Comparative Study of Different Types of Waterproofing Screeds with a Focus on Cohesion with Selected Building Materials after the Freeze-Thaw Exposure

Abstract

:1. Introduction

1.1. Bituminous Screeds

1.2. Silicate (Mineral) Screeds

1.3. Polymer Screeds

2. Materials and Methods

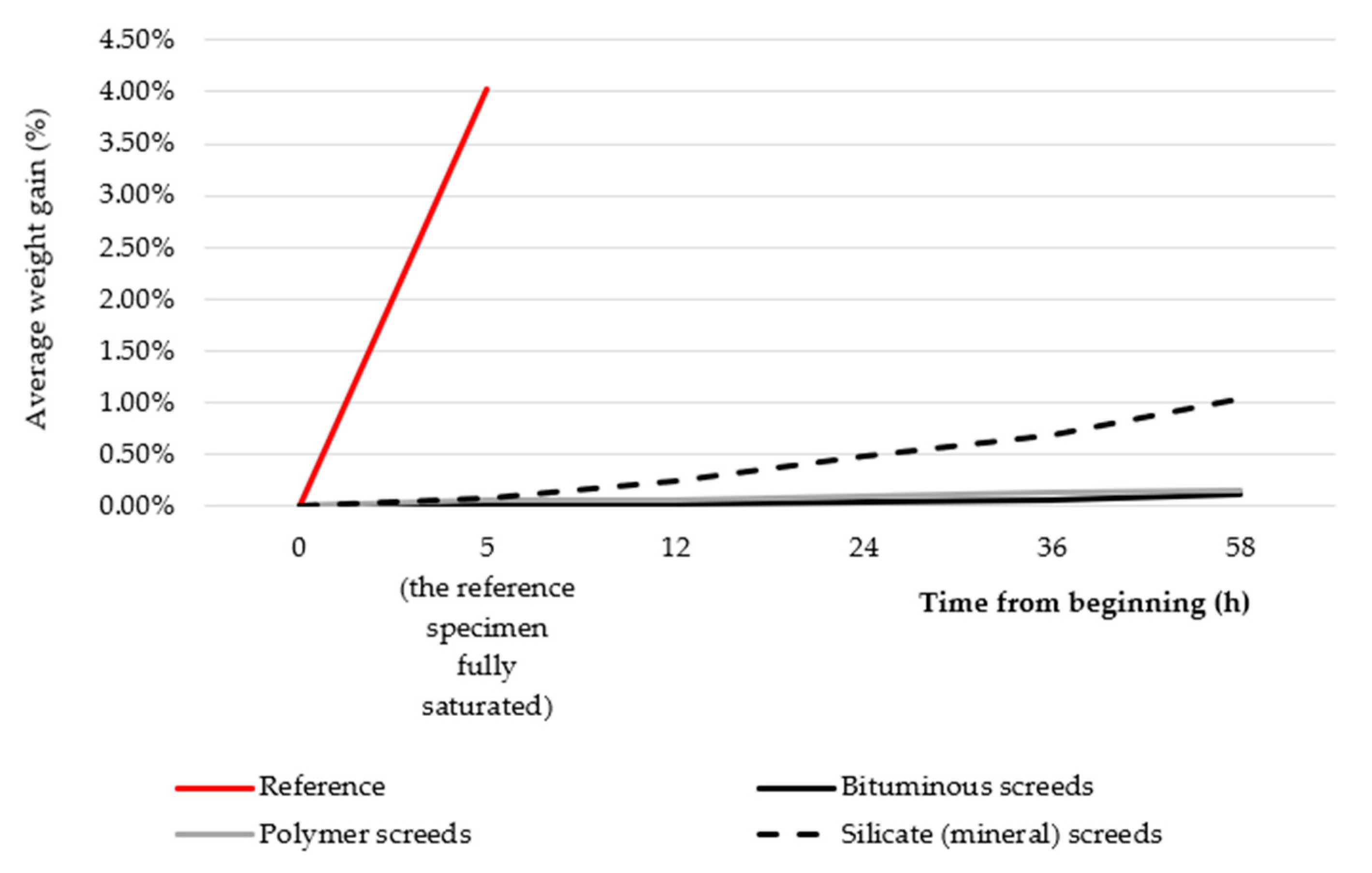

2.1. Basic Study—Water Pressure Test

2.2. Additional “Masonry Test”—Influence of Joints

2.3. Main Study—Cohesion to Structures

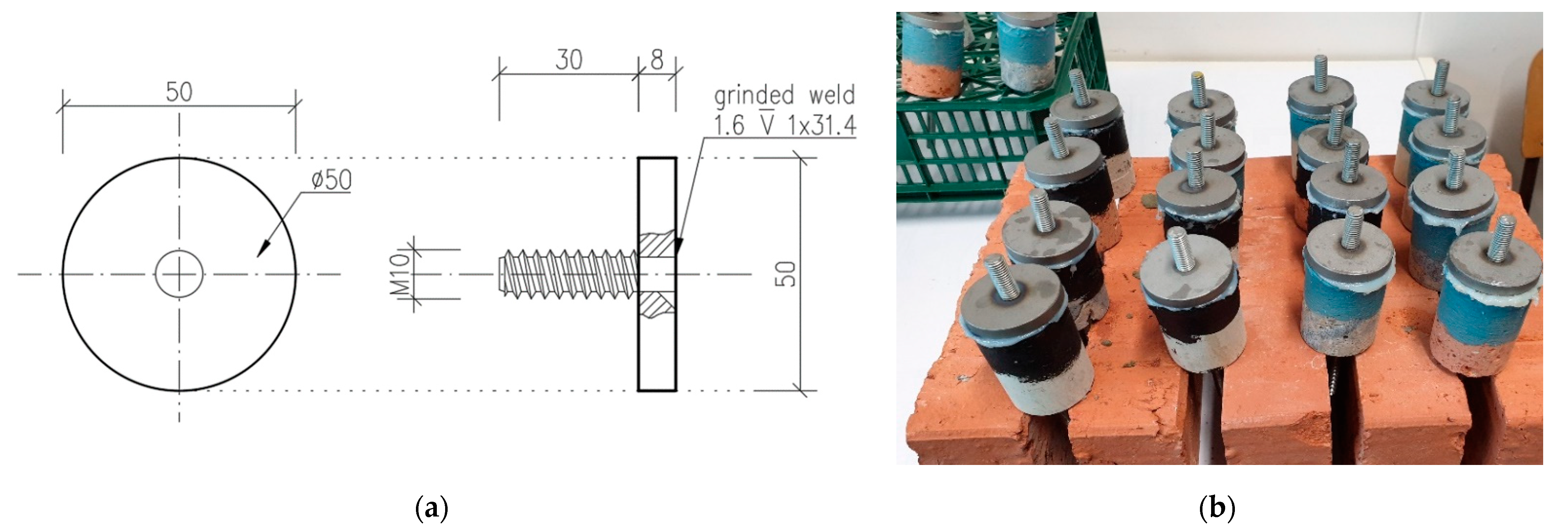

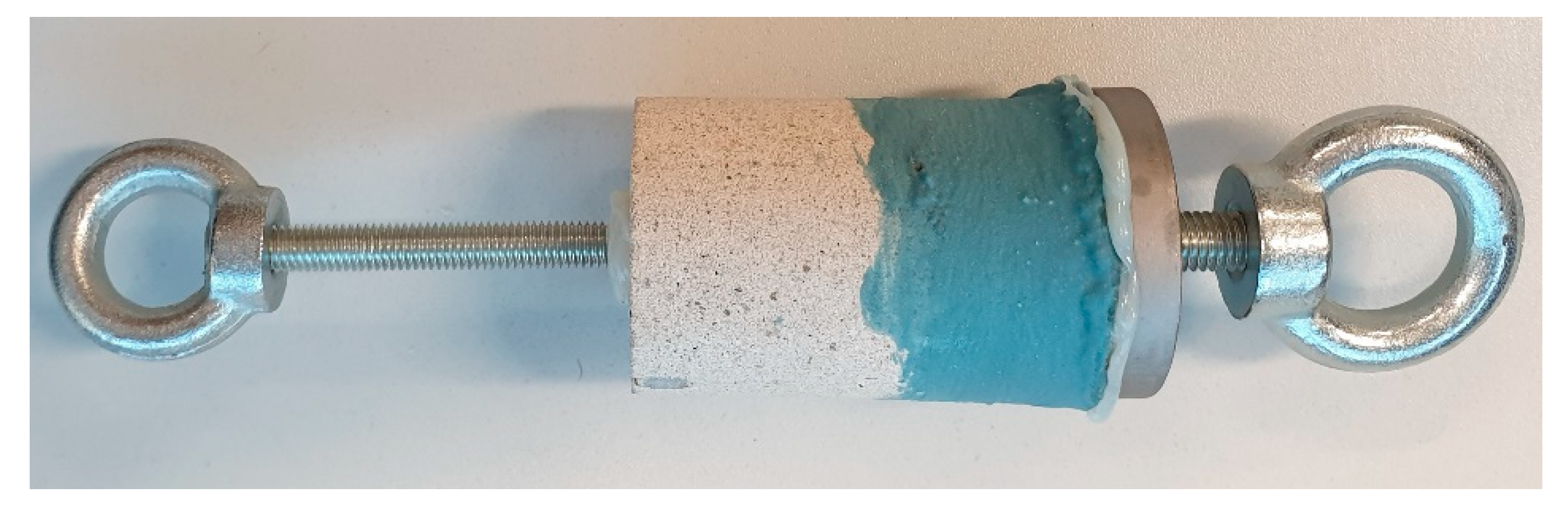

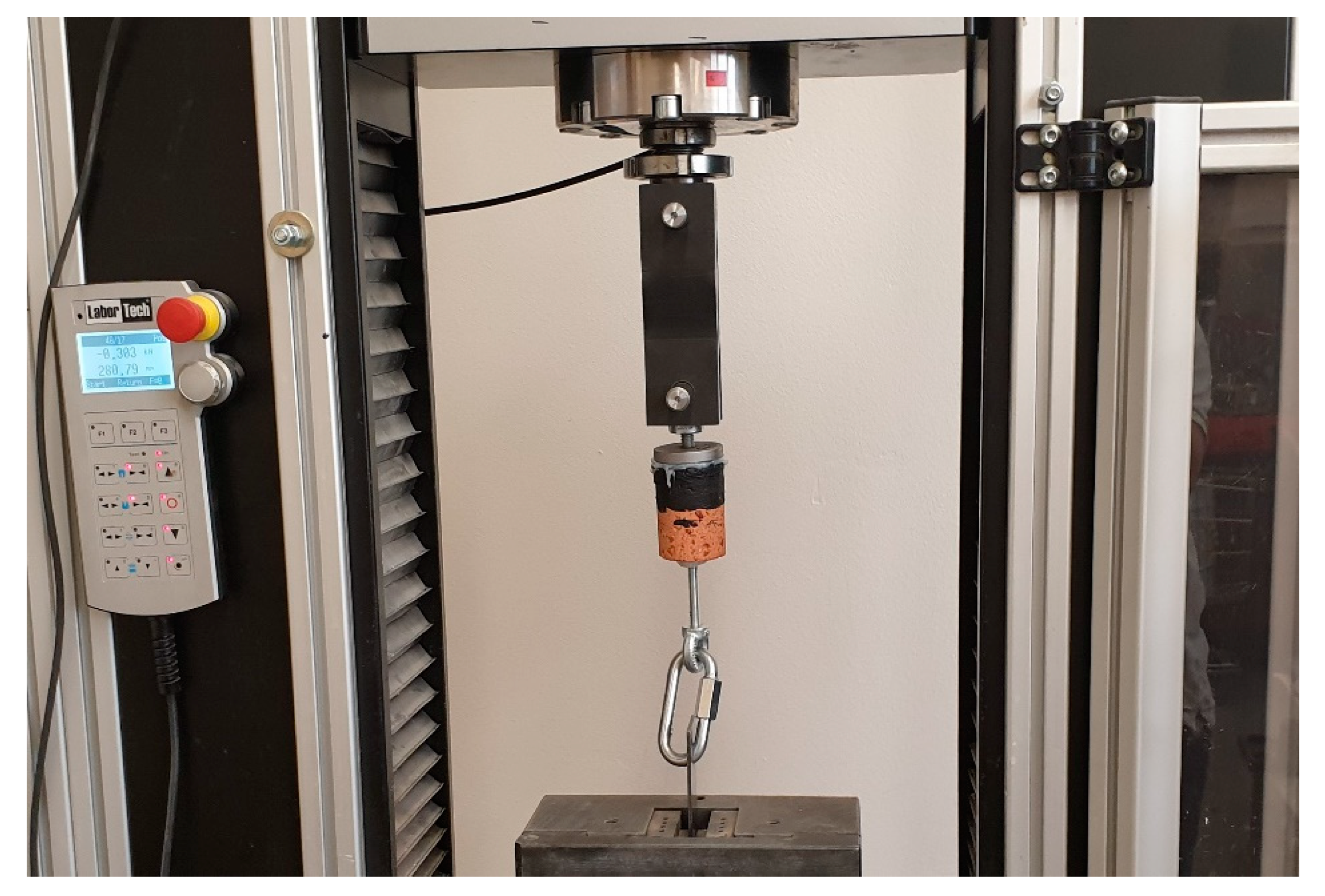

3. Results and Discussion

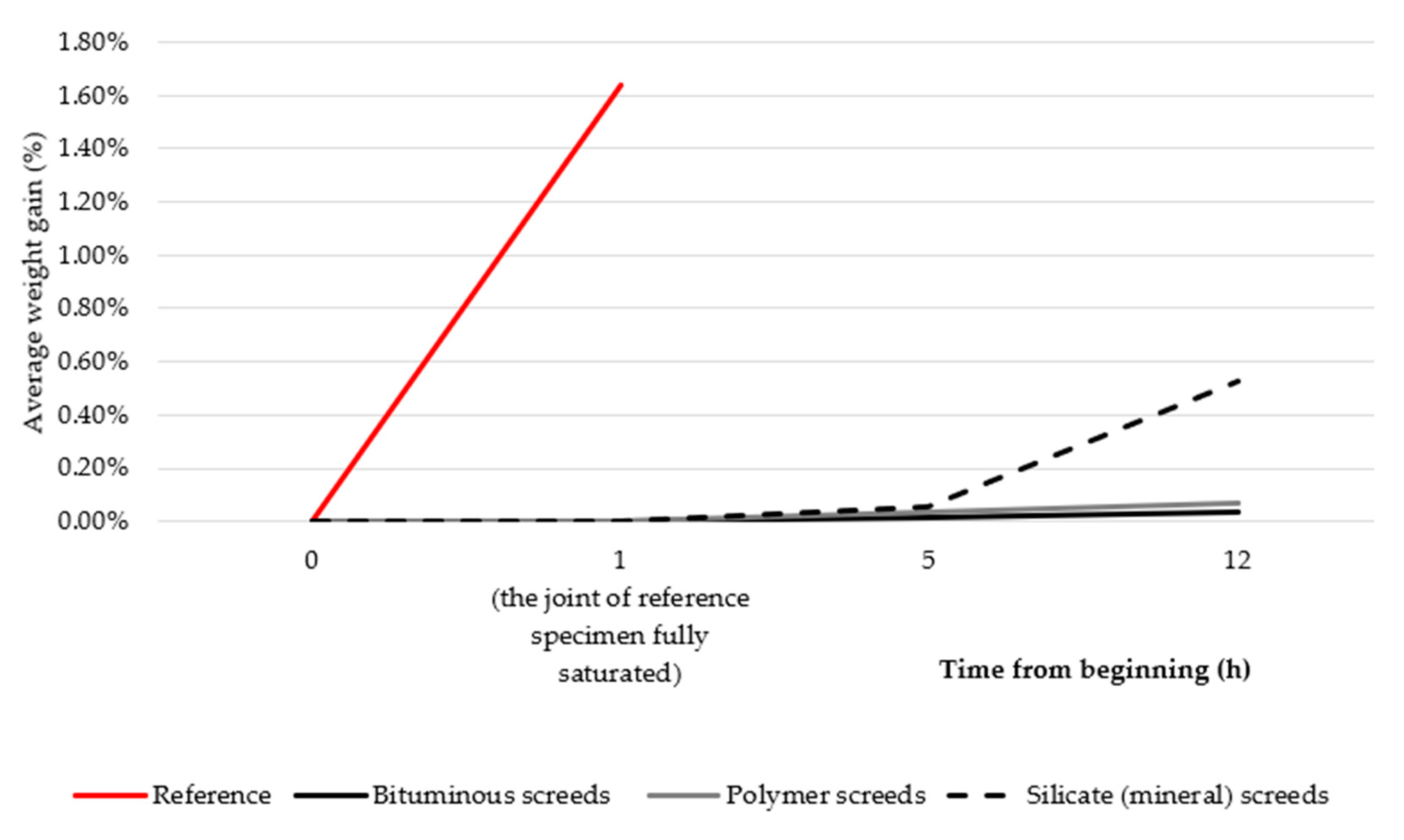

3.1. Basic Study—Water Pressure Test

3.2. Additional “Masonry Test”—Influence of Joints

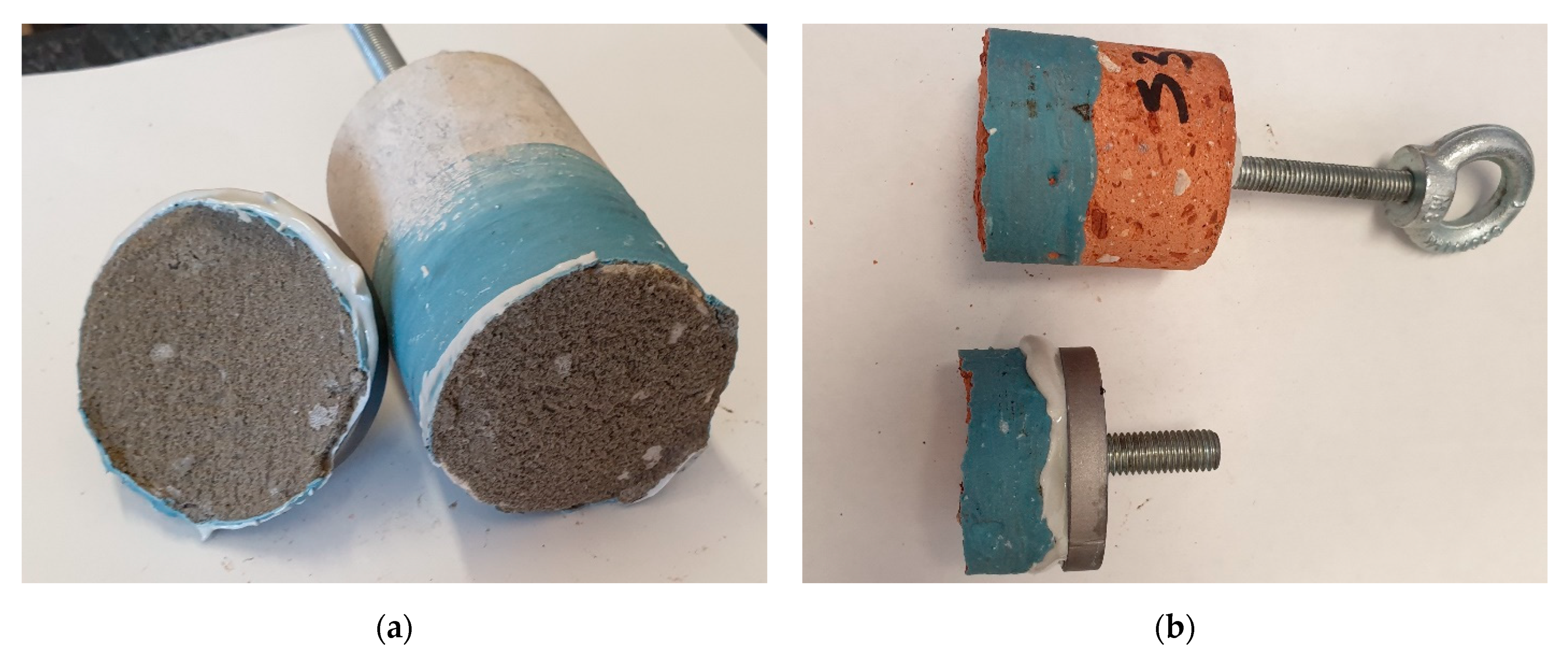

3.3. Main Study—Cohesion to Structures

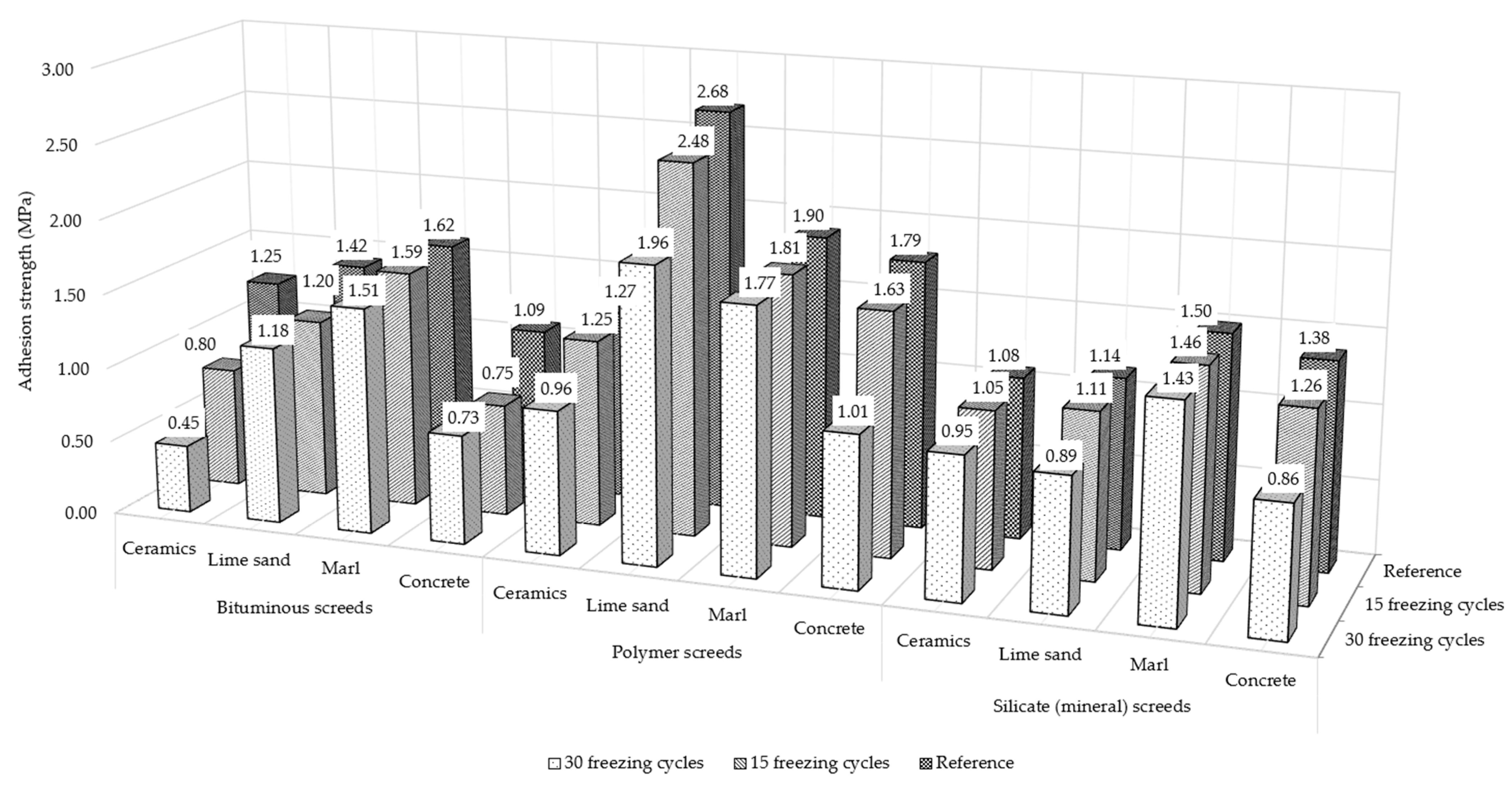

3.3.1. Results with the Substrate Influence

Results—Bituminous Screeds

Results—Polymer Screeds

Results—Silicate (Mineral) Screeds

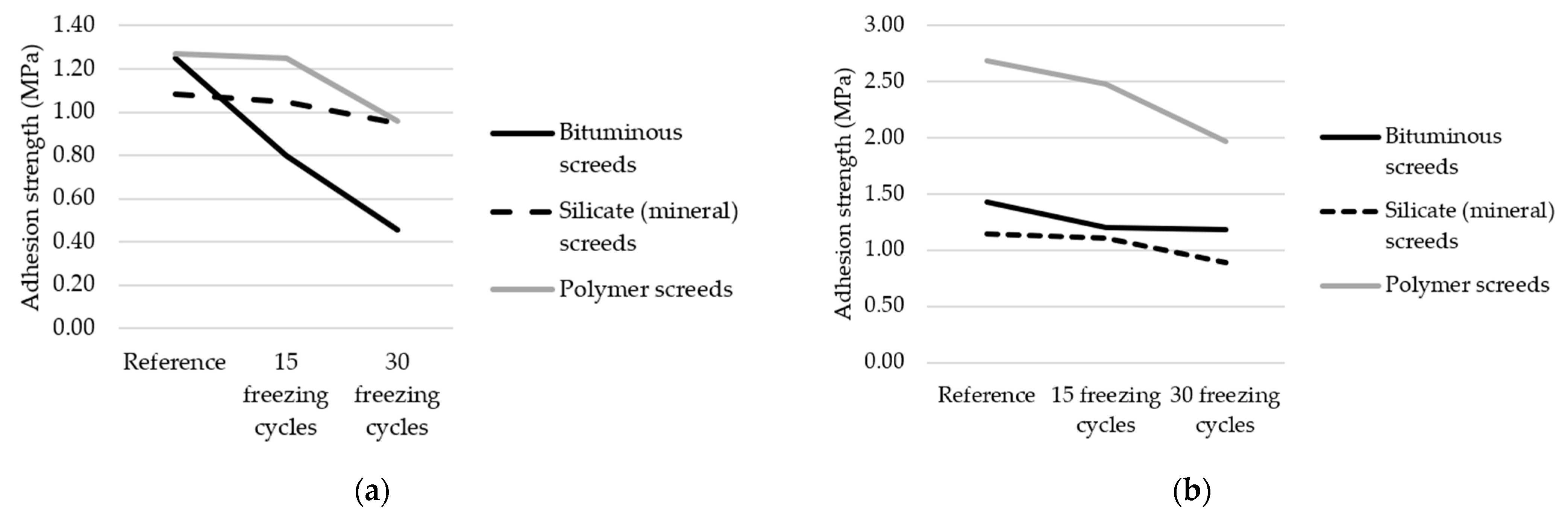

3.3.2. Results without the Substrate Influence

4. Conclusions

- -

- The suitable waterproofing ability of all types of the tested screeds applied on building materials was confirmed.

- -

- All studied screeds resisted the water pressure of 0.12 MPa, however the mineral screed exhibited a seepage into the substrate material;

- -

- The permeability testing performed on the “whole masonry” blocks declared no negative influence of the joints on the tightness of the studied screeds;

- -

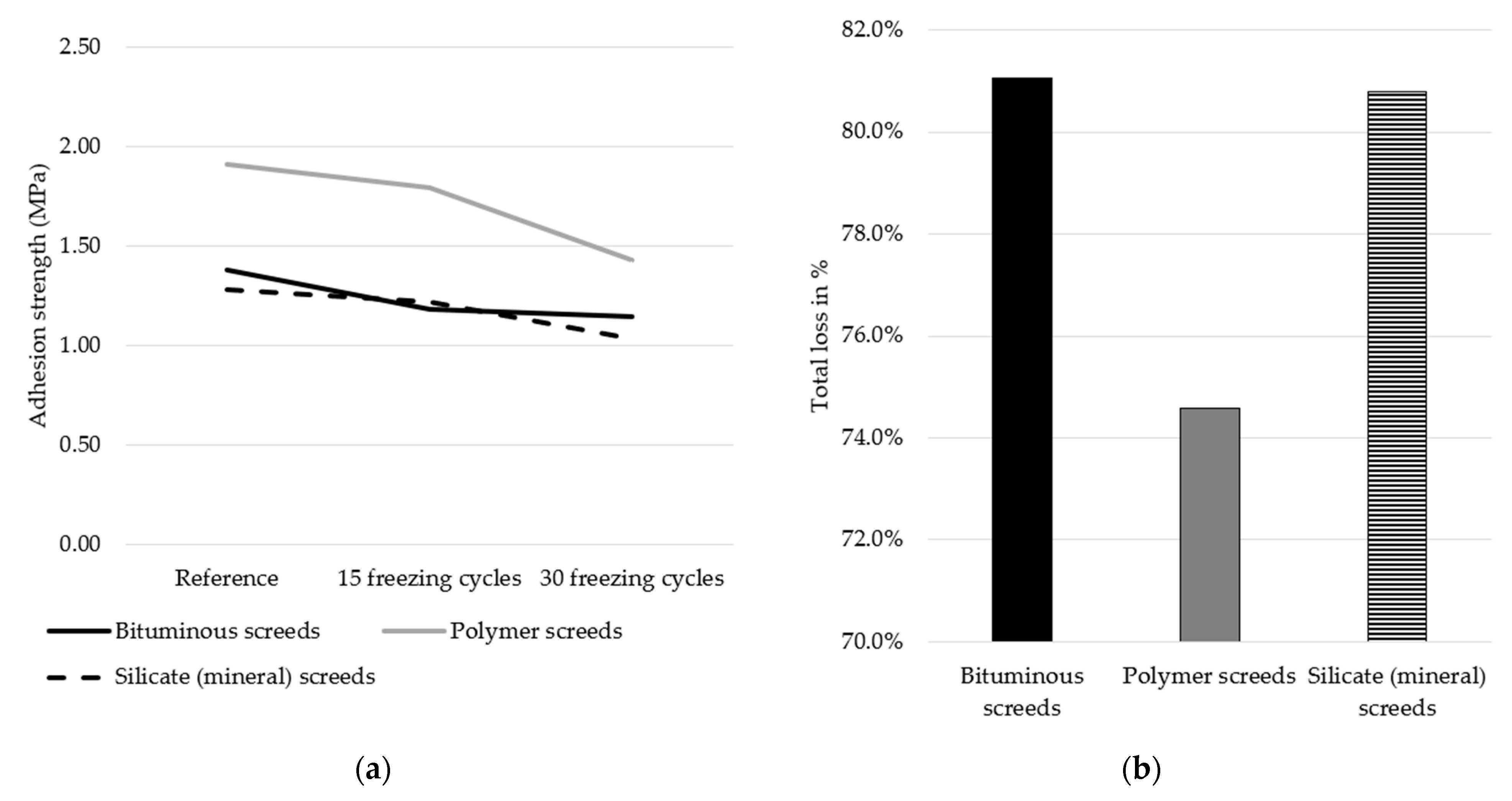

- The best cohesion exhibited the polymer screed, however concurrently achieved the highest decay of the cohesion during freeze-thaw cycling;

- -

- The cohesion of the bitumen and mineral screed were very similar. While, the decay of mechanical properties of mineral screed was proportional to passed freeze-thaw cycles, the bitumen screed exhibited significant drop of the mechanical performance after 15 cycles, however following freeze-thaw exposure caused negligible deterioration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kubal, M. Construction Waterproofing Handbook, 2nd ed.; McGraw-Hill Publishing: New York, NY, USA, 2008. [Google Scholar]

- Chew, M.Y.L.; De Silva, N. Benchmarks to Minimize Water Leakages in Basements. Struct. Surv. 2003, 21, 131–145. [Google Scholar] [CrossRef]

- Larisch, M. Modern Concrete Technology and Placement Methods and Their Influence on Waterproofing Performance of Diaphragm Walls. In Proceedings of the New Zealand Concrete Industry Conference 2016, Auckland, New Zealand, 6–8 October 2016. [Google Scholar]

- Pazderka, J. Concrete with Crystalline Admixture for Ventilated Tunnel against Moisture. Key Eng. Mater. 2016, 677, 108–113. [Google Scholar] [CrossRef]

- Dao, V.; Dux, P.; Morris, P.H.; Carse, A.H. Performance of Permeability-reducing Admixtures in Marine Concrete Structures. Aci. Mater. J. 2010, 107, 291–296. [Google Scholar]

- Furuya, T.; Iwasa, T.; Sasajima, Y. An Effective and Eternal Maintenance Method for Concrete Tunnel Structures. Tunn. Struct. 1998, 78, 439–447. [Google Scholar]

- Zhu, K.; He, X.; Quan, Y.; Zhong, W.; Zhang, K. Application of Non-curing Rubber Asphalt Screed in Waterproofing of Shield Tunnel Segment Joints in Water-rich Stratum. Mod. Tunn. Tech. 2019, 56, 201–205. [Google Scholar] [CrossRef]

- Kho, C.; Tan, S.C.; Kog, Y.C. A Strategy for Waterproofing of Underground Structures. Underground Singapore 2014, Singapore, 25 September 2014. Available online: https://docplayer.net/29928088-Underground-singapore-2014-day-1-25-th-september-thursday-furama-riverfront-hotel.html (accessed on 29 October 2021).

- Martin, K. Flexible Plastics Sheets for Waterproofing. Build. Forum. 1970, 2, 109. [Google Scholar]

- Lim, S.; Kawashima, S. Mechanisms Underlying Crystalline Waterproofing Through Microstructural and Phase Characterization. J. Mater. Civ. Eng. 2019, 31, 9. [Google Scholar] [CrossRef]

- Song, S.; Xue, X.; Li, Y.; Yang, J.; He, Z.; Shen, S.; Jiang, L.; Zhang, W.; Xu, L.; Zhang, H. Experimental Exploration of the WaterProofing Mechanism of Inorganic Sodium Silicate-based Concrete Sealers. Constr. Build. Mater. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Wong, I.H. Experience with Waterproofness of Basements Constructed of Concrete Diaphragm Walls in Singapore. Tunn. Undergr. Space Technol. 1997, 12, 491–495. [Google Scholar] [CrossRef]

- Bochen, J. Weathering Effects on Physical–chemical Properties of External Plaster Mortars Exposed to Different Environments. Constr. Build. Mater. 2015, 79, 192–206. [Google Scholar] [CrossRef]

- WTA. Merkblatt 4-6-05 Wissenschaftlich-Technische Arbeitsgemeinschaft für Bauwerkserhaltung und Denkmalpflege e.V.; Fraunhofer IRB Verlag: Stuttgart, Deutschland, 2005; ISBN 978-3-8167-6996-5. [Google Scholar]

- DIN 18195-1:2000-08. Water-Proofing of Buildings—Part 1: Principles, Definitions, Attribution of Waterproofing Types, 2000-08. Available online: https://www.din.de/en/getting-involved/standards-committees/nabau/publications/wdc-beuth:din21:272715755 (accessed on 29 October 2021).

- Kaya, D.; Topal, A.; Gupta, J.; McNally, T. Aging Effects on the Composition and Thermal Properties of Styrene-butadiene-styrene (SBS) Modified Bitumen. Constr. Build. Mater. 2020, 235, 117450. [Google Scholar] [CrossRef]

- He, Y.H.; Cao, Z.L.; Liu, Z.Y.; Li, J.T.; Yu, J.Y.; Ge, Y.Y. Influence of Heat and Ultraviolet Aging on the Structure and Properties of High Dosage SBS Modified Bitumen for Waterproof. Constr. Build. Mater. 2021, 287, 122986. [Google Scholar] [CrossRef]

- Zheng, C.F.; Xu, J.P.; Zhang, T.; Tan, J.G. Study on the Microscopic Damage of Porous Asphalt Mixture Under the Combined Action of Hydrodynamic Pressure and Ice Crystal Frost Heave. Constr. Build. Mater. 2021, 303, 124489. [Google Scholar] [CrossRef]

- Bader, T.; Waldner, B.J.; Unterberger, S.H.; Lackner, R. On the Performance of Film Formers Versus Penetrants as Water-repellent Treatment of High-performance Concrete (HPC) Surfaces. Constr. Build. Mater. 2019, 203, 481–490. [Google Scholar] [CrossRef]

- Kim, J.; Kitagaki, R. Chemical Properties and Mass Transfer Resistance of Mortar Surface Modified with Silicate-based Surface Impregnant. Constr. Build. Mater. 2020, 262, 120806. [Google Scholar] [CrossRef]

- Chang, J.; Li, W.Z.; Wang, D.; Zhang, Y.Y. Effect of Silicate Modulus on Tensile Properties and Microstructure of Waterproof Coating Based on Polymer and Sodium Silicate-activated GGBS. Constr. Build. Mater. 2020, 252, 119056. [Google Scholar] [CrossRef]

- Rahman, M.; Chamberlain, D. Performance of Crystalline Hydrophobic in Wet Concrete Protection. J. Mater. Civ. Eng. 2017, 29, 04017008. [Google Scholar] [CrossRef] [Green Version]

- Almusallam, A.; Khan, F.; Dulaijan, S.; Al-Amoudi, O. Effectiveness of Surface Screeds in Improving Concrete Durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Scancella, R.J. Use of Xypex Admixture to Concrete as an Inhibitor to Reinforcement Steel Corrosion. In Proceedings of the Materials Engineering Conference, Washington, DC, USA, 10–14 November 1996; Volume 2, pp. 1276–1280. [Google Scholar]

- Chang, S.H.; Kang, T.H.; Choi, S.W.; Lee, C.; Hwang, G.S.; Choi, M.S. An Experimental Study on Fundamental Properties of A Sprayable Waterproofing Membrane. Tunn. Undergr. Space 2016, 26, 220–234. [Google Scholar] [CrossRef]

- Pan, X.Y.; Shi, Z.G.; Shi, C.J.; Ling, T.C.; Li, N. A Review on Surface Treatment for Concrete—Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Chatterji, S. Aspects of the Freezing Process in a Porous Material–Water System: Part 1. Freezing and the Properties of Water and Ice. Cem. Concr. Res. 1999, 29, 627–630. [Google Scholar] [CrossRef]

- Klovas, A.; Dauksys, M.; Ciuprovaite, G. Frost Resistance of Concrete Surfaces Coated with Waterproofing Materials. In Proceedings of the AIP Conference Proceedings, Fethiye, Turkey, 24–27 April 2015; Volume 1653, p. 020060. [Google Scholar] [CrossRef] [Green Version]

- ČSN 73 2579:1981–Test for Frost Resistance of Surface Finish of Building Structures, 1981-04. Available online: http://csnonlinefirmy.agentura-cas.cz/html_nahledy/73/32733/32733_nahled.htm (accessed on 29 October 2021).

| Boundary Conditions | Bitumen Screed | Polymer Screed | Silicate (Mineral) Screed | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ceramics | Reference | spec. 1 | spec. 2 | spec. 3 | spec. 4 | spec. 5 | spec. 6 | spec. 7 | spec. 8 | spec. 9 |

| 15 freezing cycles | spec. 10 | spec. 11 | spec. 12 | spec. 13 | spec. 14 | spec. 15 | spec. 16 | spec. 17 | spec. 18 | |

| 30 freezing cycles | spec. 19 | spec. 20 | spec. 21 | spec. 22 | spec. 23 | spec. 24 | spec. 25 | spec. 26 | spec. 27 | |

| Concrete | Reference | spec. 28 | spec. 29 | spec. 30 | spec. 31 | spec. 32 | spec. 33 | spec. 34 | spec. 35 | spec. 36 |

| 15 freezing cycles | spec. 37 | spec. 38 | spec. 39 | spec. 40 | spec. 41 | spec. 42 | spec. 43 | spec. 44 | spec. 45 | |

| 30 freezing cycles | spec. 46 | spec. 47 | spec. 48 | spec. 49 | spec. 50 | spec. 51 | spec. 52 | spec. 53 | spec. 54 | |

| Lime sand | Reference | spec.55 | spec. 56 | spec.57 | spec. 58 | spec. 59 | spec. 60 | spec. 61 | spec.62 | spec. 63 |

| 15 freezing cycles | spec. 64 | spec. 65 | spec. 66 | spec. 67 | spec. 68 | spec. 69 | spec. 70 | spec. 71 | spec. 72 | |

| 30 freezing cycles | spec. 73 | spec. 74 | spec. 75 | spec. 76 | spec. 77 | spec. 78 | spec. 79 | spec. 80 | spec. 81 | |

| Marl | Reference | spec. 82 | spec. 83 | spec. 84 | spec. 85 | spec. 86 | spec. 87 | spec. 88 | spec. 89 | spec. 90 |

| 15 freezing cycles | spec. 91 | spec. 92 | spec. 93 | spec. 94 | spec. 95 | spec. 96 | spec. 97 | spec. 98 | spec. 99 | |

| 30 freezing cycles | spec. 100 | spec. 101 | spec. 102 | spec. 103 | spec. 104 | spec. 105 | spec. 106 | spec. 107 | spec. 108 | |

| Water Pressure | 0.06 MPa | 0.12 MPa | 0.24 MPa | ||

|---|---|---|---|---|---|

| Time (h) | after 5 h (the reference specimen fully saturated) | after 12 h | after 24 h | after 36 h | after 58 h |

| Average Weight Gain (%) | |||||

| Reference | 4.02 | - | - | - | - |

| Bituminous Screeds | 0.03 | 0.03 | 0.03 | 0.06 | 0.11 |

| Polymer Screeds | 0.05 | 0.06 | 0.10 | 0.13 | 0.15 |

| Silicate (Mineral) Screeds | 0.07 | 0.24 | 0.49 | 0.69 | 1.03 |

| Type of the Screeds | Type of Substrate | After 15 Freezing Cycles | After 30 Freezing Cycles |

|---|---|---|---|

| Bituminous Screeds | Ceramics | 64.0% | 36.3% |

| Lime sand | 84.1% | 83.1% | |

| Marl | 97.8% | 93.0% | |

| Concrete | 68.8% | 67.1% | |

| Polymer Screeds | Ceramics | 98.1% | 75.4% |

| Lime sand | 92.4% | 73.3% | |

| Marl | 95.1% | 93.1% | |

| Concrete | 90.9% | 56.5% | |

| Silicate (Mineral) Screeds | Ceramics | 96.7% | 87.7% |

| Lime sand | 96.9% | 77.9% | |

| Marl | 97.7% | 95.2% | |

| Concrete | 91.0% | 62.4% |

| Average Adhesion Strength without the Influence of the Substrate (MPa) | Average Residual Strength after 30 Freezing Cycles without the Influence of the Substrate (%) | |||

|---|---|---|---|---|

| Type of Screed | Reference | 15 Freezing Cycles | 30 Freezing Cycles | |

| Bituminous Screeds | 1.35 | 1.08 | 0.97 | 81.1% |

| Polymer Screeds | 1.91 | 1.79 | 1.43 | 74.6% |

| Silicate (Mineral) Screeds | 1.28 | 1.22 | 1.03 | 80.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nývlt, M.; Pazderka, J.; Reiterman, P. Comparative Study of Different Types of Waterproofing Screeds with a Focus on Cohesion with Selected Building Materials after the Freeze-Thaw Exposure. Appl. Sci. 2021, 11, 11256. https://doi.org/10.3390/app112311256

Nývlt M, Pazderka J, Reiterman P. Comparative Study of Different Types of Waterproofing Screeds with a Focus on Cohesion with Selected Building Materials after the Freeze-Thaw Exposure. Applied Sciences. 2021; 11(23):11256. https://doi.org/10.3390/app112311256

Chicago/Turabian StyleNývlt, Michal, Jiří Pazderka, and Pavel Reiterman. 2021. "Comparative Study of Different Types of Waterproofing Screeds with a Focus on Cohesion with Selected Building Materials after the Freeze-Thaw Exposure" Applied Sciences 11, no. 23: 11256. https://doi.org/10.3390/app112311256

APA StyleNývlt, M., Pazderka, J., & Reiterman, P. (2021). Comparative Study of Different Types of Waterproofing Screeds with a Focus on Cohesion with Selected Building Materials after the Freeze-Thaw Exposure. Applied Sciences, 11(23), 11256. https://doi.org/10.3390/app112311256