Design and Test of Load-Lifting Performance for Hydraulic Linkage of the High-Medium Horsepower Tractor

Abstract

:Featured Application

Abstract

1. Introduction

2. Device Design

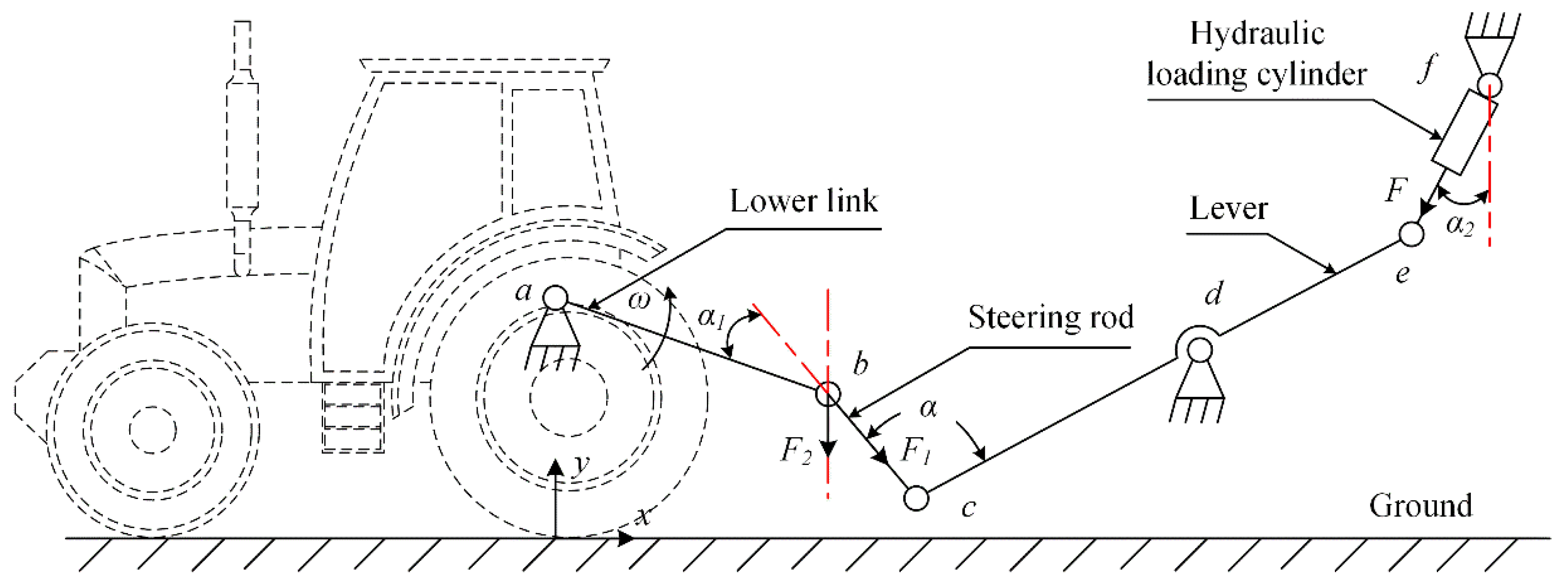

2.1. Principle of Design

2.2. Hooking Structure

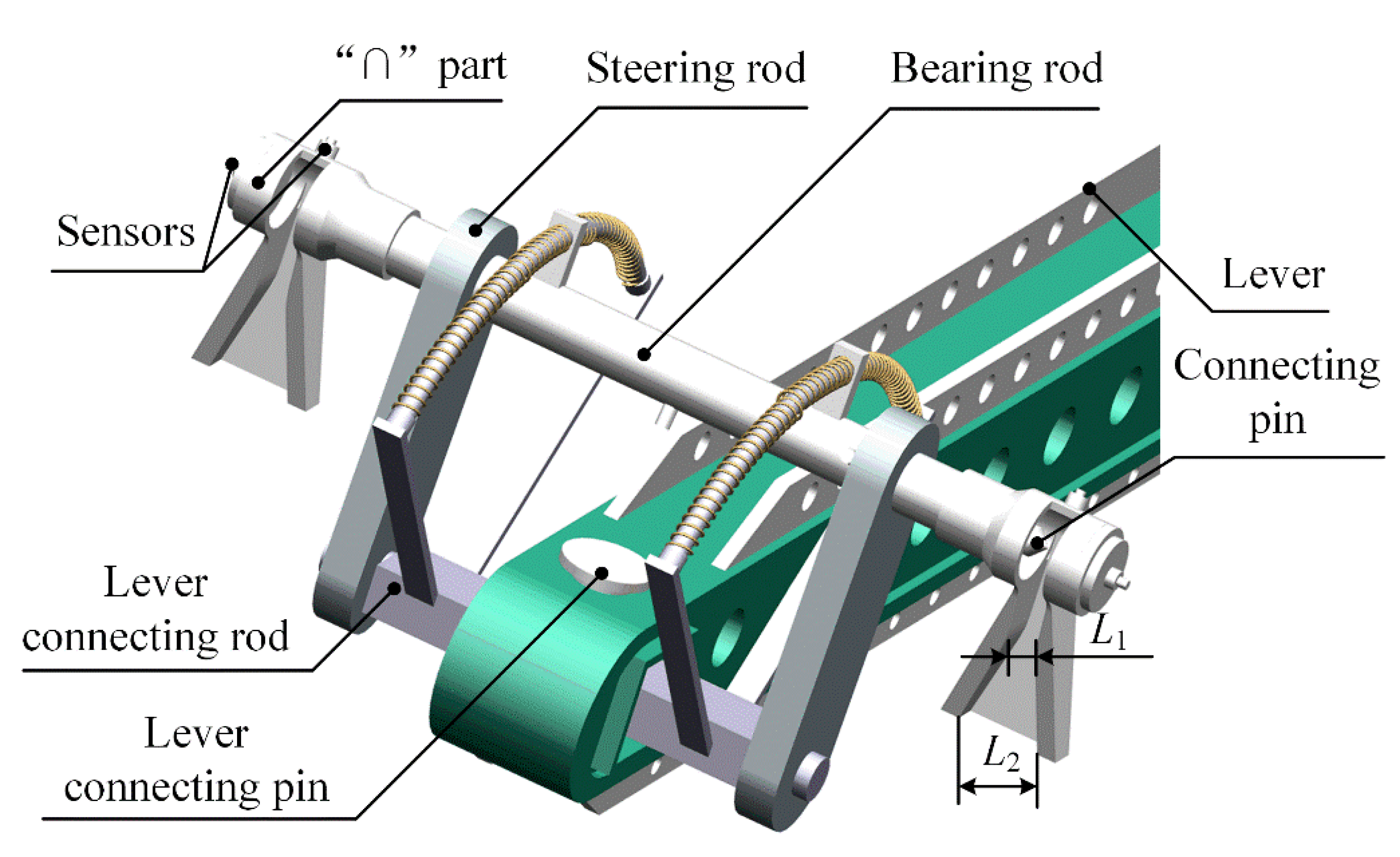

2.3. Connecting Structure

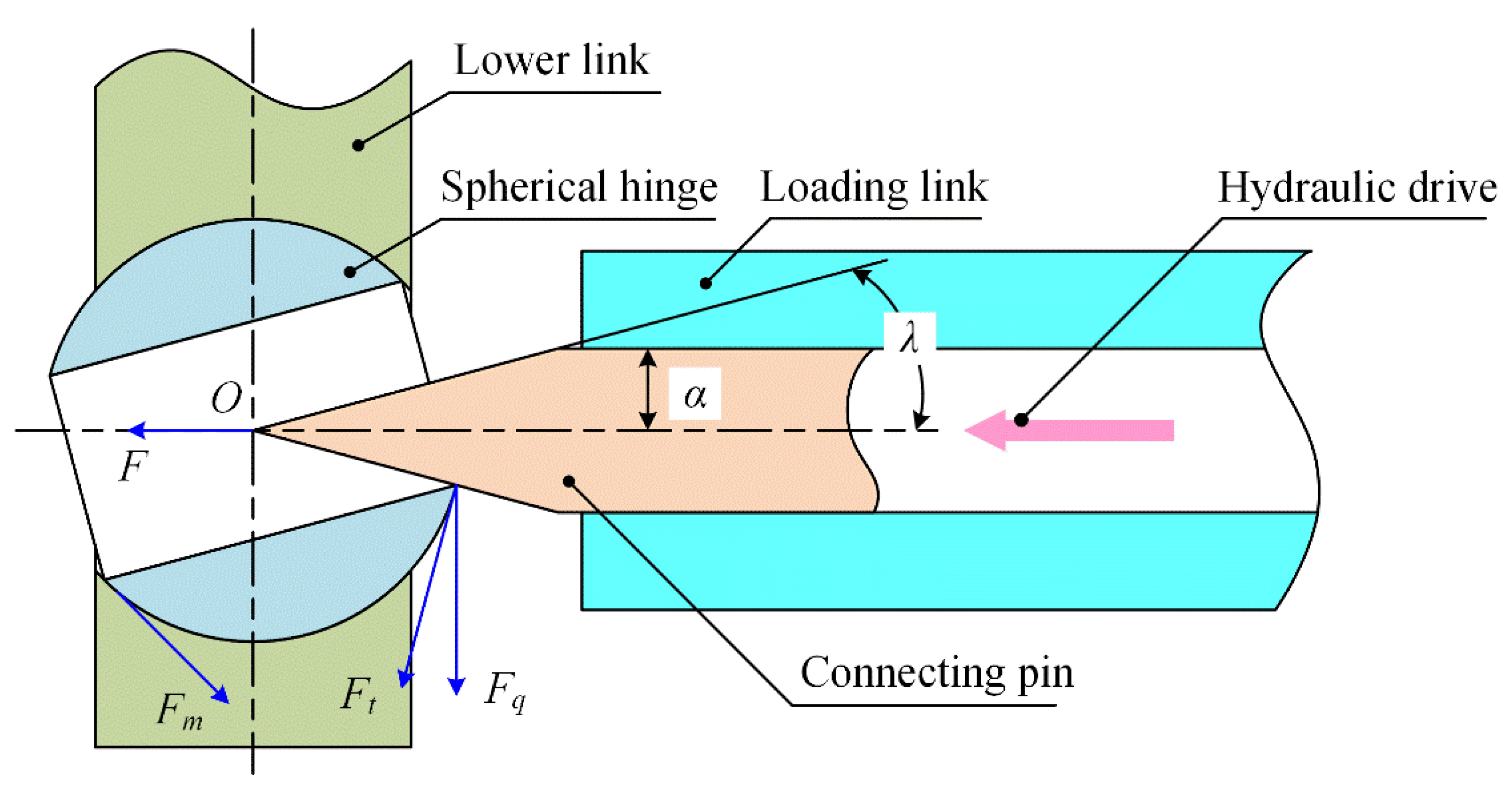

2.4. Load-Lifting Structure

3. Simulation and Experiment

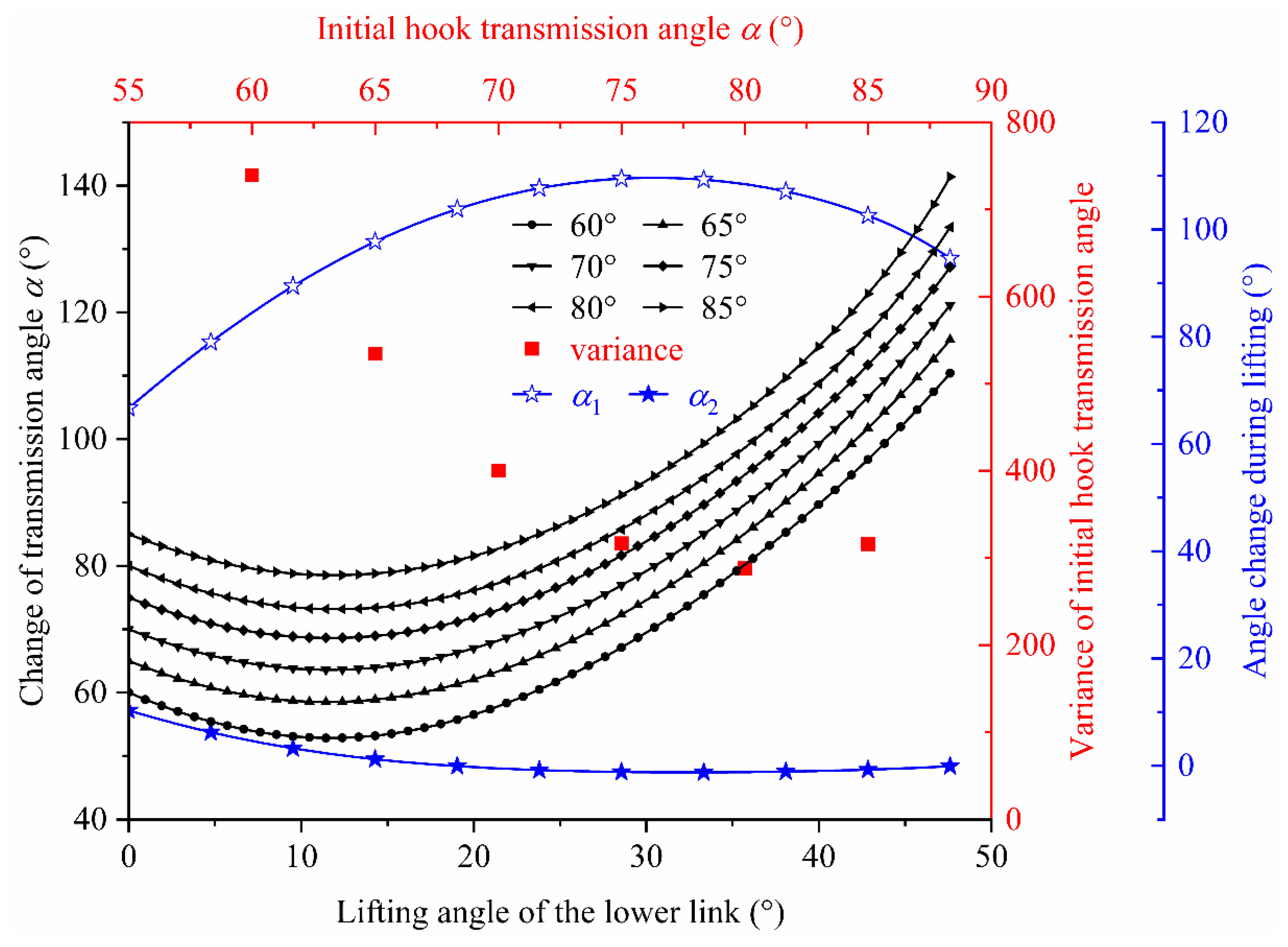

3.1. Kinematics Simulation

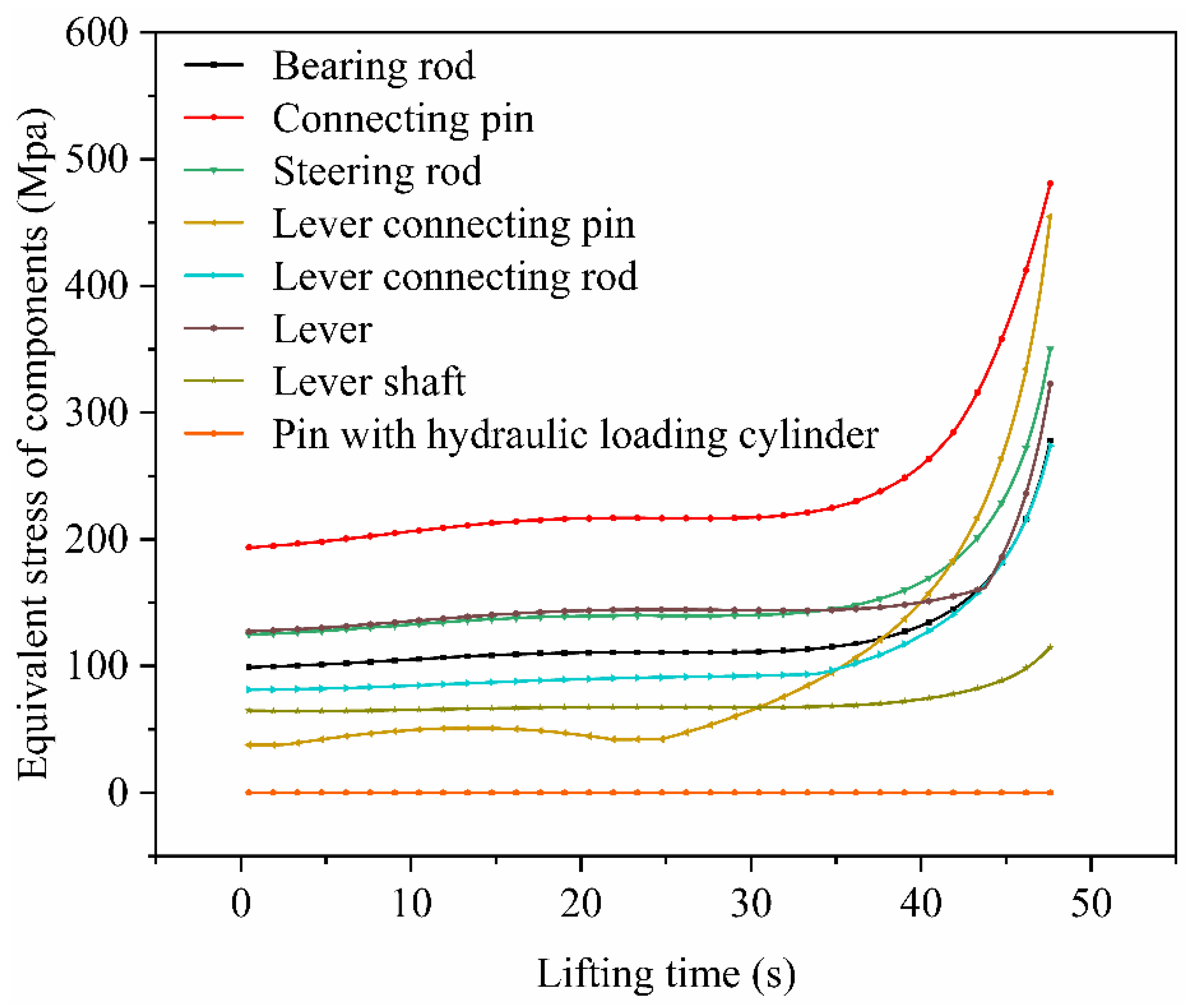

3.2. Mechanical Simulation

3.3. Loading and Lifting Test

3.3.1. Hooking and Lifting Test

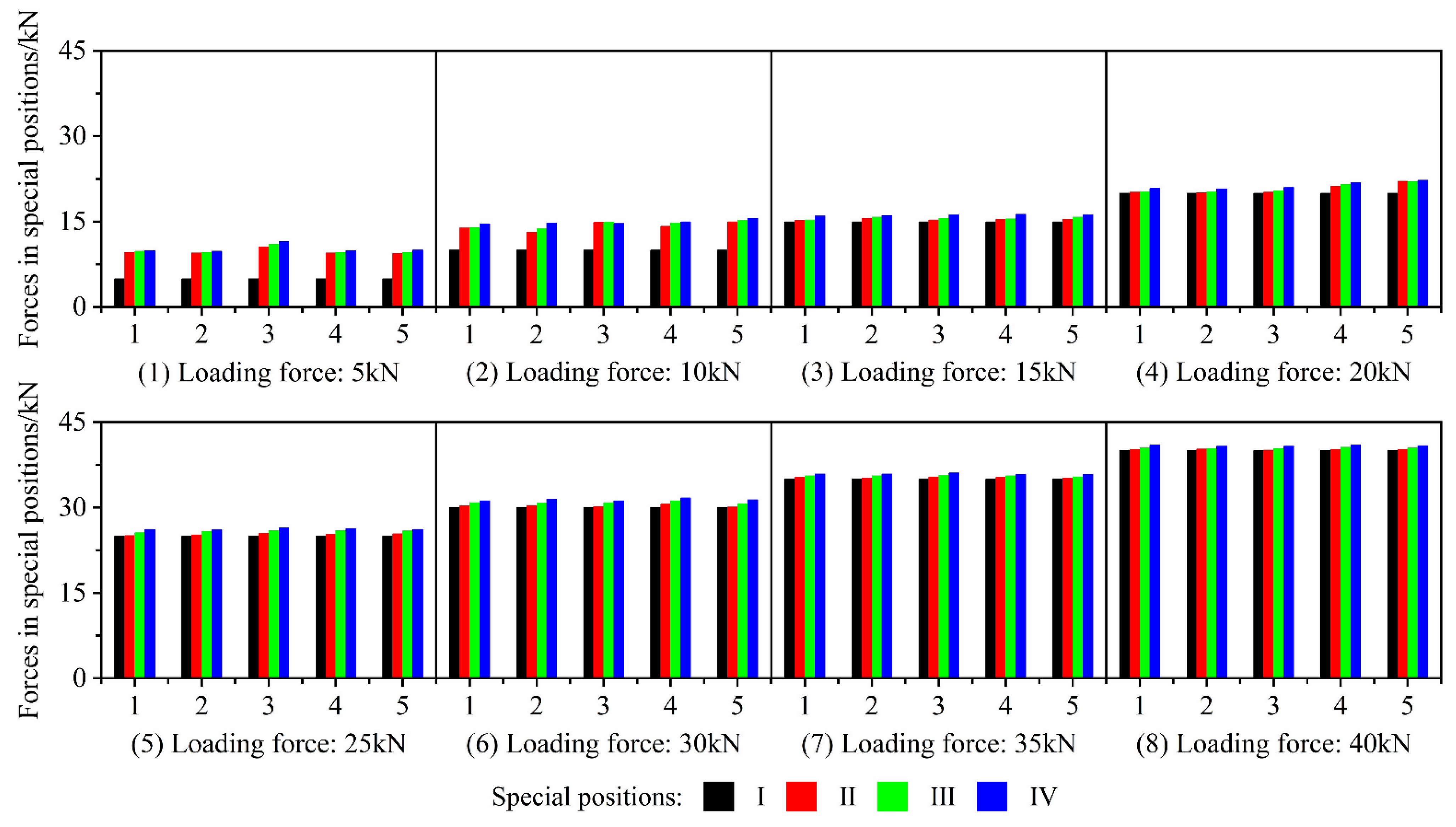

3.3.2. Loading Test

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- National Bureau of Statistics of China. 2020 China Statistical Yearbook, 1st ed.; China Statistics Press: Beijing, China, 2020.

- Bentaher, H.; Hamza, E.; Kantchev, G.; Maalej, A.; Arnold, W. Three-point hitch-mechanism instrumentation for tillage power optimization. Biosyst. Eng. 2008, 100, 24–30. [Google Scholar] [CrossRef]

- Eltom AE, F.; Ding, W.M.; Ding, Q.S.; Tagar, A.A.; Talha, Z. Field investigation of a trash-board, tillage depth and low speed effect on the displacement and burial of straw. CATENA 2015, 133, 385–393. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Munkholm, L.J.; Lamande, M.; Norremark, M.; Skou-Nielsen, N.; Edwards GT, C.; Green, O. Seed drill instrumentation for spatial coulter depth measurements. Comput. Electron. Agric. 2017, 141, 207–214. [Google Scholar] [CrossRef]

- Tarighi, J.; Ghasemzadeh, H.R.; Bahrami, M.; Abdollahpour, S.; Mahmoudi, A. Optimization of a lower hitch link for a heavy duty tractor using finite element method. J. Fail. Anal. Prev. 2016, 16, 123–128. [Google Scholar] [CrossRef]

- Nielse, S.K.; Munkholm, L.J.; Lamande, M.; Norremark, M.; Edwards GT, C.; Green, O. Seed drill depth control system for precision seeding. Comput. Electron. Agric. 2018, 144, 174–180. [Google Scholar]

- Wang, Y.X.; Jing, H.R.; Zhang, D.X.; Cui, T.; Zhong, X.J.; Yang, L. Development and performance evaluation of an electric-hydraulic control system for subsoiler with flexible tines. Comput. Electron. Agric. 2018, 151, 249–257. [Google Scholar] [CrossRef]

- Laceklis-Bertmanis, J.; Pirs, V.; Kronbergs, E.; Metla-Rozentals, A. Evaluation of hydraulic hitch-system improvement. In Proceedings of the 13th International Scientific Conference on Engineering for Rural Development, Jelgava, Latvia, 29–30 May 2014; pp. 74–78. [Google Scholar]

- Laceklis-Bertmanis, J.; Pirs, V.; Kronbergs, E.; Metla-Rozentals, A.; Metla, M. Hydropneumatic suspension for tractor implement. In Proceedings of the 11th International Scientific Conference on Engineering for Rural Development, Jelgava, Latvia, 24–25 May 2012; pp. 372–376. [Google Scholar]

- Mohammadikia, R.; Aliasghary, M. Design of an interval type-2 fractional order fuzzy controller for a tractor active suspension system. Comput. Electron. Agric. 2019, 167, 105049. [Google Scholar] [CrossRef]

- Chang, J.X. Research on hydraulic suspension technology of tractor. Adv. Intel. Syst. Res. 2017, 154, 552–555. [Google Scholar]

- Gao, Q.; Lu, Z.X.; Xue, J.L.; Gao, H.S. Design and test of hydraulic device for electro-hydraulic controlled hitch system of a horticultural tractor. Inmateh-Agric. Eng. 2020, 60, 253–260. [Google Scholar] [CrossRef]

- Meng, C.Y.; Li, G.Y.; Xu, F.; Li, J.F. Tractors hydraulics system stress testing design and experiment. IOP Conf. Ser. Earth Environ. Sci. 2019, 252, 032134. [Google Scholar] [CrossRef]

- Laceklis-Bertmanis, J.; Kronbergs, E. Model of hydropneumatic three point hitch. In Proceedings of the 12th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–24 May 2013; pp. 49–54. [Google Scholar]

- National Manufacturing Strategy Advisory Committee. China Manufacturing 2025 Bluebook, 1st ed.; Publishing House of Electronics Industry: Beijing, China, 2018. [Google Scholar]

- GB/T 3871.4-2006. Agricultural Tractors-Test Procedures—Part 4: Rear Three-Point Linkage Lifting Capacity; General Administration of Quality Supervision, Inspection and Quarantine of China; Standardization Administration of China: Beijing, China, 2006.

- GB/T 1593-2015. Agricultural Wheeled Tractor-Rear-Mounted Three-Point Linkage-Categories 0, 1N, 1, 2N, 2, 3N, 3, 4N and 4; General Administration of Quality Supervision, Inspection and Quarantine of China; Standardization Administration of China: Beijing, China, 2015.

- Qin, D.T.; Xie, L.Y. Modern Handbook of Mechanical of Design, 1st ed.; Chemical Industry Press: Beijing, China, 2011. [Google Scholar]

- Seyedabadi, E. Finite element analysis of lift arm of a MF-285 tractor three-point hitch. J. Fail. Anal. Prev. 2015, 15, 737–743. [Google Scholar] [CrossRef]

| Test Requirements | Indexes |

|---|---|

| Maximum lifting force | 40 kN |

| Number of lifts | 10 |

| Lifting height | 750 ± 10 mm |

| Lifting time | 15 s |

| No | β (%) | t1 (s) | H (mm) | t2 (s) | No | β (%) | t1 (s) | H (mm) | t2 (s) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 5 | 760 | 7 | 11 | 100 | 4 | 760 | 6 |

| 2 | 100 | 6 | 762 | 8 | 12 | 100 | 7 | 760 | 7 |

| 3 | 100 | 4 | 761 | 8 | 13 | 100 | 5 | 760 | 6 |

| 4 | 100 | 6 | 760 | 9 | 14 | 100 | 5 | 759 | 7 |

| 5 | 100 | 6 | 759 | 8 | 15 | 100 | 5 | 758 | 7 |

| 6 | 100 | 4 | 759 | 7 | 16 | 100 | 7 | 756 | 8 |

| 7 | 100 | 4 | 761 | 6 | 17 | 100 | 6 | 761 | 6 |

| 8 | 100 | 5 | 760 | 9 | 18 | 100 | 4 | 761 | 7 |

| 9 | 100 | 5 | 760 | 8 | 19 | 100 | 5 | 761 | 7 |

| 10 | 100 | 6 | 760 | 7 | 20 | 100 | 4 | 760 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, Q.; Yang, Z.; Xu, J.; Ma, B.; Chen, T.; Zhang, X.; Wang, L.; Ru, S. Design and Test of Load-Lifting Performance for Hydraulic Linkage of the High-Medium Horsepower Tractor. Appl. Sci. 2021, 11, 9758. https://doi.org/10.3390/app11209758

Cong Q, Yang Z, Xu J, Ma B, Chen T, Zhang X, Wang L, Ru S. Design and Test of Load-Lifting Performance for Hydraulic Linkage of the High-Medium Horsepower Tractor. Applied Sciences. 2021; 11(20):9758. https://doi.org/10.3390/app11209758

Chicago/Turabian StyleCong, Qian, Zhengwen Yang, Jin Xu, Boshuai Ma, Tingkun Chen, Xiaochao Zhang, Lin Wang, and Shaofeng Ru. 2021. "Design and Test of Load-Lifting Performance for Hydraulic Linkage of the High-Medium Horsepower Tractor" Applied Sciences 11, no. 20: 9758. https://doi.org/10.3390/app11209758

APA StyleCong, Q., Yang, Z., Xu, J., Ma, B., Chen, T., Zhang, X., Wang, L., & Ru, S. (2021). Design and Test of Load-Lifting Performance for Hydraulic Linkage of the High-Medium Horsepower Tractor. Applied Sciences, 11(20), 9758. https://doi.org/10.3390/app11209758