Abstract

The present study examined the effect of ultrasonic pretreatment at three time the levels of 10, 20 and 30 min on some thermodynamic (effective moisture diffusivity coefficient(Deff), drying time, specific energy consumption (SEC), energy efficiency, drying efficiency, and thermal efficiency) and physical (color and shrinkage) properties of kiwifruit under hybrid hot air-infrared(HAI) dryer at different temperatures (50, 60 and 70 °C) and different thicknesses (4, 6 and 8 mm). A total of 11 mathematical models were applied to represent the moisture ratio (MR) during the drying of kiwifruit. The fitting of MR mathematical models to experimental data demonstrated that the logistic model can satisfactorily describe the MR curve of dried kiwifruit with a correlation coefficient (R2) of 0.9997, root mean square error (RMSE) of 0.0177 and chi-square (χ2) of 0.0007. The observed Deff of dried samples ranged from 3.09 × 10−10 to 2.26 × 10−9 m2/s. The lowest SEC, color changes and shrinkage were obtained as 36.57 kWh/kg, 13.29 and 25.25%, respectively. The highest drying efficiency, energy efficiency, and thermal efficiency were determined as 11.09%, 7.69% and 10.58%, respectively. The results revealed that increasing the temperature and ultrasonic pretreatment time and decreasing the sample thickness led to a significant increase (p < 0.05) in drying efficiency, thermal efficiency, and energy efficiency, while drying time, SEC and shrinkage significantly decreased (p < 0.05).

1. Introduction

Kiwifruit with the scientific name of Actinidia deliciosa is a subtropical fruit belonging to the Actinidiaceae family. This fruit is rich in vitamins E and C, phenolic substances, flavonoids, various pigments, and antioxidants [1]. According to the research by the Food and Agriculture Organization (FAO) of the United Nations, kiwifruit is the fourth most popular fruit in the world after banana, citrus fruits, and apple [2].

Fruits and vegetables with a moisture content (MC) of about 80% are classified as highly perishable materials. The high-potential drying is one of the most common methods to preserve and increase the productivity of food [3]. The most common method for drying food is to use hot air flow, which requires hot air to provide a simultaneous transfer of heat and moisture between hot air and food to evaporate water and to bring the moisture to the desired level [4]. In addition to having advantages, such as the possibility of accurate temperature control regardless of the size and shape of the product and not needing direct contact, the drying with hot air also has some disadvantages. These disadvantages include the long time and high temperature for drying the product during the period of descending speed. In addition, high temperatures reduce the nutritional value and increase energy consumption [5]. The infrared dryers have been commonly used in recent years and have received more attention in developing countries due to the low cost, simple equipment, and low price. Infrared drying is the process in which wet materials are heated by infrared radiation. Infrared radiation is a type of electromagnetic radiation with a wavelength between 0.76 and 400 μm [6]. In the hybrid method, the use of hot air and infrared waves coincide in all stages of product drying. The reports show that the hybrid method at mild air speeds can improve energy consumption and drying time while increasing product quality [7]. The application of the pretreatments that reduce the initial moisture of the food and also modify the food texture to accelerate the transfer of moisture and reduce drying time will be very useful.

Ultrasonic pretreatment is performed by immersing the fruit in water and applying ultrasound waves. Ultrasonic waves cause a series of rapid, intermittent contractions and expansions of the cell wall (sponge effect), which creates microscopic channels in the structure of the material and increases the possibility of moisture transfer. As a result, an ultrasound can be used as a pretreatment in drying heat-sensitive food products without adversely affecting the qualitative characteristics of the food, since it improves the speed and decreases the temperature required for drying [8].

Mierzwa et al. examined the effect of ultrasonic pretreatment with two types of microwaves and hot air dryers on some drying parameters (kinetics, shrinkage, specific energy consumption, and rehydration ratio) of raspberry, and stated that the use of ultrasonic pretreatment reduced specific energy consumption and shrinkage in both types of dryers [9]. Abbaspour et al. investigated the drying kinetics, SEC, color, shrinkage, and rehydration of carrots using three types of hot air, microwave and infrared dryers with ultrasonic pretreatment [10]. They reported that the use of ultrasonic pretreatment reduced the drying time of the sample compared to the control treatment. The use of ultrasonic pretreatment in all three types of hot air, microwave and infrared dryers also increased the Deff and reduced the SEC, color changes, and shrinkage. Dehghannya et al. studied the effect of using ultrasonic pretreatment on the drying of potato slices in hot air microwave dryers and measured the MC, Deff, SEC, rehydration percentage, and shrinkage [11]. They stated that the application of ultrasonic waves reduced the drying time. Additionally, the samples under ultrasonic pretreatment had lower shrinkage and SEC and a higher moisture diffusivity coefficient and rehydration percentage than the control sample. Ghanbarian et al. dried peppermint using the hot air dryer (at three temperature levels) with ultrasonic pretreatment (four levels of ultrasonic power) [12]. They examined MC, drying time, SEC, and energy efficiency of peppermint. The results showed that the use of ultrasonic pretreatment reduced the drying time and SEC and increased the energy efficiency of peppermint. Thus far, various studies have been conducted on the drying of kiwifruit using hot air dryer [13,14], hot air dryer with recirculation under heat pump [15], microwave [16], infrared-vacuum dryer [17], vacuum-hot air dryer [18], hot air, vacuum, freezer, hot air-microwave-vacuum [19], hot air, microwave and freezer [20], HAI [21], freezer [22], and short and medium-wave infrared radiation with/without osmotic dehydration [23].

Due to the importance of kiwifruit in the human diet and the effect of the drying process on the maintenance of this product with high qualitative properties and low energy consumption, and given the lack of a comprehensive study on the effect of ultrasound on the qualitative and thermodynamic properties of kiwifruit, this research aimed to evaluate the effect of ultrasonic pretreatment on the changes in Deff, SEC, energy efficiency, drying efficiency, color, shrinkage, and drying time of kiwifruit slices during drying with the hybrid HAI dryer.

2. Materials and Methods

Fresh Hayward kiwifruit was bought from the local market of ParsAbad, Ardabil province, Iran and stored at 4 °C. One hour before the test, the samples were removed from the refrigerator and kept at 24 °C. Using an electric slicer (Celme GE300, Montebello Vicentino, Italy), kiwifruits were cut into 4, 6 and 8 mm thick slices and the slices were then cut into 24 mm discs by a circular slicer. The initial MC of kiwifruit samples was obtained in an oven at 105 °C for 24 h. The initial MC of kiwifruit (6.85% (d.b.)) was determined and the drying continued until reaching an MC of 0.2% (d.b.).

2.1. Ultrasonic

The kiwifruit samples selected for ultrasonic pretreatment were transferred to an ultrasonic bath. All samples were placed in a 6 Lultrasonic bath (Parsonic 7500S, Tehran, Iran), which was filled with distilled water at an ambient temperature of 25 °C in a ratio of 1:4. The samples were then exposed to ultrasonic waves for 0, 10, 20 and 30 min. The frequency and power of this test were 28 kHz and 70 W, respectively.

2.2. Hybrid Hot Air-Infrared (HAI) Dryer

A hybrid HAI dryer (GC 400, Grouc, Tehran, Iran) was used for the experiments. The dryer consisted of two infrared lamps (Philips, Flemish, Belgium), each with a rated power of 250 W (500 W in total), which was installed in the upper part of the drying chamber at a height of 30 cm. The flow rate of the air entering the dryer was set to 1 m/s. The kiwifruits under study were placed in the middle of the channel on the containers made from wire mesh on digital scales (AND, GF–6000, A&D Company Ltd, Tokyo, Japan) with a precision of 0.01 g embedded below and outside the channel. The drying of kiwifruit was performed at three air temperature levels of 50, 60 and 70 °C. To start the test, the machine was put into operation for 15 min to fix the temperature and flow rate of the dryer’s air. In each experiment, 55 g of kiwifruit was placed in a single layer on a drying tray. During the drying experiments, the mean range of changes in ambient temperature and the relative humidity were 20 ± 4 °C and 15 ± 5%, respectively.

2.3. Moisture Ratio (MR) and Mathematical Modeling

To model the drying process, the MR parameter during the kiwifruit drying was obtained using the following Equation (1) [24]:

MR: moisture ratio (dimensionless), Mt: MC of samples at any given time on dry basis (d.b.), Me: equilibrium moisture content (d.b.), and Mo: initial moisture of samples (d.b.). According to Equation (1), the moisture ratio depends on the initial moisture, balanced moisture, and moisture of samples at any time during the drying. For long drying times, the Me values are very small compared to the Mo and Mt values. Therefore, the equation of MR during the drying can be simplified, as in Equation (2), and to calculate the MR, it is not necessary to measure the balanced moisture [25].

2.4. Modeling

In this study, a number of experimental and proposed models were used to model the drying kinetics (fitting of MR versus drying time) of green kiwifruit samples (Table 1). To select the most appropriate model to describe the drying kinetics of green kiwifruit, the criteria of determination coefficient (R2), root mean square error (RMSE), and chi-square (χ2) were calculated by each model and compared with other models. The higher the R2 value and the lower the RMSE and χ2 values, the better the model fitting to the experimental data and it is chosen as the best model. The R2, RMSE and χ2 values were calculated according to Equations (3)–(5):

Table 1.

Applied models to fit the experimental data .

N, z, MRpre,i and MRexp,i are the number of observations, number of dryer constants, predicted MRi, and experimental MRi, respectively [20].

2.5. Determination of Effective Moisture Diffusivity Coefficient (Deff)

The number of moisture transfer mechanisms is extensive and often complex. Transfer phenomena are usually classified into pressure diffusion, forced diffusion, and ordinary diffusion (net transfer of matter without fluid motion). According to Equation (6), the Fick’s second law for unstable conditions can describe the transfer of moisture in the descending stage of the drying process [29,30]:

where X is the local MC on dry basis, t is the time and x is the spatial index. The study of the Fick’s second law of diffusion indicates the mass transfer during the period of the declining drying rate of agricultural products [26]. To apply Fick’s law, it is assumed that the food product is one-dimensional, the initial MC is uniform, and it has an internal movement of moisture such as the major resistance to moisture transfer. The Fick’s equation for a plane sheet is solved as follows [31,32]:

From 1 to infinity, t is the drying time (s), and Deff is the effective diffusivity coefficient (m2/s). The effective diffusivity coefficient is obtained by calculating the slope in Equation (8) [11]:

The diffusivity coefficient is usually determined by plotting the experimental drying data versus LnMR over time. When plotting the LnMR value over time, place the resulting line slope in Equation (9) to obtain the Deff:

where K is the line slope.

2.6. Calculation of Some Thermodynamic Parameters

2.6.1. Energy Consumption

The thermal energy consumed by the hybrid HAI dryer for drying kiwifruit at infrared temperature and power at constant air flow rate is obtained using Equation (10) [33]:

where EUter is the total thermal energy consumption per drying period (kWh), A is the area of the container in which the test sample is placed (m2), v is the wind speed (m/s), ρa is the air density (kg/m3), t is the total drying time of each sample (h), ΔT is the temperature difference (°C), and Ca is the specific heat (KJ/kg °C).

The mechanical energy consumed by the blower in the dryer during the drying process is obtained from Equation (11) [34]:

EUmec is the total mechanical energy consumption per period (kJ), ΔP is the pressure drop (Pa), and Wair is the airflow rate (m3/s).

The energy consumption for ultrasonic pretreatment can be obtained using the following equation [10]:

where EUult is the ultrasonic power (kw), U (V) and I (A) are the input voltage and current in the ultrasonic machine, respectively, and cosΦ is the power factor equal to 0.8.

The energy consumption required for 1 kg of moisture to be removed from the drying product is calculated by Equation (13):

where SEC is the specific energy consumption (kWh/kg), EU(mec+ter+ult) is the total energy consumption during the drying process (kWh), and Mw is the amount of moisture removed from the product (kg).

2.6.2. Drying Efficiency

Drying efficiency is the division of the total energy required to heat the drying product and the energy required to evaporate moisture by the total energy consumption during the drying process (De):

where De is the drying efficiency (%), Eheating is the energy required to increase the temperature of the dried product (kJ), Eevap is the energy needed to evaporate moisture (kJ), and SEC is the total energy consumption (kJ).

2.6.3. Energy Efficiency

Energy efficiency is obtained by dividing the energy required to evaporate moisture from the drying product by the total energy SEC during the drying process.

where ηe is the energy efficiency and Eeva is the energy required to evaporate moisture (kJ).

2.6.4. Thermal Efficiency

Thermal efficiency is the division of the moisture evaporated from the product by the heat used to dry the product, which can be calculated from Equation (16):

where TE is the thermal efficiency (kg/kJ), Mevap is the weight of moisture evaporated from the product (kg), and Htotal is the total heat consumption (kg).

2.6.5. Energy Required to Evaporate Moisture from Product

The energy required to evaporate moisture from the product during the kiwifruit drying process in the hybrid HAI dryer with ultrasonic pretreatment is calculated from Equation (17):

where Qw is the energy required to evaporate moisture (kJ), hfg is the latent heat of vaporization (kJ/kg), and Mw is the moisture evaporated from the product (kg).

The latent heat of vaporization can be obtained from Equation (18):

2.6.6. Energy Required to Increase Product Temperature

The energy required to increase the product temperature from the initial temperature (temperature before entering the drying chamber) to the latent temperature (highest product temperature) can be calculated from Equations (19)–(21):

where Eheating is the energy required to increase the product temperature (kJ), Wd is the dry matter weight (kg), Cm is the specific heat of the product (kJ/kg K), T1 is the initial product temperature (K), T2 is the latent product temperature (K), Mp is the MC of the product on dry basis (kg water/kg solid), and Mw is the initial weight of the product (kg).

2.7. Shrinkage

Shrinkage is the ratio between the initial volume of fresh kiwifruit and the final volume of dried kiwifruit, which is expressed by the following equation:

where Sv is the percentage of shrinkage (dimensionless), Vt is the volume at the desired time (cm3) and V is the initial sample volume (cm3). The sample volume is obtained by the toluene displacement method according to Dehghannya et al. [11].

2.8. Color

The color of the samples prior to and following the drying was measured by a color meter (Portable colorimeter, HP–200, China). To describe the color changes during the drying, the ΔE index (color difference of total dried samples from fresh samples) was used. This index is defined by Equation (8) where L represents the brightness, b represents the yellow-blue color and a indicates the red-green color [25,35]:

2.9. Data Analysis

In this study, the factorial experiment was used in a completely randomized design. The treatments were considered at three drying temperatures (50, 60 and 70 °C), three levels of thickness (4, 6 and 8 mm) and three levels of ultrasonic radiation time (10, 20 and 30 min). Additionally, the effect of treatments on the qualitative (color changes and shrinkage) and thermodynamic parameters (Deff, SEC, thermal efficiency, energy efficiency, and drying efficiency) was investigated for the drying of kiwifruit slices. To examine the significance of the factors, the data analysis of variance was performed using SPSS software and the mean comparison of treatments was made at the 5% probability level.

3. Results and Discussion

3.1. Mathematical Modeling

Table 2 shows the statistical parameters obtained from the fitting of the experimental data of the drying experiments to the 11 models listed in Table 1. According to the tables, it can be seen that, in the method of hybrid HAI drying with ultrasonic pretreatment, the logistic model has the highest value of determination coefficient (0.9997) and the lowest values of chi-square (χ2 = 0.0007) and root mean square error (RMSE = 0.0177) compared to other models.

Table 2.

Statistical analysis of mathematical modeling of kiwifruit slices drying kinetics.

3.2. Drying Time

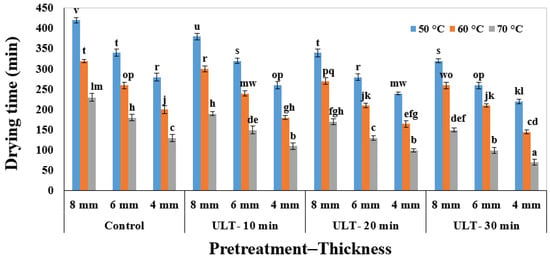

Figure 1 shows the effect of drying air temperature, thickness and ultrasonic pretreatment time on the drying time of kiwifruit slices. As shown in Figure 1, the maximum drying time was obtained at 50 °C with a thickness of 8 mm (control sample) for 420 min. Also, the minimum drying time was obtained at 70 °C, 4 mm thickness and ultrasonic radiation time of 30 min for 70 min. As expected, the drying time is significantly reduced (p < 0.05) by raising the temperature due to the increased thermal gradient (as a result of higher mass and heat transfer) and greater and quicker removal of moisture from the product [36].

Figure 1.

Drying time under different conditions for drying kiwifruit slices.

The results obtained in Figure 1 also show that the highest effect of using ultrasonic pretreatment on the drying time of kiwifruit is seen for 30 min of ultrasonic application and the lowest one is seen for the control sample. By applying the cavitation process (asymmetric bursting of bubbles) near the foodsurface, ultrasonic pretreatment causes the rapid and eruptive flow of sound waves to the surface and forms microscopic channels in the samples by creating successive contractions and expansions. In addition, by increasing the duration of applying this energy (ultrasound), the channels expands and the product has a spongy texture, facilitating the flow of water out of the product during the drying through the created channels [37]. Similar results were observed for carrot drying [24], banana drying [31], and blackberry drying [29]. They showed that, by increasing the ultrasonic radiation time, the drying time decreases significantly (p < 0.05). As shown in Figure 1, the drying time was longer as the thickness of the samples increased. The reason for this issue is the hardening mechanism of the cutting surface, increased amount of water, and also a longer path of vaporremoval, which made it difficult to transfer moisture through the texture and ultimately increased the drying time [38]. Doymaz and Ozdemir for drying tomatoes and Onwude et al. for drying potatoes showed that the drying time increases by enlarging the thickness of the samples [28,36].

3.3. Deff

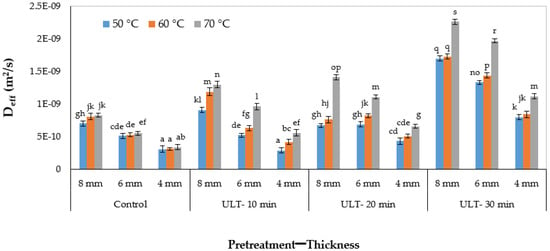

Different values of Deff for different treatments of this study are reported in Figure 2. By increasing the drying temperature, the sample thickness and ultrasonic radiation time during the kiwifruit drying process Deff had a significantly (p < 0.05) increasing trend. By increasing the air temperature from 50 to 70 °C, it was observed that the moisture diffusivity coefficient increased from 3.09 × 10−10 to 2.26 × 10−9 m2/s. The reason for this issue is the significant effect of air temperature in creating more molecular movement and surface suction, and increasing the diffusivity coefficient. Additionally, increasing the temperature increases the enthalpy of the entering air, and increasing the enthalpy increases the mass and heat transfer, which increases Deff. Further, by increasing the thickness of the samples, the amount of Deff increased. Nguyen and Price reported that superficial hardening generally occurs much faster in thinner samples than in thicker samples, while the rate of moisture evaporation in thinner samples is much higher [39]. Therefore, rapid superficial hardening in the samples with less thickness causes a restriction in moisture transfer compared to thicker samples and thus leads to a decrease in moisture diffusivity coefficient in thinner samples [40,41]. Similar observations on the effect of thickness on moisture diffusivity coefficient have been reported by other researchers, including Doymaz and Gol, Azimi-Nejadian and Hoseini and Onwude et al. [28,40,42]. The Deff increased by prolonging the ultrasonic pretreatment time from 0 to 30 min. Ultrasonic pretreatment causes the opening of the capillary tubes due to the dispersion of surface compounds and the formation of longer microscopic channels due to the deformation of the cells, followed by the formation ofmore open capillary tubes [43]. Therefore, ultrasonic pretreatment accelerates the removal of moisture from the product by deforming the cells and destroying the cell wall.

Figure 2.

The value of Deff under different conditions for drying kiwifruit slices.

Many researchers have reported Deff for other products with ultrasonic pretreatment. For instance, the obtained moisture diffusivity coefficient values for potatoes in the hybrid microwave-hot air dryer with ultrasonic pretreatment ranged from 1.07 × 10−7 to 1.283 × 10−7 m2/s [11]. Vallespir et al. obtained the Deff for kiwifruit in a hot air dryer with ultrasonic pretreatment ranging from 3.67 × 10−11 to 9.45 × 10−11 m2/s [5]. Abbaspour-Gilandeh et al. calculated the diffusivity coefficient for the drying of walnut in the microwave and hot air dryers at different ultrasonic pretreatment times between 3.12 × 10−9 and 8.99 × 10−9 m2/s and between 2.77 × 10−9 and 5.56 × 10−9 m2/s [43].

3.4. Thermodynamic Parameters

3.4.1. SEC

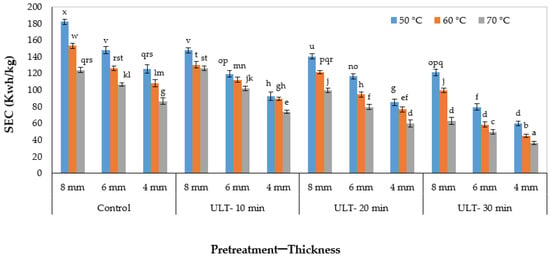

According to Figure 3, the lowest SEC (36.57 kWh/kg) was obtained with a significant difference (p < 0.05) at an air temperature of 70 °C, ultrasonic radiation time of 30 min, and thickness of 4 mm. Additionally, the control sample with a thickness of 8 mm for drying kiwifruit significantly (p < 0.05) had the highest SEC (181.97 kWh/kg). This can be due to the low moisture removal from the drying product and the increase in drying time. As the air temperature grows from 50 to 70 °C, the thermal gradient within the drying product increases, resulting in an increase in the moisture evaporation rate (the downward slope of the MR variation diagram becomes steeper as the temperature increases). Therefore, with the increasing temperature, the total energy consumption decreases [44]. Further, by enhancing the drying temperature from 50 to 70 °C, the difference between the drying temperature and the ambient temperature increased. As a result, increasing the temperature difference significantly decreased the drying time of the product, which is a strong reason for the reduced energy consumption. Motevali et al. and Kaveh et al., for drying Roman chamomile and Pistacia Atlantica, respectively, showed decreased energy consumption with increasing temperatures [33,44].

Figure 3.

Amounts of SEC under different conditions for kiwifruit slices.

Increasing the ultrasonic radiation time from 0 (control sample) to 30 min significantly decreased the SEC (p < 0.05), because with increasing the ultrasonic pretreatment time, the product texture is more destroyed and the hard layer does not form in the product during the drying process, and thus, the product dries faster, and consequently, the SEC in the dryer is reduced [45]. The researchers showed that, with an increasing ultrasonic radiation time, the SEC decreases during the drying of blackberries [29].

The study of the effect of thickness on energy consumption revealed that reducing the thickness during the drying of kiwi reduces the drying time due to the increased thermal gradient and accelerated the removal of moisture from the product, thus reducing the total energy consumption. Darvishi et al., for drying kiwifruit in different thicknesses using the microwave dryer, showed that by reducing the thickness of the samples, the SEC is significantly reduced (p < 0.05) [16].

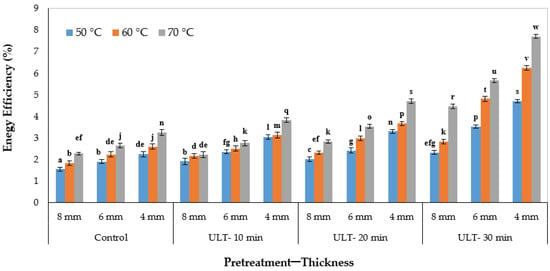

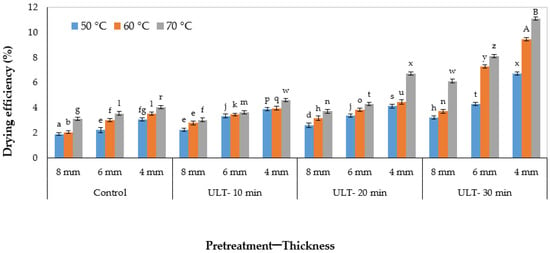

3.4.2. Energy Efficiency and Drying Efficiency

Figure 4 and Figure 5 show the effect of different treatments (temperature, thickness and ultrasonic radiation time) on energy efficiency and drying efficiency, respectively. The highest energy efficiency and drying efficiency values (7.69% and 11.09%) were obtained at 70 °C, 4 mm thickness, and 30 min ultrasonic radiation time, respectively. Increasing the temperature from 50 to 70 °C increases the energy efficiency and the drying efficiency. Drying temperature increases the rate of moisture removal from the product and reduces the drying time, and consequently, both efficiency values will increase with increasing temperatures. However, comparing the application times of ultrasonic pretreatment shows that the highest values of both efficiencies occur when the 30 min ultrasonic pretreatment is used. According to Figure 4 and Figure 5, it can be seen that reducing the thickness of kiwifruit samples will significantly (p < 0.05) increase energy efficiency and drying efficiency, because less thickness will increase the gradient of the drying product and more moisture is removed from the product, and as a result, the drying time of kiwifruit at low thicknesses is reduced. The lowest energy efficiency and drying efficiency values can be seen in the control treatment with a thickness of 8 mm (1.54% and 1.88%), respectively. The results show that increasing the ultrasonic pretreatment time improves both energy efficiency and drying efficiency. This is because, by increasing the ultrasonic pretreatment time, the changes in the product texture increases and the hard layer does not form in the process of drying this pretreated product and the product dries faster.

Figure 4.

Energy efficiency under different conditions for kiwifruit slices drying.

Figure 5.

Drying efficiency under different conditions for drying kiwifruit slices.

The results of this study are consistent with the results published by other researchers. The energy efficiency values for drying chamomile in hot air dryers ranged between 1.91% and 6.76% [44], for apple slices between 2.87% and 9.11% [46], for Pistacia atlantica in a hot air dryer equal to 5.65% [47], and for peppermint leaves in a hot air dryer with ultrasonic pretreatment varying between 1.41% and 3.69% [12]. Albini et al. obtained the drying efficiency and energy efficiency for barley drying in a hot air dryer ranging 8%–17.4% and 24%–34.2%, respectively [48]. In another study, the drying efficiency was calculated between 3.42% and 12.29% for apple drying and showed that the drying efficiency increases by increasing the temperature [46].

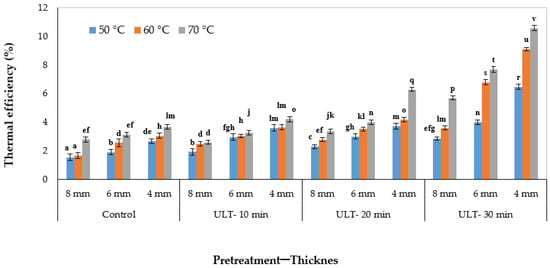

3.4.3. Thermal Efficiency

Figure 6 depicts the effect of different treatments on thermal efficiency. It shows that the highest amount of thermal efficiency (10.58%) was achieved at 70 °C, ultrasonic radiation time of 30 min, and thickness of 4 mm, while the lowest value of this efficiency (1.54%) was obtained at 50 °C, control sample, and thickness of 8 mm. The results show that, with increasing temperatures, the changes in thermal efficiency have a significantly (p < 0.05) upward trend. The increase in thermal efficiency is due to the fact that, with increasing temperatures, the difference between the temperature of the drying product and the temperature of the drying air increases and leads to the accelerated removal of moisture from the product and thus reduces the time and amount of energy required.

Figure 6.

Thermal efficiency under different conditions for drying kiwifruit slices.

Thermal efficiency had an upward trend when using ultrasonic pretreatment. In the case of ultrasonic pretreatment, due to the reduced relative humidity of the drying air, the drying time is significantly (p < 0.05) shorter, and as a result, the share of energy consumption is smaller. The effect of thickness on the changes in thermal efficiency shows that, with decreasing thicknesses, the amount of thermal efficiency increases significantly (p < 0.05). This can be due to the increased drying rate as a result of the decreased thickness, because with decreasing thicknesses, the thermal gradient increases, the removal of moisture from within the product to the surface increases, and the drying time decreases.

Torki-Harchegani et al. showed that the thermal efficiency of peppermint leaf drying was 38.36%–49.33% for the microwave dryer and 3.69%–5.47% for the hot air dryer [49]. In another study by Beigi for drying apple, the thermal efficiency was calculated as ranging 3.70%–9.44%, and it was shown that, with increasing temperatures, the thermal efficiency increases [46]. Motevali et al. calculated the thermal efficiency for drying chamomile in a hot air dryer between 2.12% and 6.87% and stated that the thermal efficiency increases with increasing drying temperatures [44].

3.5. Qualitative Properties

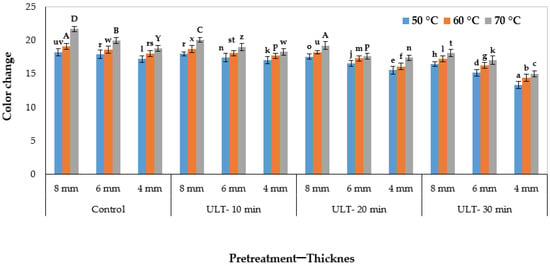

3.5.1. Color

As can be seen in Figure 7, by raising the air temperature from 50 to 70 °C, the overall color change significantly increased (p < 0.05). One of the reasons is that, during the process of food drying, the pigments are decomposed due to slow heating and will cause discoloration in the products [18]. Islam et al. showed that increasing the temperature causes papaya color changes in a hot air dryer [35]. Sufer and Palazoglu achieved similar results for drying pomegranate [50]. For drying kiwifruit in a hot air dryer at different temperatures, Izli et al. showed that the color changes of kiwifruit increased by increasing the temperature [20]. Additionally, by increasing the thickness of the sample, the overall color changes increased, which was due to the fact that at high thicknesses, as the drying time increases, the kiwifruits slices were exposed to hot air for a longer period of time, and the high heat exposure to kiwifruit slices intensified the decomposition of pigments [26]. Therefore, at a thickness of 4 mm, the least amount of overall color changes was seen. The use of ultrasonic pretreatment also reduced color changes. Increasing the time of ultrasonic application reduced the rate of color changes in the ultrasonic pretreatment. Additionally, applying ultrasonic pretreatment time had less color changes than the control sample. The color changes during kiwifruit drying are due to various factors such as thermal degradation of chlorophyll, oxidation, enzymatic reactions and non-enzymatic browning reactions [51]. Taghinezhad et al. studied the drying of blackberries and concluded that the least amount of overall color change was observed at 30 min ultrasonic radiation time [37]. In another study, Dehghannya et al. examined the color changes of Mirabelle plum in the hot air dryer with ultrasonic pretreatment [52]. They showed that the amount of color changes decreases with increasing ultrasonic radiation time. Further, the results obtained by Wang et al. study, which was gathered on kiwifruit slices in the hot air dryer with ultrasonic pretreatment, showed that the highest amount of overall color change was 32.45 in the control sample and the lowest color change amount of 9.59 was observed in the ultrasonic radiation time of 30 min [27].

Figure 7.

Color changes of kiwifruit slices under different drying conditions.

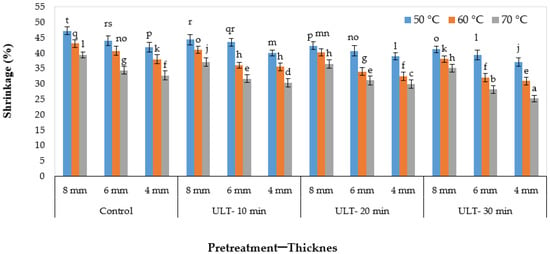

3.5.2. Shrinkage

Figure 8 shows the percentage of shrinkage changes in the HAI dryer with ultrasonic pretreatment at different thicknesses of kiwifruit. The results show that, at high temperatures, high ultrasonic radiation time and less thickness, the amount of shrinkage is significantly reduced (p < 0.05). As kiwifruit has a high initial moisture, due to the shrinkage, which is also significant, some changes occur in the initial structure during the drying process. In this way, the fluid in the cell wall exerts pressure to the cell wall and the fluid inside the cell is put under pressure [51]. During the drying process, the removal of water from the cell reduces the stress induced by the liquid on the cell wall. This reduction in stress causes the shrinkage of the constituent texture of the substance [26]. However, air temperature, high ultrasonic radiation time and less thickness accelerate the water removal rate and do not allow the product to deform. The results of this study corroborate those obtained by Kaveh et al. [29]. They investigated the effect of ultrasonic radiation time on blackberry shrinkage in the hot air dryer, and demonstrated that with increasing air temperature and ultrasonic radiation time, the amount of shrinkage decreased. Dehghannya et al. also achieved similar results for drying potato slices [11].

Figure 8.

Shrinkage of kiwifruit slices under different drying conditions.

4. Conclusions

In this study, drying of kiwifruit was performed at thicknesses of 4, 6 and 8 mm with a hybrid HAI dryer at air temperatures of 50, 60 and 70 °C and ultrasonic times of 0 (control sample), 10, 20 and 30 min. The results showed that, by increasing the temperature, ultrasonic time and decreasing the thickness, the drying time and SEC decreased. The logistic model was able to predict the MR with the highest value of R2 = 0.9997 and the lowest values of RMSE = 0.0117 and χ2 = 0.0007 were chosen as the best model. Additionally, by increasing the thickness of the samples, ultrasonic pretreatment time and by prolonging the air temperature, the amount of Deff increased from 3.09 × 10−10 to 2.26 × 10−9 m2/s. The SEC value decreased significantly (p < 0.05) by increasing the temperature, ultrasonic time and decreasing the thickness. The lowest SEC value was obtained at 70 °C, ultrasonic time of 30 min, and thickness of 4 mm. The highest values of drying efficiency, energy efficiency, and thermal efficiency were 11.09%, 7.69% and 10.58%, respectively, at air an temperature of 70 °C, an ultrasonic time of 30 min, and sample thickness of 4 mm. The lowest color changes and shrinkage values were 13.2%9 and 25.25%, respectively, at 50 °C air temperature, 30 min ultrasonic time, and 4 mm thickness.

Author Contributions

Conceptualization, E.T. and M.K.; methodology, E.T. and M.K.; validation, E.T. and M.K.; formal analysis, E.T.; investigation, E.T. and M.K.; resources, E.T. and A.S.; data curation, E.T. and M.K.; writing—original draft preparation, E.T. and A.S.; writing—review and editing, E.T., A.S.; and M.K.; visualization, E.T. and A.S.; funding acquisition, E.T. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the office of vice chancellor for research at Mohaghegh Ardabili University, and Wrocław University of Environmental and Life Sciences.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data for this research will available.

Acknowledgments

The authors are highly thankful to Department of Agricultural Technology Engineering, Mohaghegh Ardabili University, Ardabil, Iran for providing facilities to conduct this research work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, Y.; Zeng, Y.; Hu, X.; Sun, X. Effect of Ultrasonic Power on Water Removal Kinetics and Moisture Migration of Kiwifruit Slices During Contact Ultrasound Intensified Heat Pump Drying. Food Bioprocess Technol. 2020, 13, 430–441. [Google Scholar] [CrossRef]

- Zakipour-Molkabadi, E.; Hamidi-Esfahani, Z.; Abbasi, S. Formulation of leather from kiwi fruit losses. Iranian Food Sci. Technol. Res. J. 2011, 6, 263–271. [Google Scholar]

- Kumar, C.; Karim, A.; Saha, S.C.; Joardder, M.U.H.; Brown, R.J.; Biswas, D. Multiphysics modelling of convective drying of food materials. In Proceedings of the Global Engineering, Science and Technology Conference, Marrakech, Morocco, 17–20 April 2012. [Google Scholar]

- Taghinezhad, E.; Szumny, A.; Kaveh, M.; Rasooli Sharabiani, V.; Kumar, A.; Shimizu, N. Parboiled Paddy Drying with Different Dryers: Thermodynamic and Quality Properties, Mathematical Modeling Using ANNs Assessment. Foods 2020, 9, 86. [Google Scholar] [CrossRef] [PubMed]

- Vallespir, F.; Rodríguez, Ó.; Cárcel, J.A.; Rosselló, C.; Simal, S. Ultrasound assisted low-temperature drying of kiwifruit: Effects on drying kinetics, bioactive compounds and antioxidant activity. J. Sci. Food Agric. 2019, 99, 2901–2909. [Google Scholar] [CrossRef]

- Salehi, F. Recent applications and potential of infrared dryer systems for drying various agricultural products: A review. Int. J. Fruit Sci. 2020, 20, 586–602. [Google Scholar] [CrossRef]

- Barzegar, M.; Zare, D.; Stroshine, R.L. An integrated energy and quality approach to optimization of green peas drying in a hot air infrared-assisted vibratory bed dryer. J. Food Eng. 2015, 166, 302–315. [Google Scholar] [CrossRef]

- Charoux, C.M.; Ojha, K.S.; O’Donnell, C.P.; Cardoni, A.; Tiwari, B.K. Applications of airborne ultrasonic technology in the food industry. J. Food Eng. 2017, 208, 28–36. [Google Scholar] [CrossRef]

- Mierzwa, D.; Szadzińska, J.; Pawłowski, A.; Pashminehazar, R.; Kharaghani, A. Nonstationary convective drying of raspberries, assisted by microwaves and ultrasound. Dry. Technol. 2019, 37, 988–1001. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Aziz, M. Ultrasonic-Microwave and Infrared Assisted Convective Drying of Carrot: Drying Kinetic, Quality and Energy Consumption. Appl. Sci. 2020, 10, 6309. [Google Scholar] [CrossRef]

- Dehghannya, J.; Kadkhodaei, S.; Heshmati, M.K.; Ghanbarzadeh, B. Ultrasound-assisted intensification of a hybrid intermittent microwave-hot air drying process of potato: Quality aspects and energy consumption. Ultrasonics 2019, 96, 104–122. [Google Scholar] [CrossRef]

- Ghanbarian, D.; Torki-Harchegani, M.; Sadeghi, M.; Pirbalouti, A.G. Ultrasonically improved convective drying of peppermint leaves: Influence on the process time and energetic indices. Renew. Energy 2020, 153, 67–73. [Google Scholar] [CrossRef]

- Darıcı, S.; Şen, S. Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat Mass Transfer. 2015, 51, 1167–1176. [Google Scholar] [CrossRef]

- Mahjoorian, A.; Mokhtarian, M.; Fayyaz, N.; Rahmati, F.; Sayyadi, S.; Ariaii, P. Modeling of drying kiwi slices and its sensory evaluation. Food Sci. Nutr. 2017, 5, 466–473. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, I.; Tabatabaekoloor, R.; Motevali, A. Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 2019, 170, 149–158. [Google Scholar] [CrossRef]

- Darvishi, H.; Zarein, M.; Farhudi, Z. Energetic and exergetic performance analysis and modeling of drying kinetics of kiwi slices. J. Food Sci. Technol. 2016, 53, 2317–2333. [Google Scholar] [CrossRef] [PubMed]

- Aidani, E.; Hadadkhodaparast, M.; Kashaninejad, M. Experimental and modeling investigation of mass transfer during combined infrared-vacuum drying of Hayward kiwifruits. Food Sci. Nutr. 2017, 5, 596–601. [Google Scholar] [CrossRef]

- Orikasa, T.; Koide, S.; Okamoto, S.; Imaizumi, T.; Muramatsu, Y.; Takeda, J.-I.; Shiina, T.; Tagawa, A. Impacts of hot air and vacuum drying on the quality attributes of kiwifruit slices. J. Food Eng. 2014, 125, 51–58. [Google Scholar] [CrossRef]

- Akar, G.; Barutçu Mazı, I. Color change, ascorbic acid degradation kinetics, and rehydration behavior of kiwifruit as affected by different drying methods. J. Food Process Eng. 2019, 42, e13011. [Google Scholar] [CrossRef]

- Izli, N.; Izli, G.; Taskin, O. Drying kinetics, colour, total phenolic content and antioxidant capacity properties of kiwi dried by different methods. J. Food Meas. Charact. 2017, 11, 64–74. [Google Scholar] [CrossRef]

- Nadian, M.H.; Abbaspour-Fard, M.H.; Martynenko, A.; Golzarian, M.R. An intelligent integrated control of hybrid hot air-infrared dryer based on fuzzy logic and computer vision system. Comput. Electron. Agric. 2017, 137, 138–149. [Google Scholar] [CrossRef]

- Ergün, K.; Çalışkan, G.; Dirim, S.N. Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transfer. 2016, 52, 2697–2705. [Google Scholar] [CrossRef]

- Lyu, J.; Chen, Q.; Bi, J.; Zeng, M.; Wu, X. Drying characteristics and quality of kiwifruit slices with/without osmotic dehydration under short-and medium-wave infrared radiation drying. Inter. J. Food Eng. 2017, 13. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Nadian, M.H.; Abbaspour-Fard, M.H.; Sadrnia, H.; Golzarian, M.R.; Tabasizadeh, M. Optimal pretreatment determination of kiwifruit drying via online monitoring. J. Sci. Food Agric. 2016, 96, 4785–4796. [Google Scholar] [CrossRef]

- Jahanbakhshi, A.; Kaveh, M.; Taghinezhad, E.; Rasooli Sharabiani, V. Assessment of kinetics, effective moisture diffusivity, specific energy consumption, shrinkage, and color in the pistachio kernel drying process in microwave drying with ultrasonic pretreatment. J. Food Process. Preserv. 2020, 44, e14449. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, H.-W.; Ye, J.-H.; Wang, J.; Raghavan, V. Ultrasound pretreatment to enhance drying kinetics of Kiwifruit (Actinidia deliciosa) slices: Pros and cons. Food Bioprocess Technol. 2019, 12, 865–876. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. Modelling the mid-infrared drying of sweet potato: Kinetics, mass and heat transfer parameters, and energy consumption. Heat Mass Transfer. 2018, 54, 2917–2933. [Google Scholar] [CrossRef]

- Kaveh, M.; Taghinezhad, E.; Aziz, M. Effects of physical and chemical pretreatments on drying and quality properties of blackberry (Rubus spp.) in hot air dryer. Food Sci. Nutr. 2020, 8, 3843–3856. [Google Scholar] [CrossRef]

- Varzakas, T.H.; Leach, G.C.; Israilides, C.J.; Arapoglou, D. Theoretical and experimental approaches towards the determination of solute effective diffusivities in foods. Enzyme Microb. Technol. 2005, 37, 29–41. [Google Scholar] [CrossRef]

- La Fuente, C.I.; Tadini, C.C. Ultrasound pre-treatment prior to unripe banana air-drying: Effect of the ultrasonic volumetric power on the kinetic parameters. J. Food Sci. Technol. 2018, 55, 5098–5105. [Google Scholar] [CrossRef]

- Varzakas, T.; Escudero, I.; Economou, I.G. Estimation of endoglucanase and lysozyme effective diffusion coefficients in polysulphone membranes. J. Biotechnol. 1999, 72, 77–83. [Google Scholar] [CrossRef]

- Kaveh, M.; Chayjan, R.A.; Taghinezhad, E.; Sharabiani, V.R.; Motevali, A. Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia Atlantica). J. Clean. Prod. 2020, 259, 120963. [Google Scholar] [CrossRef]

- Motevali, A.; Koloor, R.T. A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 2017, 154, 445–461. [Google Scholar] [CrossRef]

- Islam, M.; Saha, T.; Monalisa, K.; Hoque, M. Effect of starch edible coating on drying characteristics and antioxidant properties of papaya. J. Food Meas. Charact. 2019, 13, 2951–2960. [Google Scholar] [CrossRef]

- Doymaz, İ.; Özdemir, Ö. Effect of air temperature, slice thickness and pretreatment on drying and rehydration of tomato. Int. J. Food Sci. Tech. 2014, 49, 558–564. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Kaveh, M.; Khalife, E.; Chen, G. Drying of organic blackberry in combined hot air-infrared dryer with ultrasound pretreatment. Dry. Technol. 2020. [Google Scholar] [CrossRef]

- Doymaz, İ. Drying kinetics, rehydration and colour characteristics of convective hot-air drying of carrot slices. Heat Mass Transfer. 2017, 53, 25–35. [Google Scholar] [CrossRef]

- Nguyen, M.-H.; Price, W.E. Air-drying of banana: Influence of experimental parameters, slab thickness, banana maturity and harvesting season. J. Food Eng. 2007, 79, 200–207. [Google Scholar] [CrossRef]

- Azimi-Nejadian, H.; Hoseini, S.S. Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transfer. 2019, 55, 2921–2930. [Google Scholar] [CrossRef]

- Varzakas, T.; Arapoglou, D.; Israilides, C. Kinetics of endoglucanase and endoxylanase uptake by soybean seeds. J. Biosci. Bioeng. 2006, 101, 111–119. [Google Scholar] [CrossRef]

- Doymaz, I.; Göl, E. Convective drying characteristics of eggplant slices. J. Food Process. Eng. 2011, 34, 1234–1252. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Jahanbakhshi, A. The effect of microwave and convective dryer with ultrasound pre-treatment on drying and quality properties of walnut kernel. J. Food Process. Preserv. 2019, 43, e14178. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Banakar, A.; Ghobadian, B.; Khoshtaghaza, M.H. Comparison of energy parameters in various dryers. Energy Convers. Manag. 2014, 87, 711–725. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Kaveh, M.; Jahanbakhshi, A.; Golpour, I. Use of artificial intelligence for the estimation of effective moisture diffusivity, specific energy consumption, color and shrinkage in quince drying. J. Food Process Eng. 2020, 43, e13358. [Google Scholar] [CrossRef]

- Beigi, M. Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci. Technol. 2016, 36, 145–150. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Hernández-Hernández, J.L.; Fuentes-Penna, A.; Hernández-Hernández, M. Evaluation of the Changes in Thermal, Qualitative, and Antioxidant Properties of Terebinth (Pistacia atlantica) Fruit under Different Drying Methods. Agronomy 2020, 10, 1378. [Google Scholar] [CrossRef]

- Albini, G.; Freire, F.B.; Freire, J.T. Barley: Effect of airflow reversal on fixed bed drying. Chem. Eng. Process. Process. Intensif. 2018, 134, 97–104. [Google Scholar] [CrossRef]

- Torki-Harchegani, M.; Ghanbarian, D.; Pirbalouti, A.G.; Sadeghi, M. Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew. Sustain. Energy Rev. 2016, 58, 407–418. [Google Scholar] [CrossRef]

- Sufer, O.; Palazoglu, T.K. A study on hot-air drying of pomegranate Kinetics of dehydration, rehydration and effects on bioactive compounds. J. Therm. Anal. Calorim. 2019, 137, 1981–1990. [Google Scholar] [CrossRef]

- Motevali, A.; Zabihnia, F. Effect of the Different Pre-Treatments Thermal, Pulse, Chemical and Mechanical on the External Mass Transfer Coefficient Changes, Moisture Diffusion Coefficient and Activation Energy. J. Res. Innov. Food Sci. Technol. 2017, 6, 277–290. [Google Scholar]

- Dehghannya, J.; Gorbani, R.; Ghanbarzadeh, B. Influence of combined pretreatments on color parameters during convective drying of Mirabelle plum (Prunus domestica subsp. syriaca). Heat Mass Transfer. 2017, 53, 2425–2433. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).