Railway Axle and Wheel Assembly Press-Fitting Force Characteristics and Holding Torque Capacity

Abstract

:1. Introduction

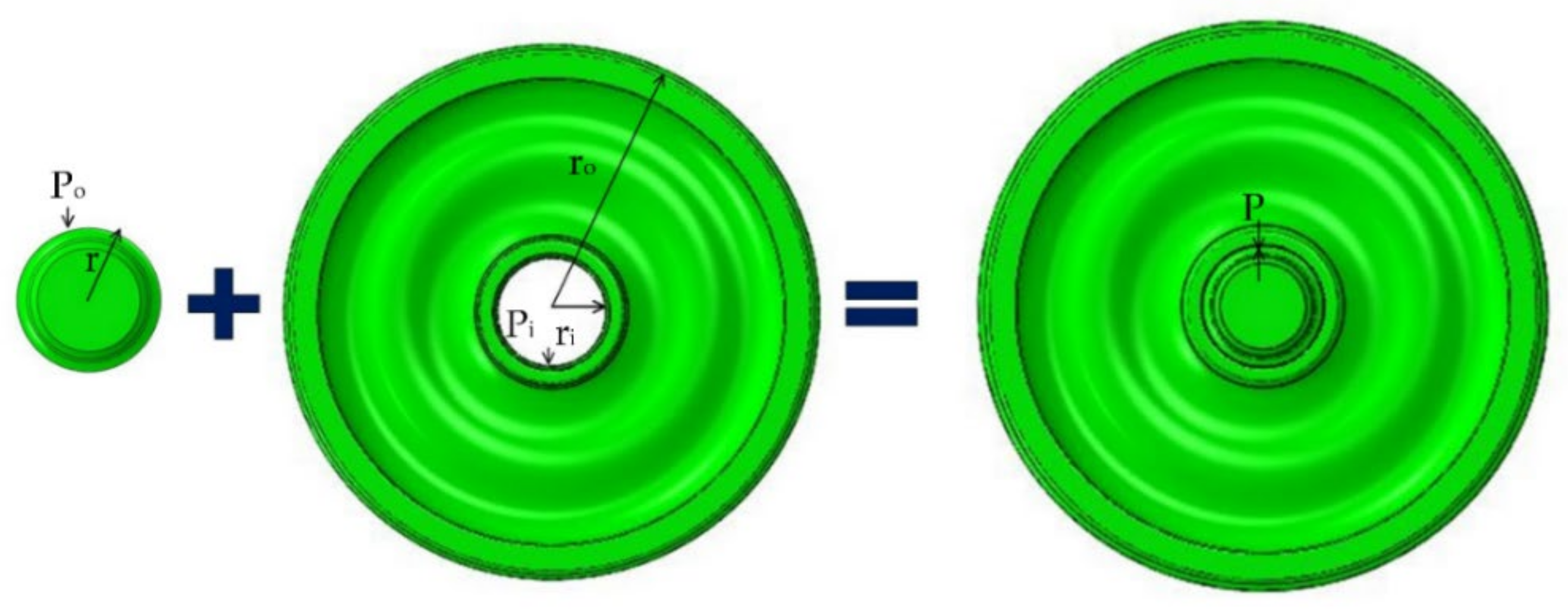

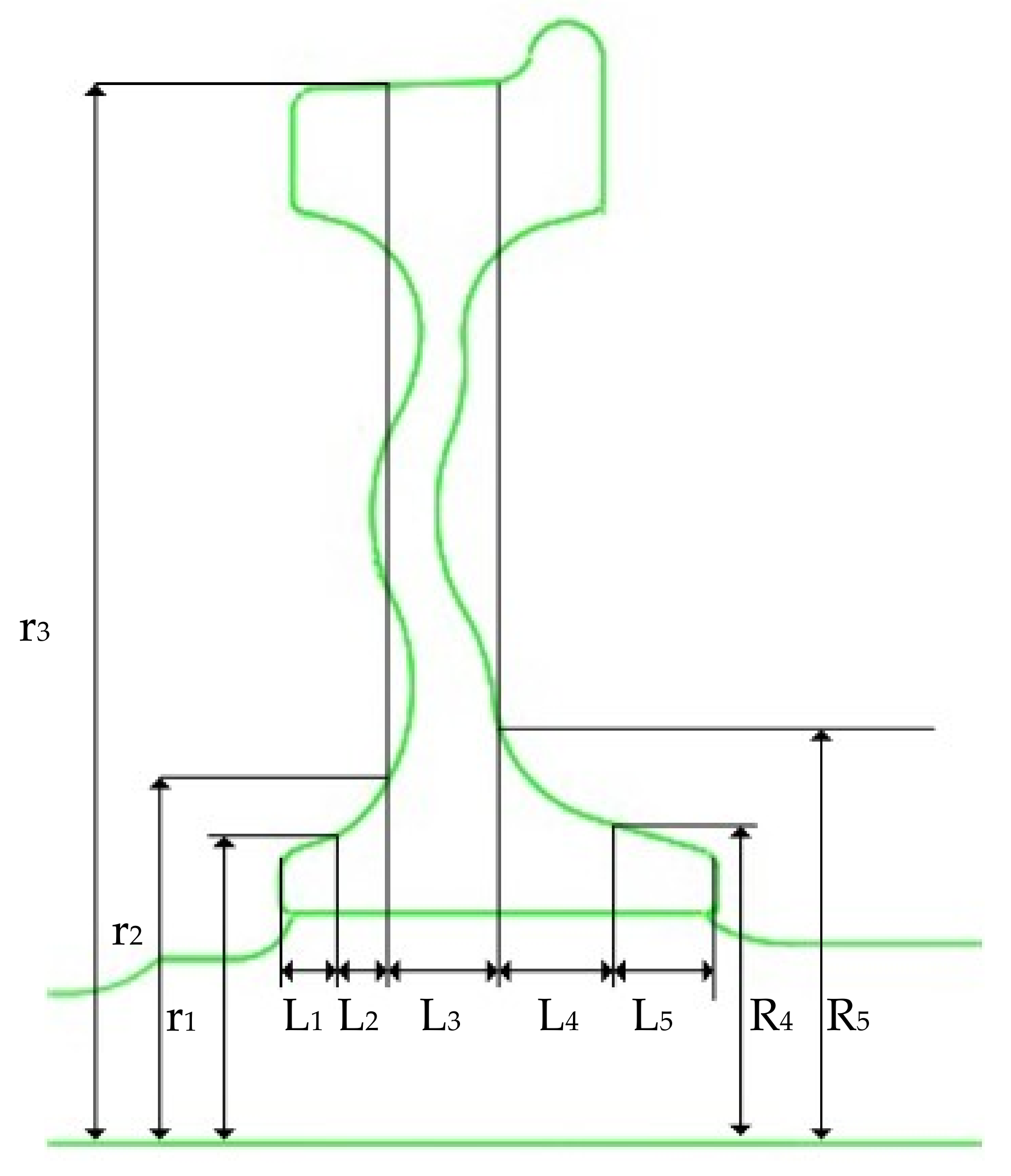

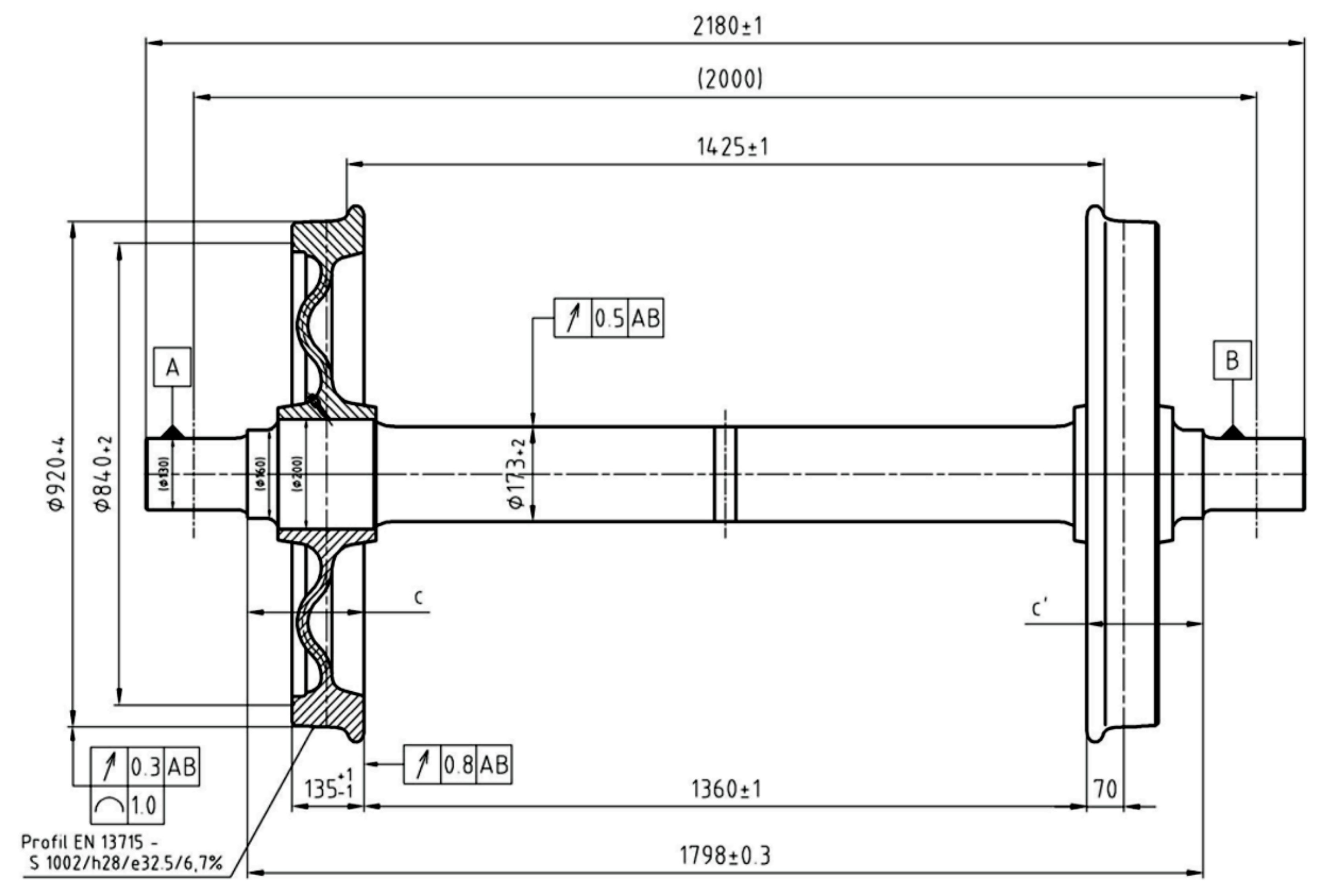

2. Theoretical Analysis of Press-Fitting

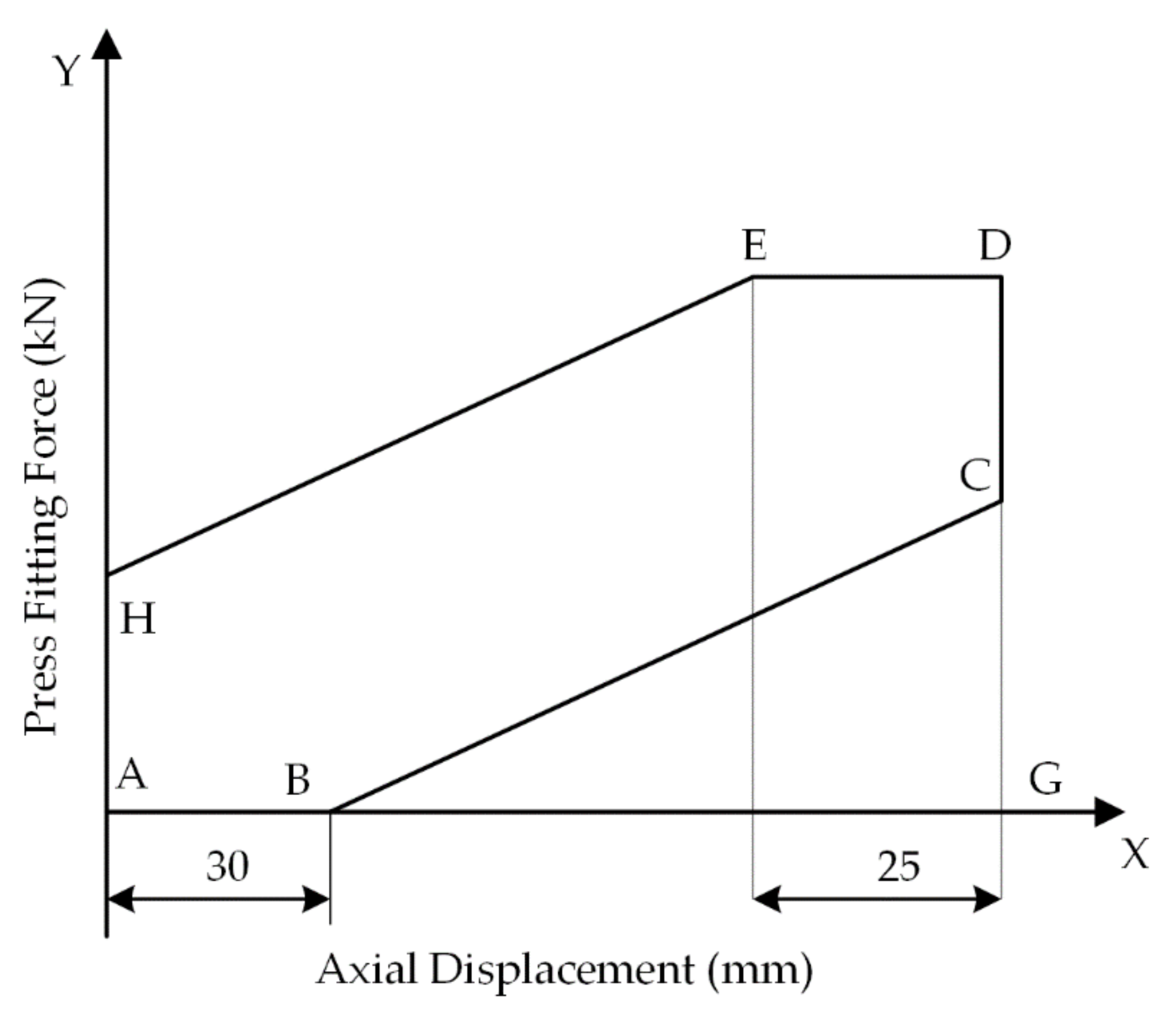

2.1. Characteristics of the Press-Fitting Curve

- YH = 1.3 ϕ;

- YC = 0.85 F;

- YD = YE = 1.45 F;

2.2. Determination of the Press-Fitting Force

3. Finite Element Modelling and Simulation

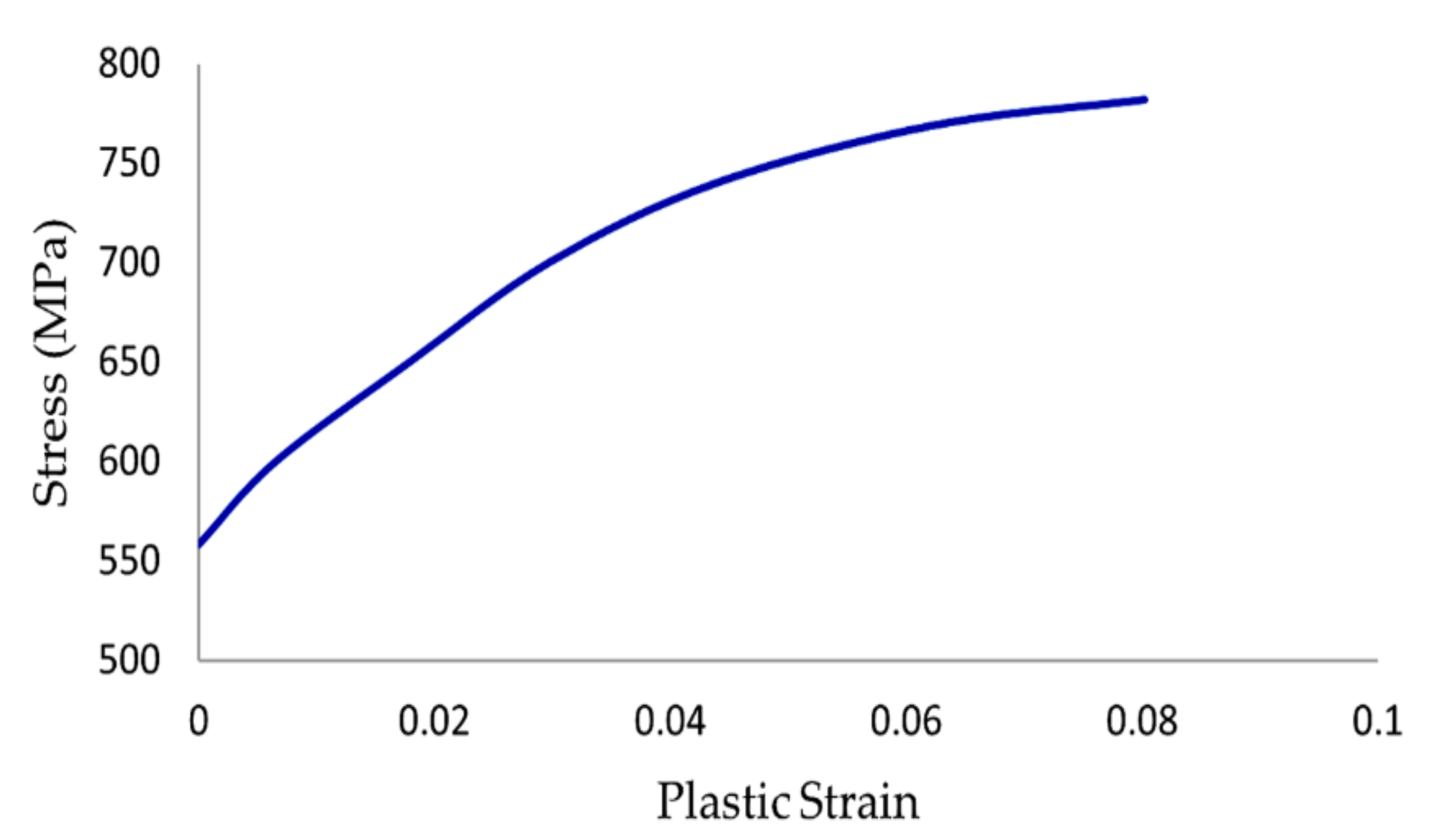

3.1. Materials

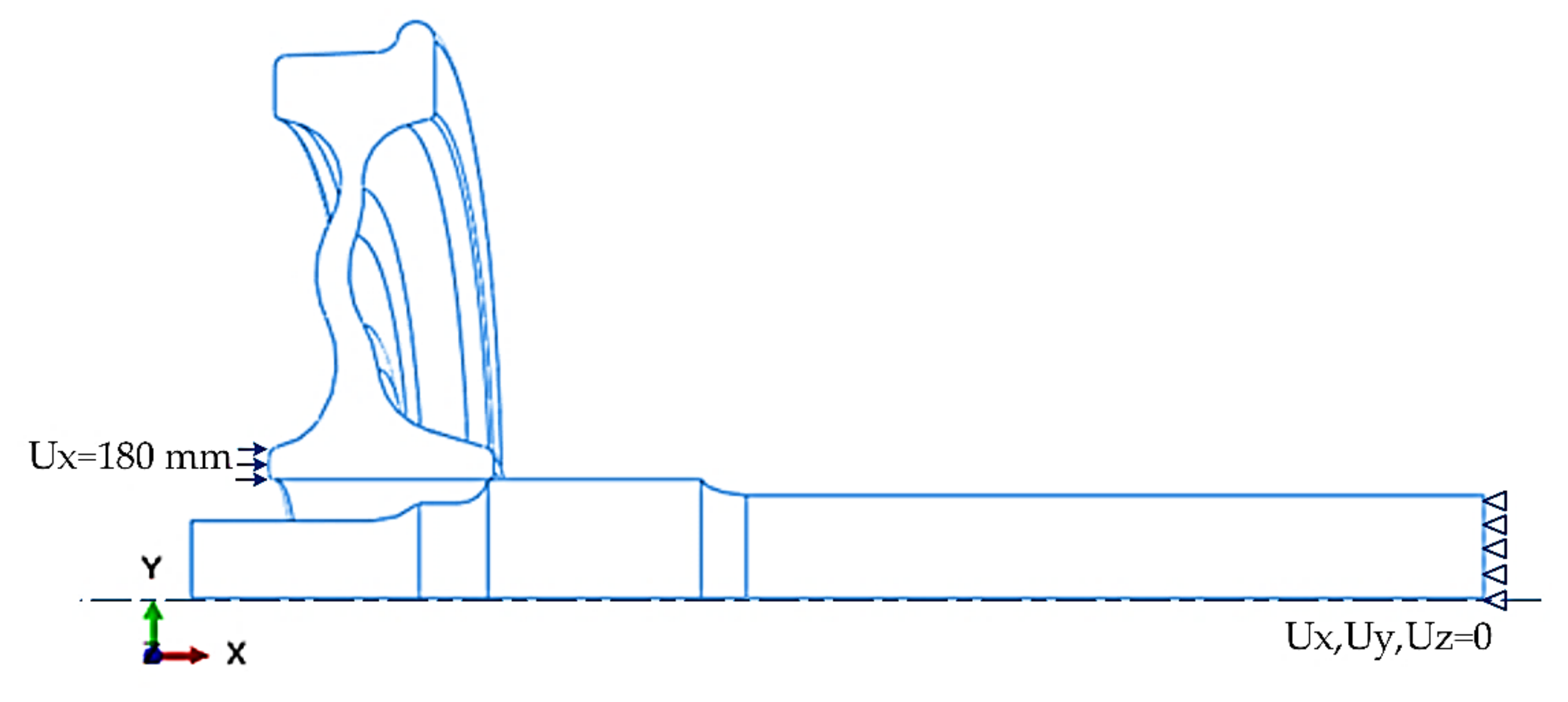

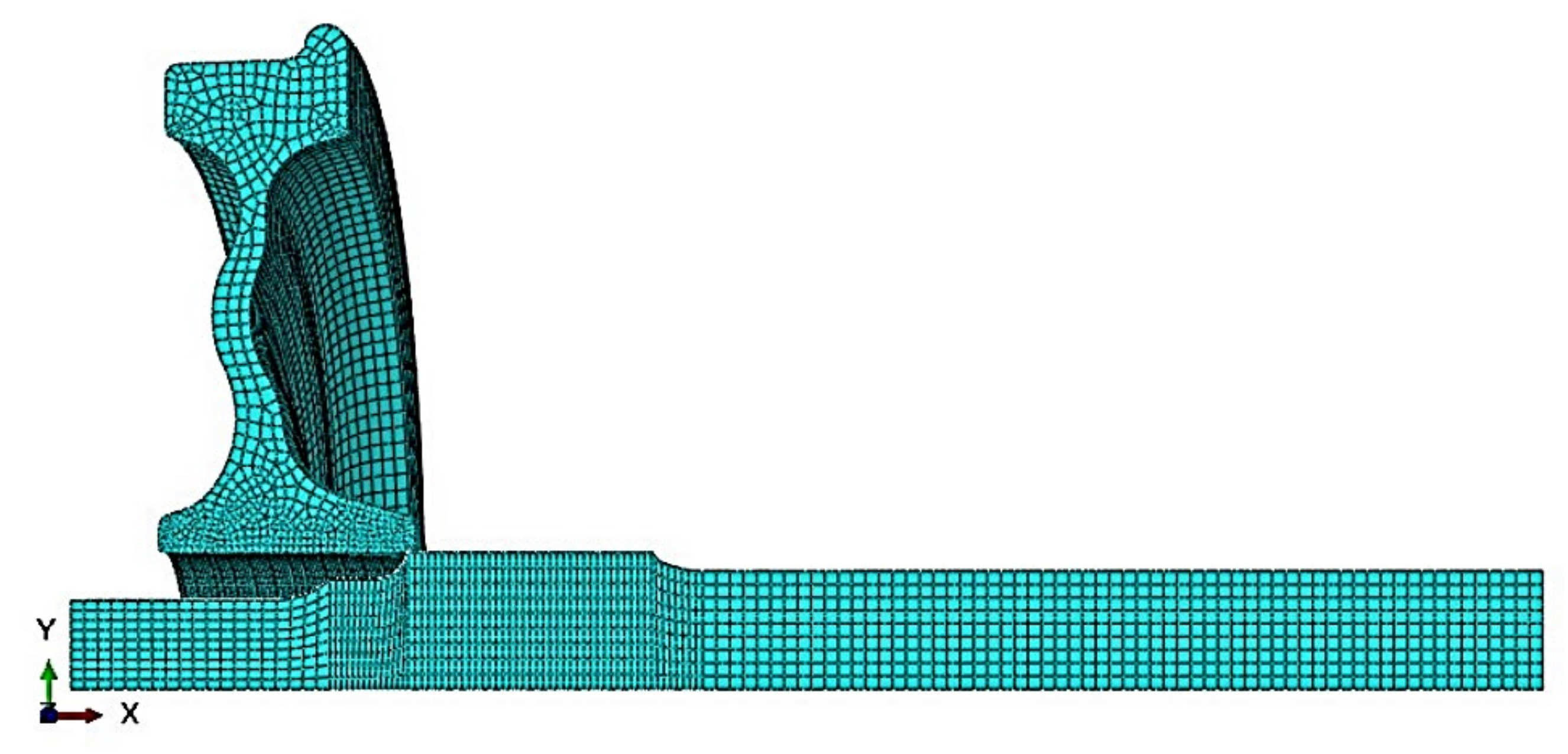

3.2. Modelling and Simulation

4. Results and Discussion

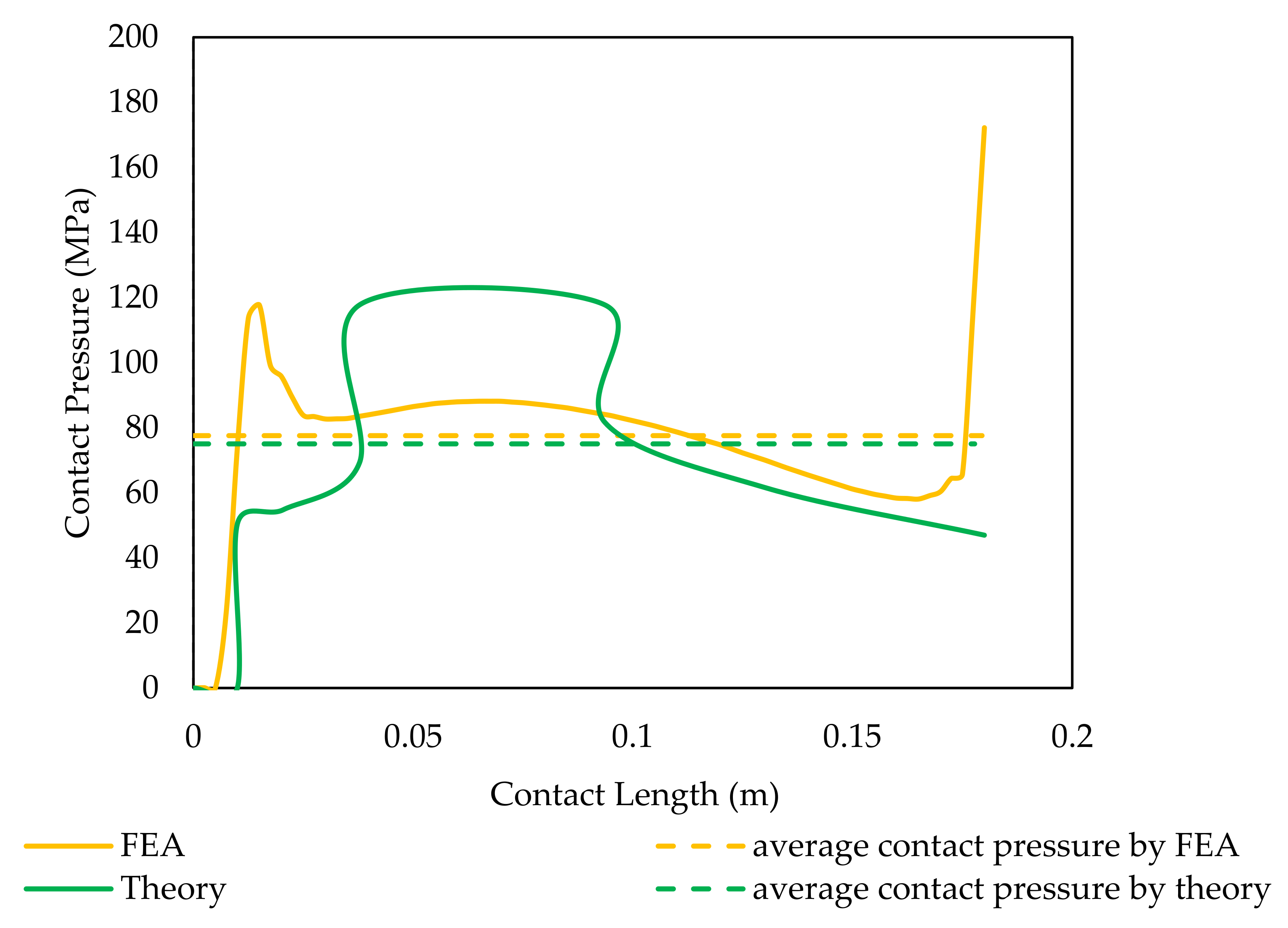

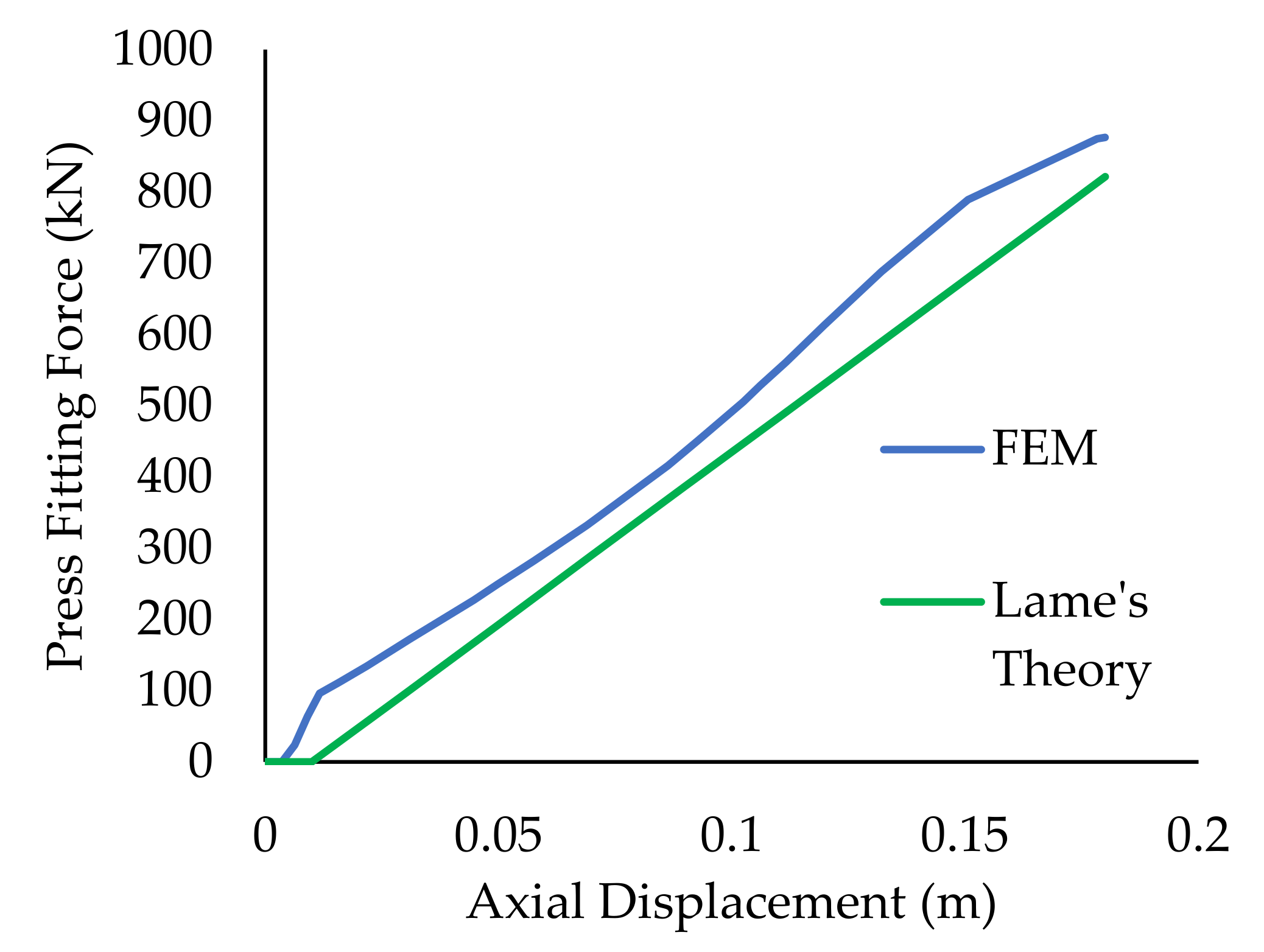

4.1. Comparison between the FEA and Theoretical Results

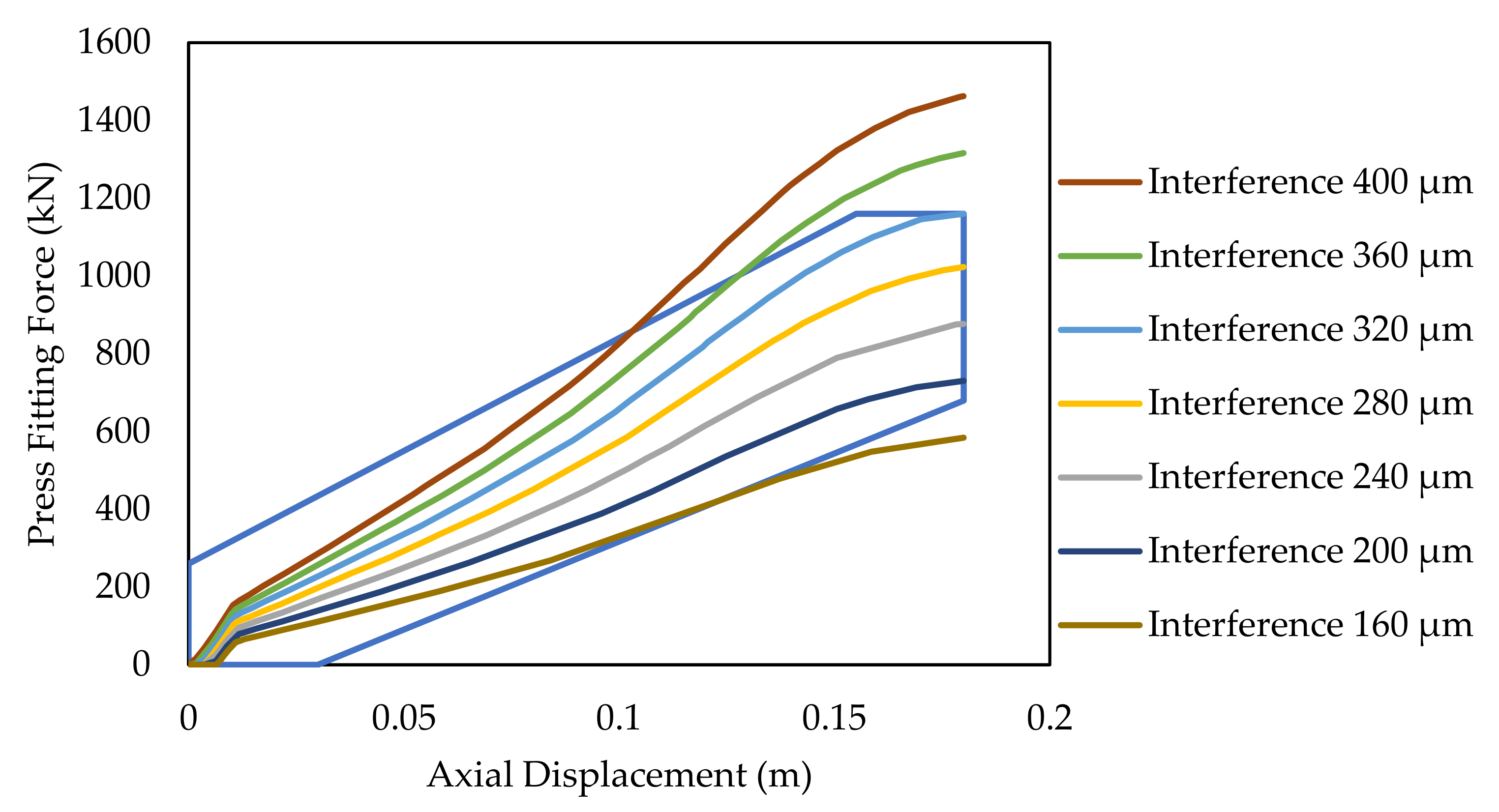

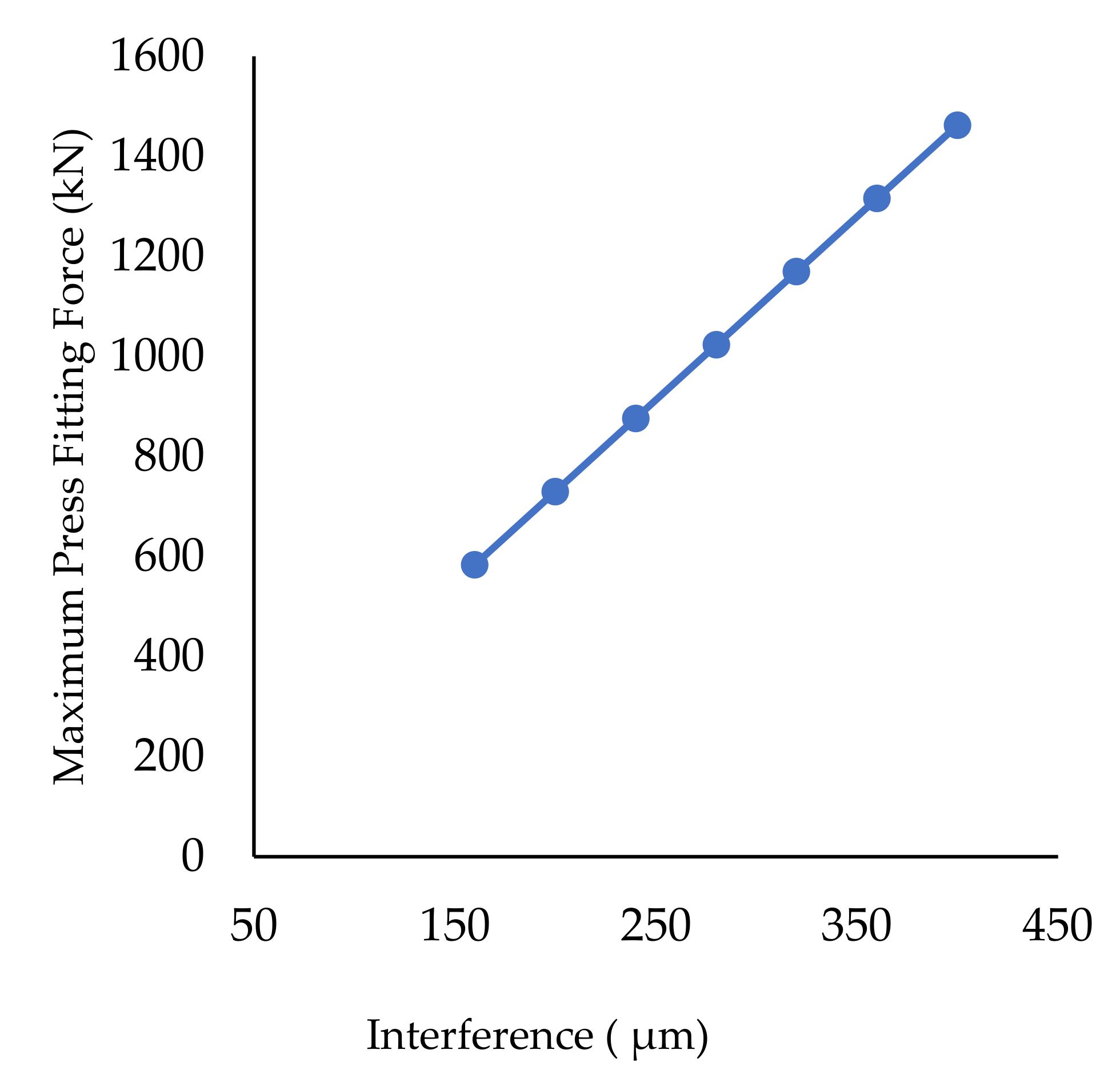

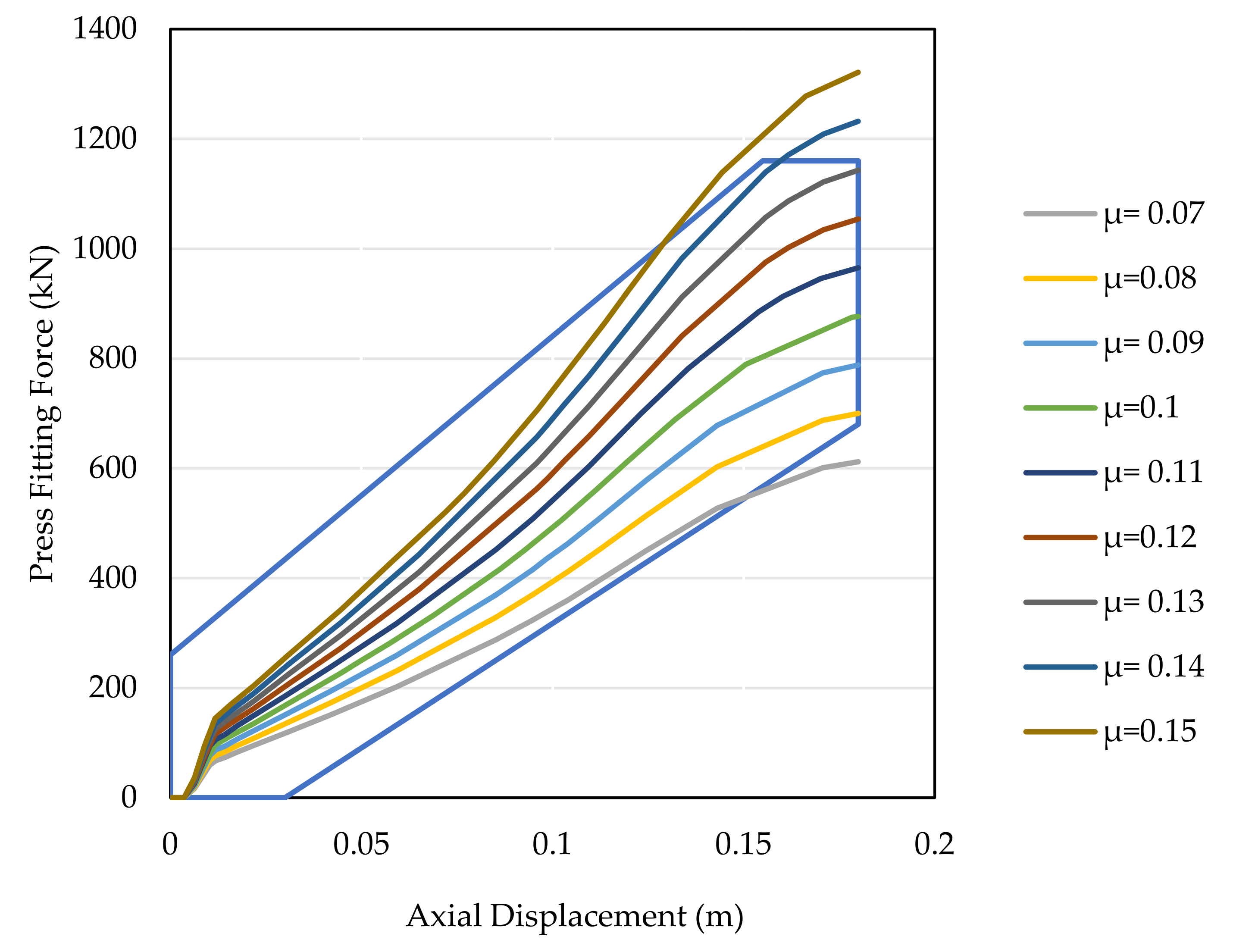

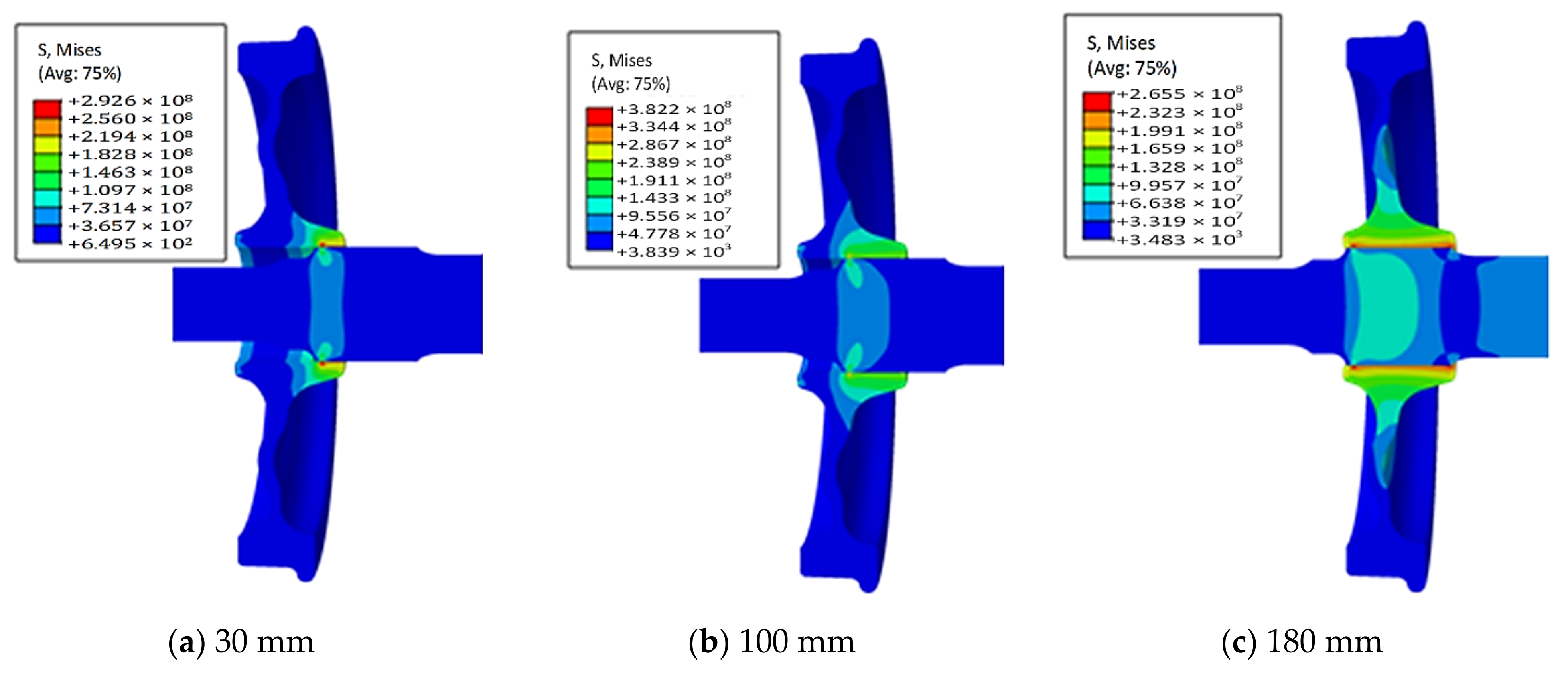

4.2. Effect of the Interference and Friction Coefficient on Press-Fitting Curves

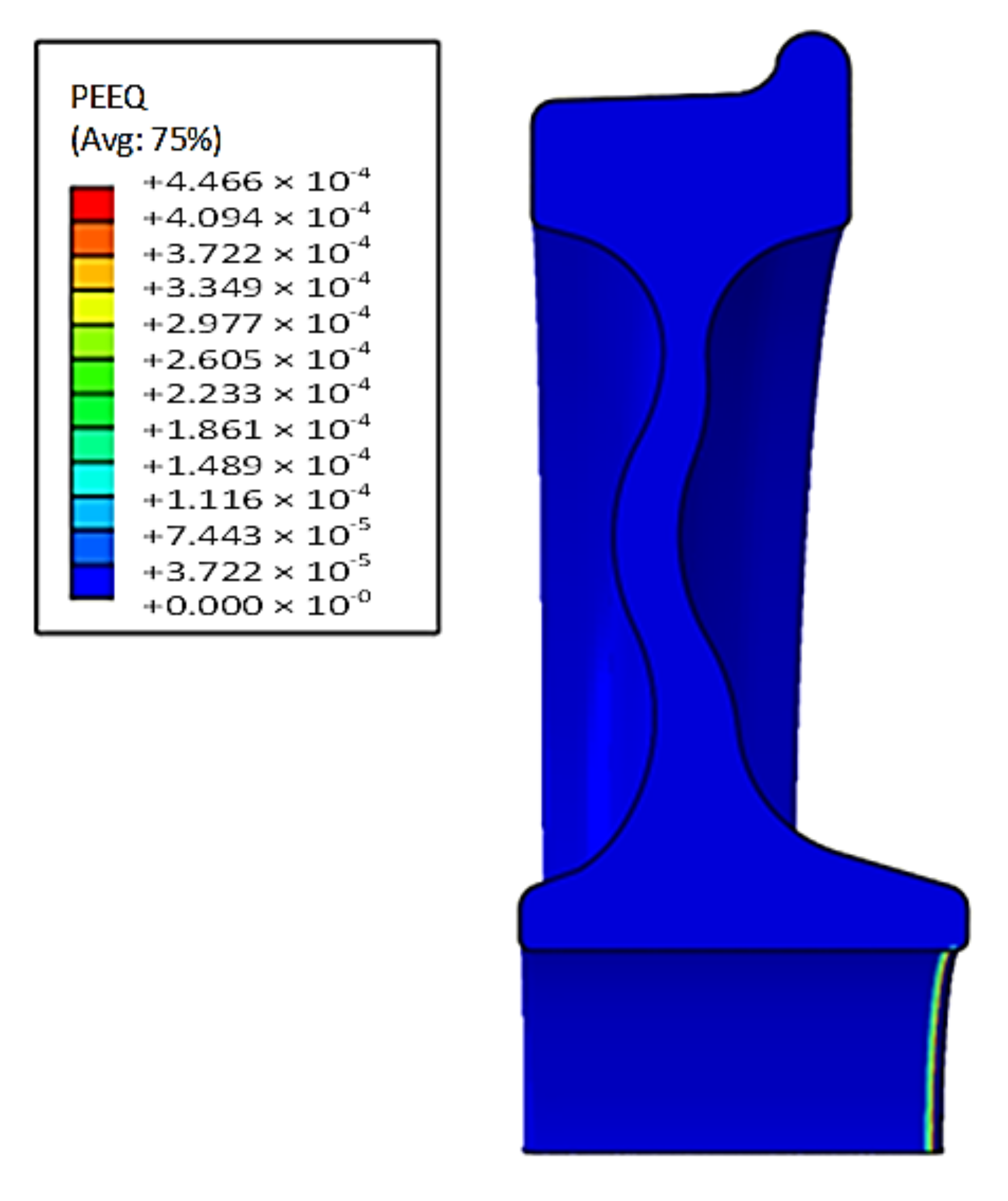

4.3. Contact Strength Analysis

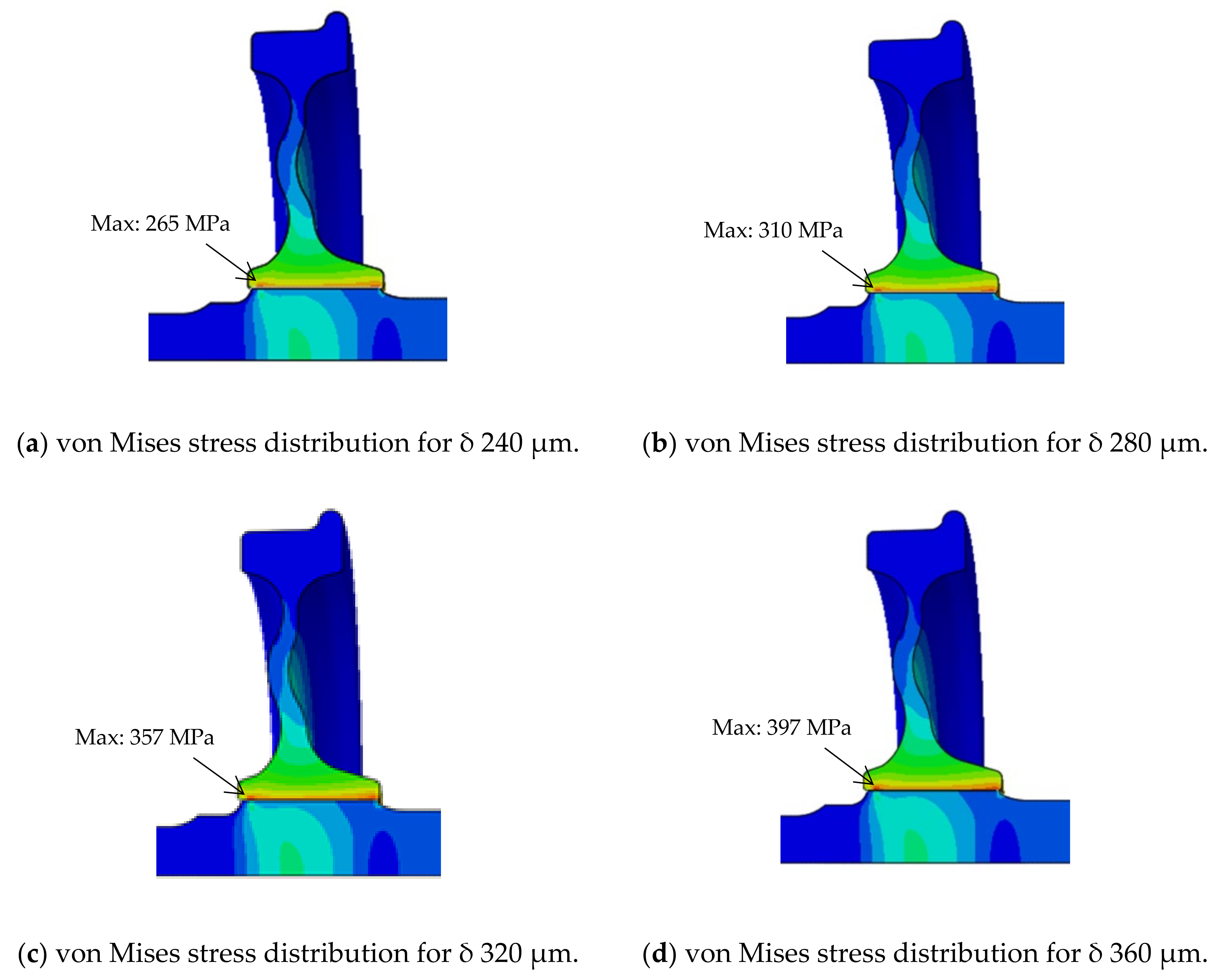

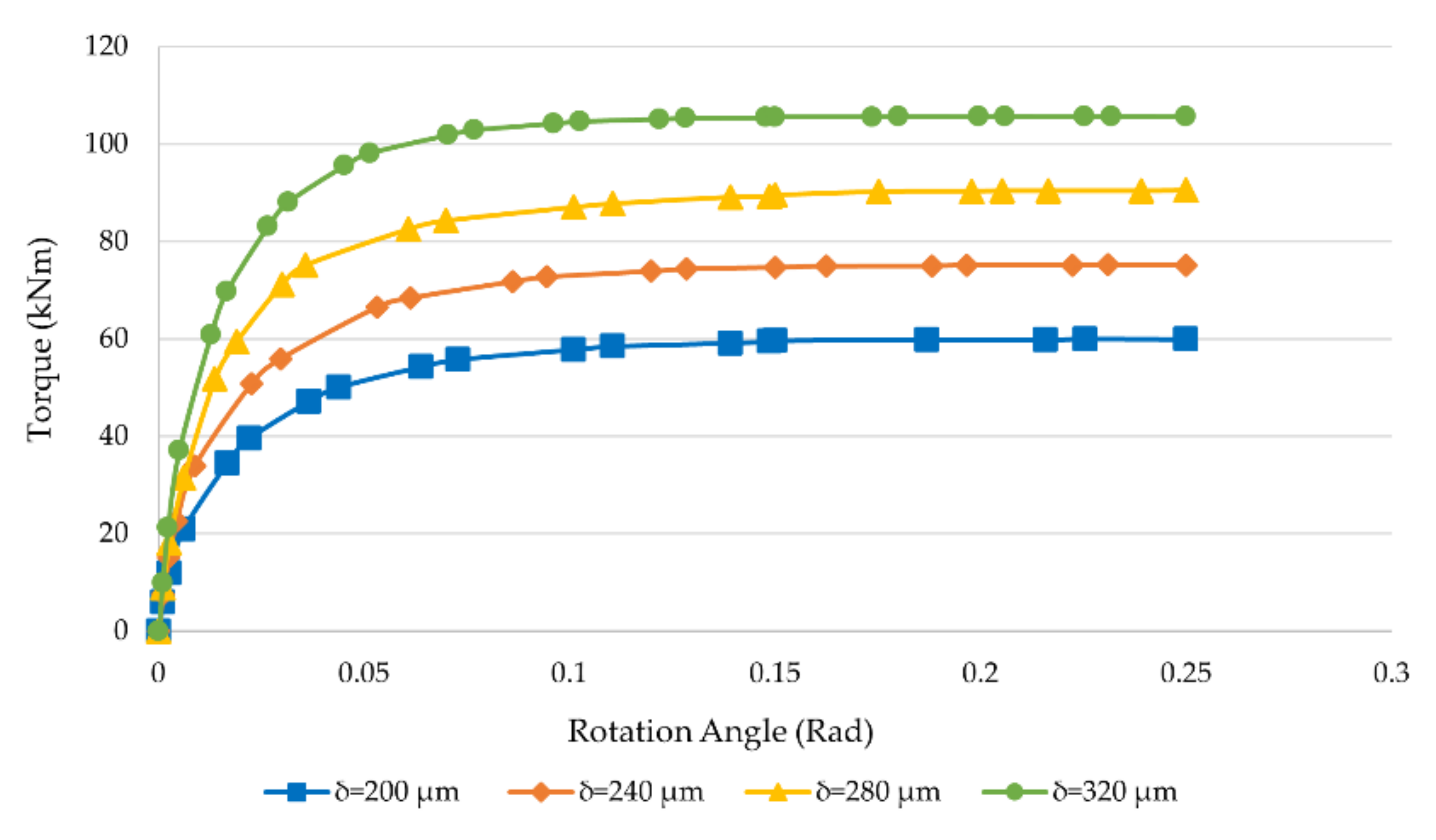

5. Effect of the Interference on the Holding Torque Capacity

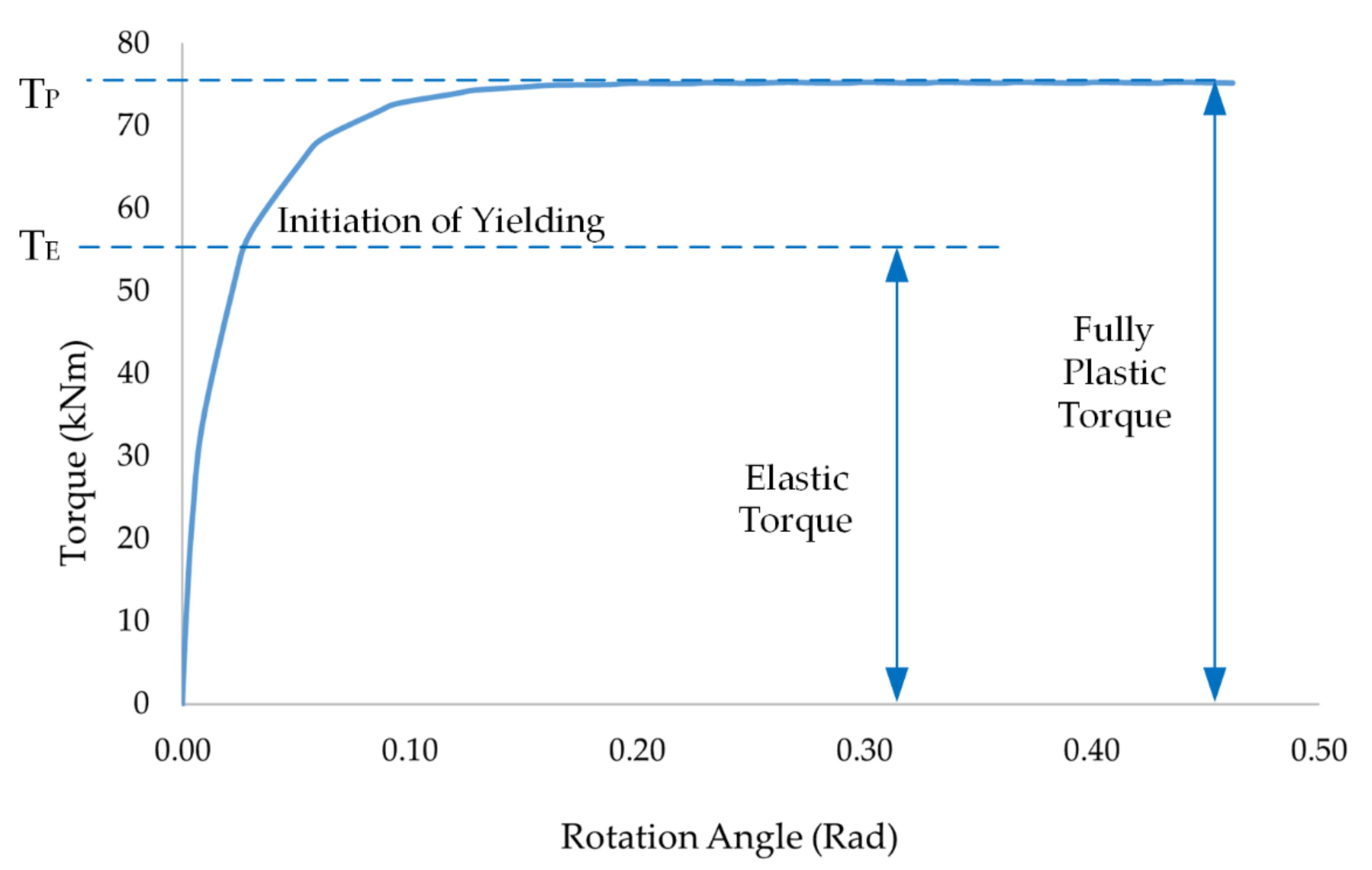

5.1. Maximum Holding Torque Capacity Theoretical Analysis

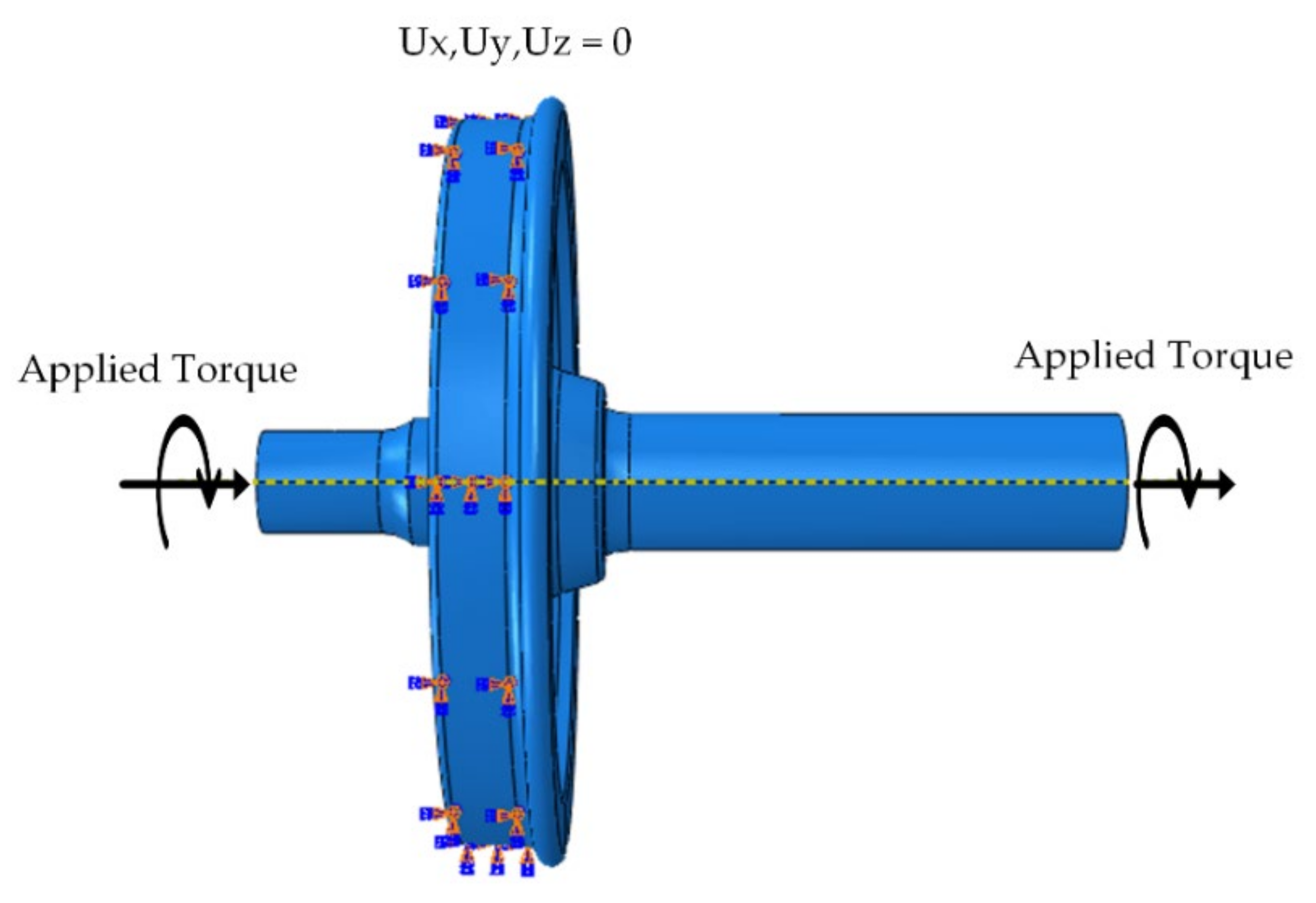

5.2. Finite Element Analysis of the Holding Torque Capacity

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kowalski, S. Failure Analysis of the Elements of a Forced-in Joint Operating in Rotational Bending Conditions. Eng. Fail. Anal. 2020, 118, 104864. [Google Scholar] [CrossRef]

- Kowalski, S. Fretting Wear in Selected Elements of Rail Vehicles. Teh. Vjesn. 2018, 25, 481–486. [Google Scholar] [CrossRef]

- Japanese Industrial Standard (JIS); Japanese Standards Association (JSA). JIS E 4504:2015-Rolling Stock–Wheelsets–Quality Requirements; JSA: Tokyo, Japan, 2015. [Google Scholar]

- European Committee For Standardization. EN 13260:2009+A1:2010: Railway Applications–Wheelsets and Bogies–Wheelsets–Product Requirements; BSI: London, UK, 2010. [Google Scholar]

- ISO 1005-7:1982. Railway Rolling Stock Material; Part 7: Wheelsets for Tractive and Trailing Stock; Quality Requirements, 1st ed.; International Organization for Standardization: Geneva, Switzerland, 1982. [Google Scholar]

- AAR. Manual of Standards and Recommended Practices Section G-II Wheel and Axle Manual; Association of American Railroads: Washington, DC, USA, 2019. [Google Scholar]

- Benuzzi, D.; Donzella, G. Prediction of the Press-Fit Curve in the Assembly of a Railway Axle and Wheel. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2004, 218, 51–65. [Google Scholar] [CrossRef]

- Lu, J.; Xiao, J.; Gao, D.J.; Zong, S.Y.; Li, Z. Research on Standard and Automatic Judgment of Press-Fit Curve of Locomotive Wheel-Set Based on AAR Standard. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2018; Volume 326. [Google Scholar] [CrossRef] [Green Version]

- Saad, S.; Magnier, V.; Dufrenoy, P.; Charkaluk, E.; Demilly, F. Numerical Chain of Forging Railway Axle Andwheel Press Fitting Operation. Lect. Notes Mech. Eng. 2015, 789, 115–127. [Google Scholar] [CrossRef]

- Stamenković, D.; Milošević, M.; Mijajlović, M.; Banić, M. Recommendations for the Estimation of the Strength of the Railway Wheel Set Press Fit Joint. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2012, 226, 48–61. [Google Scholar] [CrossRef]

- Michnej, M.; Guzowski, S. Fretting Wear Simulation in a Clamped Joint Based on the Example of a Rail Vehicle Wheel Set. Wear 2019, 438, 102654. [Google Scholar] [CrossRef]

- Booker, J.D.; Truman, C.E. Strengthing And Weakening Mechanisms in Interference-Fitted Joints. In Proceedings of the IRF2020: 7th International Conference Integrity-Reliability-Failure, Funchal, Portugal, 6–10 September 2020; pp. 405–418. [Google Scholar]

- Zhao, J.; Wang, J.-X.X.; Yu, C.; Tang, S.-Q.Q.; Yao, J. Influence of Radial Interference on Torque Capacity of Shrink-Fit Camshaft. Adv. Mech. Eng. 2019, 11, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Joannides, T.; Leggoe, J.; Sercombe, T.; Mcarthur, J. Effects of Surface Topography and Interference on the Mounting Curve of Railway Wheel-Set Press-Fit Assembly; CEED: Crawley, Australia, 2017; pp. 25–30. [Google Scholar]

- SIMULIA. Abaqus Analysis User’s Manual; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2010; Volume I–IV. [Google Scholar]

- European Committee for Standardization. BS EN 13261: 2020 Railway Applications–Wheelsets and Bogies–Axles–Product Requirements; BSI: London, UK, 2020. [Google Scholar]

- European Committee for Standardization. BS EN 13262: 2020 Railway Applications Wheelsets and Bogies–Wheels–Product Requirements; BSI: London, UK, 2020. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shingley’s Mechanical Engineering Design, 8th ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Son, S.-W.; Jung, H.-S.; Kwon, T.-S.; Kim, J.-S. Fatigue Life Prediction of a Railway Hollow Axle with a Tapered Bore Surface. Eng. Fail. Anal. 2015, 58, 44–55. [Google Scholar] [CrossRef]

- Uni Rail. Wheelset Catalouge; UniRail Ltd.: Sofia, Bulgaria, 2003. [Google Scholar]

- Rothbart, H. Mechanical Design Handbook, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar]

- Hibbeler, R.C. Mechanics of Materials, 8th ed.; Prentice Hall: Hoboken, NJ, USA, 2010. [Google Scholar]

- Beer, F.P.; Johnston, E.R.; DeWolf, J.T.; Mazurek, D.F. Mechanics of Materials, 6th ed.; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

| Grade | C | Mn | Si | S | P | Cr | Cu | Ni | Mo | V |

|---|---|---|---|---|---|---|---|---|---|---|

| EA4T | 0.29 | 0.8 | 0.4 | 0.015 | 0.02 | 1.2 | 0.3 | 0.3 | 0.3 | 0.06 |

| Material | Young’s Modulus (GPa) | Poisson Ratio | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Absorbed Energy |

|---|---|---|---|---|---|---|

| EA4T | 206 | 0.3 | 650–800 | ≥420 | ≥24 | ≥30 |

| Interference (µm) | Maximum Holding Torque Capacity | ||

|---|---|---|---|

| Theory (Equation (5)) (kNm) | Finite Element Method (kNm) | Percent Deviation (%) | |

| 200 | 71 | 60 | 15 |

| 240 | 85 | 75 | 12 |

| 280 | 99 | 91 | 8 |

| 320 | 113 | 106 | 6 |

| Percent Deviation was calculated as Percent Deviation = [(Theory-FEM)/Theory] × 100% | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nwe, T.; Pimsarn, M. Railway Axle and Wheel Assembly Press-Fitting Force Characteristics and Holding Torque Capacity. Appl. Sci. 2021, 11, 8862. https://doi.org/10.3390/app11198862

Nwe T, Pimsarn M. Railway Axle and Wheel Assembly Press-Fitting Force Characteristics and Holding Torque Capacity. Applied Sciences. 2021; 11(19):8862. https://doi.org/10.3390/app11198862

Chicago/Turabian StyleNwe, Theingi, and Monsak Pimsarn. 2021. "Railway Axle and Wheel Assembly Press-Fitting Force Characteristics and Holding Torque Capacity" Applied Sciences 11, no. 19: 8862. https://doi.org/10.3390/app11198862

APA StyleNwe, T., & Pimsarn, M. (2021). Railway Axle and Wheel Assembly Press-Fitting Force Characteristics and Holding Torque Capacity. Applied Sciences, 11(19), 8862. https://doi.org/10.3390/app11198862