1. Introduction

The most used control algorithm in the industry is PID control. It is widely used in various processes due to its tuning simplicity, good control performance, and robustness in a wide range of operating conditions. Disturbance-rejection and set-point tracking performance depends on controller tuning. In addition to typical tuning rules, such as Cohen–Coon, Chien–Hrones–Reswick, Ziegler–Nichols, or refined Ziegler–Nichols rules, more advanced methods have also been proposed. Usually, they use more complex algorithms to identify the processes [

1,

2,

3,

4,

5,

6].

Integrating systems contain at least one pole in the origin. Since they are not self-regulating, in the case of process input disturbance, process output might drift. Consequently, efficient control of integrating processes (IP) is a challenging task. There are different types of integrating systems that can be classified according to the number of poles in the origin and location of other poles in the transfer function. Integrating systems are frequently encountered in the industry. For example, representatives of industrial processes that exhibit pure integrator plus time-delay (ITD) transfer function models are oil–water–gas separators in the oil industry [

7], bottom-level control in a distillation column [

8], composition control loop of a high-purity distillation column [

9], heat-integrated distillation columns [

10], isothermal continuous copolymerisation reactors [

11], storage tanks with an outlet pump [

12], pulp and paper plants [

7], and high-pressure steam flowing to a steam-turbine generator in a power plant [

13]. First-order integrating systems with/without delay (IFOTD) can be encountered in liquid-storage tanks [

14], a jacketed continuous stirred tank reactor (CSTR) carrying out an exothermic reaction [

15], and paper-drum-dryer cans [

16].

Several tuning methods for IP have been developed so far [

17,

18]. They can be classified according to models of integrating systems, i.e., tuning methods for integrating systems with time-delay [

7,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28], for first-order integrating systems with time-delay [

18,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51], for higher-order integrating systems with time-delay [

52], and nonparametric tuning methods for integrating systems [

53,

54,

55,

56].

Tunings methods for integrating systems with time-delay can also be applied to a first- or higher-order integrating system by using a relay feedback identification method to model the system as an integrating system with time-delay [

21,

24,

26,

27]. The method of Mercader and Baños [

19] takes into account process uncertainties. The PD controller, based on the Smith predictor scheme with gain- and phase-margin specifications for an integrating-with-time-delay (ITD) process, was proposed by Chakraborty et al. [

21]. Raza et al. [

26] developed a tuning rule derived in terms of maximal sensitivity (M

S) that was based on pole-placement and frequency-response matching criteria. Visioli [

7,

20] proposed a three-state and PID controller structure to obtain a time-optimal set-point response. The process model is neatly calculated by the least-squares-based identification technique during a process set-point change. Therefore, the process model does not have to be known a priori, before changing the process set point.

Most tunings methods for first-order integrating systems with time-delay can also be applied in higher-order systems by approximating the process as an IFOTD model [

30,

32,

33,

34,

35,

39,

40,

43,

44,

45,

47,

48,

50,

51]. Controller design based on IMC PID tuning rules was proposed by Kumar and Padma Sree [

18], Skogestad [

39], Jin and Liu [

43], Panda [

41], Ghousiya Begum et al. [

35], and Najafizadegan et al. [

34]. The IMC filter time constant in the Kumar and Padma Sree [

18] method was chosen to set the trade-off between performance and robustness of tracking and control responses. Similarly, it was used to choose the robustness degree in the Jin and Liu [

43] method. Anil and Padma Sree [

44] developed a PID controller tuning method for IFOTD processes with or without additional process zero. The method is based on a pole-placement strategy, while the tuning parameter is the maximal sensitivity (M

S) value. This is similar for the Medarametla and Komanapalli [

32] method. Srivastava and Pandit [

31] developed a PID controller with a unique set-point filter that created a two-degrees-of-freedom (2-DOF) control system. Controller tuning is based on the linear quadratic regulator (LQR) using a dominant pole-placement approach to obtain a good regulatory response. Bingul and Karahan [

49] tuned a PID controller using particle-swarm-optimisation (PSO) and artificial-bee-colony (ABC) algorithms. Atic et al. [

51] proposed a tuning method where the controller parameters are determined by obtained stability-boundary loci. Controller parameters for IFOTD or unstable first- and second-order processes with time-delay in a discrete domain were developed by Wang et al. [

42]. A predictor-based 2-DOF control design was proposed by Wang et al. [

36]. The proposed control-system design was based on using a dead-time compensator (DTC) to predict non-minimal-phase (NMP) dynamics. Some of the tuning methods set the controller integrating gain to zero (Eriksson et al. [

38], Kuzishchin et al. [

46]). Those methods are not suitable for rejecting process input disturbances. A modified series cascade control structure (SCCS) with two PI and one P controller for a class of IP models with/without positive zero was proposed by Raja and Ali [

29]. PI and P controller parameters are obtained using the method of moments and Routh–Hurwitz stability criterion, respectively.

Papadopoulos [

52] proposed the tuning of PID controllers for general IP by using the symmetrical-optimum method. The method is effective for disturbance rejection, while it results in higher process output overshoots on reference changes.

Nonparametric controller-tuning methods are model-free (data-based), i.e., they directly exploit a set of closed- or open-loop-process data without requiring the use of a process model. Jeng [

53] proposed a PI/PID controller method that was based on the direct synthesis approach and specification of the desired closed-loop transfer function for disturbances. The set-point response can be independently improved by using set-point weighting in the PID controllers. Dey, Mudi, and Simhachalam [

54] developed an autotuning PD controller that adjusts proportional and derivative gains to achieve improved overall performance during set-point changes and load disturbances. Due to the lack of an integrator, the tuning rule is not suitable for rejecting process input disturbances. Mataušek and Šekara [

56] proposed PI and PID tuning rules on the basis of an extended Ziegler–Nichols experiment (besides ultimate gain and frequency, the steady-state gain and angle of the tangent to the process Nyquist curve at ultimate frequency should be obtained). Controller parameters are calculated by means of optimisation (solution of two nonlinear algebraic equations).

Most of the mentioned methods require the exact process model, they are limited to a few IP models, or the calculation of controller parameters requires optimisation.

One of the more sophisticated tuning approaches is the magnitude optimum (MO) method [

57,

58,

59]. The MO method can be applied to various processes frequently encountered in chemical and processing industries. Tracking and disturbance-rejection closed-loop responses are usually fast without oscillations [

60]. The applicability of the MO method has been extended by using a nonparametric approach in the time-domain instead of using explicit parametric identification of the process. The extension is based on multiple integrations of process input and output signals, and is hence called the magnitude optimum multiple integration (MOMI) method [

61]. The MOMI method extracts the required information from a simple time-domain experiment while retaining all advantages of the MO method [

60].

Since the original MO method was developed for stable (non-integrating) processes, the MOMI method cannot be used for IP. Namely, when using a one-degree-of-freedom (1-DOF) controller structure [

62], MO criteria result in integrating gain of the PI(D) controller equal to zero. Namely, proportional (P) and PD controllers are not capable of rejecting input disturbances. However, in the paper, we show that MO criteria can be met by using 2-DOF PI controllers, similar to the case when optimising disturbance-rejection performance [

60]. A 2-DOF controller implements reference weighting factor

b.

The advantages of an extension of the MOMI tuning method to integrating processes are a tuning formula in closed form for an IP of arbitrary order with delay, and the selection of the process data in the time-domain (given by the process open- or closed-loop time responses) or in the frequency domain (given by the arbitrary-order process transfer function). Moreover, the frequency- and time-domain approaches are equivalent, and the latter does not introduce any errors in the calculation of controller parameters (according to MO criteria). Reference weighting factor b allows users to emphasize either disturbance-rejection or reference following in a continuous matter. Besides the mentioned advantages, the extension provides efficient closed-loop control, while PI controller parameters calculation is still based on simple algebraic expressions, making it suitable for less demanding hardware, like slower PLC controllers.

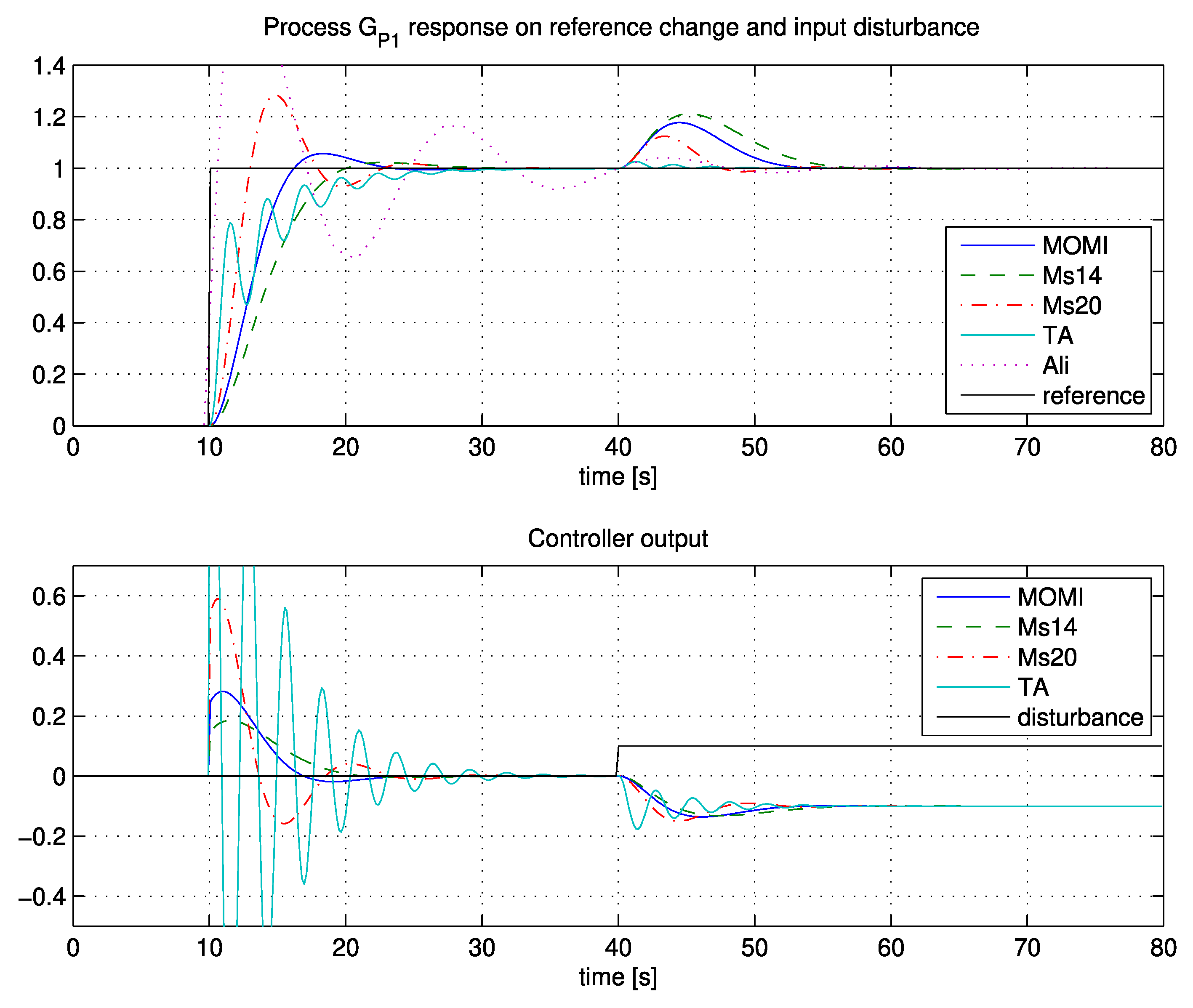

The content of this paper is organised as follows. First, the MOMI tuning method for IP is presented. In

Section 3, the stability and robustness of the MOMI tuning method are evaluated.

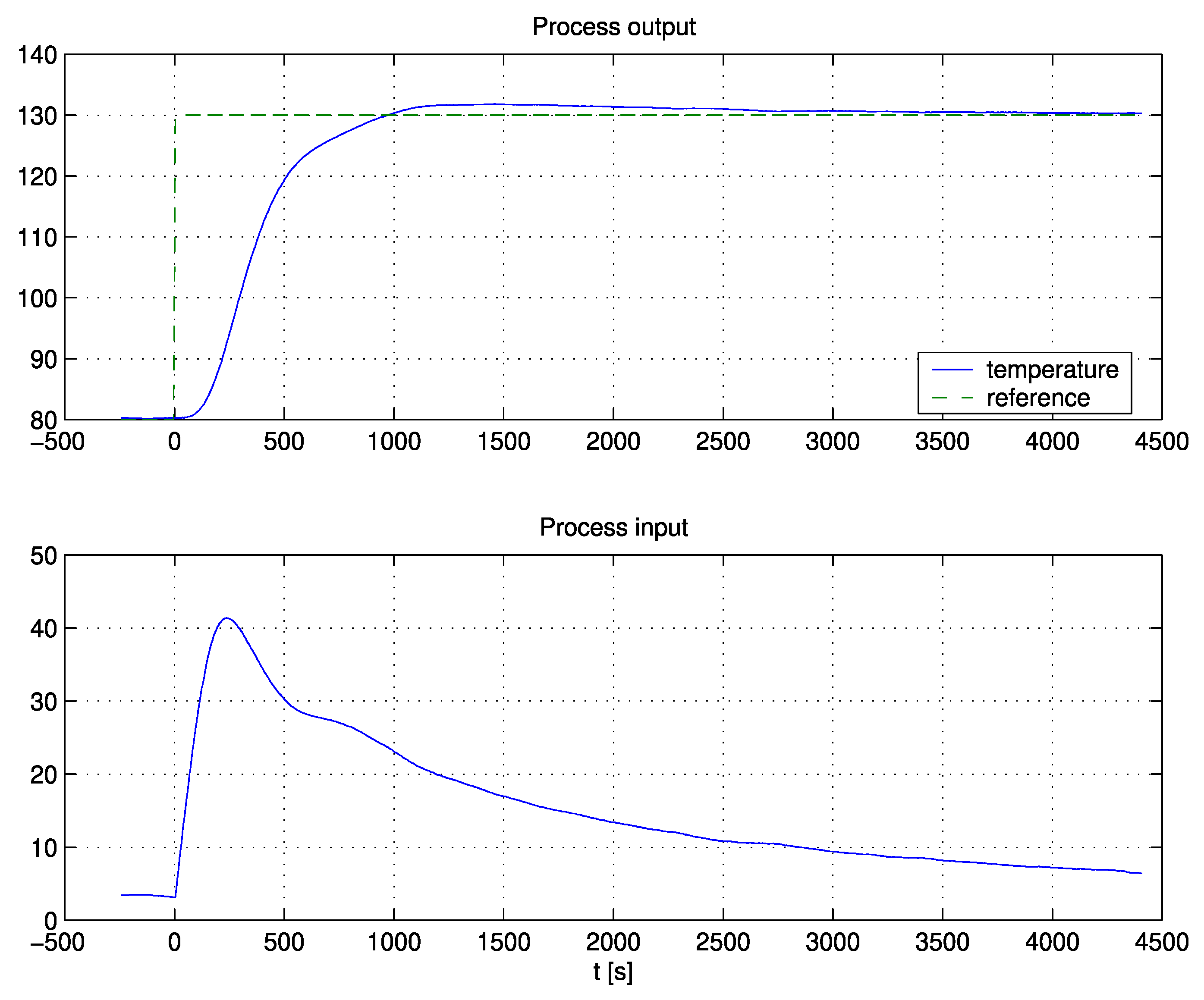

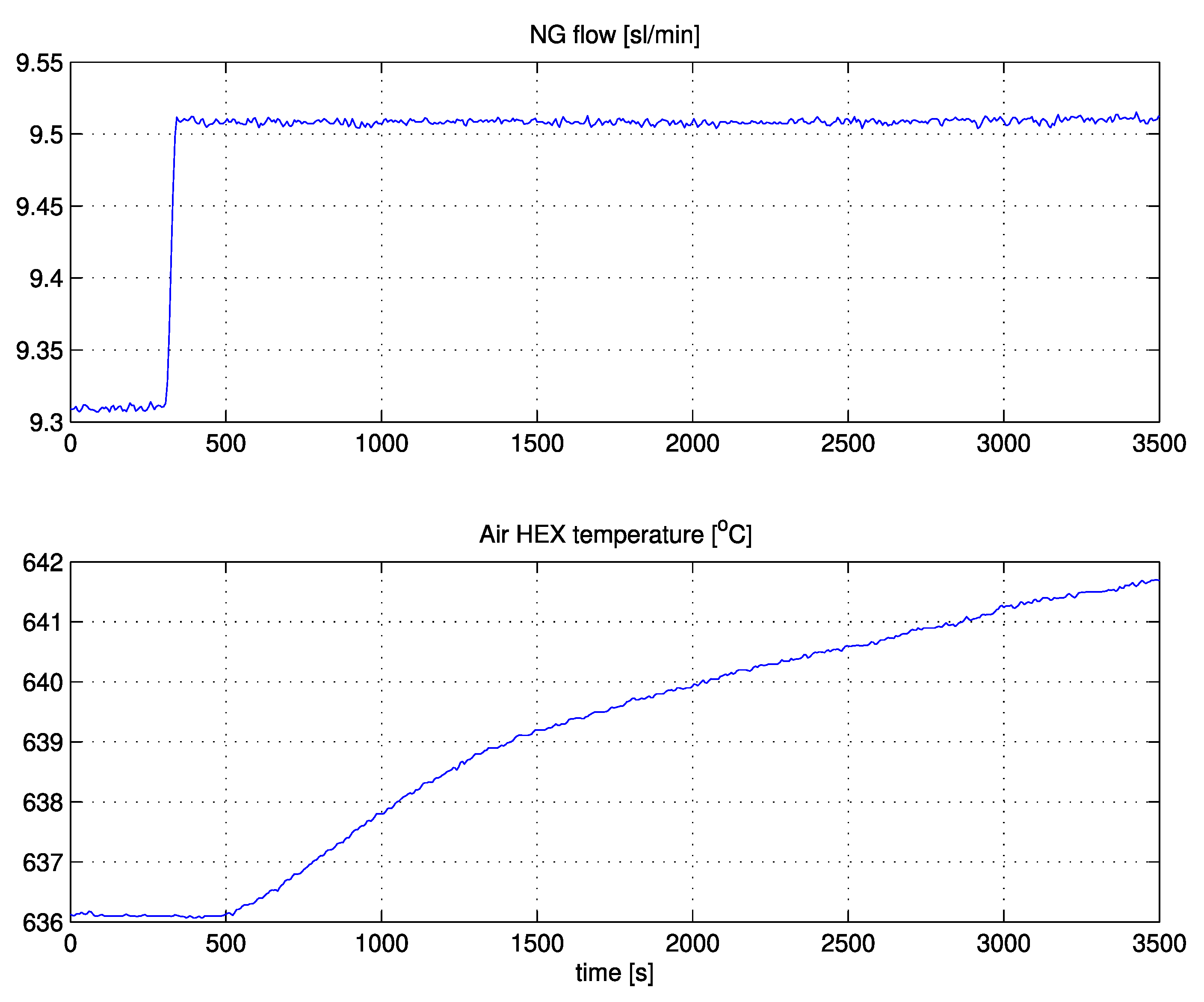

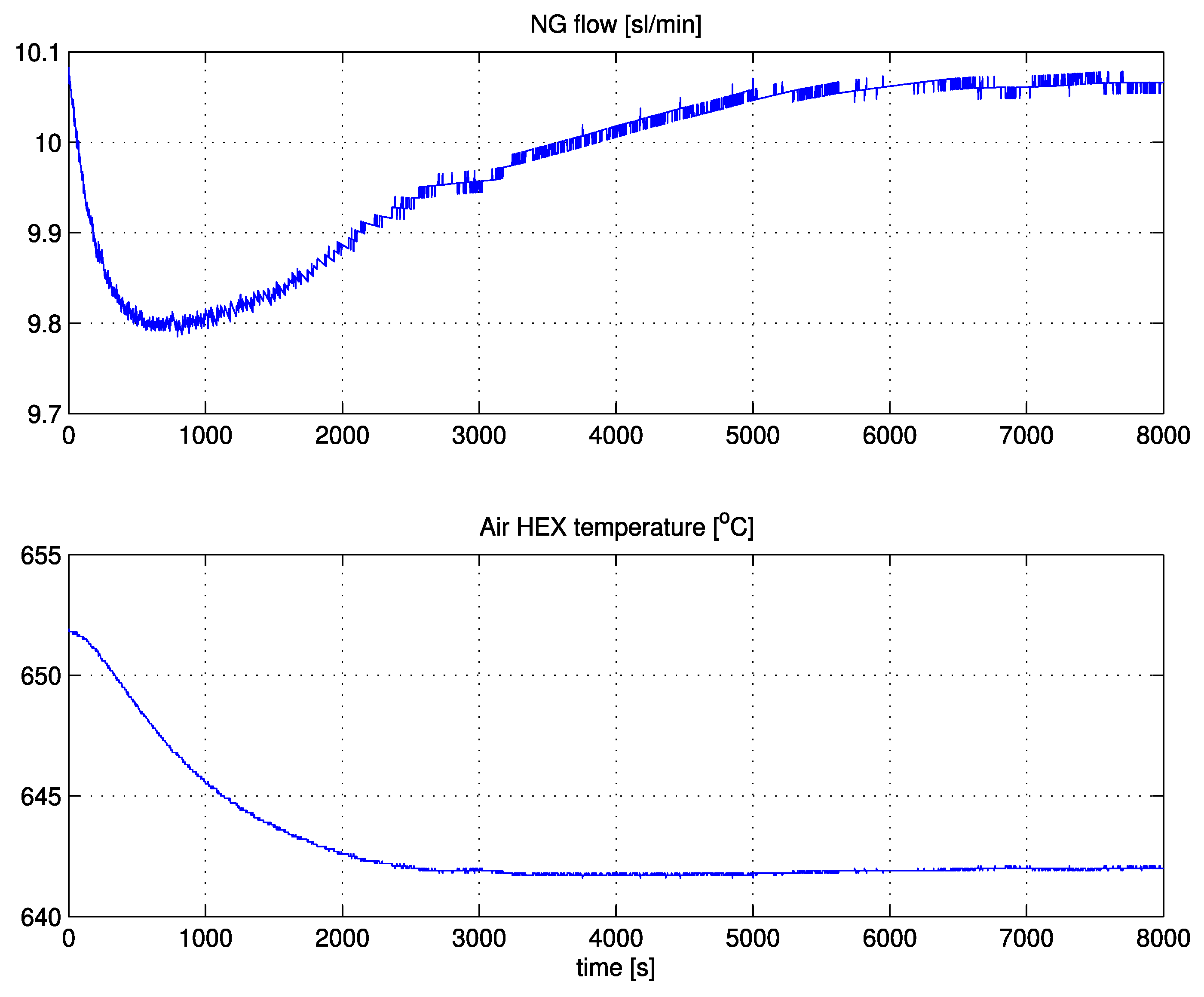

Section 4 provides examples on several different process models and compares the proposed method to other tuning methods made for IP. Real-time experiments in the time-domain on a charge-amplifier drift-compensation system, a laboratory plant, on an industrial autoclave, and on a solid-oxide fuel-cell temperature control are outlined in

Section 5.

2. MOMI Tuning Method for Integrating Processes

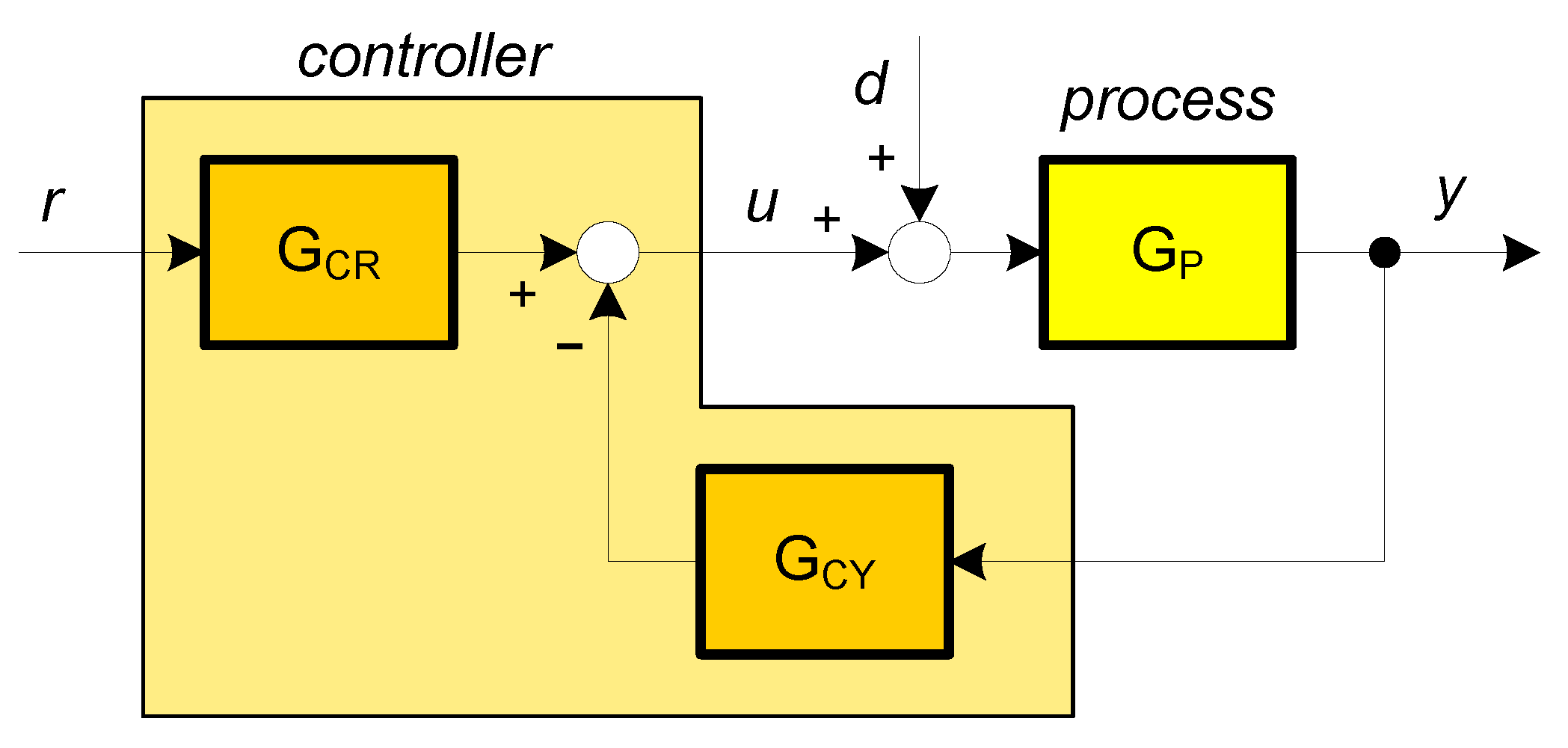

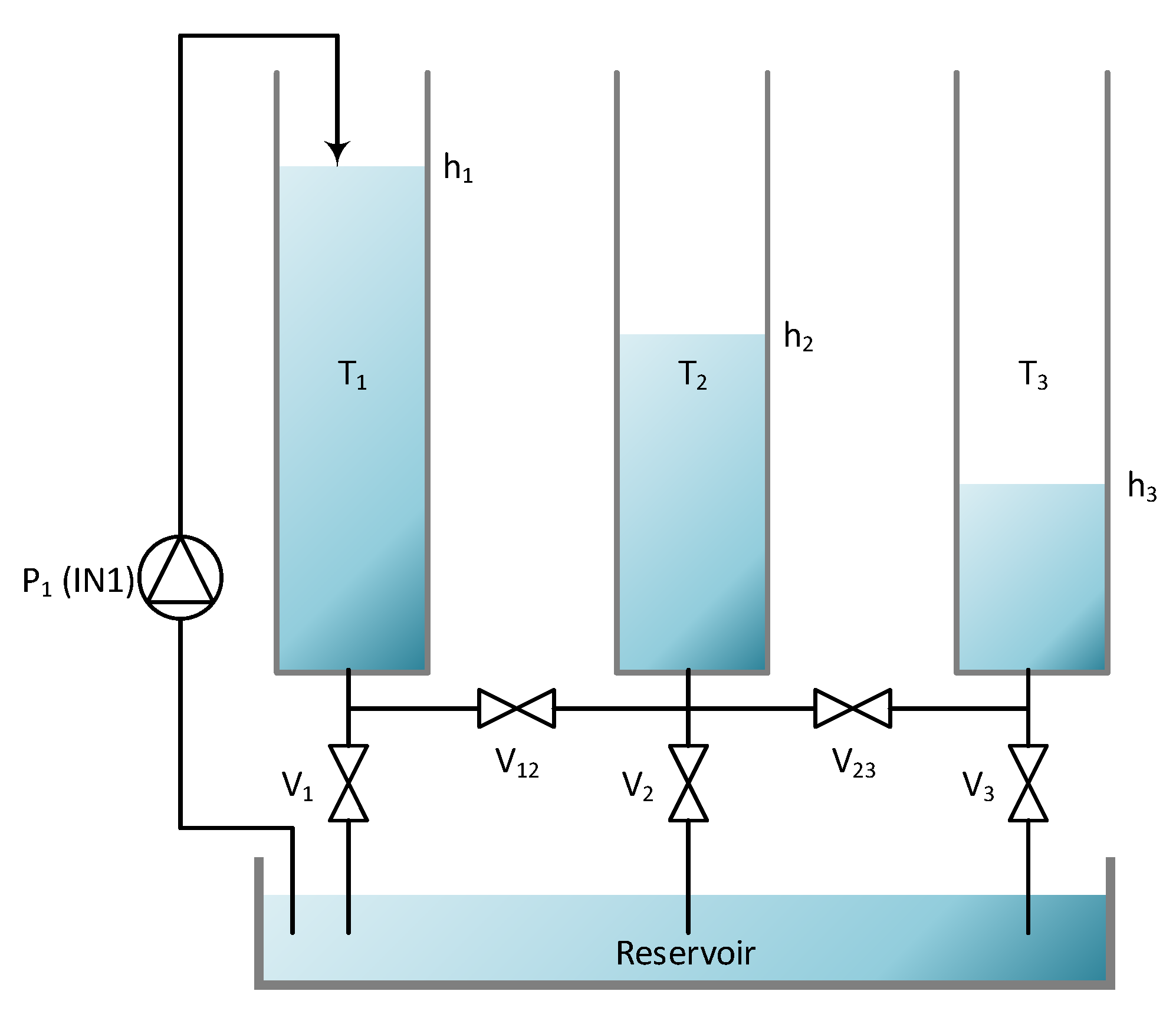

The process in a closed-loop configuration with a 2-DOF controller is presented in

Figure 1. Signals

d,

y,

r, and

u represent input disturbance, process output, controller reference, and controller output, respectively.

The stable process was modelled with the rational transfer function:

where

Tdelay represents the time-delay. According to [

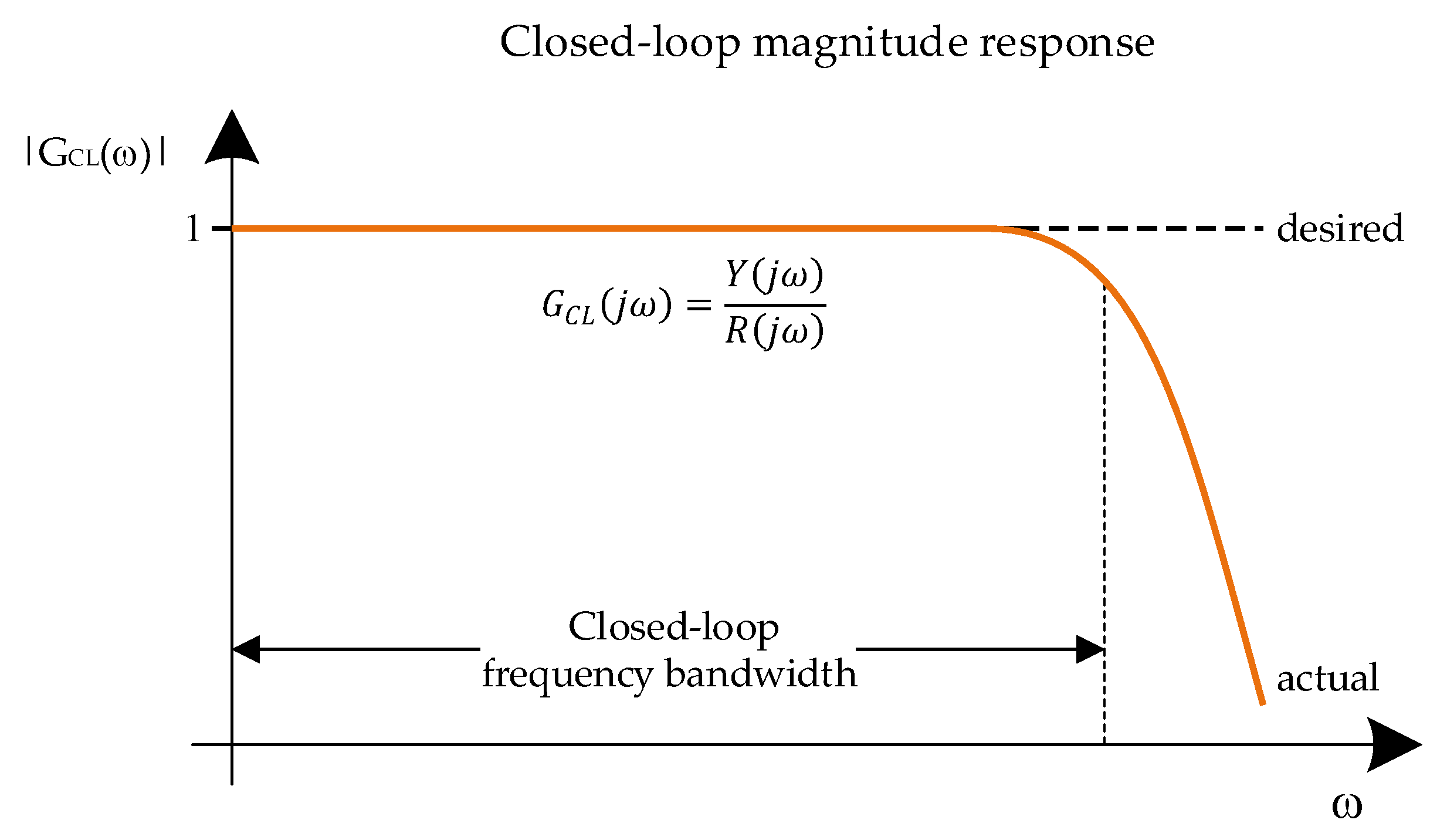

58], “one possible design aim is to maintain the closed-loop magnitude response curve as flat and as close to unity for as large a bandwidth as possible” (see

Figure 2).

This technique is called magnitude optimum (MO), modulus optimum, or Betragsoptimum, and results in a fast and non-oscillatory closed-loop time response for a large class of process models [

60].

If we have closed-loop transfer function

the controller is determined in such a way that

for as many

k as possible [

58,

61]. The fulfilment of Equation (3) is simple. When using the controller structure containing an integral term, the steady-state control error becomes zero (under the condition that the closed-loop response is stable). Controller order (number of controller parameters) impacts the number of satisfied conditions in Equation (4).

If the closed-loop transfer function is described by equation

then Expressions (4) can be met by satisfying the following conditions [

60]:

The next step is the calculation of the 2-DOF PI controller parameters. A controller may be defined by the next transfer functions:

where

b,

KP, and

Ki are the reference weighting factor, proportional gain, and integral gain, respectively. In order to simplify subsequent derivations, let us develop Process (1) into an infinite Taylor series [

61]:

where

Ai represent the so-called “characteristic areas” of the process [

60]. The areas can be expressed by process Parameters (1) in the following way [

58]:

By applying Expressions (7) and (1) to Expression (2), the following closed-loop transfer function parameters (5) are obtained:

In order to calculate two PI controller parameters, the first two equations in Conditions (6) should be satisfied. The first condition in (6) gives the following result:

and the second condition in (6) results in

The controller gain (

KP) can be calculated by equating Expressions (12) and (13):

where

Remark 1. If either reference weighting factor b is close or equal to 1, or the value of ξ in Equation (15) approaches zero, proportional gain KP can be calculated by developing the expression under the square root in Equation (14) into a Taylor series. In this case, the proportional gain becomes However, if b = 1 (1-DOF PI controller), integral Gain (12) becomes Ki = 0, and we obtain a proportional (P) controller. Therefore, disturbance-rejection performance is degraded when increasing the value of factor b. The influence of factor b on tracking and disturbance-rejection performance is shown through an illustrative example in Section 2.1.

Remark 2. While Expressions (12) and (14) result in stable and fast closed-loop responses for a large majority of IP models, closed-loop stability is still not guaranteed for an arbitrary process model. Closed-loop stability and robustness are discussed in detail in Section 3.

Therefore, PI controller parameters can be expressed in terms of characteristic areas or process parameters by using Expression (9). However, characteristic areas can also be calculated from the process time response while changing the process steady state. To this end, the multiple integrations of the process input (

u(

t)) and output (

y(

t)) signals should be calculated [

58,

61]:

where

u0 is normalised process input signal, and

The areas are expressed as follows:

where

. In practice, integration time can be limited. The integration can be terminated when the process input and output signals in Equation (17) settle. Therefore, Equation (17) can be easily and recursively calculated in practice, and process Model (1) is not required [

58,

62,

63].

The controller tuning steps are as follows:

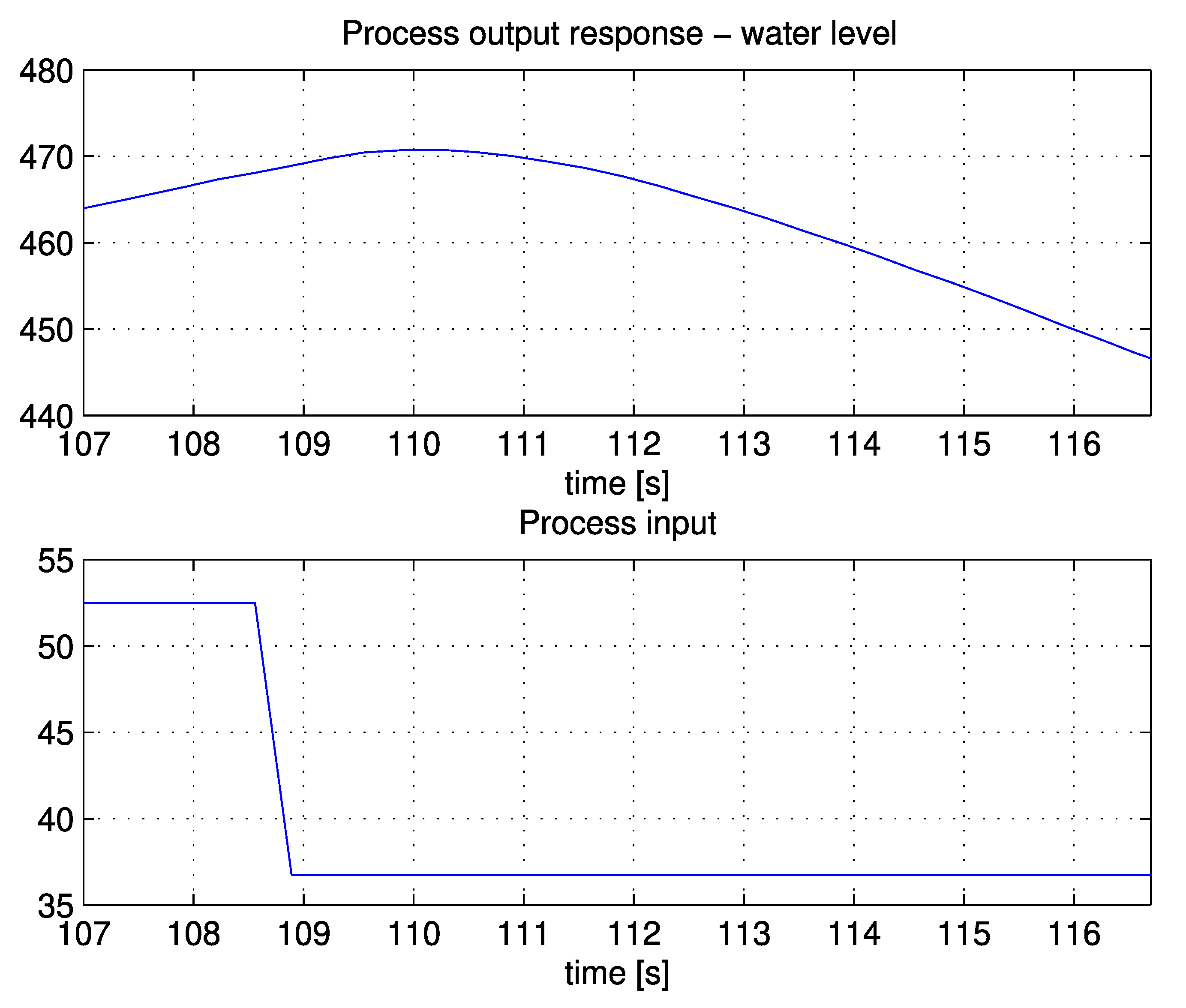

Determine characteristic areas from Expression (9) if the process model is known. Otherwise, modify the process steady state. During the process transient response, sample the controller and process output signals. Areas A0 to A2 are calculated from Expressions (17)–(19). The initial values of the process input and output signals can be estimated by averaging them before the change of the controller output signal.

Choose appropriate reference weighting factor 0 ≤ b < 1.

Calculate controller parameters according to Equations (12) and (14).

All MATLAB and Simulink files required for controller parameters calculation are electronically accessible [

63].

Remark 3. Proportional gain KP for a second-order IP (bn = 0, a3-an = 0) can be calculated by the following expression:where Integral gain Ki can be calculated from Expression (12) when taking into account that A0 equals KPR: When calculating PI controller parameters for a first-order process, a2 in Expression (21) is replaced by 0.

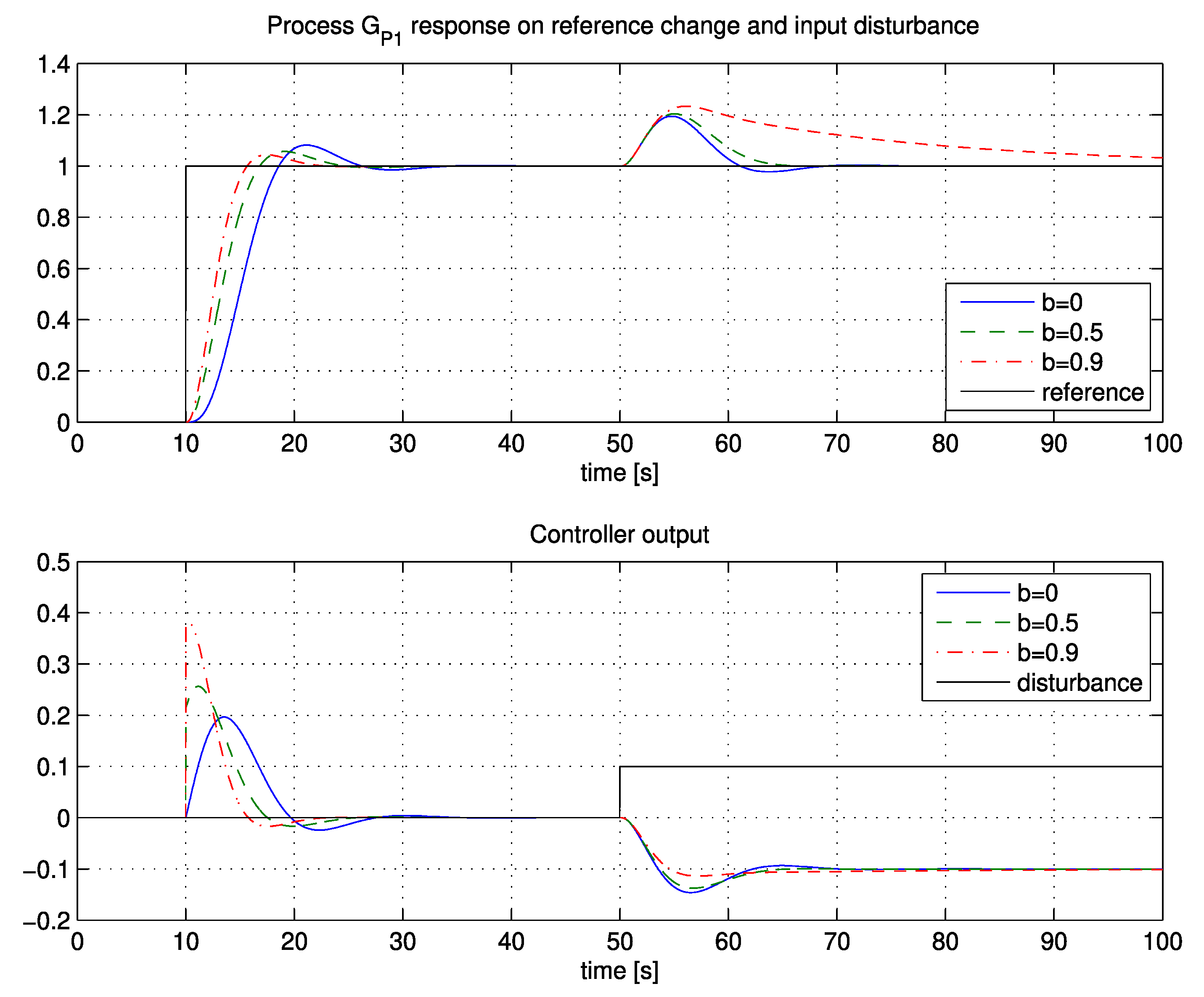

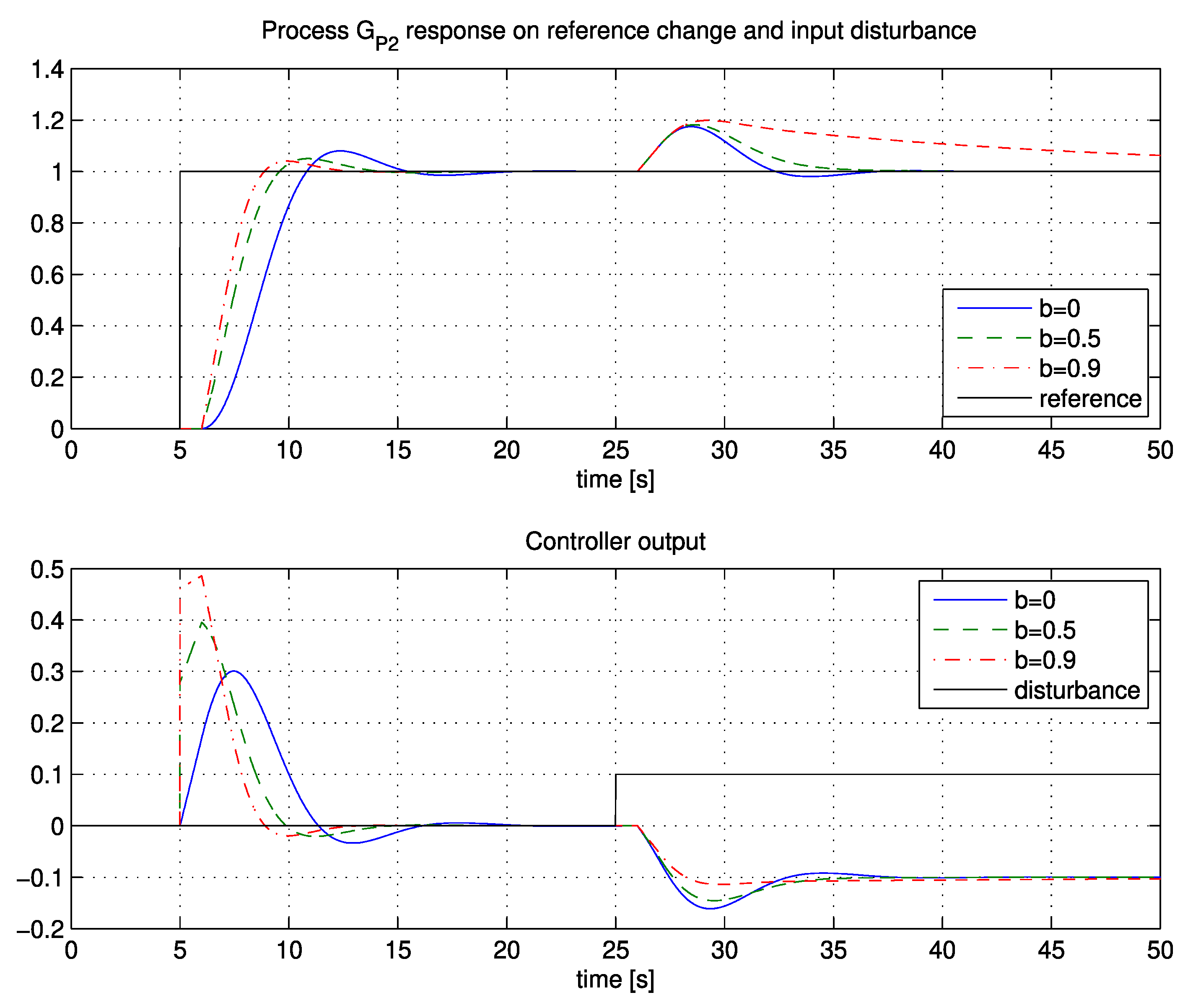

2.1. Illustrative Example

For the illustrative example, a second-order IP was selected:

Characteristic areas were calculated from Expression (9):

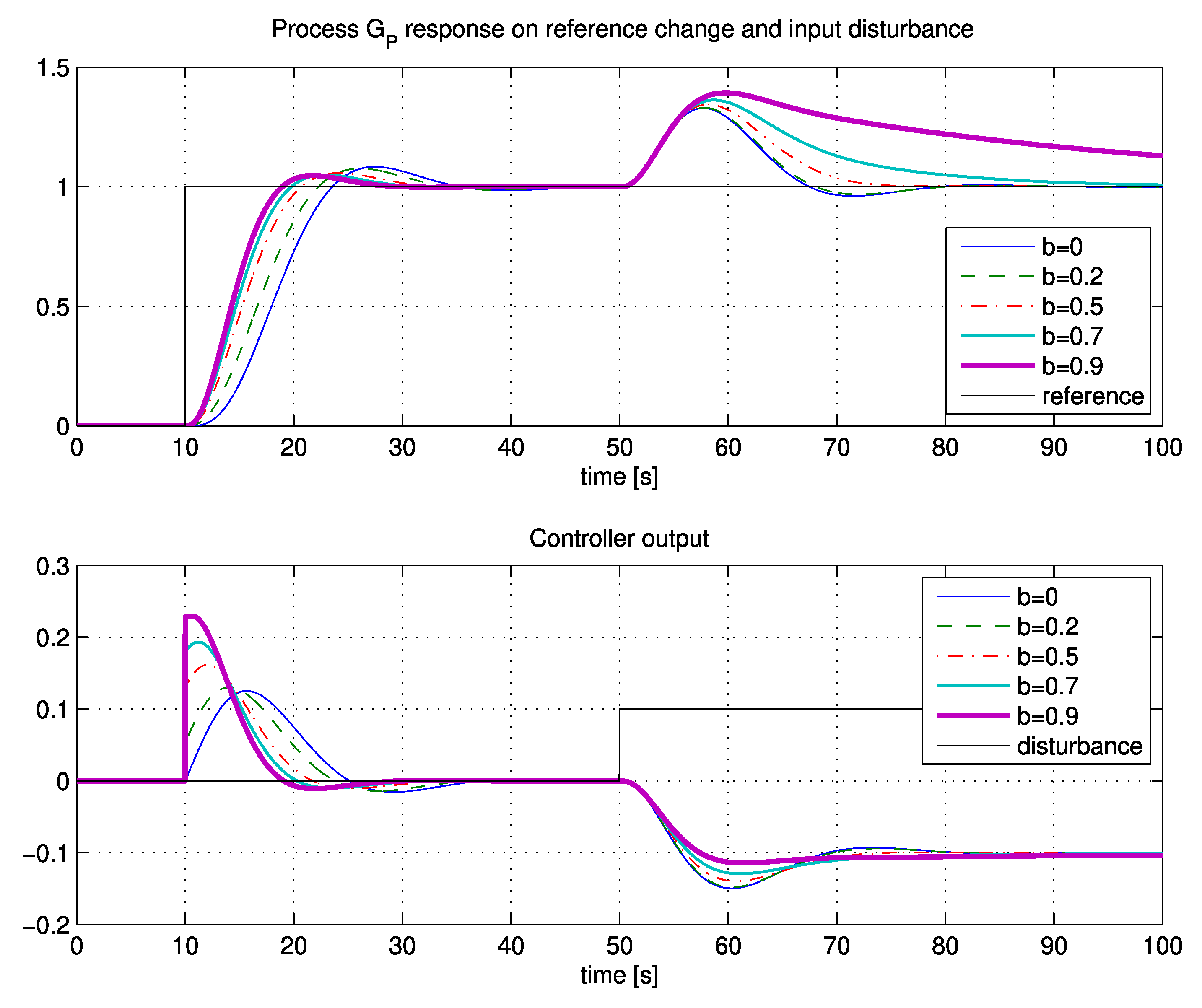

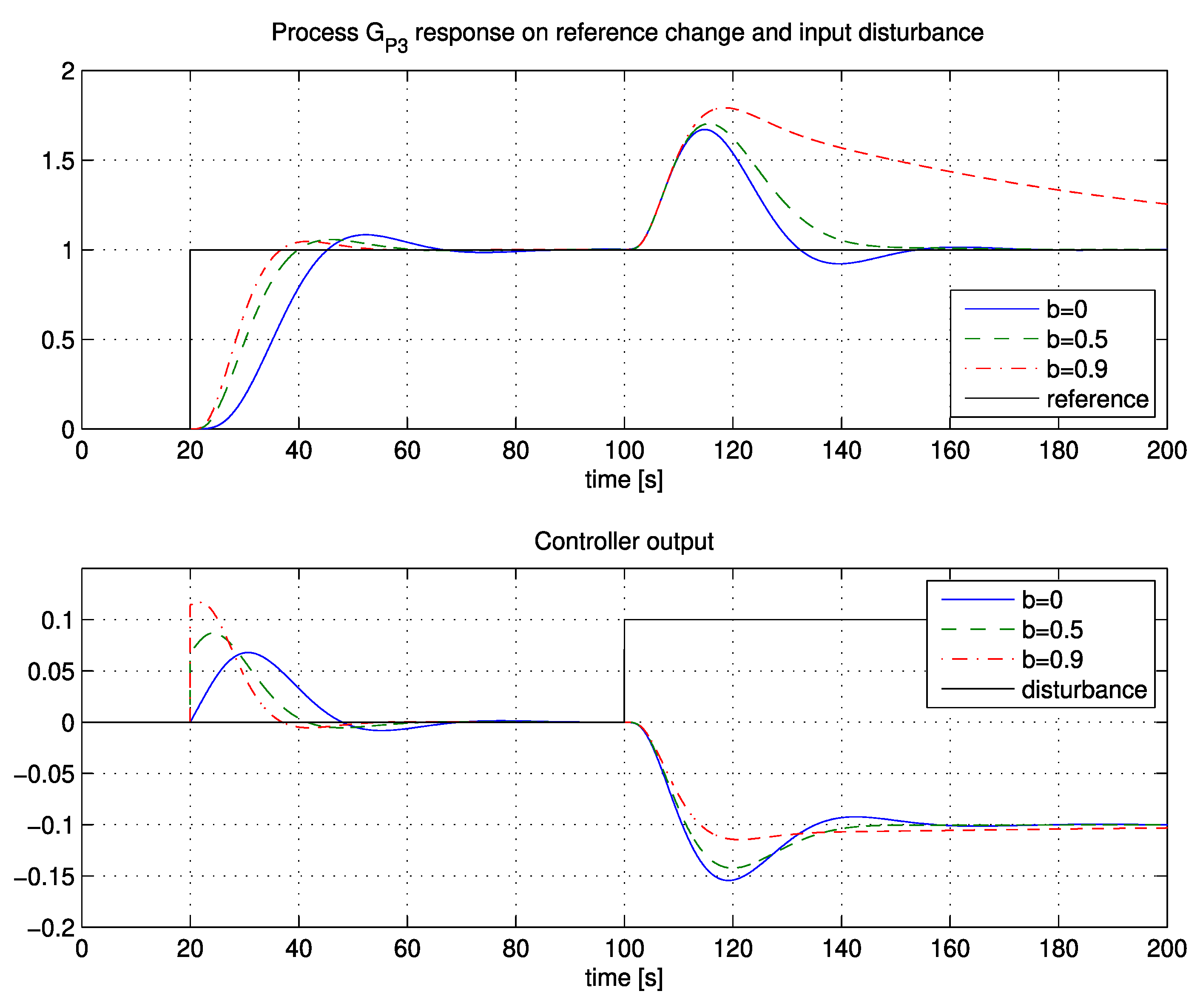

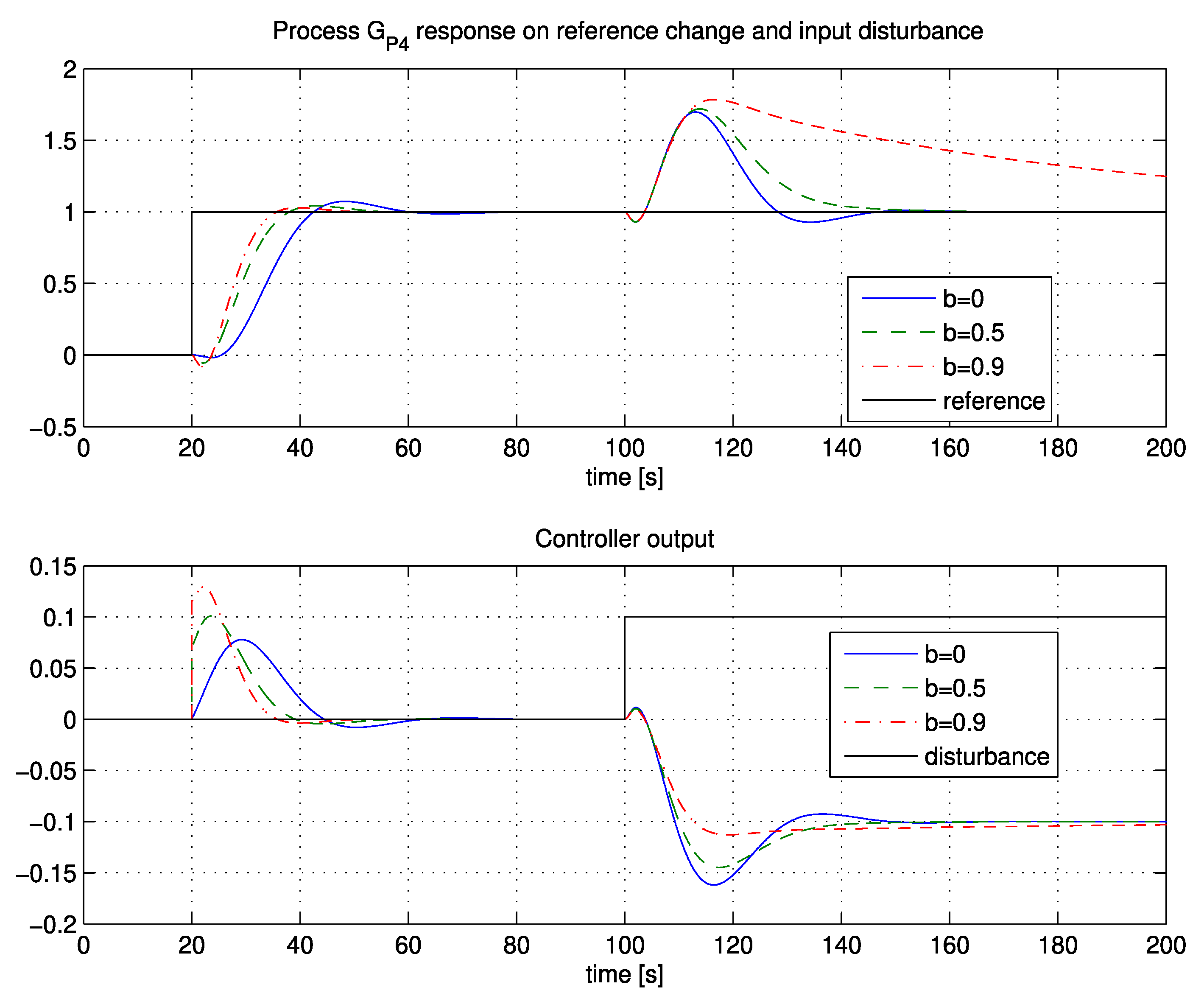

The PI controller parameters, presented in

Table 1, were calculated from Expressions (12) and (14), or by Expressions (20) and (22). Parameters were calculated for different values of reference weighting factor

b. The closed-loop responses for the input disturbance and for the reference change when applying a 2-DOF PI controller are shown in

Figure 3.

As seen from

Figure 3, tracking and disturbance-rejection performance are correlated with factor

b. The reference following performance increases by increasing factor

b. Therefore, if tracking performance is the most important, select a value of

b ≥ 0.7. On the other hand, the best disturbance-rejection performance is achieved with

b ≤ 0.2. A good compromise between reference following and disturbance-rejection performance is

b = 0.5.

Remark 4. The best overall response (optimal reference-tracking and disturbance-rejection) could be obtained by using a higher-order reference pre-filter instead of reference weighting factor b, similar to the proposed solution for non-integrating processes [64]. In this case, controller parameters should be the same as the ones calculated with b = 0, while pre-filter parameters should be adjusted so as to achieve the most optimal tracking response. However, such a solution would require calculating a relatively precise process model, and controller realisation would become much more complex, which is in contrast to the simplicity of the presented tuning method. 3. Stability and Robustness

Stability can be assessed from closed-loop characteristic polynomial

where process model

GP is given by Expression (8), and controller

GCY by Expression (7). It follows that

Considering Condition (25), the necessary (but not sufficient) condition that all poles of the characteristic polynomial are in the left half plane is that coefficients of Equation (26) are positive. Consequently, the necessary conditions for closed-loop stability are

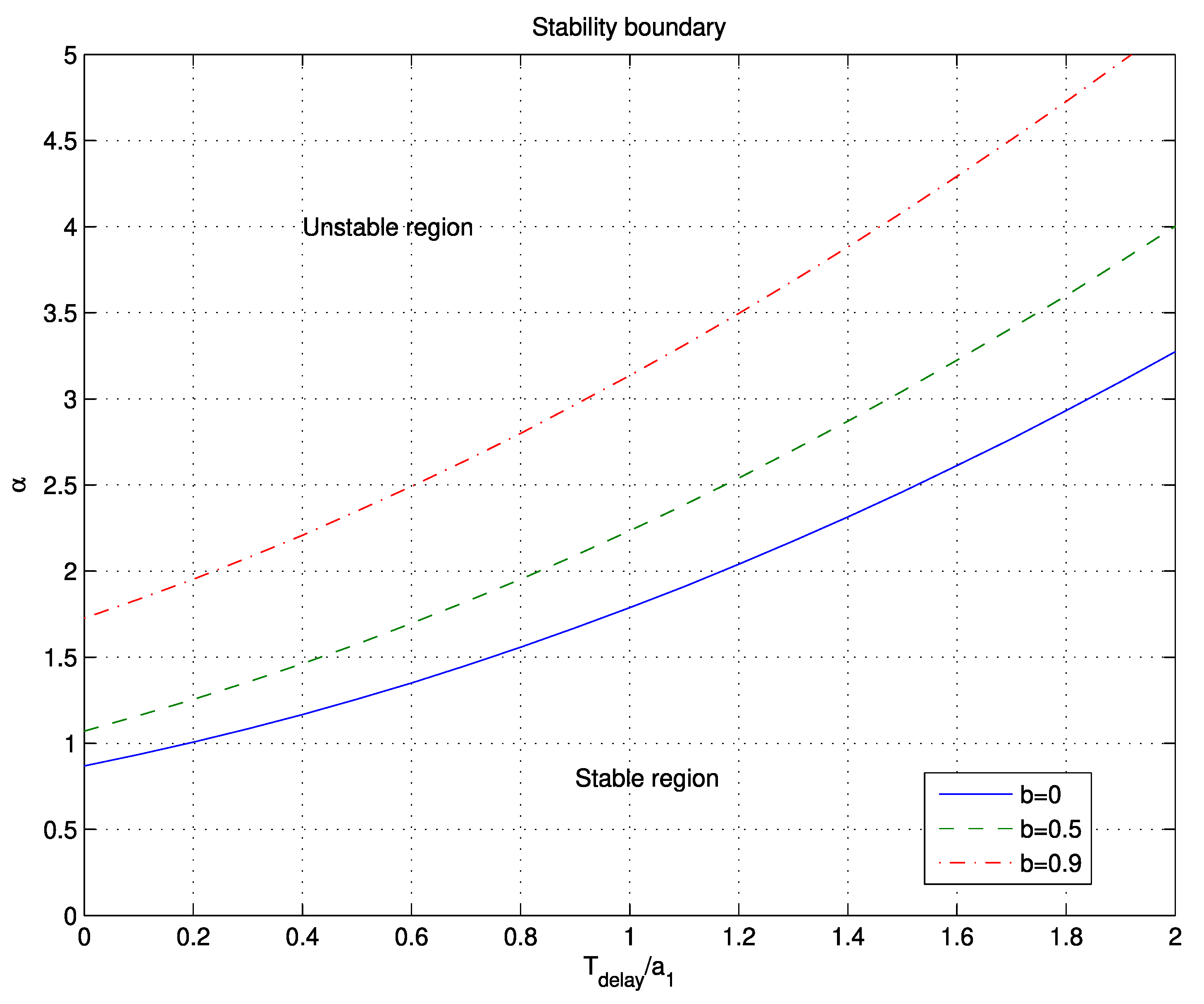

Sufficient stability conditions might be established by testing the Routh determinants. However, introducing pure time-delays into the process transfer function makes such analysis difficult or even impossible. Therefore, closed-loop stability and robustness were studied in detail on the following process model:

The process (G(s)) represents the first- or second-order integrating system with or without time-delay. The stability and robustness of the closed-loop system when applying the proposed tuning method depend on the ratio between parameter a1 and Tdelay, parameter α, and on chosen parameter b. Processes with real poles have α ≤ 0.25.

The closed-loop system is stable for any chosen time-delay and controller parameter

b (between 0 and 1) if ratio

α < 0.869. Therefore, the closed-loop response is stable for all processes with real poles, or with moderate complex conjugate poles (up to

α < 0.869). Stability improves by increasing time-delay and controller parameter

b (see

Figure 4).

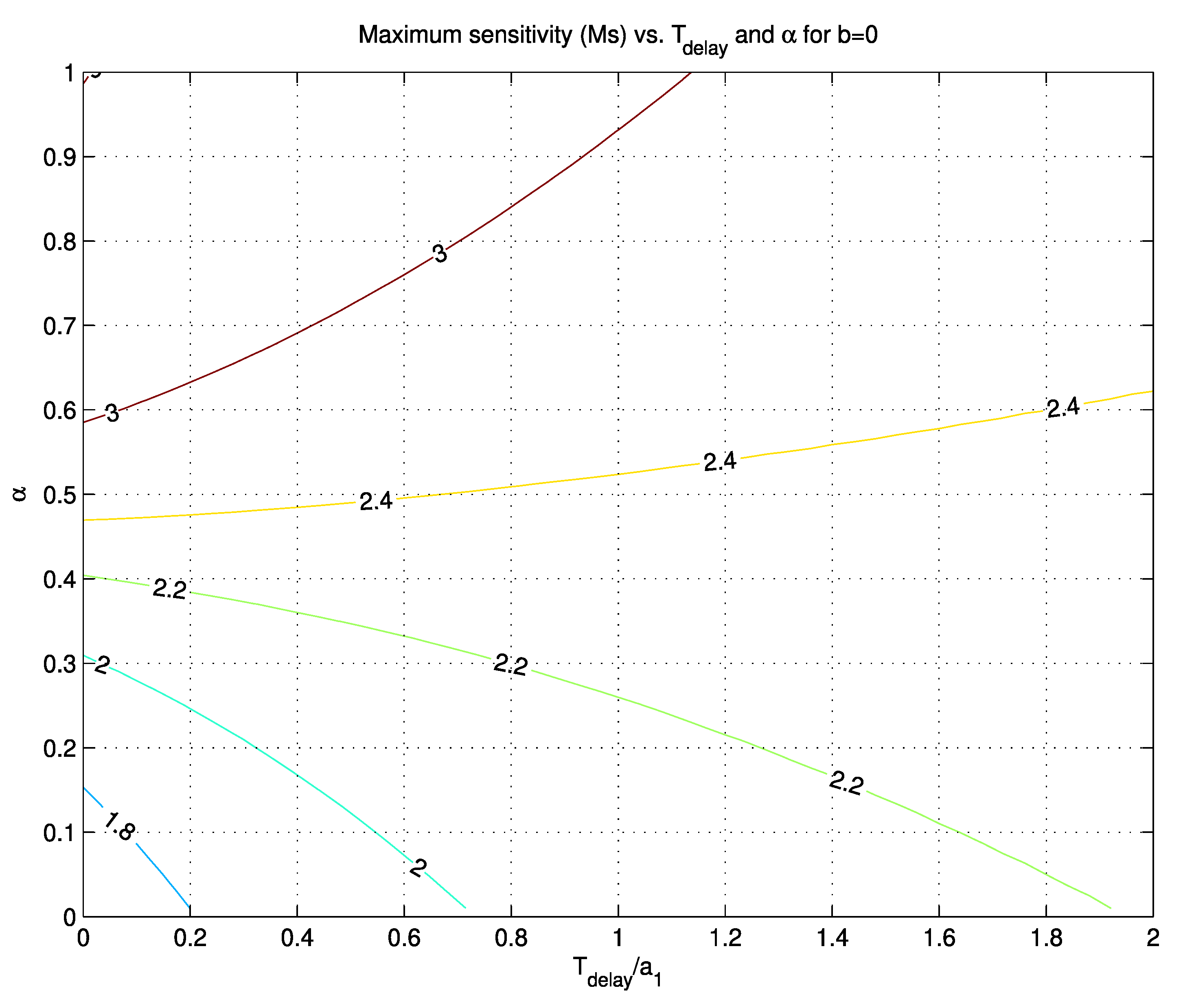

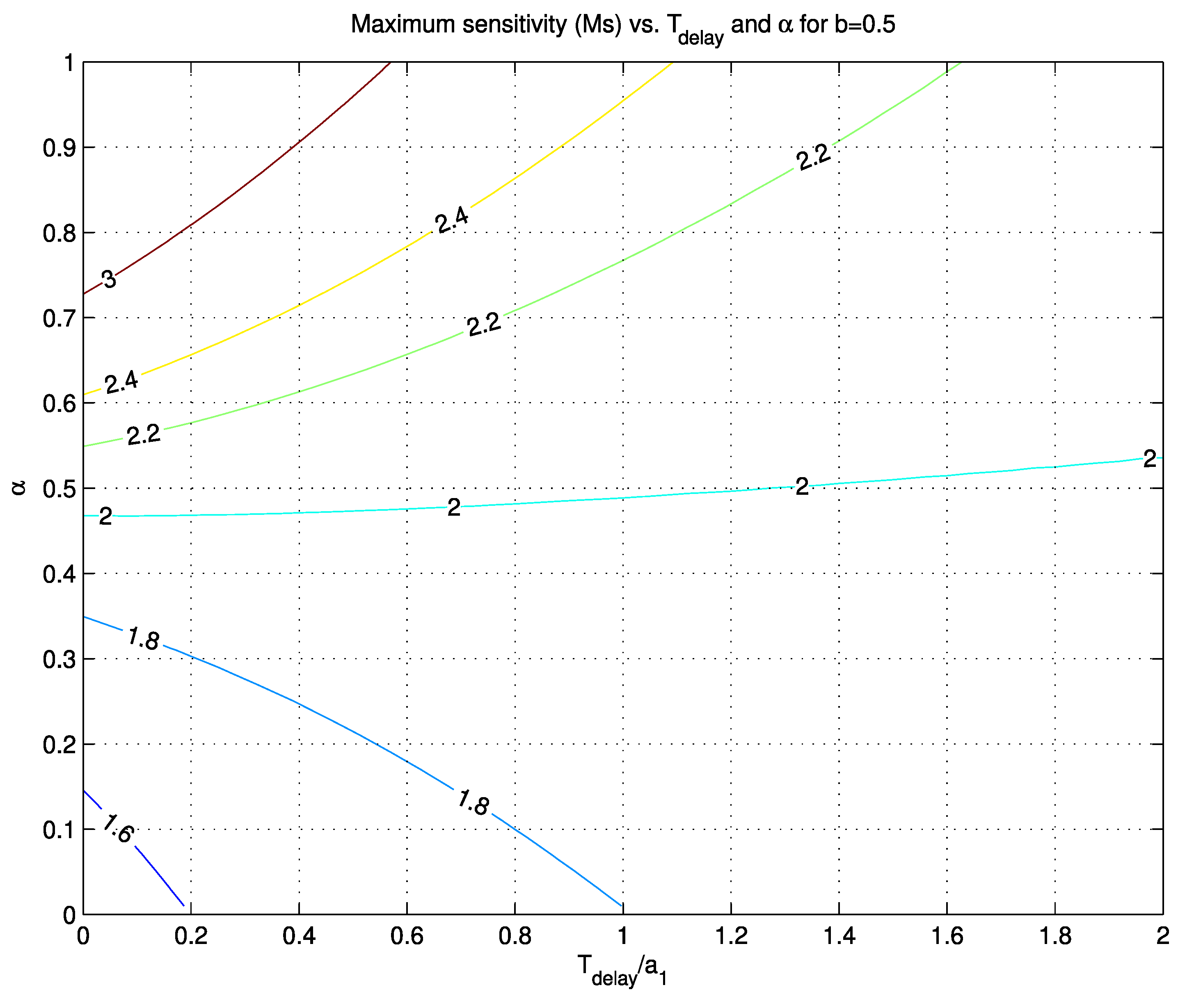

The robustness of the tuning method was evaluated by measuring the maximal sensitivity of the system (M

s) [

1]. Parameter M

s represents the inverse of the shortest distance of open-loop transfer function G

PG

CY Nyquist curve to critical point –1. Larger M

s values denote a less stable system. Usual design values for M

s are in the range of 1.4–2 [

1].

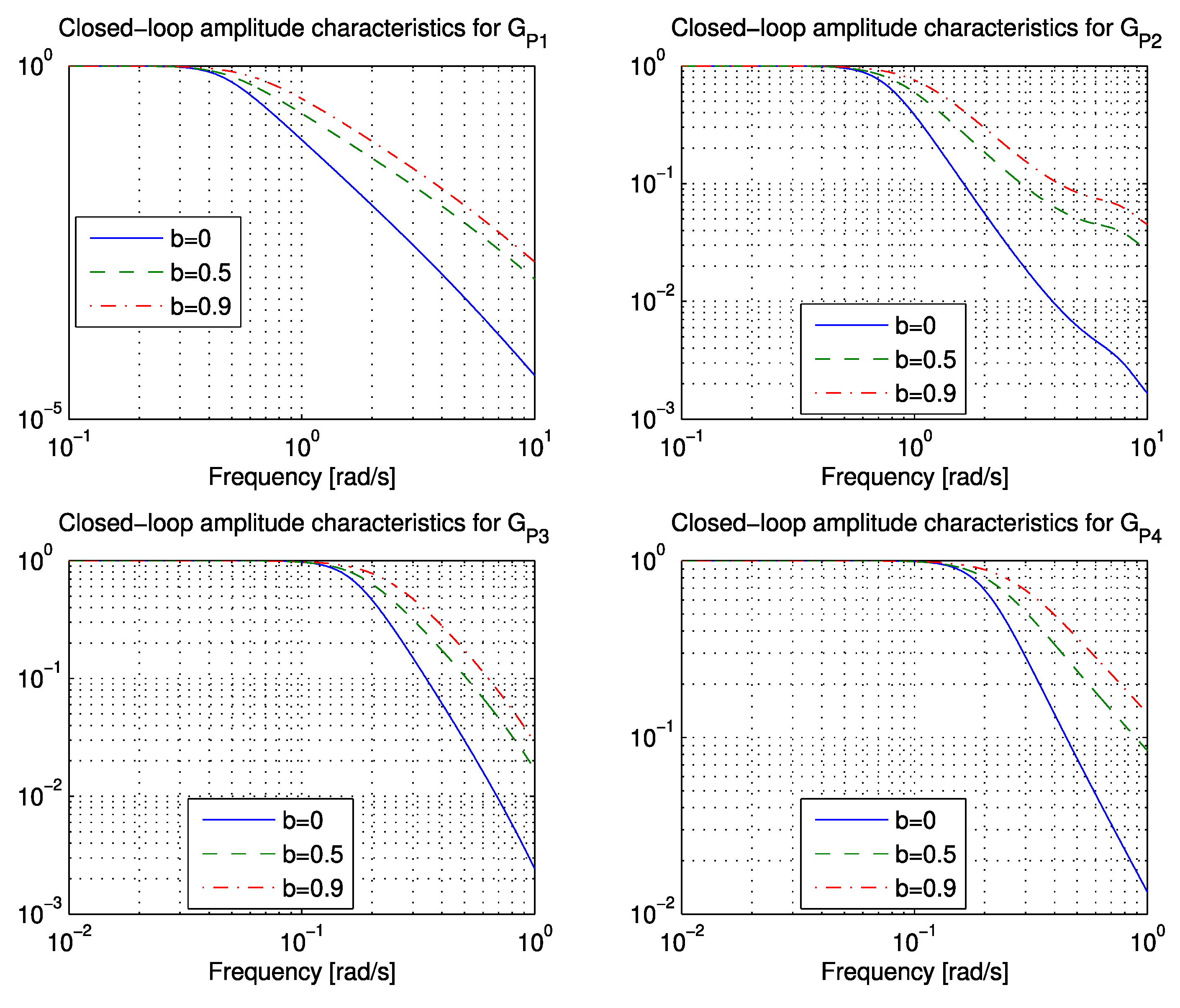

M

s values, obtained for controller parameters calculated at

b = 0,

b = 0.5, and

b = 0.9, are shown in

Figure 5,

Figure 6 and

Figure 7, respectively. For processes with real poles (

α ≤ 0.25), expected M

s values were approximately between 1.7 and 2.3 for

b = 0, between 1.5 and 1.9 for

b = 0.5, and between 1.3 and 1.7 for

b = 0.9 (upper values of M

s were obtained for highly delayed processes). Expected closed-loop robustness is therefore relatively high for a variety of process models.

6. Discussion

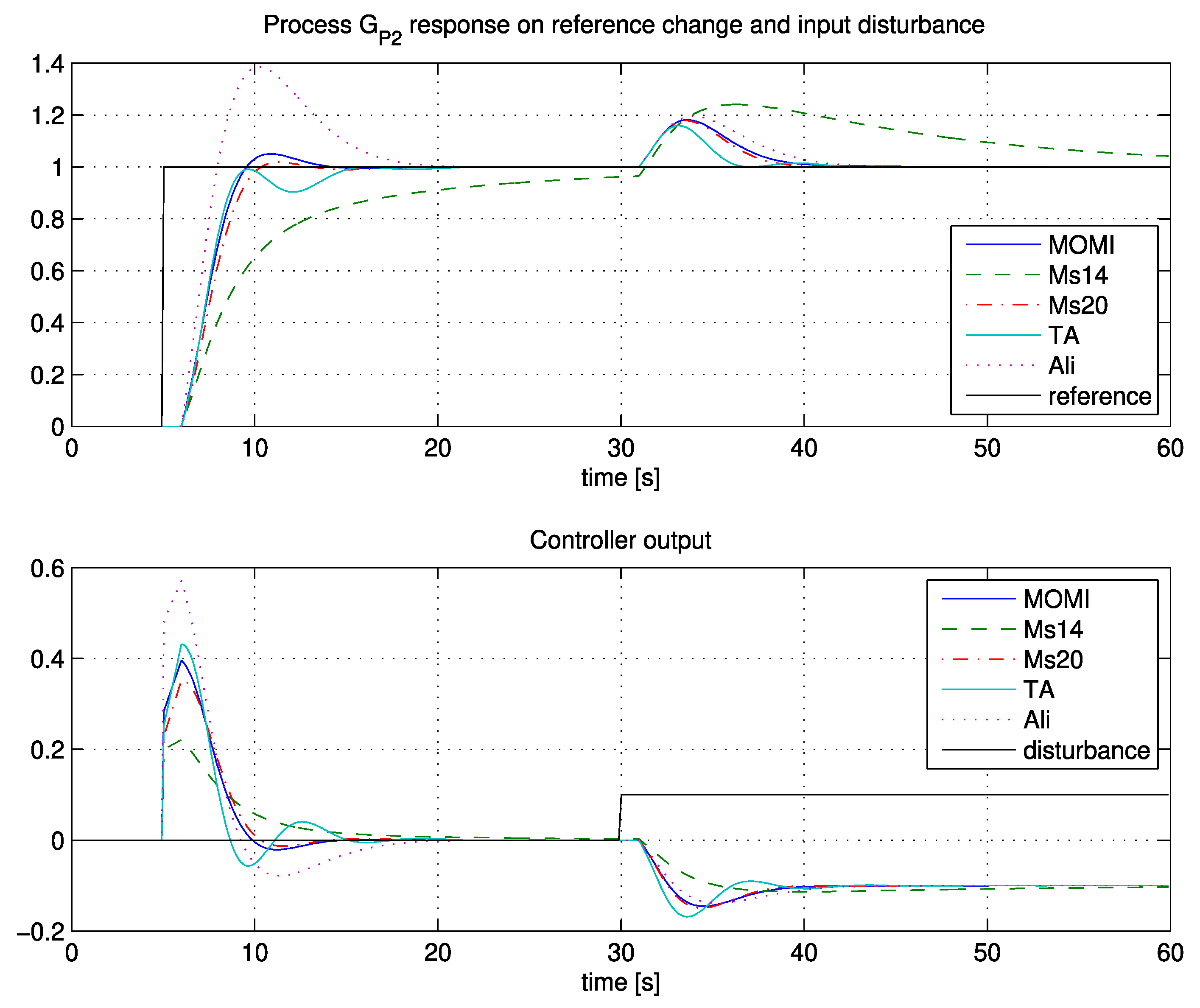

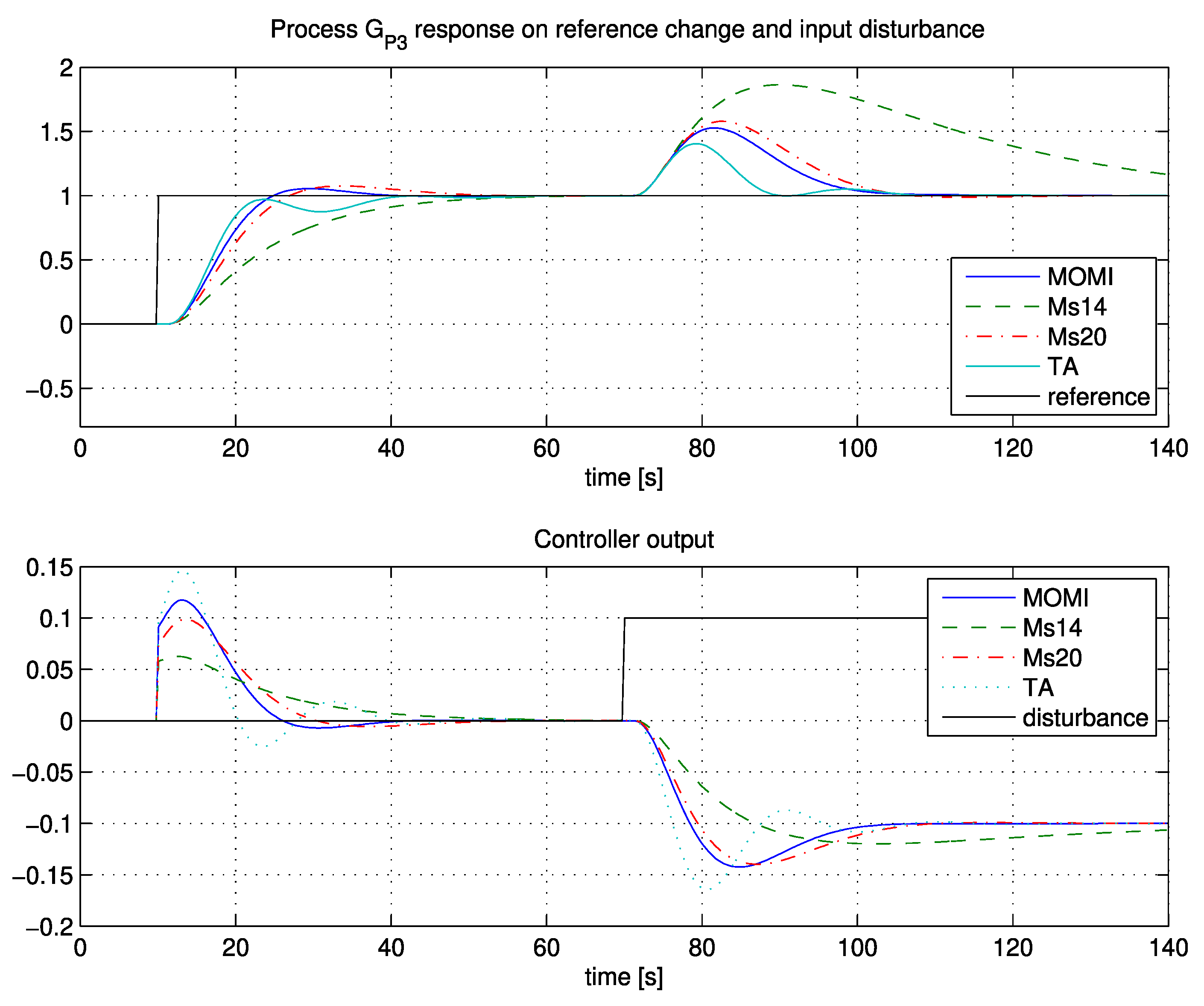

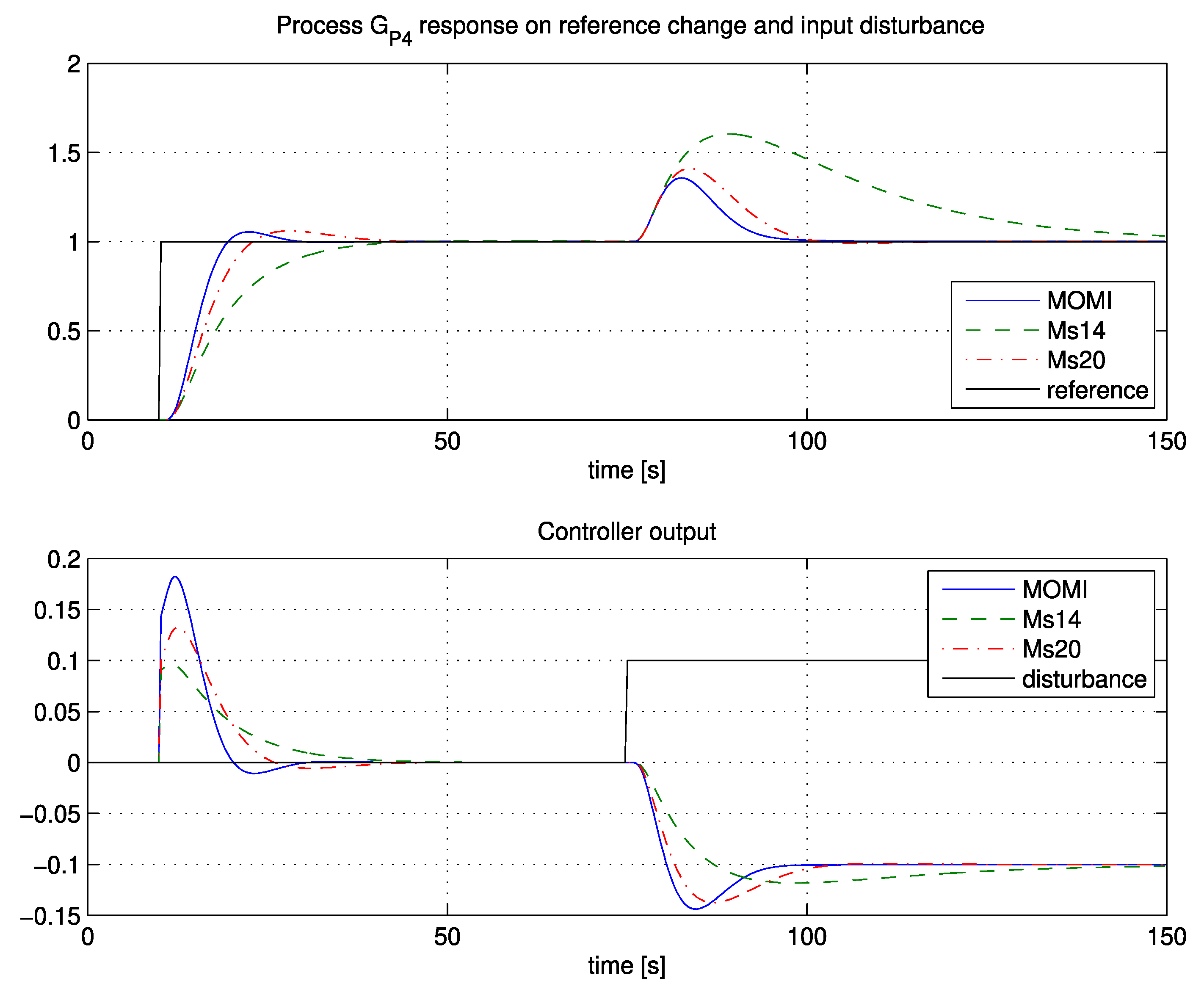

Adoption of the MOMI tuning method for integrating processes (IP) was presented in this paper. The closed-loop responses on several different IP models showed that the proposed method resulted in relatively fast closed-loop responses while retaining system stability. Furthermore, the proposed method was also compared to existing tuning methods that are suitable for IP. By using simulated examples, the two distinctive advantages of the proposed method over existing approaches were shown, namely, the closed-loop responses were evaluated by 5% settling time and the ITSE criterion. The comparison with other methods revealed that the proposed method was very good.

Another advantage is that the MOMI method does not require an explicit process model. Besides the calculation of the controller parameters from the general transfer function with pure time-delay, a process open- or closed-loop time response can also be used to calculate the controller parameters. Moreover, both approaches were equivalent, and the latter did not introduce any error in the calculation of controller parameters. Since the computation of the controller parameters is based on relatively simple analytical equations (in the frequency- or time-domain), the proposed tuning method for IP is useful in practice, especially for less-demanding hardware like simpler PLC controllers. Furthermore, reference weighting factor b allows users to emphasise disturbance rejection, reference following, or something in between.

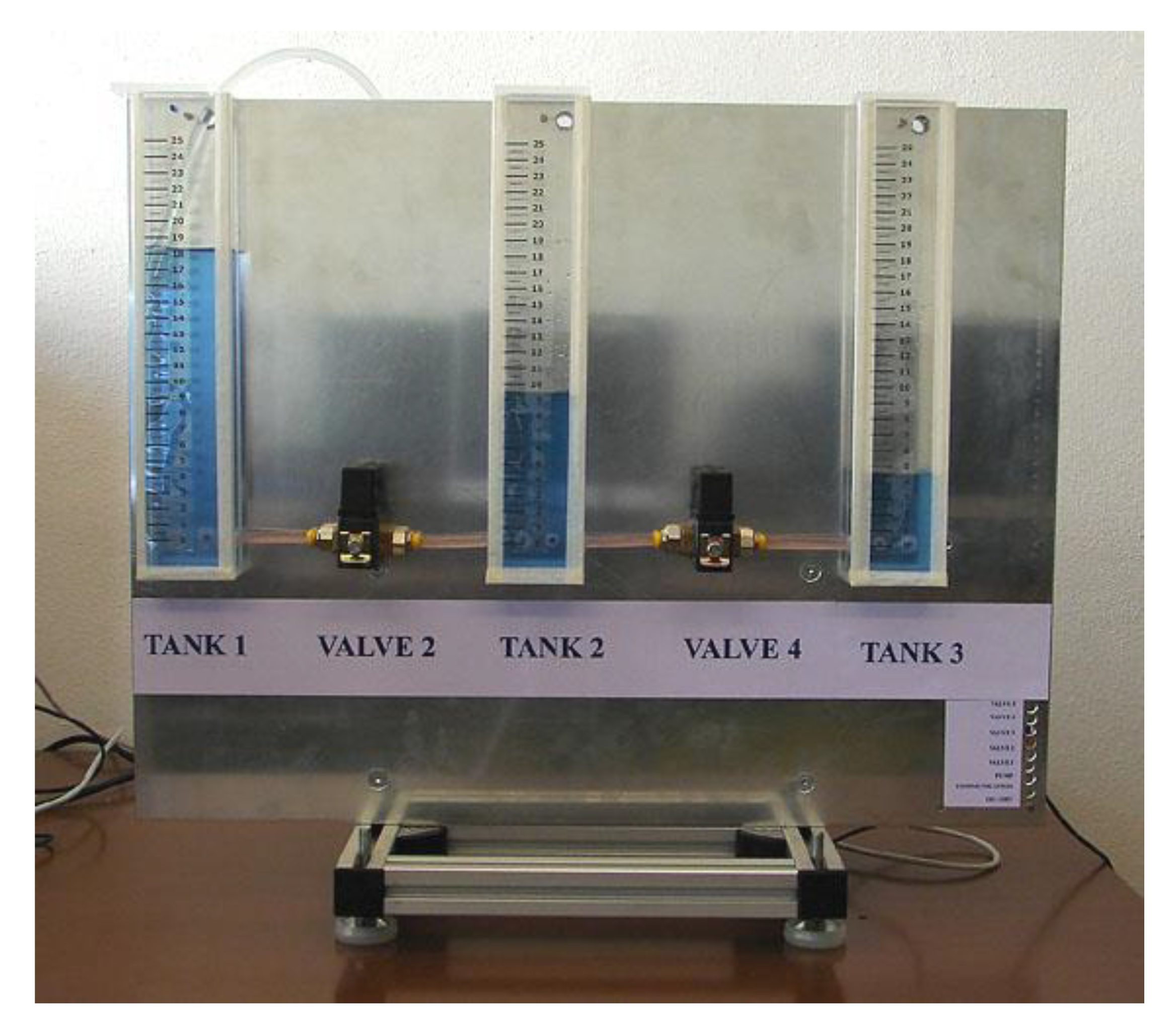

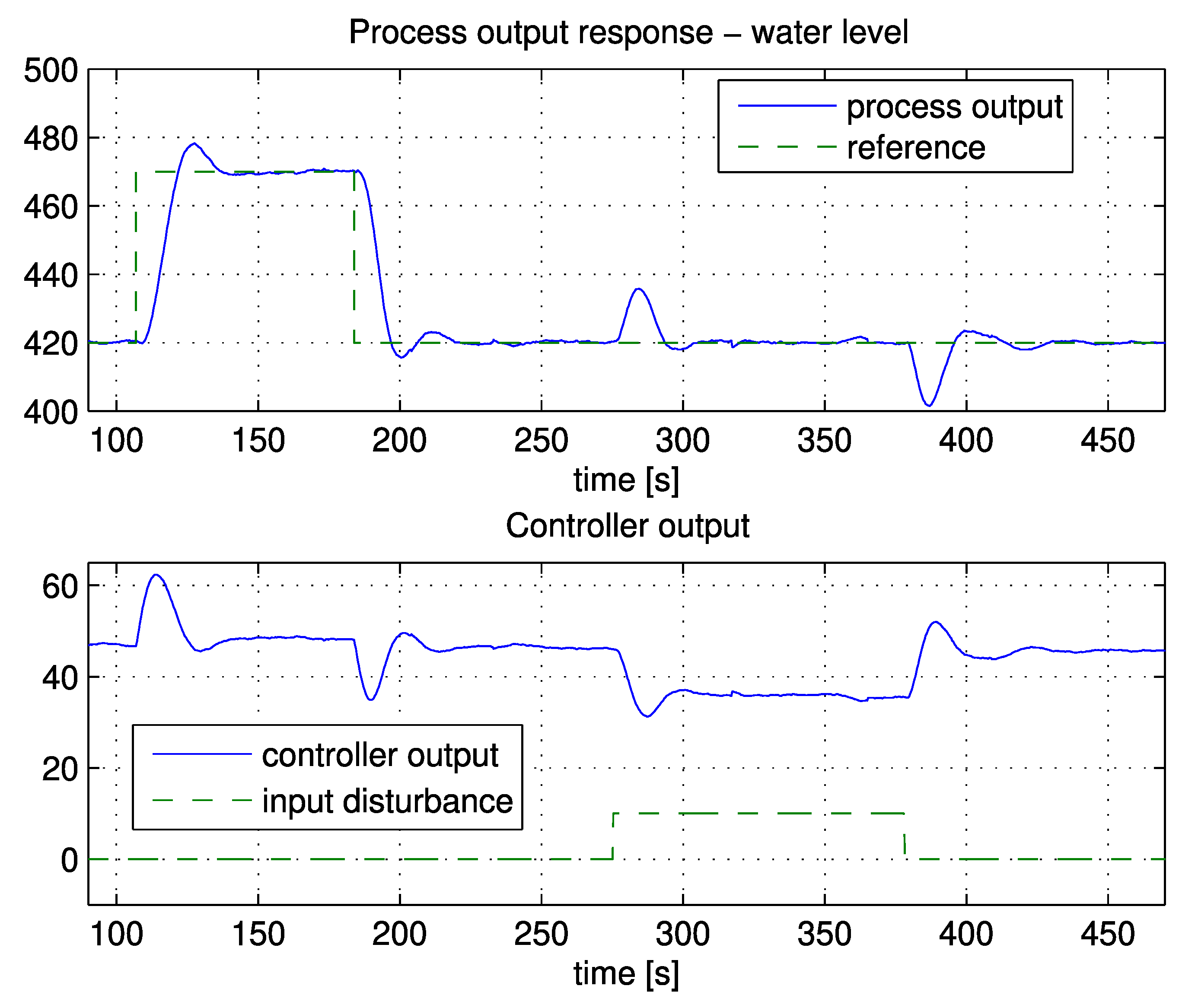

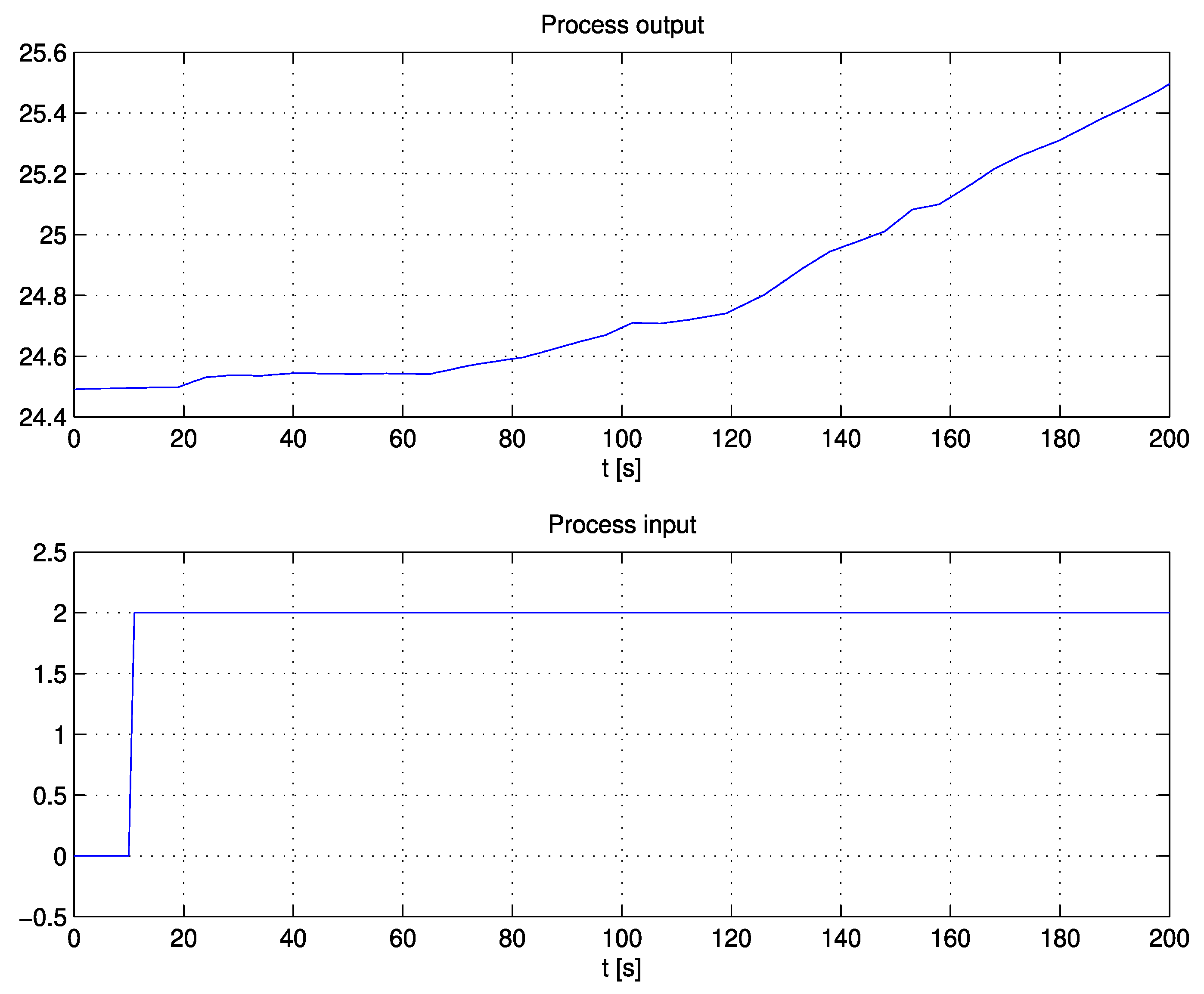

The method was tested on a control system for charge-amplifier drift compensation, laboratory plant, industrial autoclave, and solid-oxide fuel cell. The responses on all processes were relatively fast and highly damped.

In future work, we will concentrate on additionally improving the tracking response while retaining the best disturbance-rejection performance. As already mentioned in

Section 2, this can be done by implementing the reference pre-filter instead of reference weighting factor

b. Although a pre-filter solution (realisation and parameter computation) is much more complex than reference weighting factor

b, it could be beneficial to obtain the overall optimal response if the process model is well defined.