Annual Cost and Loss Minimization in a Radial Distribution Network by Capacitor Allocation Using PSO

Abstract

:1. Introduction

2. Problem Formulation

3. Implemented Strategy

3.1. Loss Sensitivity Indices ()

3.2. Proposed Algorithm

3.3. Steps for Implemented Methodology

- Read system data, specify base values for S, V, I, and Z.

- Run load flow to find and , and at each node, i.e., uncompensated values.

- Calculate for each bus using (12) and (13) and arrange in respective order. Top 50% of buses from list will be stored in (reduced search space) and considered for capacitor placement.

- Set , i.e., total number of capacitors to be placed. In this work, it is 10–15% of total buses.

- Initialize PSO parameters, i.e., set number of particles , w, , , , and .

- Generate random particles (candidate solutions) with position and velocity.

- Set the iteration count i to zero.

- Using (14) and (15), the velocity and the position of the particle are updated, respectively.

- The local best, i.e., and global best, i.e., solutions are found as:

- Among total , correspond to the number of candidate buses and correspond to each capacitor size to be placed.

- Place the capacitors at the respective buses and calculate , and .

- Evaluate fitness function given by (1).

- If , display results and end, else go to step 7.

4. Results and Discussion

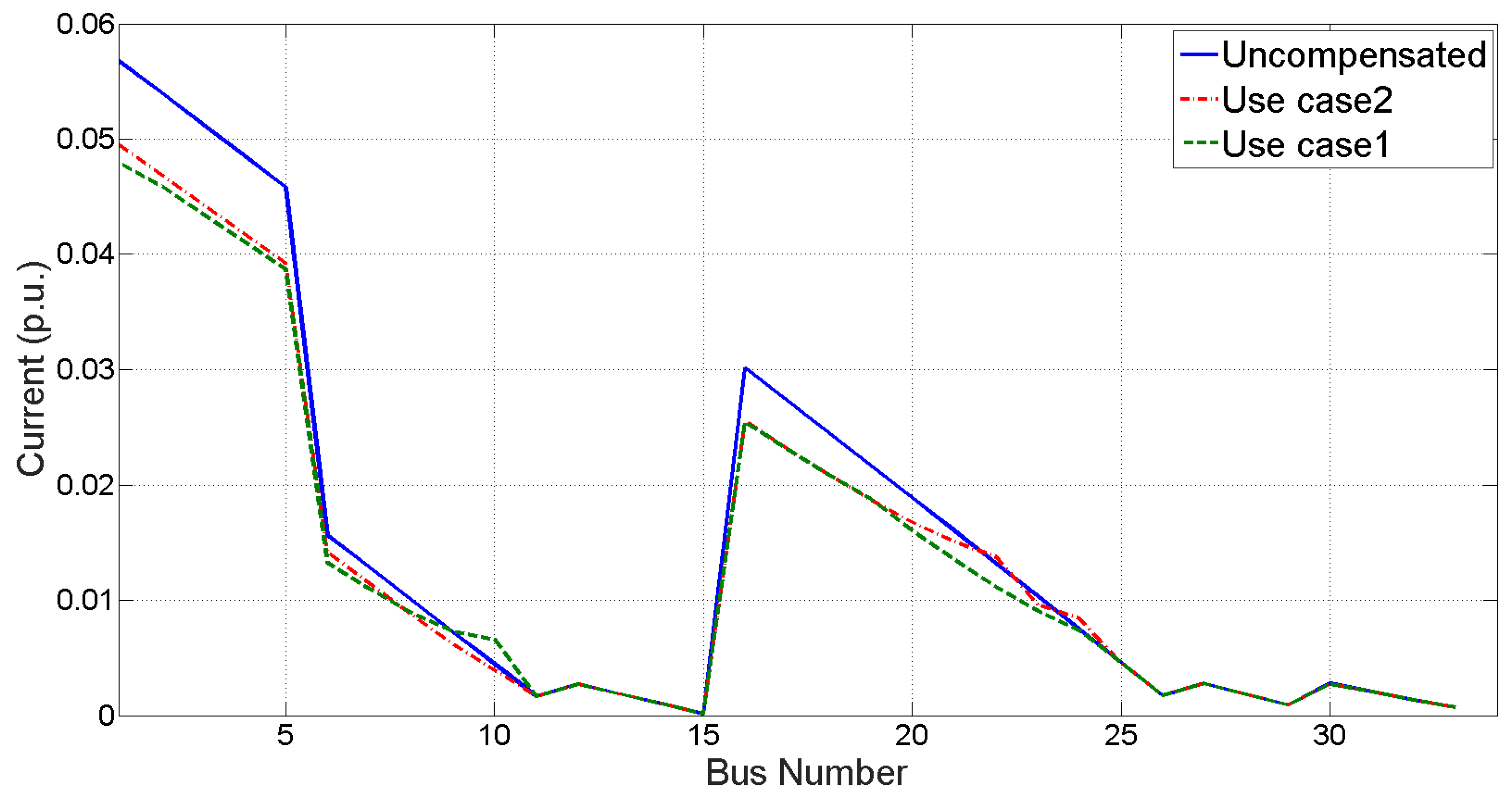

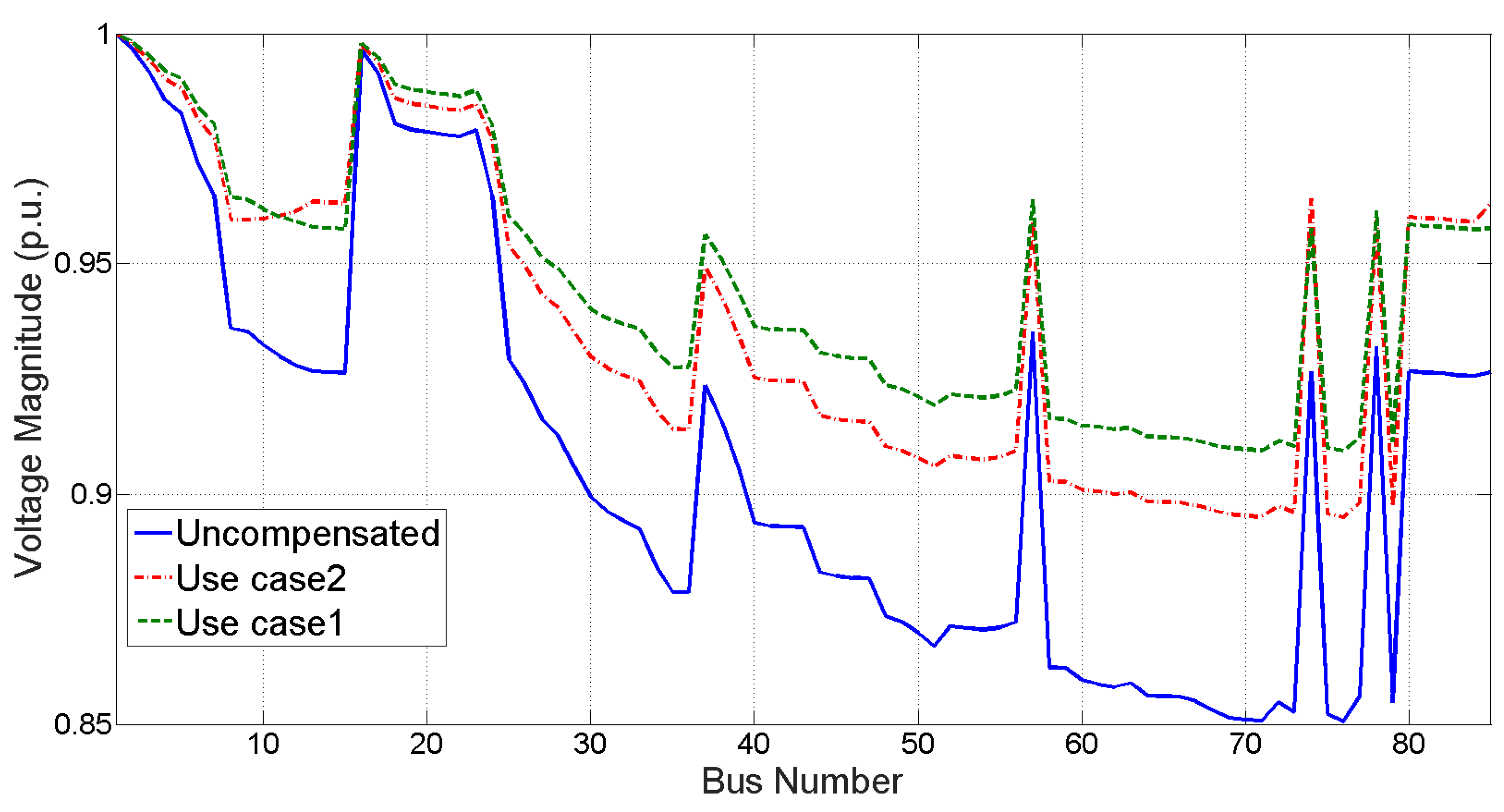

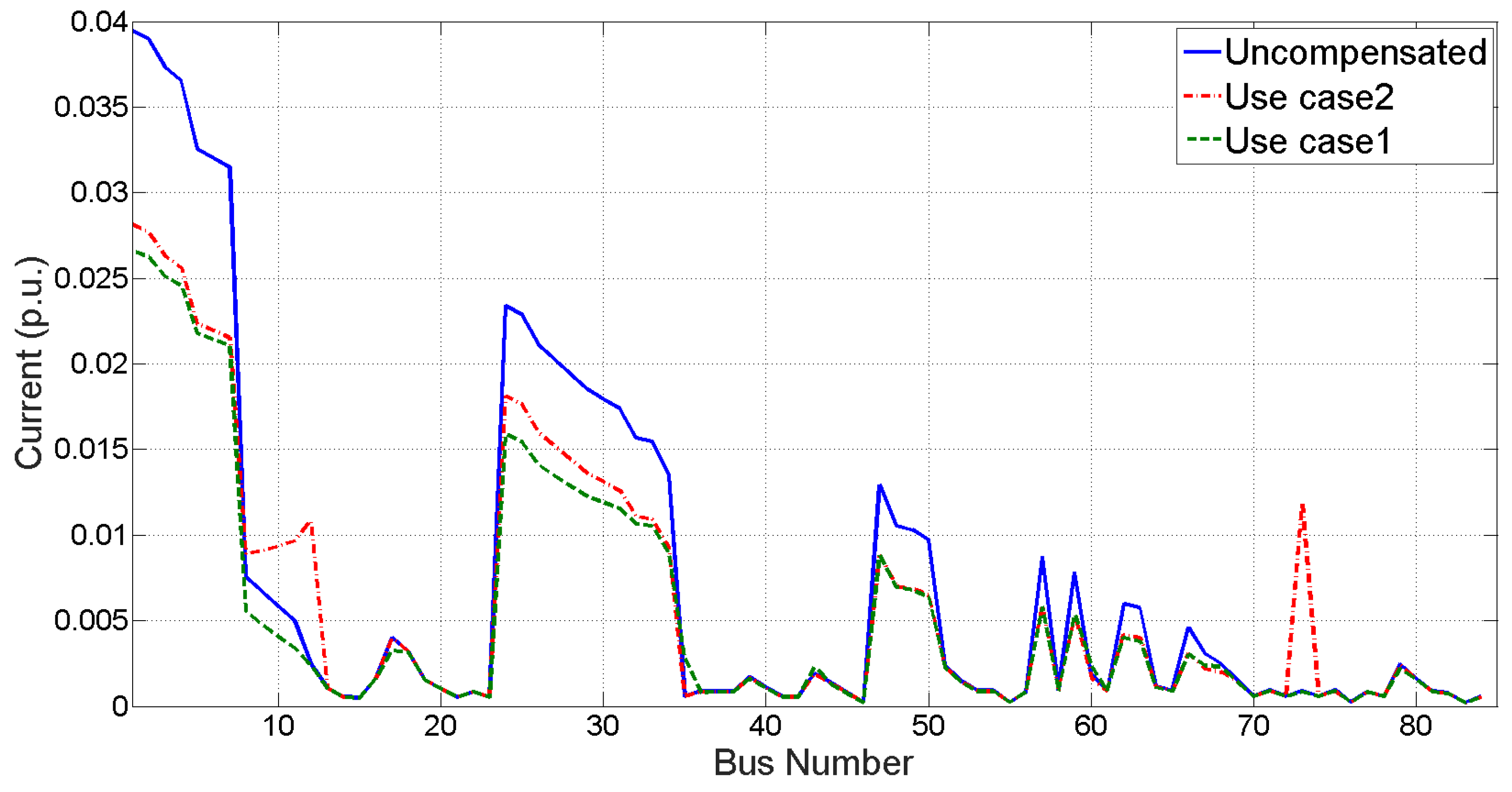

4.1. 34 and 85 Node RDNs –

4.2. 34 and 85 Node RDNs –

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| F | Total cost per year ($/Year) |

| Cost of per unit active power loss per year ($/kW-Year) | |

| Cost of per unit reactive power loss per year ($/kvar-Year) | |

| Purchasing and installation cost of capacitor installed ($/kvar) | |

| Total active power loss kW | |

| Total reactive power loss kvar | |

| Total injected reactive power (kvar) | |

| Reactive power injection at location q | |

| Number of nodes in the system | |

| Number of capacitors to be placed in system | |

| Maximum permissible number of capacitors to be placed in the system | |

| n | Life expectancy of the capacitors |

| Total required reactive power by load | |

| Bus voltage at node q | |

| Minimum voltage at node q | |

| Maximum voltage at node q | |

| Reactive power injection at node q | |

| Minimum reactive power injection at node q | |

| Maximum reactive power injection at node q | |

| Total active power loads beyond the bus q | |

| Total reactive power loads beyond bus q | |

| Total active power loss in line k | |

| Total reactive power loss in line k | |

| Total current flowing over the line k | |

| Total resistance of the line k | |

| Total reactance of the line k | |

| Initial position of particle in iteration | |

| Initial velocity of particle in iteration | |

| Modified velocity of particle in iteration | |

| Modified position of particle in iteration | |

| Personal best position of the particle | |

| Global best position of the particle | |

| w | The inertia weight |

| Constant for acceleration | |

| Constant for acceleration | |

| Random numbers between 0 and 1 | |

| Random numbers between 0 and 1 |

References

- Mtonga, T.P.; Kaberere, K.K.; Irungu, G.K. Optimal Shunt Capacitors’ Placement and Sizing in Radial Distribution Systems Using Multiverse Optimizer. IEEE Can. J. Electr. Comput. Eng. 2021, 44, 10–21. [Google Scholar] [CrossRef]

- Safayet, A.; Fajri, P.; Husain, I. Reactive power management for overvoltage prevention at high PV penetration in a low-voltage distribution system. IEEE Trans. Ind. Appl. 2017, 53, 5786–5794. [Google Scholar] [CrossRef]

- Abou El-Ela, A.A.; El-Sehiemy, R.A.; Abbas, A.S. Optimal placement and sizing of distributed generation and capacitor banks in distribution systems using water cycle algorithm. IEEE Syst. J. 2018, 12, 3629–3636. [Google Scholar] [CrossRef]

- Shahzad, M.; Akram, W.; Arif, M.; Khan, U.; Ullah, B. Optimal Siting and Sizing of Distributed Generators by Strawberry Plant Propagation Algorithm. Energies 2021, 14, 1744. [Google Scholar] [CrossRef]

- Ismail, B.; Wahab, N.I.A.; Othman, M.L.; Radzi, M.A.M.; Vijyakumar, K.N.; Naain, M.N.M. A comprehensive review on optimal location and sizing of reactive power compensation using hybrid-based approaches for power loss reduction, voltage stability improvement, voltage profile enhancement and loadability enhancement. IEEE Access 2020, 8, 222733–222765. [Google Scholar] [CrossRef]

- Srikanth, T.; Selvi, S.C.; Pushya, V.P. Optimal placement of static VAR compensator (SVC) in power system along with wind power generation. In Proceedings of the 2017 IEEE International Conference on Electrical, Instrumentation and Communication Engineering (ICEICE), Karur, India, 27–28 April 2017; pp. 1–6. [Google Scholar]

- Mohanan, V.A.V.; Mareels, I.M.; Evans, R.J.; Kolluri, R.R. Stabilising influence of a synchronous condenser in low inertia networks<? show [AQ="" ID=" Q1]"? IET Gener. Transm. Distrib. 2020, 14, 3582–3593. [Google Scholar]

- Hannan, M.A.; Islam, N.N.; Mohamed, A.; Lipu, M.S.H.; Ker, P.J.; Rashid, M.M.; Shareef, H. Artificial intelligent based damping controller optimization for the multi-machine power system: A review. IEEE Access 2018, 6, 39574–39594. [Google Scholar] [CrossRef]

- Jahromi, M.H.M.; Dehghanian, P.; Khademi, M.R.M.; Jahromi, M.Z. Reactive Power Compensation and Power Loss Reduction using Optimal Capacitor Placement. In Proceedings of the 2021 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2–5 February 2021; pp. 1–6. [Google Scholar]

- Díaz, P.; Pérez-Cisneros, M.; Cuevas, E.; Camarena, O.; Martinez, F.A.F.; González, A. A swarm approach for improving voltage profiles and reduce power loss on electrical distribution networks. IEEE Access 2018, 6, 49498–49512. [Google Scholar] [CrossRef]

- Noori, A.; Zhang, Y.; Nouri, N.; Hajivand, M. Multi-Objective Optimal Placement and Sizing of Distribution Static Compensator in Radial Distribution Networks With Variable Residential, Commercial and Industrial Demands Considering Reliability. IEEE Access 2021, 9, 46911–46926. [Google Scholar] [CrossRef]

- Das, S.; Das, D.; Patra, A. Operation of distribution network with optimal placement and sizing of dispatchable DGs and shunt capacitors. Renew. Sustain. Energy Rev. 2019, 113, 109219. [Google Scholar] [CrossRef]

- Singh, S.P.; Prakash, T.; Singh, V.; Babu, M.G. Analytic hierarchy process based automatic generation control of multi-area interconnected power system using Jaya algorithm. Eng. Appl. Artif. Intell. 2017, 60, 35–44. [Google Scholar] [CrossRef]

- Sinha, A.; Malo, P.; Deb, K. A review on bilevel optimization: From classical to evolutionary approaches and applications. IEEE Trans. Evol. Comput. 2017, 22, 276–295. [Google Scholar] [CrossRef]

- Shahzad, M.; Shafiullah, Q.; Akram, W.; Arif, M.; Ullah, B. Reactive Power Support in Radial Distribution Network Using Mine Blast Algorithm. Elektron. Elektrotechnika 2021, 27, 33–40. [Google Scholar] [CrossRef]

- Elsayed, A.M.; Mishref, M.M.; Farrag, S.M. Optimal allocation and control of fixed and switched capacitor banks on distribution systems using grasshopper optimisation algorithm with power loss sensitivity and rough set theory. IET Gener. Transm. Distrib. 2019, 13, 3863–3878. [Google Scholar] [CrossRef]

- Jafari, A.; Ganjehlou, H.G.; Khalili, T.; Mohammadi-Ivatloo, B.; Bidram, A.; Siano, P. A two-loop hybrid method for optimal placement and scheduling of switched capacitors in distribution networks. IEEE Access 2020, 8, 38892–38906. [Google Scholar] [CrossRef]

- Tamilselvan, V.; Jayabarathi, T.; Raghunathan, T.; Yang, X.S. Optimal capacitor placement in radial distribution systems using flower pollination algorithm. Alex. Eng. J. 2018, 57, 2775–2786. [Google Scholar] [CrossRef]

- Almabsout, E.A.; El-Sehiemy, R.A.; An, O.N.U.; Bayat, O. A hybrid local search-genetic algorithm for simultaneous placement of DG units and shunt capacitors in radial distribution systems. IEEE Access 2020, 8, 54465–54481. [Google Scholar] [CrossRef]

- Hussain, A.N.; Shakir Al-Jubori, W.K.; Kadom, H.F. Hybrid design of optimal capacitor placement and reconfiguration for performance improvement in a radial distribution system. J. Eng. 2019, 2019, 1696347. [Google Scholar] [CrossRef] [Green Version]

- Reddy, A.; Reddy, M.D. Optimal Capacitor allocation for the reconfigured Network using Ant Lion Optimization algorithm. Int. J. Appl. Eng. Res. 2017, 12, 3084–3089. [Google Scholar] [CrossRef]

- Tolba, M.A.; Diab, A.A.Z.; Tulsky, V.N.; Abdelaziz, A.Y. VLCI approach for optimal capacitors allocation in distribution networks based on hybrid PSOGSA optimization algorithm. Neural Comput. Appl. 2019, 31, 3833–3850. [Google Scholar] [CrossRef]

- Diab, A.A.Z.; Tolba, M.A.; Tulsky, V.N. A new hybrid PSOGSA algorithm for optimal allocation and sizing of capacitor banks in RDS. In Proceedings of the 2017 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg and Moscow, Russia, 1–3 February 2017; pp. 1496–1501. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November—1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Rani, B.J.; Reddy, A.S. Optimal allocation and sizing of multiple DG in radial distribution system using binary particle swarm optimization. Int. J. Intell. Eng. Syst. 2019, 12, 290–299. [Google Scholar] [CrossRef]

- Veerasamy, V.; Wahab, N.I.A.; Ramachandran, R.; Othman, M.L.; Hizam, H.; Irudayaraj, A.X.R.; Guerrero, J.M.; Kumar, J.S. A Hankel matrix based reduced order model for stability analysis of hybrid power system using PSO-GSA optimized cascade PI-PD controller for automatic load frequency control. IEEE Access 2020, 8, 71422–71446. [Google Scholar] [CrossRef]

- Llerena-Pizarro, O.; Proenza-Perez, N.; Tuna, C.E.; Silveira, J.L. A PSO-BPSO technique for hybrid power generation system sizing. IEEE Lat. Am. Trans. 2020, 18, 1362–1370. [Google Scholar] [CrossRef]

- Yousaf, S.; Mughees, A.; Khan, M.G.; Amin, A.A.; Adnan, M. A Comparative Analysis of Various Controller Techniques for Optimal Control of Smart Nano-Grid Using GA and PSO Algorithms. IEEE Access 2020, 8, 205696–205711. [Google Scholar] [CrossRef]

- Kefale, H.A.; Getie, E.M.; Eshetie, K.G. Optimal design of grid-connected solar photovoltaic system using selective particle swarm optimization. Int. J. Photoenergy 2021, 2021. [Google Scholar] [CrossRef]

- Ahshan, R. Analysis of Loss Reduction Techniques for Low Voltage Distribution Network. J. Eng. Res. 2020, 17, 100–111. [Google Scholar]

- Amara, T.; Asefi, S.; Adewuyi, O.B.; Ahmadi, M.; Yona, A.; Senjyu, T. Technical and economic performance evaluation for efficient capacitors sizing and placement in a real distribution network. In Proceedings of the 2019 IEEE Student Conference on Research and Development (SCOReD), Bandar Seri Iskandar, Malaysia, 15–17 October 2019; pp. 100–105. [Google Scholar]

- Abou El-Ela, A.A.; El-Sehiemy, R.A.; Kinawy, A.M.; Mouwafi, M.T. Optimal capacitor placement in distribution systems for power loss reduction and voltage profile improvement. IET Gener. Transm. Distrib. 2016, 10, 1209–1221. [Google Scholar] [CrossRef]

- Rao, R.S.; Narasimham, S.; Ramalingaraju, M. Optimal capacitor placement in a radial distribution system using plant growth simulation algorithm. Int. J. Electr. Power Energy Syst. 2011, 33, 1133–1139. [Google Scholar] [CrossRef] [Green Version]

- Raju, M.R.; Murthy, K.R.; Ravindra, K. Direct search algorithm for capacitive compensation in radial distribution systems. Int. J. Electr. Power Energy Syst. 2012, 42, 24–30. [Google Scholar] [CrossRef]

- Reddy, V.; Sydulu, M. 2Index and GA based optimal location and sizing of distribution system capacitors. In Proceedings of the 2007 IEEE Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007; pp. 1–4. [Google Scholar]

- Tabatabaei, S.; Vahidi, B. Bacterial foraging solution based fuzzy logic decision for optimal capacitor allocation in radial distribution system. Electr. Power Syst. Res. 2011, 81, 1045–1050. [Google Scholar] [CrossRef]

- Upper, N.; Hemeida, A.M.; Ibrahim, A. Moth-flame algorithm and loss sensitivity factor for optimal allocation of shunt capacitor banks in radial distribution systems. In Proceedings of the 2017 Nineteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 19–21 December 2017; pp. 851–856. [Google Scholar]

- Jumani, T.A.; Mustafa, M.W.; Alghamdi, A.S.; Rasid, M.M.; Alamgir, A.; Awan, A.B. Swarm intelligence-based optimization techniques for dynamic response and power quality enhancement of AC microgrids: A comprehensive review. IEEE Access 2020, 8, 75986–76001. [Google Scholar] [CrossRef]

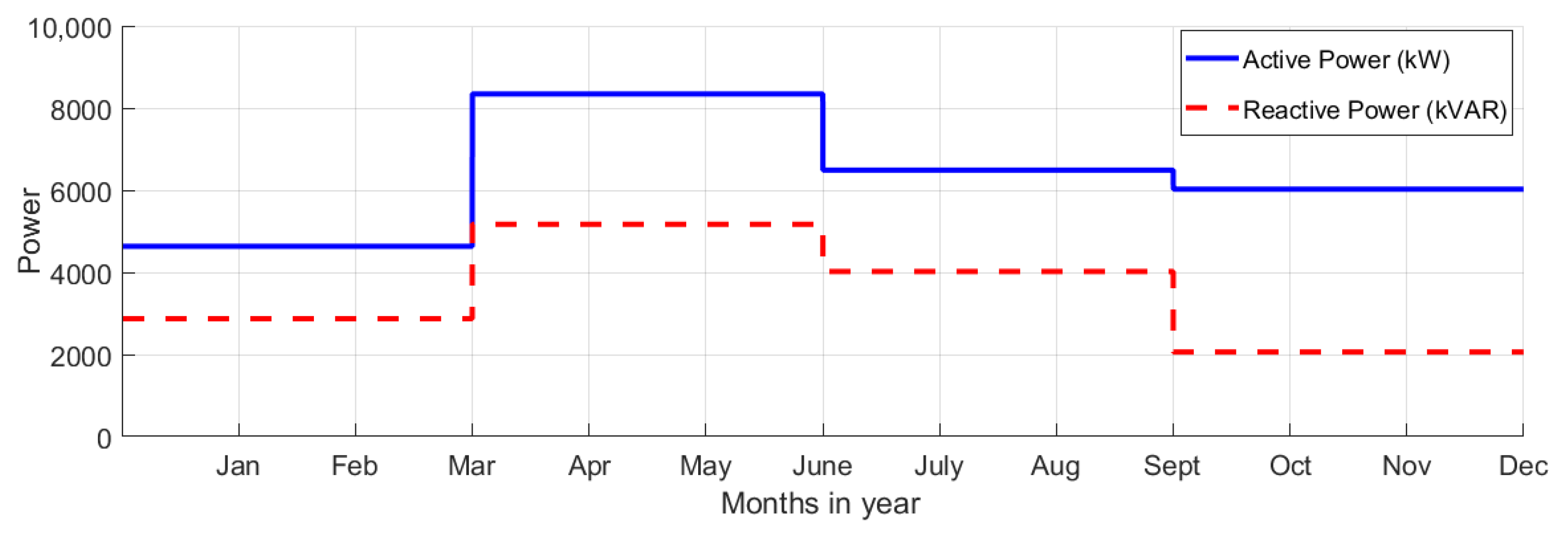

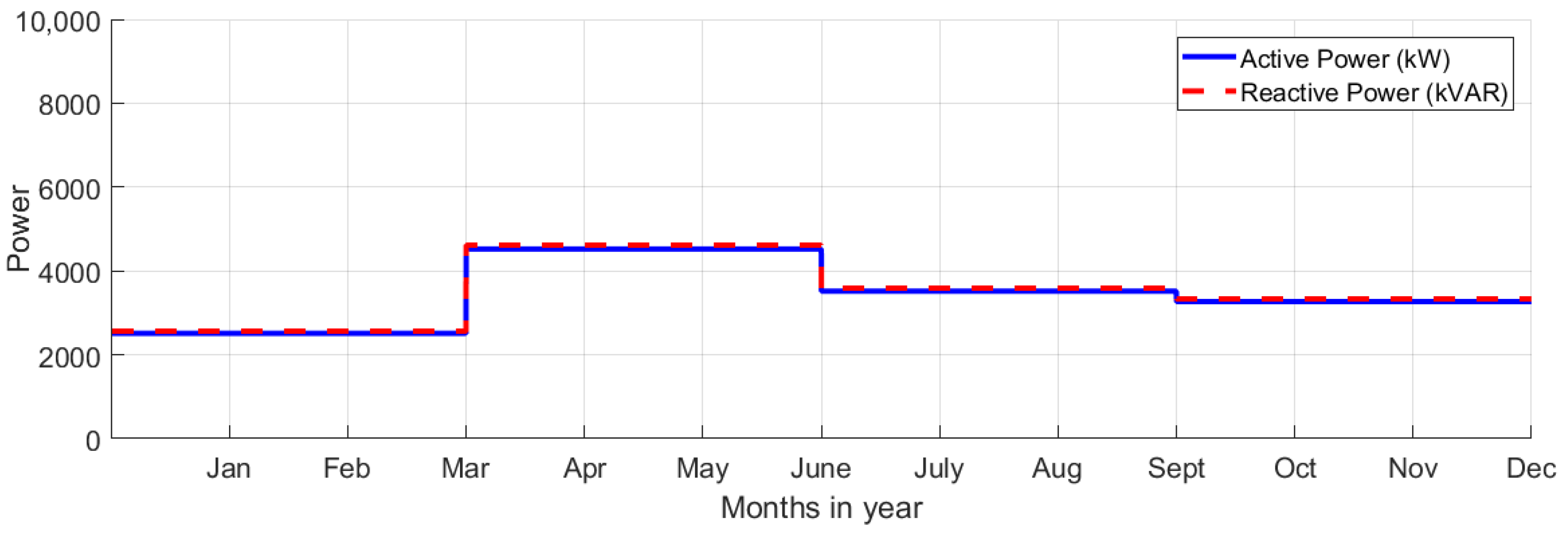

| Months | Active Load (kW) | Reactive Load (kvar) | ||

|---|---|---|---|---|

| Network | ||||

| January–March | 4636 | 2514 | 2873 | 2564 |

| April–June | 8345 | 4525 | 5172 | 4616 |

| July–September | 6491 | 3520 | 4022 | 3590 |

| October–December | 6027 | 3268 | 2061 | 3333 |

| Items | Uncom- Pensated | Compensated | ||||||

|---|---|---|---|---|---|---|---|---|

| PGSA | BFA | GA | ACO Algorithm | Proposed Algorithm | ||||

| Use Case1 | Use Case2 | Use Case1 | Use Case2 | |||||

| kvar injected at node | - | 1200 (19) 200 (20) 639 (22) | 600 (9) 900 (22) | 1629 (7) | 645 (9) 719 (22) 665 (25) | 450 (9) 450 (19) 450 (25) | 150 (19) 481 (21) 836 (24) 539 (8) | 300 (17) 300 (20) 600 (23) 600 (8) |

| Total kvar injected | - | 2039 | 1500 | 1629 | 2029 | 1950 | 2007 | 1800 |

| Active loss (kW) | 221.7 | 169.1 | 169.1 | 168.9 | 162.7 | 164.5 | 158.7 | 160.1 |

| Reactive loss (kvar) | 65.1 | - | - | - | - | - | 43.3 | 45.2 |

| Active loss reduction (%) | - | 23.7 | 23.7 | 23.8 | 26.6 | 25.8 | 28.5 | 27.9 |

| Reactive loss reduction (%) | - | - | - | - | - | - | 33.4 | 30.5 |

| at node | 0.94 (27) | 0.95 (27) | 0.94 (27) | 0.95 (27) | 0.95 (27) | 0.95 (27) | 0.95 (27) | 0.95 (27) |

| at node | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) |

| Annual cost USD ($)/year | 37,241 | 28,420 | 28,404 | 28,384 | 27,330 | 27,637 | 26,655 | 26,894 |

| Capacitor cost UD ($)/year | - | 1019.5 | 750 | 814.5 | 1014 | 975 | 1003.5 | 900 |

| Net saving USD ($)/year | - | 8821 | 8837 | 8857 | 9911 | 9604 | 10586 | 10,347 |

| Items | Uncom- Pensated | Compensated | ||||||

|---|---|---|---|---|---|---|---|---|

| PGSA | DSA | GA | ACO Algorithm | Proposed Algorithm | ||||

| Use Case1 | Use Case2 | Use Case1 | Use Case2 | |||||

| kvar injected at node | - | 200 (7) 1200 (8) 908 (58) | 150 (6) 150 (8) 150 (14) 150 (17) 150 (18) 150 (20) 150 (26) 150 (30) 450 (37) 150 (57) 150 (61) 150 (66) 300 (69) 150 (80) | 48.4 (26) 214 (28) 103.1 (37) 120.3 (38) 178 (39) 100 (51) 212.5 (54) 101.5 (55) 4.6 (59) 157 (60) 112.5 (61) 104 (62) 9.3 (66) 100 (69) 67 (72) 112.5 (74) 71.9 (76) 356.2 (80) 31.2 (82) | 186 (4) 150 (7) 210 (9) 10 (13) 280 (18) 320 (26) 250 (31) 205 (35) 200 (53) 220 (61) 330 (68) 196 (80) | 150 (7) 300 (8) 300 (19) 300 (27) 300 (32) 300 (48) 300 (61) 300 (68) 300 (80) | 150(27) 150 (29) 203.5 (30) 439.4 (64) 295 (51) 150 (50) 150 (67) 150 (19) 161 (46) 286 (80) | 300(25) 150 (48) 600 (51) 150 (64) 300 (18) 150 (68) 300 (12) 150 (61) 150 (44) |

| Total kvar injected | - | 2308 | 2550 | 2207 | 2726 | 2550 | 2134.9 | 2250 |

| Active loss (kW) | 319 | 174.9 | 144.0 | 146 | 143.3 | 143.9 | 140.9 | 145.2 |

| Reactive loss (kvar) | 182 | - | - | - | - | - | 80.7 | 82.6 |

| Active loss reduction (%) | - | 44 | 54.4 | 53.7 | 54.6 | 54.4 | 55.8 | 54.5 |

| Reactive loss reduction (%) | - | - | - | - | - | - | 55.7 | 54.6 |

| at node | 0.85 (76) | 0.90 (54) | 0.92 (54) | 0.92 (55) | 0.92 (54) | 0.92 (27) | 0.91 (76) | 0.91 (76) |

| at node | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) |

| Annual cost USD ($)/year | 53,619 | 29,385 | 24,194 | 24,538 | 24,082 | 24,171 | 23,670 | 24,394 |

| Capacitor cost USD ($)/year | - | 1154 | 1275 | 1103 | 1363 | 1275 | 1067.4 | 1125 |

| Net saving USD ($)/year | - | 24,234 | 29,425 | 29,081 | 29,537 | 29,448 | 29,949 | 29,225 |

| Months | Uncompensated | |||

|---|---|---|---|---|

| January–March | April–June | July–September | October–December | |

| Active loss (kW) | 221.7 | 782.1 | 674 | 523.5 |

| Reactive loss (kvar) | 65.1 | 229.3 | 198 | 153 |

| Total cost (USD ($)/year) | 37,241 | 131,394 | 113,372 | 87,991 |

| at node | 0.94 (27) | 0.89 (27) | 0.88 (27) | 0.90 (27) |

| at node | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) |

| Months | Uncompensated | |||

|---|---|---|---|---|

| January–March | April–June | July–September | October–December | |

| Total active loss (kW) | 319.2 | 1436.9 | 717.6 | 595.7 |

| Reactive loss (kvar) | 182.1 | 810.9 | 407.7 | 338.9 |

| Total cost (USD ($)/year) | 53,619.6 | 241,406.4 | 120,556.7 | 100,082.8 |

| at node | 0.85 (76) | 0.67 (76) | 0.77 (76) | 0.79 (76) |

| at node | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) |

| Months | Compensated | |||||||

|---|---|---|---|---|---|---|---|---|

| January–March | April–June (1.8) | July–September (1.4) | October–December (1.3) | |||||

| Use Cases | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 |

| kvar injected at node | 150 (19) 481 (21) 836 (24) 539 (8) | 300 (17) 300 (20) 600 (23) 600 (8) | 150 (19) 481 (21) 836 (24) 539 (8) | 300 (17) 300 (20) 600 (23) 600 (8) | 150 (19) 481 (21) 836 (24) 539 (8) | 300 (17) 300 (20) 600 (23) 600 (8) | 150 (19) 481 (21) 836 (24) 539 (8) | 300 (17) 300 (20) 600 (23) 600 (8) |

| Total kvar injected | 2007 | 1800 | 2007 | 1800 | 2007 | 1800 | 2007 | 1800 |

| Active loss (kW) | 158 | 160 | 719 | 722 | 611 | 613 | 460 | 462 |

| Reactive loss (kvar) | 43.3 | 45.2 | 207 | 209 | 176 | 78 | 131 | 133 |

| Active loss reduction (%) | 28.5 | 27.9 | 8 | 7.7 | 9.5 | 9 | 13 | 11.7 |

| Reactive loss reduction (%) | 33.4 | 30.5 | 9.7 | 8.7 | 11 | 10 | 14 | 13 |

| at node | 0.95 (27) | 0.95 (27) | 0.79 (27) | 0.77 (27) | 0.80 (27) | 0.80 (27) | 0.86 (27) | 0.82 (27) |

| at node | 0.99 (2) | 0.99 (2) | 0.90 (2) | 0.90 (2) | 0.93 (2) | 0.92 (2) | 0.94 (2) | 0.94 (2) |

| Annual cost (USD ($)/year) | 26,655 | 26,894 | 120,883 | 121,277 | 102,602 | 103,169 | 76,553 | 77,697 |

| Capacitor cost (USD ($)/year) | 1003 | 900 | 1003 | 900 | 1003 | 900 | 1003 | 900 |

| Net saving (USD ($)/year) | 10,586 | 10,347 | 10,511 | 10,117 | 10,777 | 10,203 | 11,438 | 10,294 |

| Months | Compensated | |||||||

|---|---|---|---|---|---|---|---|---|

| January–March | April–June (1.8) | July–September (1.4) | October–December (1.3) | |||||

| Use Cases | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 |

| kvar injected at node | 150 (19) 481 (21) 836 (24) 539 (8) | 300 (17) 300 (20) 600 (23) 600 (8) | 160 (19) 1134 (21) 1200 (24) 853 (8) | 600 (17) 600 (20) 600 (23) 600 (8) | 426 (19) 475 (21) 722 (24) 723 (8) | 450 (17) 450 (20) 600 (23) 600 (8) | 445 (19) 353 (21) 602 (24) 589 (8) | 450 (17) 600 (20) 300 (23) 450 (8) |

| Total kvar injected | 2007 | 1800 | 3347 | 2400 | 2350.9 | 2100 | 1990 | 1800 |

| Active loss (kW) | 158 | 160 | 555 | 557 | 479 | 497 | 370 | 375 |

| Reactive loss (kvar) | 43.3 | 45.2 | 156.5 | 162.8 | 140.3 | 143 | 105 | 109 |

| Active loss reduction (%) | 28.5 | 27.9 | 28.9 | 28.7 | 28.9 | 26.2 | 29.2 | 28.2 |

| Reactive loss reduction (%) | 33.4 | 30.5 | 31.7 | 28.9 | 29.1 | 27.4 | 31.6 | 28.7 |

| at node | 0.95 (27) | 0.95 (27) | 0.91 (27) | 0.90 (27) | 0.90 (27) | 0.89 (27) | 0.91 (27) | 0.90 (27) |

| at node | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) |

| Annual cost (USD ($)/year) | 26,655 | 26,894 | 93,292 | 93,613 | 80,505 | 83,624 | 62,252 | 63,111 |

| Capacitor cost (USD ($)/year) | 1003 | 900 | 1673 | 1200 | 1175 | 1050 | 995 | 900 |

| Net saving (USD ($)/year) | 10,586 | 10,347 | 38,101 | 37,781 | 32,866 | 29,748 | 25,740 | 24,880 |

| Months | Compensated | |||||||

|---|---|---|---|---|---|---|---|---|

| January–March | April–June (1.8) | July–September (1.4) | October–December (1.3) | |||||

| Use Cases | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 |

| kvar injected at node | 150 (27) 150 (29) 203 (30) 439 (64) 295 (51) 150 (50) 150 (67) 150 (19) 161 (46) 286 (80) | 300 (25) 150 (48) 600 (51) 150 (64) 300 (18) 150 (68) 300 (12) 150 (61) 150 (44) | 150 (27) 150 (29) 203 (30) 439 (64) 295 (51) 150 (50) 150 (67) 150 (19) 161 (46) 286 (80) | 300 (25) 150 (48) 600 (51) 150 (64) 300 (18) 150 (68) 300 (12) 150 (61) 150 (44) | 150 (27) 150 (29) 203 (30) 439 (64) 295 (51) 150 (50) 150 (67) 150 (19) 161 (46) 286 (80) | 300 (25) 150 (48) 600 (51) 150 (64) 300 (18) 150 (68) 300 (12) 150 (61) 150 (44) | 150 (27) 150 (29) 203 (30) 439 (64) 295 (51) 150 (50) 150 (67) 150 (19) 161 (46) 286 (80) | 300 (25) 150 (48) 600 (51) 150 (64) 300 (18) 150 (68) 300 (12) 150 (61) 150 (44) |

| Total kvar injected | 2134 | 2250 | 2134 | 2250 | 2134 | 2250 | 2134 | 2250 |

| Active loss (kW) | 140.9 | 145.2 | 1257 | 1262 | 3341 | 3346 | 3089 | 3094 |

| Reactive loss (kvar) | 80.7 | 82.6 | 708 | 710 | 3488 | 3490 | 3231 | 3233 |

| Active loss reduction (%) | 55.8 | 54.5 | 12 | 12 | 24.9 | 24.5 | 30 | 29 |

| Reactive loss reduction (%) | 55.7 | 54.6 | 12.5 | 12.3 | 25 | 24.7 | 30 | 29 |

| at node | 0.91 (76) | 0.90 (76) | 0.79 (76) | 0.68 (76) | 0.70 (76) | 0.70 (76) | 0.70 (76) | 0.73 (76) |

| at node | 0.99 (2) | 0.99 (2) | 0.89 (2) | 0.89 (2) | 0.87 (2) | 0.83 (2) | 0.88 (2) | 0.87 (2) |

| Annual cost (USD ($)/year) | 23,670 | 24,394 | 212,438 | 212,438 | 90,538 | 91,120 | 70,058 | 71,059 |

| Capacitor cost (USD ($)/year) | 1067 | 1125 | 1067 | 1125 | 1067 | 1125 | 1067 | 1125 |

| Net saving (USD ($)/year) | 29,950 | 29,225 | 28,968 | 28,968 | 30,018 | 29,436 | 30,024 | 29,023 |

| Months | Compensated | |||||||

|---|---|---|---|---|---|---|---|---|

| Jan-March | April–June (1.8) | July–September (1.4) | October–December (1.3) | |||||

| Use Cases | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 | Use Case 1 | Use Case 2 |

| kvar injected at node | 150 (27) 150 (29) 203 (30) 439 (64) 295 (51) 150 (50) 150 (67) 150 (19) 161 (46) 286 (80) | 300(25) 150 (48) 600 (51) 150 (64) 300 (18) 150 (68) 300 (12) 150 (61) 150 (44) | 300 (27) 150 (29) 1200 (30) 446 (64) 330 (51) 179 (50) 465 (67) 150 (19) 287 (46) 270 (80) 1046 (35) 150 (45) 1200 (68) 482 (10) 150 (17) 740 (9) | 600 (25) 300 (48) 600 (51) 300 (64) 600 (18) 600 (68) 600 (12) 600 (61) 600 (44) 150 (50) 150 (67) 150 (19) 600 (80) 150 (2) | 150 (27) 205 (29) 212 (30) 511 (64) 299 (51) 150 (50) 150 (67) 150 (19) 372 (46 363 (80) 875 (35) 150 (45) 1168 (68) 190 (60) 150 (17) | 600 (25) 150 (48) 600 (51) 600 (64) 450 (18) 150 (68) 600 (12) 600 (61) 150 (44) 150 (50) 600 (80) | 150 (27) 556 (29) 366 (30) 632 (64) 401 (51) 210 (50) 150 (19) 906 (80) 297 (57) | 150 (25) 300 (48) 600 (51) 150 (64) 150 (18) 150 (68) 300 (12) 600 (61) 150 (44) 150 (50) 150 (61) |

| Total kvar injected | 2134 | 2250 | 7545 | 6000 | 5096 | 4650 | 3668 | 2850 |

| Active loss (kW) | 140 | 145 | 993 | 1119 | 387 | 410 | 273 | 289 |

| Reactive loss (kvar) | 80 | 82 | 584 | 679 | 223 | 237 | 159 | 164 |

| Active loss reduction (%) | 55.8 | 55.5 | 30.8 | 22.1 | 46 | 42 | 54 | 51 |

| Reactive loss reduction (%) | 55.7 | 54.6 | 28.0 | 22.1 | 45 | 41 | 52 | 51 |

| at node | 0.91 (76) | 0.90 (76) | 0.91 (76) | 0.90 (76) | 0.90 (76) | 0.90 (76) | 0.90 (76) | 0.90 (76) |

| at node | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) | 0.99 (2) |

| Annual cost (USD ($)/year) | 23,670 | 24,394 | 166,960 | 188,020 | 65,037 | 69,015 | 45,862 | 48,627 |

| Capacitor cost (USD ($)/year) | 1067 | 1125 | 3772.5 | 3000 | 2548 | 2325 | 1834 | 1425 |

| Net saving (USD ($)/year) | 29,950 | 29,225 | 74,446 | 53,383 | 55,519 | 51,541 | 54,220 | 51,455 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilal, M.; Shahzad, M.; Arif, M.; Ullah, B.; Hisham, S.B.; Ali, S.S.A. Annual Cost and Loss Minimization in a Radial Distribution Network by Capacitor Allocation Using PSO. Appl. Sci. 2021, 11, 11840. https://doi.org/10.3390/app112411840

Bilal M, Shahzad M, Arif M, Ullah B, Hisham SB, Ali SSA. Annual Cost and Loss Minimization in a Radial Distribution Network by Capacitor Allocation Using PSO. Applied Sciences. 2021; 11(24):11840. https://doi.org/10.3390/app112411840

Chicago/Turabian StyleBilal, Muhammad, Mohsin Shahzad, Muhammad Arif, Barkat Ullah, Suhaila Badarol Hisham, and Syed Saad Azhar Ali. 2021. "Annual Cost and Loss Minimization in a Radial Distribution Network by Capacitor Allocation Using PSO" Applied Sciences 11, no. 24: 11840. https://doi.org/10.3390/app112411840

APA StyleBilal, M., Shahzad, M., Arif, M., Ullah, B., Hisham, S. B., & Ali, S. S. A. (2021). Annual Cost and Loss Minimization in a Radial Distribution Network by Capacitor Allocation Using PSO. Applied Sciences, 11(24), 11840. https://doi.org/10.3390/app112411840