MnAl–C1 (x = 1), MnAl–C2 (x = 2), and MnAl–C3 (x = 3) were annealed at 550 °C for 20 min under argon atmosphere.

3.3. MnAl-C/PLA Composites

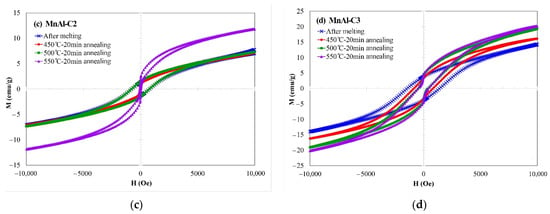

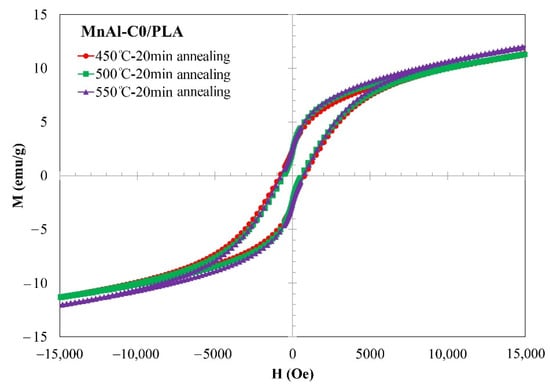

Hysteresis loops of three MnAl–C0/PLA composites in Figure 8 differ only slightly, consistent with the comparable magnetic properties of MnAl–C0 powders annealed at 450, 500, and 550 °C. Both magnetization and coercivity inevitably deteriorate as the powders are consolidated in the PLA matrix. The remanent magnetizations are 3.9–4.3 emu/g in MnAl–C0 powders, reduced to 2.3–2.6 emu/g in MnAl–C0/PLA composites because of the increase in nonmagnetic PLA mass. Interestingly, the coercivity is only reduced from 835.5 to 814.1 Oe in the case of powder annealed at 450 °C. The coercivity of magnetic polymer composites is reduced by the interactions of magnetic clusters in the polymer matrix, in the case of higher loadings or hard magnetic powders [29]. In addition to distribution of magnetic clusters, the experiment demonstrated varying values of coercivity when cobalt ferrite powders were incorporated into different polymers by different methods with varying mechanical stresses [30].

Figure 8.

Hysteresis loops of MnAl-C0/PLA prepared from magnetic powders and annealed at 450, 500, and 550 °C for 20 min under argon atmosphere.

The coercivity around a half of the value previously reported in MnAl–C/PE [5], and the modest magnetization, would rather be raised in the MnAl–C powder preparation. By doping MnAl with 2%–3% C, the substantial coercivity could be obtained as a result of domain wall pinning by the AlMn3C phase. The subsequent annealing is still useful for increasing magnetizations, as shown in Figure 4 and Figure 5. The magnetizations of MnAl–C2 and MnAl–C3 samples are maximized after the annealing at the highest temperature of 550 °C.

4. Conclusions

Magnetic properties of MnAl were sensitive to the C doping, and the addition of 2% and 3% C directly gave rise to the ferromagnetic τ phase in the as-melted MnAl–C alloys. In the case of 0% and 1% C, the subsequent annealing for 20 min at 450–550 °C is still required to increase the coercivity. Nonmagnetic Al4C3 and oxide phases were removed from the MnAl–C powders by the magnetic separation, before mixing with PLA solution. The obtained MnAl–C/PLA composites exhibited a decrease in magnetization and coercivity from the MnAl–C powders. Nevertheless, these composites can be further used in the 3D printing of magnets of varying shapes and sizes.

Author Contributions

W.T. fabricated the composites. T.C. characterized the magnetic powders. P.S. synthesized the magnetic powders. P.J. measured magnetic properties. C.R. fabricated the composites. C.S. acquired the funding and wrote the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This project was funded by the Thailand Excellent Center in Physics (ThEP-63-PIP-WU3) and financially supported by the new strategic research project (P2P), Walailak University, Thailand. XRD was supported by the National Science Technology and Innovation Policy Office for Integrated Research and Innovation Plan (Grant No.256113A3050001) for services.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Vogler, C.; et al. 3D print of polymer bonded rare-earth magnets, and 3D magnetic field scanning with an end-user 3D printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Jacimovic, J.; Binda, F.; Herrmann, L.G.; Greuter, F.; Genta, J.; Calvo, M.; Tomse, T.; Simon, R.A. NdFeB net shape 3D printed permanent magnet. Adv. Eng. Mater. 2017, 19, 1700098. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Yildirim, V.; Lamichhane, T.N.; Begley, B.A.; Post, B.K.; Hassen, A.A.; Sales, B.C.; Gandha, K.; Nlebedim, I.C. Additive manufacturing of isotropic NdFeB PPS bonded permanent magnets. Materials 2020, 13, 3319. [Google Scholar] [CrossRef] [PubMed]

- von Petersdorff-Campen, K.; Hauswirth, Y.; Carpenter, J.; Hagmann, A.; Boës, S.; Daners, M.S.; Penner, D.; Meboldt, M. 3D printing of functional assemblies with integrated polymer-bonded magnets demonstrated with a prototype of a rotary blood pump. Appl. Sci. 2018, 8, 1275. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; Jiménez, N.A.; Rial, J.; de Vicente, J.; Nieto, A.; Altimira, R.; Bollero, A. Magnetic-polymer composites for bonding and 3D printing of permanent magnets. IEEE Trans. Magn. 2019, 55, 2101004. [Google Scholar] [CrossRef]

- Sonnleitner, K.; Huber, C.; Teliban, I.; Kobe, S.; Saje, B.; Kagerbauer, D.; Reissner, M.; Lengauer, C.; Groenefeld, M.; Suess, D. 3D printing of polymer-bonded anisotropic magnets in an external magnetic field and by a modified production process. Appl. Phys. Lett. 2020, 116, 092403. [Google Scholar] [CrossRef]

- Domingo-Roca, R.; Jackson, J.C.; Windmill, J.F.C. 3D-printing polymer-based permanent magnets. Mater. Des. 2018, 153, 120–128. [Google Scholar] [CrossRef]

- Hodaei, A.; Akhlaghi, O.; Khani, N.; Aytas, T.; Sezer, D.; Tatli, B.; Menceloglu, Y.Z.; Koc, B.; Akbulut, O. Single additive enables 3D printing of highly loaded iron oxide suspensions. ACS Appl. Mater. Interf. 2018, 10, 9873–9881. [Google Scholar] [CrossRef] [PubMed]

- Khazdozian, H.A.; Manzano, J.S.; Gandha, K.; Slowing, I.I.; Nlebedim, I.C. Recycled Sm-Co bonded magnet filaments for 3D printing of magnets. AIP Adv. 2018, 8, 056722. [Google Scholar] [CrossRef]

- Liu, Z.W.; Chen, C.; Zheng, Z.G.; Tan, B.H.; Ramanujan, R.V. Phase transitions and hard magnetic properties for rapidly solidified MnAl alloys doped with C, B, and rare earth elements. J. Mater. Sci. 2012, 47, 2333–2338. [Google Scholar] [CrossRef]

- Zhao, S.; Wu, Y.; Zhang, C.; Wang, J.; Fu, Z.; Zhang, R.; Jiang, C. Stabilization of τ–phase in carbon-doped MnAl magnetic alloys. J. Alloys Compd. 2018, 755, 257–264. [Google Scholar] [CrossRef]

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Yaqub, R.; Baker, I. Microstructure and magnetic properties of bulk nanocrystalline MnAl. Metals 2014, 4, 20–27. [Google Scholar] [CrossRef]

- Thielsch, J.; Bittner, F.; Woodcock, T.G. Magnetization reversal processes in hot-extruded τ-MnAl-C. J. Magn. Magn. Mater. 2017, 426, 25–31. [Google Scholar] [CrossRef]

- Qian, H.D.; Si, P.Z.; Park, J.; Cho, K.M.; Choi, C.J. Structure and magnetic properties of nanocrystalline MnAl-C prepared by solid-state reaction and high-pressure compaction. J. Electron. Mater. 2019, 48, 1395–1399. [Google Scholar] [CrossRef]

- Si, P.Z.; Park, J.; Qian, H.D.; Choi, C.J.; Li, Y.S.; Ge, H. Enhanced magnetic performance of bulk nanocrystalline MnAl-C prepared by high pressure compaction of gas atomized powder. Bull. Mater. Sci. 2019, 42, 95. [Google Scholar] [CrossRef]

- Si, P.Z.; Qian, H.D.; Wang, X.Y.; Yang, Y.; Park, J.H.; Ge, H.L.; Choi, C.J. High-pressure synthesis of high coercivity bulk MnAl-C magnets from melt-spun ribbons. J. Electron. Mater. 2019, 48, 794–798. [Google Scholar] [CrossRef]

- Tyrman, M.; Ahmim, S.; Pasko, A.; Etgens, V.; Mazaleyrat, F.; Quetel-Weben, S.; Perrière, L.; Guillot, I. Anisotropy of the ferromagnetic L10 phase in the Mn-Al-C alloys induced by high-pressure spark plasma sintering. AIP Adv. 2018, 8, 056217. [Google Scholar] [CrossRef]

- Madugundo, R.; Koylu-Alkan, O.; Hadjipanayis, G.C. Bulk Mn-Al-C permanent magnets prepared by various techniques. AIP Adv. 2016, 6, 056009. [Google Scholar] [CrossRef]

- Palmero, E.M.; Rial, J.; de Vicente, J.; Camarero, J.; Skårman, B.; Vidarsson, H.; Larsson, P.O.; Bollero, A. Development of permanent magnet MnAlC/polymer composites and flexible filament for bonding and 3D-printing technologies. Sci. Technol. Adv. Mater. 2018, 19, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Charoensuk, T.; Saetang, P.; Ruttanapun, C.; Phrompet, C.; Pinitsoontorn, S.; Sirisathitkul, C. Ferromagnetism of manganese-aluminium alloyed with 0–3% carbon from direct induction melting and subsequent annealing. Rom. Rep. Phys. 2020, 72, 507. [Google Scholar]

- Vorokh, A.S. Scherrer formula: Estimation of error in determining small nanoparticle size. Nanosyst. Phys. Chem. Math. 2018, 9, 364–369. [Google Scholar] [CrossRef]

- Crisan, A.D.; Vasiliu, F.; Nicula, R.; Bartha, C.; Mercioniu, I.; Crisan, O. Thermodynamic, structural and magnetic studies of phase transformations in MnAl nanocomposite alloys. Mater. Charact. 2018, 140, 1–8. [Google Scholar] [CrossRef]

- Lu, W.; Niu, J.; Wang, T.; Xia, K.; Xiang, Z.; Song, Y.; Mi, Z.; Zhang, W.; Tian, W.; Yan, Y. Phase transformation kinetics and microstructural evolution of MnAl permanent magnet alloys. J. Alloys Compd. 2016, 685, 992–996. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Calvayrac, F.; Bajorek, A.; Randrianantoandro, N. Mechanical alloying and theoretical studies of MnAl(C) magnets. J. Magn. Magn. Mater. 2018, 462, 96–104. [Google Scholar] [CrossRef]

- Palanisamy, D.; Srivastava, C.; Madras, G.; Chattopadhyay, K. High-temperature transformation pathways for metastable ferromagnetic binary Heusler (Al–55 at.% Mn) alloy. J. Mater. Sci. 2017, 52, 4109–4119. [Google Scholar] [CrossRef]

- Tang, F.; Bogdanovski, D.; Bajenova, I.; Khvan, A.; Dronskowski, R.; Hallstedt, B. A CALPHAD assessment of Al-Mn-C system supported by ab initio calculations. Calphad 2018, 60, 231–239. [Google Scholar] [CrossRef]

- Dierkes, H.; van Leusen, J.; Bogdanovski, D.; Dronskowski, R. Synthesis, crystal structure, magnetic properties, and stability of the manganese-rich “Mn3AlC” κ phase. Inorg. Chem. 2017, 56, 1045–1048. [Google Scholar] [CrossRef]

- Makled, H.; Matsui, T.; Tsuda, H.; Mabuchi, M.; El-Mansy, M.K.; Morii, K. Magnetic and dynamic mechanical properties of barium ferrite–natural rubber composites. J. Mater. Process. Technol. 2005, 160, 229–233. [Google Scholar] [CrossRef]

- Hunyek, A.; Sririsathitkul, C.; Jantaratana, P. Magnetic and dielectric properties of natural rubber and polyurethane composites filled with cobalt ferrite. Plast. Rubber Compos. 2013, 42, 89–92. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).