Feasibility Study of Emission Reduction on Marine Engine with Variation of Emulsified Water Concentration and Turbocharger Compression Ratio

Abstract

1. Introduction

2. Materials and Research Methods

2.1. Experiment Method

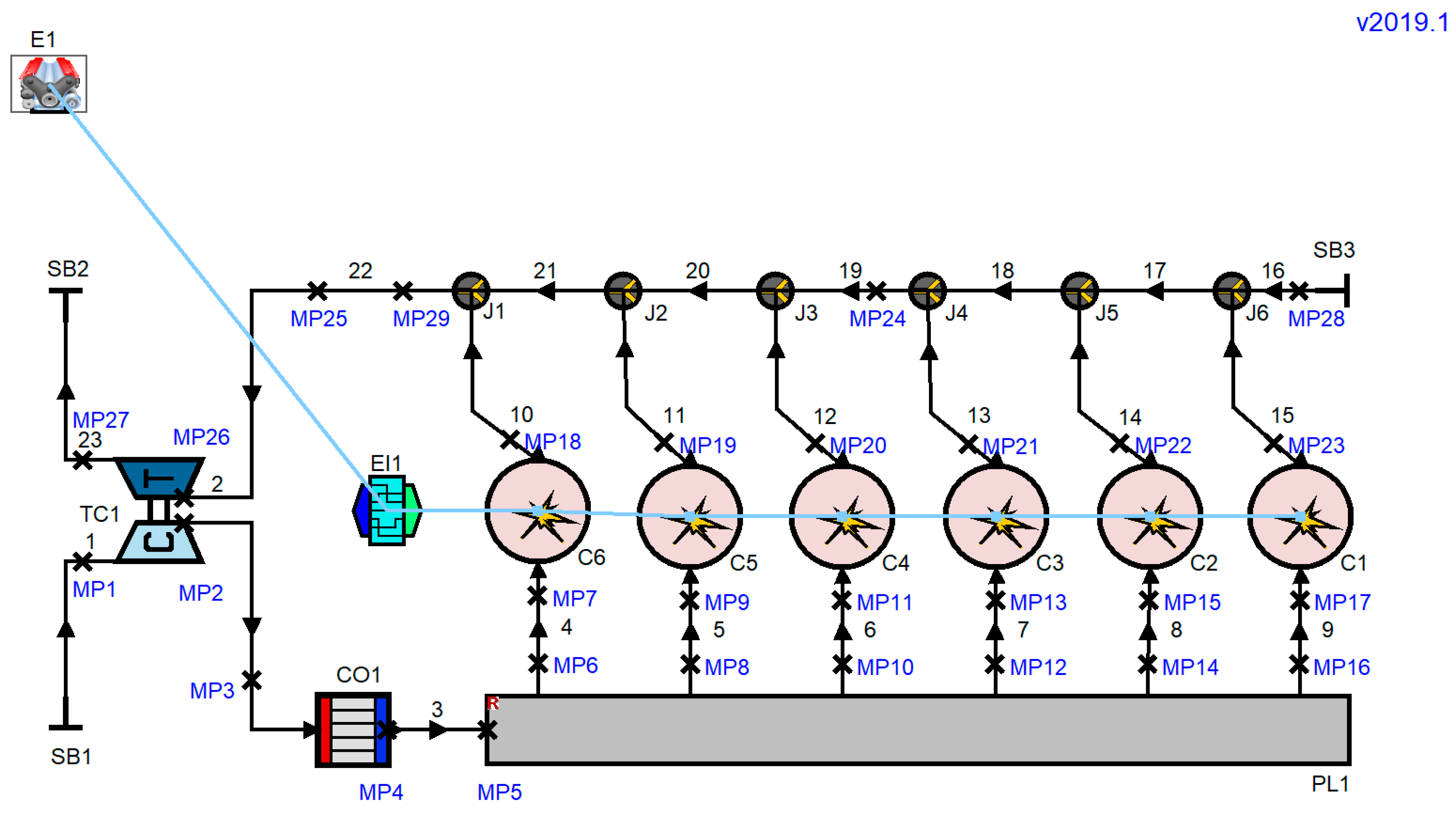

2.2. Numerical Analysis Method

3. Results

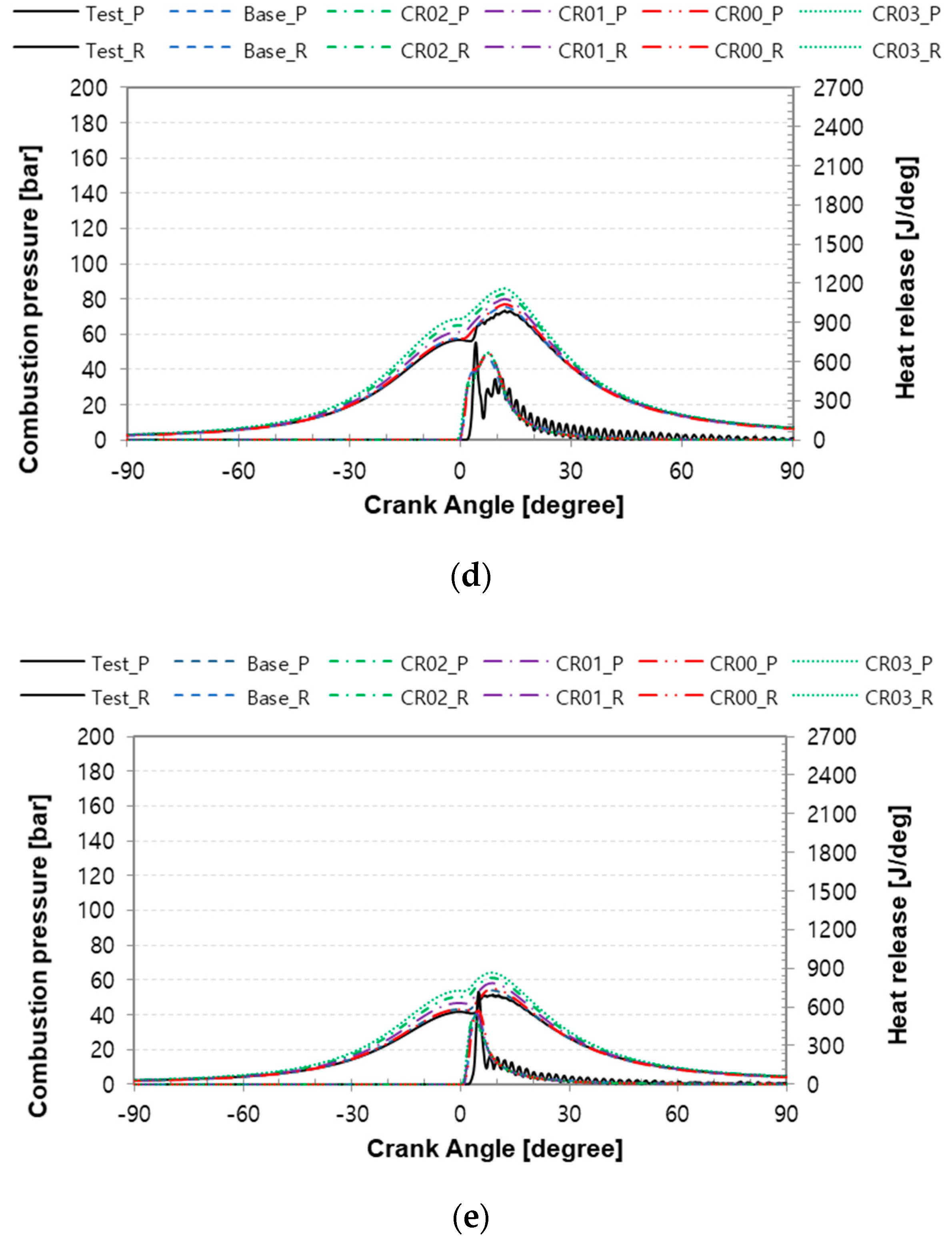

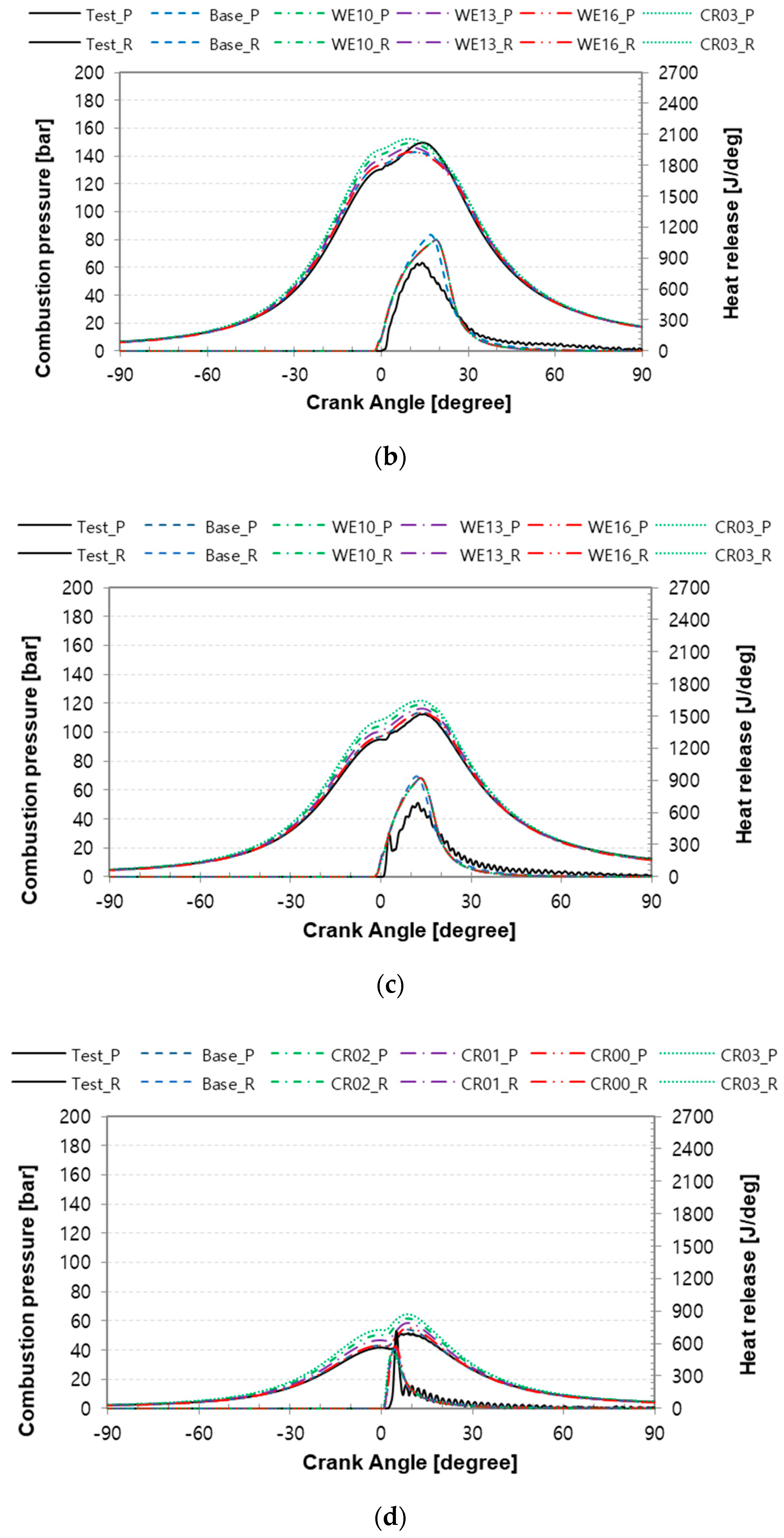

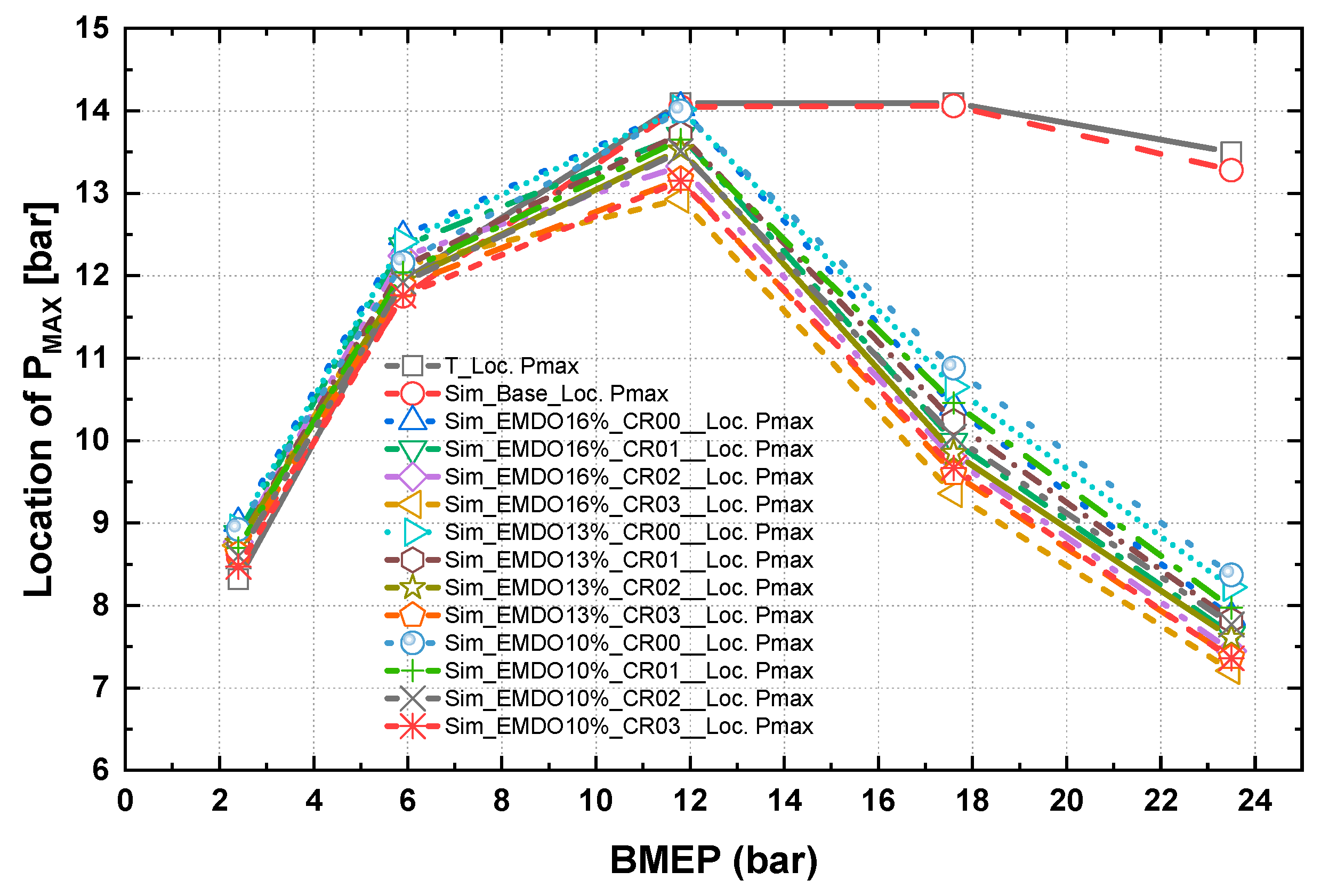

3.1. Characteristics of Combustion Pressure and Rate of Heat Release versus the Compression Ratio of the Turbocharger Nozzle Ring

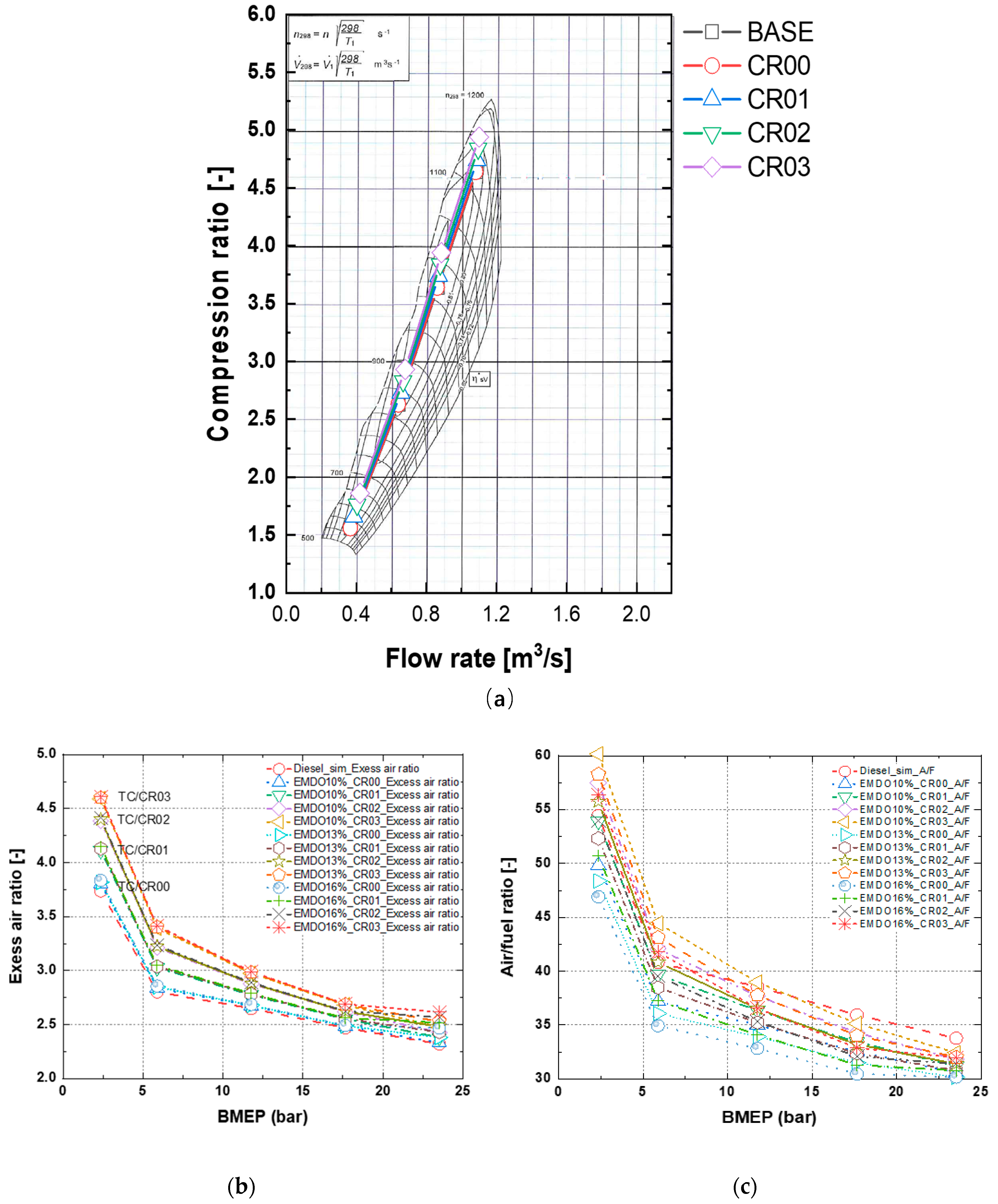

3.2. Characteristics of Combustion and ROHR versus the Compression Ratio of the Turbocharger

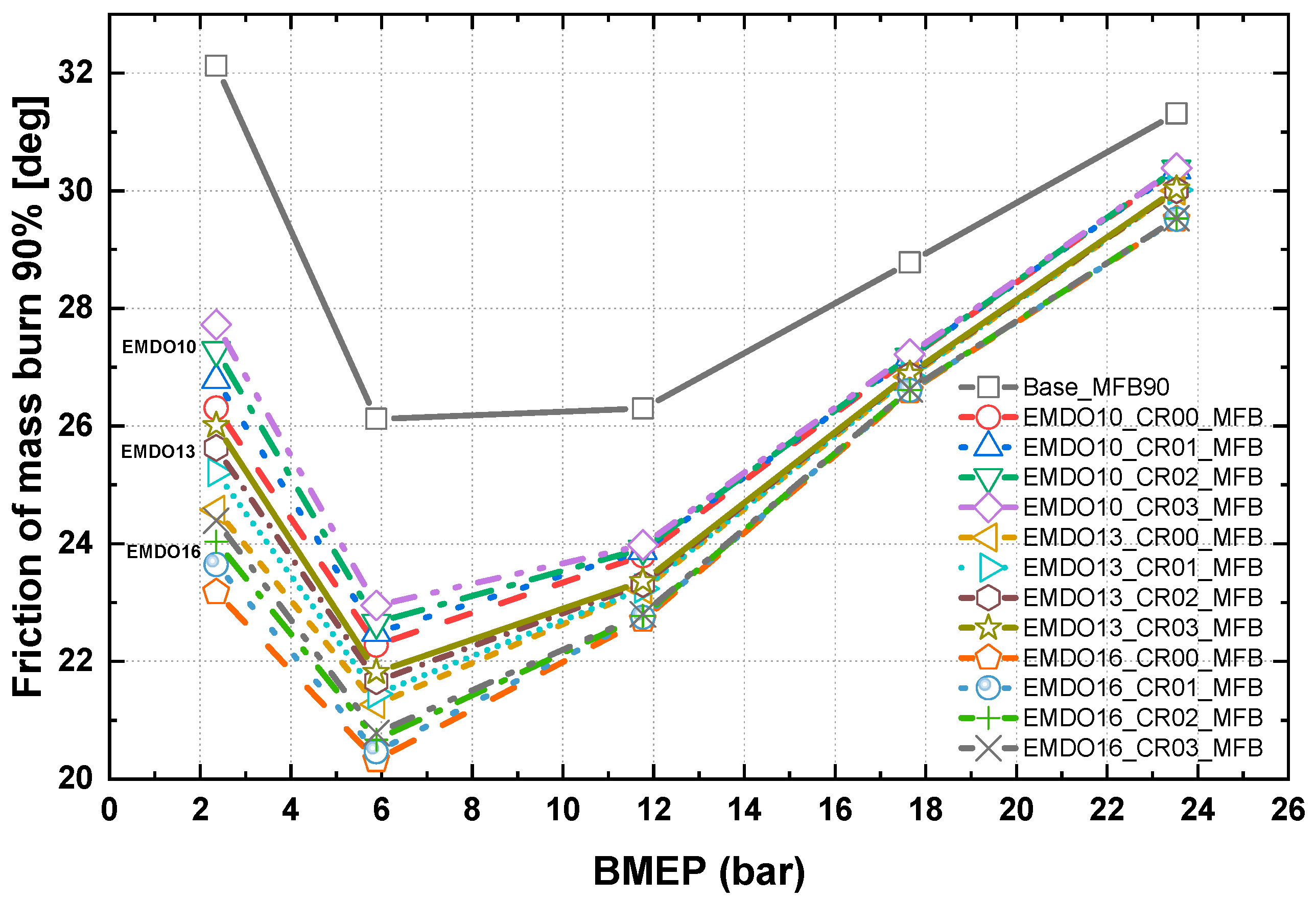

3.3. Characteristics of the Combustion Duration versus the Compression Ratio of the Turbocharger and the Water Concentration of the Emulsified Marine Diesel Oil

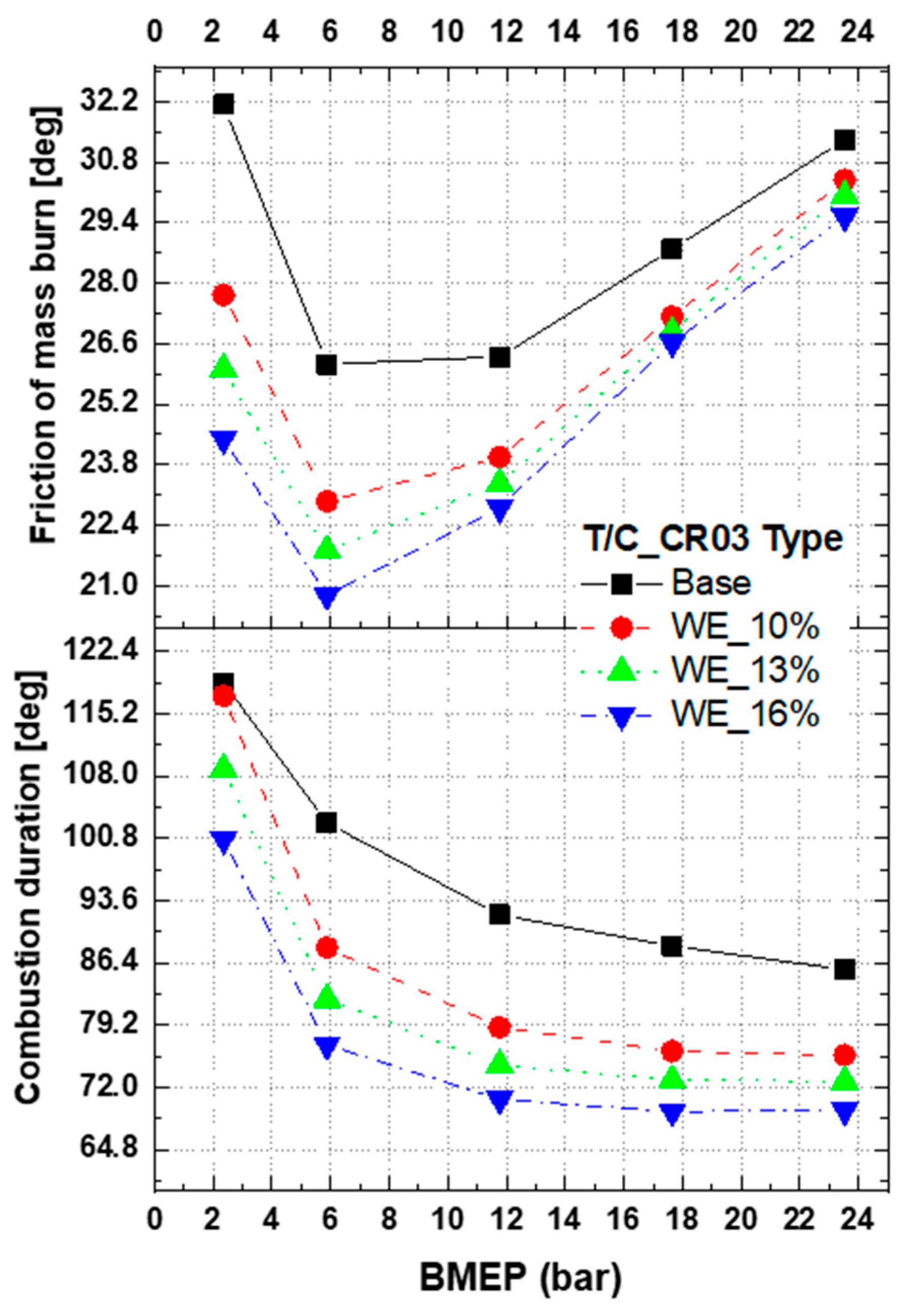

3.4. Characteristics of the Combustion Duration versus the Compression Ratio of the Turbocharger and the Water Concentration of the Emulsified Marine Diesel Oil

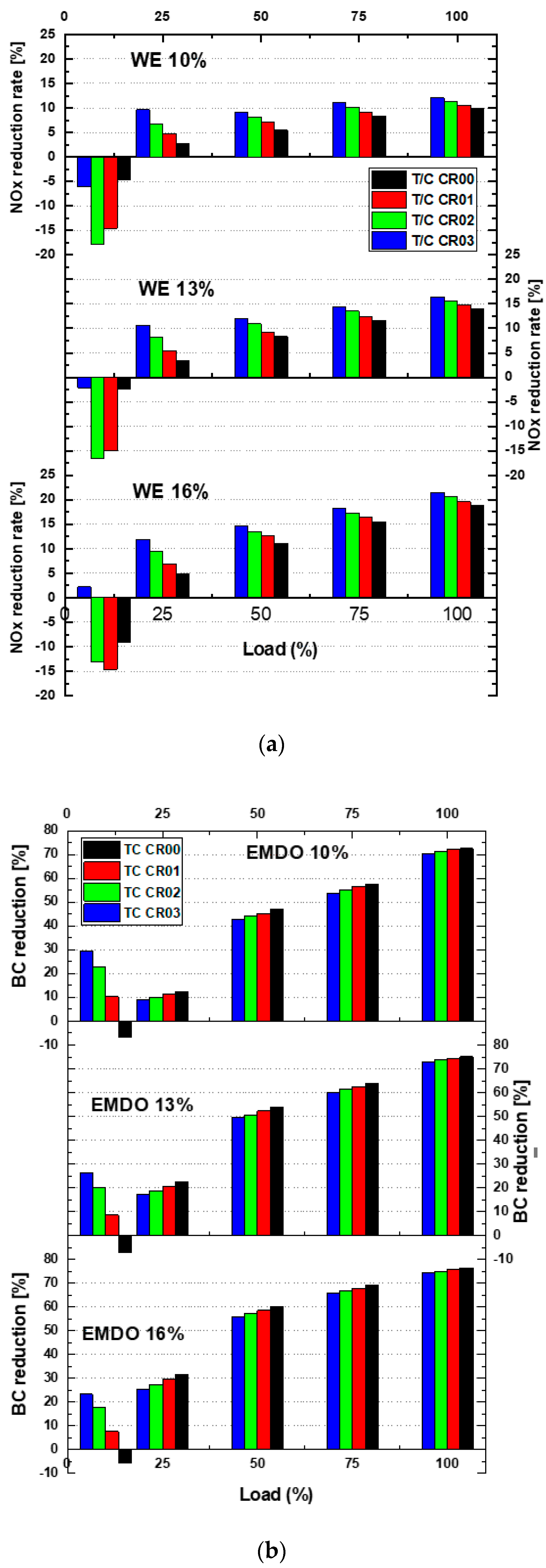

3.5. NOx and Black Carbon Reduction Rates versus the Compression Ratio of the Turbocharger and the Water Concentration of the Emulsified Marine Diesel Oil

4. Discussion

- (1).

- Using the comprehensive results of the maximum pressure position of combustion versus the turbocharger compression ratio and the moisture content of the emulsion fuel, in the lower load region, the position of the maximum pressure of combustion was retarded in the model of the basic engine. In the region of more than 50% load, the position of the maximum pressure of combustion is advanced.

- (2).

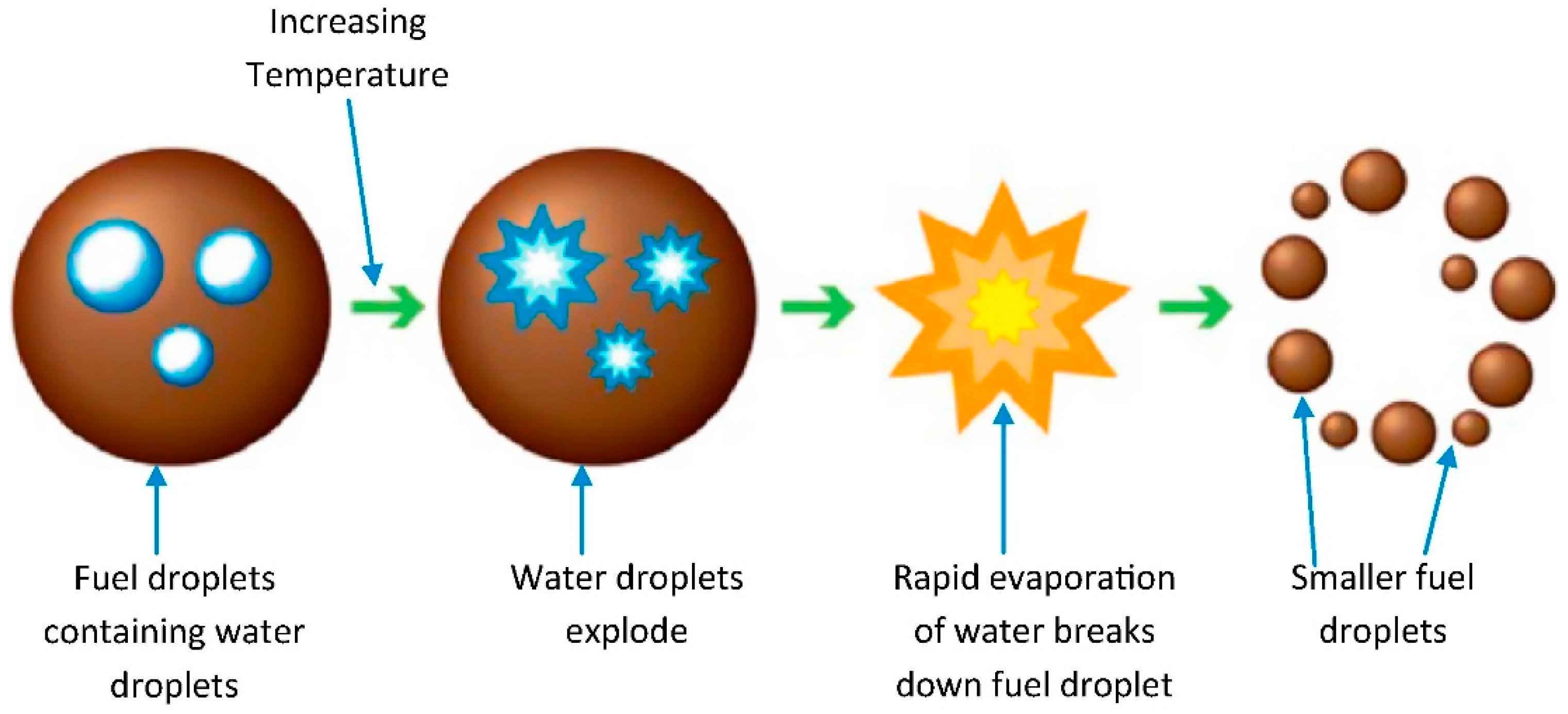

- Characteristics of the turbocharger compression ratio and the emulsion fuel versus the position of maximum combustion pressure were studied. As a result, the turbocharger compression ratio is CR03 and the moisture content is 16%, according to the moisture content of the emulsion fuel. Due to this phenomenon, fuel atomization was accelerated, due to micro-explosion of water, and combustion time was shortened, due to sufficient air, in turn due to the increased compression ratio of the turbocharger.

- (3).

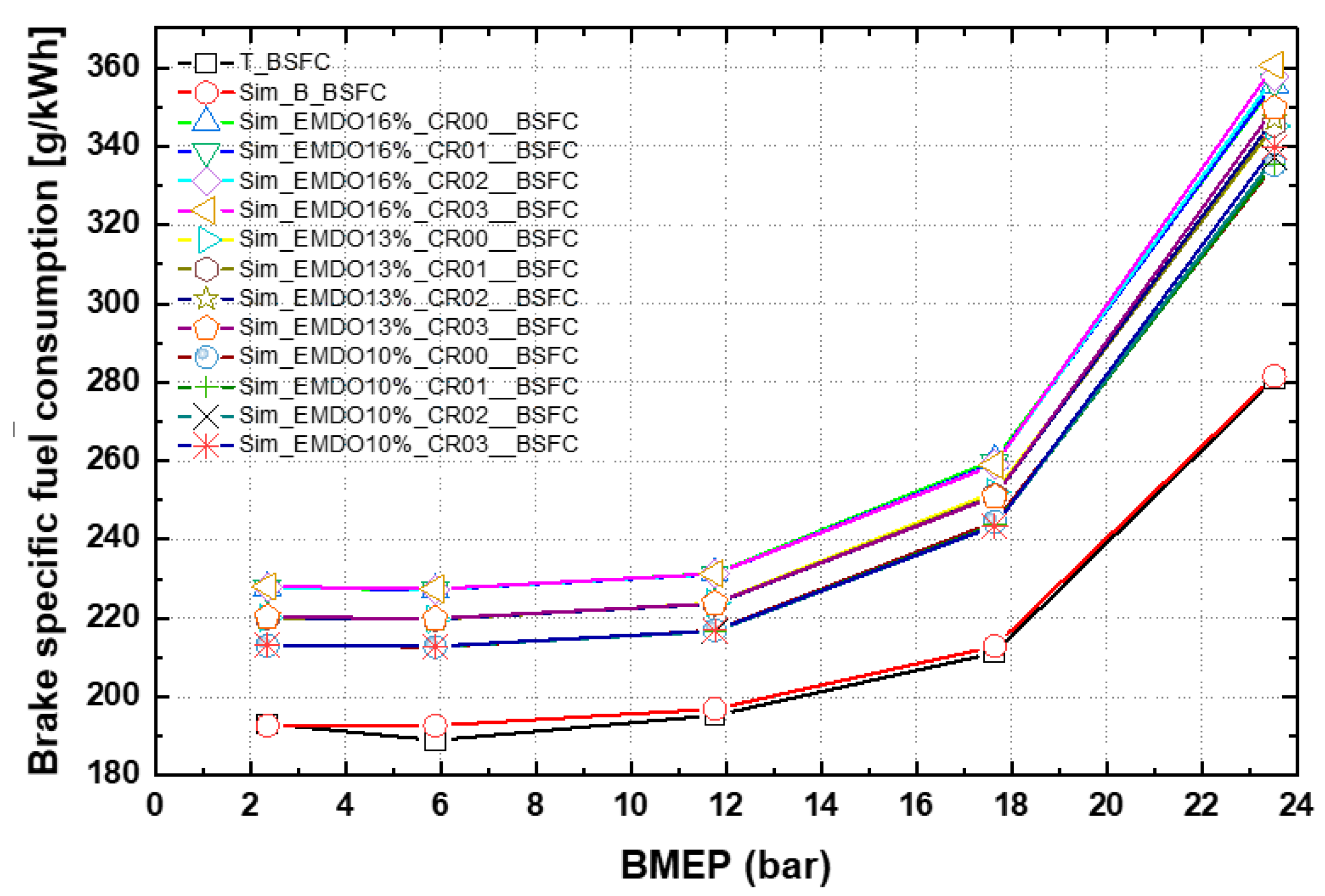

- As a result of comparing the turbocharger compression ratio and the fuel consumption, in the cases of including water and excluding water, for the three types of emulsified fuels, the fuel consumption of the emulsified fuel containing water tended to increase. However, as a result of comparing the consumption of pure fuel, excluding moisture contained in emulsified fuel, the fuel consumption rate decreased in the order of EMDO10 < EMDO13 < EMDO16.

- (4).

- The results of the combustion period characteristics, versus the three types of emulsion fuel and the turbocharger compression ratios, shows that the combustion period is shortened in the order of CR00 > CR01 > CR02 > CR03, according to the compression ratio of the turbocharger. As the fuel water content increases, the combustion period is shortened in the order of EMDO16 < EMDO13 < EMDO10.

- (5).

- The nitrogen oxide and black carbon reduction was because the combustion period increased, with increasing compression ratio, while the combustion period was shortened, with increasing moisture content of emulsion fuel. This causes the combustion temperature to be lowered due to latent evaporation, in turn due to a phase change under high temperature and high-pressure combustion conditions of water contained in the fuel. Additionally, it caused an increase in the combustion pressure and a shortening of the combustion period, due to the expansion of the volume, in turn due to the micro-explosion of water. This may be due to the shortening of the post combustion period and the reduction of black carbon emissions. In addition, combustion was accelerated in the order—CR00 > CR01> CR02> CR03.

- (6).

- As a result of reducing exhaust emissions, black carbon reduction was lowered as the compression ratio of the turbocharger was increased, but black carbon reduction was clearly shown as the water content of the emulsion fuel increased. By optimizing the water content of the emulsion fuel and the compression ratio of the turbocharger, versus the exhaust emissions and the combustion state, it is shown that not only is the fuel consumption rate reduced but also the output improvement is very significant.

Author Contributions

Funding

Conflicts of Interest

References

- Kwon, K.-S.; Choi, K.-J. Development of technology about fuel change and miniature of fuel sludge for medium and low engine. In Proceedings of the MarineCom Technology Seminar, Boston, MA, USA, 6 October 2007. [Google Scholar]

- Hsu, A.; Esty, D.C.; Levy, M.A.; de Sherbinin, A. 2016 Environmental Performance Index (EPI); Yale Center for Environmental Law and Policy (YCELP) and Center for International Earth Science Information Network (CIESIN), Columbia University: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Subramanian, K. A comparison of water–diesel emulsion and timed injection of water into the intake manifold of a diesel engine for simultaneous control of NO and smoke emissions. Energy Convers. Manag. 2011, 52, 849–857. [Google Scholar] [CrossRef]

- Andrea, B.; Renxian, L.; Konstantinos, B. Influence of Water-Diesel Fuel Emulsions and EGR on Combustion and Exhaust Emissions of Heavy Duty DIDiesel Engines Equipped with Common-Rail Injection System; SAE Technical Paper 2003-01-3146; SAE: Warrendale, PA, USA, 2003. [Google Scholar]

- MEPC. 66/6/Consideration and Adoption of Amendments to Mandatory Instruments. In Comments to the Approval at MEPC 65 of Amendments to the Effective Date of the NOx Tier III Standards; MEPC: Marshall Islands, Norway, 2013. [Google Scholar]

- International Organization for Standards. Petroleum Products-Fuels (Class F)-Specifications of Marine Fuels; International standard, ISO 8217:2012(E); ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Hironori, S.; Koji, U. Feasibility Study on the Utilization of Water-in-Oil Type Emulsified Fuels to Small DI Diesel Engines; SAE 2011-32-0602; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Park, J.W.; Huh, K.Y.; Park, K.H. Experimental Study on the Combustion Characteristics of Emulsified Diesel in a RCEM. In Proceedings of the Seoul FISITA World Automotive Congress, Seoul, Korea, 12–15 June 2000. [Google Scholar]

- Park, J.K.; Oh, J.M.; Kim, H.I.; Lee, C.H.; Lee, K.H. Combustion Characteristics of MDO and MDO Emulsion in Automotive Diesel Engine. Trans. KSME 2012, 36, 945–951. [Google Scholar] [CrossRef]

- Kim, M.C.; Lee, C.S. It’s Effects for Engine Emission of Water/Oil Emulsified Fuel. Anal. Sci. Technol. 2008, 21, 159–166. [Google Scholar]

- Han, D.H.; Kang, J.H.; Kim, M.C.; Lee, K.B.; Roh, H.H. A Study on Emission Characteristics of MDO Emulsion Using the FT-IR Spectroscopy. In Proceedings of the KSAE Spring Conference Proceedings, Seoul, Korea, May 2013; pp. 554–559. [Google Scholar]

- Attia AM, A.; Kulchitskiy, A.R. Influence of the Structure of Water-in-Fuel Emulsion on Diesel Engine Performance. Fuel 2014, 116, 706–708. [Google Scholar] [CrossRef]

- Huo, M.; Lin, S.; Liu, H.; Lee, C.F. Study on the Spray and Combustion Characteristics of Water-Emulsified Diesel. Fuel 2014, 123, 218–229. [Google Scholar] [CrossRef]

- Ojala, J.; Sirviö, J.A.; Liimatainen, H. Nanoparticle emulsifiers based on bifunctionalized cellulose nanocrystals as marine diesel oil–water emulsion stabilizers. Chem. Eng. J. 2016, 288, 312–320. [Google Scholar] [CrossRef]

- Ithnin, A.M.; Ahmad, M.A.; Bakar MA, A.; Rajoo, S.; Yahya, W.J. Combustion Performance and Emission Analysis of Diesel Engine Fuelled with Water-in-Diesel Emulsion Fuel Made from Low-Grade Diesel Fuel. Energy Convers. Manag. 2015, 90, 375–382. [Google Scholar] [CrossRef]

- Lim, J.K.; Cho, S.G.; Hwang, S.J.; Yoo, D.H. Effect on Characteristics of Exhaust Emissions by Using Emulsified Fuel in Diesel Engine. J. Korean Soc. Mar. Eng. 2007, 31, 44–50. [Google Scholar]

- Oh, J.; Im, M.; Oh, S.; Lee, C. Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-kW Marine Generator Engine. Energies 2019, 12, 228. [Google Scholar] [CrossRef]

- Kim, D.; Lee, C. SCR Performance Evaluations in Relation to Experimental Parameters in a Marine Generator Engine. J. Mar. Sci. Eng. 2019, 7, 67. [Google Scholar] [CrossRef]

- Kim, M.; Oh, J.; Lee, C. Study on Combustion and Emission Characteristics of Marine Diesel Oil and Water-In-Oil Emulsified Marine Diesel Oil. Energies 2018, 11, 1830. [Google Scholar] [CrossRef]

- Kim, M.C. The Exhaust Gas Reduction of Diesel Engine by MDO (Marine Diesel Oil) Emulsion Fuel. J. Korean Soc. Environ. Eng. 2014, 36, 476–482. [Google Scholar] [CrossRef][Green Version]

- Chen, Z.; Wing, X.; Pei, Y.; Zhang, C.; Xiao, M.; He, J. Experimental Investigation of Performance and Emissions of Diesel Engines by Novel Emulsified Diesel Fuel. Energy Convers. Manag. 2015, 95, 334–341. [Google Scholar] [CrossRef]

- Park, S.; Woo, S.; Kim, H.; Lee, K. The characteristic of spray using diesel water emulsified fuel in a diesel engine. Appl. Energy 2016, 176, 209–220. [Google Scholar] [CrossRef]

- AVL BOOST Theory Reference. v2019 R1. Available online: https://www.avl.com/-/avl-boost-2019-r1 (accessed on 6 November 2019).

| Regulation | Area | Year | Remarks | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | ||||

| NOx | MARPOL Annex 6 Regulation 13 | ECA | Tier II (14.4 g/kWh) | Tier III (3.4g/kWh, n<130, 9 n (−0.2) g/kWh, n<2000 | Similar stage of constructions | ||||||||

| GLOBAL | Tier II (14.4 g/kWh) n<130, n<130, 44 n (−0.23) g/kWh, n<2000 | ||||||||||||

| SOx | MARPOL Annex 6 Regulation 14 | ECA | 1.0%S | 0.1%S | Review in 2018 if no, will be delayed to 2025 | ||||||||

| GLOBAL | 3.5%S | 0.5%S | |||||||||||

| PM | US-EPA | ECA/ GLOBAL | Under Discussions | US-EPA: Already applied | |||||||||

| Items/Descriptions | Specifications |

|---|---|

| Engine type | Four-stoke turbo-charged Direct Injection marine generator engine |

| Number of cylinders | 6 |

| Compression ratio | 15.9 |

| Bore × Stroke (mm) | 165 × 265 |

| Displacement (cc) | 20,000 |

| Fuel injection system | Mechanical pumping system (Max. 1400 bar) |

| Engine’s maximum continuous rating (MCR) (kW/rpm) | 600 kW/900 rpm |

| Fuel | MDO, EMDO (10%, 13%, and 16%) |

|---|---|

| Engine speed (rpm) | 900 |

| Load (kW) | 60 (10%), 150 (25%), 300 (50%), 450 (75%), 600 (100%) |

| Items/Classifications | MDO | 10% EMDO | 13% EMDO | 16% EMDO |

|---|---|---|---|---|

| Lower calorific value (J/g) | 41,860 | 36,760 | 34,610 | 33,430 |

| Gross calorific value (J/g) | 44,810 | 39,990 | 37,880 | 36,690 |

| Hydrogen (m/m %) | 13.06 | 13.06 | 12.87 | 12.73 |

| Carbon (m/m %) | 85.90 | 79.08 | 77.55 | 78.97 |

| Sulfur content (Weight %) | 0.19 | 0.15 | 0.14 | 0.13 |

| Density @ 20 °C (kg/m3) | 858.9 | 872.3 | 878.5 | 882.3 |

| Moisture (Volume %) | 0.3 | 11.0 | 14.5 | 15.2 |

| Flash point (°C) | 104 | 102 | 114 | 118 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, I.; Lee, C. Feasibility Study of Emission Reduction on Marine Engine with Variation of Emulsified Water Concentration and Turbocharger Compression Ratio. Appl. Sci. 2020, 10, 1215. https://doi.org/10.3390/app10041215

Choi I, Lee C. Feasibility Study of Emission Reduction on Marine Engine with Variation of Emulsified Water Concentration and Turbocharger Compression Ratio. Applied Sciences. 2020; 10(4):1215. https://doi.org/10.3390/app10041215

Chicago/Turabian StyleChoi, Iksoo, and Changhee Lee. 2020. "Feasibility Study of Emission Reduction on Marine Engine with Variation of Emulsified Water Concentration and Turbocharger Compression Ratio" Applied Sciences 10, no. 4: 1215. https://doi.org/10.3390/app10041215

APA StyleChoi, I., & Lee, C. (2020). Feasibility Study of Emission Reduction on Marine Engine with Variation of Emulsified Water Concentration and Turbocharger Compression Ratio. Applied Sciences, 10(4), 1215. https://doi.org/10.3390/app10041215