Compensation Method for Diurnal Variation in Three-Component Magnetic Survey

Abstract

1. Introduction

2. Methods

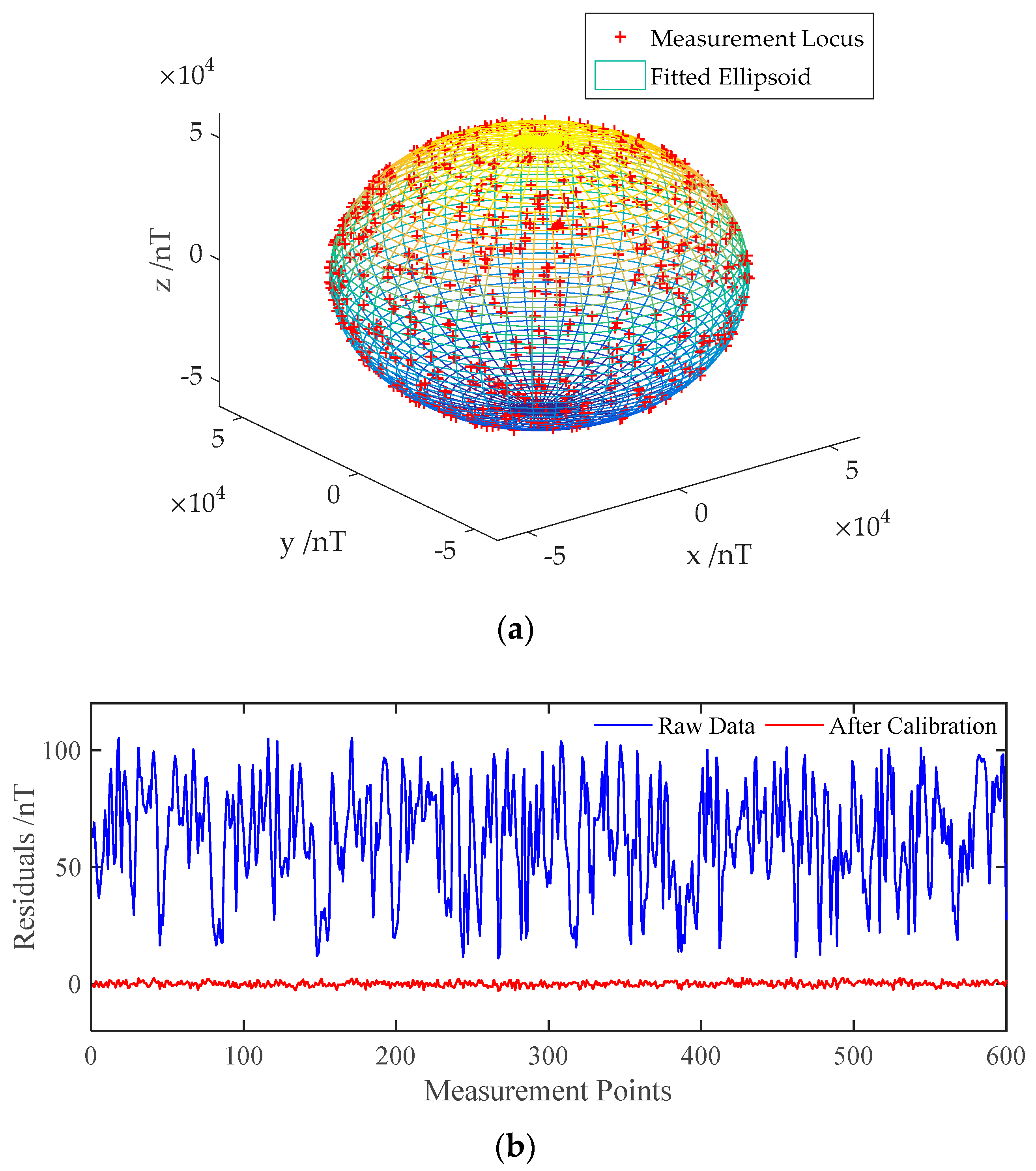

2.1. Magmetometer Error Calibration

- Scaling error. Scaling error denotes the difference in sensitivity of each axis due to the different characteristics of the internal electronic devices. The scaling error matrix can be modeled aswhere denote the axial scaling errors of the magnetometer respectively.

- Offset error. Offset error denotes the deviation between magnetometer’s output and true value, which can be modeled aswhere denote the axial offset errors of the magnetometer respectively.

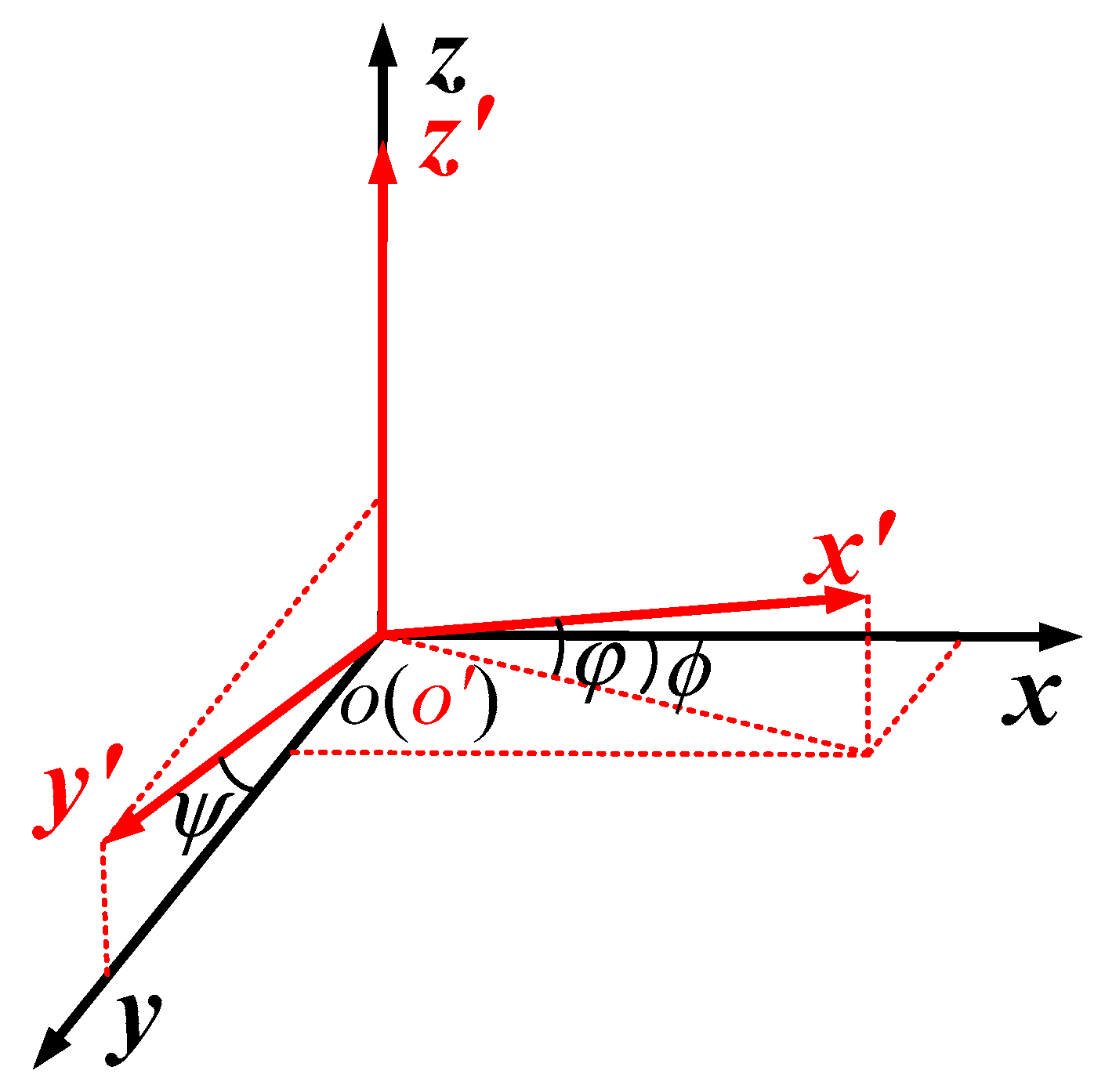

- Non-orthogonality error. The orthogonality between three axes of the magnetometer cannot be guaranteed due to manufacturing precision limitations, thus resulting in non-orthogonal error, as illustrated in Figure 1. As is shown, denotes the ideal tri-axial magnetometer while denotes the non-orthogonal magnetometer.

2.2. Misalignment Error Calibration

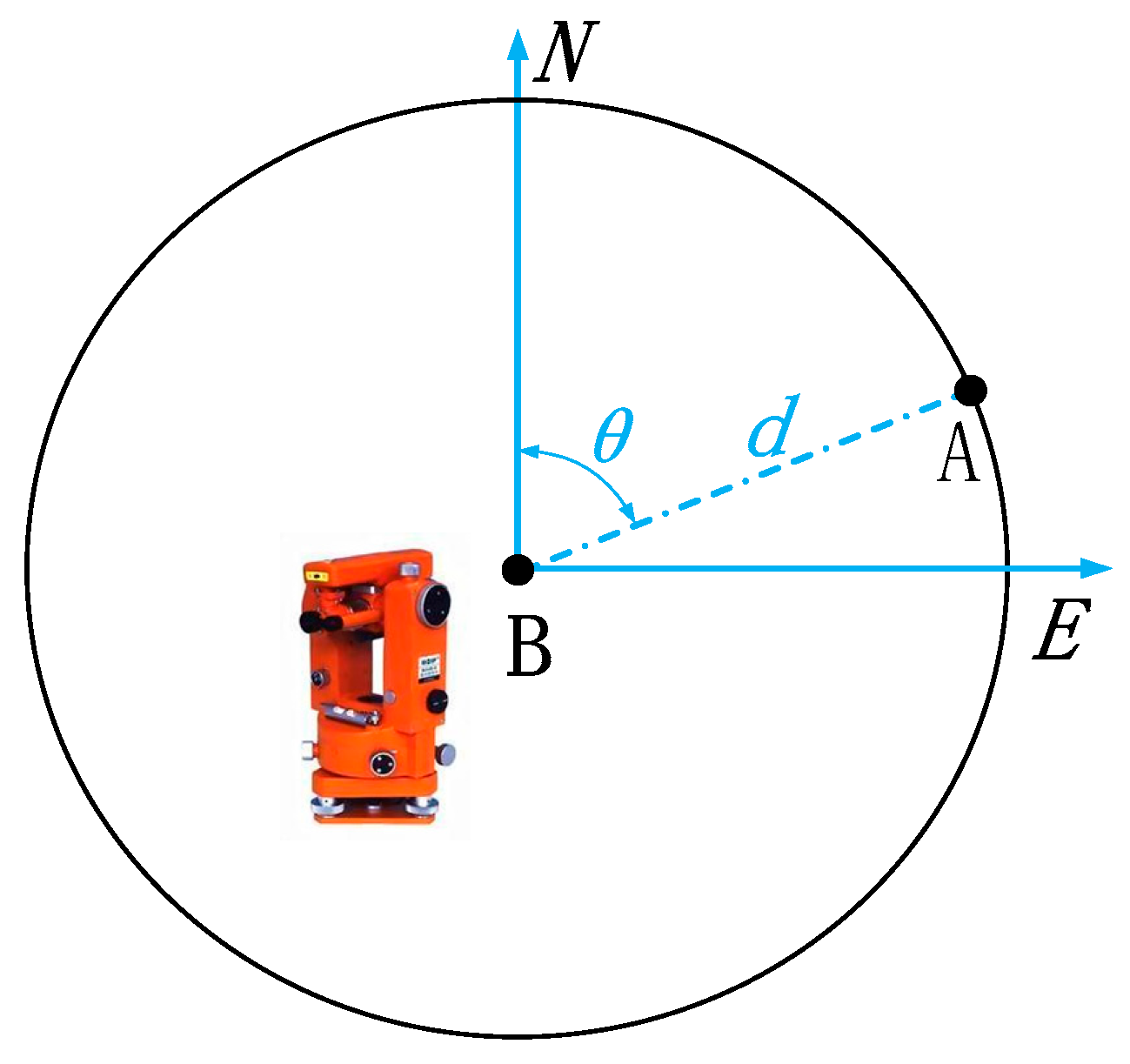

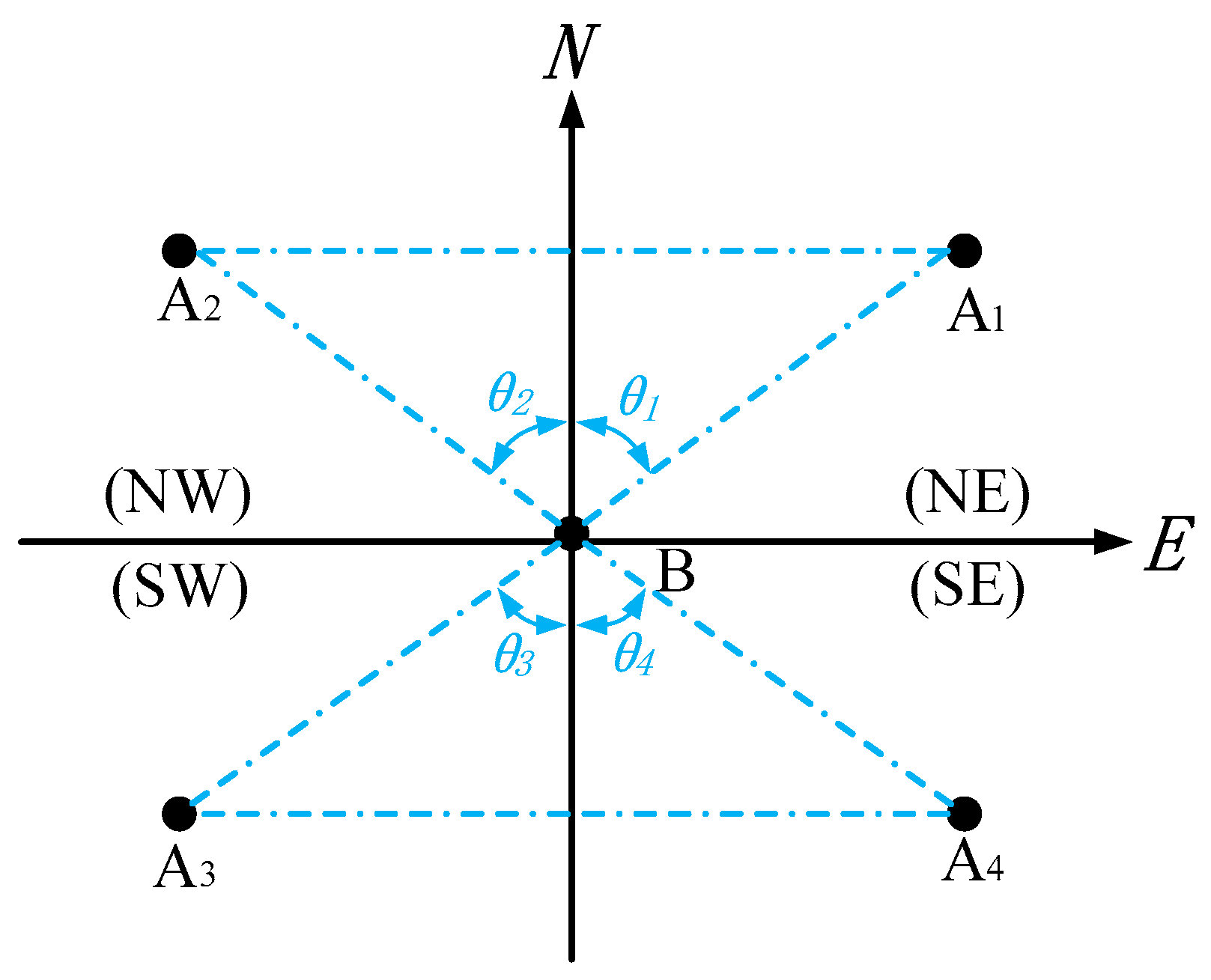

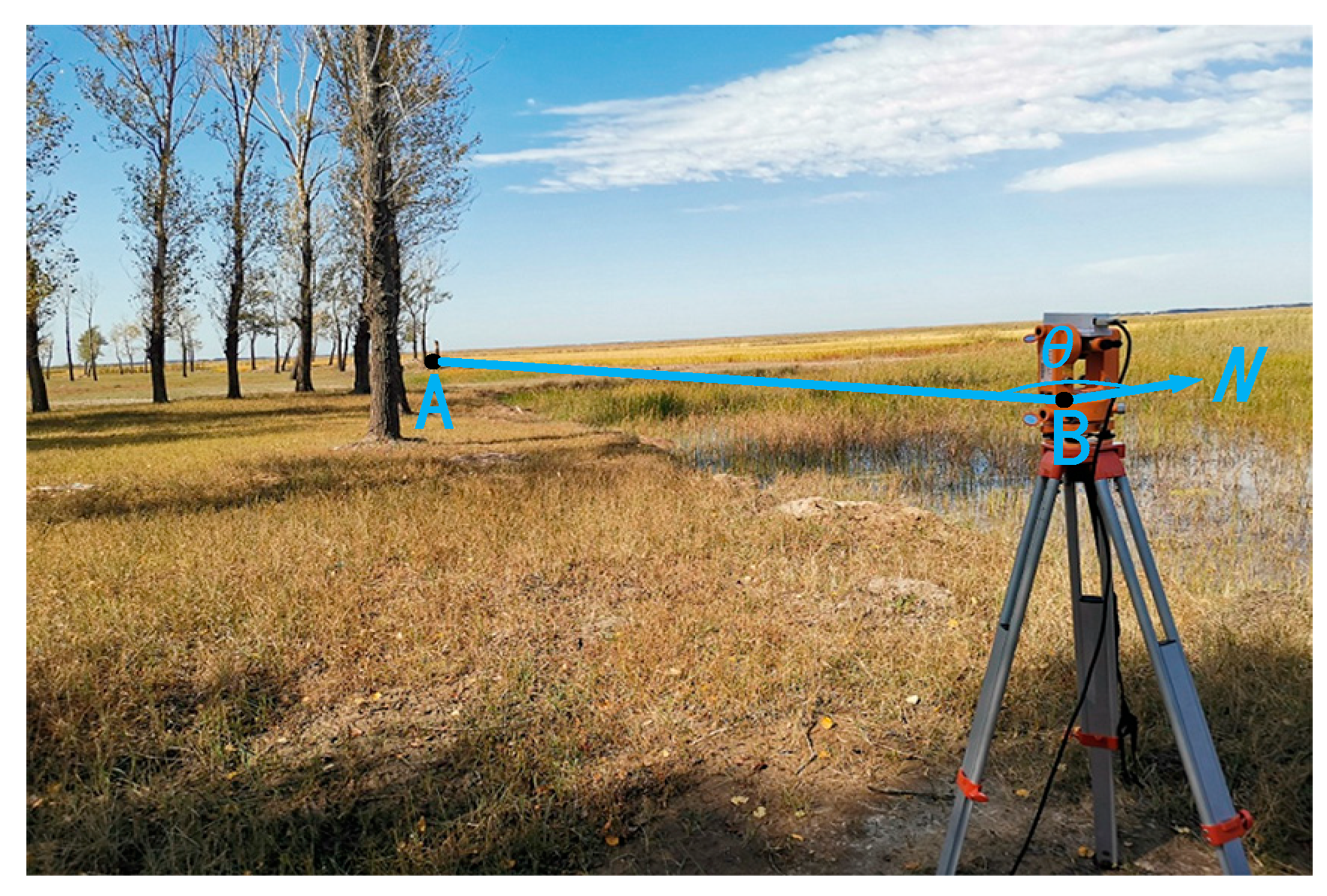

2.3. Alignment to North

3. Experiments

3.1. Experimental Setup

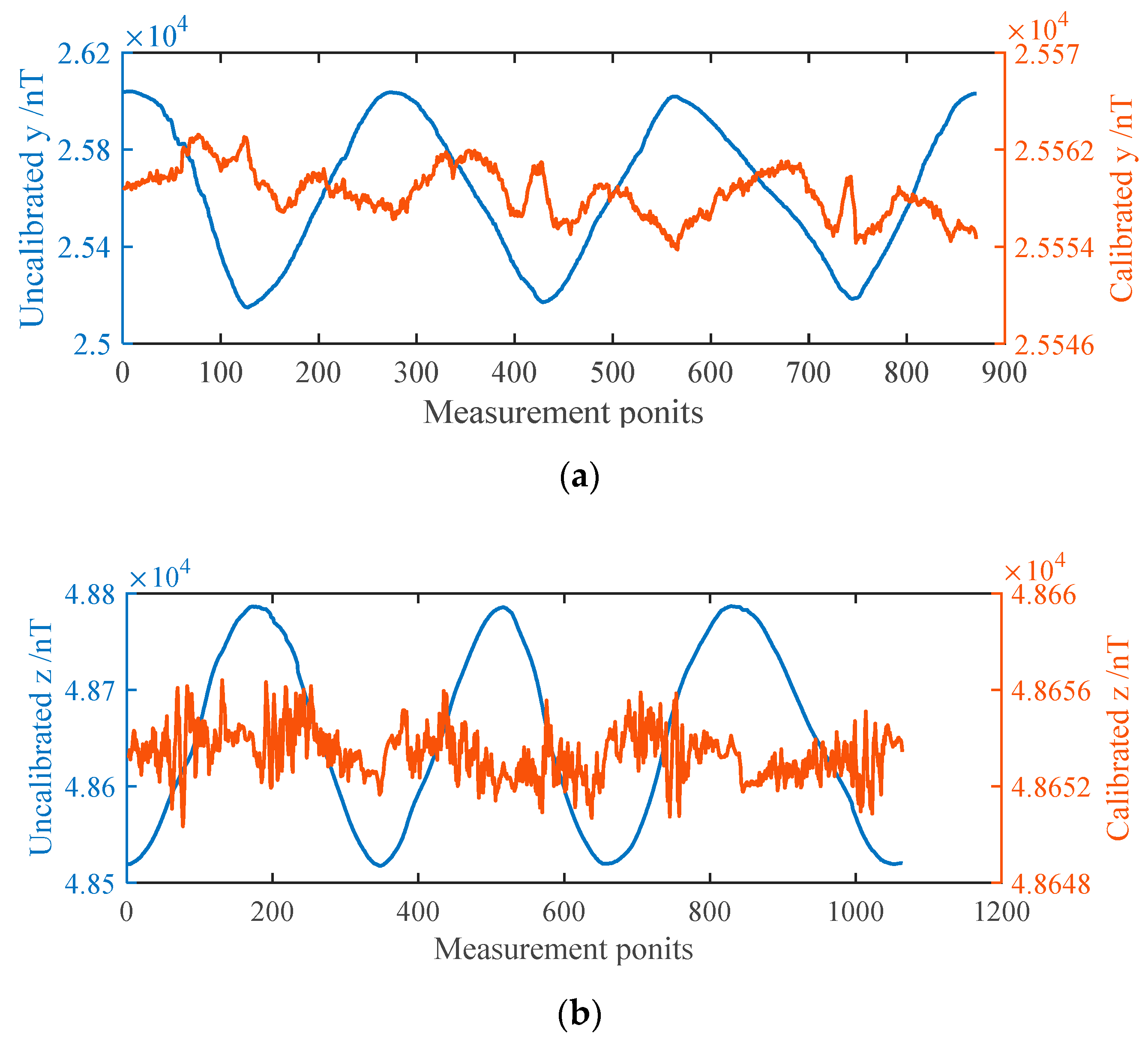

3.2. Calibration Results

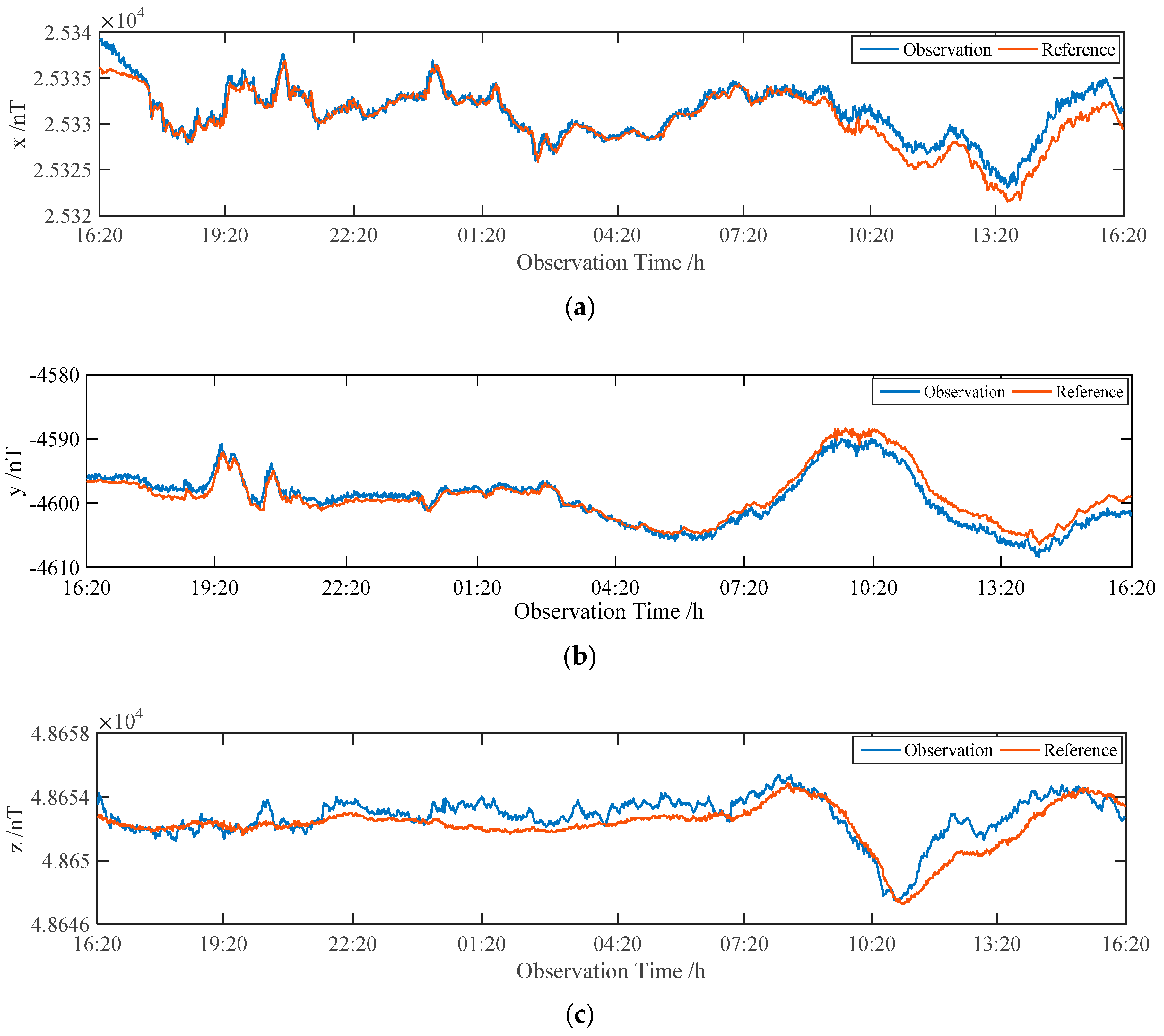

3.3. Diurnal Variation Observation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sheinker, A.; Frumkis, L.; Ginzburg, B.; Salomonski, N.; Kaplan, B.Z. Magnetic anomaly detection using a three-axis magnetometer. IEEE Trans. Magn. 2009, 45, 160–167. [Google Scholar] [CrossRef]

- Tominaga, M.; Tivey, M.A.; MacLeod, C.J.; Morris, A.; Lissenberg, C.J.; Shillington, D.J.; Ferrini, V. Characterization of the in situ magnetic architecture of oceanic crust (Hess Deep) using near-source vector magnetic data. Geophys. Res.-Solid Earth. 2016, 6, 4130–4146. [Google Scholar] [CrossRef]

- Liu, S.; Hu, X.; Cai, J.; Li, J.; Shan, C.; Wei, W.; Liu, Y. Inversion of borehole magnetic data for prospecting deep-buried minerals in areas with near-surface magnetic distortions: A case study from the Daye iron-ore deposit in Hubei, central China. Near Surf. Geophys. 2017, 3, 298–310. [Google Scholar] [CrossRef]

- Munschy, M.; Simon, F. Scalar vector, tensor magnetic anomalies: Measurement or computation? Geophys. Prospect. 2011, 6, 1035–1045. [Google Scholar] [CrossRef]

- Munschy, M.; Boulanger, D.; Ulrich, P.; Bouiflane, M. Magnetic mapping for the detection and characterization of UXO: Use of multi-sensor fluxgate 3-axis magnetometers and methods of interpretation. J. Appl. Geophys. 2007, 3, 168–183. [Google Scholar] [CrossRef]

- Wu, P.; Zhang, Q.; Chen, L.; Fang, G. Analysis on systematic errors of aeromagnetic compensation caused by measurement uncertainties of three-axis magnetometers. IEEE Sens. J. 2018, 1, 361–369. [Google Scholar] [CrossRef]

- Zhang, Q.; Pang, H.F.; Wan, C.B. Magnetic interference compensation method for geomagnetic field vector measurement. Measurement 2016, 91, 628–633. [Google Scholar] [CrossRef]

- Williams, P.M. Aeromagnetic compensation using neural networks. Neural Comput. Appl. 1993, 1, 207–214. [Google Scholar] [CrossRef]

- Jung, J.; Park, J.; Choi, J.; Choi, H.T. Autonomous mapping of underwater magnetic fields using a surface vehicle. IEEE Access 2018, 6, 62552–62563. [Google Scholar] [CrossRef]

- Ousaloo, H.S.; Sharifi, G.H.; Mahdian, J.; Nodeh, M.T. Complete calibration of three-axis strapdown magnetometer in mounting frame. IEEE Sens. J. 2017, 23, 7886–7893. [Google Scholar] [CrossRef]

- Long, D.; Zhang, X.; Wei, X.; Luo, Z.; Cao, J. A fast calibration and compensation method for magnetometers in strap-down spinning projectiles. Sensors 2018, 12, 4157. [Google Scholar] [CrossRef] [PubMed]

- Gebre-Egziabher, D.; Elkaim, G.H.; Powell, J.D.; Parkinson, B.W. Calibration of strapdown magnetometers in magnetic field domain. J. Aerosp. Eng. 2006, 2, 87–102. [Google Scholar] [CrossRef]

- Milligan, T. More applications of Euler rotation angles. IEEE Antennas Propag. Mag. 1999, 4, 78–83. [Google Scholar] [CrossRef]

- Hutcheson, G.D. Ordinary least-squares regression. In The Multivariate Social Scientist; SAGE Publications Ltd.: Southend Oaks, CA, USA, 2011; pp. 224–228. [Google Scholar]

- Ayer, J.; Fosu, C. Map Coordinate Referencing and the use of GPS datasets in Ghana. J. Sci. Technol. 2008, 1, 1106–1127. [Google Scholar] [CrossRef][Green Version]

- Zhu, H.; You, X.; Liu, S. Multiple Ant Colony Optimization Based on Pearson Correlation Coefficient. IEEE Access 2019, 7, 61628–61638. [Google Scholar] [CrossRef]

| Device | Quantity | Value |

|---|---|---|

| Magnetometer | Measuring range | ±100 uT |

| Measurement noise floor | 6~10 pT/√Hz at 1 Hz | |

| Non-orthogonality error | <0.1° | |

| Scaling error | <±0.5% | |

| Offset error | ≤±5 nT | |

| Non-magnetic theodolite | Magnetic contamination | ≤1 nT |

| Plate level | 20″/2 mm | |

| Mean squared error of a horizontal measured face left/right | 2″ | |

| Mean squared error of a vertical measured face up/down | 6″ | |

| Initial horizontal misalignment | <20″ | |

| Initial vertical misalignment | <25″ | |

| Differential GPS | Position accuracy (RMS) | horizontal 0.02 m |

| vertical 0.03 m |

| Component | x | y | z |

|---|---|---|---|

| 0.947 | 0.951 | 0.860 | |

| (nT) | 0.903 | 1.104 | 0.726 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Q.; Cheng, D.; Wang, Y.; Li, S.; Wang, M.; Yue, L.; Zhao, J. Compensation Method for Diurnal Variation in Three-Component Magnetic Survey. Appl. Sci. 2020, 10, 986. https://doi.org/10.3390/app10030986

Gao Q, Cheng D, Wang Y, Li S, Wang M, Yue L, Zhao J. Compensation Method for Diurnal Variation in Three-Component Magnetic Survey. Applied Sciences. 2020; 10(3):986. https://doi.org/10.3390/app10030986

Chicago/Turabian StyleGao, Quanming, Defu Cheng, Yi Wang, Supeng Li, Mingchao Wang, Liangguang Yue, and Jing Zhao. 2020. "Compensation Method for Diurnal Variation in Three-Component Magnetic Survey" Applied Sciences 10, no. 3: 986. https://doi.org/10.3390/app10030986

APA StyleGao, Q., Cheng, D., Wang, Y., Li, S., Wang, M., Yue, L., & Zhao, J. (2020). Compensation Method for Diurnal Variation in Three-Component Magnetic Survey. Applied Sciences, 10(3), 986. https://doi.org/10.3390/app10030986