Abstract

Drill and blast is the most cost-effective excavation method for underground construction, however, vibration and noise, induced by blasting, have been consistently reported as problems. Cut blasting has been widely employed to reduce the blast-induced problems during underground excavation. We propose that the large hole boring method using the state-of-the-art MSP (Multi-setting smart-investigation of the ground and pre-large hole boring) machine (“MSP method”) can efficiently improve vibration reduction. The MSP machine will be used to create 382 mm diameter empty holes at the tunnel cut area for this purpose. This study assessed the efficiency of the MSP method in reducing blast-induced vibration in five blasting patterns using a cylinder-cut, which is a traditional cut blasting method. The controlled blasting patterns using the MSP method demonstrated up to 72% reduction in blast-induced vibration, compared to the base case, Pattern B, where only cylinder-cut and smooth blasting method were applied. Therefore, the MSP method proves to be a promising alternative for blasting in sensitive urban areas where non-vibration excavation techniques were initially considered. Geological characteristics of 50 m beyond the excavation face can be acquired through the proposed real-time boring data monitoring system together with a borehole alignment tracking and ground exploration system. The obtained geological information will be a great help in preparing alternative designs, and scheduling of construction equipment and labour during the tunnel construction.

1. Introduction

Drill and blast is widely well-known as the most economical and efficient method to excavate rocks for the construction of underground structures; however, this method has consistently caused problems of vibration and noise due to a large amount of explosives in sensitive urban environments [1,2,3,4,5]. The key factor for tunnel blasting in urban areas is producing maximum blasting efficiency while controlling the blast-induced vibration, and a blasting design was carried out considering the tunnel support pattern and distance from safety facilities [6]. However, there is a limitation in minimizing the blast-induced vibration by reducing the charge per delay and advance per round. Additionally, use of a low-vibration explosive not only delays the construction period but also increases the blasting cost.

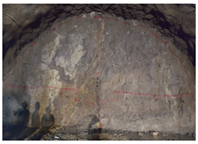

Formation of free faces is the most effective way to reduce blast-induced vibration [7,8]; however, tunnels generally have only one free face compared to open-pit mines. Cut blasting is generally performed to create an additional free face, and is the most effective and one of the most commonly utilized methods for reducing blast-induced vibration [9]. V-cut and cylinder-cut, which are traditional cut blasting methods, are mainly adopted to achieve this; however, initial blast-induced vibration is maximized due to concentrated charging of explosives on the cut area to create an additional free face [10]. For this reason, it is difficult to control the vibration within an allowable standard near safety facilities, and various tunnel blasting methods have been developed [11,12,13].

Large empty holes over 250 mm in diameter have been used to reduce the blast-induced vibration as a type of cut blasting at a tunnel site in Korea. Furthermore, having a large free face is more effective for improving blasting efficiency [14]; however, there is a limit for boring a large hole because the boring time increases, which leads to an increase of the construction period. A large hole with a 362 mm diameter has been reported to show a 25–30% vibration reduction effect compared to the conventional blasting method [15], and the effect of vibration reduction compared with V-cut was up to 79% for 2 holes [16].

However, existing outdated boring machines are not usually used because there are many critical drawbacks, such as numerous components, complex preliminary work, long installing/uninstalling and construction times, and smoke problems caused by diesel engines in the tunnel. Recently, an enhaced boring machine which greatly reduces the preparation and construction times was developed with a 382 mm hammer bit for increasing the blasting efficiency. The advantages of this method are that it not only creates a large free face but also secures the geological information beyond the tunnel face using a real-time boring data monitoring system mounted on the boring machine, and a borehole alignment tracking and ground exploration system [17].

In this study, we assessed the vibration reduction efficiency of the multi-setting smart-investigation of the ground and pre-large hole boring (MSP) method. The characteristics of the traditional blasting method and the MSP method were compared, and the effects of free face formation with respect to size of the drilled holes were analyzed theoretically. In addition, real-scale test blasting was performed at a subway construction site, utilizing various blasting patterns of general blasting and the MSP method along the tunnel. Vibration was monitored and this data was analyzed to compare the vibration reduction efficiencies, and a detailed analysis of the effect of detonation delay time on vibration propagation characteristics was performed as well.

2. Project Description

2.1. Introduction to MSP Method

The main purpose of the MSP method is to reduce the blast-induced vibration as one of the cut methods by boring a large empty hole, as shown in Figure 1. A cut blasting method using a large hole involves the utilization of 250–1000-mm diameter empty holes in Korea [14]. The MSP method usually includes 50 m boring length using a high-performance boring machine with a 382 mm hammer bit: 20 to 60 m depths can be drilled depending on the conditions of a site. This method can be used to simplify the blasting patterns of the cut area compared with other methods.

Figure 1.

Comparison of the principle between (a) general blasting method and (b) multi-setting smart-investigation of the ground and pre-large hole boring (MSP) method.

This large empty hole plays an important role in the reduction of the initial vibration by releasing the confining stress of the tunnel face before blasting, and the residual energy after rock breaking. In addition, the compressive stress wave generated by the explosion is reflected as a tension stress wave when it reaches the free face, and tensile strength of rocks is typically much lower than compressive strength; therefore, the explosives loaded into a charge hole at the cut area can break rock more efficiently [18,19,20,21,22,23]. The boost of tensile failure by producing a large-diameter empty hole at the excavation surface, which is longer than the length of the blast holes, greatly contributes to the efficiency of the blast force, thus it has a great advantage in increasing the excavation length [15].

Figure 2 depicts an earlier version of a boring machine and the newly developed high-performance MSP boring machine. One of the main issues with the old machine was a lack of mobility and necessity for multiple construction vehicles (crane, truck, etc.) for transportation and setting of the boring machine. Furthermore, a transition between various functionalities was incorporated, and required accessories and other parts to be carried around separately and manually installed. In contrast, the high-performance MSP boring machine is capable of independent movement and setting utilizing a remote control and crane system, which significantly reduces installation and uninstallation times by more than 50% compared to older boring machines. A hydraulic power pack system that generates electric power is used for boring without a diesel engine. This system improves the working environment by reducing the smoke in the tunnel.

Figure 2.

Comparison of boring machine: (a) outdated boring machine, and (b) newly developed high-performance MSP boring machine.

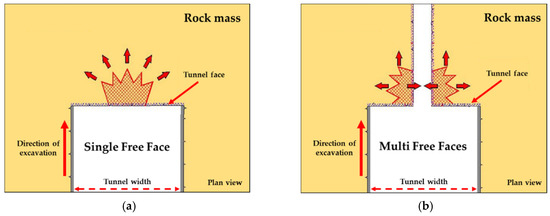

Figure 3a shows the applications of the MSP method at tunnel and shaft construction sites. This method is also used to create a free face to increase the breaking efficiency when applying a hydraulic rock splitter, which is a non-vibration excavation method, as shown in Figure 3b. The machine can not only be used for boring in the vertical shaft through mode conversion, as shown in Figure 3c, but also for slope boring in the range of 0–90°.

Figure 3.

Field applications of MSP method: (a) horizontal tunnel for blasting, (b) horizontal tunnel for non-vibration excavation, and (c) vertical shaft for blasting.

2.2. Characteristics of the MSP Method

The characteristics of the most commonly used traditional methods and the MSP method are compared in Table 1. V-cut and cylinder-cut, which are mainly used for cut blasting, have no free face or small scale before blasting. One of the most important features of the MSP method is the formation of a large empty hole of 382 mm, which is approximately 3.7 times larger than that for the cylinder-cut before blasting. This method provides a larger initial space for moving breaking rocks through a large empty hole, and then a new free face is created sequentially through the movement of the breaking rocks [24]. In particular, vibration reduction and breaking efficiency can be maximized when constructing multi-MSP with two or more holes, and this method can use both short- and long-hole blasting. In addition, the large hole serves as a groundwater discharge hole as well, and the amount of groundwater for a 50 m section ahead of the tunnel face can be predicted.

Table 1.

Comparison of characteristics of cut blasting methods.

The MSP method includes a real-time boring data monitoring system equipped with the high-performance boring machine, and a borehole alignment tracking and ground exploration system. The monitoring system measures the feed pressure, torque pressure, percussion pressure, advance speed, and percussion vibration during construction. This system can increase boring efficiency and minimize several problems, including damage or loss of equipment caused by contact with geological anomalies or the carelessness of operators.

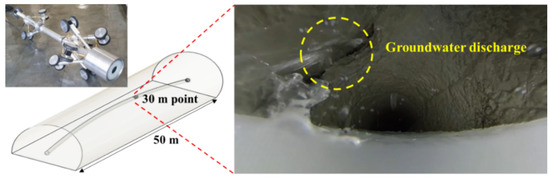

The large empty hole is not only used as a free face but also plays an important role as a guide hole. The borehole alignment tracking and ground exploration system is placed into the hole after boring is completed to observe the geological features ahead of the tunnel face. Images inside a hole are captured using a machine vision camera or 360° camera to investigate the conditions of the rock mass, joints, groundwater, and fractured zones. Figure 4 shows a case of exploring the inside of a hole in a tunnel construction site in the Gangwon region, Korea, where limestone is dominantly distributed. The image on the left shows the system equipment, and the image on the right shows a large amount of groundwater leaking from the left side of the roof at 30 m, and it can be realized that a confined aquifer exists in this section. These data provide important information for reasonable and economical design, considering safety, for tunnel support patterns and blasting designs in the 50 m section.

Figure 4.

Prediction of rock mass conditions ahead of tunnel face through borehole alignment tracking and ground exploration system.

The boring quality is highly dependent on the effects of gravity, rotation of the hammer bit, unexpected joint set, and fractured zone in the rock mass. Boring results should be checked through tunnel excavation after 2–3 weeks, and reconstruction may be required depending on the boring quality. Re-mobilization of the boring machine and additional labor required to rectify errors in free face cut blasting delay the entire construction schedule because all tunnel construction near the tunnel face must be suspended; this, in turn, would lead to significant economic losses in terms of lengthened construction period, the necessity for repetition of previously failed procedures, delay of subsequent procedures dependent on completion of free face formation, and associated increased construction and labor cost. A whole boring path can be traced using the borehole alignment tracking and ground exploration system with an inertial measurement unit sensor to estimate the quality of the boring result; thus, it is possible to determine right after boring whether the boring requires reconstruction.

3. Comparison of Blasting Efficiency by Size of Empty Hole

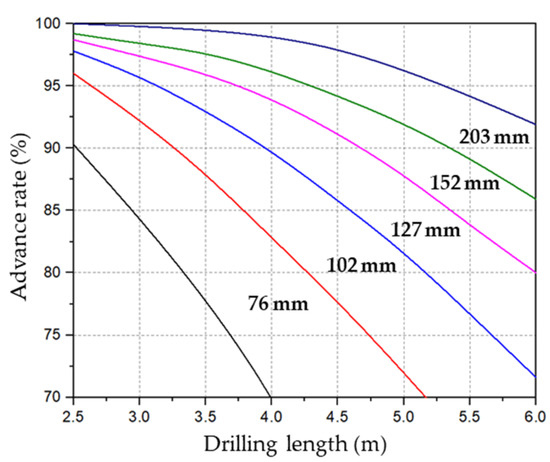

The blasting efficiencies of the MSP and cylinder-cut methods, which utilize empty holes, were compared according to the diameters of empty holes. Cylinder-cut generally includes 1–3 empty holes with a diameter of 102 mm, which is relatively less effective in reducing the vibration. Figure 5 shows the advance rate according to the drill length and diameter of the empty hole. The longer the drilling length, the lower the blasting efficiency, and the larger the empty hole, the better the blasting efficiency for the same drilling length [14]. Figure 5 does not contain detailed information for diameters over 203 mm. It can be expected that the MSP method has better blasting efficiency because it uses a 382 mm hole, almost twice as large as 203 mm.

Figure 5.

Comparison of advance rates according to the length and diameter of empty holes.

The volumes of free faces for the MSP and cylinder-cut methods were calculated to compare the effect of the free face. It was assumed that 1–3 holes of 102 mm diameter were drilled to 1.1 m and the cross-sectional area of the free face was calculated using Equation (1):

where is the cross-sectional area of the circle () and is the diameter of the drilled hole (m). The calculated areas of the free faces for 1 hole of 382 mm and 1–3 holes of 102 mm were compared, and the 382 mm diameter empty hole was found to increase the free face by 14, 7, and 4.67 times for 1–3 empty holes with the diameter of 102 mm, respectively. The MSP method, which normally bores an empty hole of 50 m depths at one time, is expected to have a greater blasting efficiency by securing an additional free face in the direction of excavation. In this case, the MSP method with a 50 m depth of the empty hole is expected to have 213 times the effect of the free face compared with the cylinder-cut method with three empty holes.

Equation (2) can be used to calculate the conversion diameter of empty holes with the same effect when using more than two empty holes as a free face:

where is the conversion diameter of the empty hole, is the diameter of the empty hole, and is the number of empty holes. Assuming the same drilling length, a hole with the diameter of 382 mm has the same effect as 14 holes with a diameter of 102 mm, which is equivalent to 636 holes of 50 m depth [14].

4. Real-Scale Test Blasting

4.1. Overview of Test Blasting

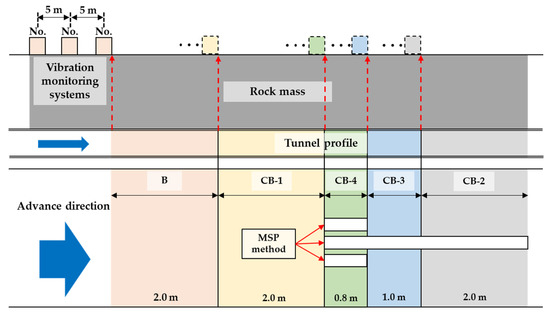

Real-scale test blasting was conducted to analyze the effects of vibration reduction depending on several blasting patterns, including the MSP method. The test blasting was carried out at a subway construction site in Seoul, concerned with damage to existing underground infrastructures due to blast-induced vibration and minimizing civil complaints in the urban area. A total of five patterns, including general blasting (B) and controlled blasting (CB), were applied in the full-face excavation method, and the order of test blasting was planned, as shown in Figure 6. The test blasting was performed at one site to compare the results under the most similar conditions as possible. The area comprised granite gneiss with approximately 80 , and rough discontinuities under slightly weathered conditions were identified in the rock mass at intervals of 0.2–0.4 m. Minimate plus (Instantel Inc., Ottawa, ON, Canada), which is a vibration monitoring system, was installed at the same distance with a total of three points just above the tunnel face for measuring blast-induced vibration, and the detailed information of the measuring instruments are shown in Table 2.

Figure 6.

Plan of test blasting and vibration measurement.

Table 2.

Specification of instruments for measuring vibration.

The patterns of test blasting for each method are shown in Table 3. The base case, Pattern B, represents a cylinder-cut utilizing smooth blasting, a conventional uncontrolled blasting pattern currently used in the field. In comparison, pattern CB-1, which also used cylinder-cut, instead utilizes a combined Controlled Blasting (CB) method. Furthermore, the other three controlled blasting patterns, CB-2, CB-3, and CB-4, are constructed with the MSP method. In particular, the CB-4 pattern was used to maximize the blast-induced vibration through the multi-MSP method using low-vibration explosives of 32 mm. Through comparison of vibration data collected from the each of the five patterns, the effect of cut and controlled blasting methods on the reduction in blast-induced vibration have been investigated and identified.

Table 3.

Patterns of real-scale test blasting (base case (B), controlled blasting (CB)).

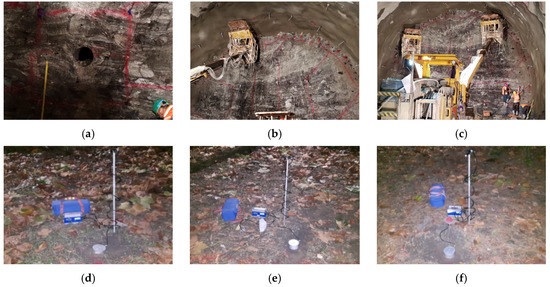

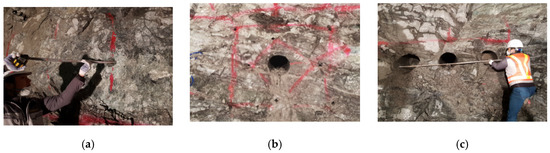

High-performance emulsion with 32 mm loaded in the cut, stoping, and lifter holes were mainly used for breaking rocks, and a finex which is low-vibration explosives of 17 mm was used in the contour hole to reduce overbreak, and the specification of the explosives are shown in Table 4. Sequential blasting was performed using millisecond (MS) delay detonators with a delay time of 20 milliseconds increments and long-period (LP) delay detonators with delay intervals between 100 and 500 milliseconds. General blasting was detonated in the order of cut holes, stoping holes, contour holes, and lifter holes. In addition, CB with pre-splitting (PS) and line drilling (LD) was detonated in the order of PS holes, cut holes, stoping holes, contour holes, and lifter holes. Figure 7 shows images of the construction procedures and installation of the vibration monitoring instruments, and Figure 8 shows images of the cut area using different cut blasting methods, such as general blasting, and the CB-2 and CB-4 patterns.

Table 4.

Specification of used explosives.

Figure 7.

Images of the construction site and installation of vibration monitoring system: (a) single-MSP, (b) drilling contour holes, (c) charging, (d) vibration monitoring-1, (e) vibration monitoring-2, and (f) vibration monitoring-3.

Figure 8.

Site images of cut sections for (a) general blasting, (b) CB-2, and (c) CB-4.

4.2. Results of Test Blasting

The results of the test blasting are summarized in Table 5, and the average peak particle velocity (PPV) for each pattern was compared based on Equation (3):

where is average PPV of general blasting, is average PPV of each controlled blasting. According to the results of test blasting, the CB-1, -3, and -4 patterns showed vibration reduction rates of approximately 16%, 39%, and 72% respectively, compared to the average PPV value of general blasting. Meanwhile, a highest amplitude vibration was generated in the CB-2 pattern, as shown in Table 5. The CB-2 pattern was expected to exhibit a 20–30% vibration reduction efficiency, but the actual data showed a 46% increase compared with general blasting.

Table 5.

Measured results of blast-induced vibration.

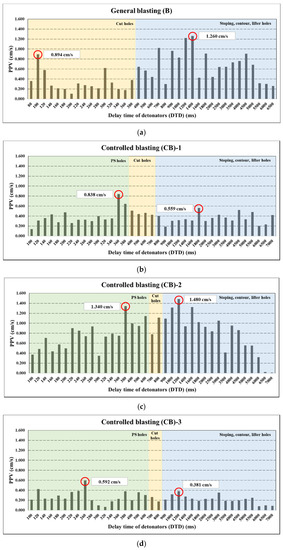

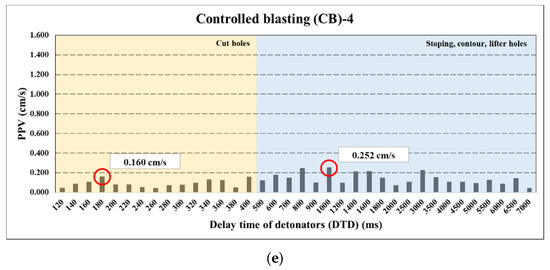

4.3. Results of PPV Histories

Based on the measured blast-induced vibration data from each of the five test blast patterns, the PPVs were extracted for each detonation time. Figure 9a–e illustrates the relationship between the PPV values and the delay time of detonators (DTD) for each of the five test blast patterns. The base case, pattern B, was measured with the maximum PPV of 0.894 and 1.260 cm/s in the cut area and stoping area, respectively. Combined CB with PS and LD was applied from CB-1 to CB-4 patterns, and although low-vibration explosives were used, a relatively high-amplitude vibration in the contour line was generated in the CB-1 to CB-3 patterns. In particular, higher vibrations were measured in the CB-2 pattern despite the use of the single-MSP method, and the vibration of 1.340 cm/s occurred in the PS holes, followed by the maximum vibration of 1.480 cm/s in the stoping holes. The CB-3 pattern greatly reduced the vibration due to the use of single-MSP and reduced charge weight by decreasing the advance. The CB-4 pattern had a significantly lower PPV compared with other methods due to the use of multi-MSP and low-vibration explosives.

Figure 9.

Histories of blast-induced vibration according to detonation delay time for: (a) B, (b) CB-1, (c) CB-2, (d) CB-3, and (e) CB-4.

5. Discussion

5.1. Analysis of Vibration-Increasing Factors

Several factors that could influence blast-induced vibration were analyzed to estimate the cause of the high level of vibrations in the CB-2 pattern. Factors can be classified into rock mass and explosion characteristics, which are summarized in Table 6 [14,25,26,27]. Blast-induced vibration is not only directly related to the quantity of explosives and the distance between blast points and structures, but also the geological and geotechnical conditions of the rock in the excavation area [28]. Geological conditions and the distance between the blast face and structures indicate the properties related to the medium through which vibrations propagate, and these variables cannot be altered [29]. In particular, the spacing and orientation of the joint set and fractured zones have a significant effect on the vibration propagation characteristics [30,31].

Table 6.

Group of factors affecting blast-induced vibration.

Furthermore, the blasting conditions indicate the properties associated with the source corresponding to the factors causing ground vibration. Several controllable parameters can be estimated using empirical methods and should be properly estimated depending on the geological conditions to minimize the vibration [32,33]. However, these changeable parameters can lead to many unexpected variables during the blasting construction process, which can occur in combination and increase the vibration. Depending on the type of explosive, the time to reach the maximum pressure varies, and the vibration and frequency increase with time [14]. A low-vibration explosive has a detonation velocity of approximately 60% of that of an emulsion, which is commonly used in tunnel blasting. Although it generates a relatively low vibration, the insufficient crushing efficiency can lead to high-amplitude vibration caused by incorrect design [34,35]. In general, electric/non-electric detonators used for blasting use chemical retarders to delay the detonation time, and these detonators can have errors in detonation time of up to 10% [36]. These errors can change the initiation time, and could cause difficulty in controlling the blast-induced vibration; thus, the error of the detonator might increase blast-induced vibration [37,38,39]. The accuracy of the delay time of the detonator is critical to the coupling of explosion energy and crack propagation between holes [40], and the sequence of detonation can be overlapped or reversed, causing greater vibration than expected [41,42]. To minimize these detonating errors, an electronic detonator with 0.01% error has recently been employed [36]. Accurate or irregular drilling can increase efficiency depending on the blasting patterns, but sometimes vibration can increase owing to unexpected drilling errors [43]. Moreover, a decrease in burden or hole spacing can increase the explosion energy or occur a dead pressure caused by locally concentrated explosives [44], meanwhile, an increase in burden or hole spacing makes it difficult to break the rock mass.

5.2. Analysis of Propagation Characteristics of Blast-Induced Vibration

In addition, combined CB is located on the tunnel contour line and generates a PS layer along the guide holes before the main blasting to control overbreak and prevent the propagation of blast-induced vibration to the outside of the tunnel [45,46]. According to the research, a vibration reduction effect of approximately 50% has been reported [47], and the vibration is usually reduced to around 30% on the construction site. However, CB-1 has a vibration reduction rate of only approximately 16%, even though combined CB was applied under the same conditions as general blasting, as shown in Table 5.

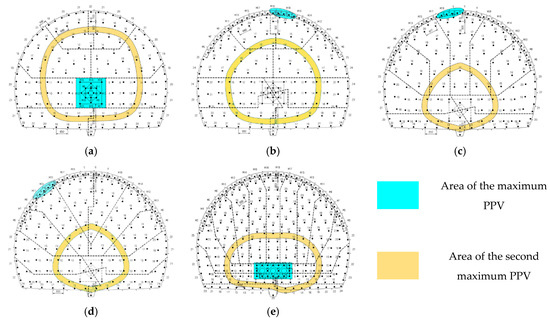

As previously stated, the PPV values were extracted in Figure 9. Then, the locations at which these maximum values were measured were overlaid onto the initial design drawings of tunnel cross-section for all blast holes, as shown in Figure 10. Each figure depicts the area showing the first and second maximum value of PPV, and each shaded area represents detonators with the same delay time. According to Figure 10, most areas showing the high-amplitude blast-induced vibration were measured at the stoping, contour, or lifter area rather than the cut area in CB-1, CB-2, and CB-3 patterns, while the CB-4 pattern showed the first maximum value of PPV in the cut area; however, the value of 0.160 cm/s is a significantly lower PPV value compared to other patterns. In particular, patterns CB-1 to CB-3 with combined CB generated maximum PPVs in the contour line despite the use of low-vibration explosives and LD holes. To generate the fracture planes smoothly through the tunnel contour line using PS blasting, appropriate blasting patterns should be designed considering the rock conditions, particularly in jointed rock. In addition, it is important for PS and LD holes to maintain regular spacing in both the longitudinal and lateral directions, and the drilling angle for all blasting holes should also maintain constant directionality, as originally designed.

Figure 10.

The area showing the first and second maximum peak particle velocity (PPV) values in (a) B, (b) CB-1, (c) CB-2, (d) CB-3, and (e) CB-4 test blast patterns.

As a result of analyzing the drilling condition, the spacing between each hole not only exceeded the design criteria but was not uniformly drilled, indicating that the LD holes failed to act as guide holes to generate the fractured planes. Furthermore, it is assumed that the cracks between the PS holes and LD holes are not smoothly connected owing to the characteristics of the rock mass with a dense distribution of multiple joint sets [48]. We estimate that, despite application of the MSP method, relatively high-amplitude blast-induced vibration partially occurred in the contour line owing to detonation without LD holes acting as free faces. Furthermore, the CB-2 pattern demonstrated high-amplitude blast-induced vibration in the contour line, and did not produce fractured layers smoothly, and it failed to prevent propagation of the vibrations generated by the main blasting. Vibration monitoring was conducted under as similar conditions as possible, and it is assumed that the variance in geological conditions between the blasting point and measurement point affected the characteristics of vibration propagation [49]. Therefore, to efficiently apply the low-vibration explosives for combined CB, the advance should be limited to the maximum of 1.5 m, and appropriate patterns should be designed considering rock characteristics. In addition, it is believed that efficient vibration reduction will be possible if drilling errors are minimized by strengthening construction standards.

5.3. Effects of MSP Method on Vibration Reduction

According to the results of the test blasting, the MSP method was generally more effective in reducing the blast-induced vibration than the traditional cut method. However, as discussed in the previous section, the CB-2 pattern with the single-MSP method unexpectedly produced a high-amplitude vibration due to the geological characteristics of the rock mass and drilling errors in the stoping area and contour line. The test blasting was performed once for each pattern, and it is difficult to establish the effect of vibration reduction of the MSP method. Based on numerous field applications of the MSP method and the results of the test blasting, a vibration reduction effect of approximately 25–30% was expected compared with the general blasting; thus, additional test blasting must be carried out to establish a tendency of the vibration reduction effect for the MSP method [15,16].

When the number of large empty holes was increased (CB-4), the free face in the cut area was expanded to increase the moving space of crushed rock in the stoping area and to reduce the crushing resistance; hence, it was possible to greatly reduce the vibration, and the MSP method with combined CB exhibited a reduction effect of approximately 70%. If maximum vibration occurs in the stoping, contour, or lifter areas rather than the cut area, there is a limit to the effect of reducing the vibration using the MSP method. Therefore, a study of a new blasting pattern is necessary that can be installed separately in each section of a tunnel face to reduce the blast-induced vibration rather than focusing on the cut area. Furthermore, since there are various variables and restrictions in the actual construction site which prevent stringent control over experimental conditions, additional field-scale experiments will be pursued to analyze the effect of precise vibration reduction with respect to the size of the empty holes and demonstrate that the enhancement in vibration reduction efficiency observed is reproducible under homogeneous conditions. These efforts will help establish optimal design patterns using large empty holes to minimize blast-induced vibration depending on the conditions of the site. It is believed that the proper combination of multi-MSP over three holes with other vibration-controlled blasting techniques, such as electronic detonators, can pose as a viable alternative cut method for non-vibration excavation sections close to safety facilities.

6. Conclusions

In this study, we studied how much the MSP method using large empty holes could efficiently reduce the vibration generated during tunnel blasting. The vibration reduction efficiency of this method was analyzed through the real-scale test blasting of five patterns, using the traditional cylinder-cut and MSP methods, at a tunnel construction site.

The MSP method creates relatively large free faces compared to the traditional parallel hole cut method in the cut area before the main blasting, significantly reducing blast-induced vibration by up to 72% compared to general blasting utilizing the traditional cylinder-cut method. Thus, the MSP method could be used as an excellent alternative method for non-vibration excavation sections, which are highly sensitive to blast-induced vibration, to reduce construction duration and costs. However, even when the stress level around the cut area was released through the application of the MSP method, there was a limit in reducing blast-induced vibration due to drilling error in the contour areas. Therefore, an improved blasting pattern using large empty holes should be considered to be located in each section of the stoping area instead of concentrating the large empty hole on the cut area.

Since it is difficult to determine the vibration reduction effect of the MSP method due to insufficient field data and lack of experimental controls in this study, we hope to reproduce our findings through continuous data collection and controlled field-scale experiments. We hope to demonstrate that the MSP method can efficiently control blast-induced vibration across various site conditions and is a viable and effective method for blast-induced vibration control. Furthermore, we expect that utilizing electronic detonators that exhibit enhanced precision of detonation delay compared to electric/non-electric detonators will maximize vibration reduction efficiency of the MSP method. Lastly, the MSP method not only reduces blast-induced vibration compared to the traditional cut blasting (pattern B) adopted in this paper but also can collect geological information without additional guide holes through the use of a real-time boring monitoring system and a borehole alignment tracking and ground exploration system and presents as a great resource for drill and blast tunneling methods.

Author Contributions

Conceptualization, S.S.L.; methodology, M.S.K.; validation, M.S.K.; formal analysis, M.S.K.; data collection, M.S.K.; writing—original draft preparation, M.S.K.; writing—review, S.S.L.; supervision, S.S.L.; project administration, S.S.L.; funding acquisition, S.S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant 21UUTI-B157786-02).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- New, B.M. Ground vibration caused by construction works. Tunn. Undergr. Space Technol. 1990, 5, 179–190. [Google Scholar] [CrossRef]

- Berta, G. Blasting-induced vibration in tunnelling. Tunn. Undergr. Space Technol. 1994, 9, 175–187. [Google Scholar] [CrossRef]

- Kuzu, C.; Guclu, E. The problem of human response to blast induced vibrations in tunnel construction and mitigation of vibration effects using cautious blasting in half-face blasting rounds. Tunn. Undergr. Space Technol. 2009, 24, 53–61. [Google Scholar] [CrossRef]

- Ferreira, C.; Freire, F.; Ribeiro, J.M.B. Life-cycle assessment of a civil explosive. J. Clean. Prod. 2015, 89, 159–164. [Google Scholar] [CrossRef]

- Lee, C.W.; Kim, J.S.; Kang, G.C. Full-scale tests for assessing blasting-induced vibration and noise. Shock Vib. 2018, 16, 1–14. [Google Scholar] [CrossRef]

- Tian, X.; Song, Z.; Wang, J. Study on the propagation law of tunnel blasting vibration in stratum and blasting vibration reduction technology. Soil Dyn. Earthq. Eng. 2019, 126, 105813. [Google Scholar] [CrossRef]

- Lee, H.; Lim, H.U. The effect of the number of free faces on the level of blasting vibration. J. Ind. Technol. 2001, 21, 267–276. [Google Scholar]

- Zare, S.; Bruland, A. Comparison of tunnel blast design models. Tunn. Undergr. Space Technol. 2006, 21, 533–541. [Google Scholar] [CrossRef]

- Xie, L.; Lu, W.; Zhang, Q.; Jiang, Q.; Chen, M.; Zhao, J. Analysis of damage mechanisms and optimization of cut blasting design under high in-situ stresses. Tunn. Undergr. Space Technol. 2017, 66, 19–33. [Google Scholar] [CrossRef]

- Oh, E.H.; Won, Y.H.; Lim, H.U. A study on the improvement of a charging and initiating method in a tunnel excavation. J. Korean Soc. Explos. Blast Eng. 2006, 24, 1–8. [Google Scholar]

- Kim, D.H.; Lee, S.P.; Lee, H.Y.; Lee, T.R.; Jeon, S.W. A case study of the new center-cut method in tunnel: SAV-Cut (Stage Advance V-Cut). J. Korean Soc. Explos. Blast Eng. 2007, 25, 31–43. [Google Scholar]

- Oh, T.-M.; Cho, G.-C.; Ji, I.-T. Effects of free surface using waterjet cutting for rock blasting excavation. J. Korean Tunn. Undergr. Space Assoc. 2013, 15, 49–57. [Google Scholar] [CrossRef]

- Park, H.; Suk, C.G.; Noh, Y.S. A comparison of ground vibration in center cut blasting using artificial joints. J. Korean Soc. Explos. Blast Eng. 2018, 36, 16–25. [Google Scholar]

- Kang, C.W. Blasting Engineering A to Z, 3rd ed.; Goomibook: Seoul, Korea, 2014; pp. 131–402. [Google Scholar]

- Beak, J.H.; Beak, S.H.; Han, D.H.; Won, A.R.; Kim, C.S. A study on the design of PLHBM. Explos. Blasting 2012, 30, 66–76. [Google Scholar]

- Choi, H.B.; Han, D.H.; Ki, K.C. A study on the decay effect of ground vibration based on the number of PLHBM holes in Gneiss area. J. Korean Soc. Explos. Blast Eng. 2016, 34, 1–9. [Google Scholar]

- Kim, M.S.; Lee, J.K.; Choi, Y.H.; Kim, S.H.; Jeong, K.W.; Kim, K.L.; Lee, S.S. A study on the optimal setting of latge uncharged hole boring machine for reducing blast-induced vibration using deep learning. J. Korean Soc. Explos. Blast Eng. 2020, 39, 16–25. [Google Scholar]

- Kolsky, H. An Investigation of the Mechanical Properties of Materials at very High Rates of Loading. In Proceedings of the Physical Society, Section B; IOP Publishing: Bristol, UK, 1949; Volume 62, pp. 676–700. [Google Scholar]

- Field, J.; Ladegaard-Pedersen, A. The importance of the reflected stress wave in rock blasting. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 1971, 8, 213–226. [Google Scholar] [CrossRef]

- Cho, S.H.; Kaneko, K. Influence of the applied pressure waveform on the dynamic fracture processes in rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 771–784. [Google Scholar] [CrossRef]

- Wang, Z.-L.; Li, Y.-C.; Shen, R. Numerical simulation of tensile damage and blast crater in brittle rock due to underground explosion. Int. J. Rock Mech. Min. Sci. 2007, 44, 730–738. [Google Scholar] [CrossRef]

- Ma, G.; An, X. Numerical simulation of blasting-induced rock fractures. Int. J. Rock Mech. Min. Sci. 2008, 45, 966–975. [Google Scholar] [CrossRef]

- Ryu, C.H.; Choi, B.H. Theory and practice of explosive blasting. J. Korean Soc. Explos. Blast Eng. 2016, 34, 10–18. [Google Scholar]

- Blair, D. The free surface influence on blast vibration. Int. J. Rock Mech. Min. Sci. 2015, 77, 182–191. [Google Scholar] [CrossRef]

- Choi, B.H.; Ryu, C.H. Consideration on the relation between vibration level and peak particle velocity in regulation of ground vibration. J. Korean Soc. Explos. Blast Eng. 2012, 30, 1–8. [Google Scholar]

- Murmu, S.; Maheshwari, P.; Verma, H.K. Empirical and probabilistic analysis of blast-induced ground vibrations. Int. J. Rock Mech. Min. Sci. 2018, 103, 267–274. [Google Scholar] [CrossRef]

- Yan, Y.; Hou, X.; Fei, H. Review of predicting the blast-induced ground vibrations to reduce impacts on ambient urban communities. J. Clean. Prod. 2020, 260, 121135. [Google Scholar] [CrossRef]

- Olofsson, S. Applied Explosives Technology for Construction and Mining, 2nd ed.; Applex: Arla, Sweden, 1988; pp. 200–237. [Google Scholar]

- Nateghi, R.; Kiany, M.; Gholipouri, O. Control negative effects of blasting waves on concrete of the structures by analyzing of parameters of ground vibration. Tunn. Undergr. Space Technol. 2009, 24, 608–616. [Google Scholar] [CrossRef]

- Xu, S.; King, M.S. Attenuation of elastic waves in a cracked solid. Geophys. J. Int. 1990, 101, 169–180. [Google Scholar] [CrossRef]

- Ahn, J.K.; Park, D.H.; Park, K.C.; Yoon, J.N. Propagation characteristics of blast-induced vibration to fractured zone. J. Korean Tunn. Undergr. Space Assoc. 2017, 19, 959–972. [Google Scholar]

- Devine, J.F.; Beck, R.H.; Meyer, A.V.C.; Duvall, W.I. Effect of Charge Weight on Vibration Levels from Quarry Blasting; U.S. Department of the Interior, Bureau of Mines: Washington, WA, USA, 1966; pp. 1–37. [Google Scholar]

- Nicholls, H.R.; Johnson, C.F.; Duvall, W.I. Blasting Vibrations and Their Effects on Structures; U.S. Department of Interior, Bureau of Mines: Denver, CO, USA, 1971; pp. 1–105. [Google Scholar]

- Lee, S.C. The influence of the detonation velocity of explosive in blasting. J. Korean Soc. Explos. Blast Eng. 2005, 23, 43–56. [Google Scholar]

- Park, Y.S.; Jeong, M.S. The development and application of low vibration explosives (NewFINECKER). J. Korean Soc. Explos. Blast Eng. 2010, 28, 11–18. [Google Scholar]

- Hwang, N.S.; Lee, D.H.; Lee, S.J. A case study of blasting with electronic detonator. J. Korean Soc. Explos. Blast Eng. 2016, 34, 40–45. [Google Scholar]

- Kim, Y.P.; Kim, G.S.; Son, Y.B.; Kim, J.H.; Kim, H.D.; Lee, J.W. Characteristics of Near-field Ground Vibration in Tunnel Blasting using Electronic Detonators. J. Korean Soc. Explos. Blast Eng. 2013, 31, 76–86. [Google Scholar]

- Iwano, K.; Hashiba, K.; Nagae, J.; Fukui, K. Reduction of tunnel blasting induced ground vibrations using advanced electronic detonators. Tunn. Undergr. Space Technol. 2020, 105, 103556. [Google Scholar] [CrossRef]

- Wang, P.; Ma, Y.-J.; Zhu, Y.; Zhu, J. Experimental Study of Blast-Induced Vibration Characteristics Based on the Delay-Time Errors of Detonator. Adv. Civ. Eng. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Cho, S.H.; Yang, H.S.; Kaneko, K. Influence of the initiation error of the delay detonator on the rock fracture process in smooth blasting. Tunn. Undergr. Space Technol. 2004, 14, 121–132. [Google Scholar]

- Winzer, S.R.; Furth, W.; Ritter, A. Initiator firing times and their relationship to blasting performance. In Proceedings of the 20th U.S Symposium on Rock Mechanics (USRMS), Austin, TX, USA, 4–6 June 1979; pp. 461–470. [Google Scholar]

- Yoon, J.S.; Lim, S.H.; Lee, J.M.; Bae, S.H. Study on comparison with electronic detonation blasting and non-electric detonation blasting. J. Korean Soc. Explos. Blast Eng. 2007, 10, 185–191. [Google Scholar]

- Singh, S.P.; Xavier, P. Causes, impact and control of overbreak in underground excavations. Tunn. Undergr. Space Technol. 2005, 20, 63–71. [Google Scholar] [CrossRef]

- Min, H.D.; Jeong, M.S.; Jin, Y.H.; Park, Y.S. Dead pressure and its measures of emulsion explosives at small sectional tunnel. J. Korean Soc. Explos. Blast. Eng. 2008, 26, 29–37. [Google Scholar]

- Kim, Y.; Moon, H.-K. Application of the guideline for overbreak control in granitic rock masses in Korean tunnels. Tunn. Undergr. Space Technol. 2013, 35, 67–77. [Google Scholar] [CrossRef]

- Sharafat, A.; Tanoli, W.A.; Raptis, G.; Seo, J.W. Controlled blasting in underground construction: A case study of a tunnel plug demolition in the Neelum Jhelum hydroelectric project. Tunn. Undergr. Space Technol. 2019, 93, 1–18. [Google Scholar] [CrossRef]

- Jung, H.S.; Jung, K.S.; Mun, H.N.; Chun, B.S.; Park, D.H. A study on the vibration propagation characteristics of controlled blasting methods and explosives in tunnelling. J. Korea GEO-Environ. Soc. 2011, 12, 5–14. [Google Scholar]

- Worsey, P.N.; Farmer, I.W.; Matheson, G.D. The mechanics of pre-splitting in discontinuous rock. In Proceedings of the 22nd U.S. Symposium on Rock Mechanics (USRMS), Cambridge, MA, USA, 29 June–2 July 1981; pp. 205–210. [Google Scholar]

- Choi, S.O.; Park, E.S.; Sunwoo, C.; Chung, S.K. A study on the blasting dynamic analysis using the measurement vibration waveform. J. Korean Soc. Rock Mech. 2004, 14, 108–120. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).