Abstract

Waste valorisation as secondary or alternative raw materials in several sectors products and processes has been an important way to implement a more sustainable and circular way to manage the efficient use of natural resources. This action contributes not only to save natural resources but also to prevent sending large amounts of wastes, some of them dangerous, to landfill disposal, creating a major environmental, economic and social impact. To promote circular economy, this work attempts to demonstrate the environmental gains in a competitive way, by bringing together in an industrial symbiosis action, two large producing sectors (the pulp and paper industry and concrete construction sector), which are also able to consume significant amounts of resources and to generate large amounts of wastes. A sustainability evaluation based on a life cycle and circular approach is presented and discussed using a simple case study performed at real industrial scale. The lime ash waste from the pulp and paper industry is used to replace 100% of the natural filler used in precast concrete production and the impacts and benefits from the technical, environmental, economic and social level were assessed. It was demonstrated that this simple action causes positive impacts in the evaluated dimensions of sustainability without causing any changes in production time and causes no degradation on relevant concrete properties.

1. Introduction

The linear production model has accentuated the problem of resource scarcity, greenhouse gases emission and waste generation [1]. Hence, the need emerged for a circular economy model, where waste is reintroduced as a new alternative resource in production processes [1,2].

The construction related sectors are also responsible for the social and economic development of society; however, this growth has been at the expense of high environmental impacts, due to the use of large amounts of natural resources, namely energy, water, soil, raw materials and other materials [3,4,5]. To achieve a higher level of sustainability and to increase the sector’s contribution to a circular economy, these sectors have sought, among other solutions, new raw materials and efficient ways to process them to combat the depletion of natural resources. A possible strategy is to incorporate wastes or by-products from the sector itself or from other industries but keeping the same technical performance as the traditionally used natural raw materials [6,7,8].

Concrete based products are widely used in the world as construction materials. This particular sector needs large amounts of resources (aggregates, binder, water and additives), which have to be sustainably obtained [8,9]. One must prevent soil erosion and ecosystem destruction resulting from large-scale extraction of natural raw materials such as the case of its major component (aggregates). In addition, the production of the traditionally used binder (cement) has been associated with high environmental impacts, due to the need for large amounts of energy to be spent in the manufacturing of clinker [8,10].

In addition to the construction sectors, there are other industrial sectors such as the pulp and paper sector that also consume large amounts of raw materials, including wood and various chemical products, or other resources such as water and energy. A substantial volume of solid wastes is also generated in the pulp and paper industry, including lime mud or lime ash, lime slaker grits, green liquor dregs, boiler ash, fly ash, primary and secondary sludges, which are mostly disposed in landfills [11,12,13,14,15,16]. The European pulp and paper industry produces around 38 Mton of air-dried pulp, representing approximately a quarter of the value of world pulp production [13]. Quina et al. [13] indicates an average production value of this lime waste of about 15 kg of lime ash per ton of air-dried pulp. Considering these production values, the pulp and paper industry thus generates a significant annual amount of this waste.

Lime ash result from the causticizing process and consist mainly of calcium carbonate (CaCO3) in its chemical composition [17], sharing similar features with the limestone filler used in construction materials [18]. Thus, several researchers have studied solutions for reusing the lime-based wastes in construction materials. For example, Modolo et al. [19] assessed this waste incorporation in cement mortars while others [18,20] have studied the production of clinker with fly ash, lime mud and biological sludge. Madrid et al. [21] have also tried using lime mud and sawdust in the production of concrete blocks with improved thermal properties. The incorporation of lime mud and fly ash in the anorthite production for the ceramic industry has also been successfully tested [17]. Mymrin et al. [22] studied the production of composites using the wastes from the pulp and paper industry, including dregs, grits and lime mud. Jia et al. [23] have studied the sealing of mine tailing landfills with wastes from the pulp and paper industry (dregs, fly ash and lime mud).

After validating the technical performance, the environmental performance was also assessed using the life cycle assessment method ((e-)LCA) [8], in order to identify the benefits and trade-offs of the best solution, following ISO standards (from ISO 14040 to ISO14044) [24]. Some authors have also analysed social and economic impacts using the social (S-LCA) and economic (LCC) life cycle assessment method, respectively [12,25,26,27].

Regarding the concrete products sector, several researchers [4,8,24] have carried out life cycle assessments to compare different products. For example, Colangelo et al. [4] analysed four concrete mixes containing different wastes, including construction and demolition waste (CDW), incinerator ashes, marble sludge and blast furnace wastes. They found out that the concrete with wastes was more sustainable than the plain concrete. Turk et al. [8] evaluated three mixtures of concrete with foundry sand steel slag and fly ash and concluded that the waste-added concrete had a beneficial scenario for the concrete industry. Domagoj et al. [24] evaluated the use of sewage sludge ash (SSA) in the production of concrete as a partial substitute of cement and found that incorporation of up to 10% did not affect technical performance and, at the same time, reduced the impact of the global warming potential (GWP).

At the level of production of aggregates for the concrete sector, Estanqueiro et al. [3] carried out a comparative life cycle assessment between natural and recycled aggregates and demonstrated that the scenarios of recycled aggregates produce less impacts than the traditional solution (natural aggregates). Hossain et al. [5] carried out a comparative study on the production of aggregates (natural, CDW and waste glass) for lower grade concrete products and found that the impacts of recycled aggregates were lower than those of virgin aggregates.

The pulp and paper sector has also been the subject of several life cycle assessment studies. For example, Lopes et al. [28] applied the methodology to printing and writing paper to compare the environmental impacts resulting from the use of heavy fuel oil and natural gas. They found that the natural gas promotes lower impacts than heavy fuel. Santos et al. [12] carried out life cycle assessment to quantify the social impacts of the value chain on different stakeholders. Waste from the pulp and paper industry has been studied in different recovery scenarios to identify the solution with fewer environmental impacts. For instance, Costa et al. [29] evaluated the environmental impacts of various recovery solutions for building materials with waste and compared them with the landfill solution, finding that all recovery solutions produce fewer environmental impacts than the current solution. Teixeira et al. [30] evaluated the technical and environmental performance of the recovery of fly ash resulting from the burning of biomass (CVB) and coal (CVC) in the production of mortar and verified that the emissions of formulations with fly ash and of biomass are lower than those of the reference mortar without residues. Deviatkin et al. [31] evaluated the environmental performance of five de-inking sludge valorisation processes and reached the best valorisation scenario in the use of that waste in the cement industry. Mohammadi et al. [32] evaluated the environmental performance of biological sludge used in the production of bioenergy through incineration, or in the production of biochar through pyrolysis or hydrothermal carbonization (HTC). These authors reported that all three systems produce lower environmental impacts than the traditional solution (landfill disposal).

The aim of this study was to assess sustainability of the precast concrete produced with lime ash (the waste from the cellulose industry) as an alternative raw material, based on a circular model approach. The case study was built and tested in a real scale industrial dimension. The economic, environmental and social impacts of the linear solution i.e., production of precast concrete along with the deposition of lime ash in landfill, and the circular solution i.e., precast concrete with incorporation of lime ash as an alternative raw material, were evaluated and compared according to the industrial scale scenarios.

2. Experimental Approach

In the case of precast concrete, the concrete is produced in a producer’s manufacturing facilities, moulded into elements of different shapes and sizes, which is then be assembled in the work field intended for the planned use. The various types of precast concrete elements today are standardized products and a target of CE marking, due to the existence of standards that define its requirements, characteristics, and test methods for this type of products. For example, columns are linear elements, regulated by the product standard EN 13225 which defines, among other parameters, a minimum class (C20/25) for concrete to be used in reinforced elements, such as columns [33].

From an experimental point of view, this work involved the design, implementation and monitoring of four frames in an industrial scale with elements in precast concrete. One frame, used as reference, was manufactured with the standard formulation of precast concrete, and three other frames were manufactured using the same precast concrete developed with a waste (lime ash) fully replacing all the natural limestone filler used in the standard precast concrete formulation (4.4 wt.% of filler). The aim was thus to promote, in a circular economy perspective, the industrial symbiosis between two industrial companies located less than 25 km from each other, making the waste of one of them (from the pulp and paper sector) into a raw material alternative in the construction sector company (concrete products manufacturer).

This represents a change in the paradigm of the current linear economy model of concrete production, which uses natural aggregates in its production combined with the fact that the pulp and paper sector still sends lime ash and other wastes to landfill disposal [13]. Hence, this was tested as a replacing raw material for natural filler in the production of precast concrete, to create an alternative to the traditional raw material, but without changing the processing conditions and the final characteristics of the precast concrete. Concrete elements were produced on an industrial scale following a traditional linear economy model (without wastes) or following a circular model (with wastes). Note that the amount of waste (lime ash) used in this work to replace the natural filler was small (around 4 wt.%) but intentionally so, it was enough to produce an impact while intending to locally exhaust the waste produced in the cellulose plant, without resorting to long-distance transports (>25 km).

Prior to implementation, the waste and the traditional raw material (natural limestone filler) were also characterised in terms of particle size analysis, density and mineralogical composition, to assess any eventual differences. During full-scale implementation, concrete specimens with and without waste were also collected to assess fundamental characteristics, such as mechanical compressive strength, hardened concrete density, water absorption and the capillarity coefficient of the concrete. All the four frames together with the characteristics of the precast concrete were monitored for 1 year. After this technical validation of the concrete produced in both contexts (circular and linear model), the sustainability of the developed circular solution was evaluated by comparing it with the linear solution. This evaluation was based on a life cycle (LC) assessment of environmental, economic and social impacts that this simple industrial symbiosis process causes.

3. Case Study—Description and Technical Assessment Results

As mentioned, the implementation of the circular model allowed not only to use lime ash as an alternative filler in the precast concrete industry but, at the same time, to avoid its landfilling in the pulp industry. The precast concrete industry produces a variety of products, such as the linear concrete elements (trusses and pillars) used in this study.

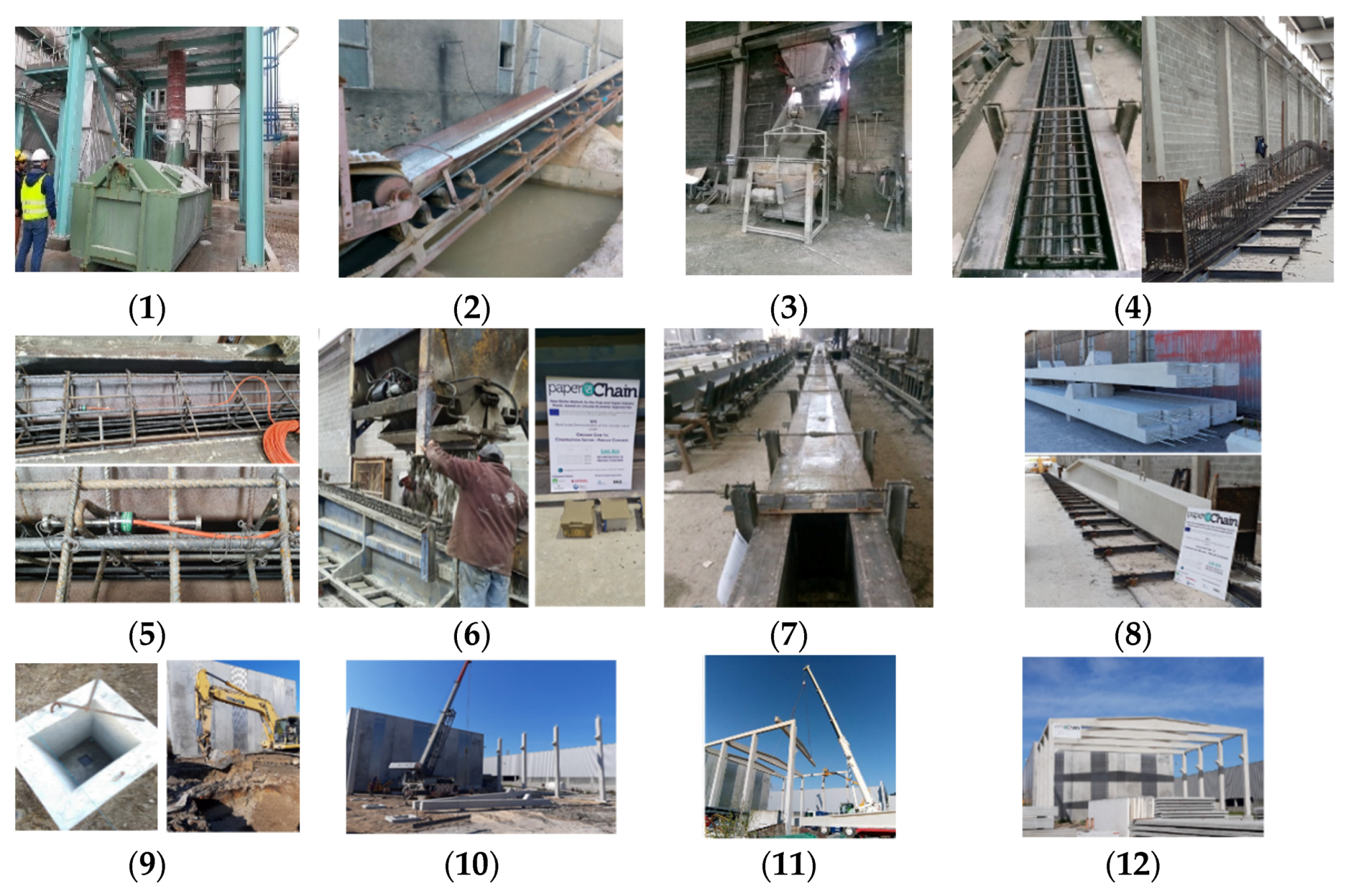

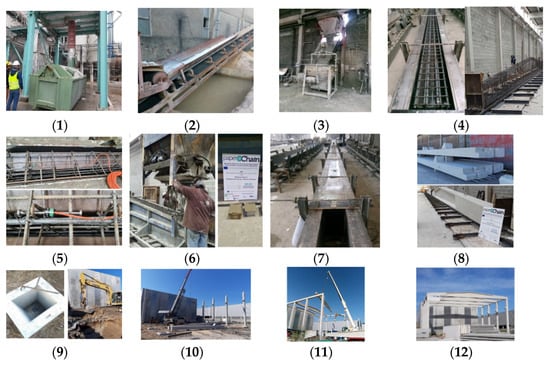

In this industrial-scale trial, implementation of the circular model involved the following 12 steps (Figure 1): 1. Lime ash storage at waste producer; 2. Lime ash transportation to the precast concrete factory; 3. Concrete mixture ready for application; 4. Preparation of the reinforcement bars and moulds for beams and columns execution; 5. Internal sensors installation for future in situ monitorisation; 6. Concrete discharge into the form and execution of concrete samples for monitoring tests; 7. Curing and drying process; 8. Columns and beams for the frames; 9. Land preparation and direct foundations execution; 10. Columns assembly; 11. Beams and girders assembly; 12. Final frames structure.

Figure 1.

Implementation of lime ash in precast concrete (12 steps).

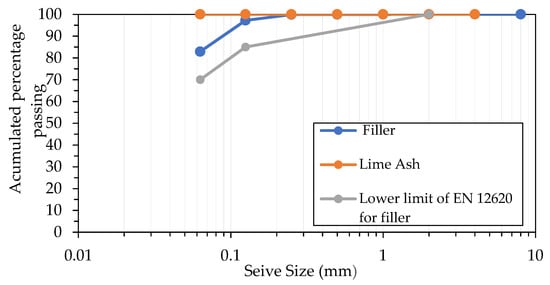

To produce the precast concrete columns, the standard formulation shown in Table 1 was used. Each column consumes 2.1 m3 of concrete and has a section of 0.5 × 0.4 m2 and 10.25 m in height, being its strength class the C30/37 one. In the case of concrete, the aggregate is based on the EN 12620 product standard, which identifies the minimum requirements that the aggregates must meet (particle size analysis) and the set of properties to be characterised (density and quality of fines). Thus, Table 2 shows the properties of lime ash and natural limestone filler (ref. Betocarb-OU), which were characterised in the laboratory. The results with lime ash are like those of the natural filler it replaced, representing, according to the formulation in Table 1, a filler percentage of 4.4 wt.% (104 kg per m3 of concrete).

Table 1.

Formulation of the precast concrete columns.

Table 2.

Characteristics for lime ash and natural filler.

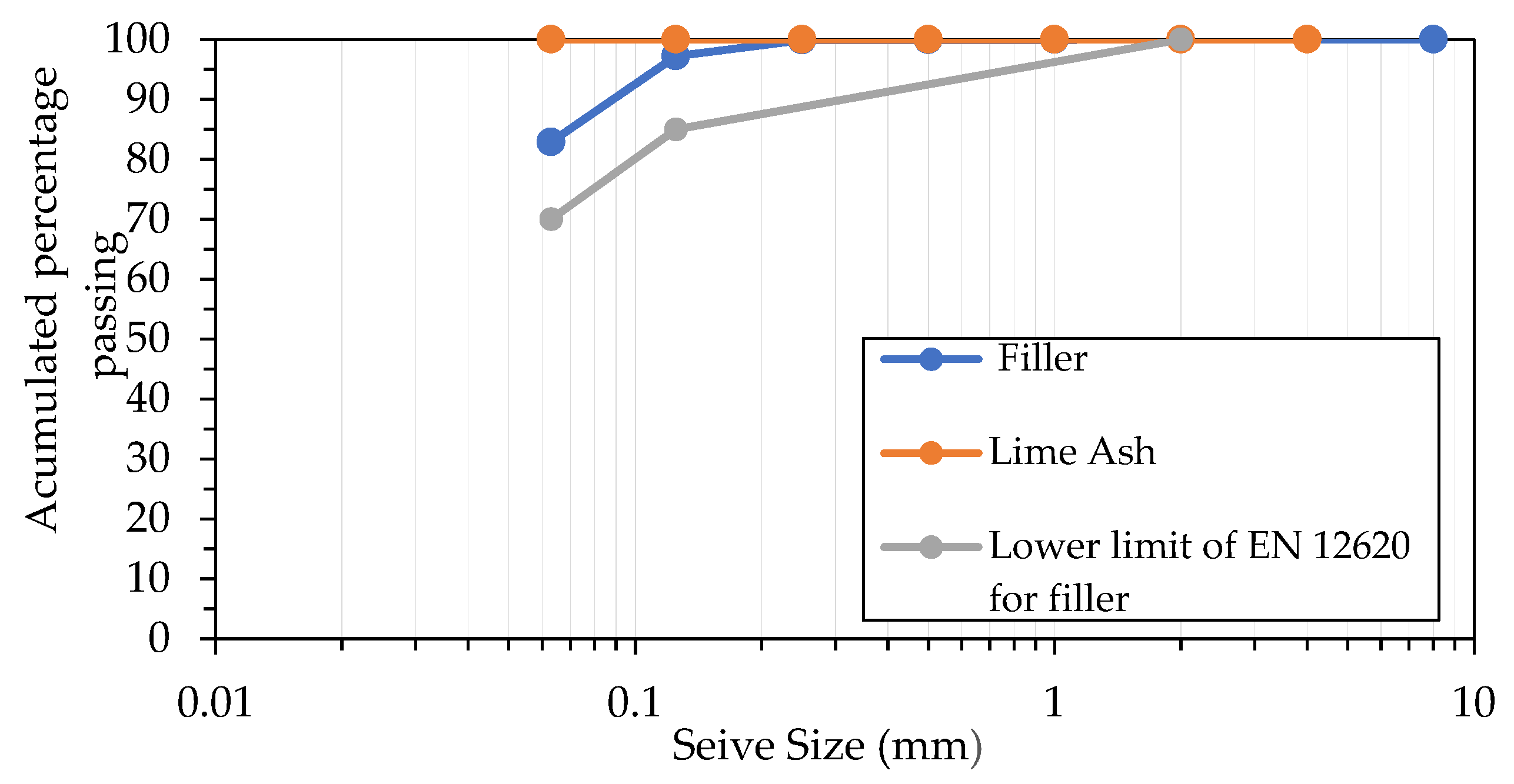

Figure 2 shows lime ash and natural filler particle size distribution (EN 933-10). A filler usually presents 70% of particles below 63 microns and, as it is possible to observe, lime ash particle size is within the defined minimum limit for a filler, making it possible lime ash to be used as such.

Figure 2.

Particle size distribution of filler and lime ash.

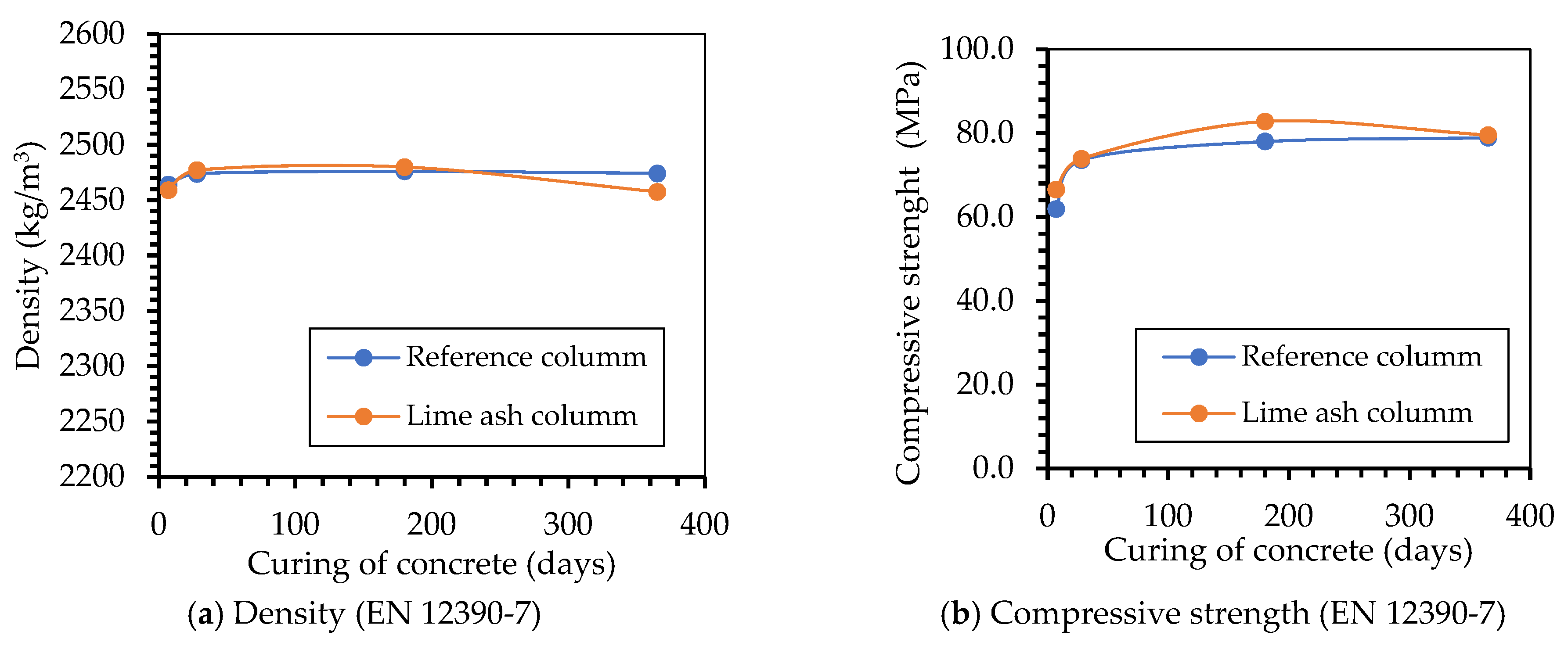

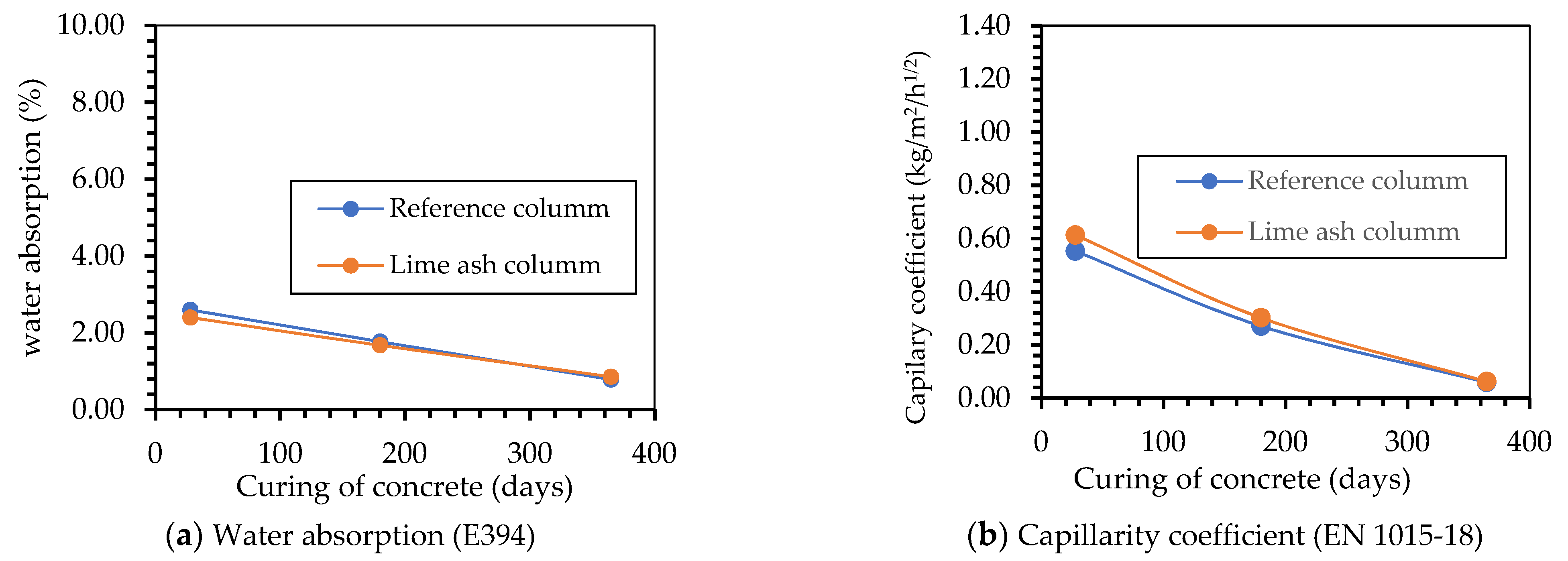

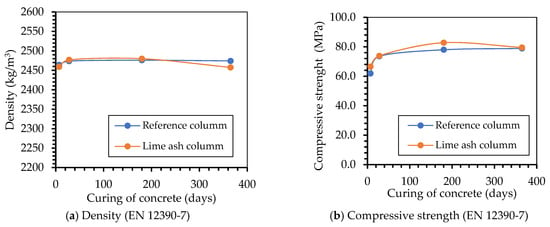

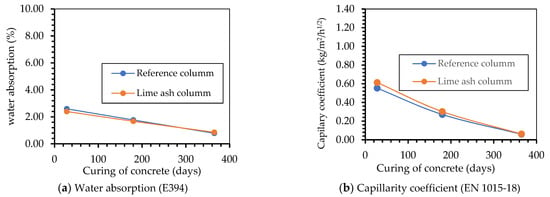

In step 6 of the implementation, 12 samples were collected from the circular (concrete with lime ash) and linear model (reference concrete) cases to evaluate the compressive strength, the concrete density in the hardened state at 7, 28, 180 and 365 days of curing (Figure 3), as well as three samples for water absorption and capillary coefficient (Figure 4) measurements with curing time (for 28, 180 and 365 days). Internal sensors placed for temperature and shrinkage control showed similar results during this time.

Figure 3.

(a) Density of hardened concrete for linear model and circular model; (b) Compressive strength for linear model and circular model.

Figure 4.

(a) Water absorption behaviour for linear model and circular model; (b) Capillarity coefficient (water absorption by capillarity) for linear model and circular model.

The harmonised standard for precast concrete establishes a minimum compressive strength class for columns and, at the beginning of the pilot design, that was defined to be C30/37. The results in Figure 3b are according to the required class from the project design. Moreover, the standard deviations in the results shown in Figure 3 and Figure 4 were so negligible that their respective statistical deviation bars would not appear in these figures scales.

Regarding water absorption and capillarity coefficient, the behaviour of concrete containing lime ash is also like that of the reference concrete. For monitoring purposes, concrete pH and chlorides content control were also carried out at the beginning of test and after 6 months of immersion in distilled water. No substantial differences between the two compositions were found in these results. In conclusion, this technical assessment showed that the introduction of this waste did not hinder the quality and performance of the standard precast concrete. In Figure 4 one should consider that as the cement hydration proceeds over time, the capillary pores of the concrete decrease and, therefore, water absorption from the concrete decrease with the concrete curing. Furthermore, the reduction of pores in the concrete will also contribute to reducing the capillary water absorption over curing time.

4. Case Study—Life Cycle Sustainability Assessment Procedure

The methods and results of the life cycle assessment in the environmental, economic and social aspects of this case study are presented here (linear vs. circular model). The concrete element (column) with the greatest amount of filler (4.4 wt.%) was used to validate the use of waste as an alternative raw material for the precast concrete industry.

4.1. Sustainability Assessment Methodology

For the assessment of each of the dimensions of sustainability, i.e., environmental, social and economic, life cycle assessment has shown its potential and adequacy. When applying life cycle perspective to the evaluation of a system (a product or a service), the evaluator considers not only the system itself but also all the systems that are related with it in its whole life cycle, upstream and downstream, i.e., from the extraction of the raw materials that are part of the system to its end of life.

Life cycle sustainability assessment is the methodology that permits the evaluation of the three dimensions of sustainability in a coordinated way. It facilitates the organization of environmental, economic and social information in a structured form; assesses the trade-offs between the three sustainability pillars, life cycle stages and impacts, products and generations by providing a more comprehensive picture of the positive and negative impacts along the product life cycle; and helps decision-makers choose sustainable technologies and products [34].

For this study, the guidelines defined in the report “Towards a Life Cycle Sustainability Assessment: Making informed choices on products” [34] were considered. Additionally, for each of the life cycle assessments performed here, additional methodologies have been followed.

4.1.1. Environmental Life Cycle Assessment ((e)-LCA) Method

In the case of the environmental life cycle assessment ((e)-LCA) the reference methodologies applied were ISO 14040:2006 [35] together with ISO 14044:2006 [36].

The environmental impact categories assessed have been those defined in the product category rules of the EPD international system for highways, streets and roads, for asphalt mixtures and for construction products [37], which are the following:

- GWP100: Emission of greenhouse gases (expressed as the sum of global warming potential, GWP, 100 years, in carbon dioxide equivalents, CO2 equivalent),

- AP: Emission of acidifying gases (expressed as the sum of acidifying potential in sulphur dioxide equivalents, SO2 eq.),

- EP: Emission of substances to water contributing to oxygen depletion, “eutrophication” (expressed as phosphate ion equivalents, PO43−eq.),

- POFP: Emission of gases that contribute to the creation of ground-level ozone, “photochemical oxygen creation potential” (expressed as the sum of ozone-creating potential, in ethylene equivalents, C2H4 eq.)

- ODP: Emission of ozone-depleting gases (expressed as the depletion potential of the stratospheric ozone layer, ODP kg CFC11 eq.)

- ADP: Depletion of abiotic resources-elements (expressed as abiotic depletion potential (ADP-elements) for non-fossil resources, kg Sb eq.)

- ADP-FF: Depletion of abiotic resources-fossil fuels (expressed as Abiotic depletion potential (ADP-fossil fuels) for fossil resources, MJ, net calorific value)

The characterisation models and factors used to calculate each environmental impact category were those developed in the CML-IA (baseline) methodology released in 2013. Likewise, another two additional environmental impacts have been assessed:

- CED: Cumulative energy demand (MJ)

- WU: Water resources used (m3)

4.1.2. Life Cycle Costing (LCC) Method

Life Cycle Costing assessment is the methodology that permits the evaluation of the costs of a product or service during its life cycle. In this case, the methodology followed as reference was the ISO 15686-5:2017 [38]. To perform this assessment, the data collected corresponded to:

- cost of materials acquisition,

- rental of equipment used which included the manpower,

- cost of transport of materials and

- cost of energy consumed, in this case, the cost of the fuel consumed by the equipment used in the manufacturing works.

4.1.3. Social Life Cycle Assessment (s-LCA) Method

For the social life cycle assessment, the methodology followed was through the Guidelines for Social Life Cycle Assessment of Products [39]. To perform this assessment, apart from the information collected for the (e)-LCA and the LCC, specific information about the workforce and operations time was gathered.

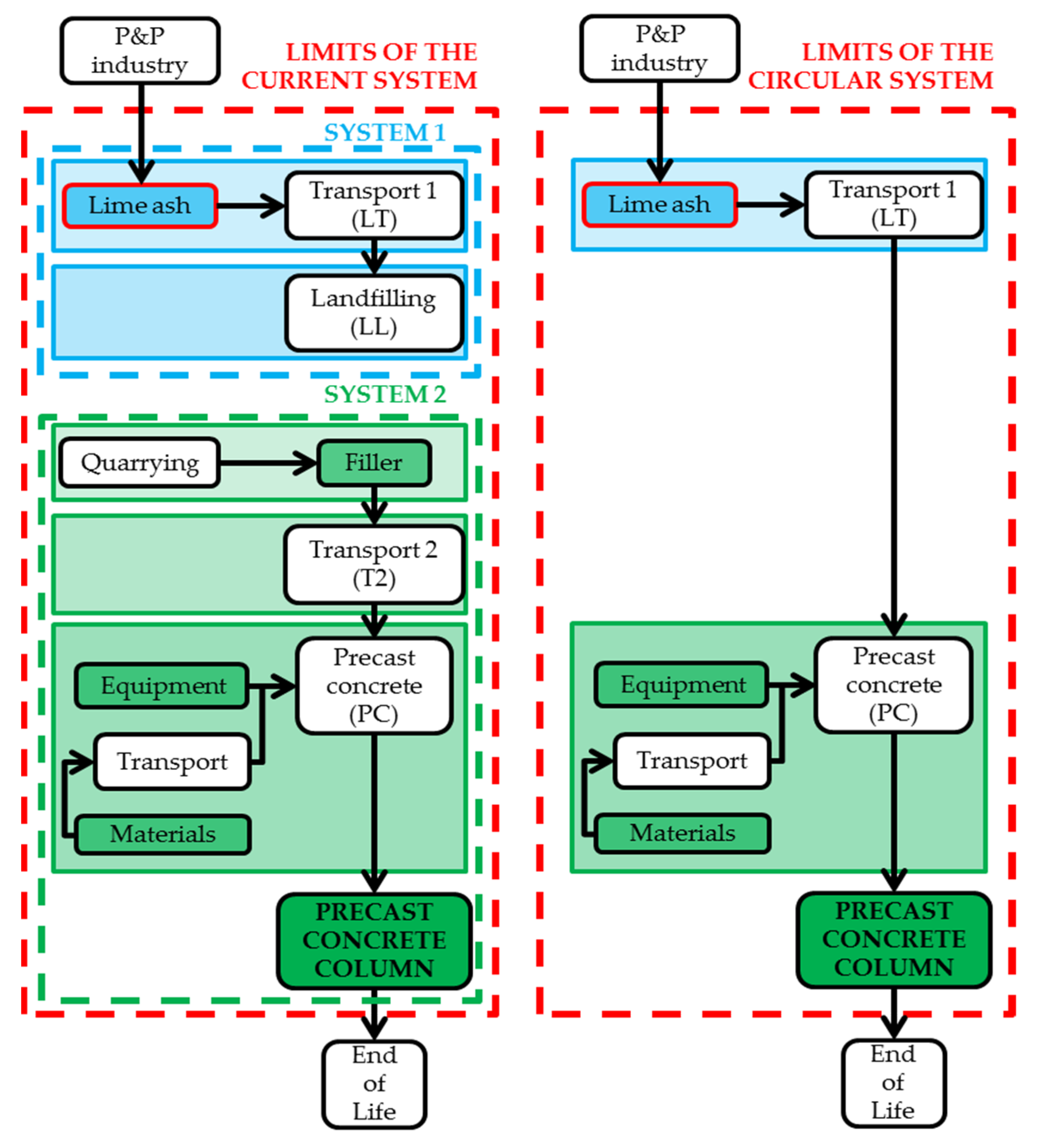

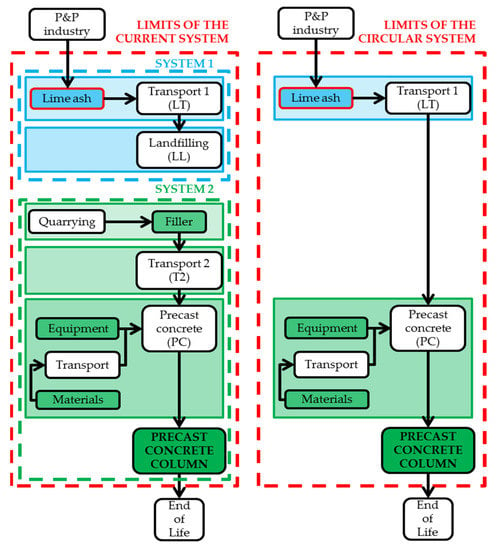

4.2. Functional Unit and Limits of the System

The functional unit was 1 m3 of precast concrete for the construction of a column. Figure 5 shows the limits of the assessed systems, in linear and circular model cases, where all processes involved during the manufacturing stage have been included. In the current linear solution, we have considered two different systems: first, the landfilling of the lime ash waste generated in the pulp and paper industry and, second, the manufacture of precast concrete using the natural filler. In the circular case solution, the natural filler is completely replaced by the lime ash waste in the precast concrete, avoiding the disposal of the waste on landfill. The end-of-life stage for both solutions has not been included within the limits of the system as there is no difference for this stage between both systems.

Figure 5.

Processes, stages and limits of the product systems.

4.3. Allocation Procedures

A cut-off system model has been applied, and consequently, recyclable materials are available burden-free to recycling processes, and secondary (recycled) materials bear only the impacts of the recycling processes. No other allocation procedure was used in this study.

5. Case Study—LCA Results and Discussion

5.1. Environmental Assessment

In the linear model, the waste is transported from the pulp and paper manufacturing facilities to the landfill (at 1.5 km). Then, in the landfill stage, there is a set of impacts resulting from the excavation work (hydraulic digger (HD) and waste movement (skid-steer loader (SSL)), as well as the waste deposition in landfill. Table 3 shows the impacts generated in the disposal of waste in landfill, according to the functional unit of the column (1 m3 of concrete). This concrete formulation uses 104 kg of filler per m3 of concrete, thus the impacts of the waste in landfill are in accordance with the amount of filler used or saved in the concrete, considering that the substitution ratio lime ash waste to natural filler is 1:1.

Table 3.

Environmental impacts for waste deposition in the landfill following column production.

Regarding the production of concrete in the linear model, there are impacts associated with the use of raw materials (gravel and sand) (Table 4), as well as other raw materials such as filer, superplasticiser, water, cement and the transport of natural filler from the producer to the precast concrete producer (82 km) (Table 5). The impacts of precast concrete production (Table 4 and Table 5) result mainly from the use of cement, except in the water use (WU) and abiotic depletion potential (ADP) categories, which result from the use of coarse sand and superplasticiser, respectively. Cement contributes between 66% and 88% to the environmental impacts of concrete production, in the categories of global warming (GWP100), ozone layer depletion (ODP), acidification (AP), eutrophication (EP), photochemical oxidant formation (POFP), abiotic depletion (fossil fuels) and cumulative energy demand (CED).

Table 4.

Environmental impacts for aggregates in precast concrete formulation.

Table 5.

Environmental impacts for other components in precast concrete formulation.

This contribution results from the production of an intermediate product (clinker) that consumes large amounts of raw materials (limestone, clay, gypsum, iron ore, bauxite, etc.) and fossil energy [29]. In the case of sands, these contribute approximately 60% of the impact of water use, due to the consumption of water in the step of washing this raw material, during the sand extraction phase [3]. On the other hand, plasticiser and cement generate 82% and 10% of the impacts of abiotic depletion potential (ADP-elements) for non-fossil resources, respectively.

Table 6 shows the impacts generated in the production of precast concrete and the deposition of lime ash in landfill (linear model). The impacts of the linear model (Table 6) resulted mainly from the production of concrete, except in the eutrophication category, which was impacted by the deposition of lime ash in landfill.

Table 6.

Environmental impacts for landfill plus precast concrete and total impacts of linear model.

To change the impacts generated in the linear model options, a circular model was developed where the waste was used as an alternative raw material in the production of precast concrete. The impacts resulting from the linear model waste management operations (Table 3) do not exist in the circular model, because the impact of landfill was eliminated and, in addition, the lime ash does not require any treatment operation to be incorporated as an alternative raw material in the precast concrete industry.

Although present in a small percentage (4.4%), the natural filler is entirely replaced by the lime ash waste and the other components in the concrete formulation (gravel, cement sand, superplasticiser and water) remain the same as the concrete formulation in the linear model (Table 1). Thus, the impacts of gravel, sand, cement and superplasticiser remain the same as in the previous case (Table 4). On the other hand, the impacts resulting from the use of natural filler disappear in this circular case and impacts of transporting lime ash are approximately reduced by 28% of the impacts of filler transportation. In other words, the use of lime ash makes it possible to reduce raw material transport impacts by 72% regarding filler transport of the linear model, due to the reduction in the current transport distance, just comparing the natural filler and the lime ash ones (82 km to 23 km).

Table 7 shows the impacts associated with the transport of lime ash, as well as the impacts of producing concrete with lime ash. The difference in impacts of the linear and circular solution of precast concrete is achieved by the elimination of impacts associated with the disposal of waste in landfills and the elimination of impacts associated with the use of filler, as well as by reducing impacts on the transport of raw material alternative to the natural filler.

Table 7.

Results of the environmental impacts for lime ash transport to precast concrete industry and total impacts of circular model for precast concrete.

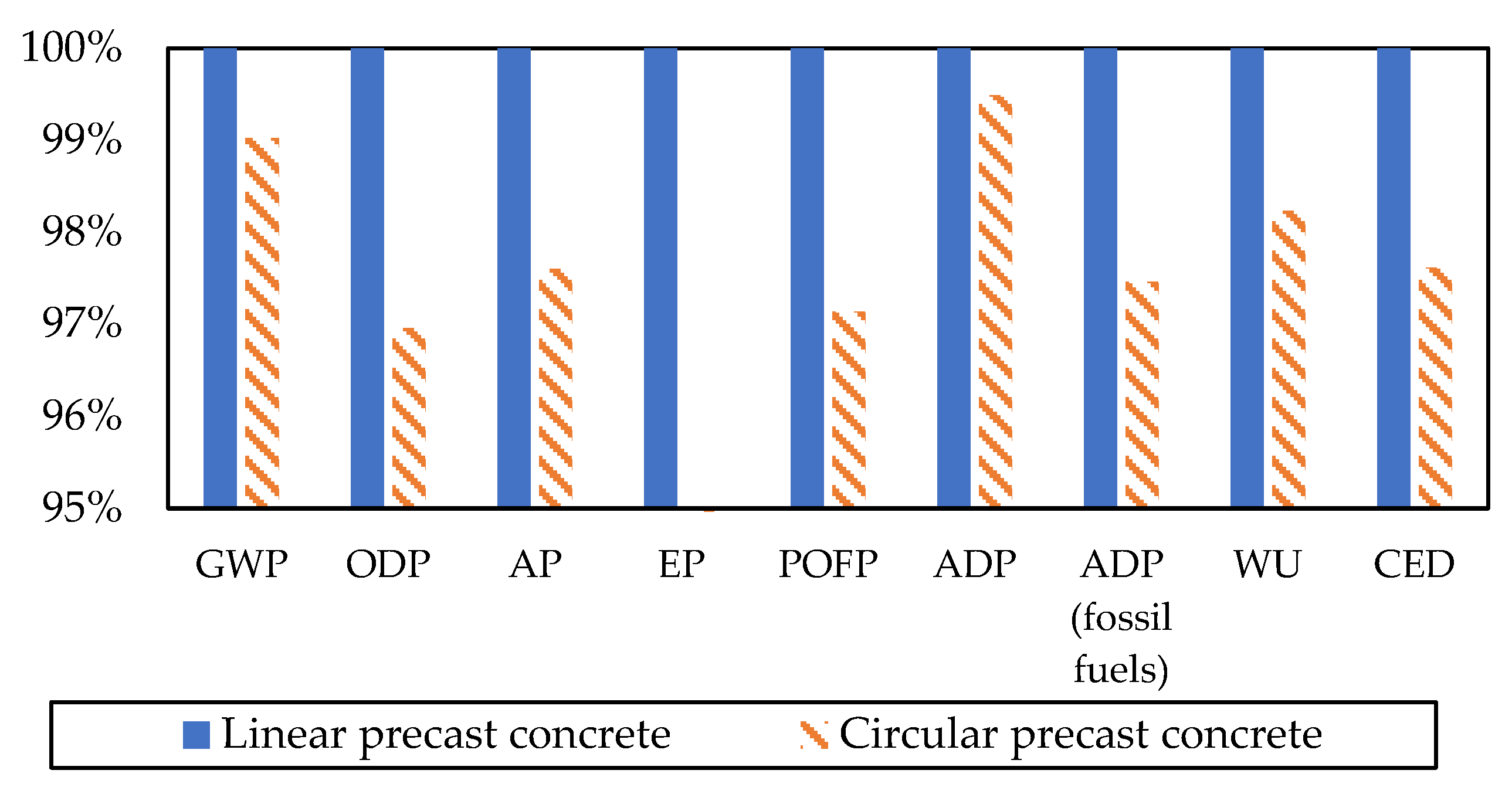

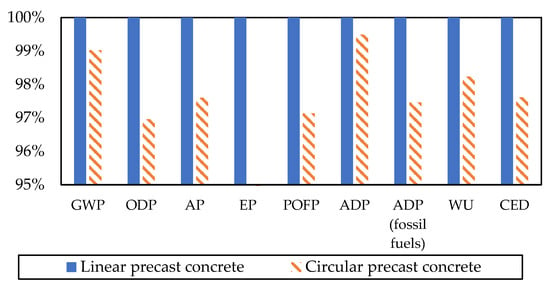

This simple case of adoption of a circular model allows for a reduction between 1% to 3% of impacts compared to the linear solution (Table 7 and Figure 6), except in the eutrophication (EP) category, since the reduction is 99%, mainly due to the elimination of operations of landfill disposal of the lime ash waste (Table 3).

Figure 6.

Environmental improvements achieved for circular model.

Figure 6 shows the comparative results of the linear and circular models. The reduction of impacts in the circular model is not greater, because the rate of incorporation of filler/lime ash is low (4.4%) but it points to a clear trend of decrease in all parameters. The impacts of cement are high compared to other traditional raw materials (sands, gravel, water and superplasticiser) [10,40]. Hence, the use of other wastes as alternative raw materials to other components should also be explored to further minimise impacts.

Finally, in statistical terms, one must also say that, although the uncertainty was higher for some of the impact categories, practically for all environmental impact categories, the difference between the concrete reference (current product) and the concrete containing waste (paperChain solution) is positive, which means that the current system has a higher impact than the paperChain system solution as observed.

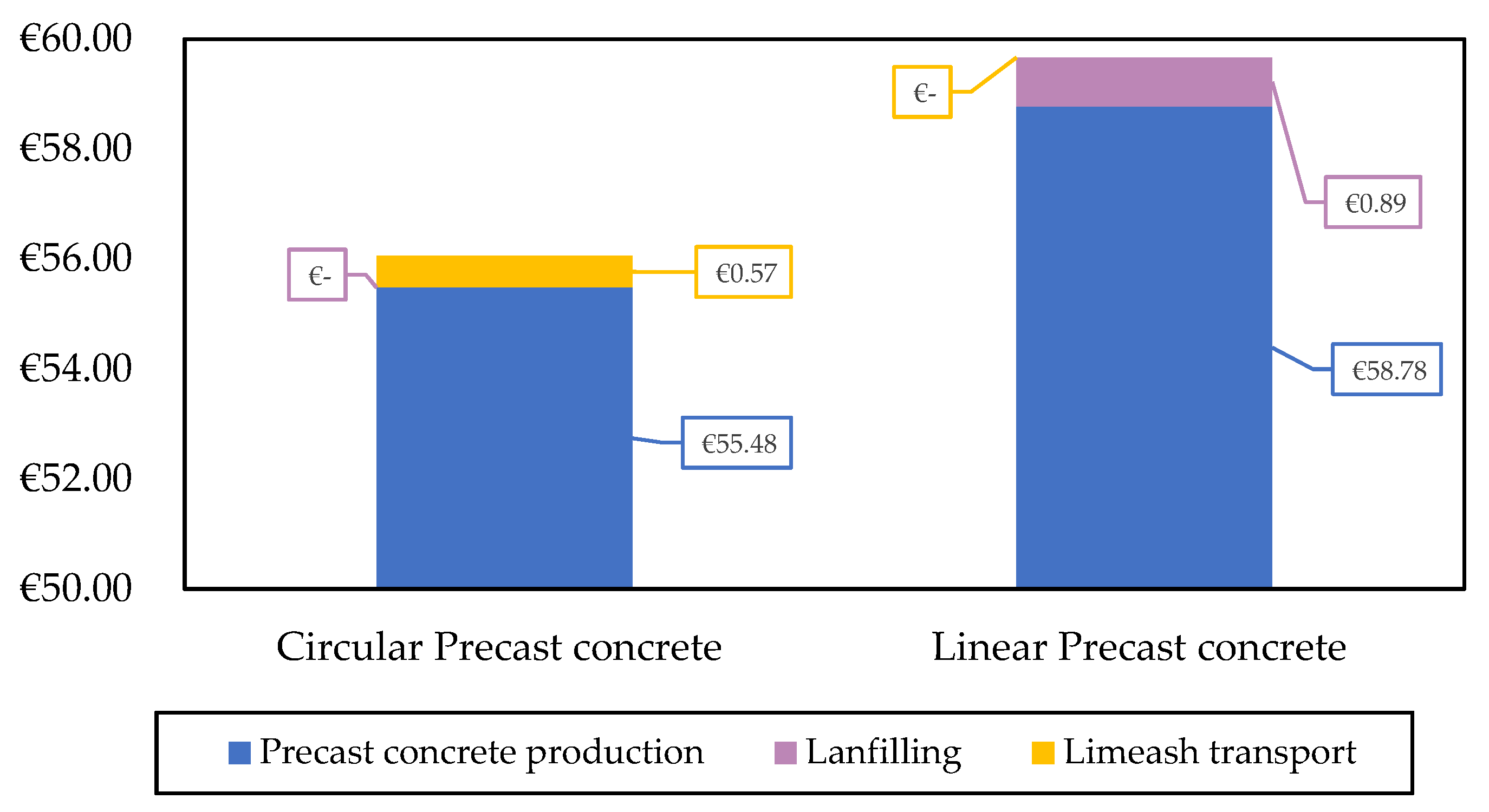

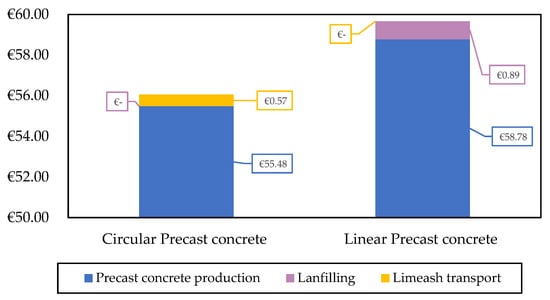

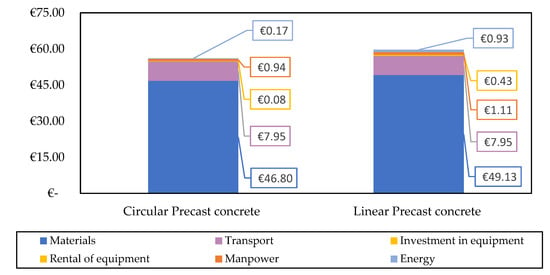

5.2. Costing Assessment

The main operation of the linear and circular model focuses on the production of precast concrete, but there are also operations of depositing the waste in landfill (linear model) and transporting the lime ash to the precast concrete producer (circular model). Figure 7 shows the operating costs of the linear and circular model. The use of lime ash in the production of concrete generates savings by EUR 3.30, due to the elimination of the cost of the filler acquisition by the concrete producer. In addition, transporting the lime ash to the concrete producer generates savings of EUR 0.32 compared to depositing the lime ash in the landfill. Thus, transporting the lime ash to the concrete producer (23 km) does not produce more costs than disposal of the waste in landfill.

Figure 7.

Costs by operation of linear and circular model.

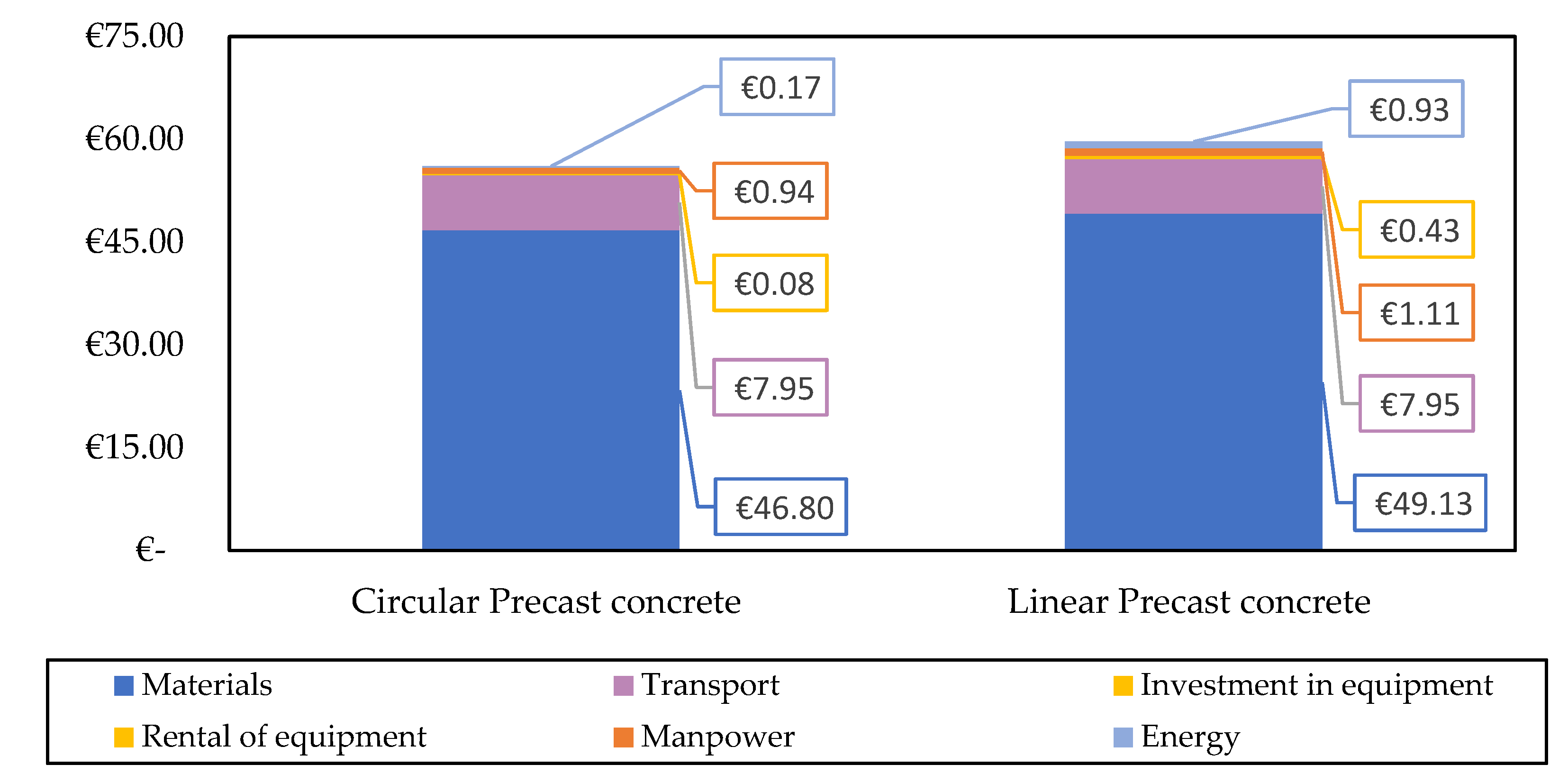

Circular model operations (production of precast concrete with waste and transport of lime ash to the concrete producer) generate savings of 6% compared to linear model operations (production of precast concrete and disposal of waste in landfill) because lime ash is free of cost for the precast concrete industry, and this saves on the cost of acquiring the filler. In addition, the waste producer also saves by eliminating the costs of depositing the waste in landfill. The costs of the linear and circular models (Figure 7) come from materials, transport, investment in equipment, rental of equipment, manpower and energy, as shown in Figure 8. The linear and circular model has no costs arising from waste treatment and external costs, but the value of investment in equipment and transport is the same for the linear and circular model, (EUR 0.12 and EUR 7.95, respectively). This means that the implementation of the circular model can use the equipment that was used in the linear model and does not require additional investment. However, the cost savings of renting equipment, manpower and energy are EUR 0.35, EUR 0.16 and EUR 0.76, respectively, because the tasks resulting from the disposal of waste in landfills disappear in the circular model.

Figure 8.

Distribution of type of cost of linear and circular model.

Furthermore, the use of lime ash as filler in concrete generates savings in transport distance (49 km) compared to the use of natural filler. Therefore, transporting lime ash consumes less manpower and energy than transporting natural filler. Finally, the biggest savings (EUR 2.33) appear in the purchase of materials from the circular model compared to the traditional model, because lime ash constitutes no cost for the concrete producer.

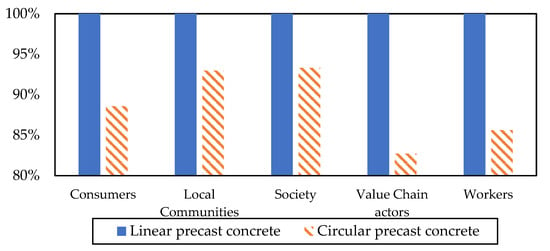

5.3. Social Assessment

The categories of social impacts considered in the linear and circular model were consumers, local communities, society, value chain actors and workers. The impacts of these categories result from the aggregation of several subcategories. Table 8 shows the stakeholder category and associated subcategories. The social impacts of the linear model result from the production process of precast concrete with natural filler, the transport of the natural filler from the producer to the concrete producer, the transport of lime ash from the producer to the landfill and the deposition of the lime ash to the landfill. Meanwhile, the social impacts of the circular model come from the production process of precast concrete with lime ash and the transport of lime ash from the producer to the precast concrete producer. Table 9 shows the results of the social impacts of the linear and circular model in the production of precast concrete.

Table 8.

Stakeholder (category) and associated subcategories for linear and circular model.

Table 9.

Social life cycle performance for linear and circular precast concrete.

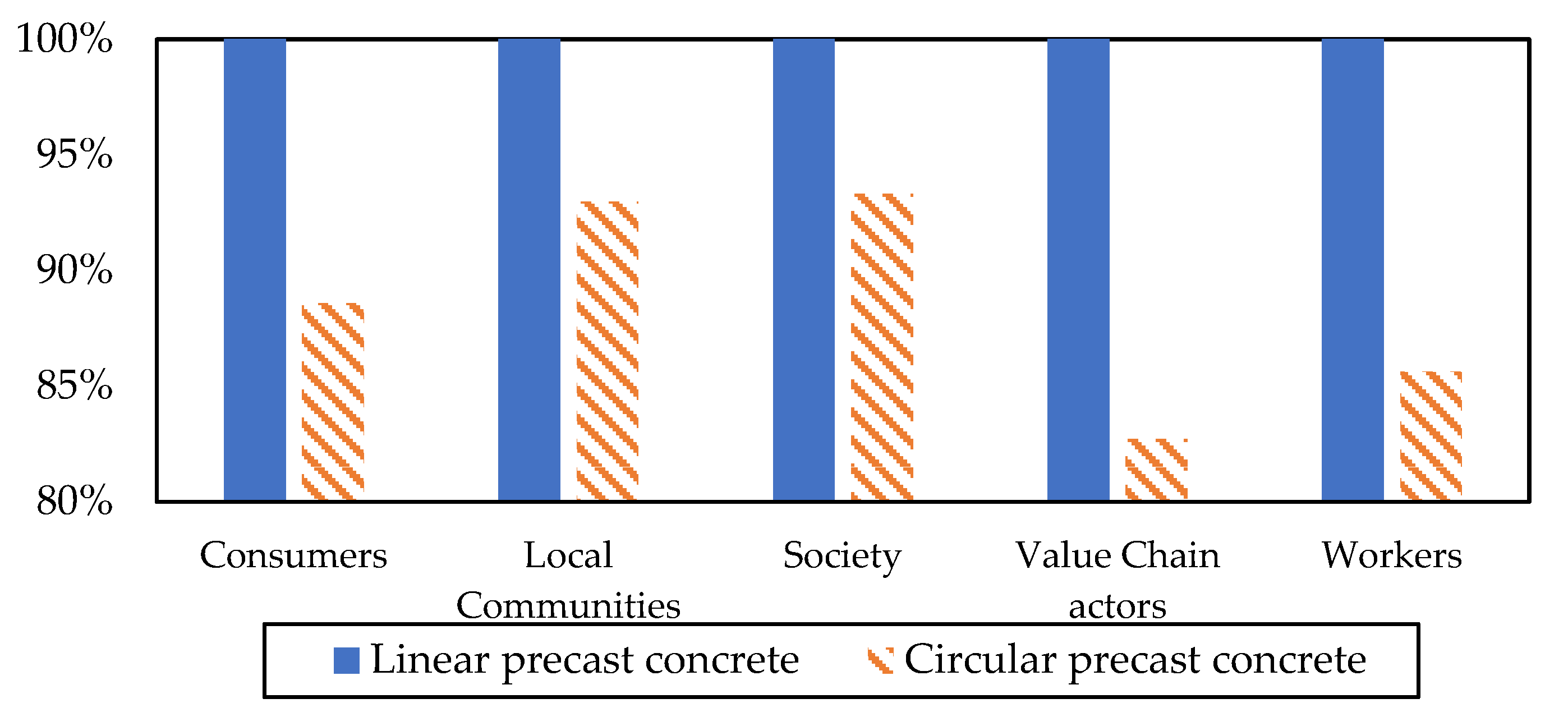

According to the results of Table 9 and Figure 9, the circular model presents a reduction of 11.4%, 7.0%, 6.7%, 17.3% and 14.4% in the category of consumers, local communities, society, value chain and workers, respectively, relative to the linear model of concrete production and waste disposal in landfill. The concrete production process in the circular and linear model consumes the same resources, thus the social impacts of concrete production are identical, but the difference in the category values in Table 9 results from the tasks associated with the linear model (transport and waste disposal in landfill, as well as the transport of the natural filler) and with the circular one (transport of the lime ash). Thus, the transport of lime ash of the circular model produces fewer social impacts than the tasks of the linear model. Both transports have the same workforce, but the execution time is lower in the circular model and consequently consumes less energy.

Figure 9.

Social improvements achieved by the circular model.

6. Conclusions

A real scale case of total replacement of a natural raw material (filler) by a lime waste from the pulp and paper industry in a precast concrete formulation was created and used to evaluate several sustainability dimensions from a life cycle and circular economy model approach. The following conclusions were reached:

- The incorporation of lime ash (PPI waste) as an alternative material in the production of precast concrete does not affect the technical performance of the developed solution.

- This waste valorisation solution also prevents landfill disposal of that waste and, at the same time, promotes the saving of a natural resource largely used in the construction sector.

- There were no induced changes in production time and procedures as well as no changes were required in composition of the standard precast concrete, when the natural limestone filler is completely replaced by the lime ash waste (100% filler replacement).

- No additional/conditioning treatments of this pulp and paper industrial waste was needed previous to the incorporation in the precast concrete.

- In terms of sustainability in the economic, social and environmental dimensions, this circular solution reduces the impacts compared to the linear model solution, even when the amount in the concrete formulation of the natural filler is quite low (4.4%).

- The development of this circular model also brings benefits to guaranteeing a constant local supply of lime ash for the precast concrete industry, ensuring local consumption in this way without involving long distance transport of the alternative raw material.

Author Contributions

Conceptualization, V.M.F.; methodology, F.S. and F.-J.R.-D.; validation, H.P., H.M., M.M. and V.M.F.; formal analysis, F.S., H.P. and F.-J.R.-D.; investigation, F.S., H.P., H.M. and F.-J.R.-D.; writing—original draft preparation, F.S. and F.-J.R.-D.; writing—review and editing, M.M., V.M.F.; visualization, supervision, V.M.F.; project administration, V.M.F.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union H2020 Program through the project PAPERCHAIN—New market niches in the paper & pulp industry, grant number 730305, 2017–2021.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors wish to acknowledge the support of the European Union Horizon 2020 Research and Innovation programme for the funding of the Paperchain project under grant agreement No. 730305. The authors also wish to acknowledge the contribution of their partners in the Paperchain project, namely, The Navigator Company and RAIZ, SPRAl and Gaiker Institute.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ferreira, I.; de Castro Fraga, M.; Godina, R.; Souto Barreiros, M.; Carvalho, H. A Proposed Index of the Implementation and Maturity of Circular Economy Practices—The Case of the Pulp and Paper Industries of Portugal and Spain. Sustainability 2019, 11, 1722. [Google Scholar] [CrossRef] [Green Version]

- Molina-Sánchez, E.; Leyva-Díaz, J.; Cortés-García, F.; Molina-Moreno, V. Proposal of Sustainability Indicators for the Waste Management from the Paper Industry within the Circular Economy Model. Water 2018, 10, 1014. [Google Scholar] [CrossRef] [Green Version]

- Estanqueiro, B.; Dinis Silvestre, J.; de Brito, J.; Duarte Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of Different Kinds of Concrete Containing Waste for Sustainable Construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Martinho, F.; Picado-Santos, L.; Capitão, S. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef] [Green Version]

- Park, W.-J.; Kim, T.; Roh, S.; Kim, R. Analysis of Life Cycle Environmental Impact of Recycled Aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef] [Green Version]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, E.R.; Mateus, R.; Camões, A.F.; Bragança, L.; Branco, F.G. Comparative environmental life-cycle analysis of concretes using biomass and coal fly ashes as partial cement replacement material. J. Clean. Prod. 2016, 112, 2221–2230. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.; Tae, S.; Chae, C. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability 2016, 8, 389. [Google Scholar] [CrossRef] [Green Version]

- Modolo, R.; Senff, L.; Tarelho, L.A.; Labrincha, J.; Ferreira, V.M. Anaysis of waste management solutions in construction materials. In Congresso de Inovaçao na Construçao Sustentável; Centro Habitat: Tamengos, Portugal, 2014; pp. 37–45. [Google Scholar]

- Santos, A.; Benoît Norris, C.; Barbosa-Póvoa, A.; Carvalho, A. Social Life Cycle Assessment of Pulp and Paper Production—A Portuguese Case Study. In Proceedings of the 30th European Symposium on Computer Aided Process Engineering, Milan, Italy, 24–27 May 2020; Volume 48, pp. 15–20. [Google Scholar] [CrossRef]

- Quina, M.J.; Pinheiro, C.T. Inorganic Waste Generated in Kraft Pulp Mills: The Transition from Landfill to Industrial Applications. Appl. Sci. 2020, 10, 2317. [Google Scholar] [CrossRef] [Green Version]

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308. [Google Scholar] [CrossRef] [Green Version]

- Vashistha, P.; Singh, S.K.; Dutt, D.; Kumar, V. Sustainable utilization of paper mill solid wastes via synthesis of nano silica for production of belite based clinker. J. Clean. Prod. 2019, 224, 557–565. [Google Scholar] [CrossRef]

- Gupta, G.K.; Shukla, P. Insights into the resources generation from pulp and paper industry wastes: Challenges, perspectives and innovations. Bioresour. Technol. 2020, 297, 122496. [Google Scholar] [CrossRef]

- Qin, J.; Cui, C.; Cui, X.; Hussain, A.; Yang, C.; Yang, S. Recycling of lime mud and fly ash for fabrication of anorthite ceramic at low sintering temperature. Ceram. Int. 2015, 41, 5648–5655. [Google Scholar] [CrossRef]

- Simão, L.; Jiusti, J.; Lóh, N.J.; Hotza, D.; Raupp-Pereira, F.; Labrincha, J.A.; Montedo, O.R.K. Waste-containing clinkers: Valorization of alternative mineral sources from pulp and paper mills. Process Saf. Environ. Prot. 2017, 109, 106–116. [Google Scholar] [CrossRef]

- Modolo, R.C.E.; Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Tarelho, L.A.C. Lime mud from cellulose industry as raw material in cement mortars. Mater. Constr. 2014, 64, e033. [Google Scholar] [CrossRef] [Green Version]

- Buruberri, L.H.; Seabra, M.P.; Labrincha, J.A. Preparation of clinker from paper pulp industry wastes. J. Hazard. Mater. 2015, 286, 252–260. [Google Scholar] [CrossRef] [PubMed]

- Madrid, M.; Orbe, A.; Carré, H.; García, Y. Thermal performance of sawdust and lime-mud concrete masonry units. Constr. Build. Mater. 2018, 169, 113–123. [Google Scholar] [CrossRef]

- Mymrin, V.; Cusma, D.F.; Nagalli, A.; Pichorim, A.; Catai, R.E.; Pawlowsky, U. New compositions of the materials from cellulose industry wastes. Clean Technol. Environ. Policy 2016, 18, 2007–2017. [Google Scholar] [CrossRef]

- Jia, Y.; Maurice, C.; Öhlander, B. Effect of the alkaline industrial residues fly ash, green liquor dregs, and lime mud on mine tailings oxidation when used as covering material. Environ. Earth Sci. 2014, 72, 319–334. [Google Scholar] [CrossRef]

- Nakic, D. Environmental evaluation of concrete with sewage sludge ash based on LCA. Sustain. Prod. Consum. 2018, 16, 193–201. [Google Scholar] [CrossRef]

- Popovic, T.; Kraslawski, A. Social Sustainability of Complex Systems. In Proceedings of the 30th European Symposium on Computer Aided Process Engineering, Online, 31 August–2 September 2015; Volume 36, pp. 605–614. [Google Scholar] [CrossRef]

- Hosseinijou, S.A.; Mansour, S.; Shirazi, M.A. Social life cycle assessment for material selection: A case study of building materials. Int. J. Life Cycle Assess. 2013, 19, 620–645. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. Social life cycle assessment of concrete bridge decks exposed to aggressive environments. Environ. Impact Assess. Rev. 2018, 72, 50–63. [Google Scholar] [CrossRef]

- Lopes, E.; Dias, A.; Arroja, L.; Capela, I.; Pereira, F. Application of life cycle assessment to the Portuguese pulp and paper industry. J. Clean. Prod. 2003, 11, 51–59. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.C.; Arroja, L.; Dias, A.C. Environmental assessment of valorisation alternatives for woody biomass ash in construction materials. Resour. Conserv. Recycl. 2019, 148, 67–79. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Mateus, R.; Camões, A.; Branco, F.G. Quality and durability properties and life-cycle assessment of high volume biomass fly ash mortar. Constr. Build. Mater. 2019, 197, 195–207. [Google Scholar] [CrossRef] [Green Version]

- Deviatkin, I.; Kapustina, V.; Vasilieva, E.; Isyanov, L.; Horttanainen, M. Comparative life cycle assessment of deinking sludge utilization alternatives. J. Clean. Prod. 2016, 112, 3232–3243. [Google Scholar] [CrossRef]

- Mohammadi, A.; Sandberg, M.; Venkatesh, G.; Eskandari, S.; Dalgaard, T.; Joseph, S.; Granström, K. Environmental analysis of producing biochar and energy recovery from pulp and paper mill biosludge. J. Ind. Ecol. 2019, 23, 1039–1051. [Google Scholar] [CrossRef]

- IPQ. NP EN 13225—Produtos Prefabricados de betão: Elementos Estruturais Lineares; IPQ: Caparica, Portugal, 2015. [Google Scholar]

- Ciroth, A.; Finkbeiner, M.; Traverso, M.; Hildenbrand, J.; Klöpffer, W.; Mazijn, B.; Prakash, S.; Sonnemann, G.; Valdivia, S.; Ugaya, C.; et al. Towards a Life Cycle Sustainability Assessment: Making Informed Choices on Products; UNEP/SETAC: Paris, France, 2011. [Google Scholar]

- ISO/TC 207. ISO 14040—Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO/TC 207. ISO 14044—Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International EPD System Product Category Rules: Highways, Streets and Roads; EPD International: Stockholm, Sweden, 2018.

- ISO/TC 59. ISO 15686-5: Buildings and Constructed Assets—Service Life Planning—Part 5: Life-Cycle Costing; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Andrews, E.S.; Barthel, L.-P.; Beck, T.; Benoît, C.; Ciroth, A.; Cucuzzella, C.; Gensch, C.-O.; Hébert, J.; Lesage, P.; Manhart, A.; et al. Guidelines for Social Life Cycle Assessment of Products; UNEP/SETAC: Paris, France, 2009. [Google Scholar]

- Roh, S.; Kim, R.; Park, W.-J.; Ban, H. Environmental Evaluation of Concrete Containing Recycled and By-Product Aggregates Based on Life Cycle Assessment. Appl. Sci. 2020, 10, 7503. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).