Autonomous Loading System for Load-Haul-Dump (LHD) Machines Used in Underground Mining

Abstract

:1. Introduction

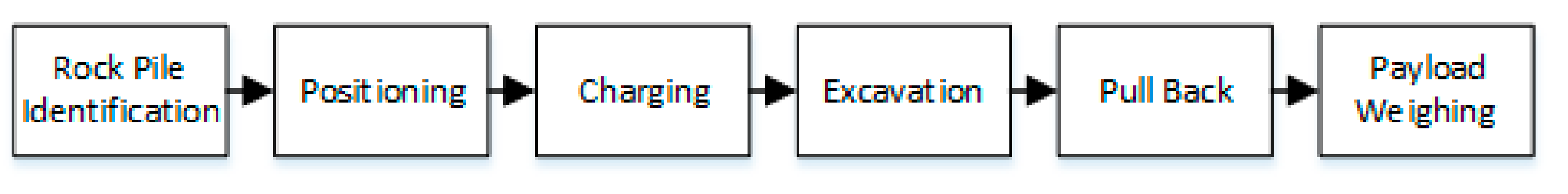

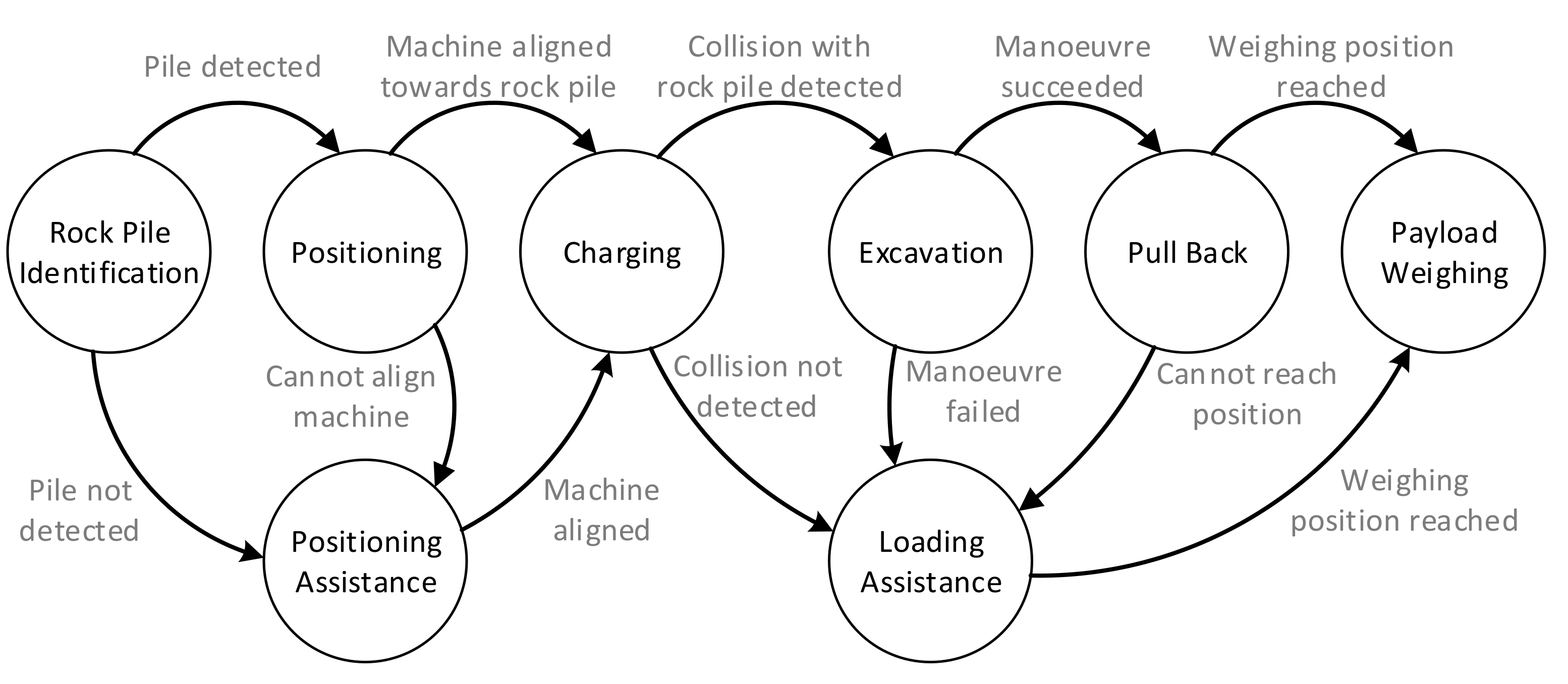

- A system that models and implements the whole loading process required in underground mining operations, from rock pile identification to payload weighing. The system is based on the shared autonomy paradigm, which allows the system to obtain assistance on demand from a human operator.

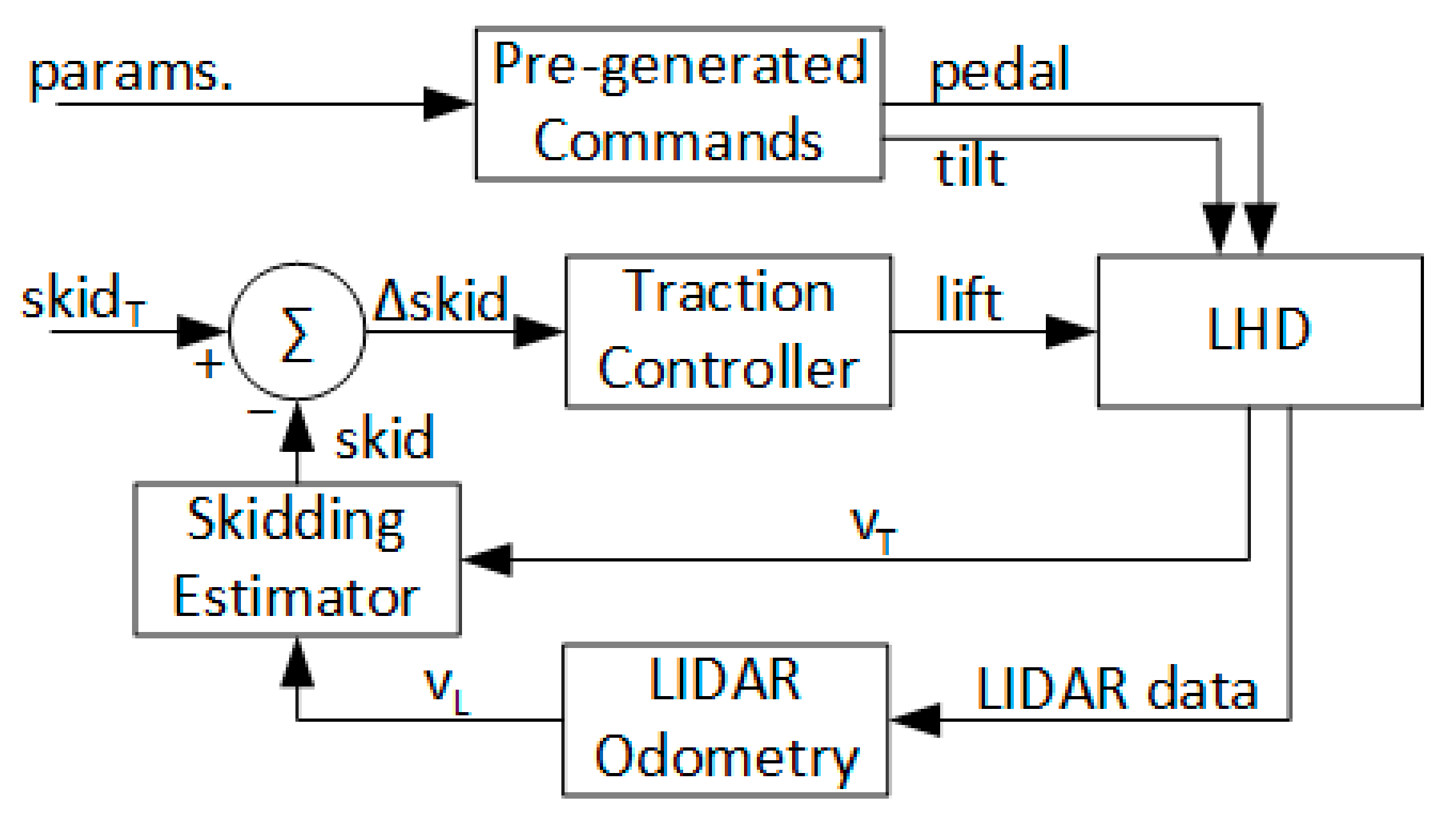

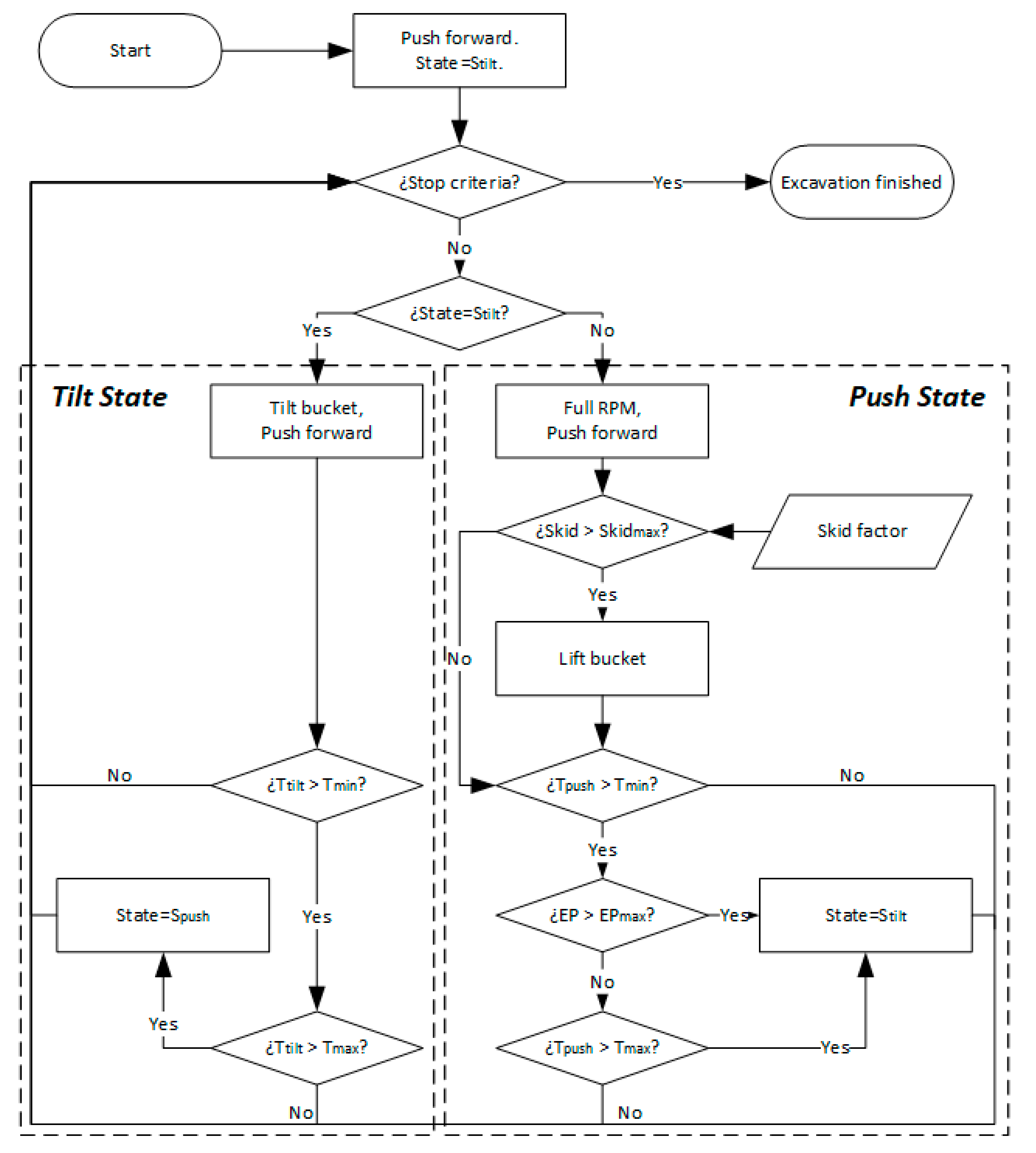

- An excavation algorithm that is based on the way that human operators excavate, and that uses a patented method for detecting wheel skidding, which is required for successful excavation of fragmented material in draw points.

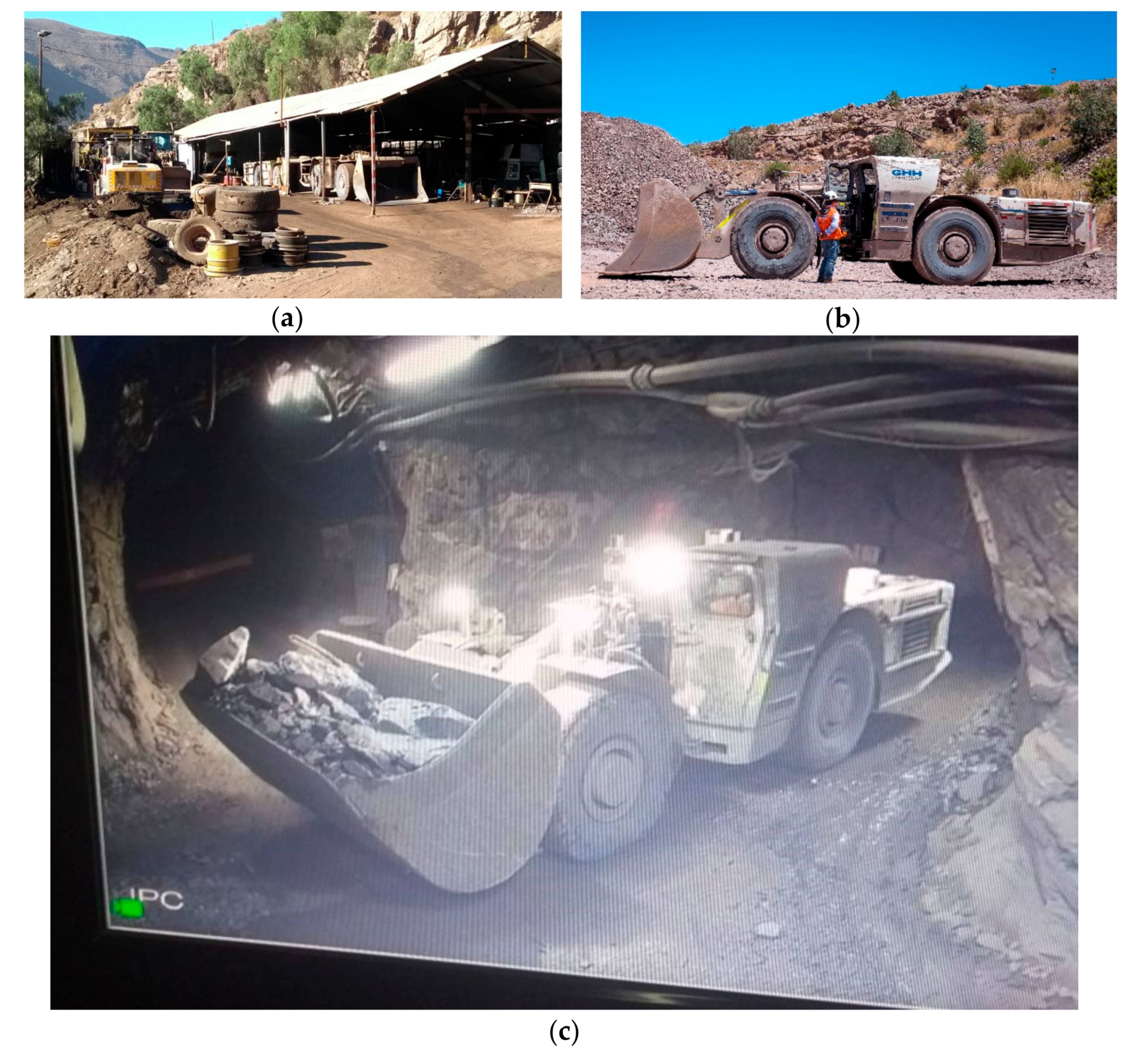

- Full-scale rock excavation experiments using a commercial LHD in a production level of a sublevel stoping mine.

2. Background and Related Work

2.1. Problem Description

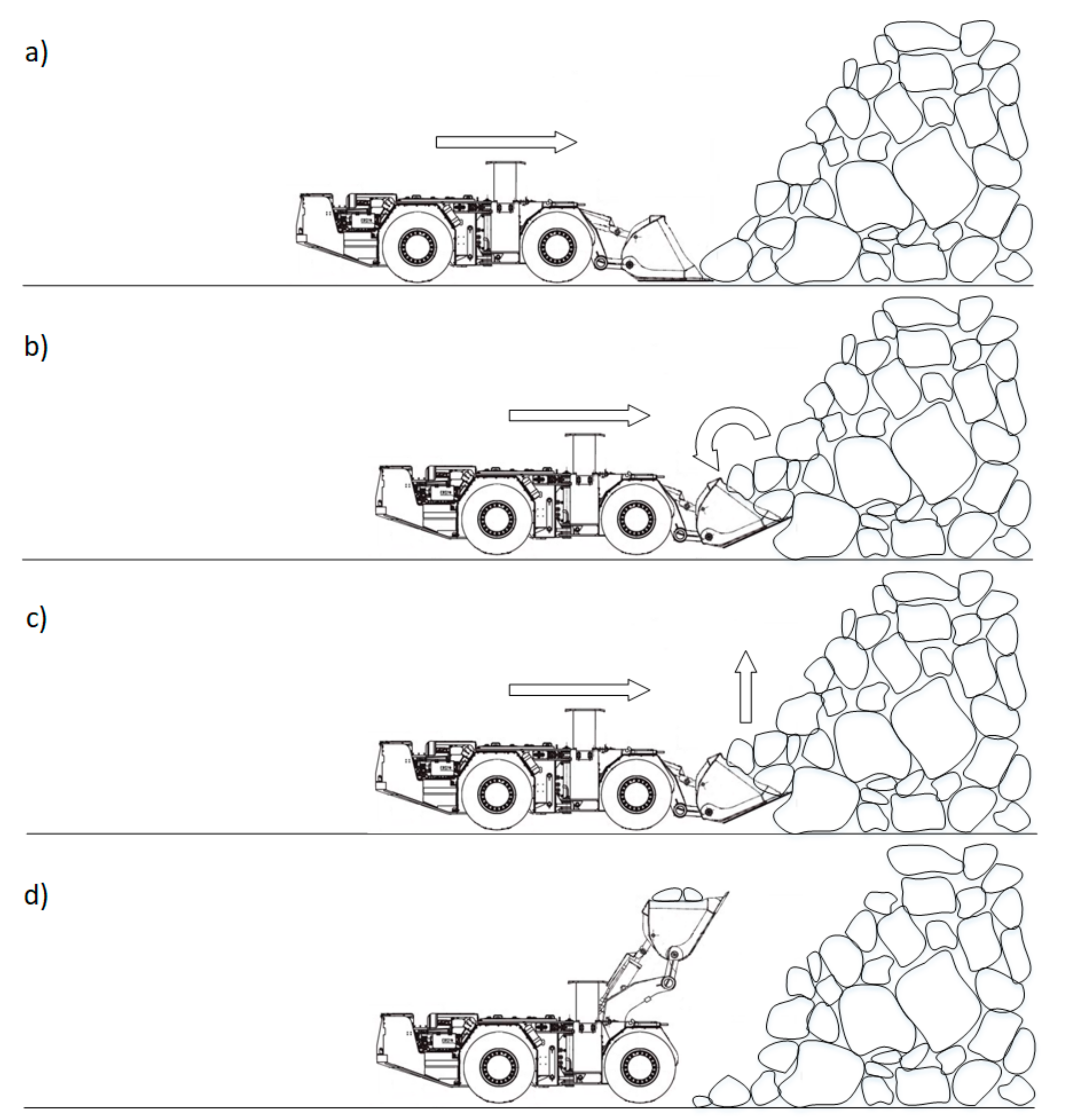

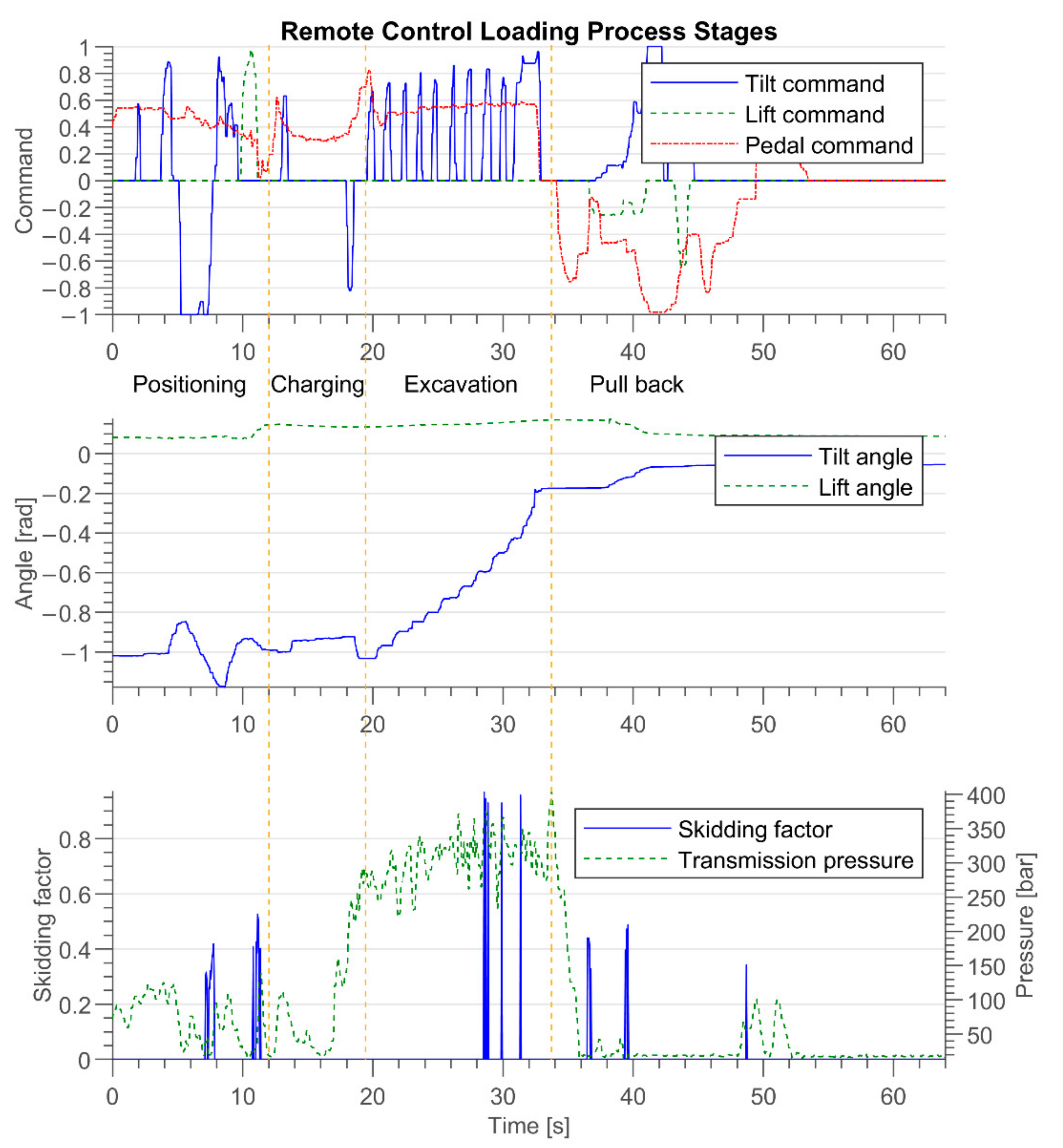

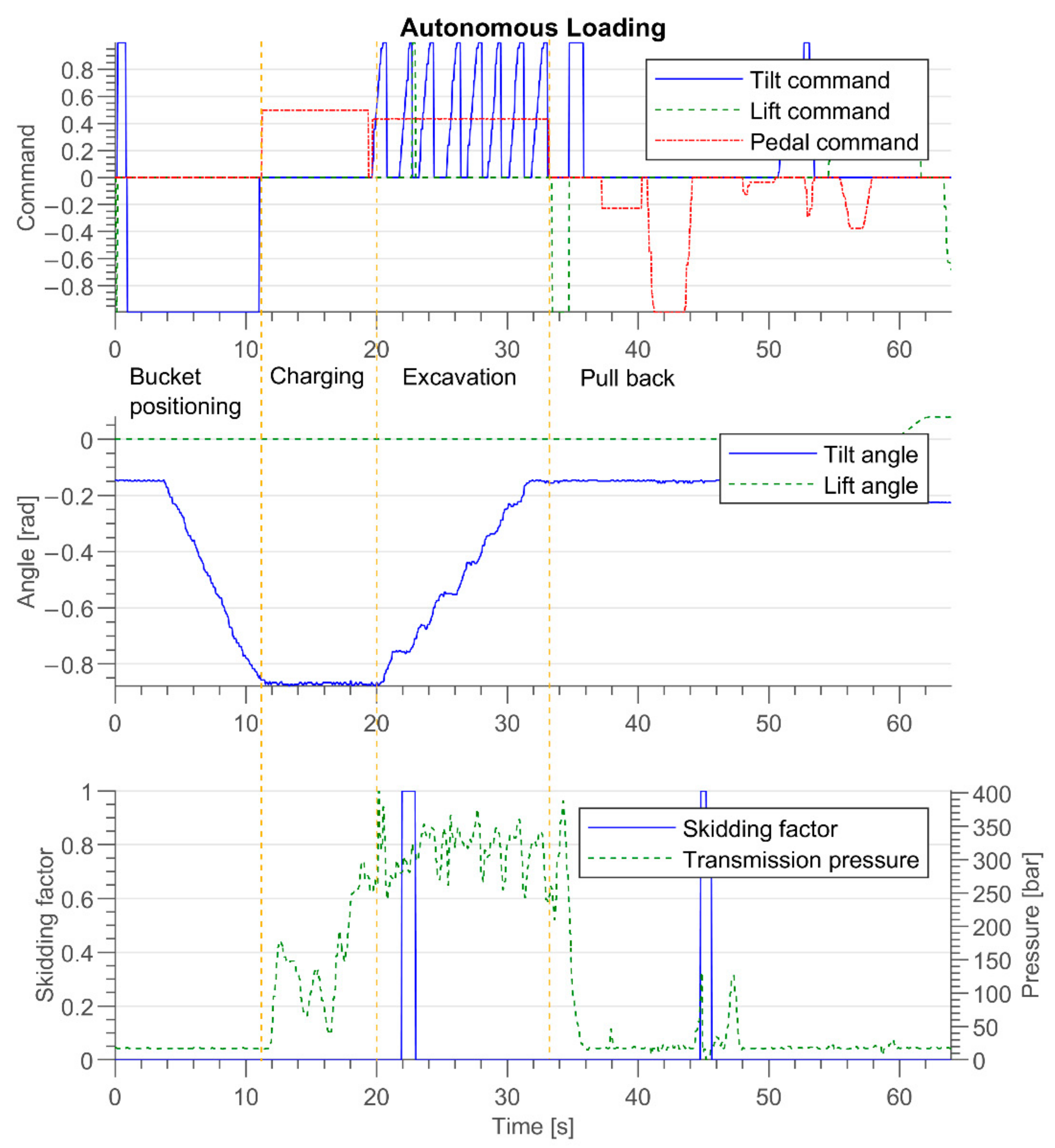

2.2. How Human Operators Excavate

- Before engaging with the rock pile, the bucket must be fully extended.

- Forward motion is selected for maximum traction (first gear).

- Intermittent tilt commands are the basis of the excavation process.

- Lift commands are mainly issued to prevent or correct wheel skidding.

2.3. Related Work

3. Proposed Autonomous Loading System

3.1. Methodology Overview

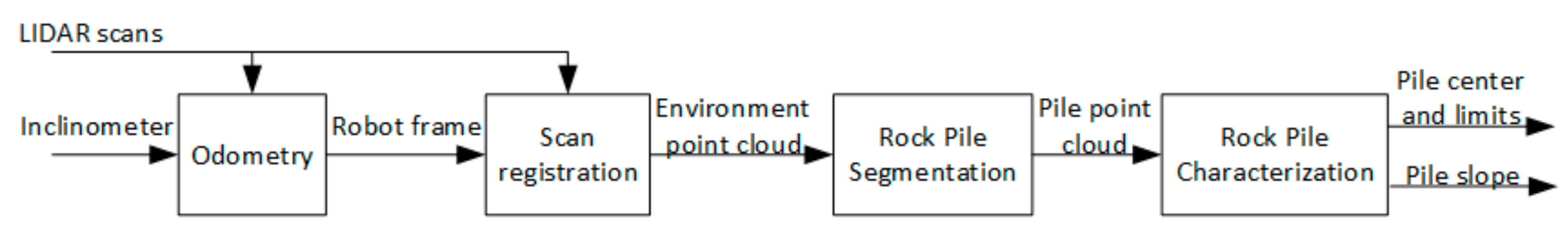

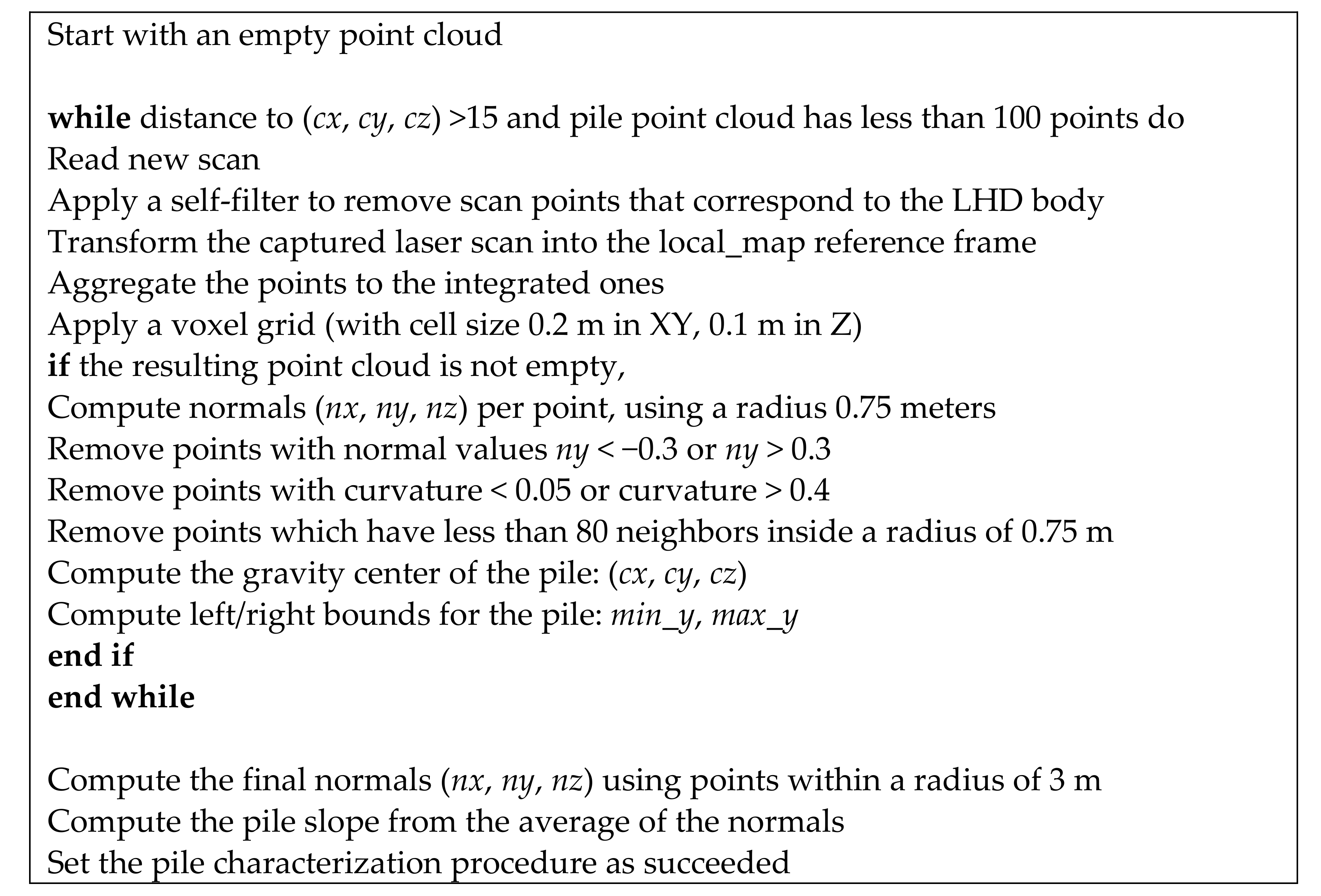

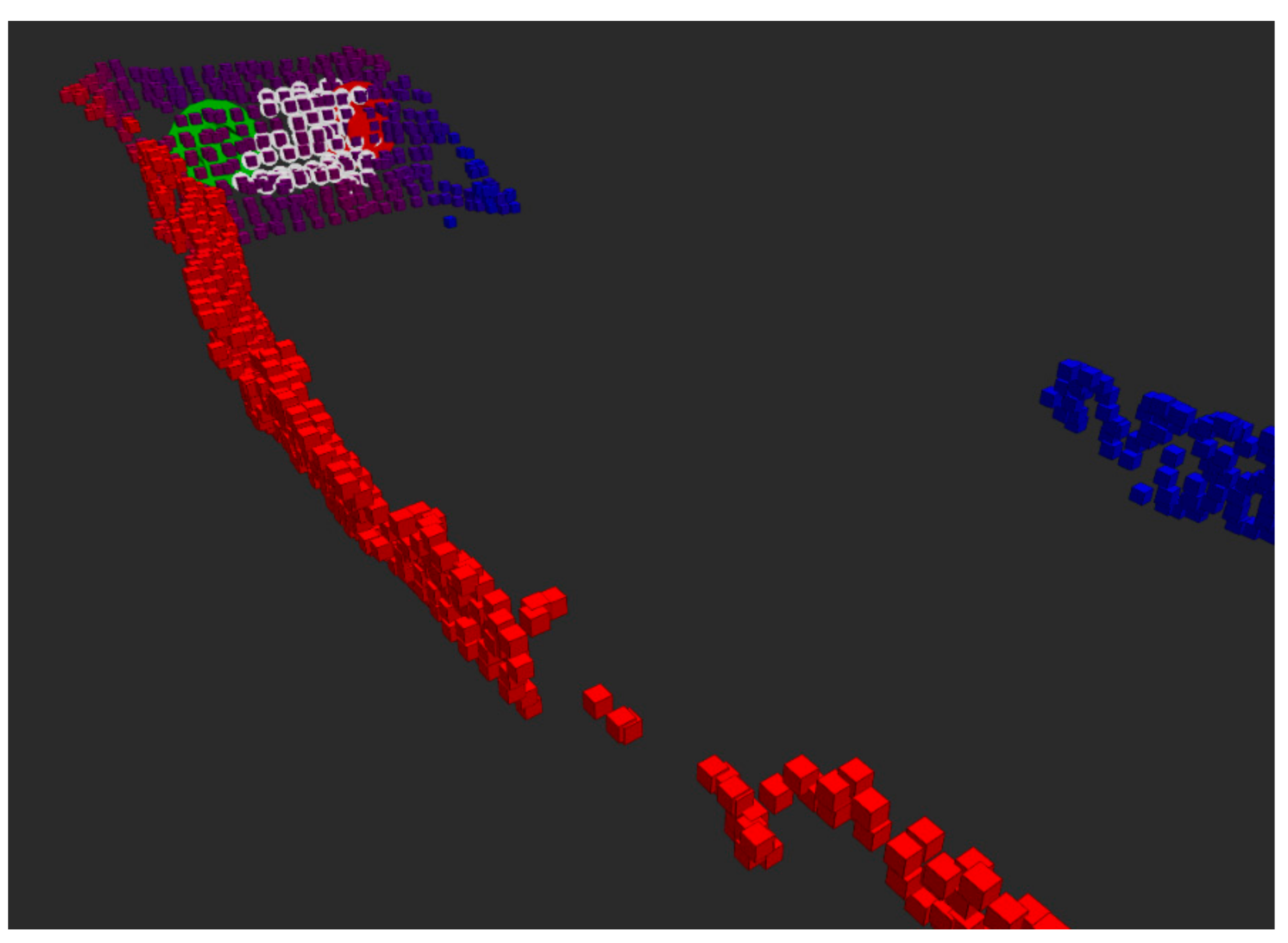

3.2. Environment Modeling and Rock Pile Identification

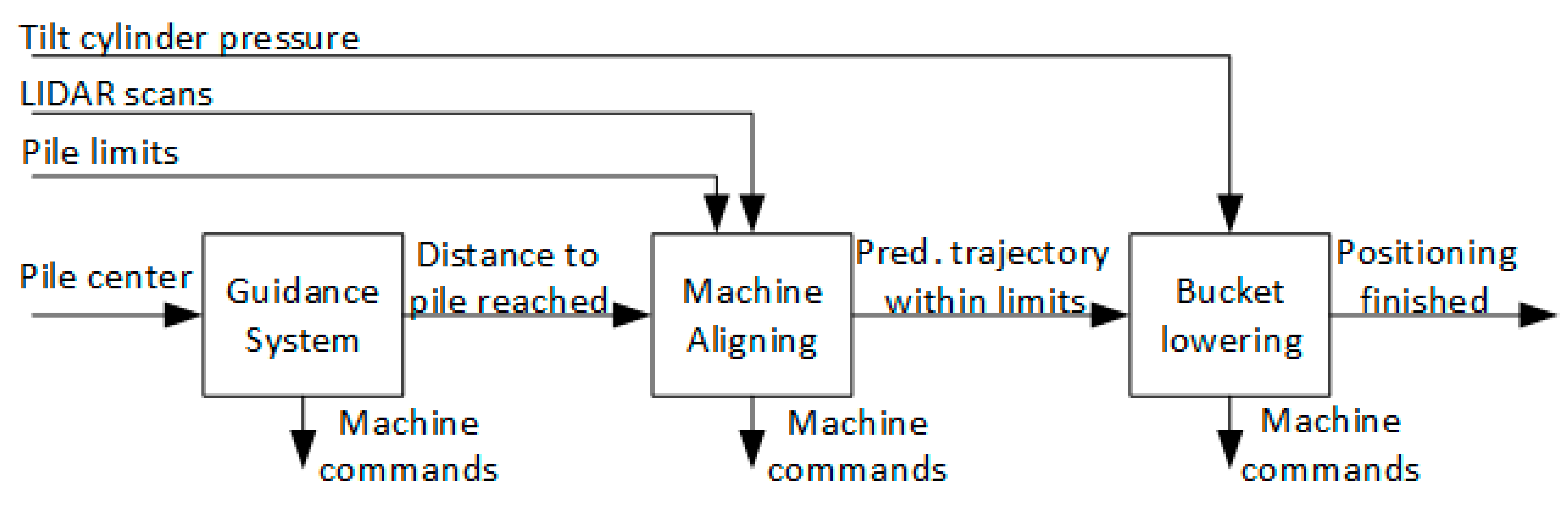

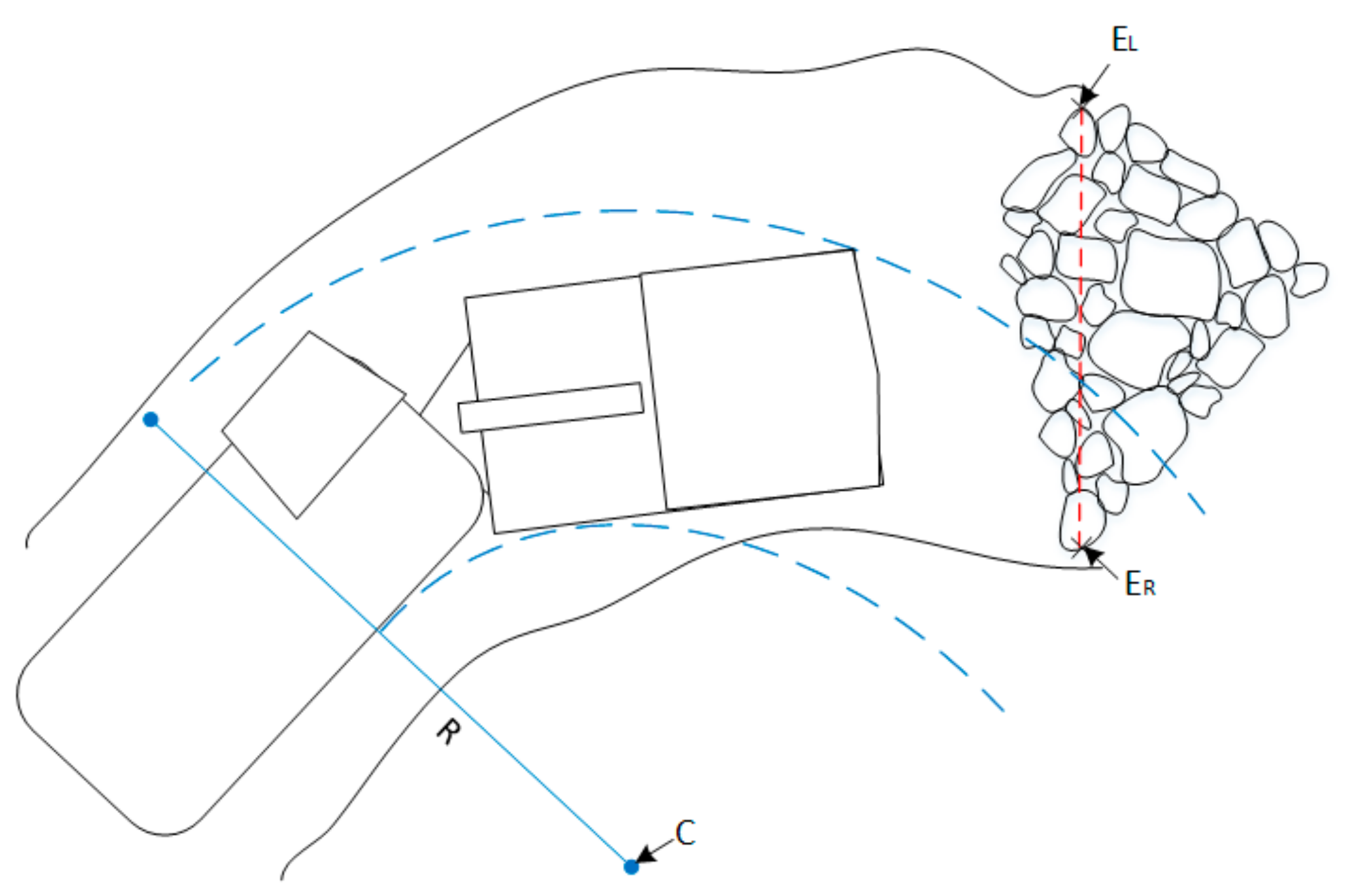

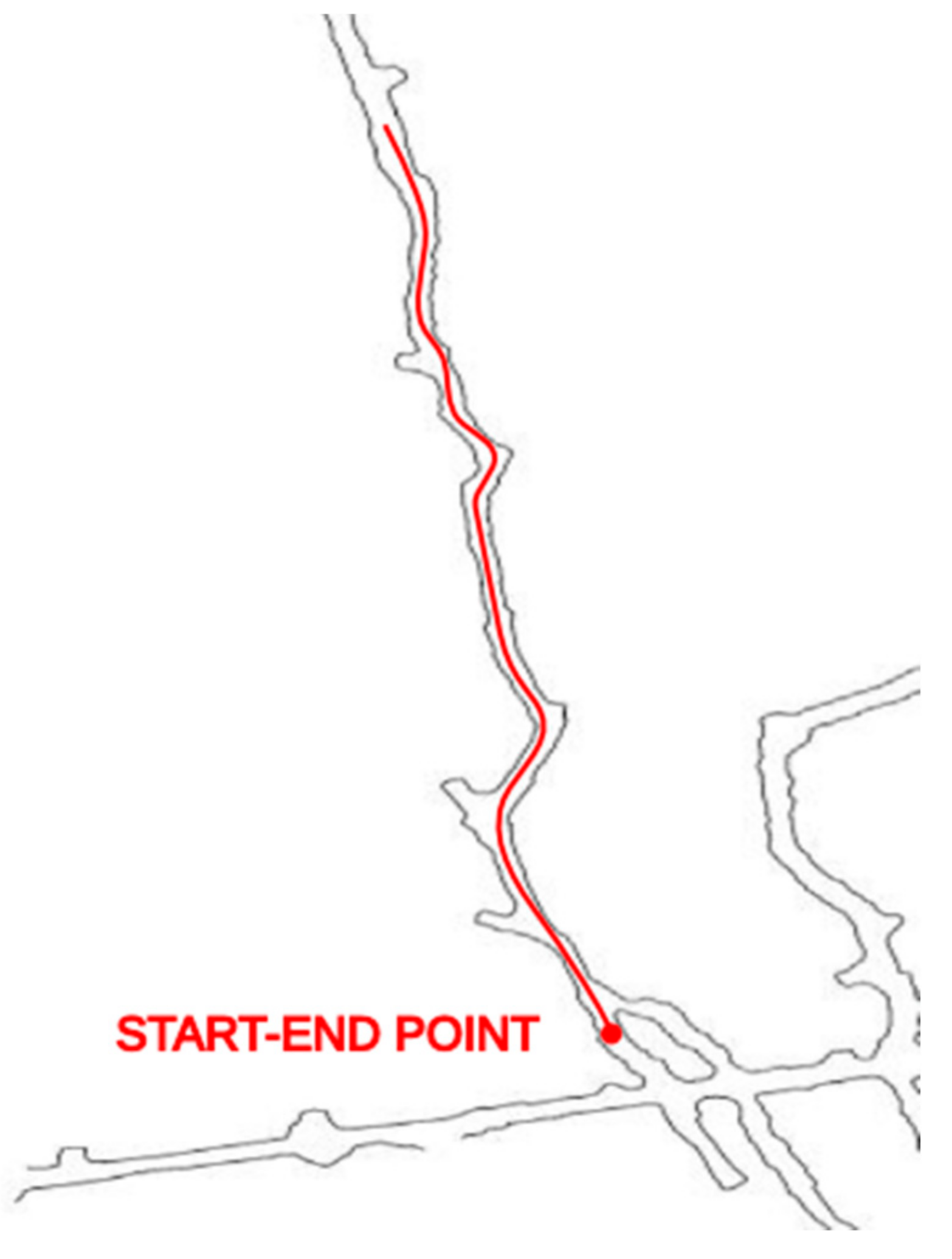

3.3. Positioning and Charging

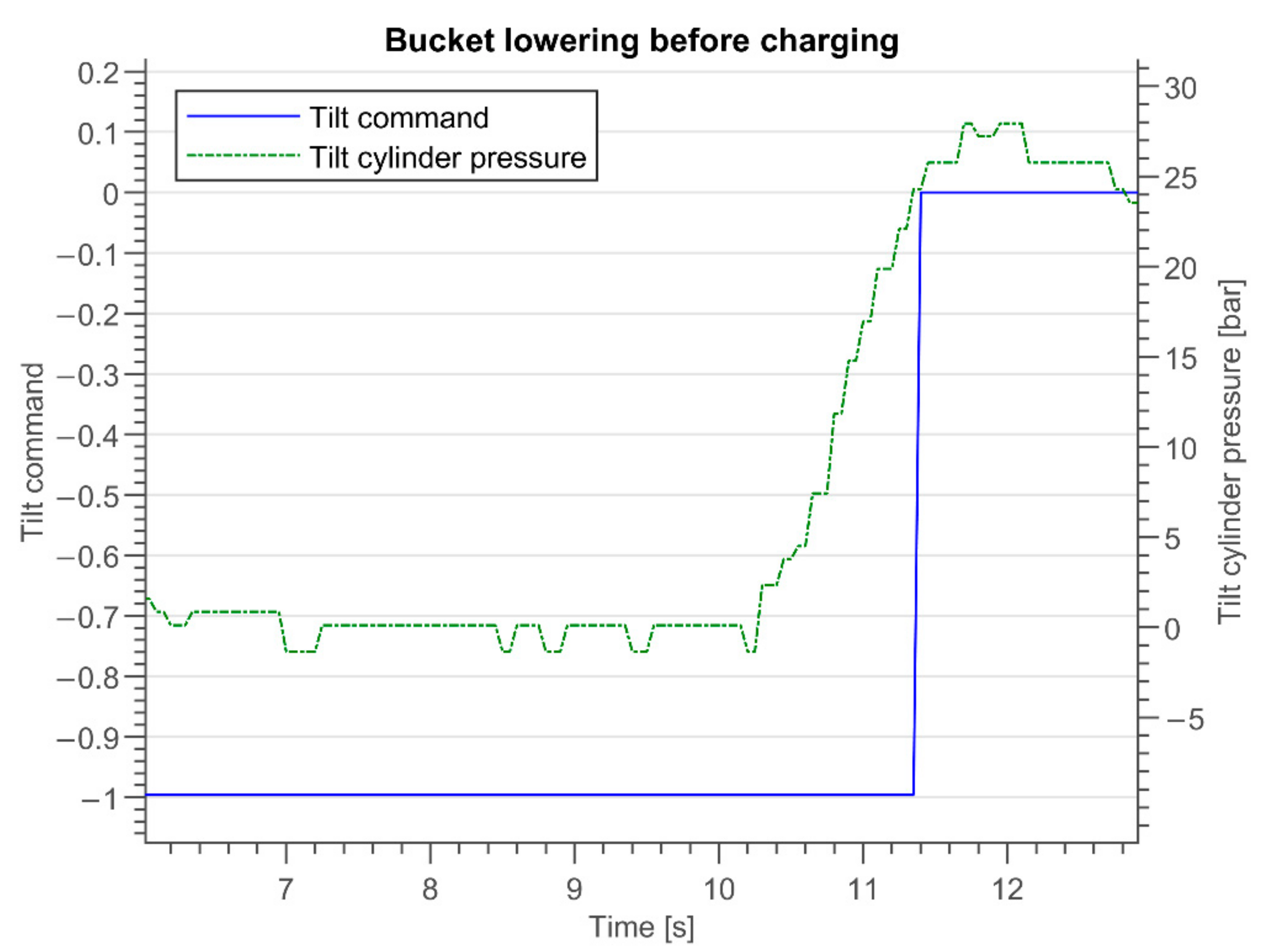

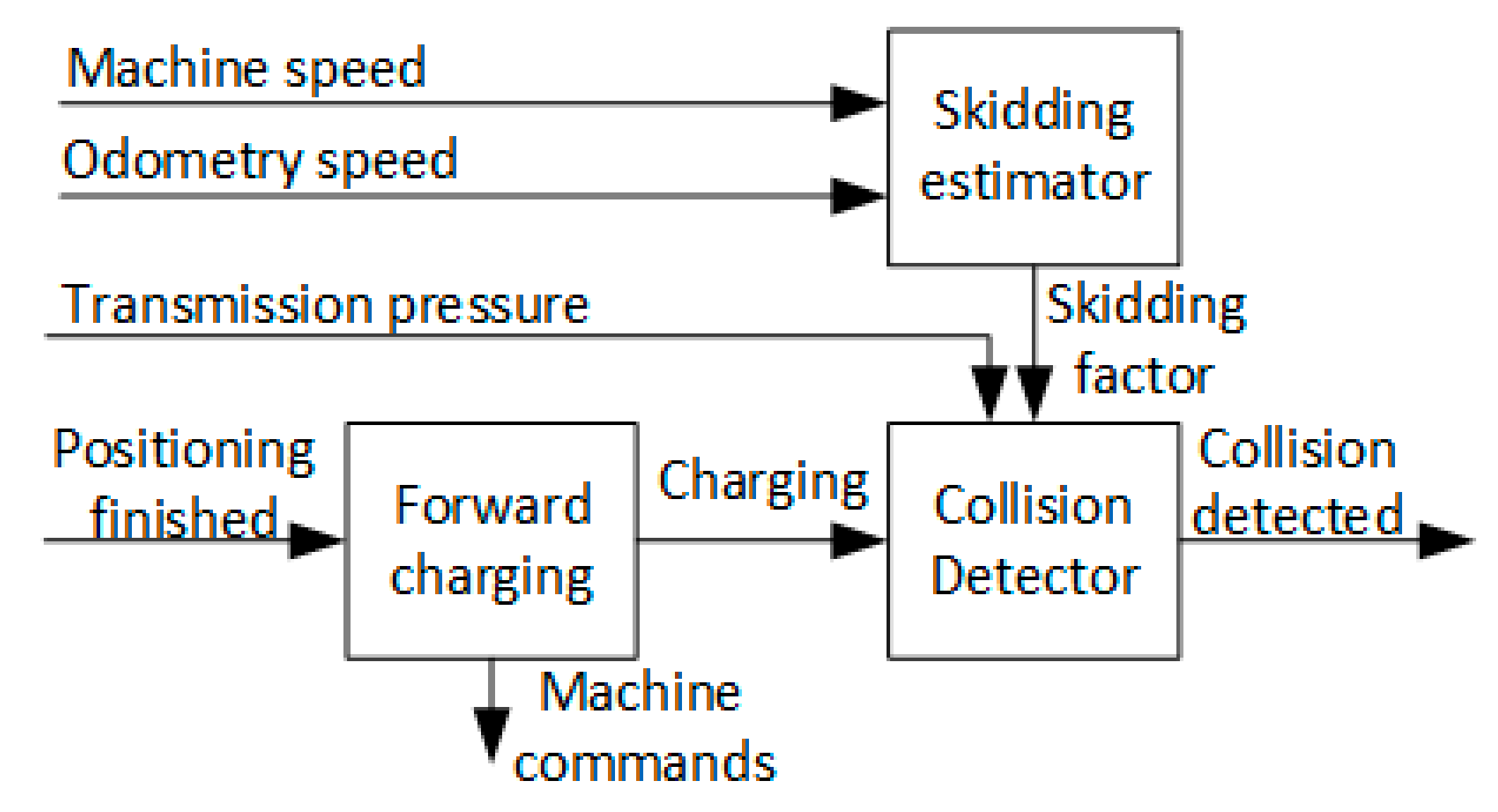

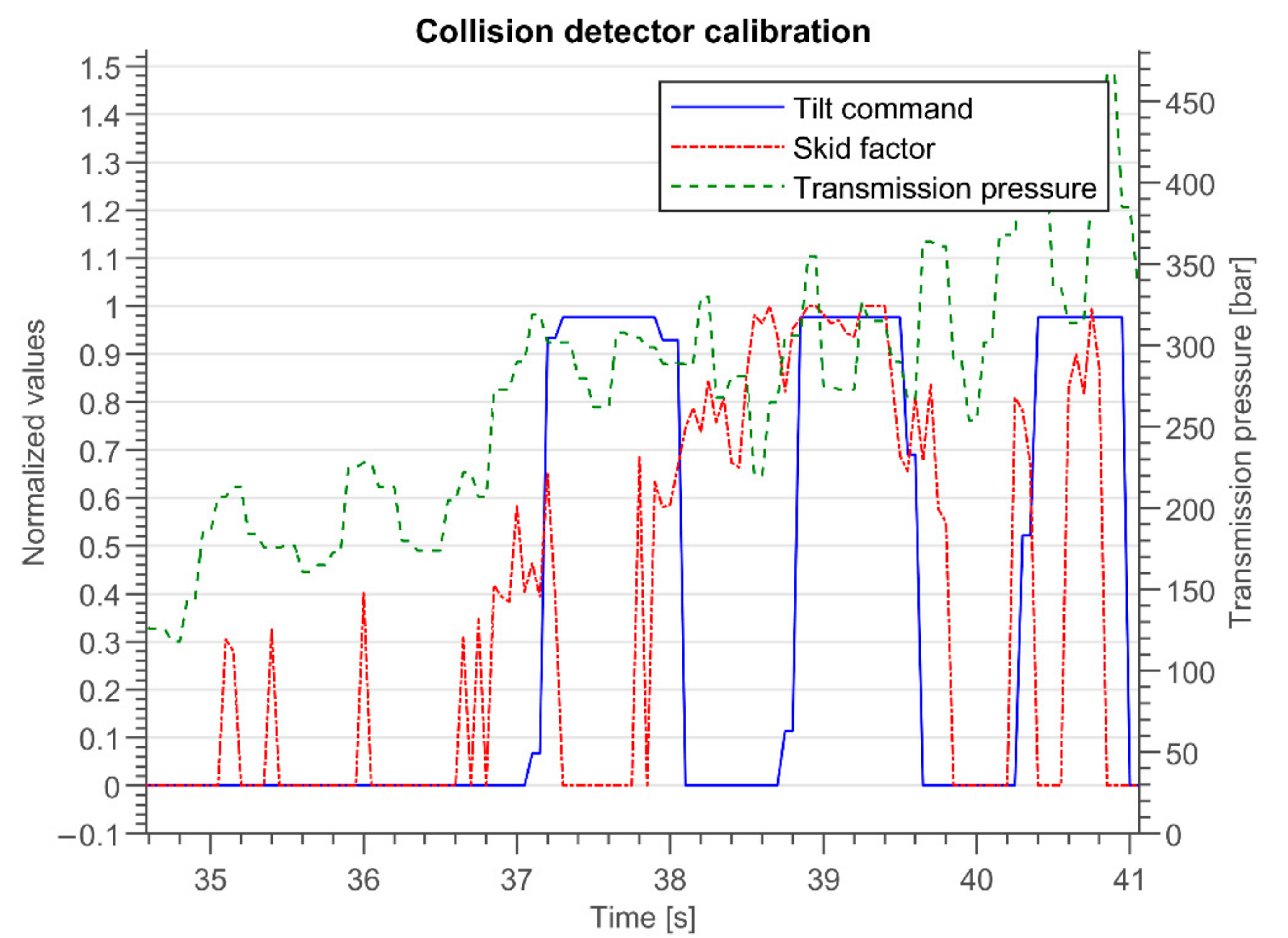

3.4. Excavation Algorithm

3.5. Pull Back and Payload Weighing

4. Experiments and Analysis

4.1. Full-Scale Rock Excavation Experiments

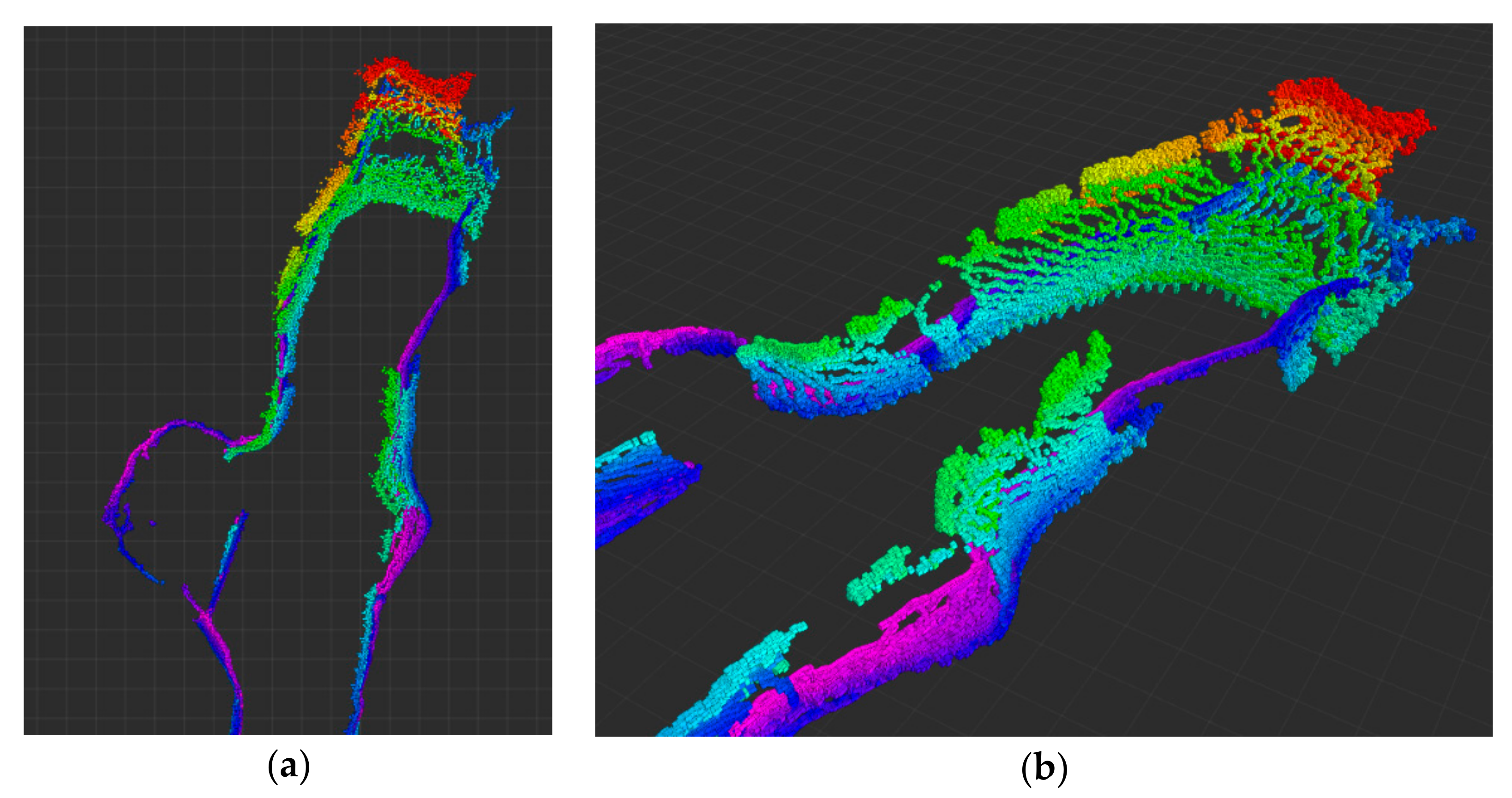

4.2. Offline Results Using Field Data: 2.5D Modeling of the Extraction Point

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salvador, C.; Mascaró, M.; Ruiz del Solar, J. Automation of Unit and Auxiliary Operations in Block/Panel Caving: Challenges and Opportunities; Massmin: Santiago, Chile, 2020. [Google Scholar]

- Scheding, S.; Nebot, E.M.; Stevens, M.; Durrant-Whyte, H.; Roberts, J.; Corke, P.; Cunningham, J.; Cook, B. Experiments in Autonomous Underground Guidance. In Proceedings of the 1997 IEEE International Conference on Robotics and Automation, Albuquerque, NM, USA, 25–25 April 1997; pp. 1898–1903. [Google Scholar]

- Cunningham, J.; Roberts, J.M.; Corke, P.; Durrant-Whyte, H. Automation of Underground LHD and Truck Haulage. In Proceedings of the AusIMM Annual Conference—“The Mining Cycle” (AUSIMM 1998), Mount Isa, Australia, 19–23 April 1998. [Google Scholar]

- Mäkelä, H. Overview of LHD Navigation without Artificial Beacons. Robot. Auton. Syst. 2001, 36, 21–35. [Google Scholar] [CrossRef]

- Duff, E.S.; Roberts, J.M.; Corke, P.I. Automation of an underground mining vehicle using reactive navigation and opportunistic localization. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 27–31 October 2003; Volume 3, pp. 3775–3780. [Google Scholar]

- Larsson, J. Reactive Navigation of an Autonomous Vehicle in Underground Mines. Ph.D. Thesis, Örebro University, Örebro, Sweden, 2007. [Google Scholar]

- Hemami, A. Modelling, analysis and preliminary studies for automatic scooping/loading in a mechanical loader, International Journal of Surface Mining. Reclam. Environ. 1992, 6, 151–159. [Google Scholar]

- Hemami, A. Study of bucket trajectory in automatic scooping with load-haul-dump loaders. Trans. Inst. Min. Metall. 1993, 102, 37–42. [Google Scholar]

- Ji, Q.; Sanford, R.L. Autonomous excavation of fragmented rock using machine vision. In Emerging Computer Techniques for the Minerals Industry; Society for Mining Metallurgy: Englewood, CO, USA, 1993; pp. 221–228. [Google Scholar]

- Hemami, A. Study of forces in the scooping operation of a mechanical loader. Trans. Can. Soc. Mech. Eng. 1994, 18, 191–205. [Google Scholar]

- Petty, M.K.; Billingsley, J.; Tran-Cong, T. Autonomous LHD loading. In Proceedings of the Fourth Annual Conference on Mechatronics and Machine Vision in Practice, Toowoomba, QLD, Australia, 23–25 September 1997. [Google Scholar]

- Takahashi, H.; Hasegawa, M.; Nakano, E. Analysis on the resistive forces acting on the bucket of a load-haul-dump machine and a wheel loader in the scooping task. Adv. Robot. 1999, 13, 97–114. [Google Scholar] [CrossRef]

- Marshall, J.A.; Murphy, P.F.; Daneshmend, L.K. Toward autonomous excavation of fragmented rock: Full-scale experiments. IEEE Trans. Autom. Sci. Eng. 2008, 5, 562–566. [Google Scholar] [CrossRef]

- Hemami, A.; Hassani, F. An overview of autonomous loading of bulk material. In Proceedings of the 26th International Symposium on Automation and Robotics in Construction, Austin, TX, USA, 24–27 June 2009. [Google Scholar]

- Dobson, A.; Marshall, J.; Larsson, J. Admittance control for robotic loading: Design and experiments with a 1-tonne loader and a 14-tonne load-haul-dump machine. J. Field Robot. 2017, 34, 123–150. [Google Scholar] [CrossRef] [Green Version]

- Heshan, F.; Marshall, J.A.; Almqvist, H.; Larsson, J. Towards Controlling Bucket Fill Factor in Robotic Excavation by Learning Admittance Control Setpoints. In Field and Service Robotics; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Heshan, F.; Marshall, J.A.; Larsson, J. Iterative learning-based admittance control for autonomous excavation. J. Intell. Robot. Syst. 2019, 96, 493–500. [Google Scholar]

- Ruiz del Solar, J.; Vallejos, P.; Tampier, C.; Leottau, D. Un Método de Estimación de Derrape y Detección de Colisión con una Pila de Mineral. Chilean Patent 201803481, 8 July 2020. [Google Scholar]

- Erikson, J.M.; Mueggenburg, N.W.; Jaeger, H.M.; Nagel, S.R. Force distributions in three-dimensional compressible granular packs. Phys. Rev. E 2002, 66, 040301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herminghaus, S. Dynamics of wet granular matter. Adv. Phys. 2005, 54, 221–261. [Google Scholar] [CrossRef]

- Mikhirev, P.A. Design of automated loading buckets. Sov. Min. 1986, 22, 292–298. [Google Scholar] [CrossRef]

- Shi, X.; Lever, P.; Wang, F. Experimental robotic excavation with fuzzy logic and neural networks. In Proceedings of the 1996 IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; Volume 1, pp. 957–962. [Google Scholar]

- Dobson, A.; Marshall, J. Autonomous Loading Vehicle Controller. WO Patent 2015/109392, 30 July 2015. [Google Scholar]

- Rocke, D.J. Control System for Automatically Controlling a Work Implement of an Earth Working Machine to Capture Material. U.S. Patent Application No. 5,528,843, 25 June 1996. [Google Scholar]

- Alshaer, B.J.; Ingram, R.G.; Krone, J.J.; Berry, J.K.; Harris, J.J. Automatic Digging and Loading System for a Work Machine. U.S. Patent Application No. 7,555,855, 7 July 2009. [Google Scholar]

- Fletcher, J.G.; Jones, D.A.; Hewavisenthi, R.D.; Chow, R.K. Excavation System Having Adaptive Dig Control. U.S. Patent Application No. 09,587,369, 7 March 2017. [Google Scholar]

- Asenjo, R.; Boulard, A.; Mascaró, M.; Tampier, C.; Ruiz del Solar, J. Autonomous Loading for an LHD. In Proceedings of the Automining 2016, Antofagasta, Chile, 30 November–2 December 2016. [Google Scholar]

- Quigley, M.; Conley, K.; Gerkey, B.; Faust, J.; Foote, T.; Leibs, J.; Wheeler, R.; Ng, A. ROS: An Open-Source Robot Operating System; ICRA Workshop on Open Source Software. 2009. Available online: http://www.cim.mcgill.ca/~dudek/417/Papers/quigley-icra2009-ros.pdf (accessed on 7 September 2021).

- Röfer, T. CABSL—C-Based Agent Behavior Specification Language. In RoboCup 2017: Robot World Cup XXI; Springer: Cham, Switzerland, 2017; pp. 135–142. [Google Scholar]

- Koenig, N.; Howard, A. Design and use paradigms for gazebo, an open-source multi-robot simulator. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and System, Sendai, Japan, 28 September–2 October 2004; Volume 3, pp. 2149–2154. [Google Scholar]

- Leottau, D.; Loncomilla, P.; Mascaró, M.; Tampier, C.; Ruiz del Solar, J. LIDAR-based odometry estimation for autonomous loading of material with LHD. In Proceedings of the Massmin 2020, Santiago, Chile, 9–11 December 2020. [Google Scholar]

- Jaimez, M.; Monroy, G.; Gonzalez, J. Planar Odometry from a Radial Laser Scanner. A Range Flow-based Approach. In Proceedings of the IEEE International Conference on Robotics and Automation, Stockholm, Sweden, 16–21 May 2016. [Google Scholar]

- Lobos, K.; Loncomilla, P.; Ruiz-del-solar, J. Rocky-YOLO: Detección de rocas usando deep learning para aplicaciones en minería. In Proceedings of the SIMIN 2019, Santiago, Chile, 21–23 August 2019. (In Spanish). [Google Scholar]

- Mascaró, M.; Tampier, C.; Ruiz del Solar, J. Topological Navigation in Tunnels: LHD Navigation as a Case Study. In Proceedings of the Automining 2020, Santiago, Chile, 30 November–4 December 2020. [Google Scholar]

- Marshall, J.; Barfoot, T.; Larsson, J. Autonomous underground tramming for center-articulated vehicles. J. Field Robot. 2008, 25, 400–421. [Google Scholar] [CrossRef]

- Ruiz del Solar, J.; Vallejos, P.; Tampier, C. Método de Carguío Autónomo Para Cargadores Frontales. Chilean Patent 201803004, 26 December 2019. [Google Scholar]

| Parameter | Value |

|---|---|

| 0.5 | |

| 1.2 | |

| 0.2 | |

| 0.5 [rad] | |

| 0.0 [rad] | |

| 2.0 [m] | |

| 1.0 [s] | |

| 0.5 [s] | |

| 300 [bar] |

| Parameter | Value |

|---|---|

| 0.2 | |

| 0.0207 | |

| 1.0774 |

| N-Attempts | N-Exp | Total-Attempts | %-Experiments | Fill-Factor |

|---|---|---|---|---|

| 1 attempt | 9 | 9 | 30% | 88% |

| 2 attempts | 4 | 8 | 13% | 107% |

| 3 attempts | 11 | 33 | 37% | 87% |

| 4 attempts | 6 | 24 | 20% | 90% |

| TOTAL | 30 | 74 | 100% | - |

| Total Average Number of Attempts | Total Average Fill Factor |

|---|---|

| 3.6 | 90% |

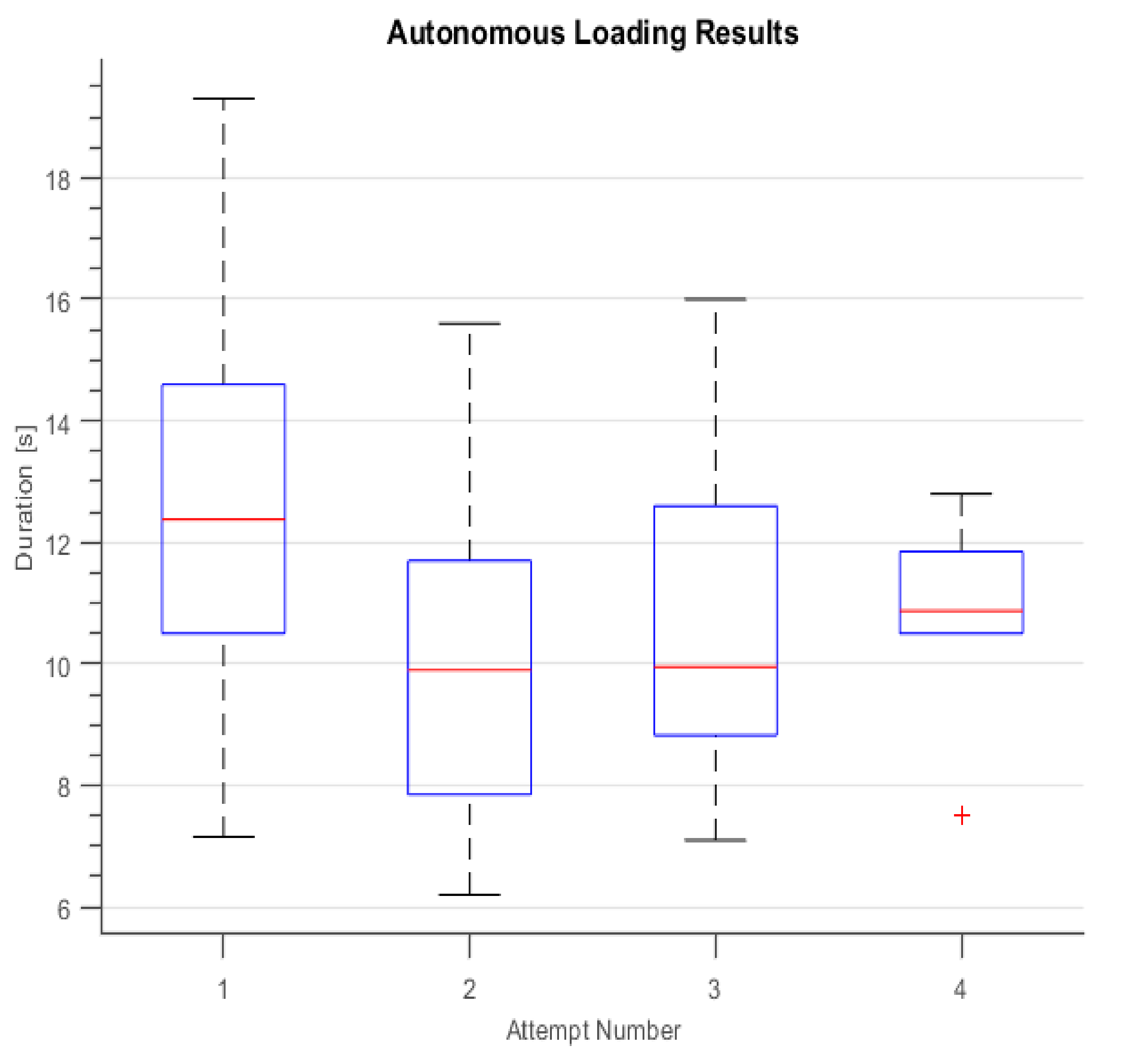

| P-Attempts | N-Exp | Percentage | Duration | Fill-Factor |

|---|---|---|---|---|

| First attempt | 30 | 100% | 12.7 s | 62% |

| Second attempt | 21 | 70% | 10.2 s | 77% |

| Third attempt | 17 | 57% | 10.8 s | 82% |

| Fourth attempt | 6 | 20% | 10.7 s | 90% |

| Modeling Attempt | Ground Truth Width (m) | Predicted Width (m) | Ground Truth Inclination (°) | Predicted Inclination (°) |

|---|---|---|---|---|

| 1 | 3.25 | 2.89 | −53.0 | −52.6 |

| 2 | 3.10 | 5.27 | −50.1 | −48.7 |

| 3 | 3.10 | 3.16 | −52.4 | −50.5 |

| 4 | 3.44 | 3.29 | −50.6 | −50.5 |

| 5 | 3.20 | 3.72 | −50.0 | −53.4 |

| 6 | 3.03 | 3.25 | −49.5 | −46.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tampier, C.; Mascaró, M.; Ruiz-del-Solar, J. Autonomous Loading System for Load-Haul-Dump (LHD) Machines Used in Underground Mining. Appl. Sci. 2021, 11, 8718. https://doi.org/10.3390/app11188718

Tampier C, Mascaró M, Ruiz-del-Solar J. Autonomous Loading System for Load-Haul-Dump (LHD) Machines Used in Underground Mining. Applied Sciences. 2021; 11(18):8718. https://doi.org/10.3390/app11188718

Chicago/Turabian StyleTampier, Carlos, Mauricio Mascaró, and Javier Ruiz-del-Solar. 2021. "Autonomous Loading System for Load-Haul-Dump (LHD) Machines Used in Underground Mining" Applied Sciences 11, no. 18: 8718. https://doi.org/10.3390/app11188718

APA StyleTampier, C., Mascaró, M., & Ruiz-del-Solar, J. (2021). Autonomous Loading System for Load-Haul-Dump (LHD) Machines Used in Underground Mining. Applied Sciences, 11(18), 8718. https://doi.org/10.3390/app11188718