1. Introduction

Demands for NiTi alloys for applications in various fields in engineering and medicine make this material one of the most investigated in both academia and industry. NiTi alloys with chemical compositions that are close to equiatomic possess the properties of good corrosive resistance, biocompatible natures, superior mechanical performances, and the functional properties of shape memory and superelasticity (SE) [

1,

2,

3]. These properties open up the application areas of NiTi alloys with shape memory effects for various application-orientated industries in material engineering, such as the aerospace industry, actuators, dampers, vibrators, and resonators. The shape memory effects (SMEs) of NiTi alloys relate to the transformation of solid-state phases from the austenite cubic B2 structure to martensitic monoclinic B19′ structure [

4,

5]. Ni–Ti offers two candidate successors with lower entropies—a monoclinic B19′ martensite and a rhombohedrally distorted martensite (R phase). The R phase can be imagined as a rhombohedral distortion of the cubic austenitic phase, with one of the four [1 1 1] directions of the cubic austenite being stretched. The transformation of the phase occurs in NiTi and shape memory alloys during cooling and heating cycles [

6,

7,

8,

9]. The loading causes the martensitic transformation and then induces a superelastic effect in the martensitic phase and returns to the austenite phase during unloading. The functional behaviors of the SME and SE effect of NiTi alloys allow the material to restore 10% of strain [

10].

Based on wide-field applications, there are various methods available for the manufacturing of NiTi alloys. One of the general and commercially approved methods of fabrication is the casting method. However, this conventional method is a multistep process that undergoes melting, casting, and postprocessing steps until the final product is achieved [

11,

12]. Melting may lead to micro- and macrosegregations that could result in chemical inhomogeneity of elemental composition and oxidization during processing. This may lead to an increase in the level of impurities in the final product. The postprocessing step of the machining could harden the NiTi alloy which may be resistant to deformation. These obstacles and limitations during standard manufacture of NiTi alloys have caused researchers to find other simpler, time-saving, effective steps for the manufacture of NiTi alloys [

13,

14,

15].

Recently, researchers have focused on alternative routes to achieve the manufacture of NiTi alloys. Powder metallurgy (PM) is the integrated process of compaction and sintering. PM has been emerging to meet the challenge of conventional casting methods by using powder routes [

2]. The PM route offers minimum contamination of impurities such as oxygen and carbon contents, without any segregation of phases, thus avoiding chemical inhomogeneity and a one-step process to reach the stage of the final product [

16,

17,

18]. PM parts of NiTi alloys show better physical and machining properties due to their finer and homogenous microstructures. However, one of the limitations lies in the area of manufacture of complex shapes by the PM route. There are various routes of PM methods such as Conventional sintering (CS), Self-propagating high-temperature synthesis (SHS), Metal injection molding (MIM), Hot isostatic pressing (HIP), Spark plasma sintering (SPS), and Plasma melting (PM), microwave sintering (MWS) methods [

19,

20,

21,

22]. Out of these sintering processes, the spark plasma sintering method stands out due to the short processing time of the reaction process. The SPS process can be feasible at low sintering temperatures, ranging from 900 to 1100 °C, which allows uniform sintering and avoids any undesired reaction products and high heating rates, with a high consolidation process for the by-products. However, the only limitation is that the process is unable to produce materials with complex shapes. SPS is a method in which integration of DC electrical pulse currents along with uniaxial pressure to consolidate powders occurs. Simultaneously with the application of pressure, load acts as an additional driving force for the sintering process, resulting in higher densification and grain growth in sintered alloys. Earlier researchers have investigated processing parameters, such as sintering time and temperature, and the magnitude of load plays a significant role in the final microstructure and densification of the NiTi alloys [

23]. The sintering temperature plays a significant role in the densification mechanisms, microstructural evolution, and mechanical properties of spark plasma sintered alloy. The particle rearrangement, localized deformation, and bulk deformation appear to be sequences of the sintering mechanism depending on the size range of powder particles used for consolidation. The compact sintered alloy strength depends on the microstructure that is derived from the arrangement of micrograins [

24,

25].

In the SPS process, graphite die has been used as the standard material for sintering; however, austenitic steel has recently emerged as a new material that could replace graphite [

26]. Consequently, it could save heat loss from the materials and achieve higher densities in the sintered by-product. As a result, the sintering process was functional with lower sintering times and temperatures, which could lead to uniformity in structure. The SPS process in the field of NiTi alloys mostly covers the output in the areas of densification with the microstructural evolution of sintered NiTi alloys. However, NiTi alloys are more applicable in terms of functional properties of the shape memory effect. SME properties are hardly discussed for the spark plasma sintered NiTi alloys. Some researchers have gone to the extent of assessing mechanical properties under compression stress and induced plastic strain. However, there is still a lack of research in the analysis of the SME effect of the sintered alloy in terms of grain distribution.

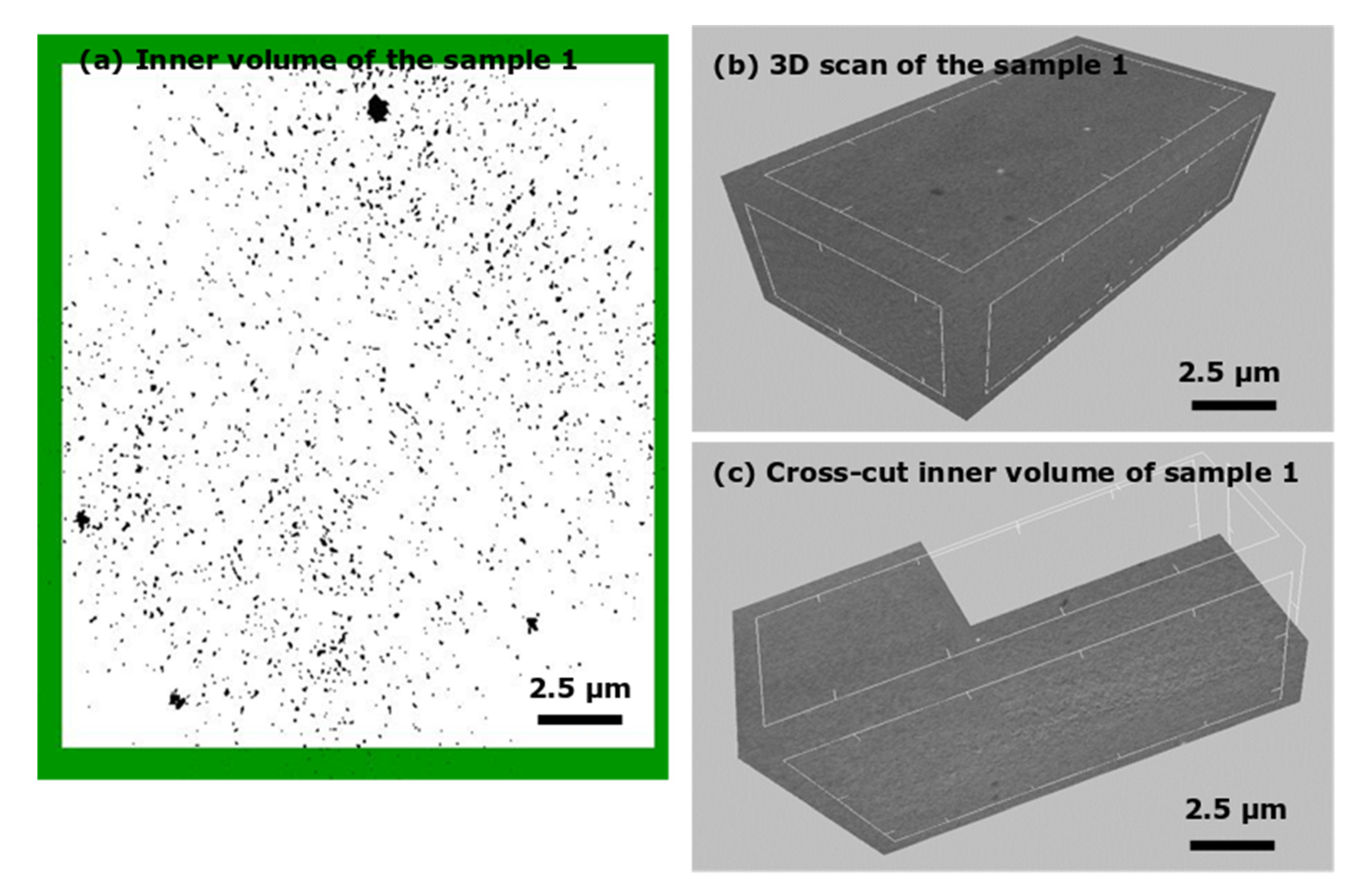

The work aims to fabricate shape memory alloys of NiTi by the SPS process. Although some articles mention this alloy, there is hardly any work published on the investigation of shape memory behavior and functional properties of alloys. Rather, most of the work on SPS concludes on microstructures, compacts, phases by EDX, and, finally, hardness. In this article, the mechanical behavior of the NiTi alloy in terms of SME is investigated. Functional properties such as shape memory behavior in relation to strain, with the stress-controlled mode and behavior of shape memory alloys (SMAs) being investigated, aiming at preparing a near-net-shape memory alloys of NiTi by the SPS process. The shape memory effect of the sintered NiTi alloys was investigated based on phase transformation as a function of temperature. The grain distribution of the sintered alloy was examined by the electron backscatter method. The polycrystalline grain growth was confirmed from the cross-section of the sintered NiTi alloy along with the thickness of the consolidation. The internal volumes of the NiTi alloys were examined by the microcomputed tomography method. Thermo-mechanical properties of the NiTi alloys were investigated to establish the functional properties of SME behavior.

2. Materials and Methods

2.1. Raw Materials for the Fabrication of NiTi Alloys

Ni

50Ti

50 powders with spherical particle sizes of 20–63 µm (purity: 99.5%) and without any porosity were used for the preparation of NiTi alloys by SPS process. The gas-atomized NiTi powders were purchased from American Elements (AE), USA. The elemental composition of the Ni:Ti powders was 50:50 (at.%).

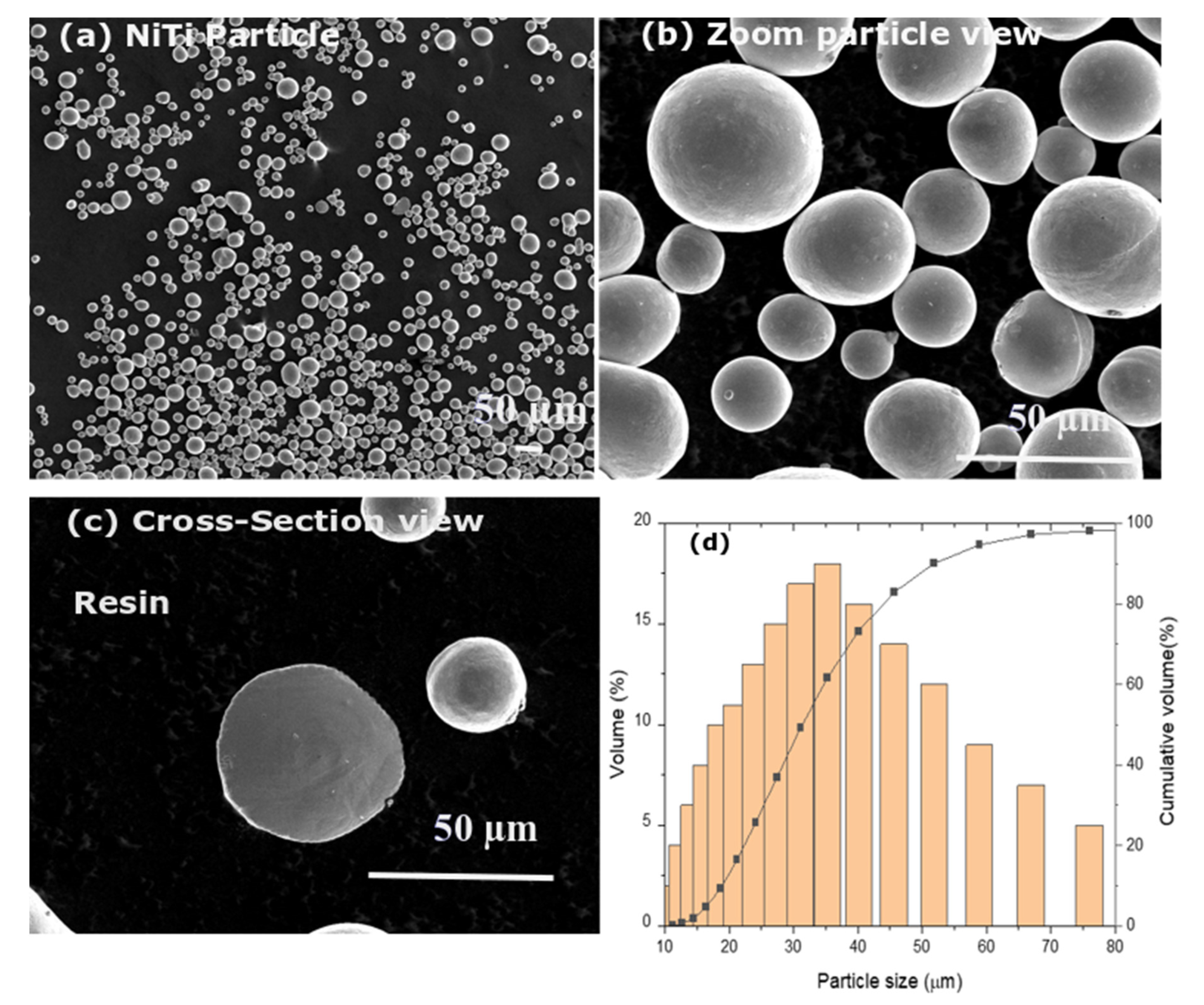

Figure 1a–d display the surface morphologies of the NiTi powder particles, the zoom view of the powders, cross-section view, and particle size distributions. The average particle size of NiTi powder (d

avg) was 50 µm. The sizes of the largest particles fall within range of 30–40 µm.

2.2. Preparation of NiTi Alloy from the Consolidation of NiTi Powders Using the SPS Process

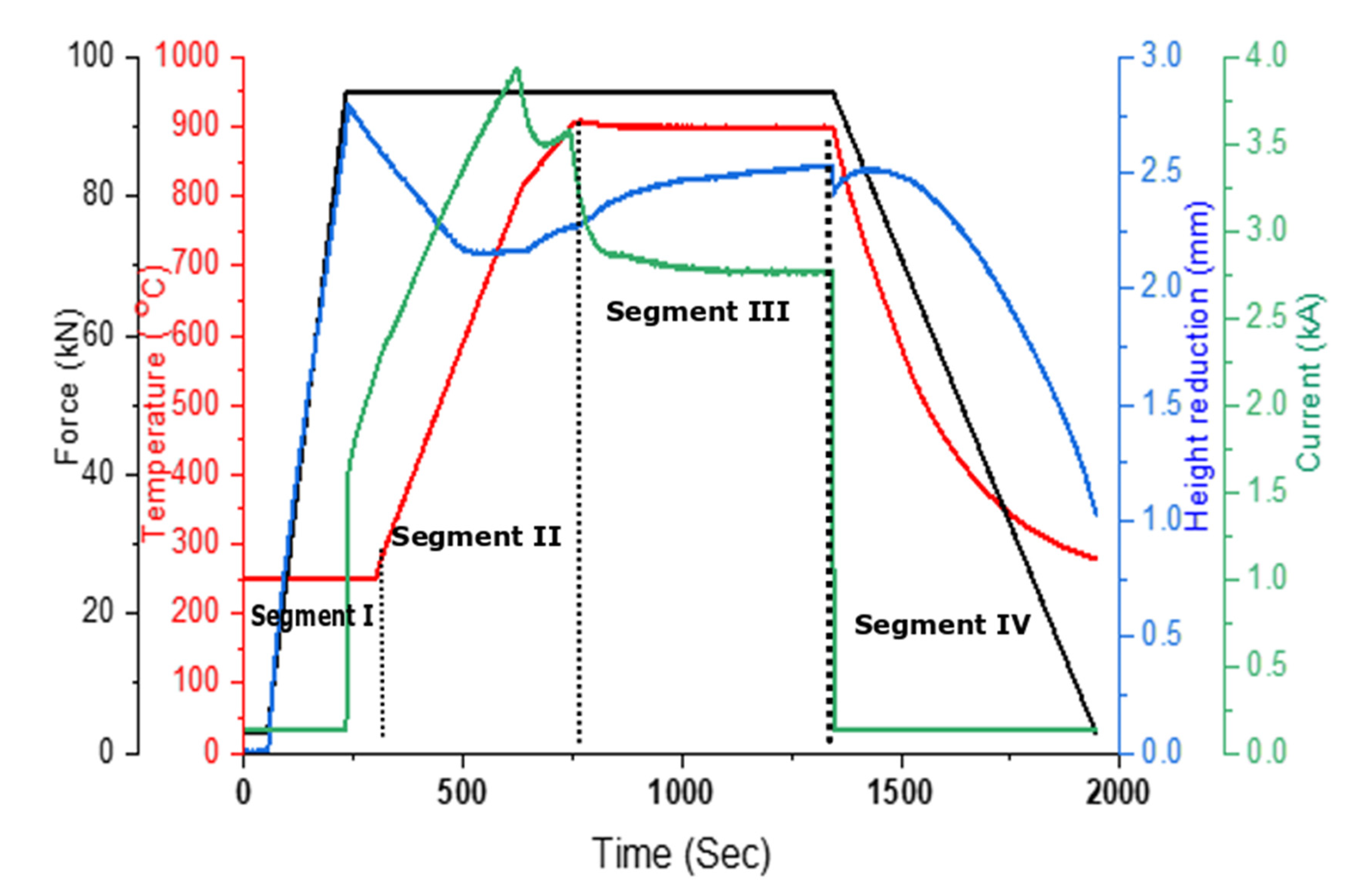

The influence of sintering temperature, applied pressure, and holding time on the relative reduction in sample thickness derived from the relative displacement of punches during the SPS process is displayed in

Figure 2. The whole process of the SPS compaction was divided into four segments. Segment I is characterized by the application of a 95 kN (approx. 48 MPa) load with a total duration of 180 s. In the case of the 50 mm sample, the compaction temperature was 900 °C and was achieved by two steps: powder was heated from 300 up to 800 °C with a heating rate of 100 °C/min. In the second step, the heating rate was lowered down to 50 °C/min and the sample was heated until reaching 900 °C, which was maintained for 10 min. Then, rapid cooling was carried out and the applied load was constantly lowered for 10 min until reaching 3 kN. Thereafter, a temperature of 900 °C was reached at 750 s in segment II. The fixed temperature with a fixed load was stable and kept constant for fixed holding time for 600 s (segment III) and then followed by machine cooling to room temperature (RT) (segment IV). The powders were placed into a graphite die with a 50 mm diameter and then consolidated using SPS equipment. Sample 1 was prepared at a sintering temperature of 900 °C and a load of 48 MPa for 10 min. NiTi powders were compressed with uniaxial pressure within the graphite die. After sintering, discs with 50 mm diameters and 2 mm in height were produced.

Figure 2 displays the process parameters for the experimental set-up of the sintered sample.

For segment I, the punch displacement corresponding to height reduction had no significant effect until 2.5 mm, as the pressure was applied at a lower temperature. In this zone, consolidation of the NiTi powders was observed due to the cold compaction. The height reduction changed after the small plateau when reaching the temperature of approximately 570 °C as a result of activation of nondiscrete dislocation movements as well as the implementation of partially considered diffusion bonding between powder particles (especially on the sites of mutual contact, segment II).

This step induces the Joule heating effect within the powders to generate localized necking within the neighboring powder particles. During segment III, holding pressure and temperature steps promoted growth and plastic deformation within the necking zones of the powder particles. Thus, the diffusion of powder particles progressed in a short processing time resulting in a dense by-product of NiTi samples. The effect of Joule heating was increased with an increase of 900 °C for sintering temperature. The powder surface smoothens at sintering temperature due to the thermal softening effect and grain shape changes with the applied load. These combined effects of particle smoothing and grain reshaping influenced the internal voids within the compact of the sintered sample. The effect of particle sizes significantly contributes to the contact surface in the vicinity region. If the particle sizes are lower, the contact surface within the vicinity region increases and allows diffusion of the lattice surface which leads to a reduction in pore size. Moreover, the size of the particle was also influenced by pressure acting on it.

2.3. Characterization Techniques for Sintered Samples

The microstructures of both powder and sintered NiTi alloys were characterized by using scanning electron microscopes: a SEM, FEI Quanta 3D Dual-Beam SEM/FIB scanning electron microscope equipped with field emission cathode; one from Thermo Fisher Scientific, Brno, Czech Republic); one from Tescan FERA 3, Brno, Czech Republic. The grain size was observed on the surface of the sintered sample by an optical microscope (OM, Thorlabs, CEA 1350). The sample specification for optical, SEM, and EBSD was 5 × 5 mm. The optical microstructure was revealed after grinding, polishing and etching with Kroll’s reagent (5 mL HNO3, 10 mL HF, and 85 mL H2O). The EBSD sample followed the procedure as samples were hot mounted in conductive Bakelite and metallographically prepared by modified procedure for nickel (ASTM C-56 recipe). The colloidal silica was used in the last polishing step and surface was finished by etching in Kroll’s reagent. Grain orientation and phase map of the sintered NiTi alloys was performed by the electron backscatter method (EBSD, using the EDAX DigiView V camera).

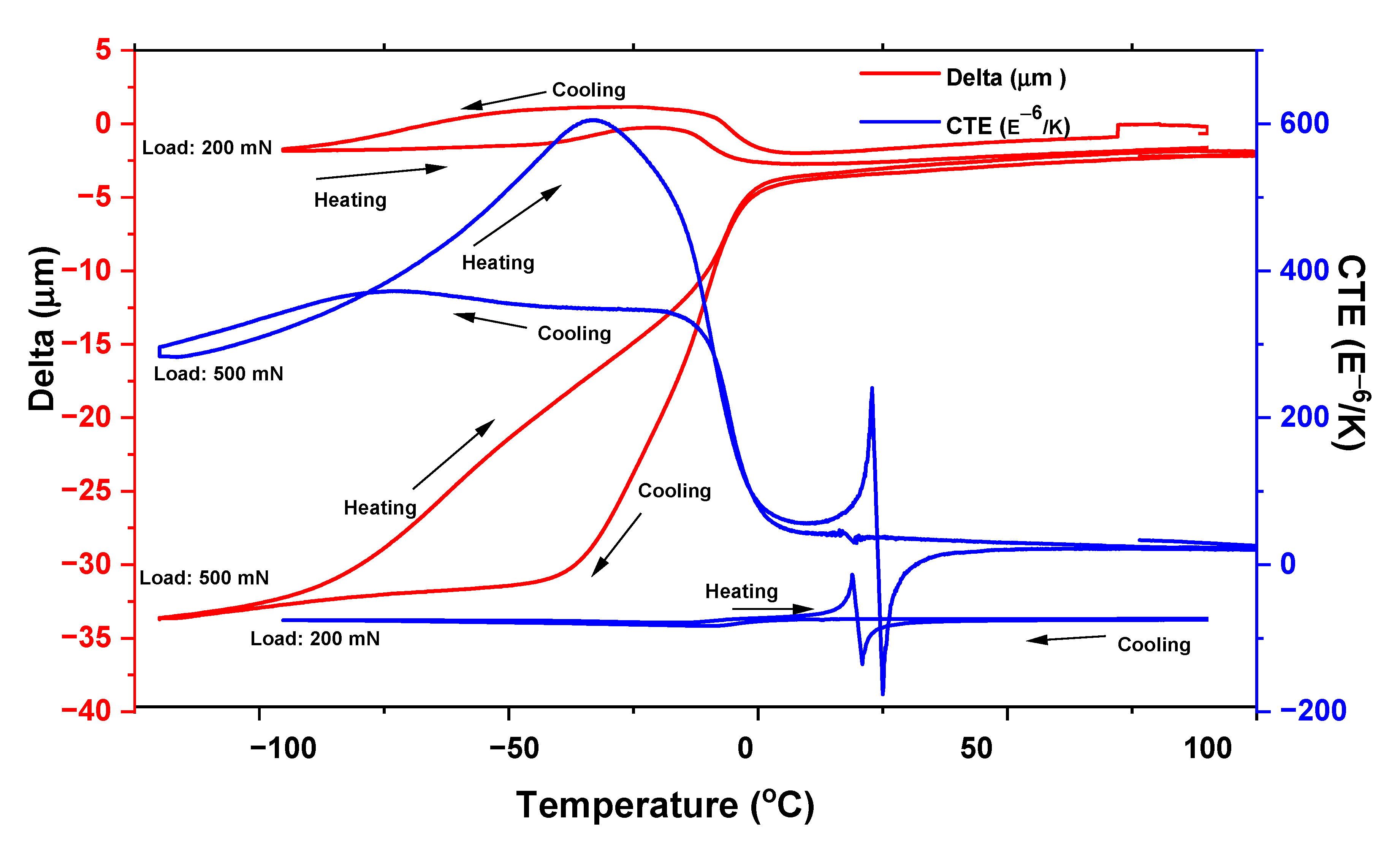

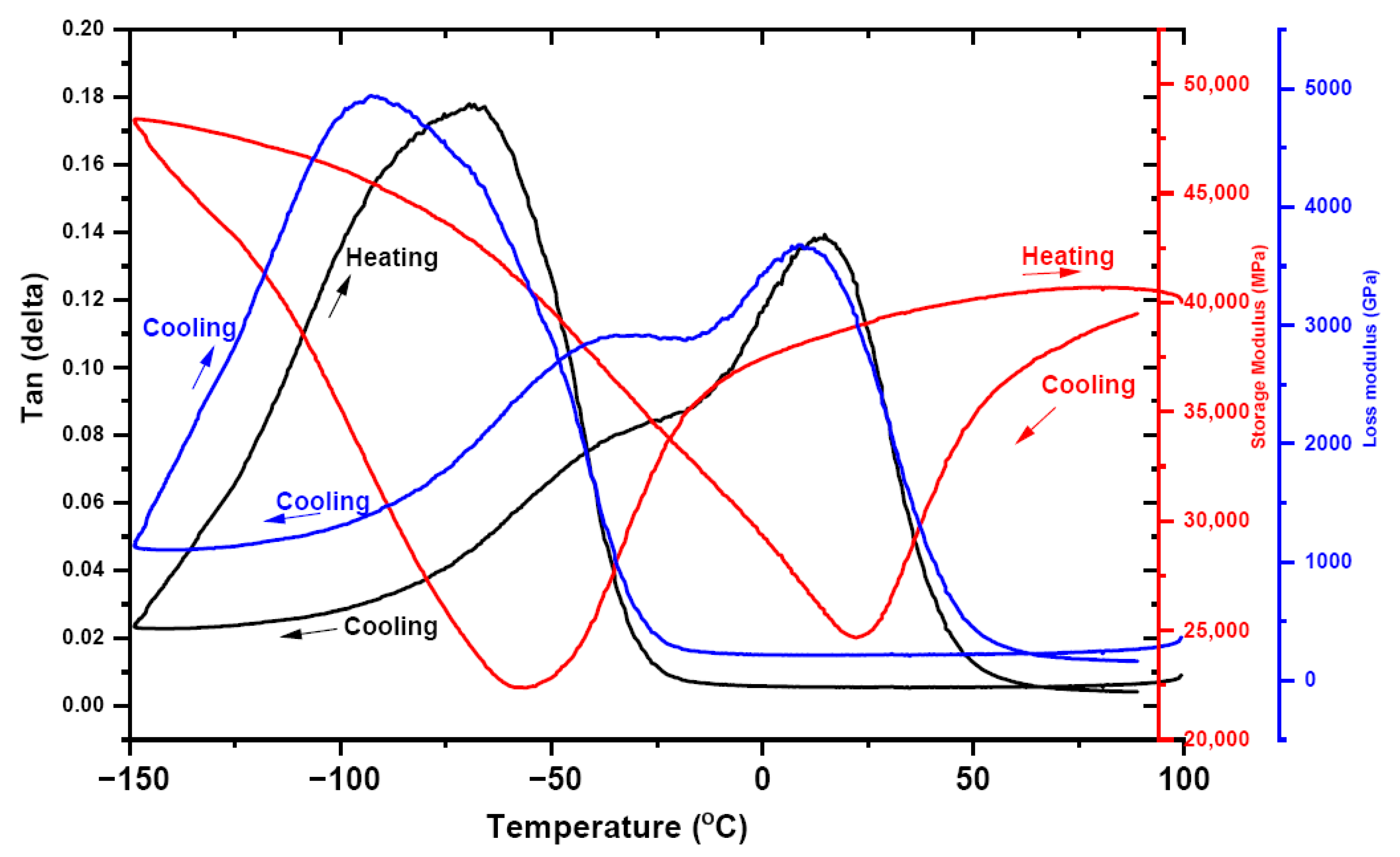

The dimension of the sample for the Differential Scanning Calorimetry (DSC) test was 1 × 1 × 0.3 mm, whilst for the DMA test the sample size was 22 × 3 × 0.3 mm. For bending for Thermo-mechanical Analysis (TMA), the sample dimension was 15 × 3 × 0.3 mm and for the tensile test sample, the dimension was gauge length 20 × 3 × 0.3 mm. A thermomechanical analyzer was used on the SPS NiTi sample (TMA, LINSEIS L75 Cryo Linseis, Selb, Germany) to observe the deflection in terms of displacement during the cooling and heating profiles. An 8000 Perkin Elmer DMA machine was used to carry out the test with a frequency of 0.1 Hz and a heating and cooling rate of 2 K/min in the temperature range of −150 to +100 °C to observe the shape memory effect [

9].

4. Discussion on the NiTi Alloy in Terms of Polycrystallinity and Composition

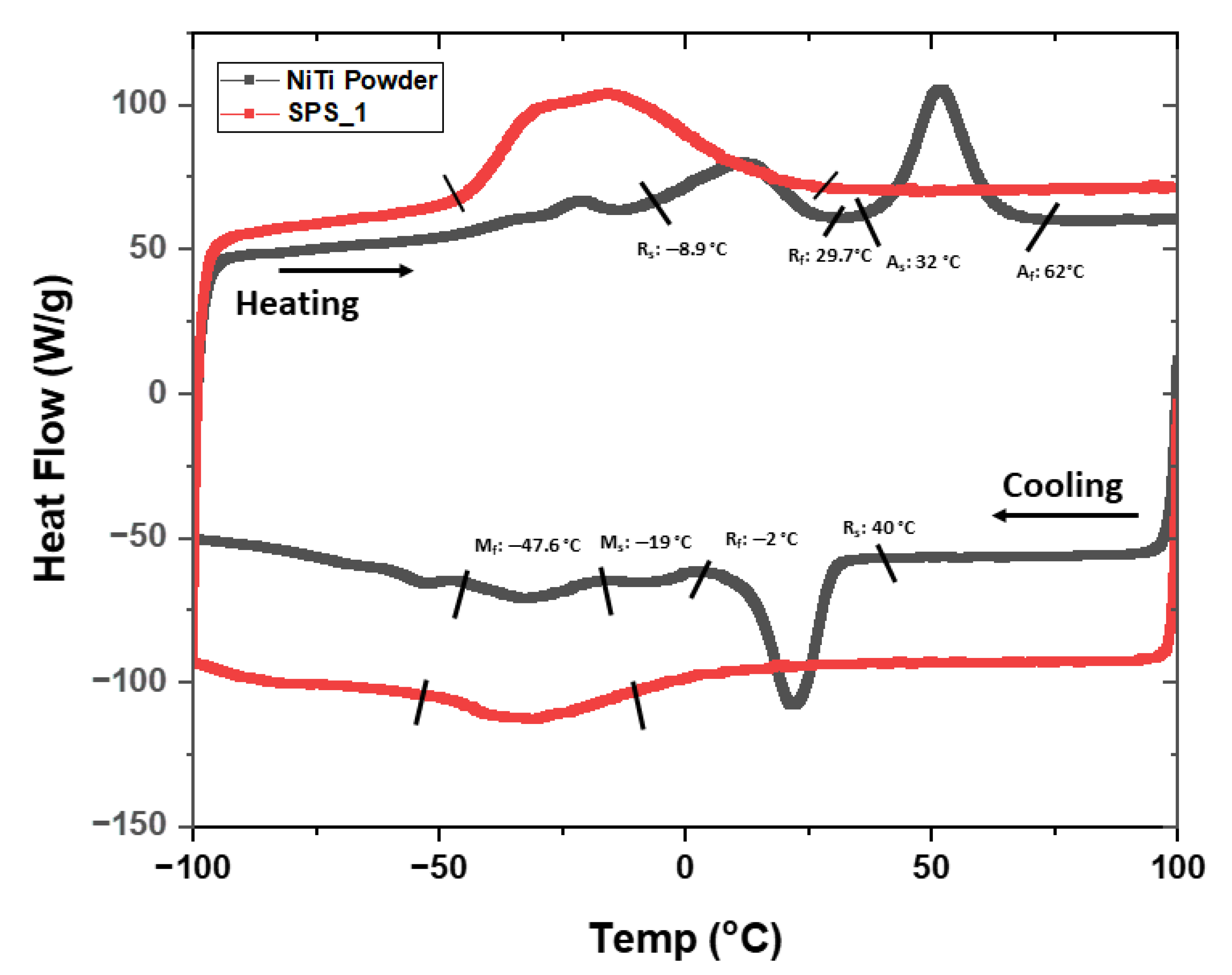

Since our aim was to study the structure of NiTi alloys, the martensitic transformation and shape memory behavior of the spark plasma sintered NiTi alloy, the relation between structure of the sintered NiTi compact alloy, and martensitic transformation were studied using thermal and thermo-mechanical characterizations. DSC curves of the SPS sintered NiTi alloy (

Figure 4) show no distinct peaks that may be a result of homogenization. NiTi powder shows two endothermic peaks during heating and two exothermic peaks in the cooling mode. The heating peak indicates a B19′→R and R→B2 transformations and two-step transformation with cooling as B2→R and R→B19′ for the first and second steps, respectively [

22,

23]. The wider distribution of peaks in the SPS sample may relate to the elimination of the dislocation networks during homogenization. The decrease in the transformation temperatures in the SPS sample may result from a local increase in Ni content in the B2 matrix and may be due to some local stress field within grains generated due to the compaction of the applied load in the sintering process [

24].

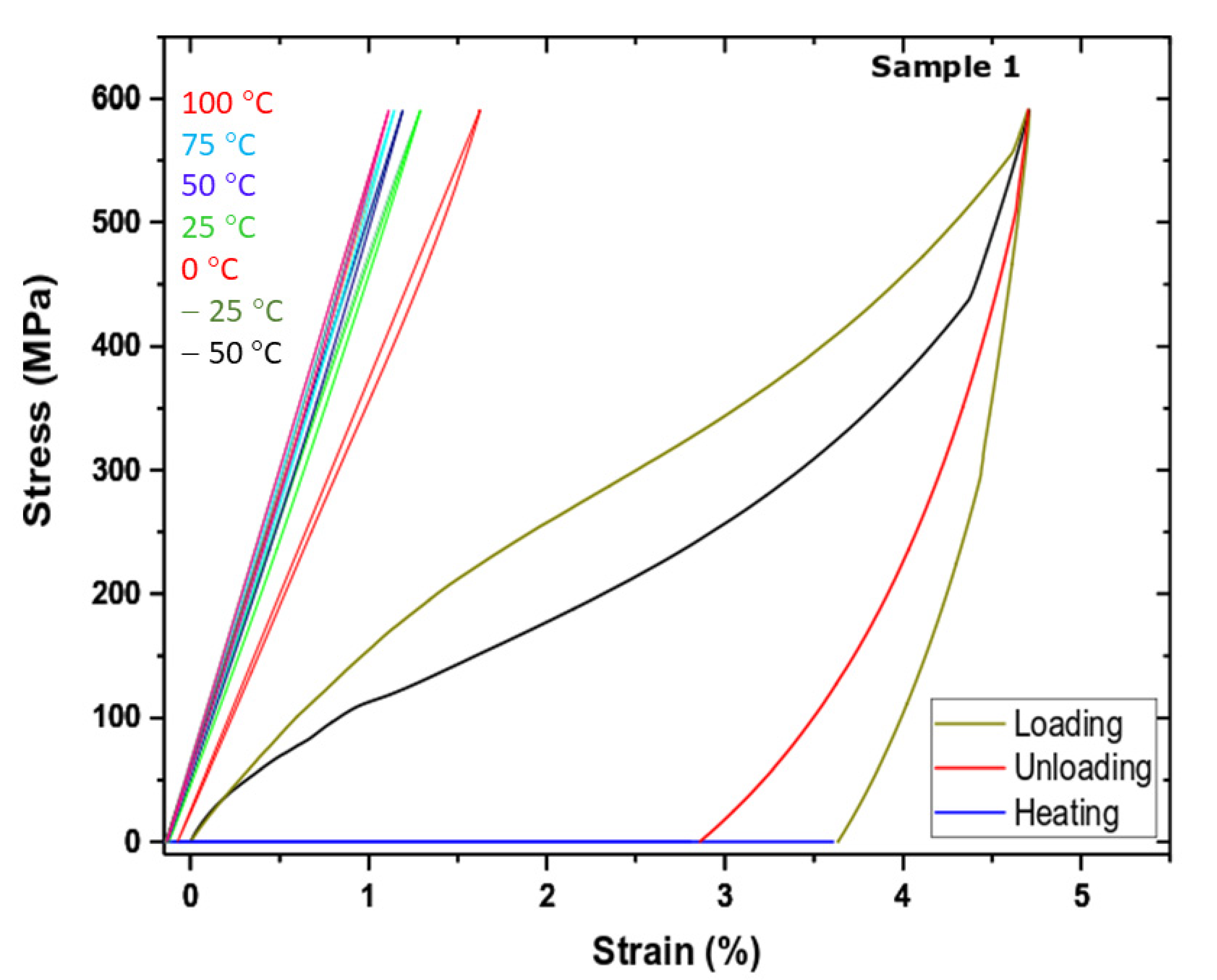

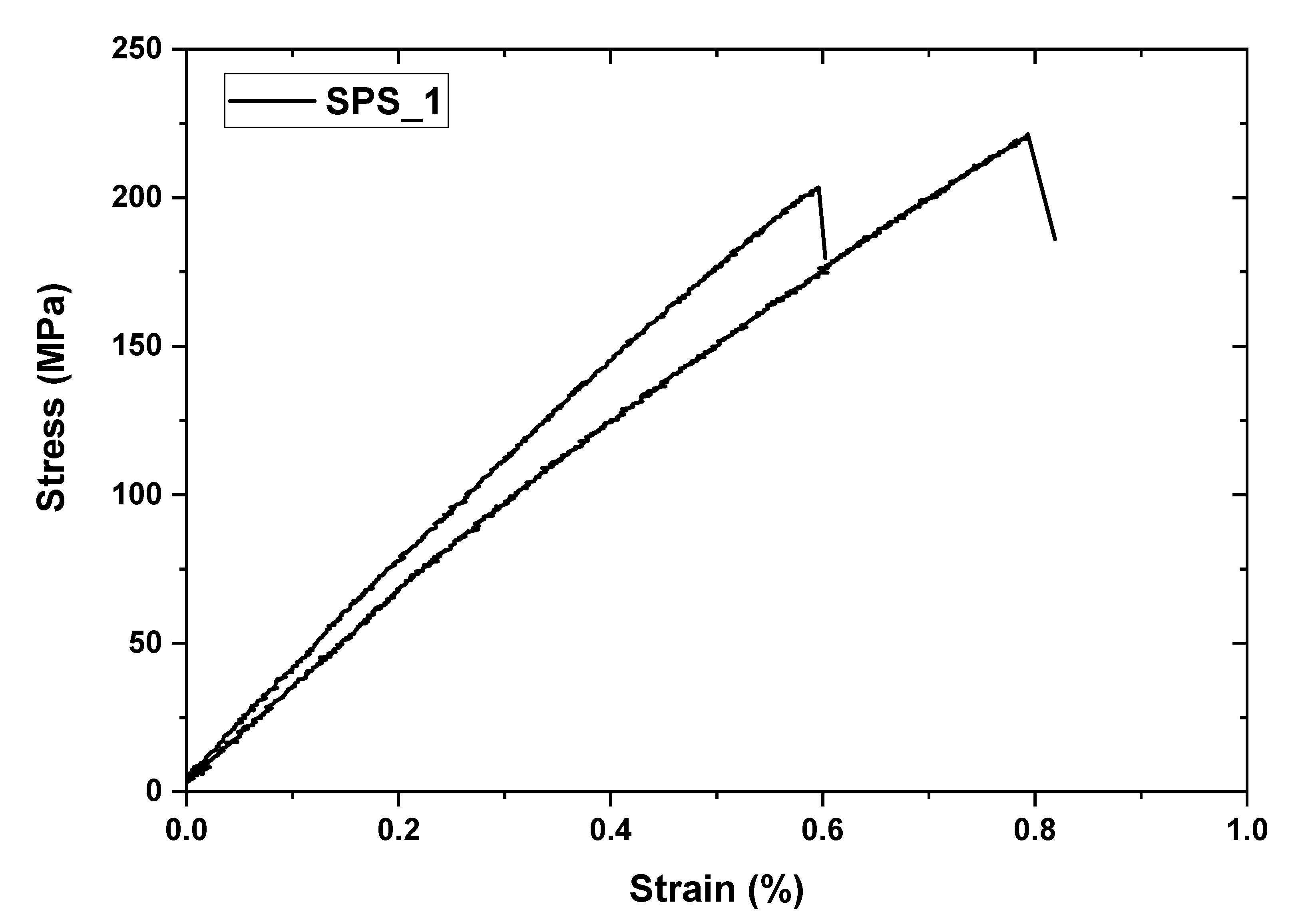

Tensile tests on NiTi alloys show three regions of interest: an elastic deformation region, a plateau region related to detwinning of martensite and, finally, a mixed elastic and plastic deformation region of martensite [

25]. The room temperature stress–strain curves of the sintered NiTi alloys show decreases in the strain and stress up to failure on tension related to brittle fracture of the surface. This may enhance the behavior upon aging. The SPS sintered NiTi alloy showed transformation temperature peaks at lower temperatures due to an increase in Ni content, and the functional behavior of the SPS sample shows an SME effect with a strain recovery of 3% at a lower temperature of −50 °C.

At high temperatures, the grain boundary mobility might become higher than the pore mobility [

24]. It causes some pores to be detached from the grain boundary and move into the grains. As it is known, removal of the pores trapped inside the grains is harder than those attached to the grain boundaries, which results in a decrease in relative density. In other words, as the sintering process starts under high pressure and high temperature, the particles become closer, and neck formation occurs between two adjacent grains due to the diffusion phenomenon, which results in intergranular pores between NiTi particles. These kinds of pores formed during sintering have cause a pinning effect on the grain boundaries (GBs) and inhibit grain boundary movement. As the densification continued at the last stage of sintering, some of the intergranular pores shrank and were removed while some others were separated from the GBs and went into the grains, forming intragranular pores [

25]. By the elimination of the intergranular pores, the GBs were freed and could move, which resulted in fast grain growth. Therefore, based on the above discussion, it can be concluded that applied pressure in the SPS method promotes the sintering and rearrangement of the particles. In addition, the pressure can act as an opponent factor against gas pressure trapped in the closed pores. Therefore, the porosities were removed more easily than those in the conventional sintering method. Some GBs and intergranular pores were formed between the particles. By raising the sintering temperature, fewer pores are detected, and grain growth occurs.

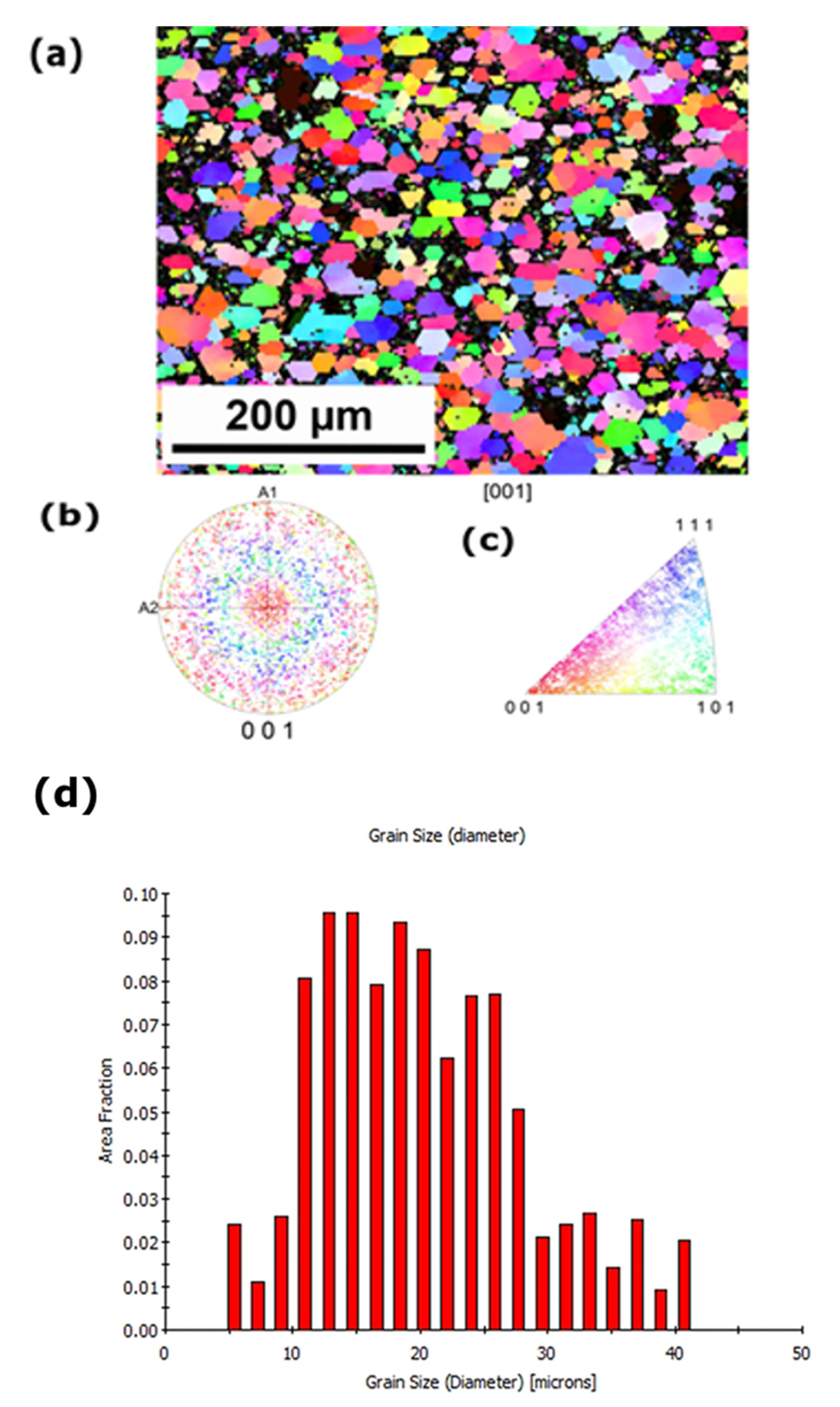

As mentioned before, the existence of the pores on the GBs pins them and retards fast grain growth. It was reported that grains might grow in a preferred crystallographic path due to uniaxial applied pressure in pressure-assisted consolidation methods such as SPS [

26]. In addition, the plastic deformation mechanism of NiTi may be triggered at high temperatures [

27]. In other words, the plastic yield stress of NiTi depletes with rising temperature [

28,

29,

30]. Moreover, the effective pressure (Peff) on the neck or GB is usually higher than the applied pressure (P), and it depends on the relative density of the sample. Therefore, effective pressure is high enough to cause deformation in the NiTi samples, which may result in layered structures. However, this laminar structure changes to an equiaxed morphology with increasing temperature and time. This may be due to the recrystallization of the grains so that the deformed NiTi grains are replaced by the new grains that nucleate and grow until the NiTi deformed grains are consumed. For the NiTi samples spark plasma sintered at lower temperatures, extending the holding time helps further elimination and removal of porosities, whereas at high sintering temperatures, holding time has no effect on porosity removal and just increases the grain size. Nevertheless, such processing would cause grain growth, which decreases the mechanical properties of the samples. This may refer to grain growth and plastic deformation generated in the polycrystalline grains. The observation of grain size distribution—the inverse pole EBSD image (

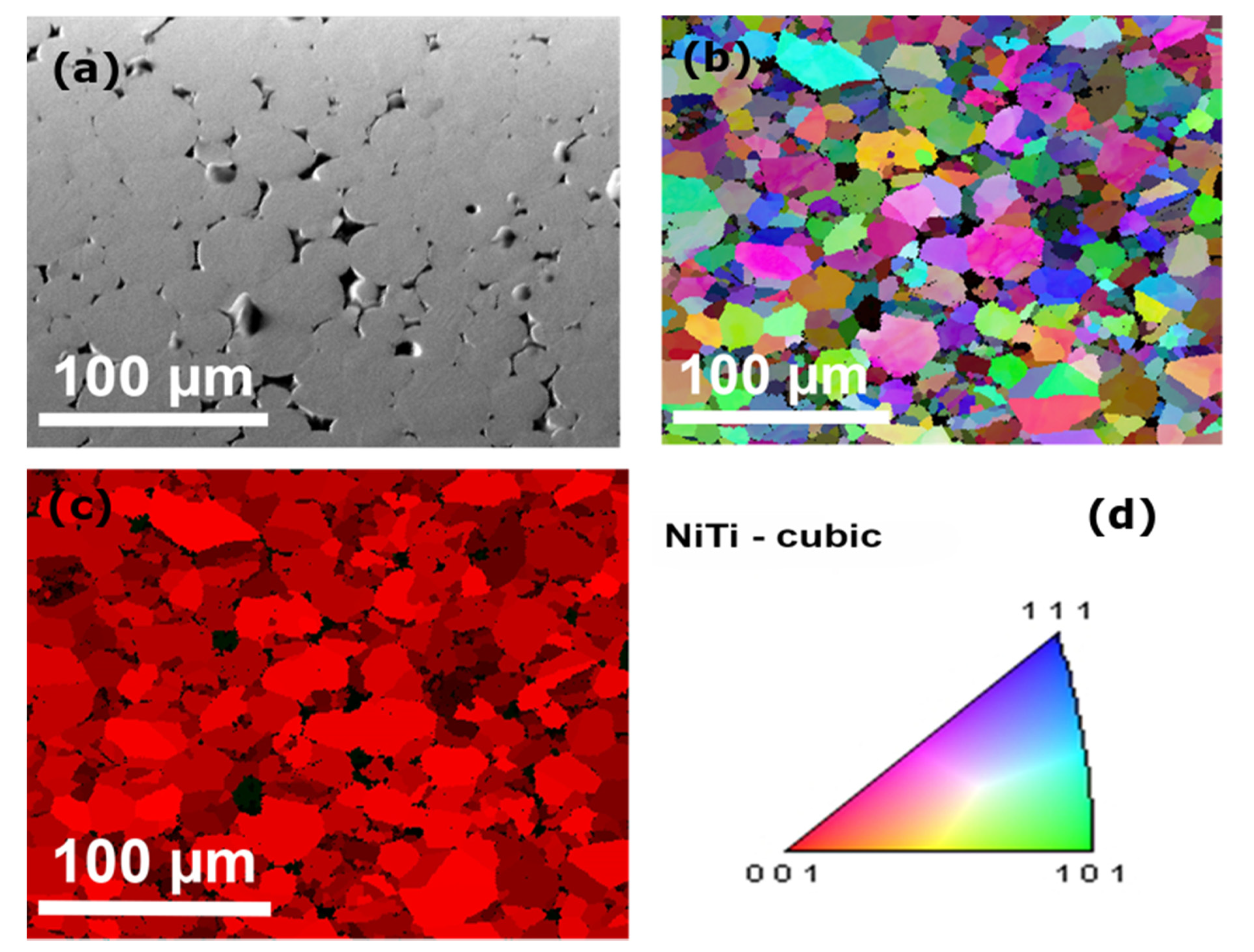

Figure 11)—reflects random distribution of grains in SPS sintered alloy. The grain size as a function of the area fraction shows that the average grain size falls within the range of 20 ± 8 µm (

Figure 11d). The fragmented grains could contribute toward grain growth with fewer mechanical properties.

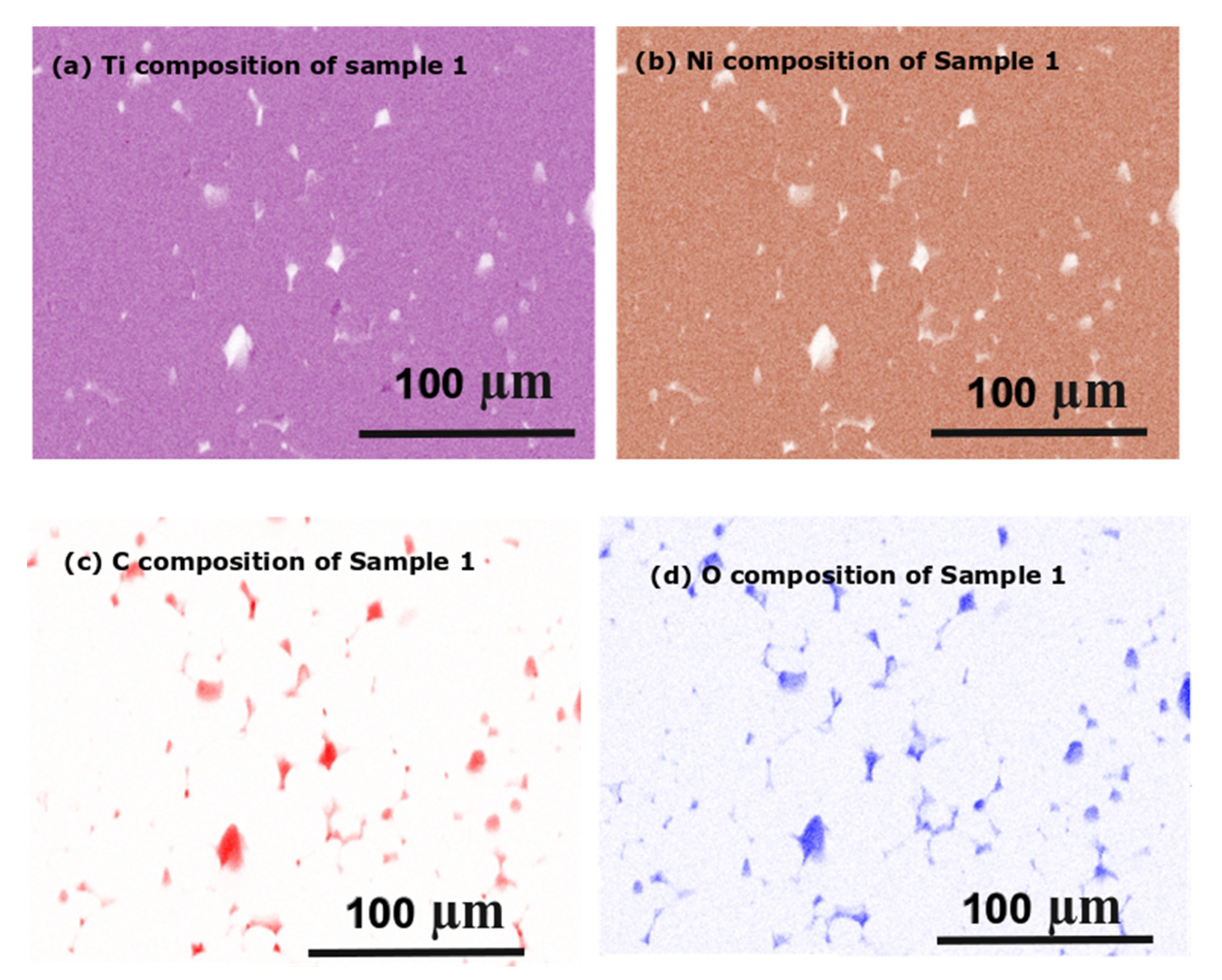

However, the overall composition of the sintered NiTi alloy for both samples shows the uniform compositions of Ti and Ni (

Figure 12). The sample shows homogeneity, with the white regions showing porosity. However, the sample shows the equiatomic composition of Ti:Ni.