Study of Rail Squat Characteristics through Analysis of Train Axle Box Acceleration Frequency

Abstract

1. Introduction

2. Description of System

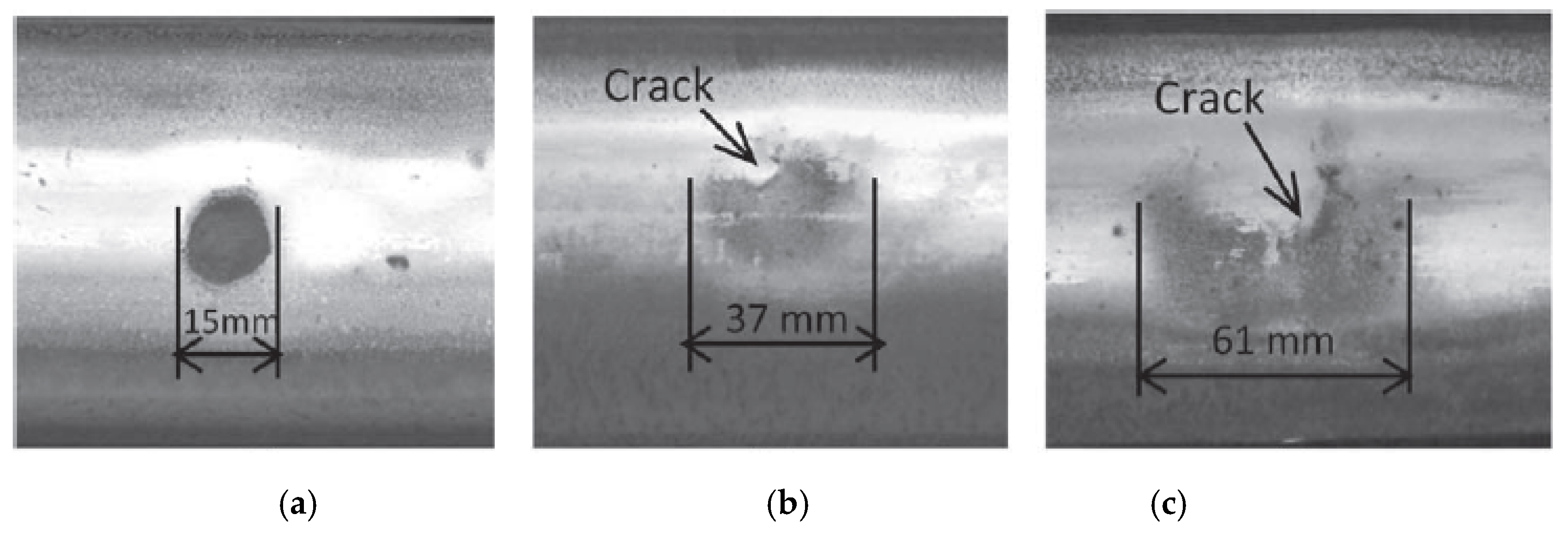

Squats

Realization of Measurement System and Data Verification

3. Wavelet Analysis

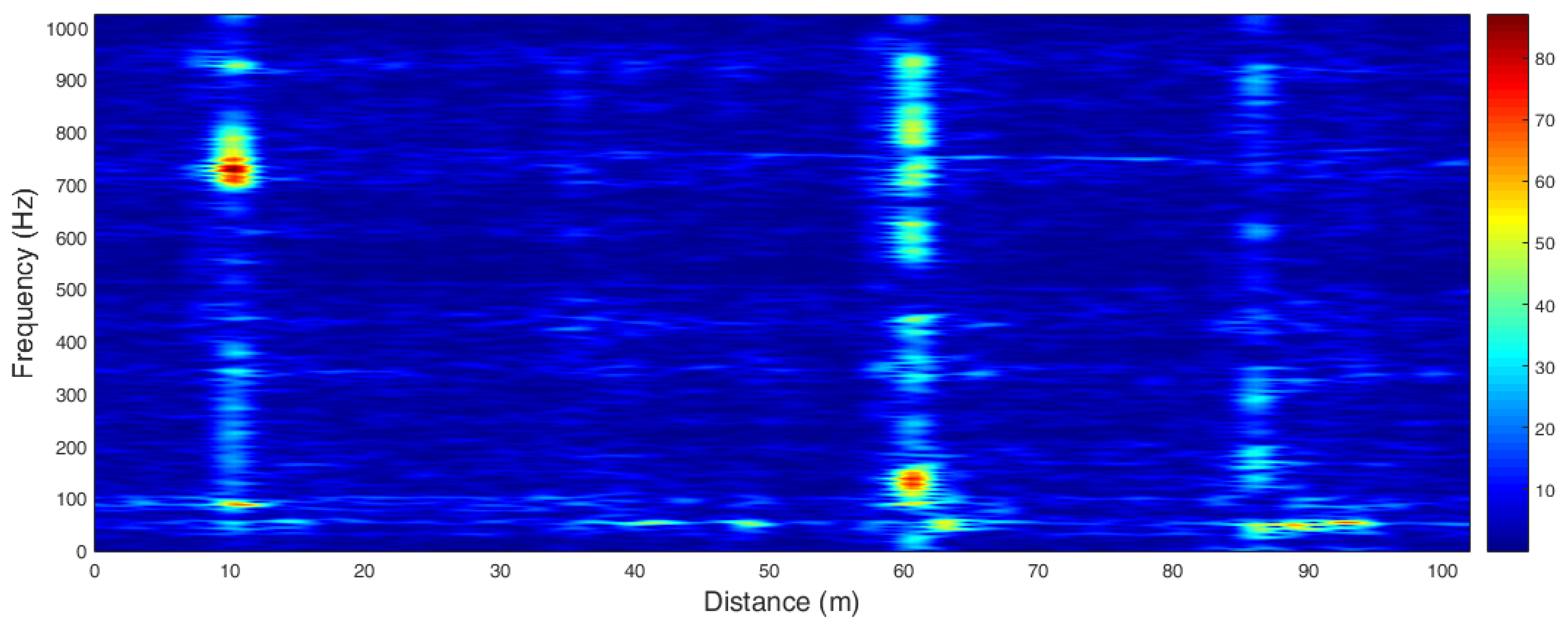

3.1. Frequency Analysis Using Wavelet Analysis

3.2. Noise Filtering

- (1)

- Axis acceleration filtering: The data were filtered using the signal processing toolbox of the MATLAB software program. A low-pass filter with a cutoff frequency of 2000 Hz was applied to separate the response data of the squats.

- (2)

- Filtering of noise due to wheel damage: Additional signal processing was performed when the wheel conditions were not good. Wheel damage is detected more easily than squats, because it causes a cyclic impact between the wheel and the rail at a wavelength corresponding to the wheel circumference. The signal is repeatedly detected by the accelerometer nearest to the damaged wheel. The problem of repeated acceleration signals was addressed by removing the repeating pattern.

4. Verification of Squat Detection

4.1. Data Acquisition

4.2. Frequency Characteristics of Squats

4.3. Detection of Squat Defects

5. Results

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Li, Z.; Dollevoet, R.; Molodova, M.; Zhao, X. Squat growth-Some observations and the validation of numerical predictions. Wear 2011, 271, 148–157. [Google Scholar] [CrossRef]

- UIC Code. Rail Defects, 4th ed.; International Union of Railways: Paris, France, 2002. [Google Scholar]

- Smulders, J. Management and research tackle rolling contact fatigue. Railw. Gaz. Int. 2003, 158, 439–442. [Google Scholar]

- Clayton, P.; Allery, M. Metallurgical aspects of surface damage problems in rails. Can. Metall. Q. 1982, 21, 31–46. [Google Scholar] [CrossRef]

- Rail Damages. The Blue Book of RailTrack; London, UK, 2001. [Google Scholar]

- Zoeteman, A. Life cycle cost analysis for managing rail infrastructure: Concept of a decision support system for railway design and maintenance. Eur. J. Transport Infrastruct. Res. 2001, 1, 391–413. [Google Scholar]

- Magel, E.; Tajaddini, A.; Trosino, M.; Kalousek, J. Traction, forces, wheel climb, and damage in high-speed railway operations. Wear 2008, 265, 1446–1451. [Google Scholar] [CrossRef][Green Version]

- Gullers, P.; Andersson, L.; Lundén, R. High-frequency vertical wheel–rail contact forces—Field measurements and influence of track irregularities. Wear 2008, 265, 1472–1478. [Google Scholar] [CrossRef]

- Nielsen, J.C. High-frequency vertical wheel–rail contact forces-Validation of a prediction model by field testing. Wear 2008, 265, 1465–1471. [Google Scholar] [CrossRef]

- Delprete, C.; Rosso, C. An easy instrument and a methodology for the monitoring and the diagnosis of a rail. Mech. Syst. Signal Process. 2009, 23, 940–956. [Google Scholar] [CrossRef]

- Peng, D.; Jones, R. Modelling of the lock-in thermography process through finite element method for estimating the rail squat defects. Eng. Failure Anal. 2013, 28, 275–288. [Google Scholar] [CrossRef]

- Thomas, H.; Heckel, T.; Hanspach, G. Advantage of a combined ultrasonic and eddy current examination for railway inspection trains, Insight—Non-Destruct. Test. Cond. Monit. 2007, 49, 341–344. [Google Scholar]

- Berry, A.; Nejikovsky, B.; Gibert, X.; Tajaddini, A. High speed video inspection of joint bars using advanced image collection and processing techniques. In Proceedings of the World Congress on Railway Research, Seoul, Korea, 18–22 May 2008; pp. 1–13. [Google Scholar]

- Marino, F.; Distante, A.; Mazzeo, P.L.; Stella, E. A real-time visual inspection system for railway maintenance: Automatic hexagonal-headed bolts detection. IEEE Trans. Syst. Man Cybern. C Appl. Rev. 2007, 37, 418–428. [Google Scholar] [CrossRef]

- Esveld, C. Modern Railway Track, 2nd ed.; MRT-Productions: Zaltbommel, The Netherlands, 2001. [Google Scholar]

- Weston, P.F.; Ling, C.S.; Goodman, C.J.; Roberts, C.; Li, P.; Goodall, R.M. Monitoring lateral track irregularity from in-service railway vehicles. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit 2007, 221, 89–100. [Google Scholar] [CrossRef]

- Bocciolone, M.; Caprioli, A.; Cigada, A.; Collina, A. A measurement system for quick rail inspection and effective track maintenance strategy. Mech. Syst. Signal Process. 2007, 21, 1242–1254. [Google Scholar] [CrossRef]

- Caprioli, A.; Cigada, A.; Raveglia, D. Rail inspection in track maintenance: A benchmark between the wavelet approach and the more conventional Fourier analysis. Mech. Syst. Signal Process. 2007, 21, 631–652. [Google Scholar] [CrossRef]

- Massel, A. Power spectrum analysis-Modern tool in the study of rail surface corrugations. NDT E Int. 1999, 32, 429–436. [Google Scholar] [CrossRef]

- Lee, J.S.; Choi, S.; Kim, S.S.; Park, C.; Kim, Y.G. A mixed filtering approach for track condition monitoring using accelerometers on the axle box and bogie. IEEE Trans. Instrum. Meas. 2013, 61, 749–758. [Google Scholar] [CrossRef]

- Shafiullah, G.M.; Azad, S.A.; Ali, A.B.M.S. Energy-efficient wireless MAC protocols for railway monitoring applications. IEEE Trans. Intell. Transp. Syst. 2013, 14, 649–659. [Google Scholar] [CrossRef]

- Sunaga, Y.; Sano, I.; Ide, T. A practical use of axle box acceleration to control the short wave track irregularities. Railw. Tech. Res. Inst. Quart. Rep. 1997, 38, 1–6. [Google Scholar]

- Weston, P.; Ling, C.; Roberts, C.; Goodman, C.; Li, P.; Goodall, R. Monitoring vertical track irregularity from in-service railway vehicles. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit 2007, 221, 75–88. [Google Scholar] [CrossRef]

- Remennikov, A.M.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health Monit. 2008, 15, 207–234. [Google Scholar] [CrossRef]

- Li, Z.; Núñez, A.; Dollevoet, R. Automatic detection of squats in railway infrastructure. IEEE Trans. Intell. Trans. Syst. 2014, 15, 1980–1990. [Google Scholar]

- Daubechies, I. The wavelet transform, time–frequency localization and signal analysis. IEEE Trans. Inf. Theory 1990, 36, 961–1005. [Google Scholar] [CrossRef]

- Wang, Q.; Deng, X. Damage detection with spatial wavelets. Int. J. Solids Struct. 1999, 36, 3443–3468. [Google Scholar] [CrossRef]

- Ovanesova, A.V.; Suárez, L.E. Applications of wavelet transforms to damage detection in frame structures. Eng. Struct. 2004, 26, 39–49. [Google Scholar] [CrossRef]

- Liew, K.M.; Wang, Q. Application of wavelet theory for crack identification in structures. J. Eng. Mech. 1998, 124, 152–157. [Google Scholar] [CrossRef]

| Location (m) | No. of Defects | No. of Predictions | No. of Detected Defects | No. of False Alarms | HR (%) | FA (%) |

|---|---|---|---|---|---|---|

| 0–1000 | 14 | 15 | 12 | 2 | 85.7 | 13.3 |

| 1000–2000 | 10 | 10 | 9 | 1 | 90.0 | 10.0 |

| 2000–3000 | 10 | 13 | 9 | 1 | 90.0 | 7.7 |

| Total | 34 | 38 | 30 | 4 | 88.2 | 10.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, H.; Park, J. Study of Rail Squat Characteristics through Analysis of Train Axle Box Acceleration Frequency. Appl. Sci. 2021, 11, 7022. https://doi.org/10.3390/app11157022

Cho H, Park J. Study of Rail Squat Characteristics through Analysis of Train Axle Box Acceleration Frequency. Applied Sciences. 2021; 11(15):7022. https://doi.org/10.3390/app11157022

Chicago/Turabian StyleCho, Hojin, and Jaehak Park. 2021. "Study of Rail Squat Characteristics through Analysis of Train Axle Box Acceleration Frequency" Applied Sciences 11, no. 15: 7022. https://doi.org/10.3390/app11157022

APA StyleCho, H., & Park, J. (2021). Study of Rail Squat Characteristics through Analysis of Train Axle Box Acceleration Frequency. Applied Sciences, 11(15), 7022. https://doi.org/10.3390/app11157022