Abstract

The purpose of this study is to grasp the behavior characteristics of a single batter pile under vertical load by performing a model test. The changes in the resistance of the pile, the bending moment, etc. by the slope of the pile and the relative density of the ground were analyzed. According to the results of the test, when the relative density of the ground was medium and high, the bearing capacity kept increasing when the angle of the pile moved from a vertical position to 20°, and then decreased gradually after 20°. The bending moment of the pile increased as the relative density of the ground and the batter angle of the pile increased. The position of the maximum bending moment came closer to the ground surface as the batter angle of the pile further increased, and it occurred at a point of 5.2~6.7 times the diameter of the pile from the ground surface.

1. Introduction

Among foundation structures, a pile is used the most widely to carry the load of the superstructure to the good-quality ground layer if the good-quality ground layer is located deep under the ground. A pile refers to a construction material with a very long length compared to its cross-sectional area.

The importance of and interest in piles are increasing as the structures are becoming heavier and larger and it is difficult to secure good sites for construction works, and, as a result, structures are constructed in sites with unfavorable conditions. In addition, steel piles are being used more frequently by the necessity to sink piles into hard ground where it is difficult to use concrete piles.

So far, much research has been performed on the behavioral characteristics of vertical piles. In contrast, there has been little research conducted on batter piles, even though they are used frequently for bridge abutments, retaining walls, etc.

Awad and Petrasovits (1968) [1] proposed the load of the batter pile in the form of a percentage against the load of the vertical pile after conducting an experiment by changing the direction of action of the load. Meyerhof (1973) [2] suggested a pullout resistance calculation formula applicable to sandy soil based on an experiment on the axial pullout load of a sloped pile, concluding that the pullout coefficient of a sloped pile can be bigger in a rammed pile than in a buried pile. Meyerhof and Ranjan (1973) [3] estimated that the earth pressure coefficient used for calculation of the surface friction of the batter pile under axial load can be slightly larger than the earth pressure coefficient of a vertical pile. Hanna and Nguyen (1986) [4] confirmed the observation of Meyerhof (1973) [2] for the shaft resistance of single piles subjected to compression loading. The experimental results reported by Afram (1984) [5] showed that there was no significant change on the pullout capacity of batter piles due to an increase of the pile inclination. This investigation was performed with pile angles from 0 to 30 degrees in sand. Hanna and Afram (1986) [6] conducted indoor pullout tests with different diameters of the pile for vertical piles and batter piles and confirmed that the pullout resistance of the pile decreased gradually as the batter angle of the pile increased. Das (1990) [7] suggested the ratio of marginal length of the batter pile by relative density, assuming that the surface friction is constant.

Bae (1997) [8] verified that the roughness of the surface of the pile had the biggest influence on the pullout load of the batter pile. Zhang et al. (1999) [9] conducted a study to examine the effects of pile batter and soil density upon the lateral resistance of a single batter pile in sand. Kim (2001) [10] analyzed changes in the value of the bearing capacity and the earth pressure coefficient(K) by a model test of the batter pile, and Sung (2002) [11] conducted an experiment of the vertical bearing capacity according to the batter angle of the batter pile under vertical load using a pressure chamber. Shakarchi et al. (2004) [12] carried out an experimental work on a single batter pile in sand subjected to uplift loads of inclinations of 0°, 15°, 30°, 45°, 60°, 75°, and 90°. It was found that the uplift capacity of vertical and batter piles under inclined pulls increased with increasing inclination of pull with the vertical and the maximum value at horizontal pull. Manoppo (2010) [13] discussed experimentally the behavior of the ultimate bearing capacity of a single flexible batter pile in homogeneous sand under horizontal load. Nazir and Nasr (2013) [14] suggested that relations for the pullout capacity of a batter pile regarding the vertical pile capacity were well predicted. Al-Neami et al. (2016) [15] introduced an attempt to examine the effect of batter angle of a single pile model on its ultimate vertical load capacity. Their results indicated that there is an optimum batter angle, namely 20°, that gave a higher load capacity.

As is evident, most research on batter piles has been conducted mainly on the displacement caused by pullout force or lateral load. It is necessary to conduct research on the effect of the load on compression behavior and displacement, as the batter pile is often under the load of vertical compression, though it is used to bear pullout or lateral loading. In this regard, this study analyzed the behavior characteristics of independent batter piles when the batter piles are under vertical loads in a sandy soil ground using different relative densities of the ground and batter angles of the piles in a model test.

2. Model Test

For the model test, the generalized scaling law [16] was adopted to satisfy the scale effect by the field conditions, as shown in Table 1.

Table 1.

Generalized scaling law for model tests.

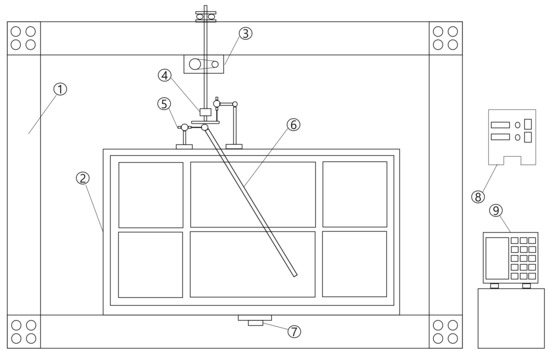

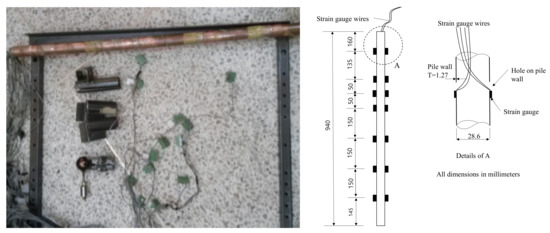

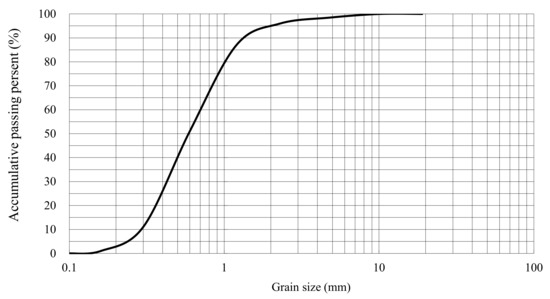

Figure 1 shows the test device set up for grasping the behavior characteristics of batter pile under vertical load in a sandy ground. The chamber used for the model test was produced with 500 mm × 1400 mm × 1000 mm steel maintaining sufficient distance for prevention of interference between the pile and the wall of the chamber with more than 5D (5 times of the diameter of the pile) interval. The model pile used for the test is a copper pipe with a closed front end as shown in Figure 2 and its specifications are summarized in Table 2. In consideration of analogous relationship, a circular copper pipe was used for the production of the model pile, and the 1 g analogue of Iai (1989) [16] was used for simulation. In addition, considering that the bending rigidity of the tile is the dominant influence factor for the behavior of the pile, the thickness of the pile was adjusted at 1.27 mm to satisfy the analogous relationship of the bending rigidity. The material used as the ground was the specimen collected at Hapcheon of the Nakdong River basin. The sand which passed through #4 sieve was used and the water content percentage was 0.08%. The physical property of the specimen and the size curve are shown in Table 3 and Figure 3. For measurement of the density of the ground, a density measurement instrument was buried at the bottom of the model ground as shown in Figure 4 and the sand was sprayed. Then the vibration was given for 2, 15 and 90 s with the vibration motor installed at the bottom of the chamber for measurement of the relative densities. The results of the measurement of the relative densities of the model ground are shown in Table 4.

Figure 1.

Schematic diagram of test setup [① Steel frame, ② Steel chamber (500 mm × 1400 mm × 1000 mm), ③ Load adding device, ④ Compression load cell, ⑤ Displacement gauge, ⑥ Model pile, ⑦ Vibrator, ⑧ Loading controller, ⑨ Strain measuring instrument].

Figure 2.

Model pile.

Table 2.

Characteristics of model pile.

Table 3.

Physical properties of Hapcheon sand for model test.

Figure 3.

Grain size distribution curve for Hapcheon sand.

Figure 4.

Setting up the molds for measuring the relative density.

Table 4.

Relative density in test ground.

The process and methods of the model test conducted for grasping the behavior characteristics of independent batter pile under vertical load are as follows; ① First, place the model pile in a certain slope using the pile holder as shown in Figure 5a. ② Lay two folds of #4 net on the chamber at intervals of 50 mm and spray sand using the sand spraying machine (Figure 5b,c). ③ Operate the vibration motor under the chamber and stomp in order to achieve a certain even density of the model ground and then remove the pile holder (Figure 5d). ④ Install perpendicular vertical displacement gauge and various other measuring instruments. (Figure 5e) ⑤ Measure the vertical displacement of the pile head until the pile displacement reaches maximum 25 mm or the vertical load becomes 20 kN at 1 mm/min of speed. ⑥ Remove the load to recover the elasticity of the pile.

Figure 5.

Procedure of Model test.

The influence of the underground water among the conditions of the model test was ignored. The pile head was free and the front end of the pile was closed. For the loading on the pile head, only the vertical load was considered. Additionally, iron beads were attached to the head of the pile to maintain the vertical load state even when horizontal and vertical displacements of the pile head occurred. Table 5 shows the conditions of the model test performed in this study.

Table 5.

The summary of test cases in model test.

3. Test Results and Analysis

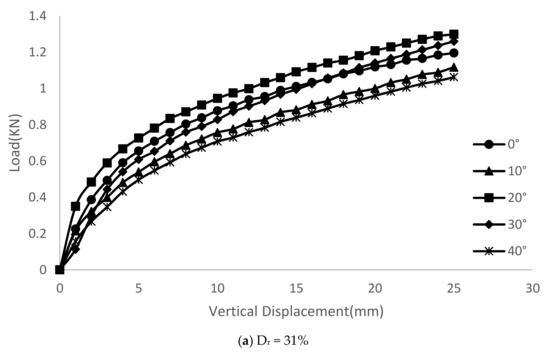

3.1. Relationship between Pile Head Displacement and Vertical Load

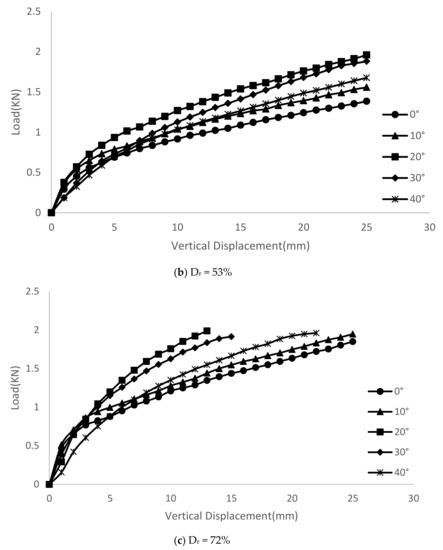

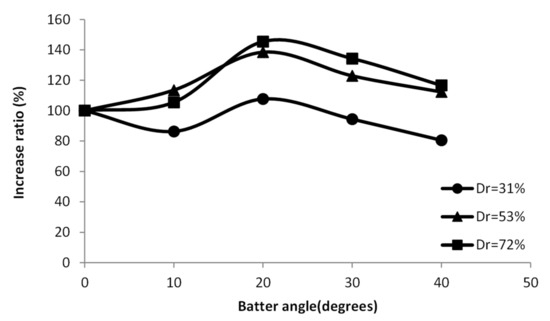

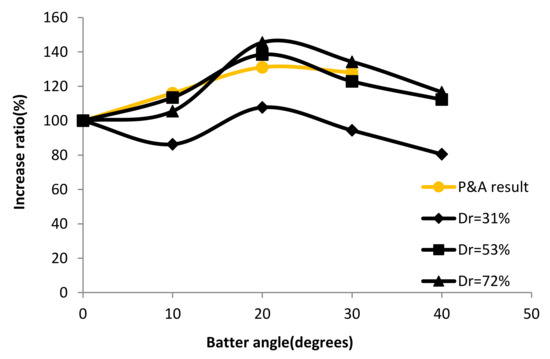

Figure 6 shows the relationship between the vertical load (Pv) of each pile slope and vertical displacement () of the pile head by relative density (Dr). The allowable load was set at 2/3 of the loading when the displacement of pile head was 1.2 cm (Indian Standard 2911), and the increment ratio of batter angle and bearing capacity in each relative density could be set using the value of the allowable load as shown in Figure 7. The increment ratio of bearing capacity was the highest when the batter angle was 20° regardless of the relative density. In ground with a low relative density (Dr = 31%), the bearing capacity was always less than the vertical pile except when the angle was 20°. In a medium and high density ground, the bearing capacity kept increasing when the angle of the pile moved from a vertical position to about 20°, and then decreased gradually after 20°. It seems that while the bearing capacity at the front end of the pile decreased as the batter angle of the pile increased, the bearing capacity was the greatest near 20° of the angle of the pile due to the increase in the surface friction of the pile.

Figure 6.

Relation of vertical load and pile head vertical displacement due to the Batter angle.

Figure 7.

Comparison of bearing capacity.

3.1.1. Relationship between Horizontal Displacement and Vertical Load of Each Pile Slope by Relative Density

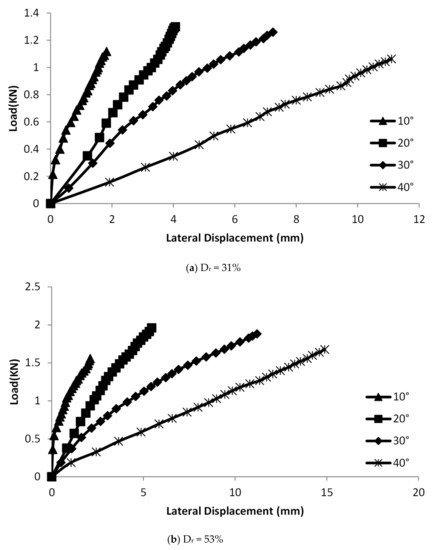

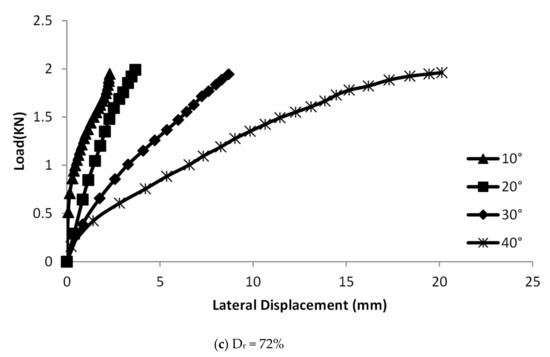

Figure 8 shows the relationship between the horizontal displacement () and vertical load of each slope by relative density. In the same vertical load, horizontal displacement increased as the batter angle increased, and the range of increase was more after 30°. It seems that the horizontal displacement increased by the increase in bending moment caused by the increase in the batter angle of the pile.

Figure 8.

Relation of load and pile head total displacement according to Batter angle.

With the same horizontal displacement, the vertical load of the pile tended to decrease as the batter angle increased, which means that if the batter angle of the batter pile under the same vertical load is large, the bending moment of the pile increases gradually and as a result the horizontal displacement increases gradually.

3.1.2. Relationship between the Total Displacement and Vertical Load of Each Slope by Relative Density

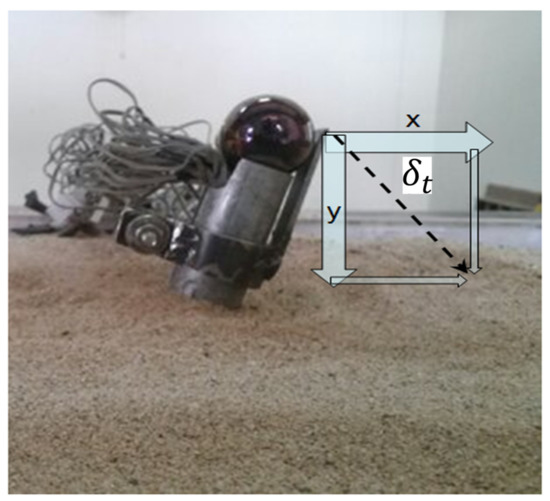

Horizontal displacement and vertical displacement occur in the slope pile under vertical load. For the two kinds of displacement, was defined as the total displacement as shown in Figure 9 using Pythagorean theorem.

Figure 9.

Total displacement of pile head.

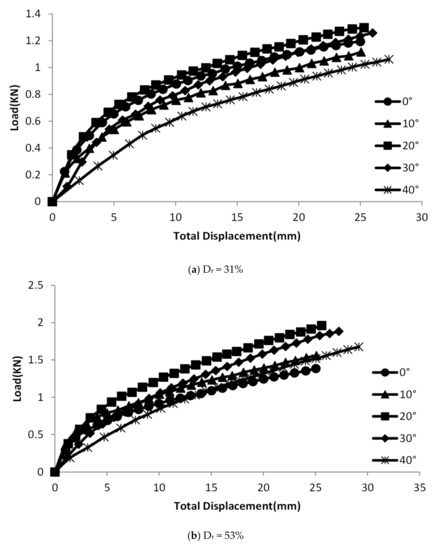

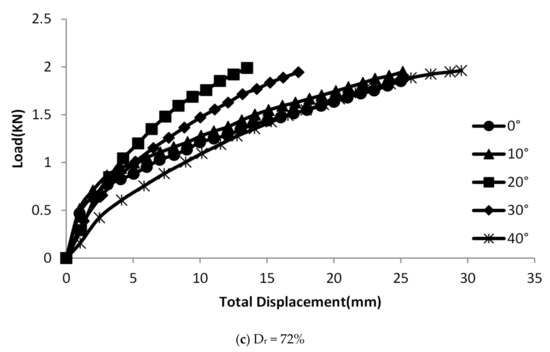

Figure 10 shows the relationship between the total displacement of the independent batter pile and the vertical load. The total displacement of the pile head increase with the increased in relative density, and the greatest bearing capacity occurred at 20° of pile slope regardless of the relative density of the ground.

Figure 10.

Relation of vertical load and pile head total displacement.

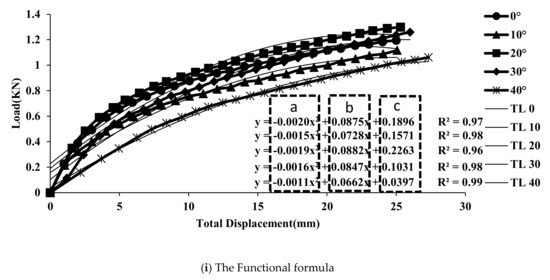

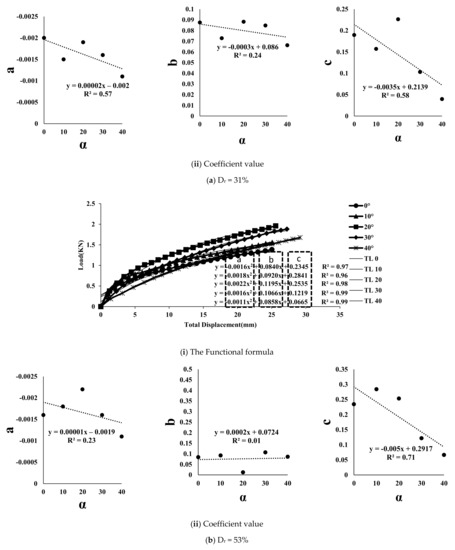

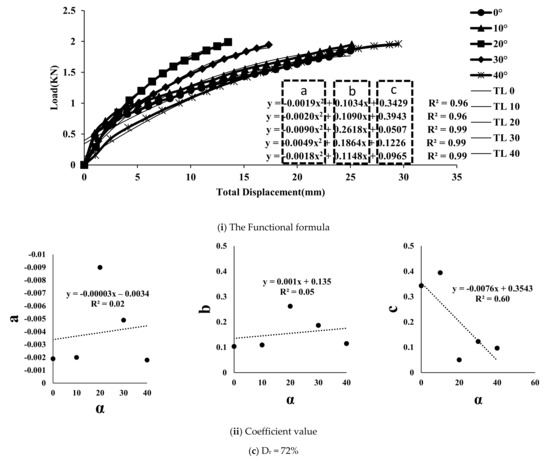

3.1.3. Proposal of an Experimental Formula for the Total Displacement and Vertical Load according to Relative Density

Figure 11 is a graph that proposes an experimental formula using the vertical load according to relative density and the trend line (TL) in the total displacement.

Figure 11.

Experimental formularization by total displacement.

In Figure 11i, y = ax2 + bx + c is used to represent a quadratic function, and the values of the a, b, and c coefficients in the trend lines can be represented as a linear function in the graph of Figure 11ii. As shown in Figure 11i, the relationship between load and total displacement was in sufficiently good agreement, and R2 was in the range of 0.96~0.99. However, the relationships between coefficients (a, b, and c) and batter angles (α) were found not to correlate relatively highly, and R2 was less than 0.71. This indicates that more model tests should be conducted in the future to increase the accuracy.

As shown in Table 6, it is possible to represent it as an experimental formula with the variables of the total displacement and the batter angle.

Table 6.

An experimental formularization by total displacement.

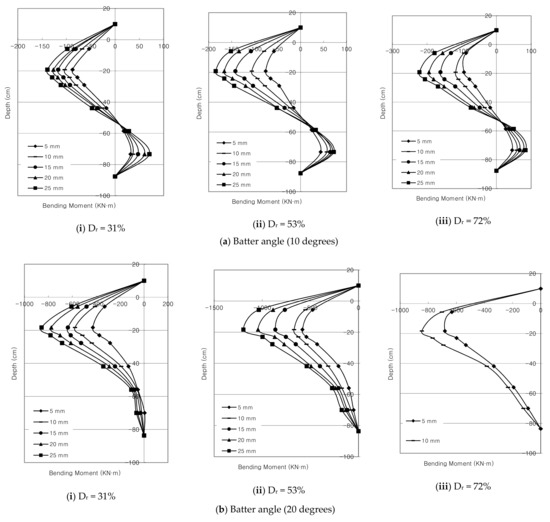

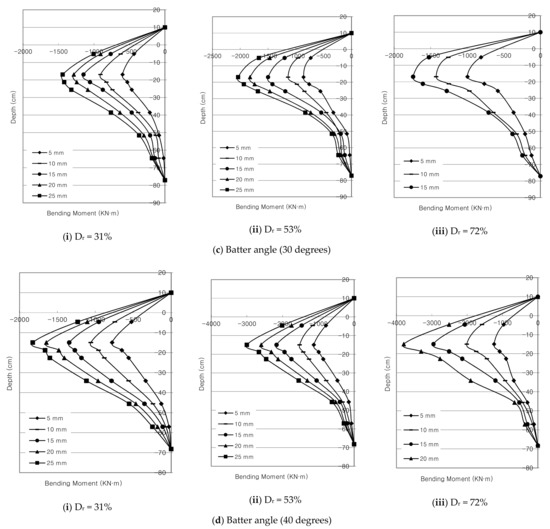

3.2. Relationship between Vertical Displacement of Pile Head and Moment

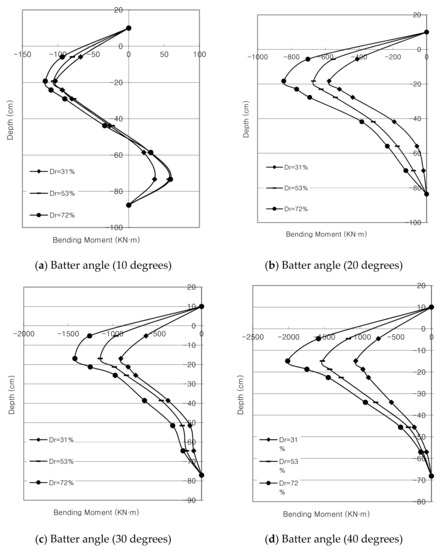

Figure 12 shows the relationship between the vertical displacement and moment of a batter pile under vertical load according to depth. Here, depth means the depth measured along the pile axis exposed above the ground, not the vertical depth of the buried pile.

Figure 12.

Relation of pile head displacement and bending moment.

The measured value of moment (M) was calculated with the compressive strain of the strain gauge attached to the pile, and the applied formula is represented as Equation (1) (Rollins. et al., 1998) [17].

- ϵ: Compressive strain

- E, I: Bending rigidity of model pile

- d: Radius of model pile

In Figure 12, the maximum bending moment was greater when the pile slope increased, or the relative density of the ground increased. In addition, the maximum bending moment occurred increasingly at a lower point when the vertical displacement of the pile head increased more. Additionally, the rate of increase of the moment ratio became higher with the increase in the batter angle of the pipe in the case with a high relative density of ground (72%) rather than the case with a low relative density of ground (31%). This is because a greater bending moment occurred by the vertical load on the pile as the ground was tamped more if the relative density increased more. Moreover, if vertical load was put on the pile in low-density ground, the fixation effect at the front end of the pile decreased, and the load was transferred to a deeper point by the compression of the ground. However, the fixation effect at the front end of the pile increased in high-density ground by the greater tamping effect. Therefore, it was thought that the bending moment became larger due to the increased subgrade reaction against the vertical load of the pile.

3.3. Changes in the Maximum Moment in Each Relative Density according to Pile Slope

Figure 13 compares the changes of momentum in each relative density according to the batter angle of the pile when the vertical displacement is 1 cm. The maximum bending moment of the pile tended to increase as the relative density increased. It seems that a greater vertical load was put on the pile as the confining pressure of the pile increased due to the increase in the relative density, even in the same vertical displacement, and as a result the bending moment increased too.

Figure 13.

Relation of the relative density and bending moment at Vertical Displacement of 1 cm.

When the batter angle of the pile increased more, the position of the maximum bending moment came closer to the ground surface, and it occurred at a point of 3.7~5.2(D) from the ground surface.

3.4. Comparison with the Existing Researches

Figure 14 compares the results of the experiment of Awad and Petrasovits (1968) obtained through a model test and the results of experiment in this study using the batter angle of the pile and the relative density of the ground. While Awad and Petrasovits (1968) represented the rate of increase of bearing capacity according to batter angle using a medium-level relative density, the experiment in this study segmented the relative density into the three levels of low density, medium density and high density. Though it was not possible to compare the values in low- and high-levels of relative density, this study obtained a value similar to that of Awad and Petrasovits (1968) when the relative density was 53%.

Figure 14.

Comparisons between the test results and a previous study.

4. Conclusions

This study examined through a model test the behavioral characteristics of independent batter piles according to relative density and batter angle when the independent batter pile was under vertical load in a sandy soil ground. The following are the results of the experiment.

- When the relative density of the ground was medium (Dr = 53%) and high (Dr = 72%), the bearing capacity kept increasing when the angle of the pile moved from a vertical position (0°) to 20°, and then decreased gradually in a batter angle larger than 20°. In a ground with a low relative density (Dr = 31%), the bearing capacity was always less than the vertical pile except when the angle was 20°.

- The bending moment of the pile increased as the relative density of the ground and the batter angle of the pile increased. The position of the maximum bending moment came closer to the ground surface as the batter angle of the pile increased more, and it occurred at a point of 5.2~6.7 times the diameter (D) of the pile from the ground surface.

- As shown in Table 6, this study proposed an experimental formula to determine the bearing capacity using the batter angle of the pile in each relative density of the ground and the total displacement.

Author Contributions

Conceptualization, methodology, G.K. and J.K.; modeling tests and data curation, S.-K.Y. and M.K.; writing—original draft preparation, J.K. and G.K.; writing—review and editing, G.K. and J.K.; supervision, G.K.; funding acquisition, G.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (No. 2020R1I1A3067248).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Awad, A.; Petrasovits, G. Consideration on the Bearing Capacity of Vertical and Batter Piles Subjected to Forces Acting in Different Directions. In Proceedings of the 3rd Budapest Conferences on Soil Mechanics and Foundation Engineering, Budapest, Hungary, 15–18 October 1968. [Google Scholar]

- Meyerhof, G.G. Uplift Resistance of Inclined Anchors and piles. In Proceedings of the 8th International Conference on Soil Mechanics and Foundation Engineering, Moscow, Russia, 2–3 August 1972; pp. 162–172. [Google Scholar]

- Meyerhof, G.G.; Ranjan, G. The Bearing Capacity of Rigid Piles under Inclined Loads in Sand II: Batter Piles. Can. Geotech. J. 1973, 10, 71–85. [Google Scholar] [CrossRef]

- Hanna, A.; Nguyen, T.Q. Ultimate Skin Friction of Single Batter Piles in Sand. In Proceedings of the International Conference on Deep Foundations, Beijing, China, 1–5 September 1986; pp. 100–108. [Google Scholar]

- Afram, A. Uplift Capacity of Battered Pile in Sand. Master’s Thesis, Concordia University, Montreal, QC, Canada, 1984. [Google Scholar]

- Hanna, A.M.; Afram, A. Pull-Out Capacity of Single Batter Piles in Sand. Can. Geotech. J. 1986, 23, 387–392. [Google Scholar] [CrossRef]

- Das, B.M. Earth Anchores; Elesvier: New York, NY, USA, 1990; pp. 193–223. [Google Scholar]

- Bae, W.S. Pullout Behavior of Inclined Piles in Sand. Master’s Thesis, Chungbuk National University, Chungju, Korea, 1997. [Google Scholar]

- Zhang, L.; McVay, M.C.; Lai, P.W. Centrifuge Modelling of Laterally Loaded Single Battered Piles in Sands. Can. Geotech. J. 1999, 36, 1074–1084. [Google Scholar] [CrossRef]

- Kim, J.H. An Experimental Study on Bearing Capacity of Battered Pile. Master’s Thesis, Keimyung University, Daegu, Korea, 2001. [Google Scholar]

- Sung, I.C. A Study on the Vertical Bearing Capacity according to Inclination of the Better Piles Subjected to Vertical Load. Master’s Thesis, Kyungsung University, Pusan, Korea, 2002. [Google Scholar]

- Shakarchi, Y.J.A.; Fattah, M.Y.; Kashat, I.K. The Behaviour of Batter Piles under Uplift Loads. In Proceedings of the An International Conference on Geotechnical Engineering, Sharjah, United Arab Emirates, 3–6 October 2004. [Google Scholar]

- Manoppo, F.J. Behaviour of the Ultimate Bearing Capacity of Single Flexible Batter Pile under Horizontal Loads in Homo-Geneous Sand. Din. Teknik Sipil 2010, 10, 116–119. [Google Scholar]

- Nazir, A.; Nasr, A. Pullout Capacity of Batter Pile in Sand. J. Adv. Res. 2013, 4, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Al-Neami, M.A.; Rahil, F.H.; Al-Bayati, K.S. Bearing Capacity of Batter Piles Embedded in Sandy Soil. Int. J. Geotech. Eng. 2016, 10, 529–532. [Google Scholar] [CrossRef]

- Iai, S. Similitude for Shaking Table Tests on Soil-Structure-Fluid Model in 1g Gravitational Field. Soils Found. 1989, 29, 105–118. [Google Scholar] [CrossRef]

- Rollins, K.M.; Peterson, K.T.; Weaver, T.J. Lateral Load Behavior of Full-Scale Pile Group in Clay. J. Geotech. Geoenviron. Eng. 1998, 124, 468–478. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).