1. Introduction

Abrasions, cuts, and bruises have been some of the leading causes of occupational injury. In Taiwan, they are the second most common injury type at workplaces [

1]. Nearly 80% of the abrasions, cuts, and bruises lead to hand or finger injuries. Research [

2], studying the incidences involving hand injuries for the US coal mine workers found that 18% of the total hand injuries were responsible for 84% of the total lost work days for the workers. The median lost workdays of those workers due to hand injuries were more than 30 days. The official statistics of the Bureau of Labour of the USA indicated that cuts and lacerations of hand accounted for 64.8% of all cut and laceration incidents [

3]. Hand injuries lead to a substantial economic burden, with both high health-care expenditures and productive costs [

4,

5]. Hand protections at work are essential for both the safety and health of workers but also for the welfare and well-beings of workers’ families [

5].

Work gloves are used for the protection of hands from potential physical, chemical, and biological hazards [

6,

7,

8,

9,

10,

11,

12]. Typical physical hazards of hand exposure at work include cuts and stabs [

13], vibrations of tools and machines [

14,

15,

16,

17], load and pressure [

18,

19,

20], high and low temperature [

11,

21,

22,

23], and so on. Typical chemical and biological hazards, on the other hand, include hazardous substances (such as pesticides and acids) and organisms such as insects, germs, and even viruses [

9,

12].

Work gloves may impose unwanted effects on hand performance [

21,

24]. Gloves separate the hand and the contact object and thus reduce the tactile sensitivity of the hand [

25,

26,

27,

28]. In addition, the structure of the glove could hamper fingers’ movements. This could reduce hand dexterity [

13,

21,

29,

30]. The literature [

7], has found a negative linear relationship between glove thickness and hand dexterity. In other words, hand dexterity decreases when the thickness of gloves is increased.

Wearing gloves could change the hand force exertion of a person. The literature indicates that wearing gloves increases forearm muscle activation [

31]. This leads to early muscle fatigue and thus increased the risk of musculoskeletal disorders (MSDs) [

29,

32,

33,

34]. The literature has also found that increasing glove thickness could decrease grip strength in addition to decreasing hand dexterity [

27,

35,

36]. The range of grip strength reduction varies, depending on factors such as the number of layers and fitness of the gloves [

15,

24,

30,

33,

37,

38]. Even though the effects of gloves on grip strength have been reported, further investigations are required to examine how those effects are affected by handedness and the grip span of the handle. Such information will be beneficial for glove design and selection of work gloves on a worksite.

There are studies assessing the effects of wearing gloves on both hand dexterity and grip strength [

31,

37]. However, investigations of the effects of wearing gloves on the capability of lifting and carrying materials are not common. Work gloves are made of various materials. Cotton polyester yarn glove, or simply cotton glove, is one of the most commonly used work gloves. This glove provides limited protection for the hand against contacting sharp objects and high/low temperature. It is commonly used in agricultural, construction, and manufacturing industries. Gloves made of knitwear and coated with composite rubber material on the palm are common. The coating on the palm increase friction at the hand-object interface and thus facilitates hand grip of the object being handled. Knitwear gloves incorporated with glass fibers provide resistance to cuts and stabs. However, such a design could increase the stiffness of the protective gloves and thus may change the material handling capabilities of hands. Studies discussing these issues are significant. They will provide useful information for practitioners to choose proper gloves in performing manual materials handling tasks. The objective of this study was to assess these three types of work gloves in terms of strengths of hand grip, one-handed carrying, and leg lifting. The performances of these gloves were discussed along with their characteristics in thickness, stiffness, and friction in the palmar regions.

2. Materials and Methods

2.1. Participants

Thirty healthy adults, including 14 males and 16 females, were recruited as human participants. Ninety percent (27) of them were right handlers. The age and anthropometric data of the participants are shown in

Table 1. None of the participants had musculoskeletal injuries within 12 months of the study. All the participants were requested not to engage in strenuous physical activities at least an hour prior to the experiment.

2.2. Strength Measurement Apparatus

A grip dynamometer (TKK 5001, GRIP-A, TAKEI, Tokyo, Japan) was used to measure the grip strength. The grip spans included 45 mm, 55 mm, 65 mm, and 75 mm, respectively. An apparatus was adopted to measure the one-handed carrying and leg lifting strength. This apparatus included a loadcell and displayer (FG-5100, Lutron, Taiwan), a steel plate, iron chain, and two handles (see

Figure 1). One of the metal handles was short (17.4 cm), which was used in the one-handed carrying strength measurement. The other handle was a long one (32.0 cm) and was wrapped with rubber. This one was used for leg lifting strength measurement. Both of these handles have a diameter of approximately 3.2 cm. Iron chains were used to connect the handle, the force gauge, and the steel plate. The height of the handle might be controlled by adjusting the length of the chains to the anchorage of the steel plate to fulfil the requirements of different measuring conditions.

2.3. Gloved Conditions

There were four gloved conditions: bare hand and wearing one of the three types of work gloves prepared. Three types of work gloves were purchased from a local hardware store (see

Figure 2). Glove 1, or simply cotton glove, is a knitted cotton polyester yarn glove. Glove 2 (SS-100, 3M, Seoul, Korea), or simply glove with NBR coating, is a knitted glove with nylon and is coated nitrile rubber (NBR) in the palmar region. Glove 3, or simply cut resistance glove, is a safety glove protecting against cuts and stabs (CP-500, 3M, Seoul, Korea). This glove is knitted with nylon, spandex, and glass fiber, and is also coated with NBR on the palmar region. The thickness of the gloves was measured in the palmar region of these gloves using a caliper (SV-03-150, E-BASE, Yunlin, Taiwan).

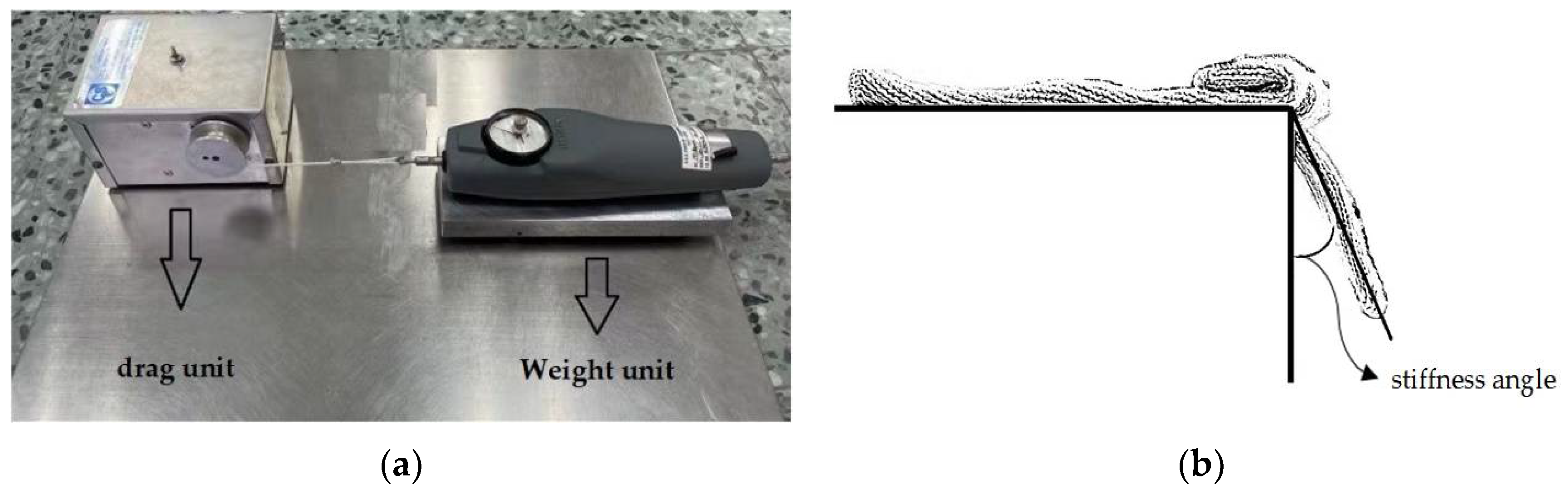

The coefficient of friction (COF) between the surface of the palmar region of each type of glove on a steel plate was measured using a Horizontal Pull Slipmeter (HPS) (C.S.C. Force Measurement, Inc., Agawam, MA, USA; ASTM, F609-13) [

39]. When measuring the COF, three circular (Ø 1 cm) glove samples were cut from one of each type of glove and were attached to the bottom of the weight unit of the HPS (see

Figure 3a). The operator pushed the drag unit downward to fix it and then turned on the power of this unit. The drag unit pulled the weight unit until the latter started to move. The COF reading was shown on the meter.

A simple test was performed to measure the stiffness of these gloves. In this test, a tested glove was placed on the edge of a workbench with the middle finger sleeve extended outside the bench and drooped. The angle between this sleeve and the vertical, or stiffness angle, was measured to indicate the stiffness of the glove (see

Figure 3b). A large angle indicates high stiffness of the sleeve.

Three different sizes were prepared for each of gloves 2 and 3 so that each participant could choose the one that fit his or her hands best. Glove 1 is relatively cheap and has only one size. The glove information is summarized in

Table 2.

2.4. Grip Strength Test

For grip strength measurement, the participant stood with his or her arm straight down by the side (see

Figure 4) and gripped the dynamometer at his or her maximum voluntary contractions for approximately 5 s. Both dominant and non-dominant hands were tested under the four gloved conditions and four grip span conditions. The experimental condition was randomly arranged. The participant took a rest for five minutes or longer between two consecutive trials on the same hand.

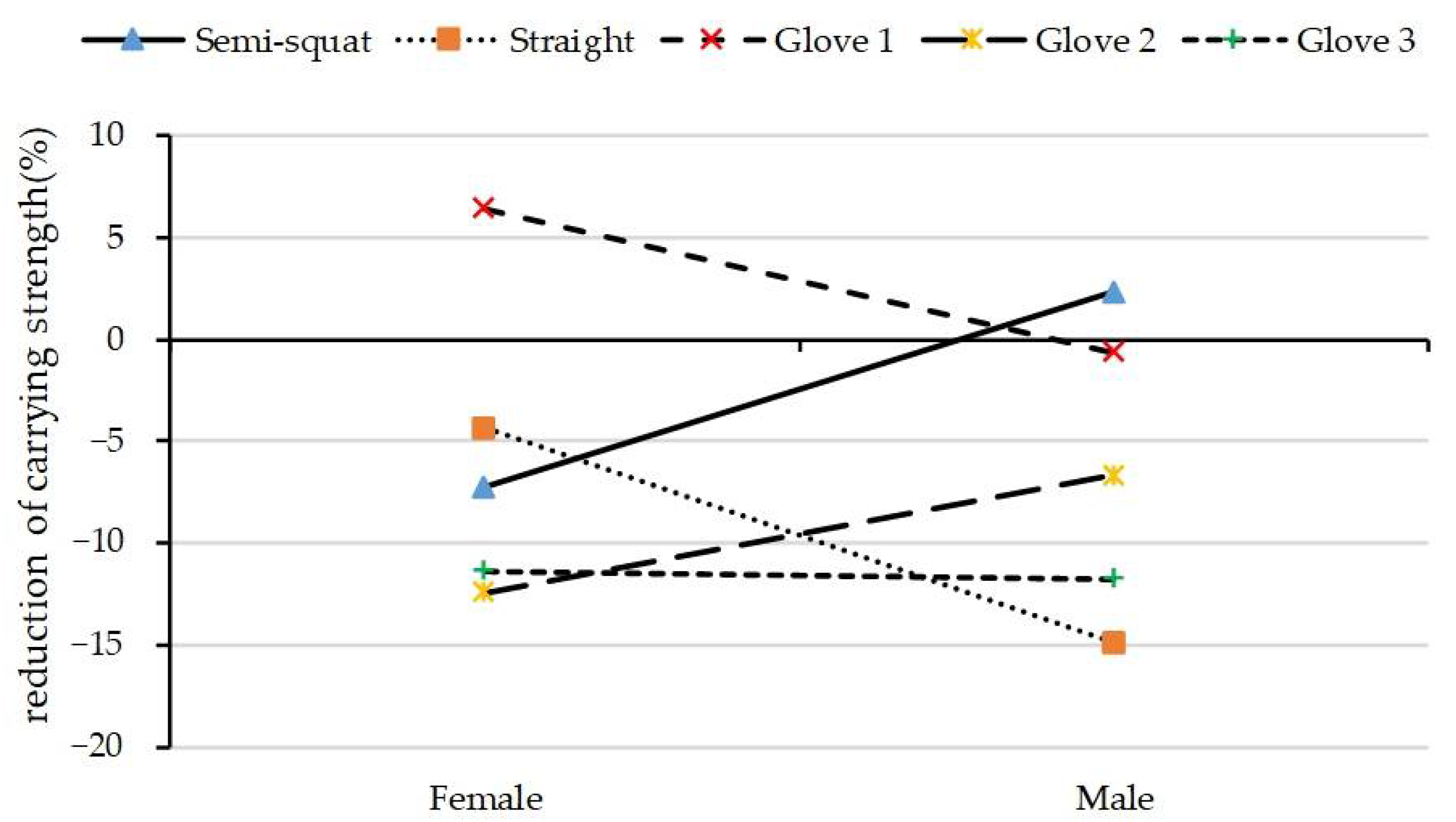

2.5. Carrying Strength Measurements

One-handed carrying strength was measured. These strengths were measured using either dominant or non-dominant hand under the gloved conditions and with two different leg postures: semi-squat and leg straight. For the semi-squat posture, the short handle of the strength measurement apparatus was at the participant’s knee height. The participant bent his or her knee to grasp the handle to pull up at his or her maximal strength (see

Figure 5a). This posture mimicked the posture when a person is lifting an object from the ground and prepares to carry it on the side. For the straight posture, the participant stood upright with his or her arm straight-down by the sides (see

Figure 5b). The height of the handle was adjusted to allow the participant to grasp the handle at his or her knuckle height. This posture mimicked the posture when a person is carrying an object using one hand on the side.

When measuring the carrying strength, the participant grasped the handle and pulled upward at his or her maximal force for 4–6 s. The participant took a break for 10 min or longer between any two trials of the same hand. The order of the experimental condition in terms of glove, posture, and handedness was randomly arranged.

2.6. Lifting Strength Measurement

For lifting strength measurement, the participants grasped the long handle using both hands with a semi-squat posture (see

Figure 6). This posture simulates that of lifting an object from the ground using a squat posture. The handle was 38 cm above the test plate. The participant pulled upward at his or her maximal force for 4–6 s. This measurement was conducted under four gloved conditions. The order of the gloved condition was randomly arranged. The participant took a break for 10 min or longer between any two trials.

2.7. Experiment Design and Data Analysis

A total of 960 (4 gloved conditions × 2 hands × 4 grip spans × 30 participants), 480 (4 gloved conditions × 2 hands × 2 postures × 30 participants), and 120 (4 gloved conditions × 30 participants) data were collected for the strength of grip, carrying, and lifting. Descriptive statistics were performed. Analyses of variance (ANOVA) were conducted to examine the significances of the factors on the strengths. Duncan’s multiple range tests were adopted as the post-hoc test to compare the difference between each pair of treatments for each factor. To study the relationship between grip strength and grip span, we performed regression analysis without intercept using grip strength as dependent variable and grip span as an independent variable for each of the gender, handedness, and gloved condition. The statistical analyses were performed using SAS® 9.0 (SAS Institute Inc., Cary, NC, USA) software. A significance level of α = 0.05 was used.

5. Conclusions

Three work gloves were assessed in terms of the strength of grip, carrying, and lifting. It was found that the gloves, grip span, gender, and handedness were all significant factors affecting grip strength. Wearing gloves could result in a reduction of grip strength up to 22.9%, on average. The reduction of grip strength varies and depends on gender, handedness, grip span, and gloves used. The gloves, posture, and gender all significantly affected the carrying strength. The cotton gloves led to carrying strength declines while both the knitted gloves with NBR coating and cut resistant gloves could increase the carrying strength. The inferiority of cotton gloves was primarily because of their insufficient friction in the palmar region. Wearing the gloves tested in this study did not change the leg lifting strength due to the good slip resistance characteristics of the long handle. This implies that gloves have little effects on the lifting strength when the handle could provide adequate friction at the hand-handle interface. These findings are beneficial for practitioners in selecting proper gloves in manual materials handling tasks.