Response-Only Parametric Estimation of Structural Systems Using a Modified Stochastic Subspace Identification Technique

Abstract

:1. Introduction

2. Stochastic Subspace Identification Method

3. Numerical Simulations and Experimental Verification

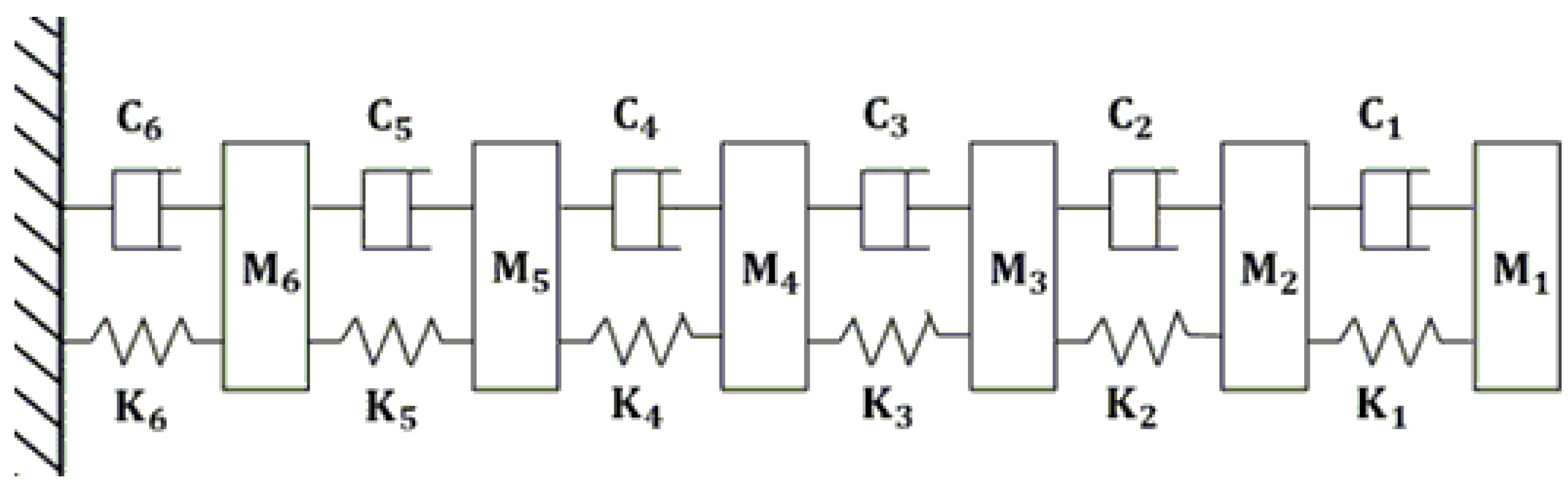

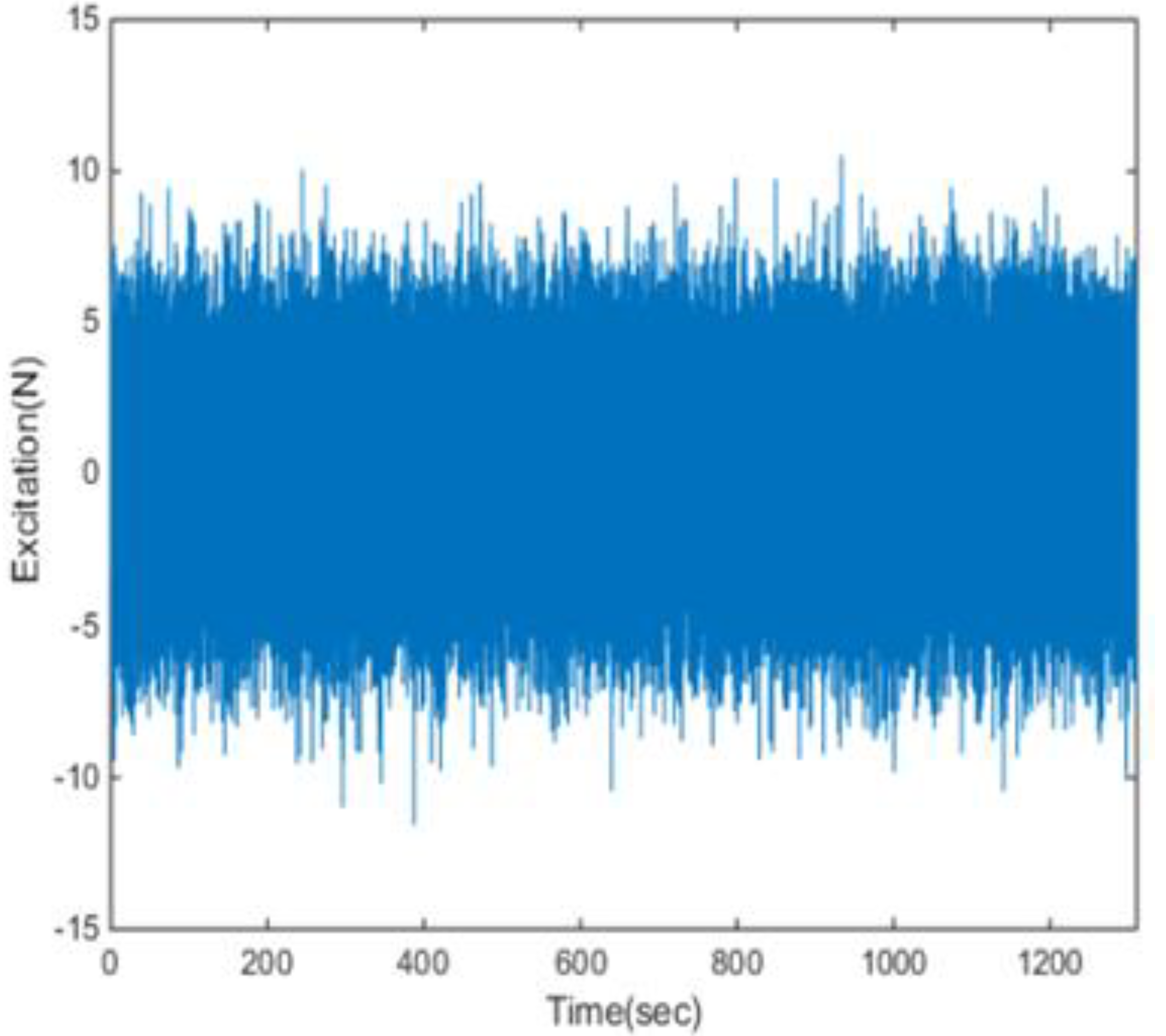

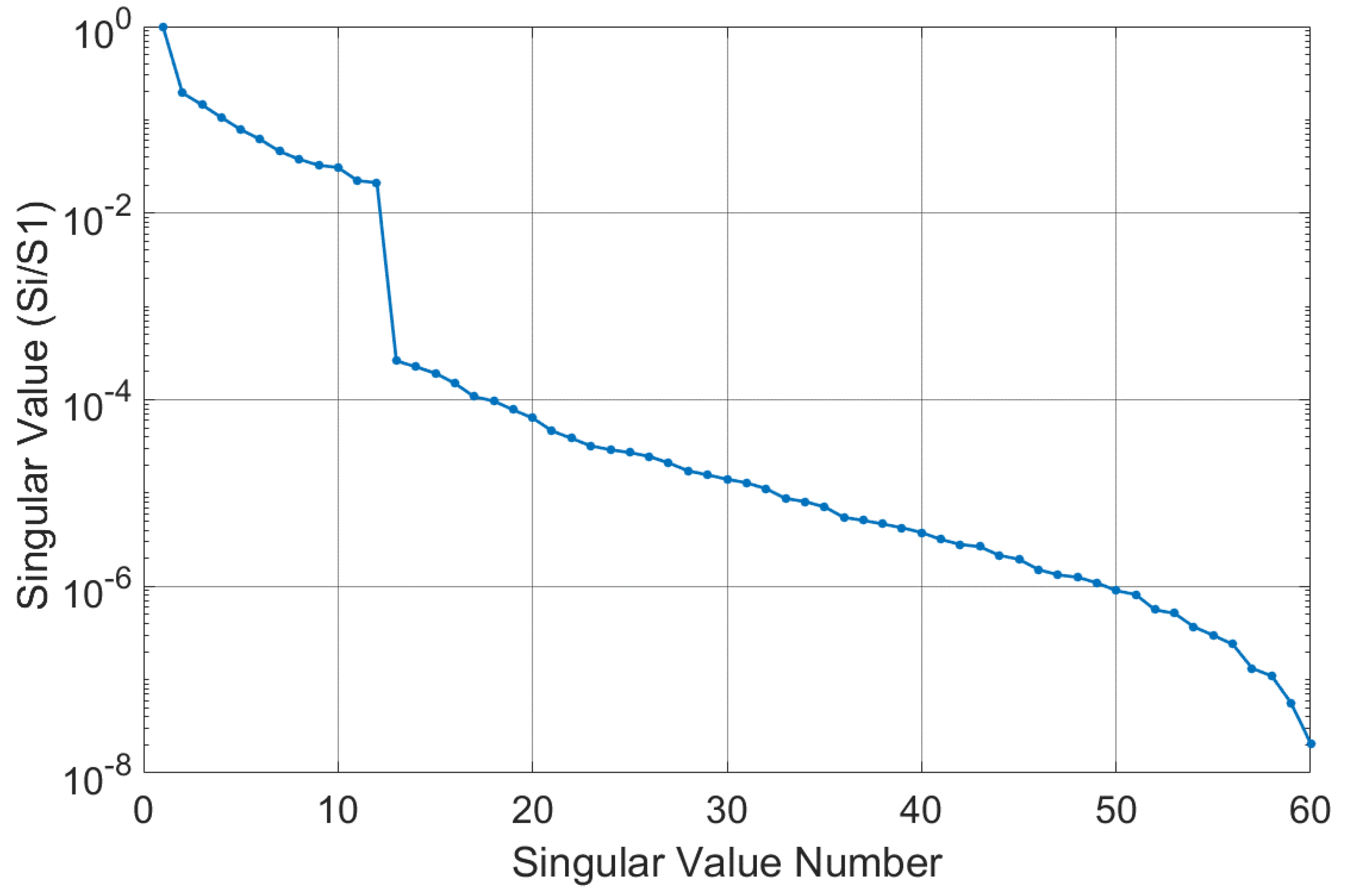

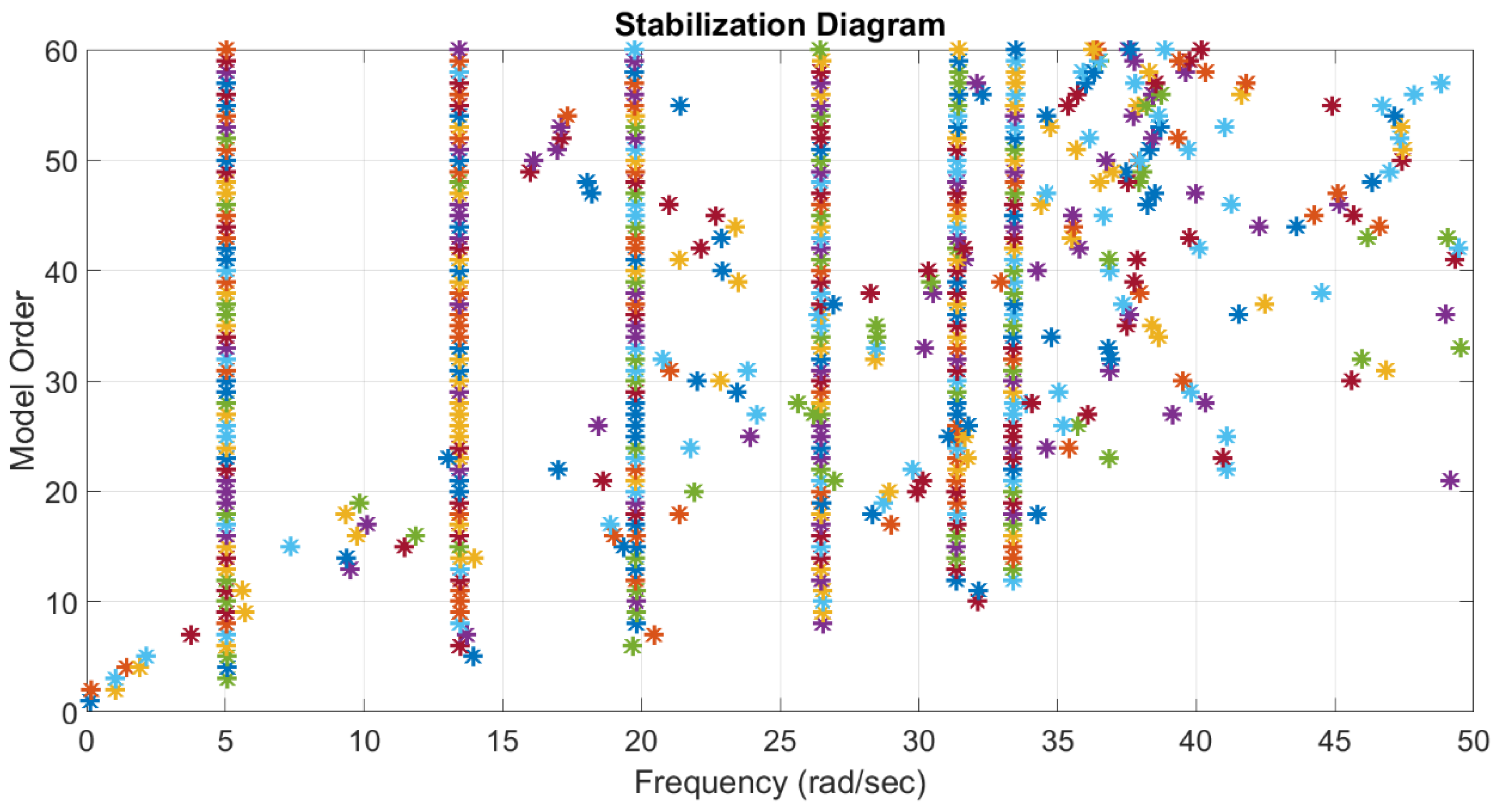

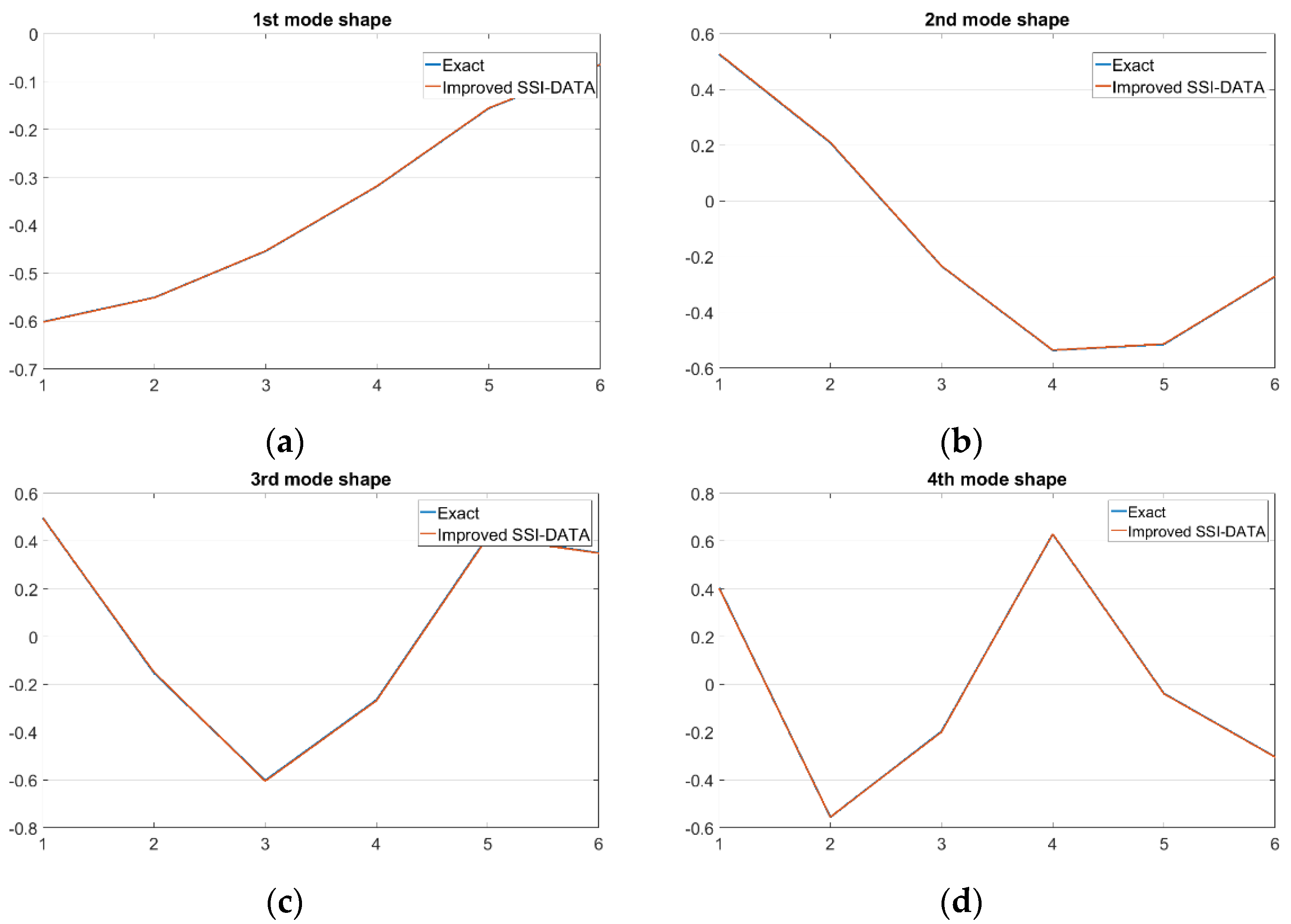

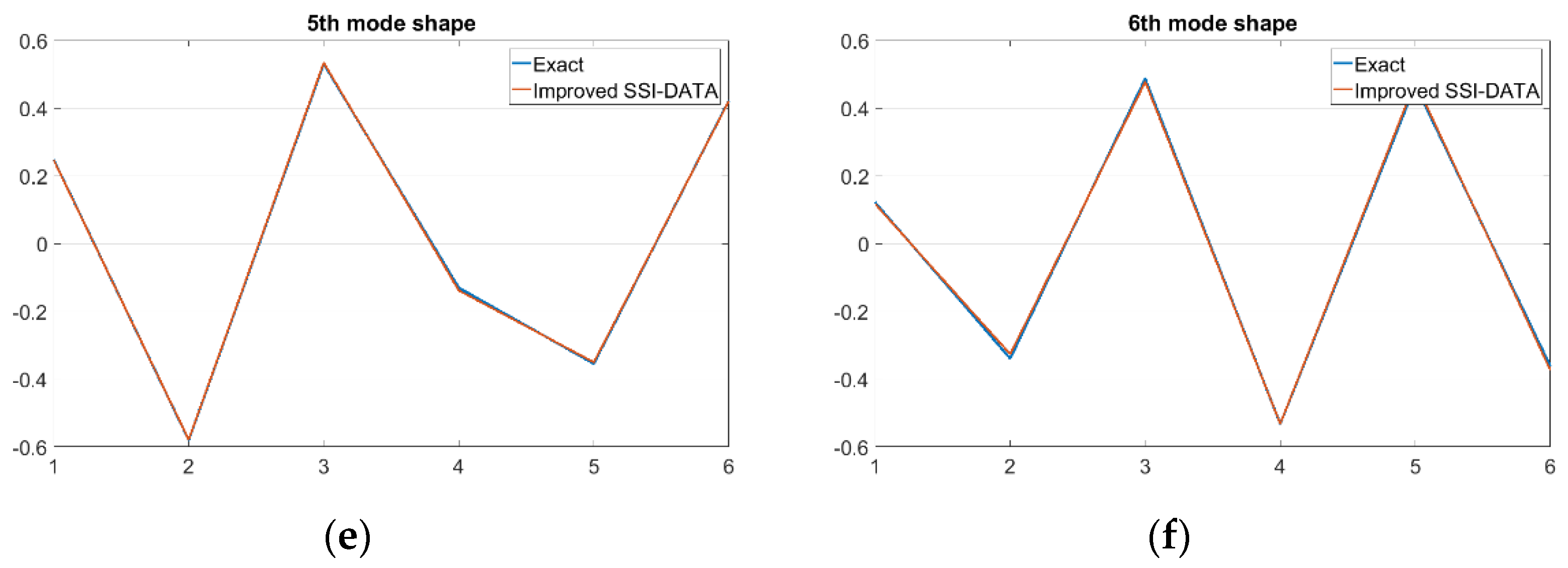

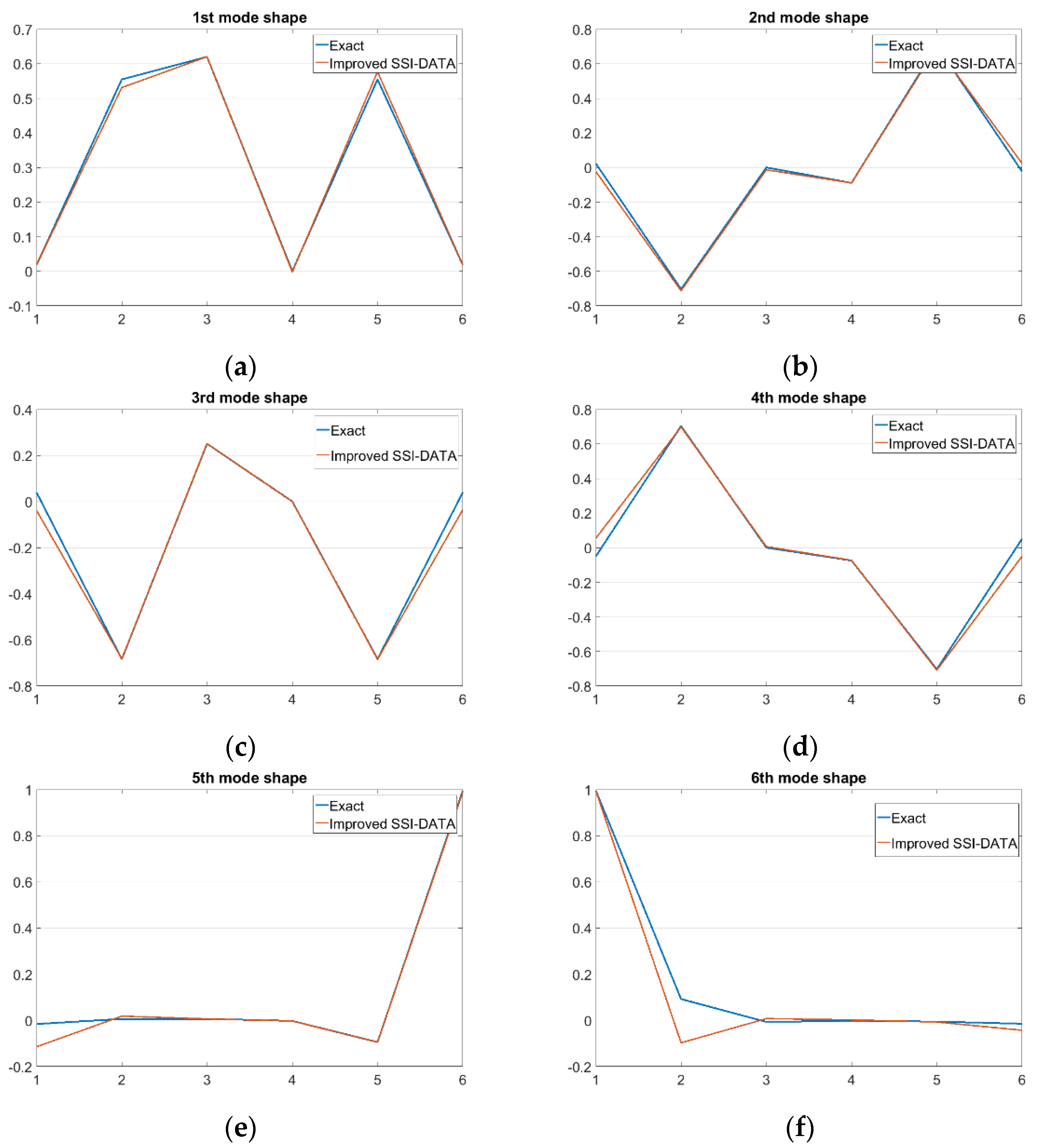

3.1. Six DOF Chain Model of a Cantilever Beam

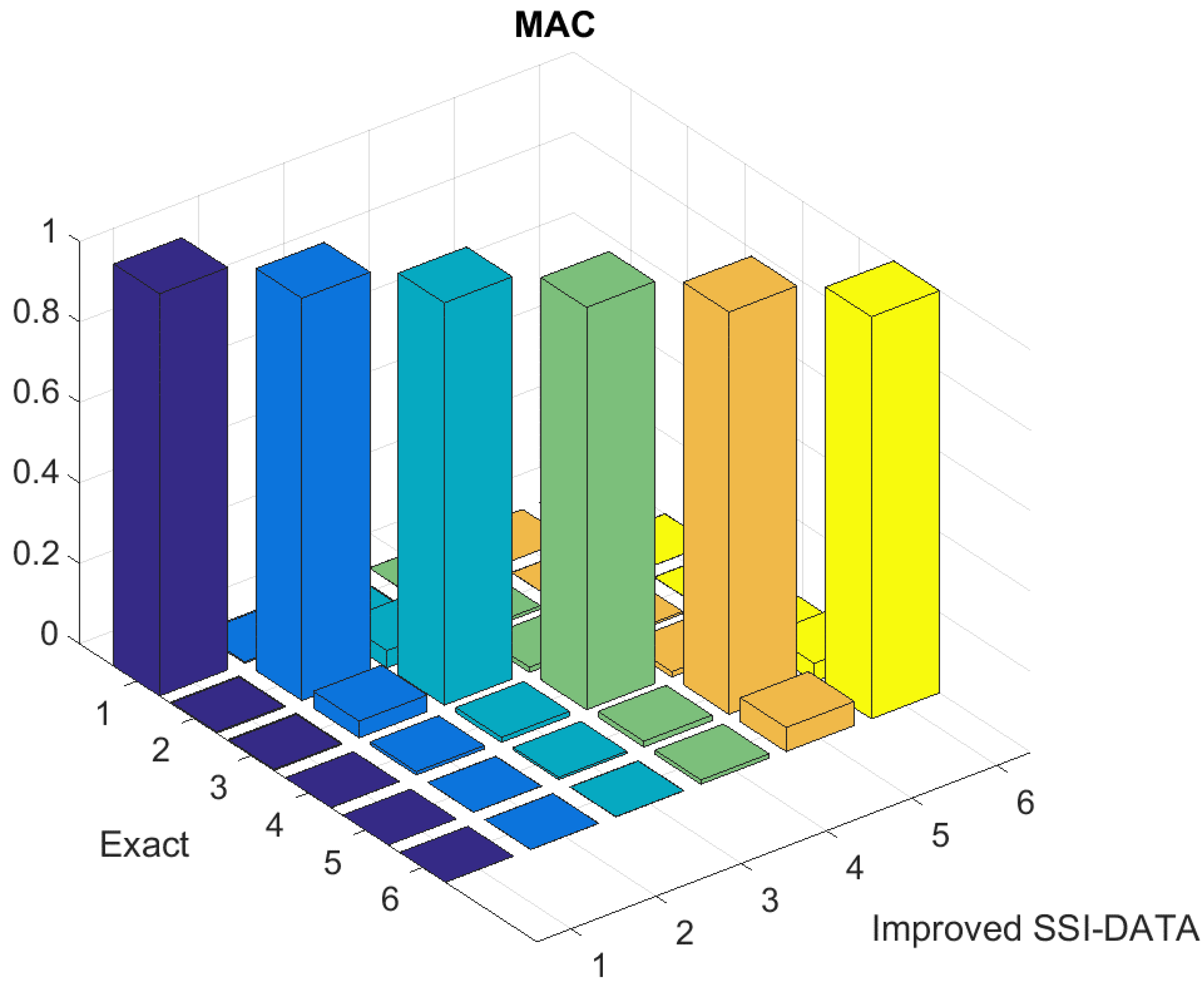

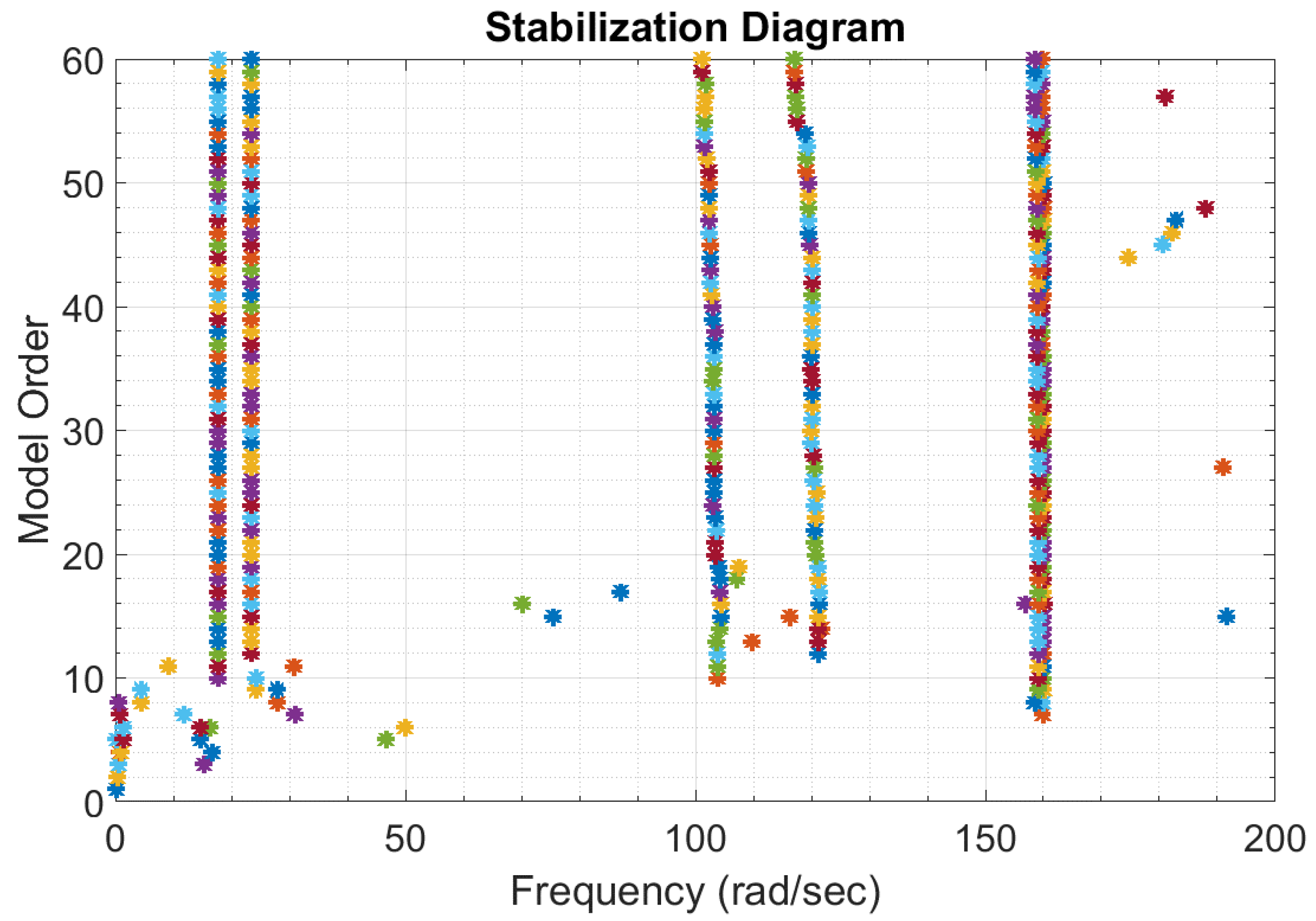

3.2. Six DOF Railway Vehicle Model with Modal Interference

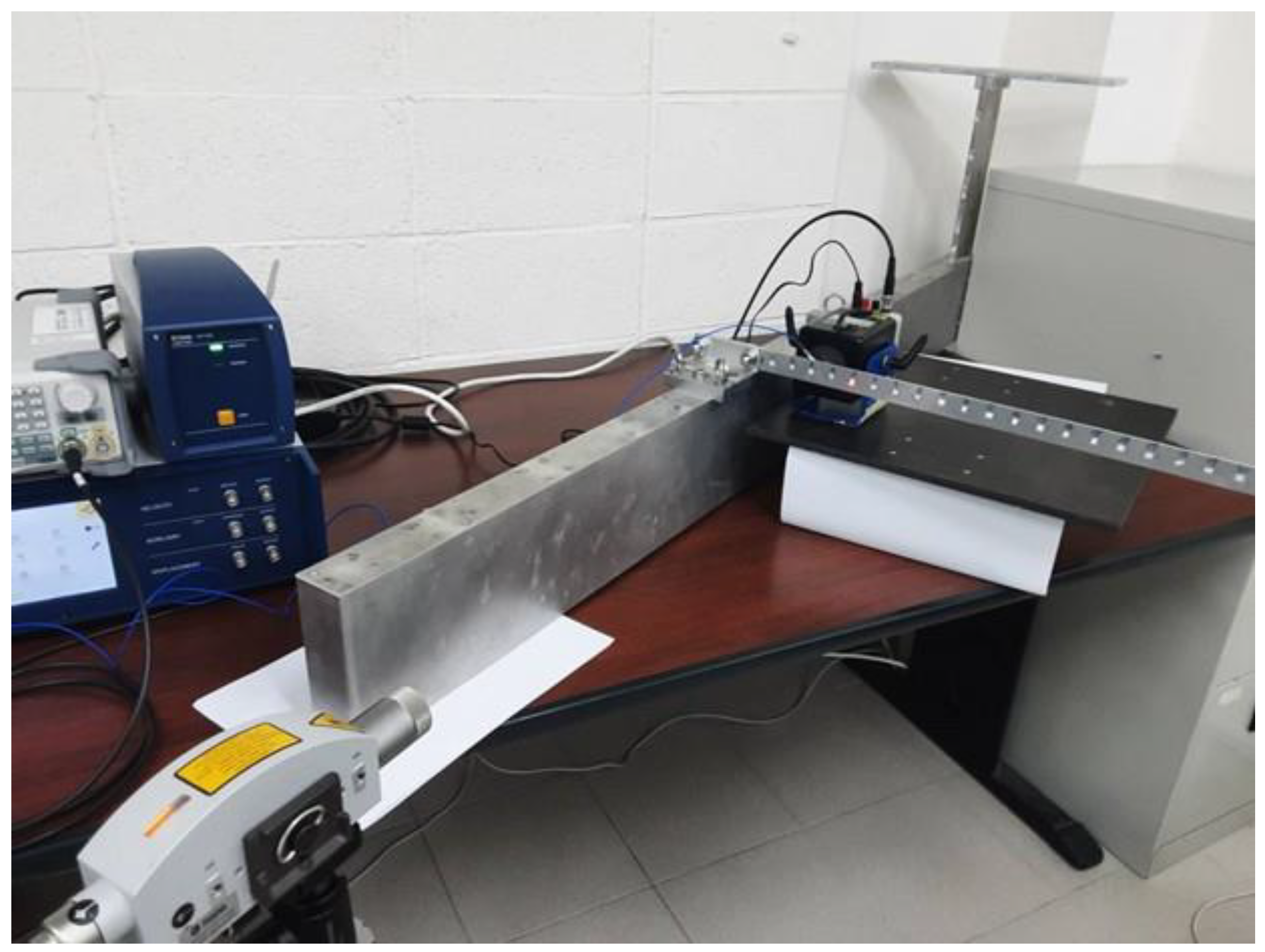

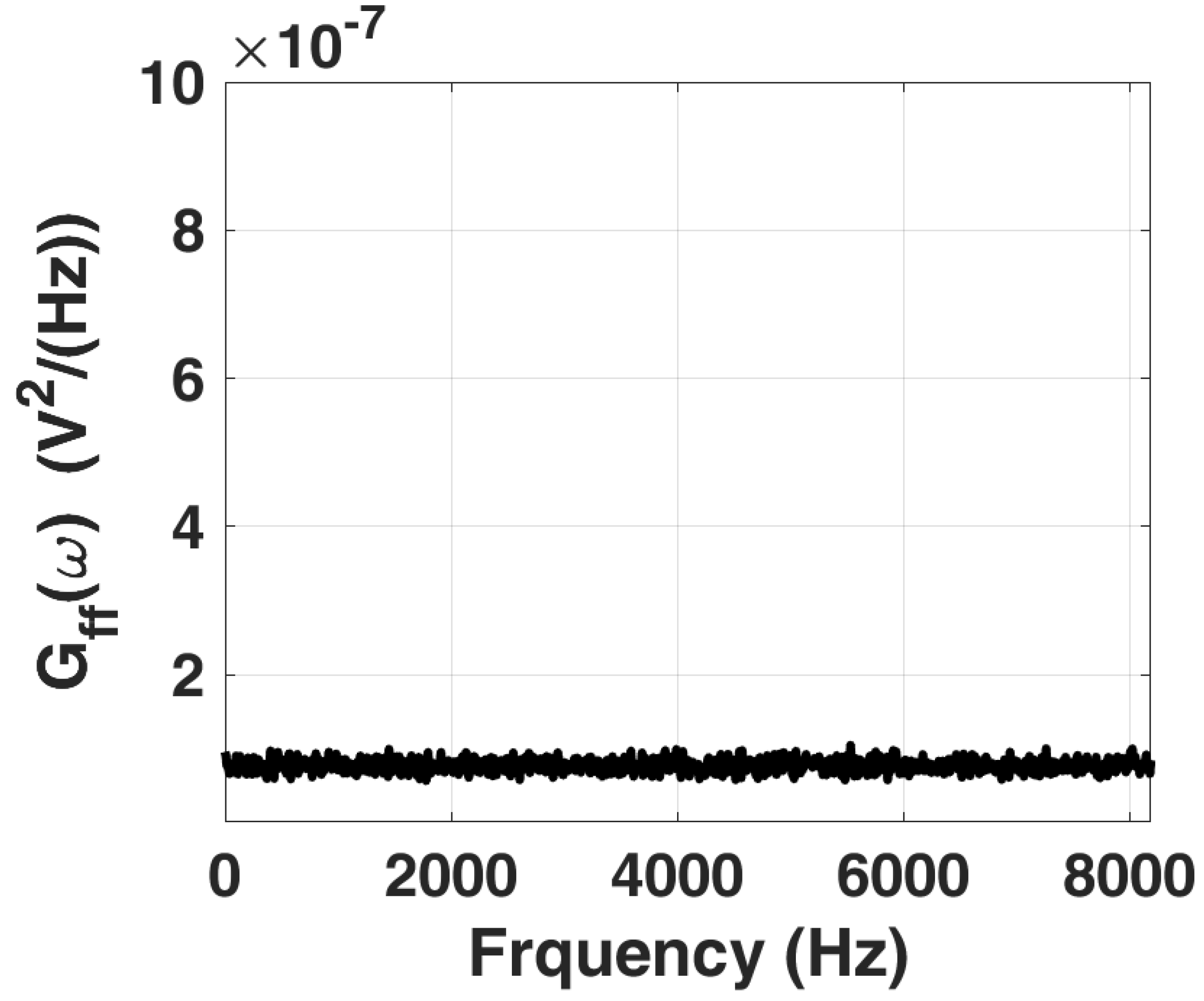

3.3. Experimental Validation of a Cantilever Beam

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martini, A.; Troncossi, M.; Vincenzi, N. Structural and elastodynamic analysis of rotary transfer machines by Finite Element model. J. Serb. Soc. Comput. Mech. 2017, 11, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Manzato, S.; Peeters, B. Wind turbine model validation by full-scale vibration test. In Proceedings of the European Wind Energy Conference (EWEC) 2010, Warsaw, Poland, 20–23 April 2010. [Google Scholar]

- Zivanovic, S.; Pavic, A.; Reynolds, P. Modal Testing and FE Model Tuning of a Lively Footbridge Structure. Eng. Struct. 2006, 28, 857–868. [Google Scholar] [CrossRef] [Green Version]

- Ren, W.X.; Peng, X.L.; Lin, Y.Q. Experimental and Analytical Studies on Dynamic Characteristics of a large Span Cables-stayed Bridge. Eng. Struct. 2005, 27, 535–548. [Google Scholar] [CrossRef]

- Orlowitz, E.; Brandt, A. Comparison of experimental and operational modal analysis on a laboratory test plate. Measurement 2007, 102, 121–130. [Google Scholar] [CrossRef]

- Moaveni, B.; Masoumi, Z. Modifying the ERA and fast ERA to improve operational performance for structural system identification. Mech. Syst. Signal Process. 2019, 120, 664–692. [Google Scholar] [CrossRef]

- Brincker, R.; Kirkegaard, P.H. Special issue on Operational Modal Analysis. Mech. Syst. Signal Process. 2010, 24, 1209–1212. [Google Scholar] [CrossRef]

- Reynders, E.; Houbrechts, J.; De Roeck, G. Fully automated (operational) modal analysis. Mech. Syst. Signal Process. 2012, 29, 228–250. [Google Scholar] [CrossRef]

- Yi, W.J.; Zhou, Y.; Kunnath, S.; Xu, B. Identification of localized frame parameters using higher natural modes. Eng. Struct. 2008, 30, 3082–3094. [Google Scholar] [CrossRef]

- Soria, L.; Peeters, B.; Anthonis, J. Operational modal analysis and the performance assessment of vehicle suspension systems. Shock. Vib. 2012, 19, 1099–1113. [Google Scholar] [CrossRef]

- Shirzadeh, R.; Devriendt, C.; Bidakhvidi, M.A.; Guillaume, P. Experimental and computational damping estimation of an offshore wind turbine on a monopile foundation. J. Wind. Eng. Ind. Aerodyn. 2013, 120, 96–106. [Google Scholar] [CrossRef]

- Peeters, B.; Van der Auweraer, H.; Vanhollebeke, F.; Guillaume, P. Operational modal analysis for estimating the dynamic properties of a stadium structure during a football game. Shock. Vib. 2007, 14, 283–303. [Google Scholar] [CrossRef]

- James, G.H.; Carne, T.G.; Lauffer, J.P. The Natural Excitation Technique for Modal Parameter Extraction from Operating Wind Turbines; SAND92-1666.UC-261; Sandia National Laboratories: Albuquerque, NM, USA, 1993.

- Chiang, D.-Y.; Lin, C.-S. Identification of Modal Parameters from Nonstationary Ambient Vibration Data Using Correlation Technique. AIAA J. 2008, 46, 2752–2759. [Google Scholar] [CrossRef]

- Lin, C.-S.; Chiang, D.-Y. Modal identification from nonstationary ambient response data using extended random decrement algorithm. Comput. Struct. 2013, 119, 104–114. [Google Scholar] [CrossRef]

- Chiang, D.-Y.; Lin, C.-S. Identification of modal parameters from ambient vibration data using eigensystem realization algorithm with correlation technique. J. Mech. Sci. Technol. 2010, 24, 2377–2382. [Google Scholar] [CrossRef]

- Liu, F.; Wu, J.; Gu, F.; Ball, A.D. An Introduction of a Robust OMA Method: CoS-SSI and Its Performance Evaluation through the Simulation and a Case Study. Shock. Vib. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- Van Overschee, P.; De Moor, B. Subspace algorithms for the stochastic identification problem. Automatica 1993, 29, 649–660. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Koloor, S.S.R.; Petrů, M. Health Monitoring of Civil Infrastructures by Subspace System Identification Method: An Overview. Appl. Sci. 2020, 10, 2786. [Google Scholar] [CrossRef] [Green Version]

- Peeters, B.; De Roeck, G. Reference-based stochastic subspace identification for output-only modal analysis. Mech. Syst. Signal Process. 1999, 13, 855–878. [Google Scholar] [CrossRef] [Green Version]

- Shinozuka, M. Simulation of Multivariate and Multidimensional Random Processes. J. Acoust. Soc. Am. 1971, 49, 357–368. [Google Scholar] [CrossRef]

- Allemang, R.J. The Modal Assurance Criterion—Twenty Years of Use and Abuse. Sound Vib. 2003, 37, 14–23. [Google Scholar]

- Troncossi, M.; Taddia, S.; Rivola, A.; Martini, A. Experimental Characterization of a High-Damping Viscoelastic Material Enclosed in Carbon Fiber Reinforced Polymer Components. Appl. Sci. 2020, 10, 6193. [Google Scholar] [CrossRef]

- Troncossi, M.; Canella, G.; Vincenzi, N. Identification of polymer concrete damping properties. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, in press. [Google Scholar] [CrossRef]

- Petsounis, K.; Fassois, S. Parametric time-domain methods for the identification of vibrating structures—A critical comparison and assessment. Mech. Syst. Signal Process. 2001, 15, 1031–1060. [Google Scholar] [CrossRef]

- Hu, S.-L.J.; Yang, W.-L.; Liu, F.-S.; Li, H.-J. Fundamental comparison of time-domain experimental modal analysis methods based on high- and first-order matrix models. J. Sound Vib. 2014, 333, 6869–6884. [Google Scholar] [CrossRef]

- Campione, I.; Fragassa, C.; Martini, A. Kinematics optimization of the polishing process of large-sized ceramic slabs. Int. J. Adv. Manuf. Technol. 2019, 103, 1325–1336. [Google Scholar] [CrossRef]

- Zaghbani, I.; Songmene, V. Estimation of machine-tool dynamic parameters during machining operation through operational modal analysis. Int. J. Mach. Tools Manuf. 2009, 49, 947–957. [Google Scholar] [CrossRef]

| Sampling Points | Computation Time (s) of SVD | Matrix Multiplication Processing Time for | |

|---|---|---|---|

| 212 | 0.570 | 0.000574 | 0.0003616 |

| 213 | 2.217 | 0.000760 | 0.0005376 |

| 214 | 9.074 | 0.001219 | 0.0009967 |

| 215 | 37.197 | 0.003244 | 0.0029074 |

| 216 | Out of memory | 0.003264 | 0.0030135 |

| 217 | Out of memory | 0.006189 | 0.0059404 |

| Mode | Natural Frequency (rad/s) | Damping Ratio (%) | ||||

|---|---|---|---|---|---|---|

| Exact | MSSI | Error (%) | Exact | MSSI | Error (%) | |

| 1 | 5.03 | 5.04 | 0.09 | 1.25 | 1.38 | 10.39 |

| 2 | 13.45 | 13.39 | 0.41 | 1.04 | 1.17 | 11.73 |

| 3 | 19.80 | 19.71 | 0.41 | 1.24 | 1.23 | 0.92 |

| 4 | 26.68 | 26.56 | 0.44 | 1.52 | 1.47 | 3.59 |

| 5 | 31.65 | 31.18 | 1.48 | 1.74 | 1.79 | 2.78 |

| 6 | 33.72 | 33.46 | 0.78 | 1.84 | 1.89 | 3.18 |

| Mode | Natural Frequency (rad/s) | Damping Ratio (%) | ||||

|---|---|---|---|---|---|---|

| Exact | MSSI | Error (%) | Exact | MSSI | Error (%) | |

| 1 | 5.03 | 5.04 | 0.08 | 1.25 | 1.38 | 8.97 |

| 2 | 13.45 | 13.39 | 0.42 | 1.04 | 1.17 | 10.11 |

| 3 | 19.80 | 19.71 | 0.42 | 1.24 | 1.23 | 2.47 |

| 4 | 26.68 | 26.56 | 0.47 | 1.52 | 1.47 | 4.88 |

| 5 | 31.65 | 31.18 | 1.50 | 1.74 | 1.79 | 1.15 |

| 6 | 33.72 | 33.46 | 0.78 | 1.84 | 1.89 | 1.19 |

| Mode | Natural Frequency (Hz) | Damping Ratio (%) | ||||

|---|---|---|---|---|---|---|

| Exact | MSSI | Error (%) | Exact | MSSI | Error (%) | |

| 1 | 2.79 | 2.79 | 0.00 | 4.89 | 4.89 | 0.01 |

| 2 | 3.71 | 3.71 | 0.00 | 6.62 | 6.62 | 0.01 |

| 3 | 16.55 | 16.53 | 0.09 | 16.65 | 16.62 | 0.17 |

| 4 | 19.27 | 19.25 | 0.11 | 18.78 | 18.74 | 0.24 |

| 5 | 25.36 | 25.30 | 0.21 | 1.74 | 1.74 | 0.42 |

| 6 | 25.57 | 25.51 | 0.21 | 1.75 | 1.75 | 0.43 |

| Mode | Natural Frequency (rad/s) | Damping Ratio (%) | ||||

|---|---|---|---|---|---|---|

| Exact | MSSI | Error (%) | Exact | MSSI | Error (%) | |

| 1 | 2.79 | 2.79 | 0.00 | 4.89 | 4.89 | 0.01 |

| 2 | 3.71 | 3.71 | 0.00 | 6.62 | 6.62 | 0.01 |

| 3 | 16.55 | 16.53 | 0.09 | 16.65 | 16.62 | 0.16 |

| 4 | 19.27 | 19.25 | 0.12 | 18.78 | 18.73 | 0.27 |

| 5 | 25.36 | 25.30 | 0.21 | 1.74 | 1.74 | 0.42 |

| 6 | 25.57 | 25.51 | 0.21 | 1.75 | 1.75 | 0.42 |

| Mode | Natural Frequency (rad/s) | MAC | ||

|---|---|---|---|---|

| Exact | MSSI | Error (%) | ||

| 1 | 10.85 | 10.98 | 1.22 | 1.00 |

| 2 | 70.32 | 70.53 | 0.30 | 1.00 |

| 3 | 176.31 | 159.00 | 9.82 | 0.95 |

| 4 | 290.31 | 246.30 | 15.16 | 0.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-S.; Wu, Y.-X. Response-Only Parametric Estimation of Structural Systems Using a Modified Stochastic Subspace Identification Technique. Appl. Sci. 2021, 11, 11751. https://doi.org/10.3390/app112411751

Lin C-S, Wu Y-X. Response-Only Parametric Estimation of Structural Systems Using a Modified Stochastic Subspace Identification Technique. Applied Sciences. 2021; 11(24):11751. https://doi.org/10.3390/app112411751

Chicago/Turabian StyleLin, Chang-Sheng, and Yi-Xiu Wu. 2021. "Response-Only Parametric Estimation of Structural Systems Using a Modified Stochastic Subspace Identification Technique" Applied Sciences 11, no. 24: 11751. https://doi.org/10.3390/app112411751

APA StyleLin, C.-S., & Wu, Y.-X. (2021). Response-Only Parametric Estimation of Structural Systems Using a Modified Stochastic Subspace Identification Technique. Applied Sciences, 11(24), 11751. https://doi.org/10.3390/app112411751