Effect of Geometrical Factors on Torsion in Cold Roll Forming of the Lower Side Beam of a Car

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Property

2.1.1. Metallographic Structure and Chemical Composition

2.1.2. Mechanical Properties

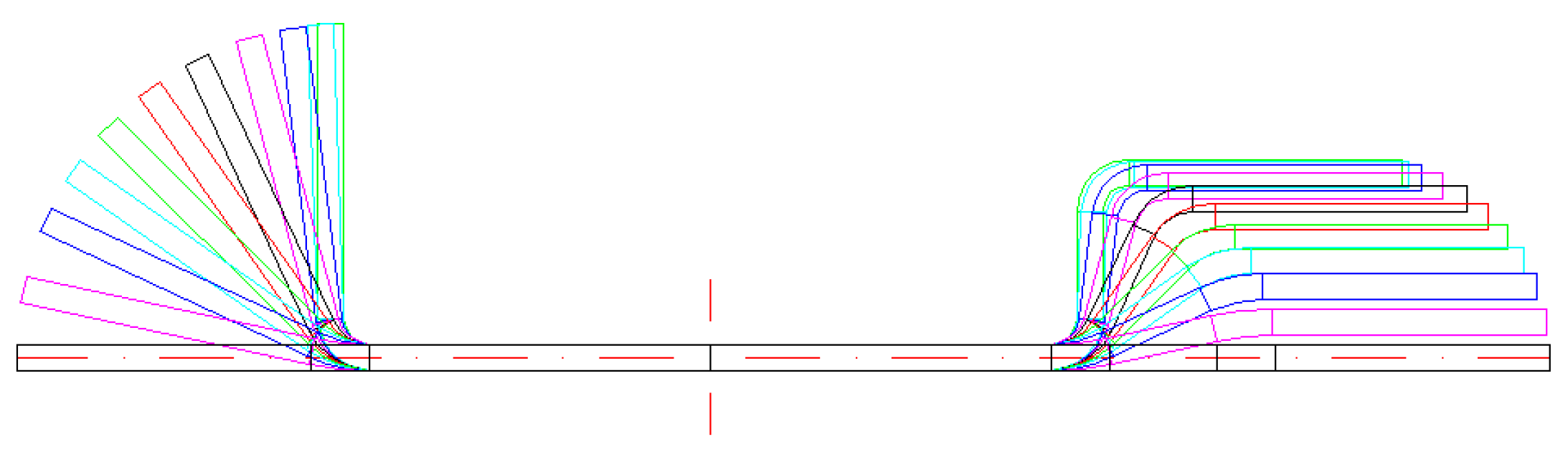

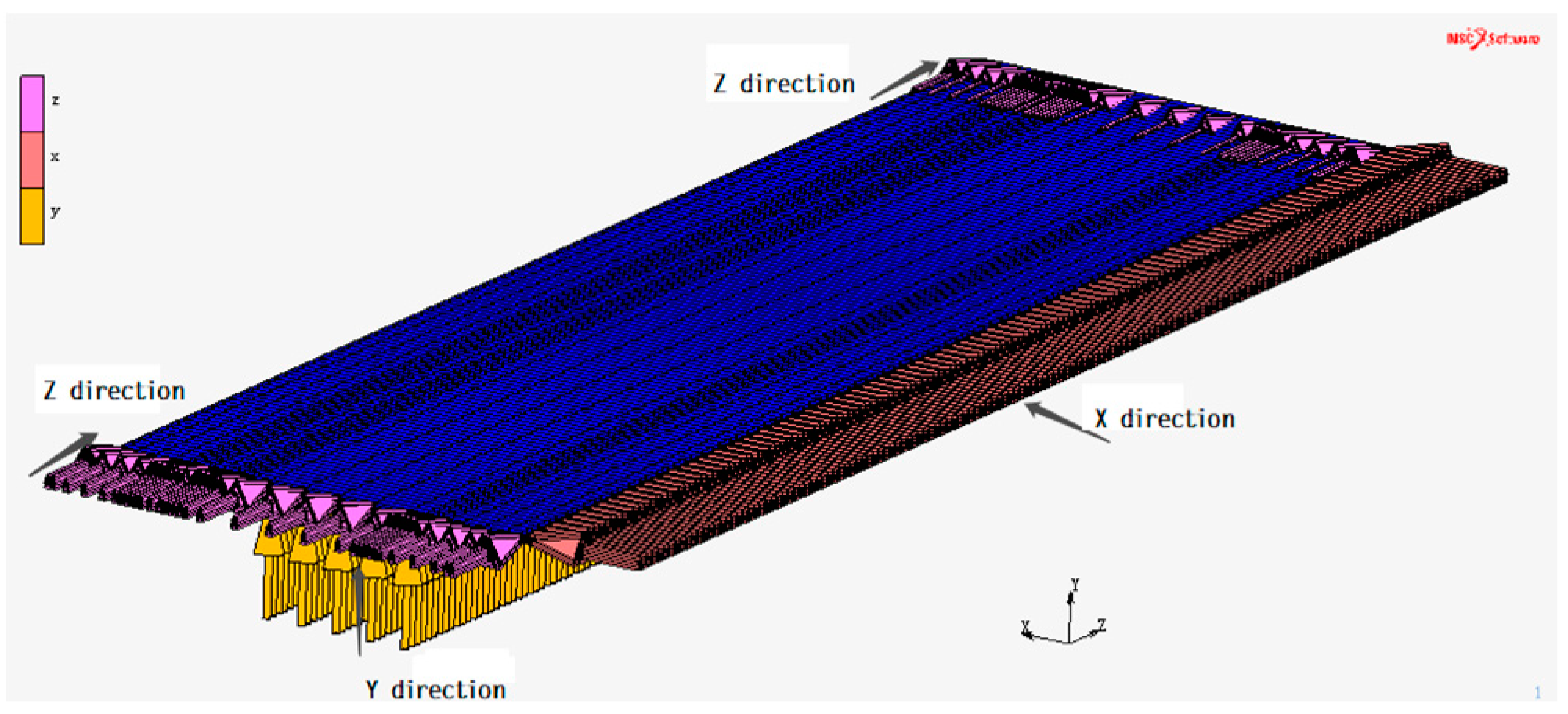

2.2. Establish the Simulation Model

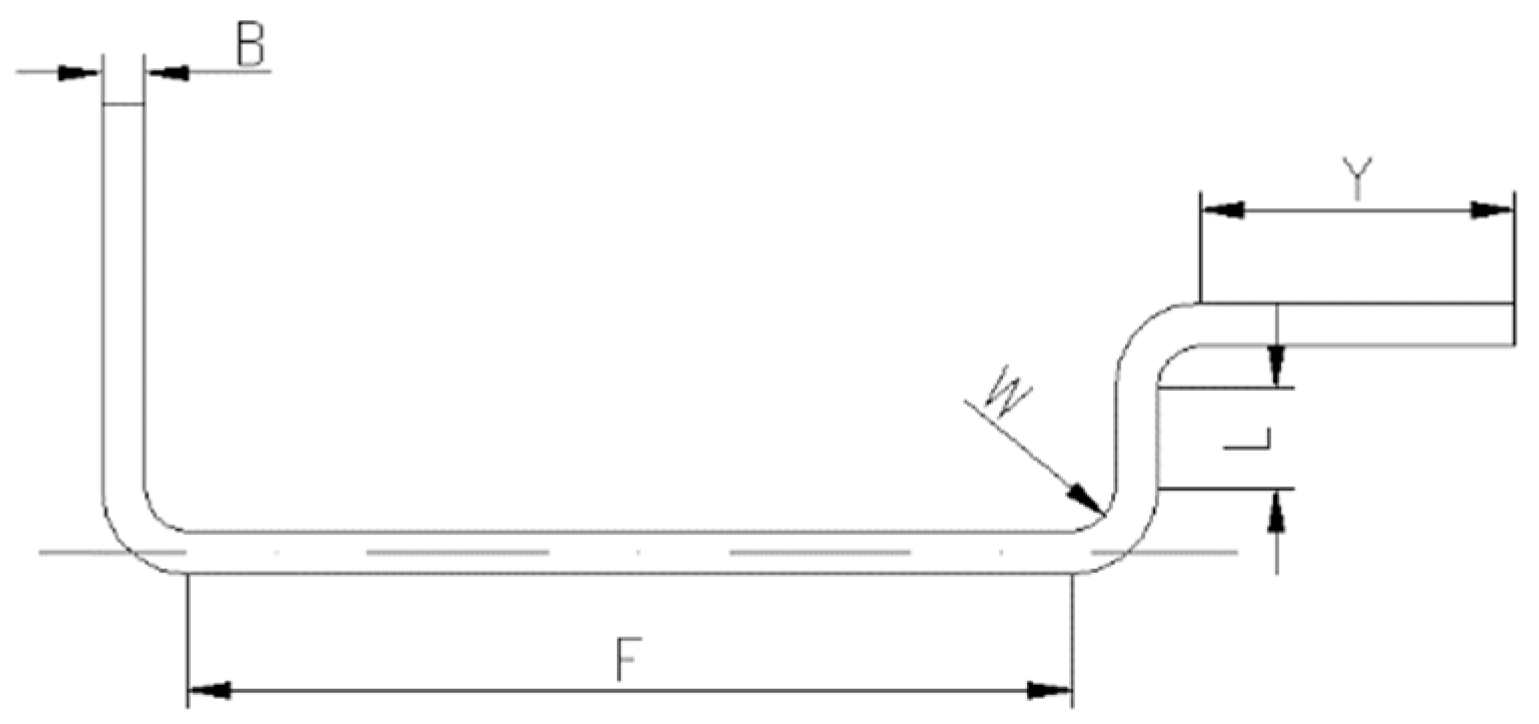

2.3. Study of Geometry Parameter

3. Results and Discussion

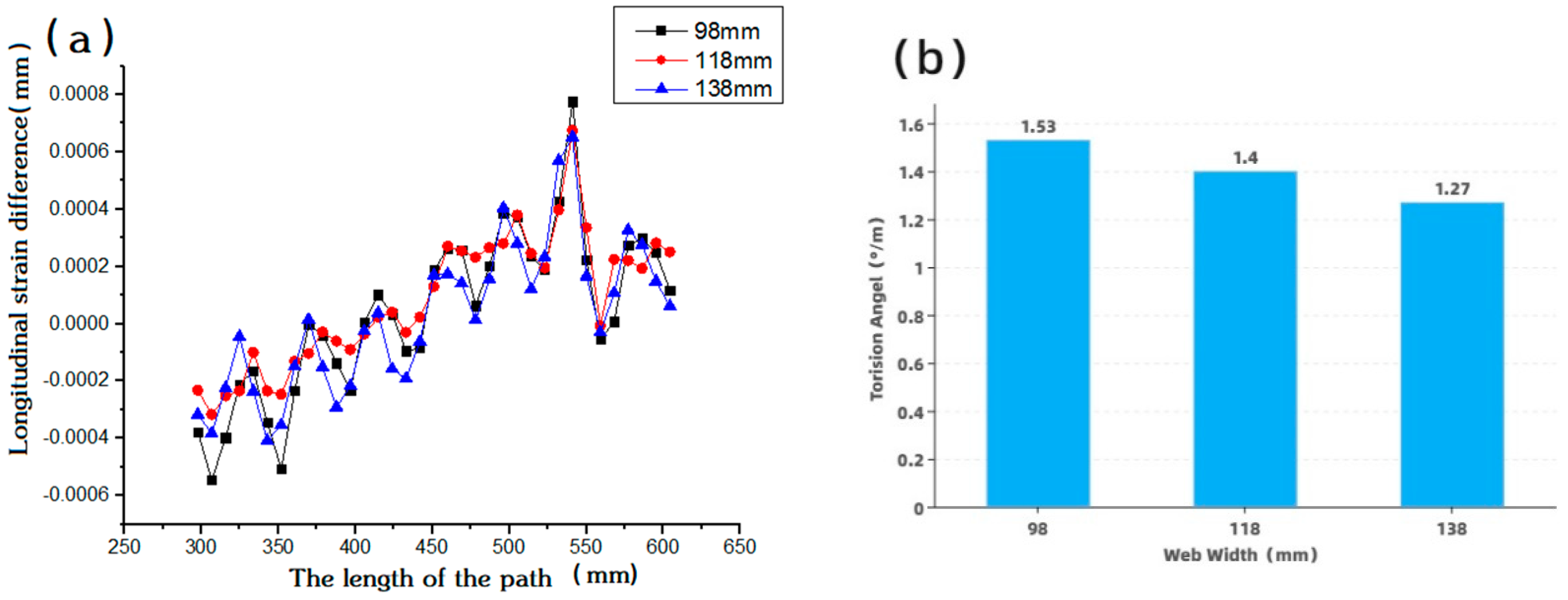

3.1. Web Width

3.2. Width of the Flange

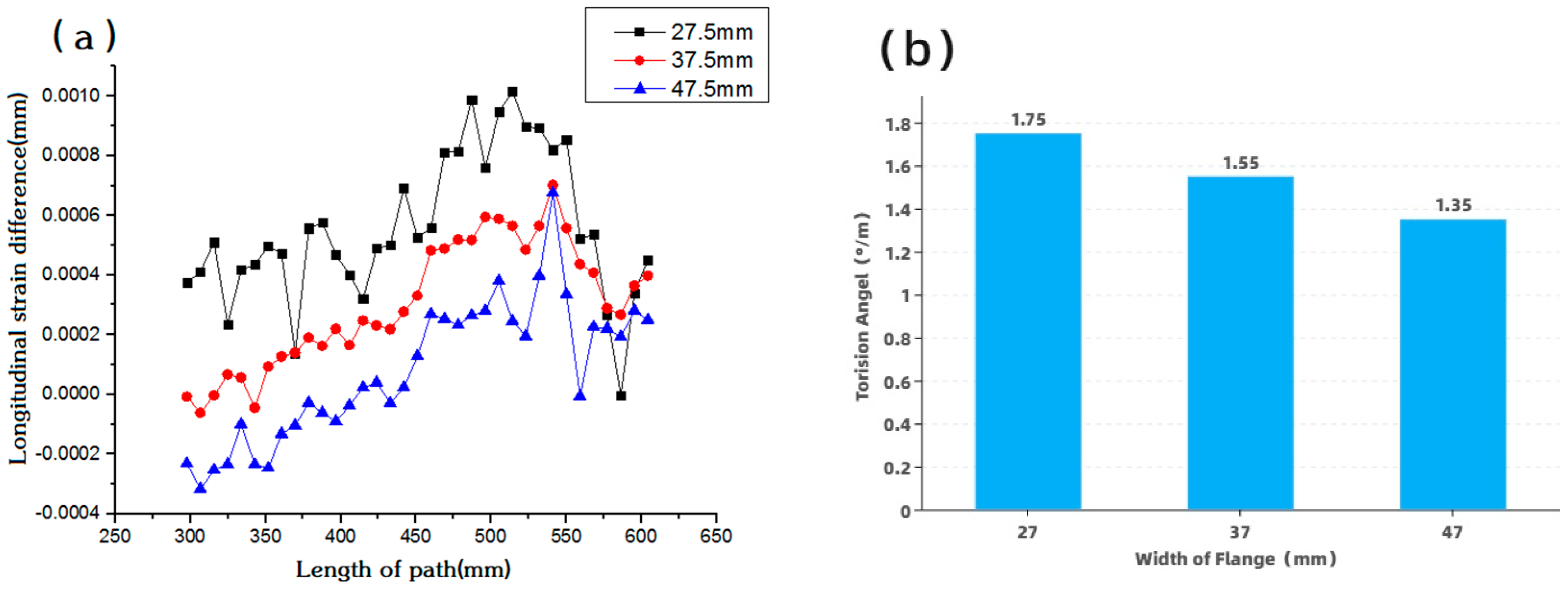

3.3. Plate Thickness

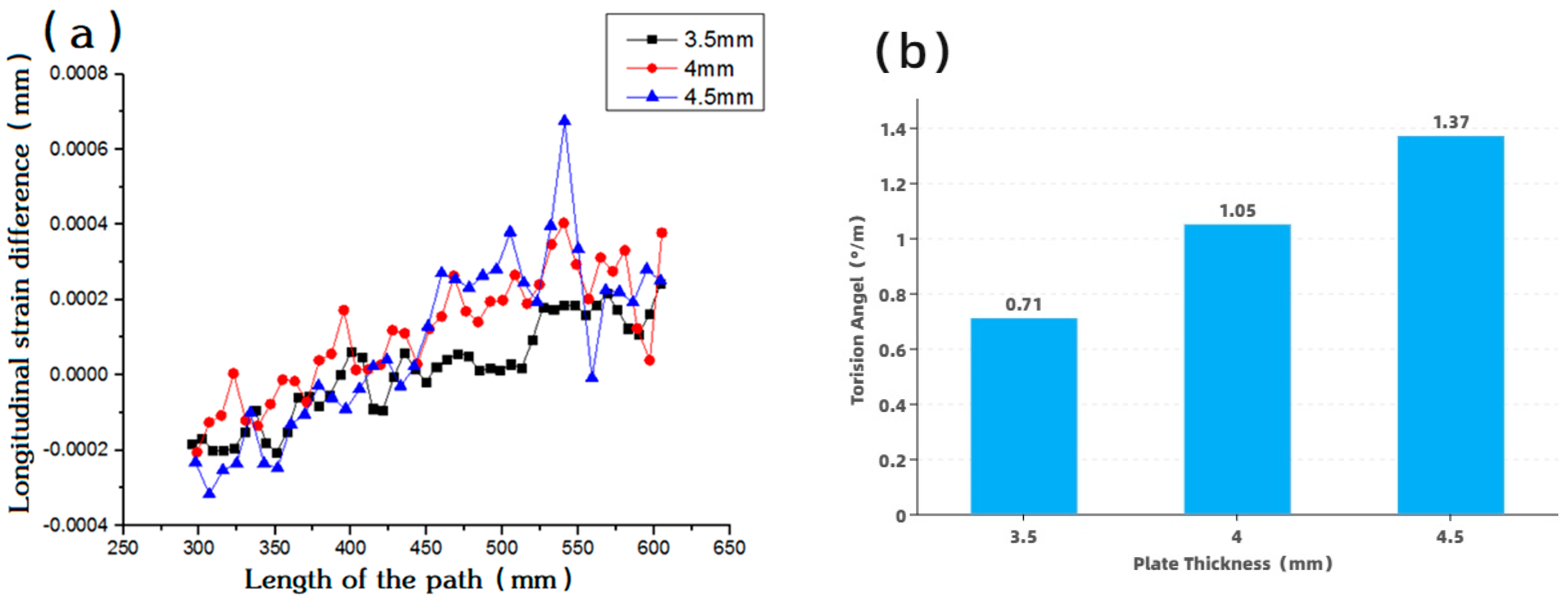

3.4. Vertical Edge Height

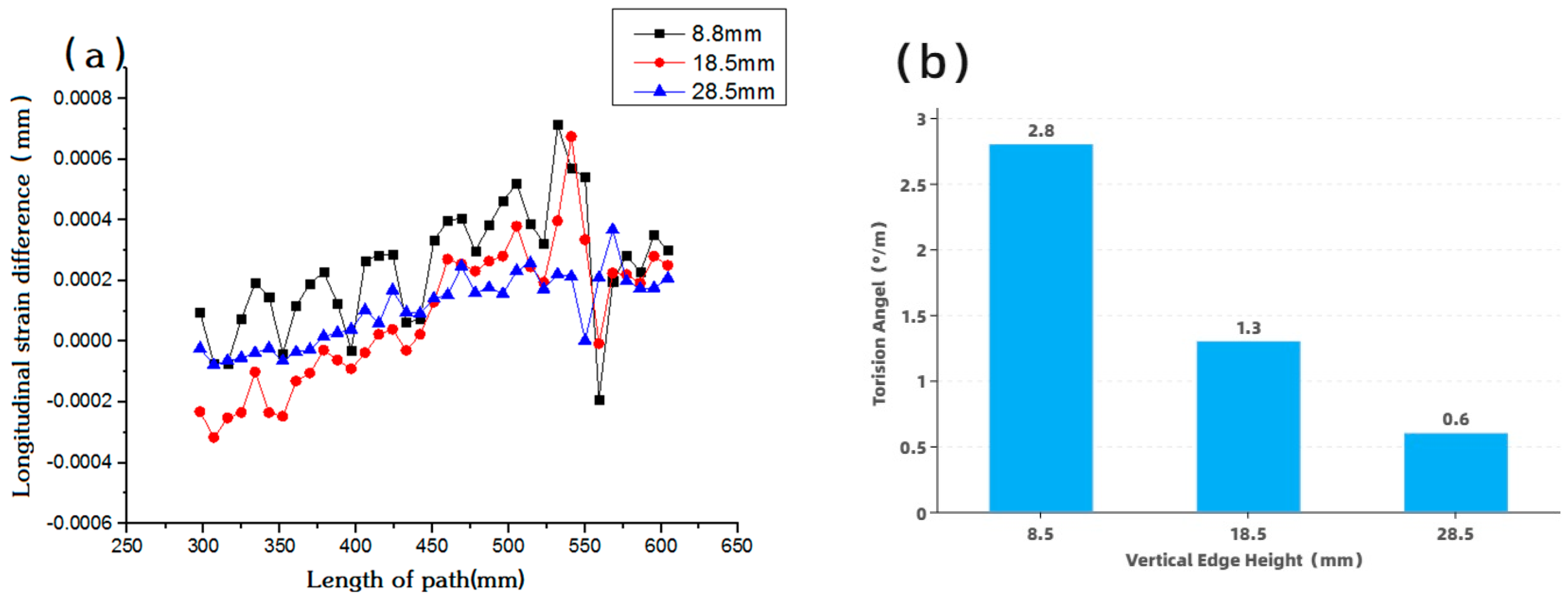

3.5. Corner Radius

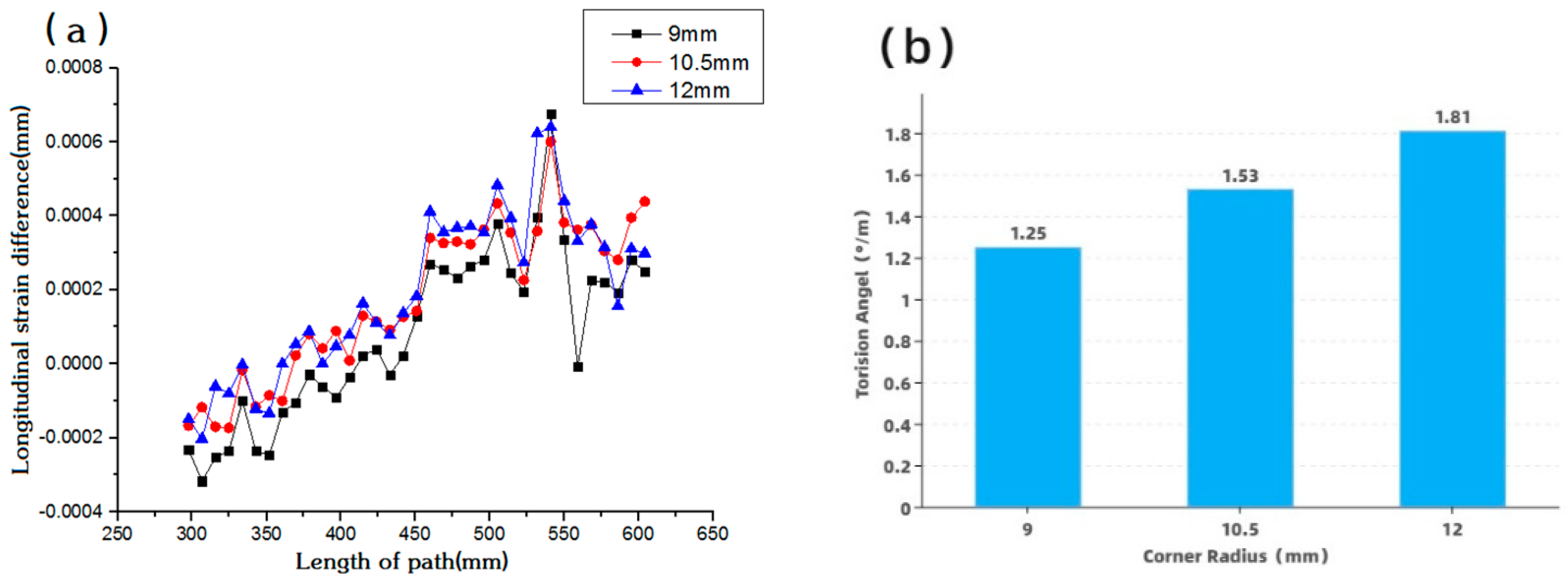

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Zhang, Y.; Li, J.; Qin, Y. Roll forming precess design and FEM analysis of automobile anti-collision beam based on copra. In Proceedings of the 15th China CAE Engineering Analysis Technology Annual Conference, Kitakyushu, Japan, 13–16 April 2019; pp. 266–269. [Google Scholar]

- Kim, Y.-I.; Kim, J.-H.; Jeoung, Y.-C.; Kim, N.-S. Buckling Analysis of Roll Forming Process using Finite element method. Trans. Korean Soc. Mech. Eng. A 2003, 27, 1451–1456. [Google Scholar] [CrossRef]

- Cha, W.-G.; Kim, N. Study on twisting and bowing of roll formed products made of high strength steel. Int. J. Precis. Eng. Manuf. 2013, 14, 1527–1533. [Google Scholar] [CrossRef]

- Tajik, Y.; Naeini, H.M.; Tafti, R.A.; Bidabadi, B.S. A strategy to reduce the twist defect in roll-formed asymmetrical-channel sections. Thin-Walled Struct. 2018, 130, 395–404. [Google Scholar] [CrossRef]

- Bidabadi, B.S.; Naeini, H.M.; Tafti, R.A. Experimental and numerical study of required torque in the cold roll forming of symmetrical channel sections. J. Manuf. Process. 2017, 27, 63–75. [Google Scholar] [CrossRef]

- Moen, C.D.; Igusa, T.; Schafer, B. Prediction of residual stresses and strains in cold-formed steel members. Thin-Walled Struct. 2008, 46, 1274–1289. [Google Scholar] [CrossRef]

- Paralikas, J.; Salonitis, K.; Chryssolouris, G. Investigation of the effects of main roll-forming process parameters on quality for a V-section profile from AHSS. Int. J. Adv. Manuf. Technol. 2008, 44, 223–237. [Google Scholar] [CrossRef]

- Davoodi, B.; Naeini, H.M.; Asl, Y.D.; Azizi, T.R.; Kasaei, M.M.; Panahizadeh, V.R.; Chinesta, F.; Chastel, Y.; El Mansori, M. Numerical and Experimental Investigation of Roll Forces and Torques in Cold Roll Forming of a Channel Section. AIP Conf. Proc. 2011, 1315, 581. [Google Scholar]

- Paralikas, J.; Salonitis, K.; Chryssolouris, G. Energy efficiency of cold roll forming process. Int. J. Adv. Manuf. Technol. 2012, 66, 1271–1284. [Google Scholar] [CrossRef]

- Lindgren, M. Cold roll forming of a U-channel made of high strength steel. J. Mater. Process. Technol. 2007, 186, 77–81. [Google Scholar] [CrossRef] [Green Version]

- Safdarian, R.; Naeini, H.M. The effects of forming parameters on the cold roll forming of channel section. Thin-Walled Struct. 2015, 92, 130–136. [Google Scholar] [CrossRef]

- Wei, L. Finite Element Analysis and Springback Prediction of U Section Steel Bending. Dalian Jiaotong University. 2010. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD2011&filename=2010236935.nh (accessed on 25 August 2021).

- Jia, G.; Sun, D.; Wang, R.; Zhao, Y. Production Practice of Medium Plate Large Beam Steel 700L. Hebei Metall. 2019, 2, 59–61. [Google Scholar] [CrossRef]

- Liu, X. Research on Springback Prediction and Control of Complex Section Ultra-High Strength Steel in Continuous Roll Bending. University of Science and Technology Beijing. 2018. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CDFD&dbname=CDFDLAST2018&filename=1018224389.nh&v=8UfAKiloKarOQVHTZMOeKFhxTOXuTr7xSTZjaKnilFMeUkSRJFa884hHkH4lnRqc (accessed on 25 August 2021).

- Paralikas, J.; Salonitis, K.; Chryssolouris, G. Optimization of roll forming process parameters—A semi-empirical approach. Int. J. Adv. Manuf. Technol. 2009, 47, 1041–1052. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr + Mo | B | Nb + V + Ti |

|---|---|---|---|---|---|

| 0.07 | ≤0.30 | ≤2.00 | ≤0.80 | ≤0.0020 | ≤0.10 |

| Thickness (mm) | Direction of Rolling | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation after Breakage (A/%) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|

| 4.5 | Transverse | 649.7 | 771.7 | 23.1 | 214 |

| Longitudinal | 631.2 | 749.3 | 23.5 | 209 |

| Pass | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Forming Angle/° | 0 | 12 | 25 | 35 | 45 | 55 | 65 | 75 | 83 | 88 | 90 |

| Geometric Factor | Code Number | Unit | Value | ||

|---|---|---|---|---|---|

| Web width | F | mm | 98 | 118 | 138 |

| Flange width | Y | mm | 27.5 | 37.5 | 47.5 |

| Plate thickness | B | mm | 3.5 | 4.0 | 4.5 |

| Vertical edge height | L | mm | 8.5 | 18.5 | 28.5 |

| Corner radius | W | mm | 9 | 10.5 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xu, X.; Ren, B.; Liu, J.; Zhao, R. Effect of Geometrical Factors on Torsion in Cold Roll Forming of the Lower Side Beam of a Car. Appl. Sci. 2021, 11, 7852. https://doi.org/10.3390/app11177852

Wang Y, Xu X, Ren B, Liu J, Zhao R. Effect of Geometrical Factors on Torsion in Cold Roll Forming of the Lower Side Beam of a Car. Applied Sciences. 2021; 11(17):7852. https://doi.org/10.3390/app11177852

Chicago/Turabian StyleWang, Yesong, Xiaodong Xu, Bobo Ren, Jiang Liu, and Rongguo Zhao. 2021. "Effect of Geometrical Factors on Torsion in Cold Roll Forming of the Lower Side Beam of a Car" Applied Sciences 11, no. 17: 7852. https://doi.org/10.3390/app11177852

APA StyleWang, Y., Xu, X., Ren, B., Liu, J., & Zhao, R. (2021). Effect of Geometrical Factors on Torsion in Cold Roll Forming of the Lower Side Beam of a Car. Applied Sciences, 11(17), 7852. https://doi.org/10.3390/app11177852