Numerical Study of the Improvement in Stability and Performance by Use of a Partial Vaned Diffuser for a Centrifugal Compressor Stage

Abstract

1. Introduction

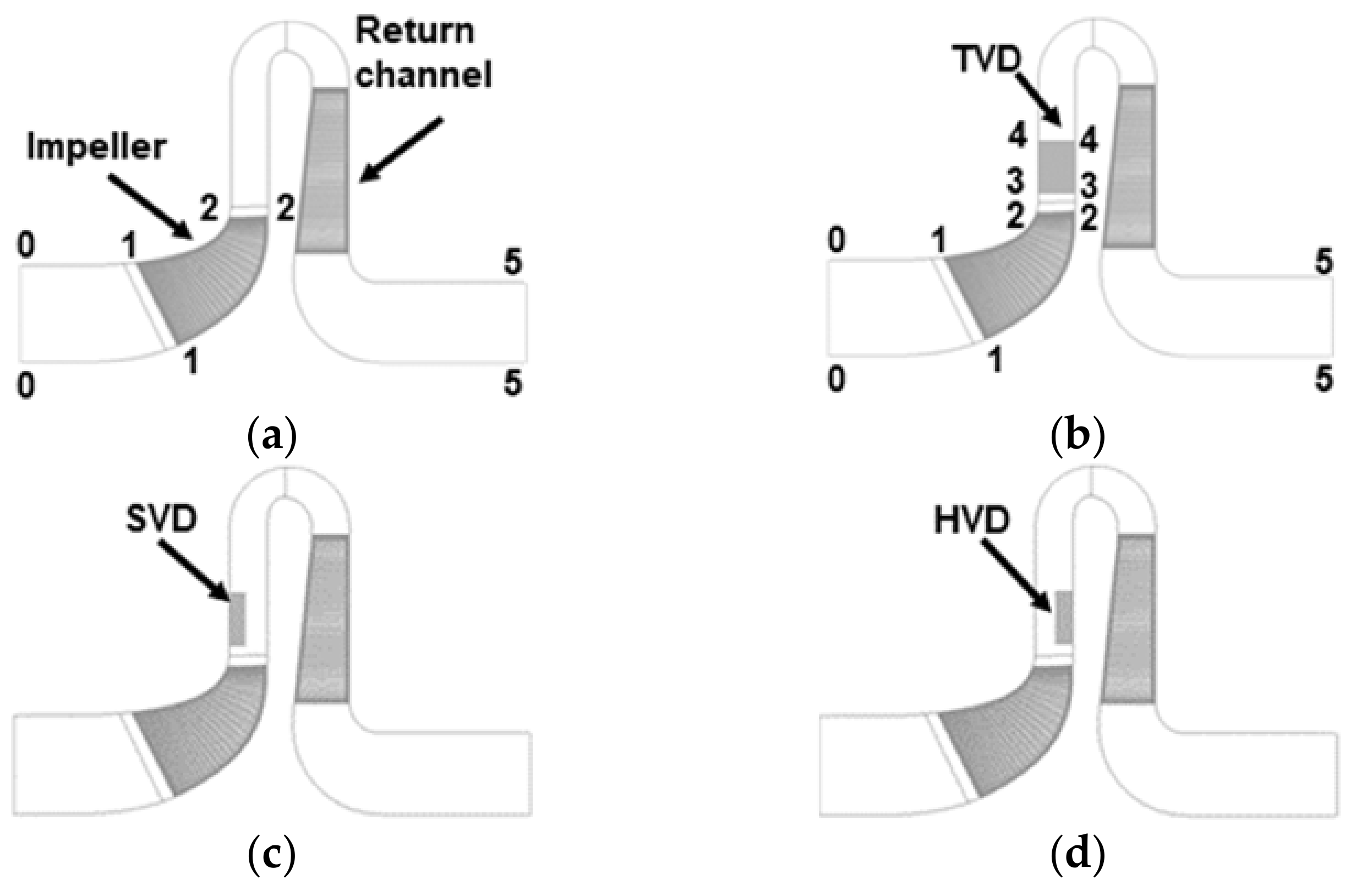

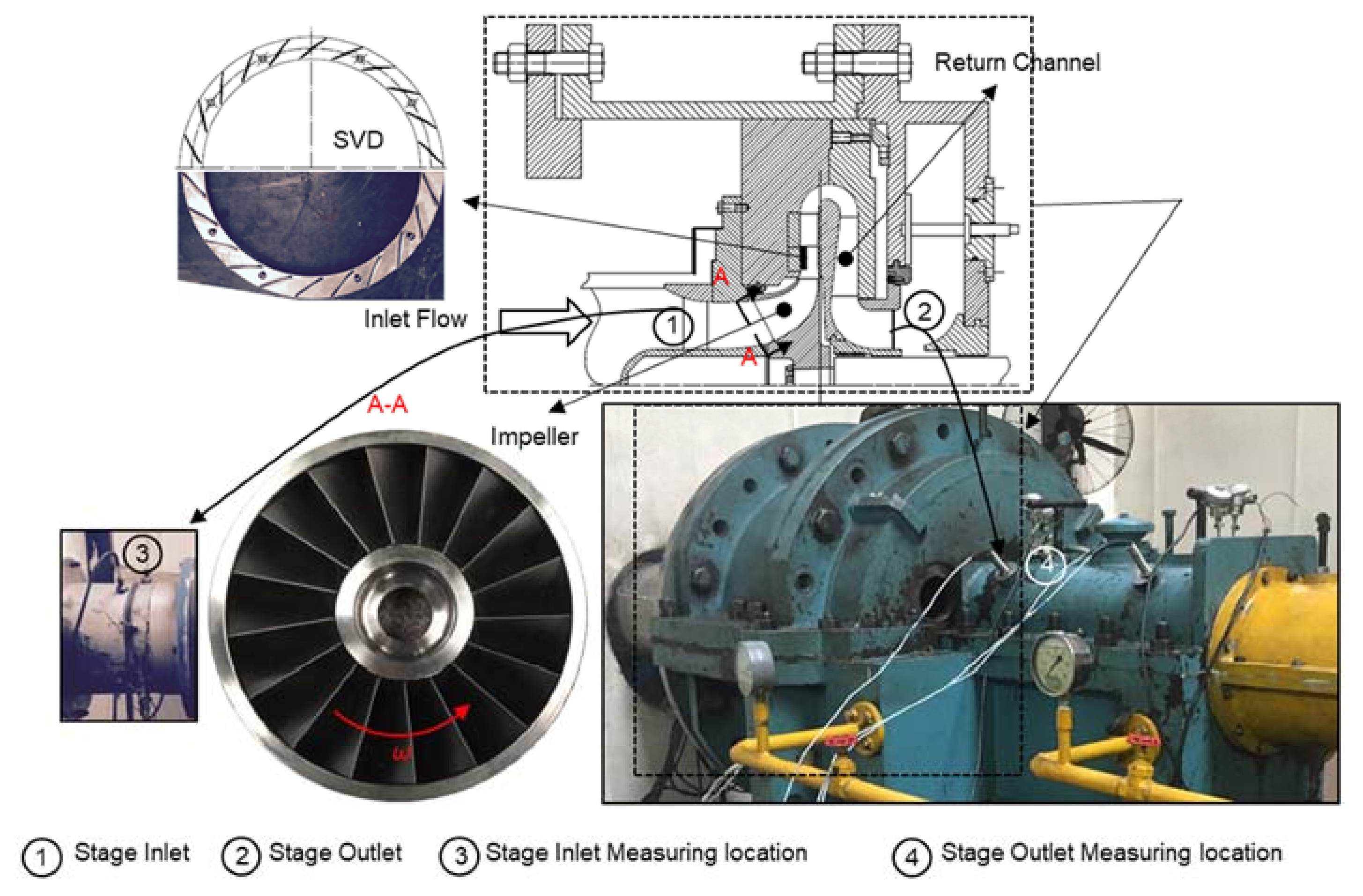

2. The Centrifugal Compressor Stage Investigated

3. Methodology

3.1. Computational Modeling and Grid

3.2. Numerical Scheme

3.3. Modal Decomposition Methods

4. Results and Discussion

4.1. Time-Averaged Unsteady Simulation Results

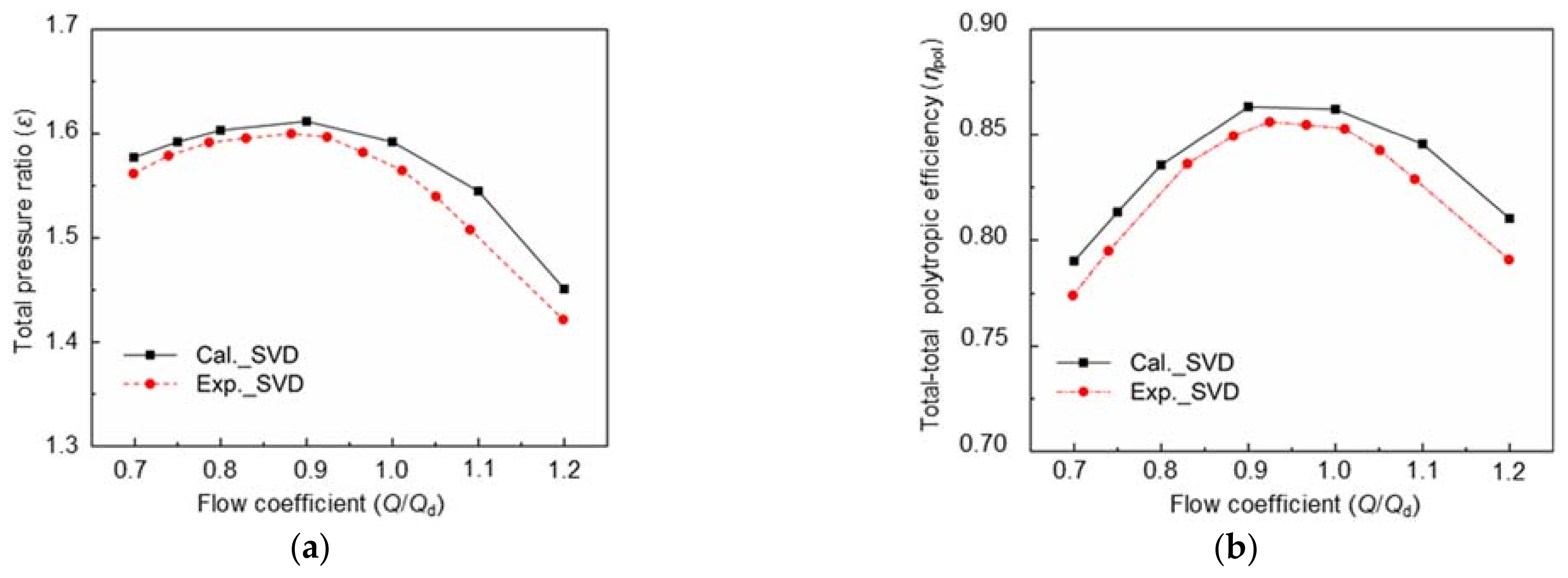

4.1.1. Numerical Method Validation

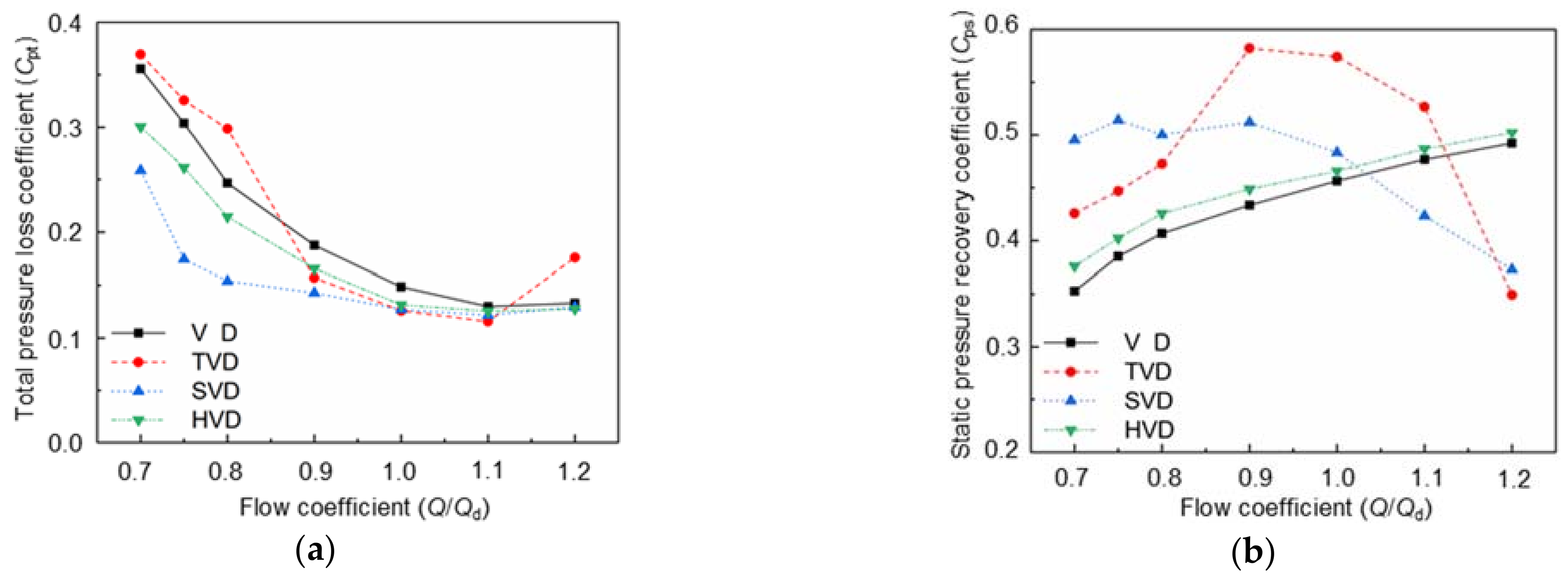

4.1.2. Investigation of Performance with Different Diffusers

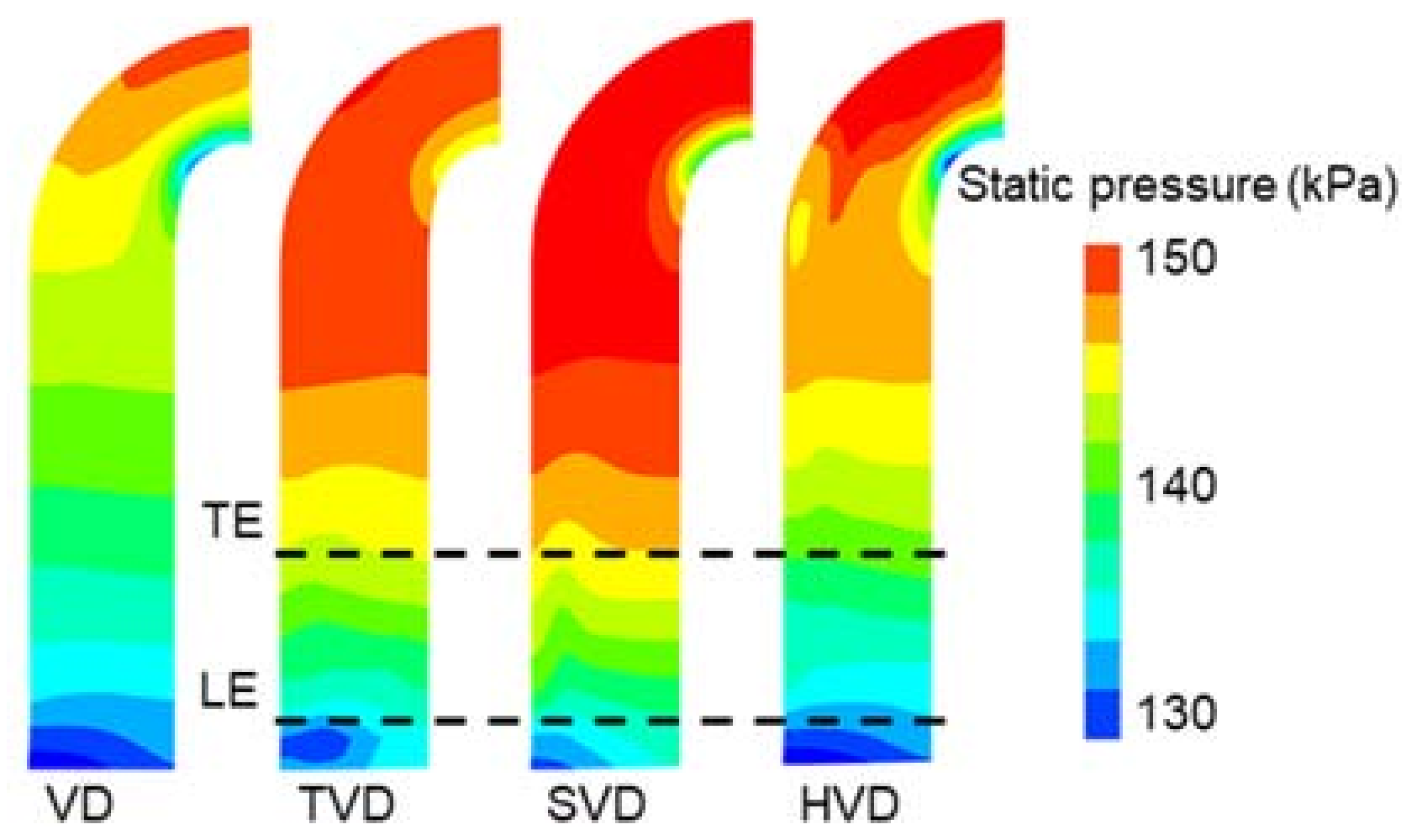

4.1.3. Investigation of the Flow Field in the Different Diffusers

4.2. Unsteady Simulation Results

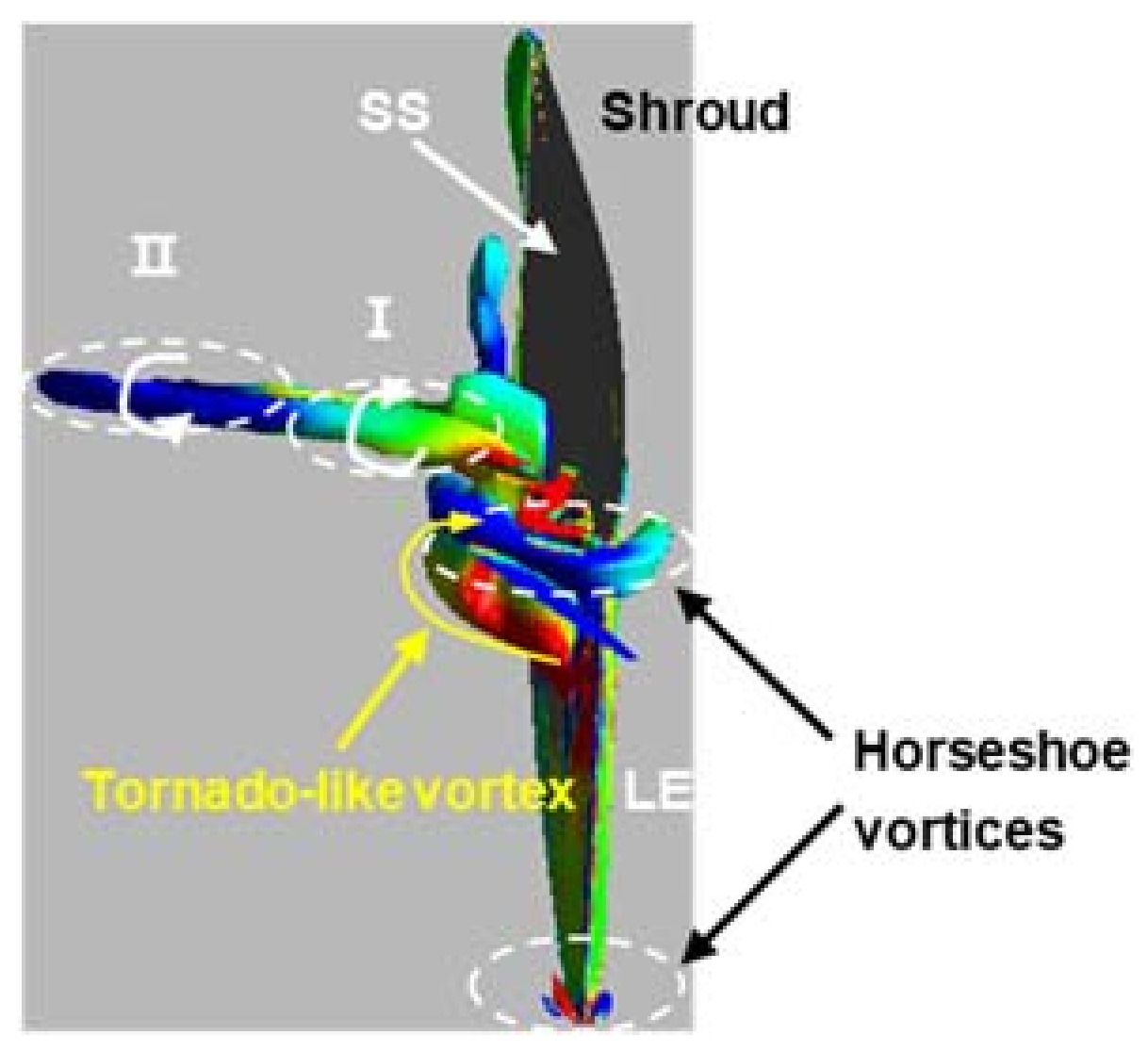

4.2.1. Characteristics of Diffuser Stall

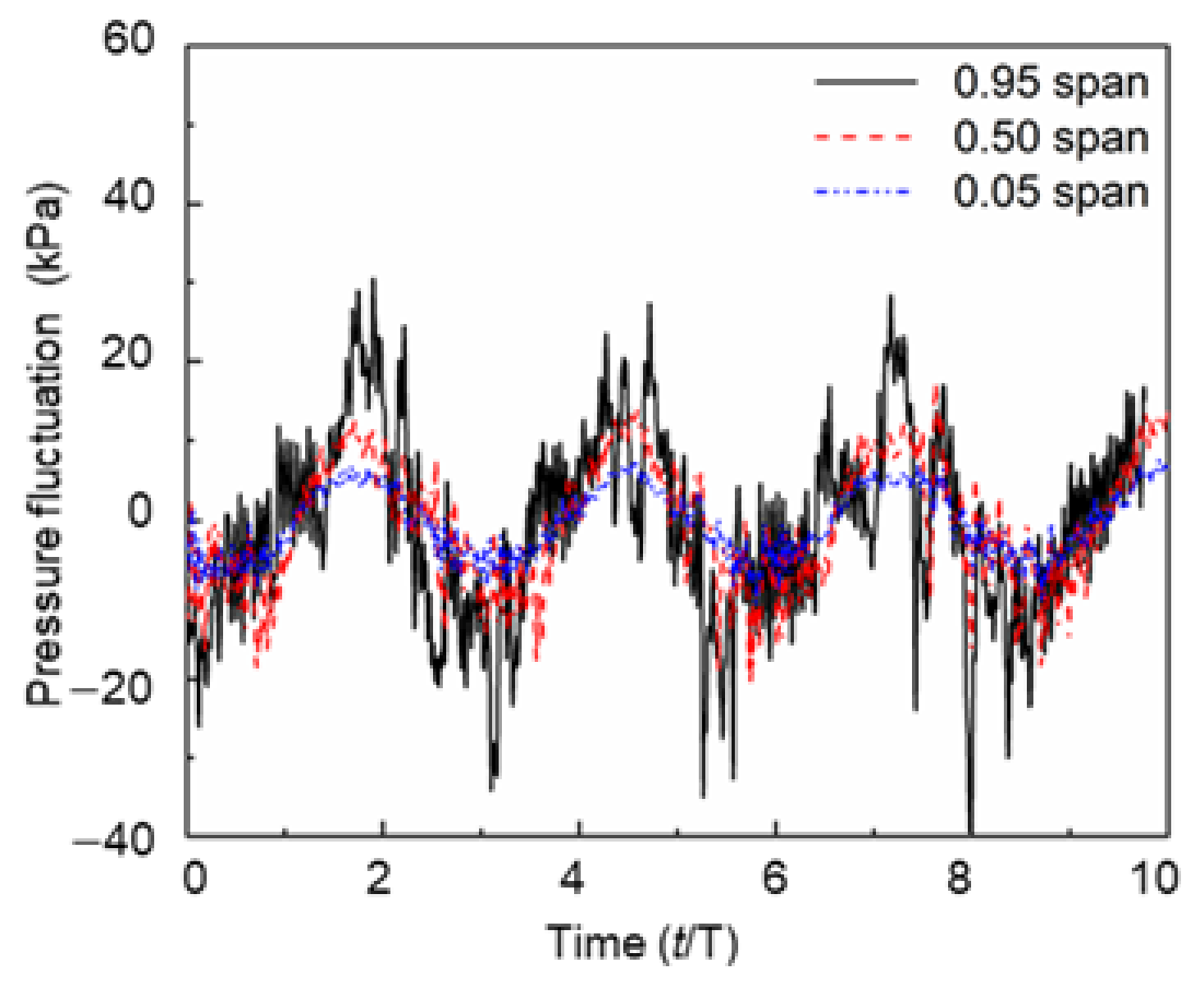

4.2.2. Unsteady Behavior of Diffuser Stall

4.2.3. Flow Field Modal Decomposition

5. Conclusions

- The centrifugal compressor with TVD has the highest total pressure ratio, the minimum Cpt, and maximum Cps at the design operating point. In contrast, SVD has better flow adaptability, and HVD has the same internal flow characteristics as VD, especially at a low mass flow rate.

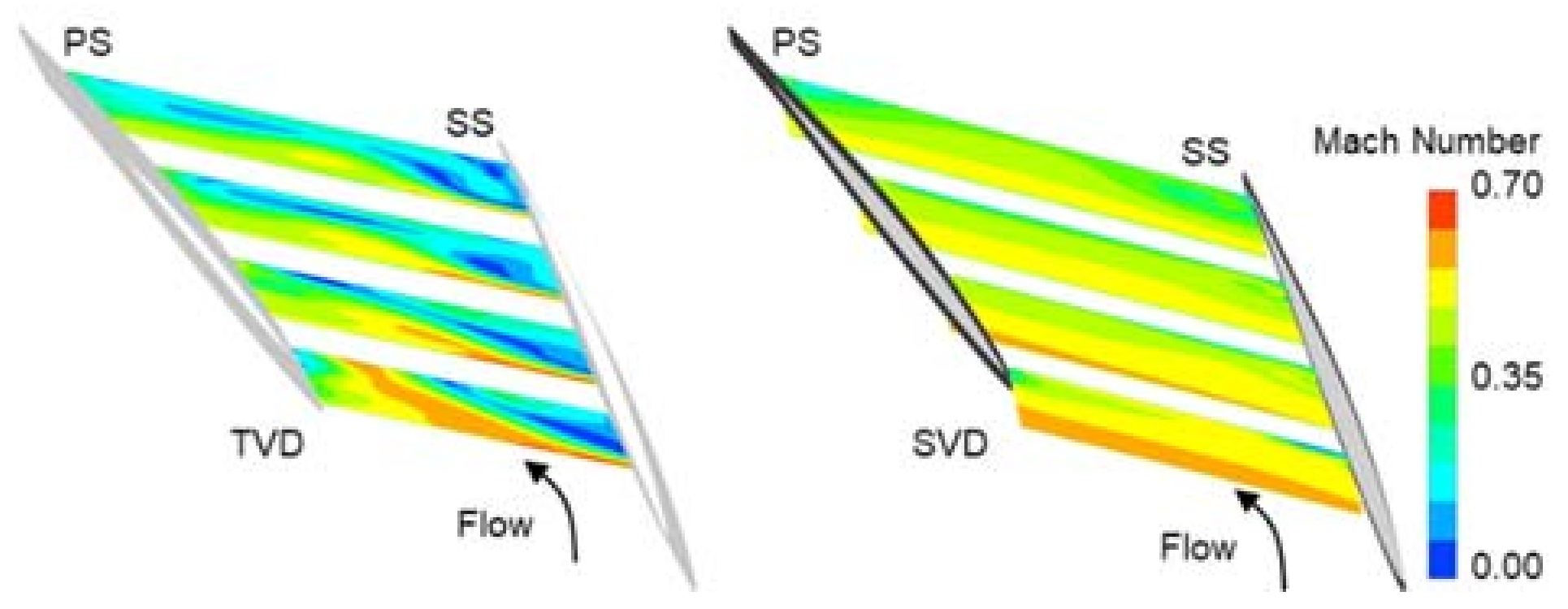

- The mechanism of the improvement in stability by the SVD is that the high-momentum fluid from the vane pressure surface to the suction surface flows to the shroud side through the vane root, which prevents the growth of the boundary layer and the generation of flow separation on the suction surface of the diffuser vane.

- The rotating stall occurs inside the TVD and SVD diffuser passages at the 70% design mass flow rate. Results show that the stall cells propagate at 35.7% of impeller rotational speed in the semi-vaneless space and diffuser passages.

- The POD and DMD analysis show that the amplitude of pressure fluctuations at the selected cross-section of TVD is higher than that of SVD under the same operating condition. The spatial distribution of the pressure field in the diffuser passages demonstrates that the large-scale flow structure almost blocks the part of diffuser passages, which is also a primary reason for the diffuser stall. Therefore, SVD can improve the stability and performance of the compressor stage when compared to TVD.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| TVD | traditional full-height vaned diffuser |

| VD | vaneless diffuser |

| SVD | shroud-side partial vaned diffuser |

| HVD | hub-side partial vaned diffuser |

| Cps | static pressure recovery coefficient |

| Cpt | total pressure loss coefficient |

| POD | proper orthogonal decomposition |

| DMD | dynamic mode decomposition |

| Mu2 | machine Mach number () |

| U2 | impeller tip speed (m/s) |

| k | adiabatic exponent |

| R | ideal gas constant (R = 287 (J/kg/K)) |

| B.C | boundary condition |

| Tt | total temperature (K) |

| Qd | mass flow rate at design point (kg/s) |

| D | diameter |

| LE | leading edge |

| TE | trailing edge |

| BPF | blade passing frequency |

| IPF | impeller passing frequency |

| SS | suction surface |

| PS | pressure surface |

| t | time |

| Δt | time step |

| 0 | centrifugal compressor stage entrance |

| 1 | impeller entrance |

| 2 | impeller exit |

| 3 | diffuser entrance |

| 4 | diffuser exit |

| 5 | centrifugal compressor stage exit |

| d | design |

| ps | static pressure |

| pt | total pressure |

| λ | POD eigenvalue |

| φ | mass flow coefficient |

| ε | total pressure ratio |

| ηpol | total–total polytropic efficiency |

| ω | direction of impeller rotation |

References

- Clarke, C.; Marechale, R.; Engeda, A.; Cave, M. Investigation of centrifugal compressor vaneless diffuser stability via a local flow angle approach. Proc. Inst. Mech. Eng. Part A J. Power Energy 2016, 230, 366–373. [Google Scholar] [CrossRef]

- Anish, S.; Sitaram, N. Computational investigation of impeller—Diffuser interaction in a centrifugal compressor with different types of diffusers. Proc. Inst. Mech. Eng. Part A J. Power Energy 2008, 223, 167–178. [Google Scholar] [CrossRef]

- Issac, J.M.; Sitaram, N.; Govardhan, M. Effect of diffuser vane height and position on the performance of a centrifugal compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2004, 218, 647–654. [Google Scholar] [CrossRef]

- Yoshinaga, Y.; Kaneki, T.; Kobayashi, H.; Hoshino, M. A Study of Performance Improvement for High Specific Speed Centrifugal Compressors by Using Diffusers with Half Guide Vanes. J. Fluids Eng. 1987, 109, 359–366. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Kong, X.Z.; Li, F.; Sun, W.; Chen, Q.G. Performance improvement of a centrifugal compressor stage by using different vaned diffusers. IOP Conf. Ser. Mater. Sci. Eng. 2013, 52, 042003. [Google Scholar] [CrossRef]

- Zhao, P.-F.; Liu, Y.; Wang, X.-F. Analysis of vortices and performance of different diffusers in a large mass flow coefficient centrifugal compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 231, 253–273. [Google Scholar] [CrossRef]

- Liu, R.; Xu, Z. Numerical investigation of a high-speed centrifugal compressor with hub vane diffusers. Proc. Inst. Mech. Eng. Part A J. Power Energy 2004, 218, 155–169. [Google Scholar] [CrossRef]

- Sitaram, N.; Issac, J.M. An experimental investigation of a centrifugal compressor with hub vane diffusers. Proc. Inst. Mech. Eng. Part A J. Power Energy 1997, 211, 411–427. [Google Scholar] [CrossRef]

- Ohta, Y.; Fujisawa, N. Unsteady behavior and control of vortices in centrifugal compressor. J. Therm. Sci. 2014, 23, 401–411. [Google Scholar] [CrossRef]

- Crevel, F.; Gourdain, N.; Moreau, S. Numerical Simulation of Aerodynamic Instabilities in a Multistage High-Speed High-Pressure Compressor on Its Test-Rig—Part I: Rotating Stall. J. Turbomach. 2014, 136, 101003. [Google Scholar] [CrossRef]

- Zamiri, A.; Lee, B.J.; Chung, J.T. Numerical evaluation of transient flow characteristics in a transonic centrifugal compressor with vaned diffuser. Aerosp. Sci. Technol. 2017, 70, 244–256. [Google Scholar] [CrossRef]

- Robinson, C.; Casey, M.; Hutchinson, B.; Steed, R. Impeller-Diffuser Interaction in Centrifugal Compressors. In Proceedings of Turbine Technical Conference and Exposition, Parts A and B; ASMEDC: Copenhagen, Denmark, 2012; Volume 8, pp. 767–777. [Google Scholar]

- Anish, S.; Sitaram, N.; Kim, H.D. A Numerical Study of the Unsteady Interaction Effects on Diffuser Performance in a Centrifugal Compressor. J. Turbomach. 2014, 136, 011012. [Google Scholar] [CrossRef]

- Lumley, J.L. The structure of inhomogeneous turbulence flows. In Atmospheric Turbulence and Radio Wave Propagation; Yaglom, A.M., Tartarsky, V.I., Eds.; Nauka: Moscow, Russia, 1967; pp. 166–177. [Google Scholar]

- Sirovich, L. Turbulence and the dynamics of coherent structures. I. Coherent structures. Q. Appl. Math. 1987, 45, 561–571. [Google Scholar] [CrossRef]

- Sirovich, L. Turbulence and the dynamics of coherent structures. III. Dynamics and scaling. Q. Appl. Math. 1987, 45, 583–590. [Google Scholar] [CrossRef]

- Kim, Y.; Rockwell, D.; Liakopoulos, A. Vortex Buffeting of Aircraft Tail: Interpretation via Proper Orthogonal Decomposition. AIAA J. 2005, 43, 550–559. [Google Scholar] [CrossRef]

- Shi, L.L.; Liu, Y.Z.; Wan, J.J. Influence of wall proximity on characteristics of wake behind a square cylinder: PIV measurements and POD analysis. Exp. Therm. Fluid Sci. 2010, 34, 28–36. [Google Scholar] [CrossRef]

- Schmid, P. Dynamic mode decomposition of numerical and experimental data. J. Fluid Mech. 2010, 656, 5–28. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, Q.; Yang, S.; Li, H. Rotating Stall Induced Non-Synchronous Blade Vibration Analysis for an Unshrouded Industrial Centrifugal Compressor. Sensors 2019, 19, 4995. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Hussain, F. On the identification of a vortex. J. Fluid Mech. 1995, 285, 69–94. [Google Scholar] [CrossRef]

- Bousquet, Y.; Carbonneau, X.; Dufour, G.; Binder, N.; Trébinjac, I. Analysis of the Unsteady Flow Field in a Centrifugal Compressor from Peak Efficiency to Near Stall with Full-Annulus Simulations. Int. J. Rotat. Mach. 2014, 2014, 729629. [Google Scholar] [CrossRef][Green Version]

- Fujisawa, N.; Ikezu, S.; Ohta, Y. Structure of Diffuser Stall and Unsteady Vortices in a Centrifugal Compressor with Vaned Diffuser. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Cumpsty, N.A.; Greitzer, E.M. A Simple Model for Compressor Stall Cell Propagation. J. Eng. Power 1982, 104, 170–176. [Google Scholar] [CrossRef]

- Tinney, C.E.; Jordan, P. The near pressure field of co-axial subsonic jets. J. Fluid Mech. 2008, 611, 175–204. [Google Scholar] [CrossRef]

- Liu, H.; Yan, C.; Zhao, Y.; Qin, Y. Analysis of pressure fluctuation in transonic cavity flows using modal decomposition. Aerosp. Sci. Technol. 2018, 77, 819–835. [Google Scholar] [CrossRef]

- Sajadmanesh, S.M.; Mojaddam, M.; Mohseni, A.; Nikparto, A. Numerical identification of separation bubble in an ultra-high-lift turbine cascade using URANS simulation and proper orthogonal decomposition. Aerosp. Sci. Technol. 2019, 93, 105329. [Google Scholar] [CrossRef]

- Sharma, S.; Broatch, A.; García-Tíscar, J.; Nickson, A.; Allport, J. Acoustic and pressure characteristics of a ported shroud turbocompressor operating at near surge conditions. Appl. Acoust. 2019, 148, 434–447. [Google Scholar] [CrossRef]

- Xue, X.; Wang, T.; Shao, Y.; Yang, B.; Gu, C. Experimental and Numerical Analysis of Unsteady Flow Structure in a Centrifugal Compressor with Variable Vaned Diffuser. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Semlitsch, B.; Mihaescu, M. Flow phenomena leading to surge in a centrifugal compressor. Energy 2016, 103, 572–587. [Google Scholar] [CrossRef]

- Lengani, D.; Simoni, D.; Pichler, R.; Sandberg, R.; Michelassi, V.; Bertini, F. Identification and quantification of losses in a LPT cascade by POD applied to LES data. Int. J. Heat Fluid Flow 2018, 70, 28–40. [Google Scholar] [CrossRef]

- Lengani, D.; Simoni, D.; Pichler, R.; Sandberg, R.D.; Michelassi, V.; Bertini, F. On the Identification and Decomposition of the Unsteady Losses in a Turbine Cascade. J. Turbomach. 2019, 141, 031005. [Google Scholar] [CrossRef]

- Yarusevych, S.; Kotsonis, M. Effect of Local DBD Plasma Actuation on Transition in a Laminar Separation Bubble. Flow Turbul. Combust. 2017, 98, 195–216. [Google Scholar] [CrossRef]

| Parameters | Value | |

|---|---|---|

| Impeller exit diameter | D2 | 360 mm |

| Diffuser entrance diameter | D3 | 390 mm |

| Diffuser exit diameter | D4 | 465 mm |

| Impeller exit width | b2 | 17 mm |

| Number of impellers | Zimp | 17 |

| Number of diffuser vanes | Zdif | 22 |

| Number of return channels | Zr | 18 |

| Rotational speed | ω | 14,562 rpm |

| Component | ε | Difference | |

|---|---|---|---|

| Impeller | Coarse | 1.3707 | 1.182% |

| Medium 1 | 1.3796 | 0.5407% | |

| Medium 2 Fine | 1.3853 1.3871 | 0.1298% - | |

| Cp | Difference | ||

| SVD | Coarse | 0.3782 | 1.843% |

| Medium 1 Medium 2 | 0.3831 0.3847 | 0.571% 0.1557% | |

| Fine | 0.3853 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Liu, Y.; Li, H.; Omidi, M. Numerical Study of the Improvement in Stability and Performance by Use of a Partial Vaned Diffuser for a Centrifugal Compressor Stage. Appl. Sci. 2021, 11, 6980. https://doi.org/10.3390/app11156980

Li S, Liu Y, Li H, Omidi M. Numerical Study of the Improvement in Stability and Performance by Use of a Partial Vaned Diffuser for a Centrifugal Compressor Stage. Applied Sciences. 2021; 11(15):6980. https://doi.org/10.3390/app11156980

Chicago/Turabian StyleLi, Shuai, Yan Liu, Hongkun Li, and Mohammad Omidi. 2021. "Numerical Study of the Improvement in Stability and Performance by Use of a Partial Vaned Diffuser for a Centrifugal Compressor Stage" Applied Sciences 11, no. 15: 6980. https://doi.org/10.3390/app11156980

APA StyleLi, S., Liu, Y., Li, H., & Omidi, M. (2021). Numerical Study of the Improvement in Stability and Performance by Use of a Partial Vaned Diffuser for a Centrifugal Compressor Stage. Applied Sciences, 11(15), 6980. https://doi.org/10.3390/app11156980