Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

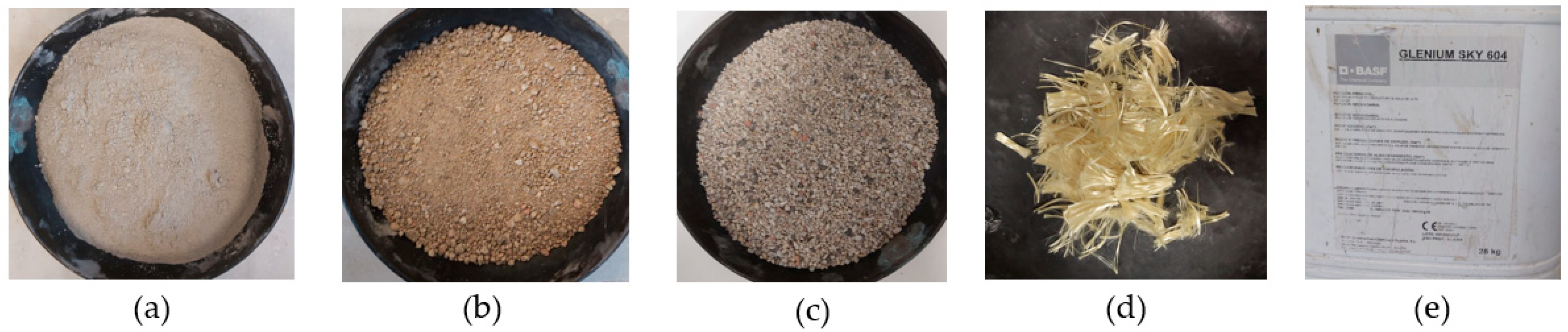

2.1. Materials

2.1.1. Cement

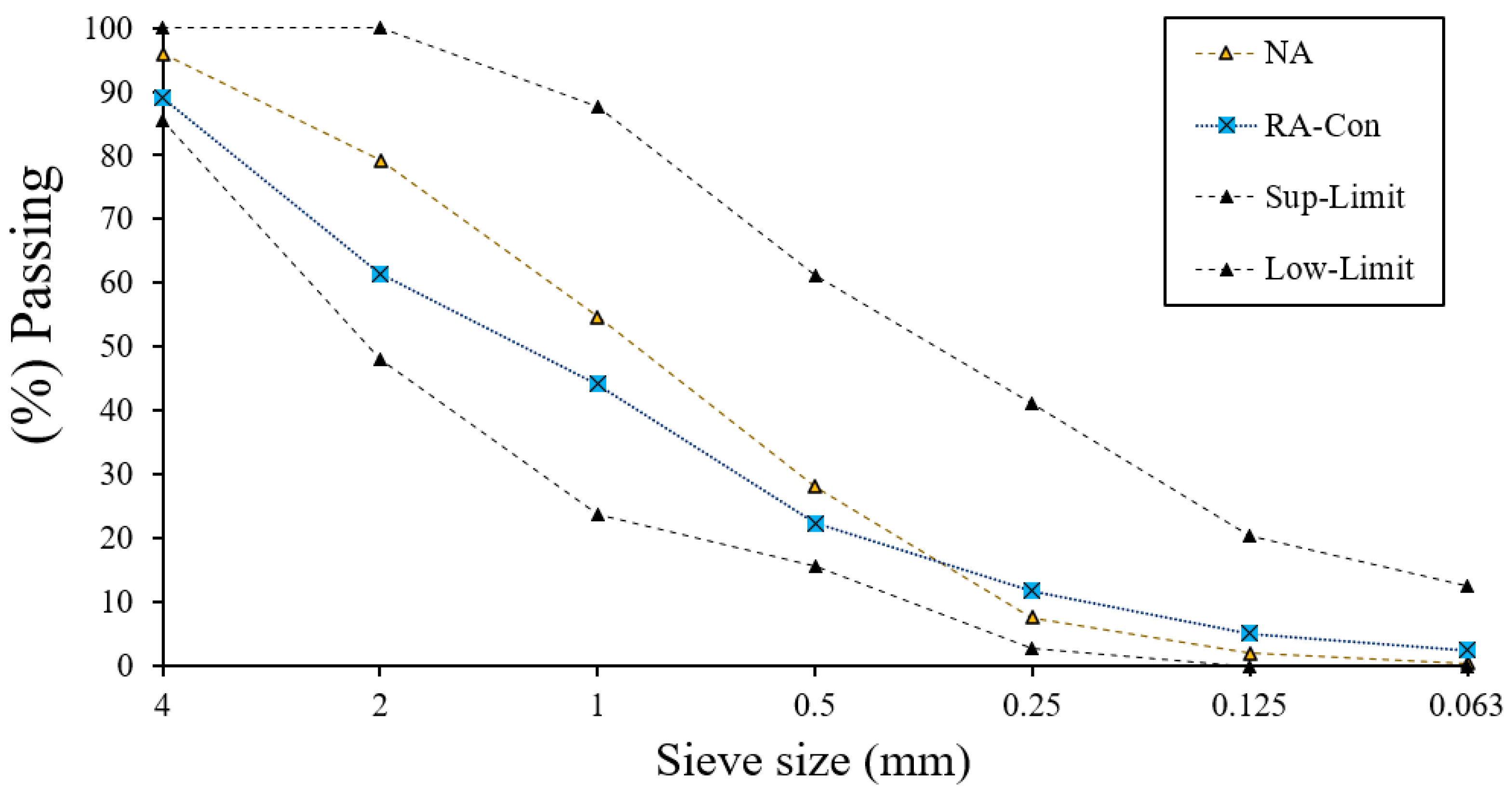

2.1.2. Aggregates

2.1.3. Aramid Fiber

2.1.4. Water and Additive

2.2. Methodology

2.2.1. Dosage

2.2.2. Experimental Program

- -

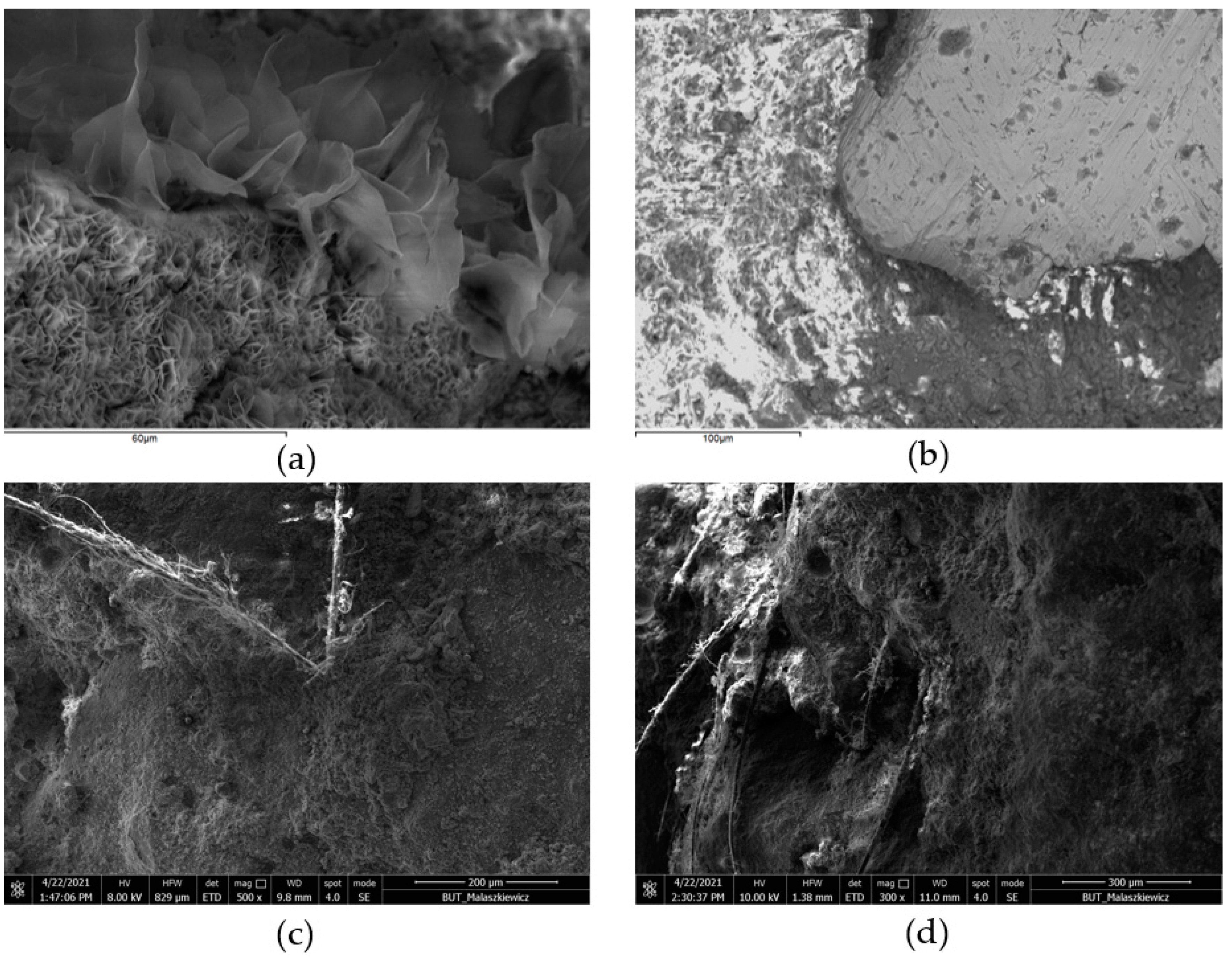

- Mechanical characterization tests: flexural and compressive strengths in prismatic specimens of 40 × 40 × 160 mm3 according to UNE-EN 101511:2000/A1:2007 [70] and for this purpose, a press model AUTETEST 200-10SW was used, together with an analysis by scanning electron microscopy (SEM), using Jeol JSM820 equipment together with EDX Oxford ISISLink software.

- -

- -

3. Results and Discussion

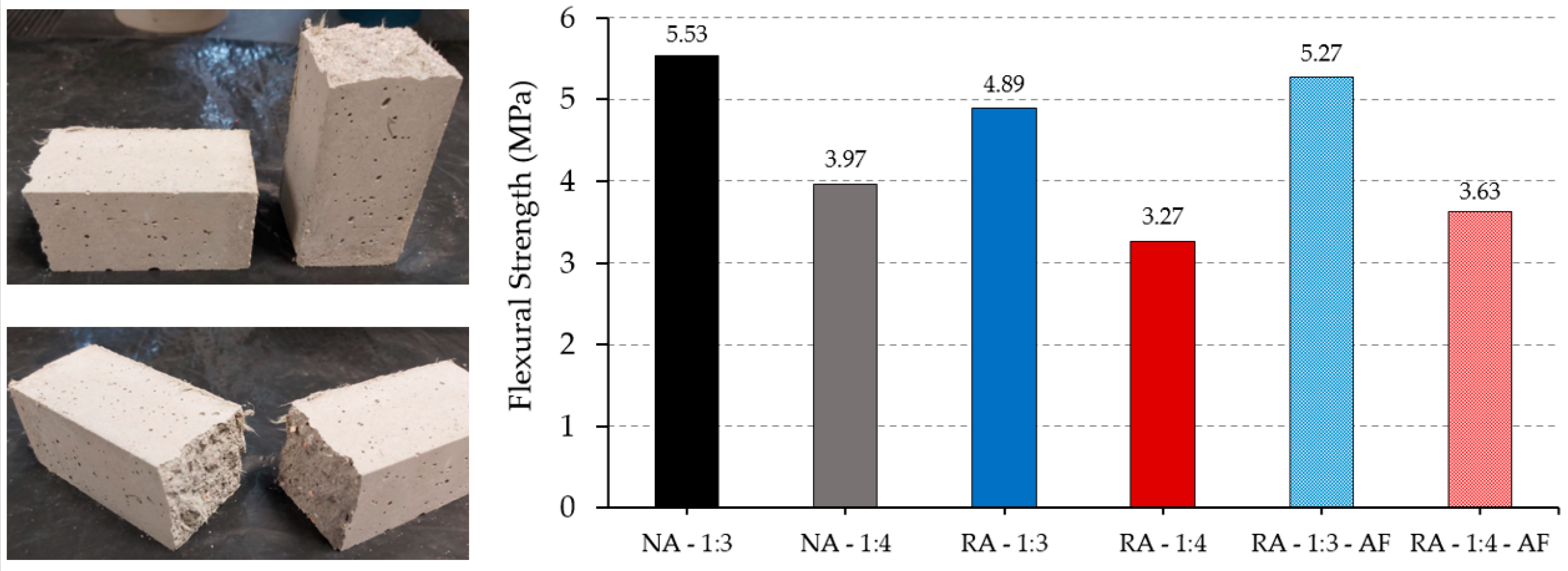

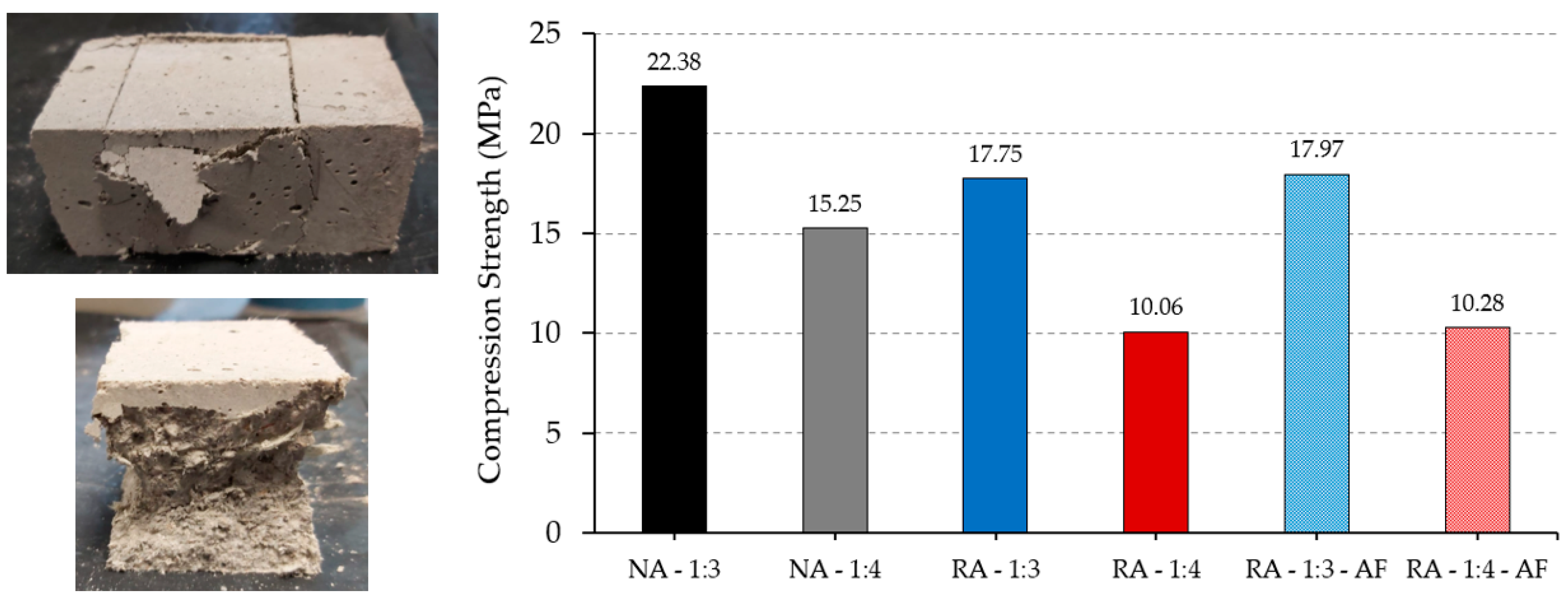

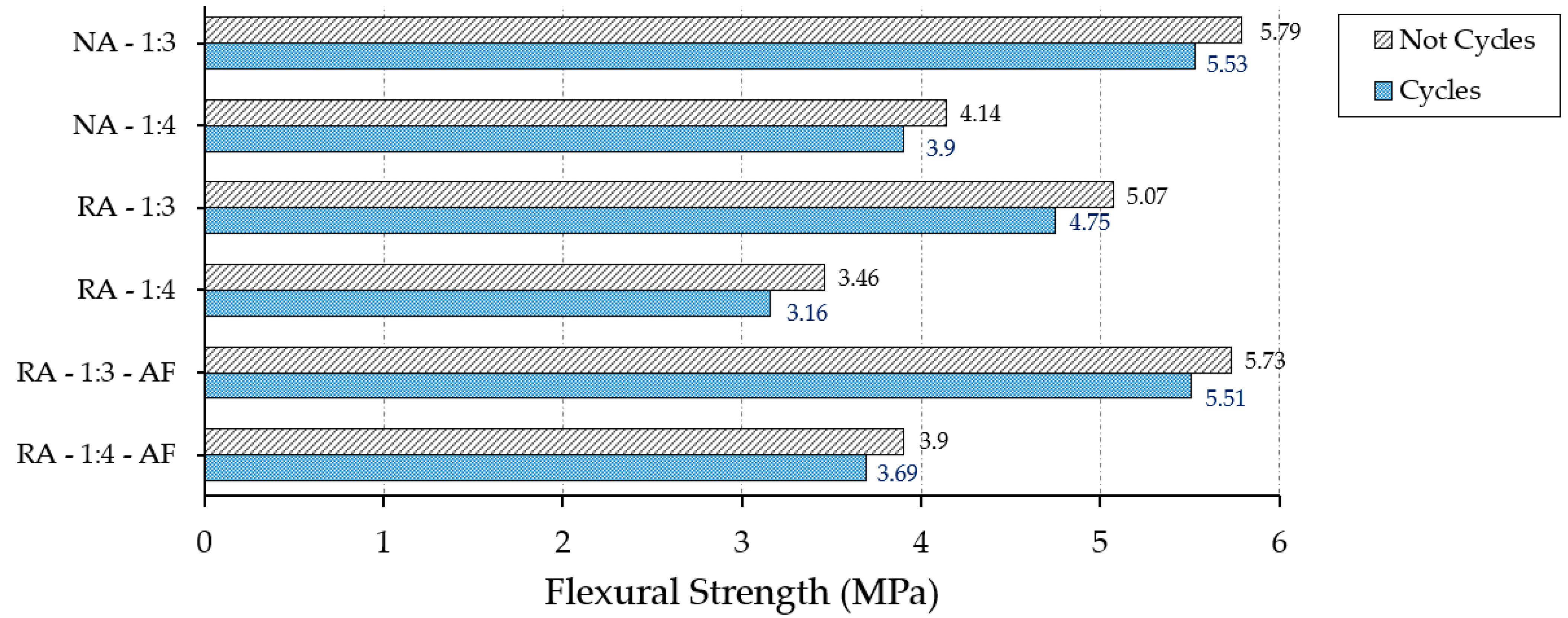

3.1. Mechanical Characterization Tests

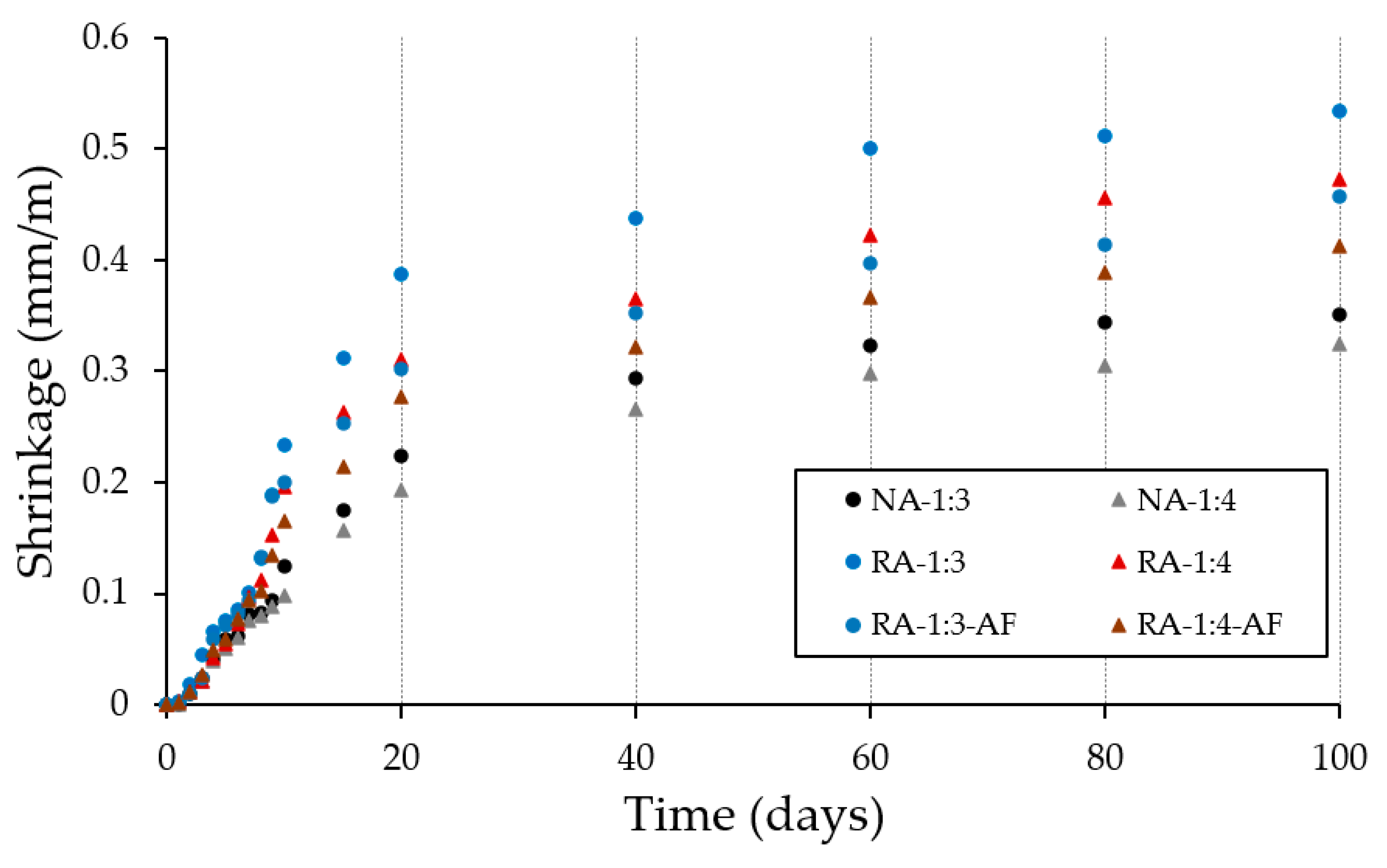

3.2. Complementary Physical Characterization Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Rodríguez, G.; Medina, C.; Alegre, F.J.; Asensio, E.; Sánchez de Rojas, M.I. Assessment of Construction and Demolition Waste plant management in Spain: In pursuit of sustainability and eco-efficiency. J. Clean. Prod. 2015, 90, 16–24. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística. Estadística Sobre Generación De Residuos En El Sector Servicios Y Construcción; Madrid, Spain, 2017; Available online: https://www.ine.es/jaxi/Table.htm?path=/t26/e068/p03/a2017/l0/&file=01001.px&L=0 (accessed on 16 July 2021).

- Kabirifar, K.; Mojtahedi, M.; Changxin, C.; Tam, V.W.Y. A conceptual foundation for effective construction and demolition waste management. Clean. Eng. Technol. 2020, 1, 10019. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Ma, Z. Properties of the foam concrete containing waste brick powder derived from construction and demolition waste. J. Build. Eng. 2020, 23, 101509. [Google Scholar] [CrossRef]

- Prasad, D.; Pandey, A.; Kumar, B. Sustainable production of recycled concrete aggregates by lime treatment and mechanical abrasion for M40 grade concrete. Constr. Build. Mater. 2021, 268, 121119. [Google Scholar] [CrossRef]

- Waskow, R.; Gonçalves, V.; Tubino, R.; Passuello, A. Environmental performance of construction and demolition waste management strategies for valorization of recycled coarse aggregate. J. Environ. Manag. 2021, 295, 113094. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Morón, C.; Zúñiga-Vicente, J.A. Analysis of the disadvantages associated with the process of reuse of recycled aggregates from construction and demolition waste. In VI International Conference on Technological Innovation in Building; Universidad Politécnica de Madrid: Madrid, Spain, 2021. [Google Scholar]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Hamed, H.; Tiznobaik, M.; Huda, S.B.; Islam, M.S.; Shahria, M. Recycled aggregate concrete from large-scale production to sustainable field application. Constr. Build. Mater. 2020, 262, 119979. [Google Scholar] [CrossRef]

- Kumar Attri, G.; Gupta, R.C.; Shrivastava, S. Impact of recycled concrete aggregate on mechanical and durability properties of concrete paver blocks. Mater. Today Proc. 2021, 42, 975–981. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F. Effects of recycled fine aggregate and steel fiber on compressive and splitting tensile properties of concrete. J. Build. Eng. 2021, in press. [Google Scholar] [CrossRef]

- Tam, V.W.; Wattage, H.; Le, K.N.; Buteraa, A.; Soomro, M. Methods to improve microstructural properties of recycled concrete aggregate: A critical review. Constr. Build. Mater. 2021, 270, 121490. [Google Scholar] [CrossRef]

- Saiz, P.; González, M.; Fernández, F.; Rodríguez, A. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef] [Green Version]

- Sánchez de Juan, M. Estudio Sobre La Utilización De Árido Reciclado Para La Fabricación De Hormigón Estructural. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2004. [Google Scholar]

- Morón, C.; Ferrández, D.; Saiz, P.; Yedra, E. Measuring system of capillary rising damp in cement mortars. Measurement 2019, 135, 252–259. [Google Scholar] [CrossRef]

- Morón, C.; Saiz, P.; Ferrández, D.; García-Fuentevilla, L. New System of Shrinkage Measurement through Cement Mortars Drying. Sensors 2017, 17, 522. [Google Scholar] [CrossRef] [Green Version]

- Pacheco, J.N.; de Brito, J.; Chastre, C.; Evangelista, L. Probabilistic Conversion of the Compressive Strength of Cubes to Cylinders of Natural and Recycled Aggregate Concrete Specimens. Materials 2019, 12, 280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raini, I.; Jabrane, R.; Mesrar, L.; Akdim, M. Evaluation of mortar properties by combining concrete and brick wastes as fine aggregate. Case Stud. Constr. Mater. 2020, 113. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Morón, C.; Diaz, J.P. Research of recycled mortars behaviour towards impact noise. Inf. Construcción 2019, 71, e292. [Google Scholar] [CrossRef]

- Sáiz Martínez, P. Utilización De Arenas Procedentes De Residuos De Construcción Y Demolición, Rcd, En La Fabricación De Morteros De Albañilería. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2015. [Google Scholar]

- Betolesi, E.; Torres, B.; Adam, J.M.; Calderón, P.A.; Moragues, J.J. Effectiveness of Textile Reinforced Mortar (TRM) materials for the repair of full-scale timbrel masonry cross vaults. Eng. Struct. 2020, 248, 118532. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Morón, C.; Atanes-Sánchez, E. Comparative analysis of fibre-reinforced plasters for the production of precast elements. DYNA 2020, 95, 333–3336. [Google Scholar] [CrossRef]

- Jao, D.; Shi, C.; Yuan, Q.; Zhu, D.; Schuteer, D. Effects of rotational shearing on rheological behavior of fresh mortar with short glass fiber. Constr. Build. Mater. 2019, 203, 314–321. [Google Scholar] [CrossRef]

- Santarelli, M.L.; Sbardella, F.; Zuena, M.; Tirillo, J.; Sarasini, F. Basalt fiber reinforced natural hydraulic lime mortars: A potential bio-based material for restoration. Mater. Des. 2014, 64, 398–406. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Hirano, Y.; Nakajima, A.; Fujikura, S.; Niimura, R. Experimental evaluation of the shear capacity of perfobond strips with steel fiber-reinforced mortar in narrow joint structures. Structures 2020, 28, 1173–1186. [Google Scholar] [CrossRef]

- Donnini, J.; Bellezze, T.; Corinaldesi, V. Mechanical, electrical and self-sensing properties of cementitious mortars containing short carbon fibers. J. Build. Eng. 2018, 20, 8–14. [Google Scholar] [CrossRef]

- Rajaei, S.; Shoaei, P.; Shariati, M.; Ameri, F.; Reza, H.; Behforouz, B.; de Brito, J. Rubberized alkali-activated slag mortar reinforced with polypropylene fibres for application in lightweight thermal insulating materials. Constr. Build. Mater. 2021, 270, 121430. [Google Scholar] [CrossRef]

- Chen, W.; Xie, Y.; Li, B.; Li, B.; Wang, J.; Thom, N. Role of aggregate and fibre in strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2021, 133, 124002. [Google Scholar] [CrossRef]

- Candamano, S.; Crea, F.; Coppola, L.; de Luca, P.; Coffetti, D. Influence of acrylic latex and pre-treated hemp fibers on cement-based mortar properties. Constr. Build. Mater. 2021, 273, 121720. [Google Scholar] [CrossRef]

- Quiñones-Bolaños, E.; Gómez, M.; Mouthon-Bello, J.; Sierra-Vitola, L.; Berardi, U.; Bustillo-Lecompte, C. Potential use of coconut fibre modified mortars to enhance thermal comfort in low-income housing. J. Environ. Manag. 2021, 277, 111503. [Google Scholar] [CrossRef] [PubMed]

- Ince, C.; Tayançlı, S.; Derogar, S. Recycling waste wood in cement mortars towards the regeneration of sustainable environment. Constr. Build. Mater. 2021, 299, 123891. [Google Scholar] [CrossRef]

- Govind-Chandrasekaran, R.; Ramakrishna, G. Experimental investigation on mechanical properties of economical local natural fibre reinforced cement mortar. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Yang, H.; Song, H.; Zhang, S. Experimental investigation of the behavior of aramid fiber reinforced polymer confined concrete subjected to high strain-rate compression. Constr. Build. Mater. 2015, 95, 143–151. [Google Scholar] [CrossRef]

- Dhanesh, S.; Senthil Kumar, K.; Maruthut, P.; Rejumon, R.; Usmansha, G.S. Experimental investigation of strength of Aramid kelvar and chopped carbon reinforced concrete beam. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Ismail, N.; de Rooij, M.B.; de Vries, E.G.; Mohd Zini, N.H.; Schipper, D.J. Friction between single aramid fibres under pre-tension load. Tribol. Int. 2019, 137, 236–245. [Google Scholar] [CrossRef]

- Jie Dong, F.G.; Tang, M.; Li, X.; Li, M.; Zhao, X.; Zhang, Q. High-tenacity and high-modulus polyimide fibers containing benzimidazole and pyrimidine units. React. Funct. Polym. 2019, 141, 112–122. [Google Scholar] [CrossRef]

- Caggegi, C.; Carozzi, F.G.; De Santis, S.; Fabbrocino, F.; Focacci, F.; Hojdys, L.; Lanoye, E.; Zuccarino, L. Experimental analysis on tensile and bond properties of PBO and aramid fabric reinforced cementitious matrix for strengthening masonry structures. Compos. Part B 2017, 127, 175–195. [Google Scholar] [CrossRef]

- Nie, L.; Xu, J.; Luo, X.; Chen, H.; Chang, S.; Wang, T.; Liu, G. Study of aramid and carbon fibers on the tensile properties of early strength cement mortar. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 032009. [Google Scholar] [CrossRef]

- Slebi-Acebedo, J.C.; Lastra-González, P.; Castro-Fresno, D.; Bueno, M. An experimental laboratory study of fiber-reinforced asphalt mortars with polyolefin-aramid and polyacrylonitrile fibers. Constr. Build. Mater. 2020, 248, 118622. [Google Scholar] [CrossRef]

- Ministerio de la Presidencia. Instrucción Para La Recepción De Cementos (rc-08); Boletín Oficial del Estado (BOE): Madrid, Spain, 2016; p. 153. [Google Scholar]

- García-Meseguer, A.; Morán-Cabré, F.; Arroyo-Portero, J.C. Hormigón Armado, Jiménez Montoya, 15th ed.; Editorial GG: Barcelona, Spain, 2011; ISBN 978-84-252-2307-5. [Google Scholar]

- Saiz, P.; Ferrández, D.; Morón, C.; Fernández, F. Behaviour of masonry mortars fabricated with recycled aggregate towards moisture. DYNA 2018, 94, 442–446. [Google Scholar] [CrossRef]

- Ramachandran, V.S.; Paroli, R.M.; Beaudoin, J.J.; Delgado, A.H. Formation and Hydration of Cement and Cement Compounds. In Handbook Therm; Anal. Constr. Mater.; William Andrew Publishing: New York, NY, USA, 2002. [Google Scholar]

- Piña, C.; Atanes Sánchez, E.; del Río, M.; Viñas, C.; Vidales, A. Feasibility of the use of mineral wool fibres recovered from CDW for the reinforcement of conglomerates by study of their porosity. Constr. Build. Mater. 2018, 191, 460–468. [Google Scholar] [CrossRef] [Green Version]

- UNE-EN 13139: 2003. Aggregates for Mortar; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 933-1: 2012. Tests for Geometrical Properties of Aggregates–Part 1: Determination of Particle Size Distribution–Sieving Method; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 146404: 2018. Aggregates for Concrete. Determination of the Coefficient of Friability of the Sands; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 1097-3: 1999. Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 1097-6: 2014. Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- Hassan, R.Y.; Ali Faroun, G.; Mohamed, S.K. Mechanical properties of concrete made with coarse and fine recycled aggregates. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Kim, J. Properties of recycled aggregate concrete designed with equivalent mortar volume mix design. Constr. Build. Mater. 2021, 301, 124091. [Google Scholar] [CrossRef]

- Eckert, M.; Oliveira, M. Mitigation of the negative effects of recycled aggregate water absorption in concrete technology. Constr. Build. Mater. 2017, 133, 416–424. [Google Scholar] [CrossRef]

- Rangel, C.S.; Toledo-Filho, R.D.; Amario, M.; Pepe, M.; Polisseni, G.C.; Puente de Andrade, G. Generalized quality control parameter for heterogenous recycled concrete aggregates: A pilot scale case study. J. Clean. Prod. 2019, 208, 589–601. [Google Scholar] [CrossRef]

- UNE-EN 933-2/1M:1999. Test for Geometrical Properties of Aggregates. Part 2: Determination of Particle Size Distribution. Test Sieves, Nominal Size of Apertures; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- NBE FL-90. Norma Básica De Edificación. Muros Resistentes De Fábrica De Ladrillo; BOE–Agencia Estatal Boletín Oficial del Estado: Madrid, Spain, 1991. [Google Scholar]

- Koushkbaghi, M.; Kazemi, M.J.; Mosavi, H.; Mohseni, E. Acid resistance and durability properties of steel fiber-reinforced concrete incorporating rice husk ash and recycled aggregate. Constr. Build. Mater. 2019, 202, 266–275. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Nigland, T.G.; Valke, S.; Schlangen, E. Physical, chemical and mineralogical characterization of Dutch fine recycled concrete aggregates: A comparative study. Constr. Build. Mater. 2020, 270, 121475. [Google Scholar] [CrossRef]

- Ulsen, C.; Kahn, H.; Hawlitscschek, G.; Masini, E.A.; Angulo, S.C.; John, V.M. Production of recycled sand from construction and demolition waste. Constr. Build. Mater. 2013, 40, 1168–1173. [Google Scholar] [CrossRef]

- Li, L.G.; Zhao, Z.W.; Zhu, J.; Kwan, A.K.H.; Zeng, K.L. Combined effects of water film thickness and polypropylene fibre length on fresh properties of mortar. Constr. Build. Mater. 2018, 174, 586–593. [Google Scholar] [CrossRef]

- ElNemr, A. Generating water/binder ratio -to- strength curves for cement mortar used in Masnory walls. Constr. Build. Mater. 2019, 233, 117249. [Google Scholar] [CrossRef]

- de Isabel, C., II. Informe Anual Sobre La Calidad Del Agua En Madrid; Canal de Isabel II: Madrid, Spain, 2012. [Google Scholar]

- Morón, A.; Ferrández, D.; Saiz, P.; Vega, G.; Morón, C. Influence of Recycled Aggregates on the Mechanical Properties of Synthetic Fibers-Reinforced Masonry Mortars. Infrastructures 2021, 6, 84. [Google Scholar] [CrossRef]

- Xu, C.; Li, H.; Dong, B.; Yang, X. Chlorine immobilization and performances of cement paste/mortar with C-S-Hs-PCE and calcium chloride. Constr. Build. Mater. 2020, 262. [Google Scholar] [CrossRef]

- Piña-Ramírez, C. Comportamiento Físico-Mecánico y Térmico de los Morteros de Cemento Aditivados con Fibras Minerales Procedentes de Residuos de Construcción y Demolición. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2018. [Google Scholar] [CrossRef]

- Bustos-García, A. Morteros con Propiedades Mejoradas de Ductilidad por Adición de Fibras de Vidrio, Carbono y Basalto. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2018. [Google Scholar] [CrossRef]

- UNE-EN 196-1:2018. Methods of Testing Cement—Part 1: Determination of Strength; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 1015-2:1999/A1:2007. Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- Máster Builders Solutions España, S.L.U. MasterGlenium SKY 604: Aditivo Superplastificante/Reductor De Agua De Alta Actividad Para Hormigón Preparado; Master Builders Solutions España, S.L.U.: Barcelona, Spain, 2021. [Google Scholar]

- UNE-EN 1015-11:2000/A1:2007. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 1015-12:2016. Methods of Test for Mortar for Masonry—Part 12: Determination of Adhesive Strength of Hardened Rendering and Plastering Mortars on Substrates; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 1015-18:2003. Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE 80-112-89. Test Methods. Cement. Determination of Shrinkage and Swelling in Water; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 12371:2011. Natural Stone Test Methods—Determination of Frost Resistance; Aenor International: Madrid, Spain, 1999. [Google Scholar]

- Peña, D. Regresión Y Diseño De Experimentos; Alianza Editorial: Madrid, Spain, 2010; ISBN 9788420693897. [Google Scholar]

- Shang, J.; Dai, J.G.; Zhao, T.J.; Guo, S.Y.; Zhang, P.; Mu, B. Alternation of traditional cement mortars using fly ash-based geopolymer mortars modified by slag. J. Clean. Prod. 2018, 203, 746–756. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, M.; Wang, L.; Ma, G. Experimental study on mechanical property and microstructure of cement mortar reinforced with elaborately recycled GFRP fiber. Cem. Concr. Compos. 2021, 117. [Google Scholar] [CrossRef]

- Bustos García, A. Estado del conocimiento de los morteros de cemento reforzados con fibras de acero, vidrio, polipropileno, basalto y acrílicas. In Congreso Internacional de Innovación Tecnológica en Edificación (CITE 2016); Escuela Técnica Superior de Edificación: Madrid, Spain, 2016; pp. 140–141. ISBN 978-84-16397-28-0. [Google Scholar]

- Angelin, A.F.; Cecche Lintz, R.C.; Gachet-Barbosa, L.A.; Osório, W.I. The effects of porosity on mechanical behavior and water absorption of an environmentally friendly cement mortar with recycled rubber. Constr. Build. Mater. 2017, 151, 534–545. [Google Scholar] [CrossRef]

- Chen, J.K.; Jiang, M.Q. Long-term evolution of delayed ettringite and gypsum in Portland cement mortars under sulfate erosion. Constr. Build. Mater. 2009, 23, 801–816. [Google Scholar] [CrossRef] [Green Version]

- Morón-Barrios, A.; Ferrández, D.; Saiz, P.; Atanes-Sánchez, E.; Morón, C. Study of the properties of lime and cement mortars made from recycled ceramic aggregate and reinforced with fibers. J. Build. Eng. 2021, 35. [Google Scholar] [CrossRef]

- Piña, C.; Vidales, A.; Serrano, R.; del Rio, M.; Atanes-Sánchez, E. Analysis of fire resistance of cement mortars with mineral wool from recycling. Constr. Build. Mater. 2020, 265. [Google Scholar] [CrossRef]

- Piña, C.; del Rio, M.; Viñas, C.; Vidales, A.; Kosior-Kazberuk, M. Analysis of the mechanical behaviour of the cement mortars with additives of mineral wool fibres from recycling of CDW. Constr. Build. Mater. 2020, 210, 56–62. [Google Scholar] [CrossRef]

- Saiz, P.; González-Cortina, M.; Fernández, F. Characterization and influence of fine recycled aggregates on masonry mortars properties. Mater. Construcción 2015, 65. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Zhu, X.; Xiong, G.; Wang, C.; Liu, D.; Liang, Z. Recycling of crushed waste clay brick as aggregates in cement mortars: An approach from macro- and micro-scale investigation. Constr. Build. Mater. 2021, 274. [Google Scholar] [CrossRef]

- Gheni, A.A.; Alghazali, H.H.; ElGawadi, M.A.; Myres, J.J.; Feys, D. Durability properties of cleaner cement mortar with by-products of tire recycling. J. Clean. Prod. 2019, 213, 1135–1146. [Google Scholar] [CrossRef]

- Saiz, P.; Ferrández, D.; Morón, C.; Payán, A. Comparative study of the influence of three types of fibre in the shrinkage of recycled mortar. Mater. Construcción 2018, 68. [Google Scholar] [CrossRef]

- Tong, Y.; Zhao, S.; Ma, J.; Wang, L.; Zhang, Y.; Gao, Y.; Min-Xie, Y. Improving cracking and drying shrinkage properties of cement mortar by adding chemically treated luffa fibres. Constr. Build. Mater. 2014, 71, 327–333. [Google Scholar] [CrossRef]

| CaO | SiO2 | SO3 | Al2O3 | Fe2O3 | K2O | TiO2 | MgO | SrO | BaO | MnO | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 69.80 | 17.05 | 4.21 | 4.10 | 3.45 | 0.66 | 0.24 | 0.23 | 0.08 | 0.07 | 0.07 | 0.04 |

| Test | Fine Content (%) | Particle Form | Fineness Modulus (%) | Friability (%) | Bulk. Dens, (Kg/m3) | Dry Dens. (Kg/m3) | Water Absorption (%) |

|---|---|---|---|---|---|---|---|

| Norma | UNE EN 933-1 [47] | UNE-EN 13139 [46] | UNE-EN 13139 [46] | UNE-EN 146404 [48] | UNE-EN 1097-3 [49] | UNE-EN 1097-6 [50] | UNE-EN 1097-6 [50] |

| NA | 1.97 | - | 4.35 | 21.12 | 1581 | 2509 | 0.91 |

| RA-Con | 3.73 | Not relevant | 4.08 | 23.17 | 1328 | 2246 | 7.06 |

| Sample | Al2O3 | CaO | Fe2O3 | K2O | MgO | SiO2 | MnO | TiO2 | SO3 | P2O5 | NaO2 | I. Loss (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-Con | 6.12 | 12.05 | 1.81 | 2.11 | 0.53 | 66.2 | 0.02 | 0.16 | - | 0.04 | 0.32 | 10.64 |

| Color | Length (mm) | Density (kg/m3) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation (%) | Decomposition Temperature (°C) | Acid/Alkali Resistance |

|---|---|---|---|---|---|---|---|

| Yellow | 20 | 1440 | 3100 | 75 | 3.5 | 157 | Inert |

| Type | Cement (g) | Aggregate (g) | Water (g) | Fiber (g) | Additive (g) | Consistency (UNE-EN 1015-2: 2007 [68]) |

|---|---|---|---|---|---|---|

| NA–1:3 | 450.0 | 1350 | 243 | - | - | 176 |

| NA–1:4 | 337.5 | 1350 | 196 | - | - | 174 |

| RA–1:3 | 450.0 | 1350 | 311 | - | 4.5 | 171 |

| RA–1:4 | 337.5 | 1350 | 250 | - | 3.4 | 169 |

| RA–1:3–AF | 450.0 | 1350 | 311 | 2.5 | 4.5 | 172 |

| RA–1:4–AF | 337.5 | 1350 | 250 | 2.5 | 3.4 | 168 |

| Factors | Levels | Nomenclature |

|---|---|---|

| Dosage | 1:3/1:4 | A/B |

| Fiber type | No Fiber/Aggregate Fiber | NF/AF |

| Property | Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|---|

| Flexural Strength (MPa) | A: Dosage | 7.954410 | 1 | 7.954410 | 539.28 | 0.0000 |

| B: Fiber type | 0.414408 | 1 | 0.414408 | 28.10 | 0.0007 | |

| AB: Interactions | 0.000075 | 1 | 0.000075 | 0.01 | 0.9449 | |

| Residual | 0.118000 | 8 | 0.014750 | |||

| Total (Corrected) | 8.486890 | 11 | ||||

| Compression Strength (MPa) | A: Dosage | 193.218000 | 1 | 193.218000 | 1212.41 | 0.0000 |

| B: Fiber type | 0.911905 | 1 | 0.911905 | 5.72 | 0.0507 | |

| AB: Interactions | 0.337345 | 1 | 0.337345 | 2.12 | 0.1838 | |

| Residual | 1.274940 | 8 | 0.159367 | |||

| Total (Corrected) | 195.742000 | 11 |

| Property | Dosage | Count | LS Mean | LS Sigma | Homogeneous Group |

|---|---|---|---|---|---|

| Flexural Strength | B | 6 | 3.45000 | 0.0495816 | X |

| A | 6 | 5.07833 | 0.0495816 | X | |

| Compression Strength | B | 6 | 10.17130 | 0.1629760 | X |

| A | 6 | 18.19670 | 0.1629760 | X |

| Property | Fiber | Count | LS Mean | LS Sigma | Homogeneous Group |

|---|---|---|---|---|---|

| Flexural Strength | NF | 6 | 4.08733 | 0.0495816 | X |

| AF | 6 | 4.45000 | 0.0495816 | X | |

| Compression Strength | NF | 6 | 13.9050 | 0.1629760 | X |

| AF | 6 | 14.1250 | 0.1629760 | X |

| Type | Hardness (Ud. Shore D) | Bulk Density (kg/m3) | Adherence (MPa) | Absorption (kg/mm2min0.5) |

|---|---|---|---|---|

| NA–1:3 | 81.7 | 2093 | 0.52 | 0.53 |

| NA–1:4 | 77.0 | 1993 | 0.57 | 0.58 |

| RA–1:3 | 72.7 | 1831 | 0.42 | 0.67 |

| RA–1:4 | 70.7 | 1754 | 0.38 | 0.76 |

| RA–1:3–FA | 71.7 | 1855 | 0.36 | 0.61 |

| RA–1:4–FA | 71.0 | 1776 | 0.32 | 0.72 |

| Property | Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|---|

| Hardness (Ud. Shore D) | A: Dosage | 21.33333 | 1 | 21.33333 | 5.82 | 0.0424 |

| B: Fiber type | 0.33333 | 1 | 0.33333 | 0.10 | 0.7655 | |

| AB: Interactions | 1.33333 | 1 | 1.33333 | 0.38 | 0.5543 | |

| Residual | 28.0000 | 8 | 3.50000 | |||

| Total (Corrected) | 35.0000 | 11 | ||||

| Bulk Density (kg/m3) | A: Dosage | 18,174.10 | 1 | 18,174.100 | 48.47 | 0.0001 |

| B: Fiber type | 1564.08 | 1 | 1564.080 | 4.17 | 0.0754 | |

| AB: Interactions | 6.75 | 1 | 6.750 | 0.02 | 0.8966 | |

| Residual | 2999.33 | 8 | 374.917 | |||

| Total (Corrected) | 22,744.30 | 11 | ||||

| Adherence (MPa) | A: Dosage | 0.00480 | 1 | 0.00480 | 36.00 | 0.0003 |

| B: Fiber type | 0.01080 | 1 | 0.01080 | 81.00 | 0.0000 | |

| AB: Interactions | 0.00013 | 1 | 0.00013 | 1.00 | 0.3466 | |

| Residual | 0.00107 | 8 | 0.00013 | |||

| Total (Corrected) | 0.01680 | 11 | ||||

| Absorption (kg/mm2min0.5) | A: Dosage | 0.02901 | 1 | 0.02901 | 145.04 | 0.0000 |

| B: Fiber type | 0.00701 | 1 | 0.00701 | 35.04 | 0.0004 | |

| AB: Interactions | 0.00007 | 1 | 0.00007 | 0.37 | 0.5573 | |

| Residual | 0.00160 | 8 | 0.00020 | |||

| Total (Corrected) | 0.03769 | 11 |

| Property | Dosage | Count | LS Mean | LS Sigma | Homogeneous Group |

|---|---|---|---|---|---|

| Hardness (Ud. Shore D) | B | 6 | 74.00 | 0.781736 | X |

| A | 6 | 76.66 | 0.781736 | X | |

| Bulk Density (kg/m3) | B | 6 | 1765.33 | 7.904820 | X |

| A | 6 | 1843.17 | 7.904820 | X | |

| Adherence (MPa) | B | 6 | 0.35 | 0.004714 | X |

| A | 6 | 0.39 | 0.004714 | X | |

| Absorption (kg/mm2min0.5) | A | 6 | 0.640 | 0.005774 | X |

| B | 6 | 0.738 | 0.005774 | X |

| Property | Fiber | Count | LS Mean | LS Sigma | Homogeneous Group |

|---|---|---|---|---|---|

| Hardness (Ud. Shore D) | NF | 6 | 71.70 | 0.781736 | X |

| AF | 6 | 71.35 | 0.781736 | X | |

| Bulk Density (kg/m3) | NF | 6 | 1792.83 | 7.90482 | X |

| AF | 6 | 1815.67 | 7.90482 | X | |

| Adherence (MPa) | AF | 6 | 0.34 | 0.004714 | X |

| NF | 6 | 0.40 | 0.004714 | X | |

| Absorption (kg/mm2min0.5) | NF | 6 | 0.665 | 0.005774 | X |

| AF | 6 | 0.713 | 0.005774 | X |

| Property | NA–1:3 | NA–1:4 | RA–1:3 | RA–1:4 | RA–1:3–FA | RA–1:4–FA |

|---|---|---|---|---|---|---|

| ∇ Mass (g) | 9.73 | 11.73 | 15.43 | 19.03 | 11.30 | 16.03 |

| ∇ Flexural Strength (%) | 4.49 | 5.80 | 6.31 | 8.67 | 3.84 | 5.38 |

| Property | Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|---|

| Shrinkage (mm/m) | A: Dosage | 0.0083003 | 1 | 0.0083003 | 78.49 | 0.0000 |

| B: Fiber type | 0.0137499 | 1 | 0.0137499 | 130.02 | 0.0000 | |

| AB: Interactions | 0.0002219 | 1 | 0.0002219 | 2.10 | 0.1855 | |

| Residual | 0.0008460 | 8 | 0.0001058 | |||

| Total (Corrected) | 0.0231180 | 11 | ||||

| Freeze/Thaw Resistance: Flexural Strength (MPa) | A: Dosage | 0.0001333 | 1 | 0.0001333 | 0.03 | 0.8734 |

| B: Fiber type | 0.0280333 | 1 | 0.0280333 | 5.69 | 0.0441 | |

| AB: Interactions | 0.0000333 | 1 | 0.0000333 | 0.01 | 0.9365 | |

| Residual | 0.0394000 | 8 | 0.0049250 | |||

| Total (Corrected) | 0.0676000 | 11 |

| Property | Dosage | Count | LS Mean | LS Sigma | Homogeneous Group |

|---|---|---|---|---|---|

| Shrinkage (mm/m) | B | 6 | 0.44265 | 0.00419821 | X |

| A | 6 | 0.49525 | 0.00419821 | X | |

| Freeze/Thaw Resistance: Flexural Strength (MPa) | B | 6 | 0.25667 | 0.02865020 | X |

| A | 6 | 0.26333 | 0.02865020 | X |

| Property | Fiber | Count | LS Mean | LS Sigma | Homogeneous Group |

|---|---|---|---|---|---|

| Shrinkage (mm/m) | AF | 6 | 0.43510 | 0.00419821 | X |

| NF | 6 | 0.05028 | 0.00419821 | X | |

| Freeze/Thaw Resistance: Flexural Strength (MPa) | AF | 6 | 0.21167 | 0.02865020 | X |

| NF | 6 | 0.30833 | 0.02865020 | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morón, A.; Ferrández, D.; Saiz, P.; Morón, C. Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers. Appl. Sci. 2021, 11, 7791. https://doi.org/10.3390/app11177791

Morón A, Ferrández D, Saiz P, Morón C. Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers. Applied Sciences. 2021; 11(17):7791. https://doi.org/10.3390/app11177791

Chicago/Turabian StyleMorón, Alberto, Daniel Ferrández, Pablo Saiz, and Carlos Morón. 2021. "Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers" Applied Sciences 11, no. 17: 7791. https://doi.org/10.3390/app11177791

APA StyleMorón, A., Ferrández, D., Saiz, P., & Morón, C. (2021). Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers. Applied Sciences, 11(17), 7791. https://doi.org/10.3390/app11177791