Analysis of Dimensional Tolerances on Hydraulic and Acoustic Properties of a New Type of Prototypal Gear Pumps

Abstract

1. Introduction

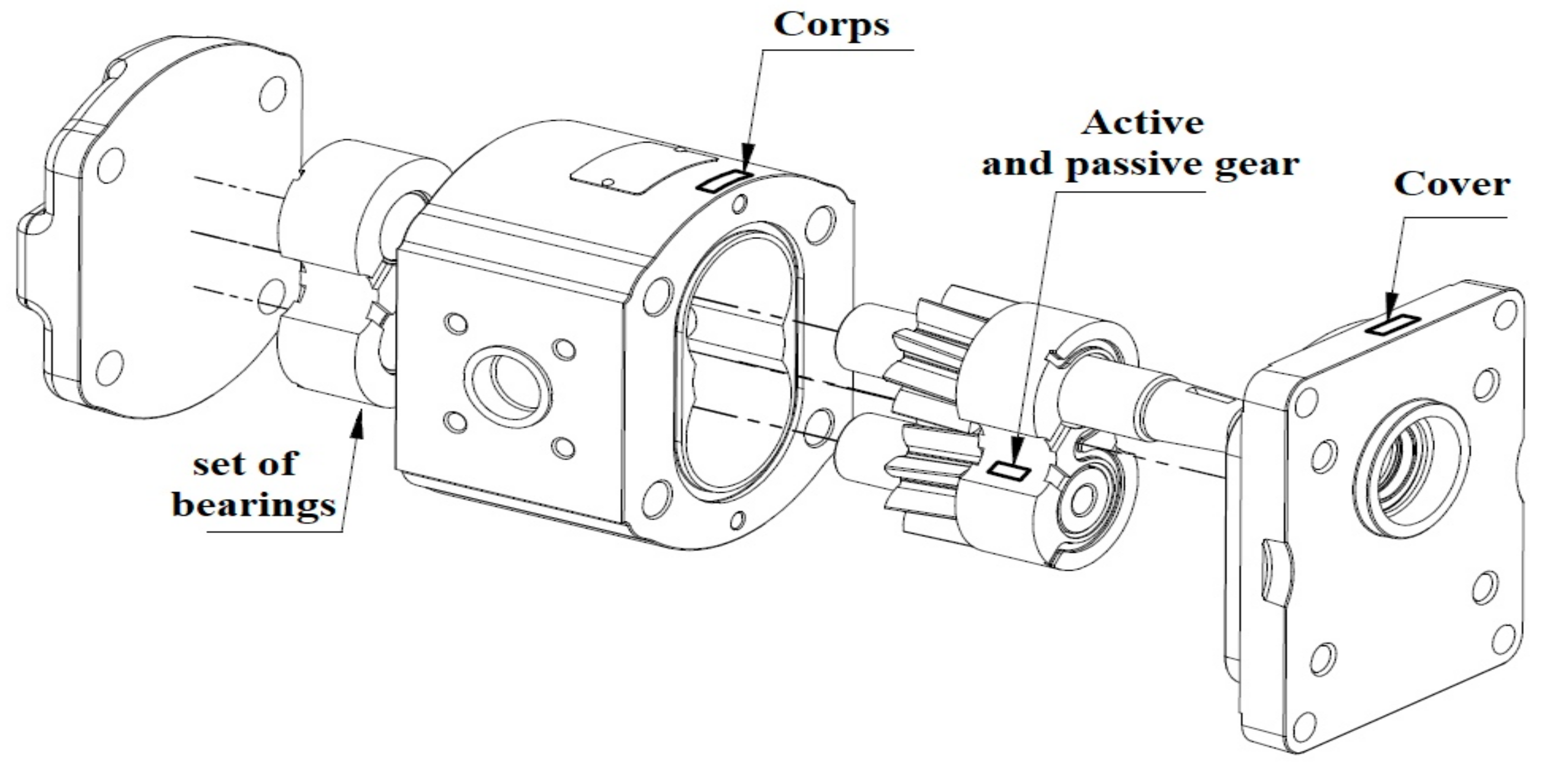

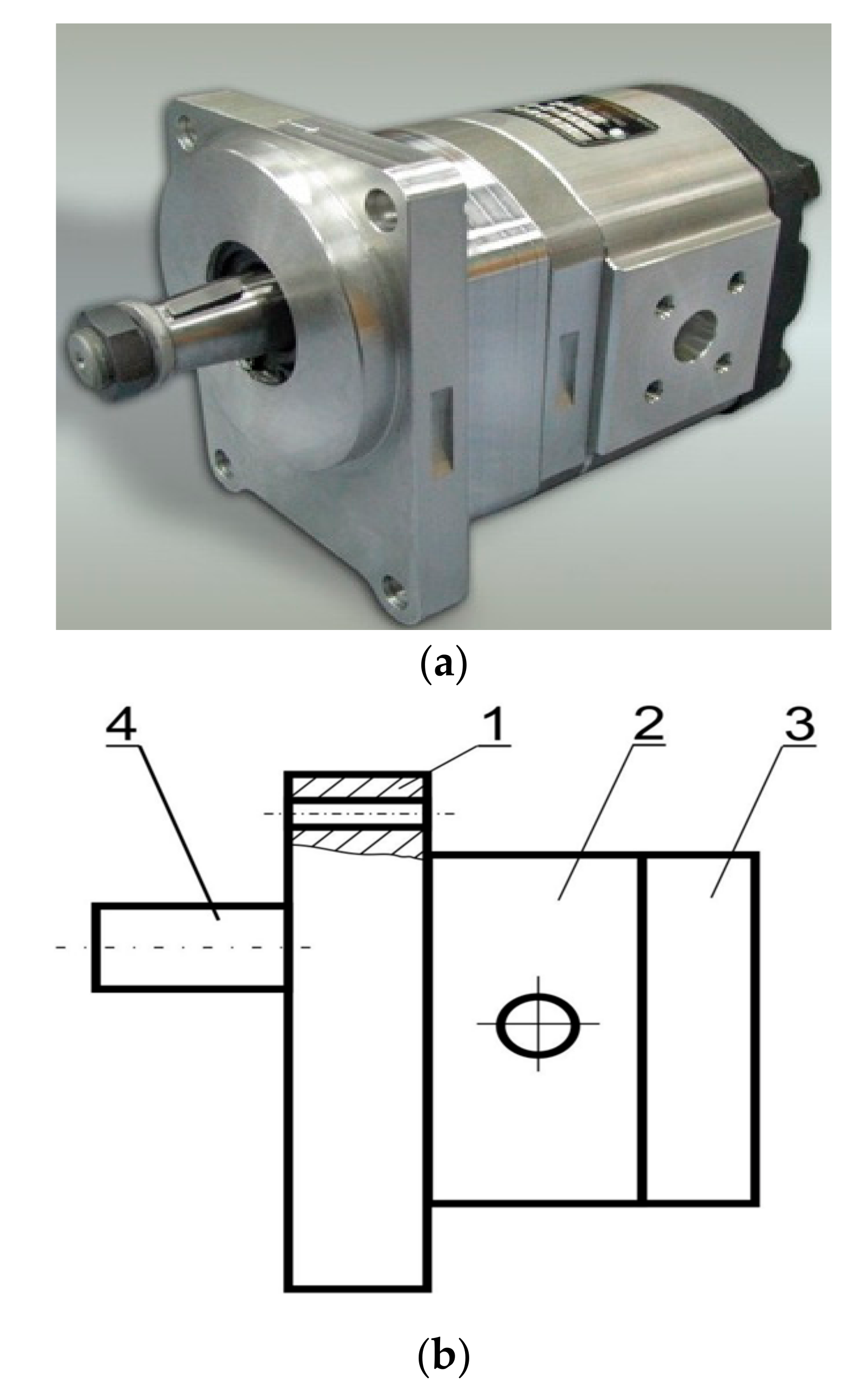

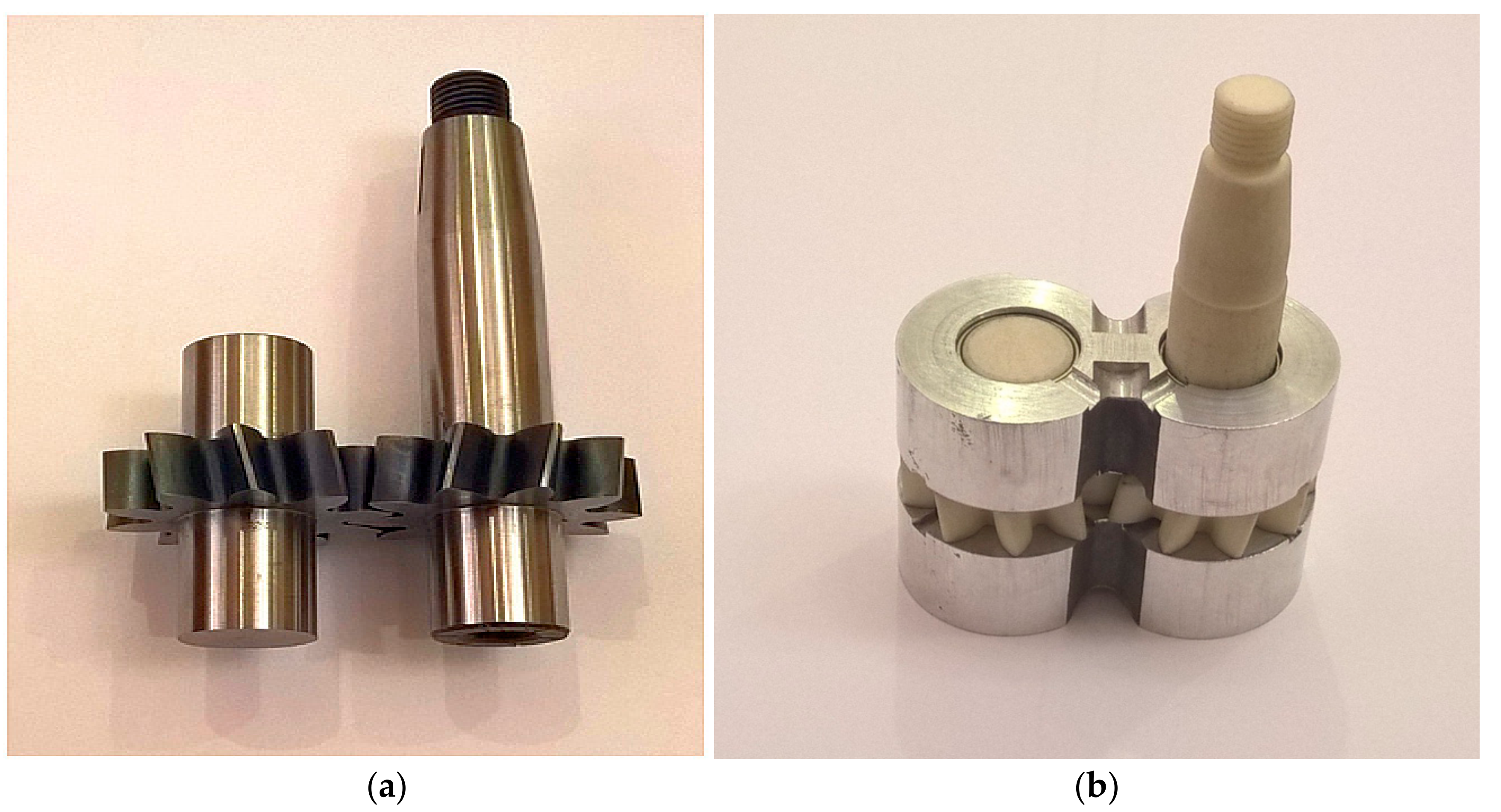

1.1. Development of Gear Unit Design

1.2. Basics of Gear Pump Design

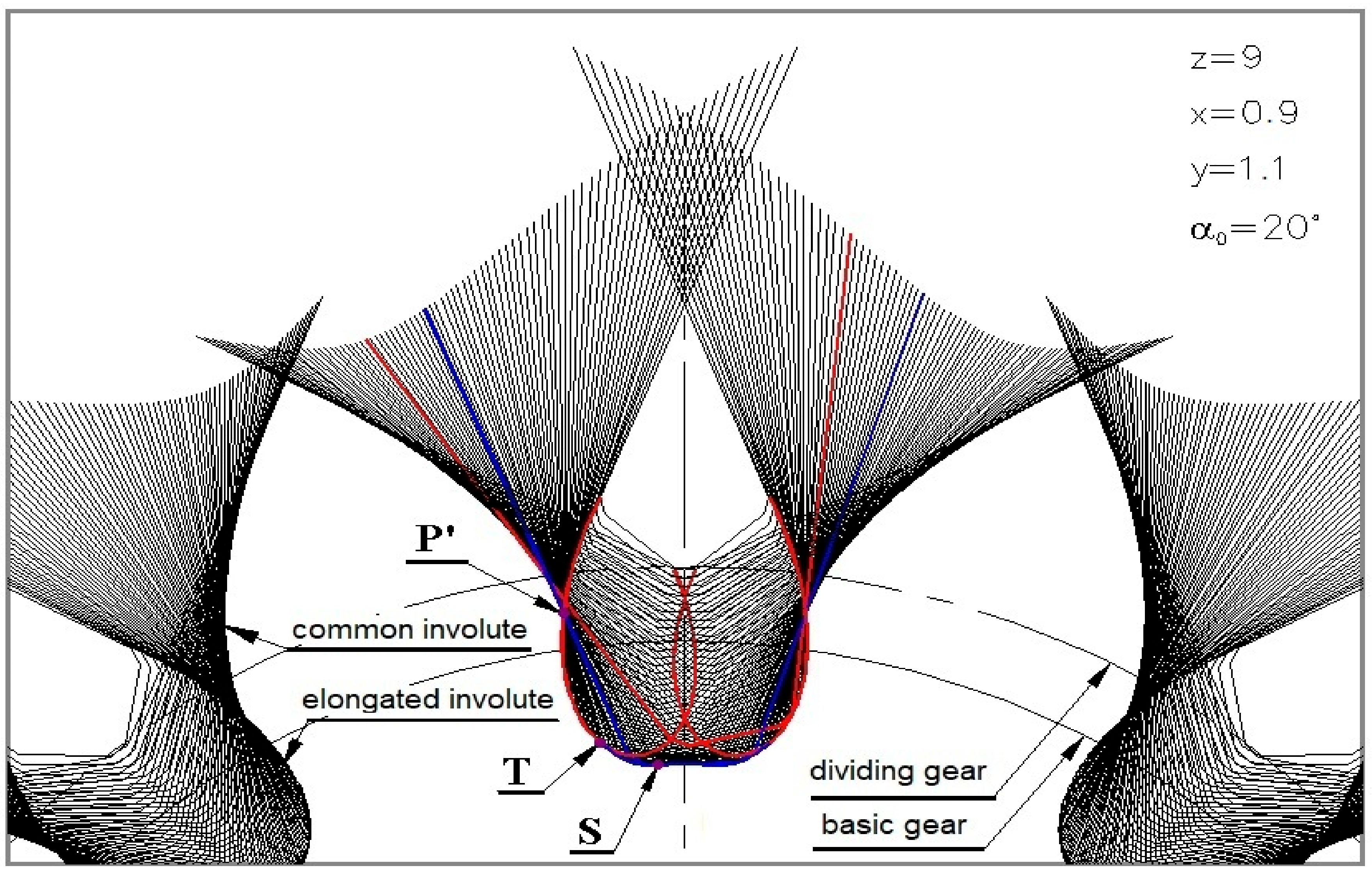

2. Optimization of the Technology of Poly-Involutedly Shaped Pump Construction

- X1:

- Ordinary evolvent: α01 > α02|Ordinaryevolvent: α02 = 20°|Elongated evolvent

- X2:

- Ordinary evolvent: α01 > α02|Ordinaryevolvent: α02 = 20°|Elongated evolvent

- X3:

- Ordinary evolvent: α01 > α02|Ordinaryevolvent: α02 = 20°|Ordinary evolvent: α01 >α02

- X4:

- Ordinary evolvent: α01 > α02|Ordinaryevolvent: α02 = 20°|Ordinary evolvent: α01 >α02

- X5:

- Ordinaryevolvent: α01 > α02|Ordinary evolvent: α02 = 20°|Ordinary evolvent: α01 >α02

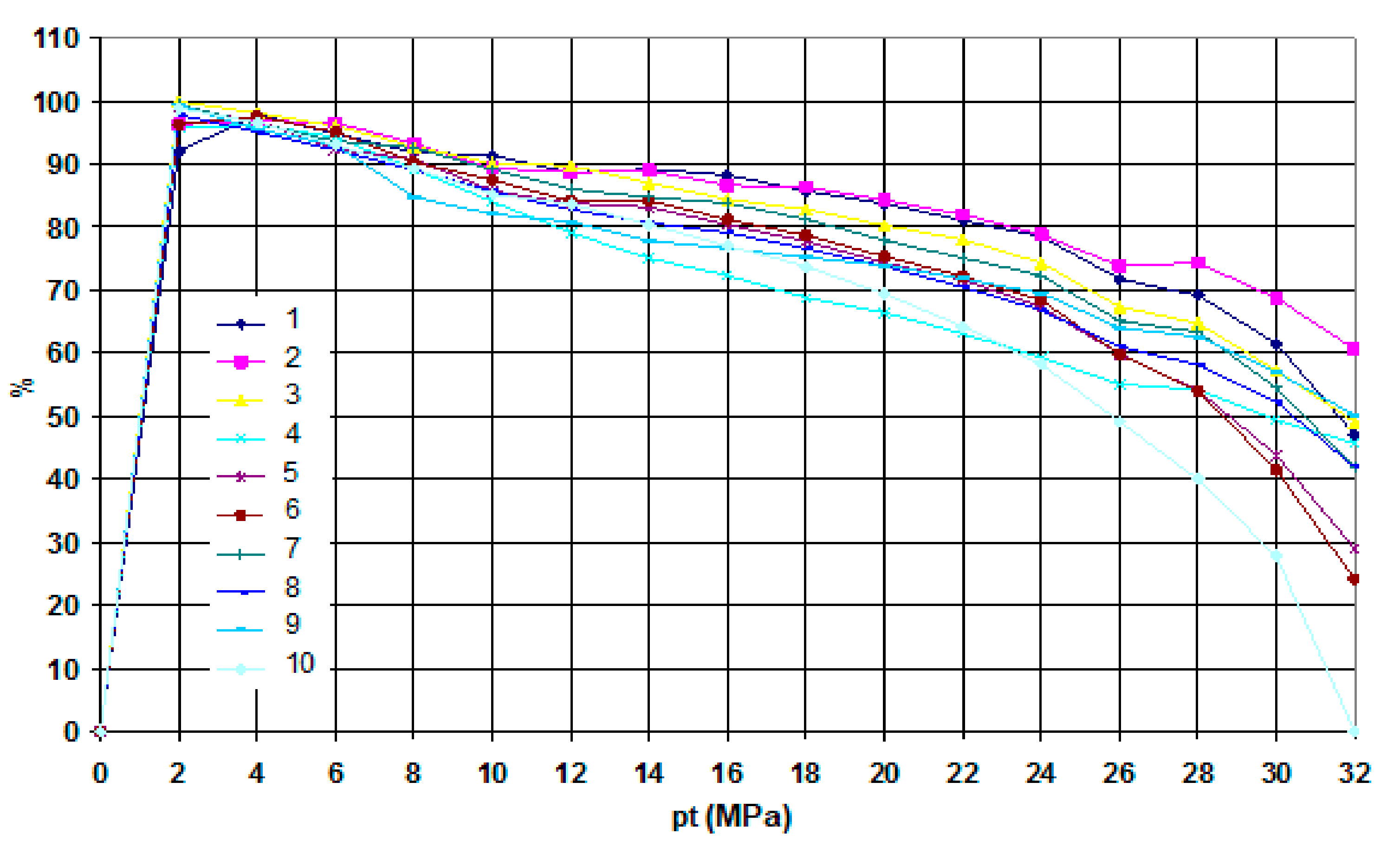

The Research Object

- -

- determination of the actual efficiency of the gear pump Qrz = f(pt) and

- -

- determination of the torque M = f(pt).

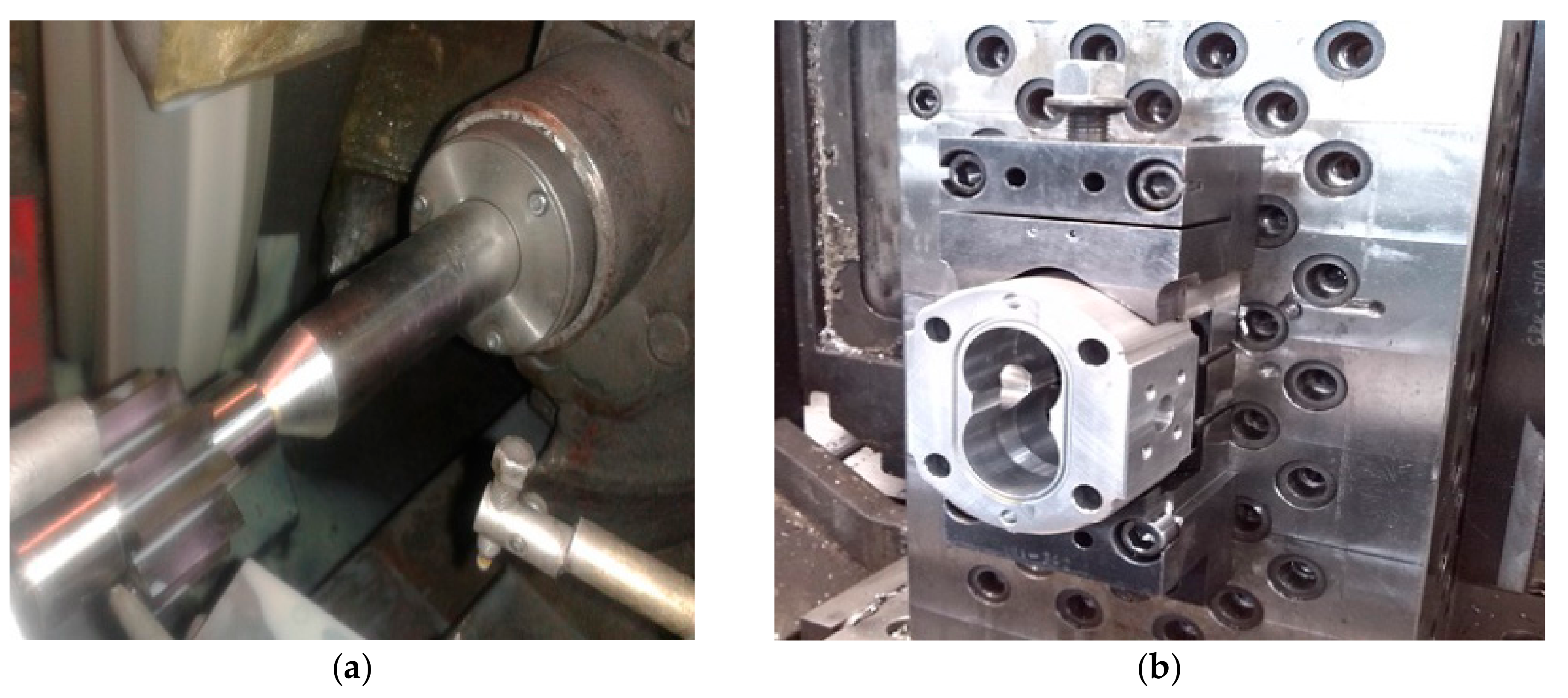

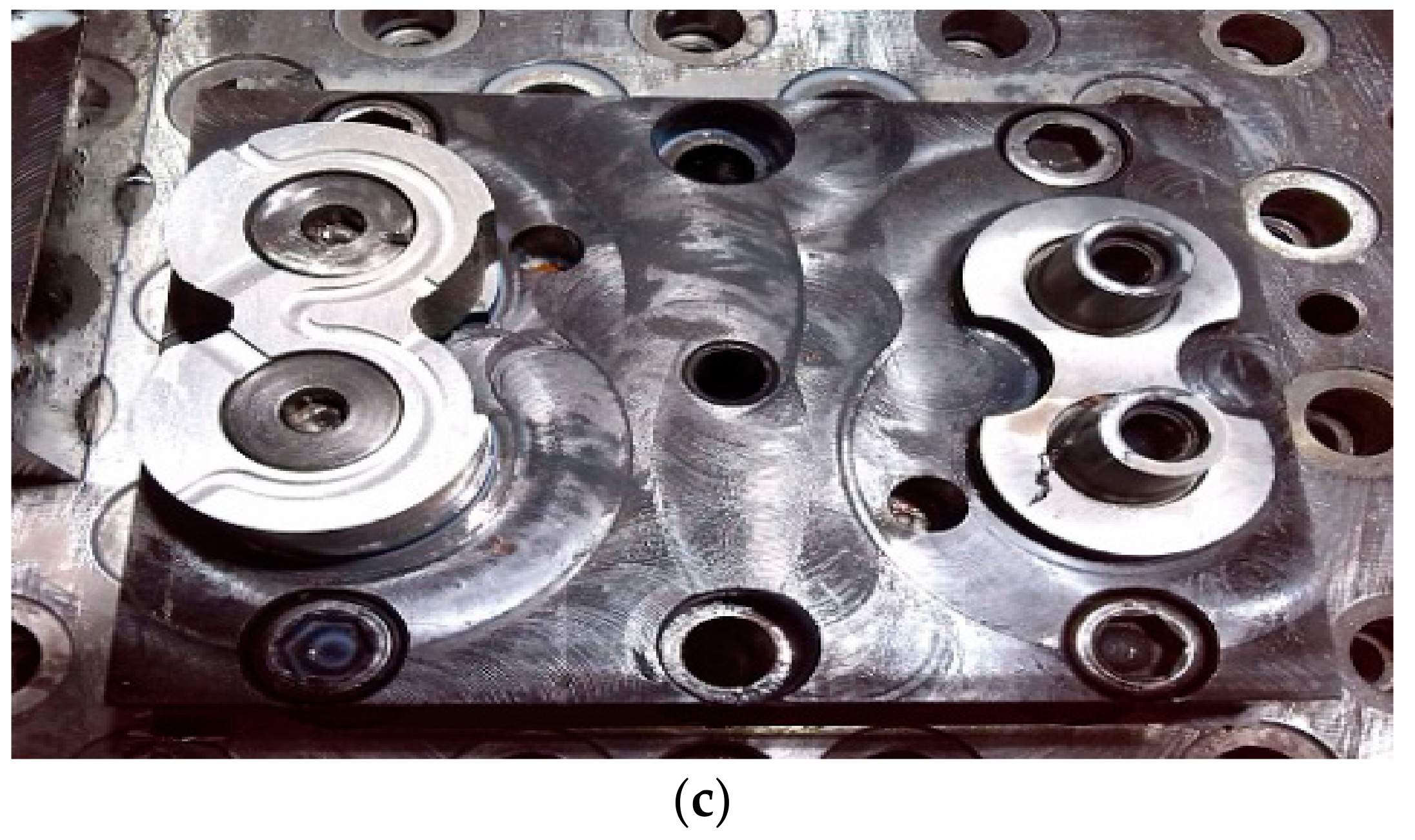

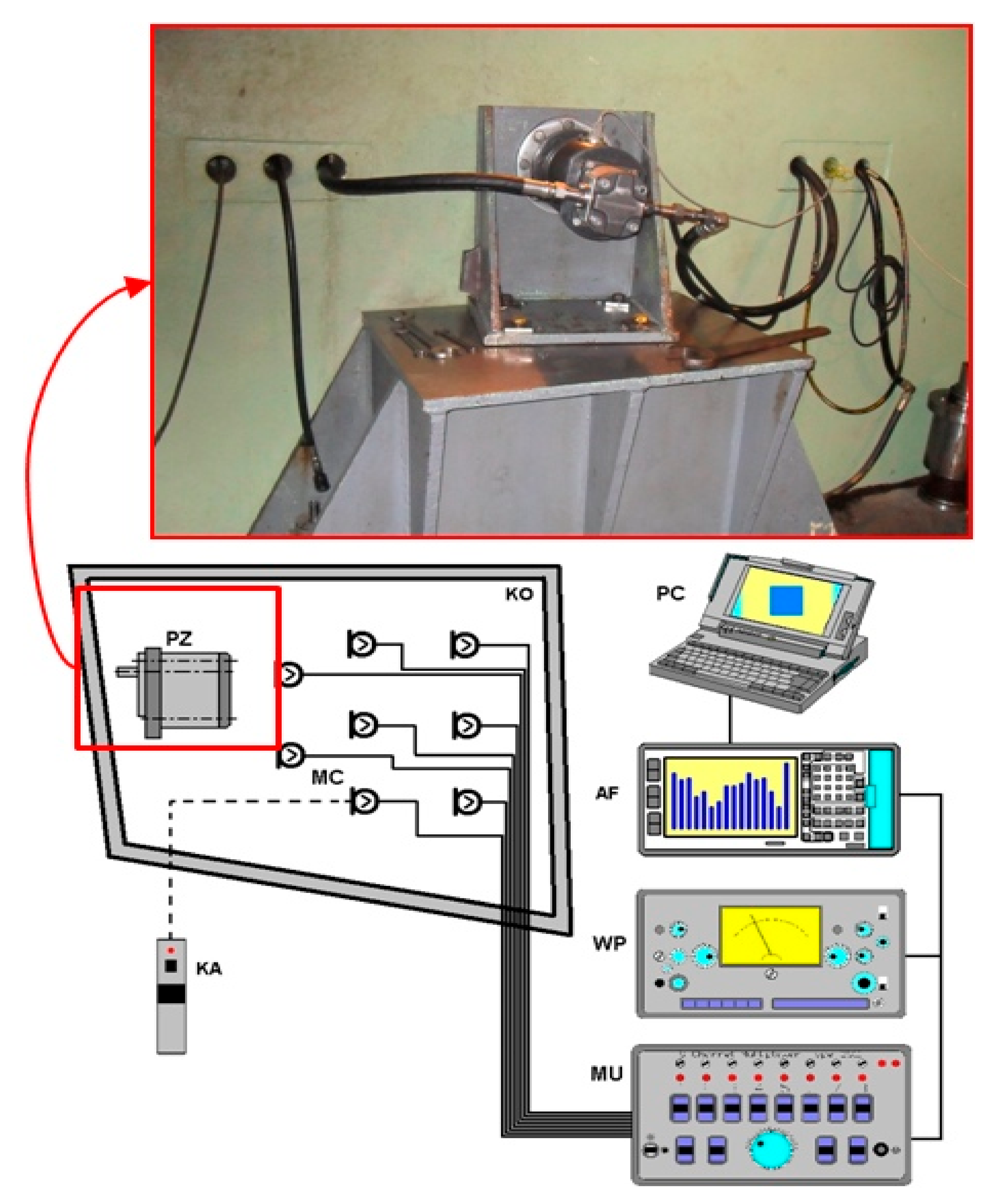

3. Measuring Rig

4. Determination of the Most Important Dimensional Tolerances for 2PW-SEW Pumps Using a Convolution Neural Network

- for gears (active and passive): 17 points,

- for the body (housing): 22 points,

- for a bearing set: 39 points, and

- for the plate: 7 points.

Application of Neural Network in Extracting Measurement Points

- AitechSPHINX artificial intelligence software (program with a license purchased for the Faculty of Production Engineering and Logistics, Opole University of Technology, Opole, Poland). The Neuronix module was used for creation of the neural network.

- —mean square error,

- i—the number of all learner vectors (in the training sequence),

- —the expected value at the output of the j neuron for the learning vector ,

- —output of the j neuron in layer i, and

- —number of neural network layers.

- / * * * Generation of the weight values ***/

- for(i=1;i<LW;i++)

- for(j=0;j<n(i);j++)

- for(k=0;k<=n(i-1);k++)

- {W(i)(j)(k) = (((rand() % 1000000L) / 1700.0) - 9.8)*0.0015;

- if(W(i)(j)(k) == 0.0) W(i)(j)(k) = 0.01492;}

- /**********************************/

- / * * * Single processing ***/

- for(i=1;i<LW;i++)

- for(j=0;j<n(i);j++)

- {I(i)(j) = 0.0;

- for(k=0;k<=n(i-1);k++)

- I(i)(j) += O(i-1)(k) * W(i)(j)(k);

- O(i)(j) = 1.0 / (1.0 + exp(beta*(-I(i)(j))));}

- /**********************************/

- for(j=0;j<n(LW-1);j++)

- B(LW-1)(j)= Wy(wu)(j) - O(LW-1)(j);

- /***********************************/

- for(j=0;j<n(LW-1);j++)

- B(LW-1)(j)= Wy(wu)(j) - O(LW-1)(j);

- /***********************************/

- for(i=1;i<LW;i++)

- for(j=0;j<n(i);j++)

- for(k=0;k<=n(i-1);k++)

- {

- W2(i)(j)(k)= W(i)(j)(k),

- (i)(j)(k) += eta * E(i)(j) * O(i-1)(k) + alfa*(W(i)(j)(k)-W1(i)(j)(k)),

- W1(i)(j)(k)= W2(i)(j)(k);

- }

- /**********************************/

- /********** Adjustment of weights *********/

- for(i=1;i<LW;i++)

- for(j=0;j<n(i);j++)

- for(k=0;k<=n(i-1);k++)

- {

- W2(i)(j)(k)= W(i)(j)(k),

- (i)(j)(k) += eta * E(i)(j) * O(i-1)(k) + alfa*(W(i)(j)(k)-W1(i)(j)(k)),

- W1(i)(j)(k)= W2(i)(j)(k);

- }

- /**********************************/

- / ***** Calculating network error *****/

- for(j=0;j<n(LW-1);j++)

- RMS += (Wy(wu)(j) - O(LW-1)(j))*(Wy(wu)(j) - O(LW-1)(j));

- ERMS = sqrt(RMS/(double)(ile_wek*n(LW-1)));

- /*********************************/

- lw—the number of layers in the network

- n(i)—the number of neurons in layer i

- i—layer number

- j—single neuron number

- k—weight number

- (i)(j)(k)—current weight k at j neuron in layer i

- w1(i)(j)(k)—previous weight k at neuron j in layer i

- i(i)(j)—input of neuron j in layer i

- o(i)(j)—output of neuron j in layer i

- e(i)(j)—delta (sigma) of neuron j in layer i

- b(lw-1)(j)—error on jth neuron output

- wy(wu)(j)—the expected value on jth neuron output for the learner vector wu

- ile_wek—the number of all learner vectors (in the training sequence)

- alfa—momentum factor

- beta—activation curve factor

- eta—learning rate

- erms—network error

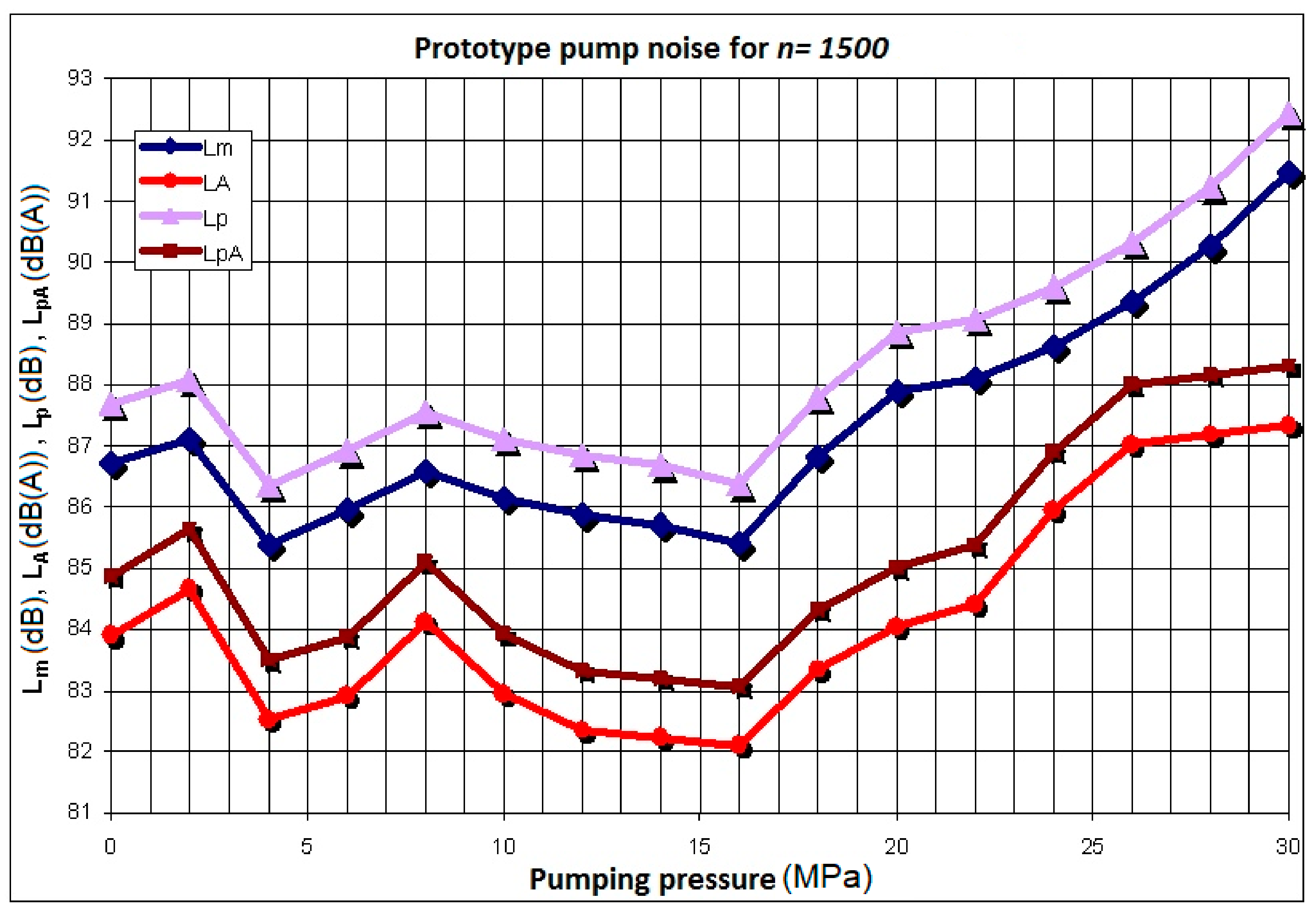

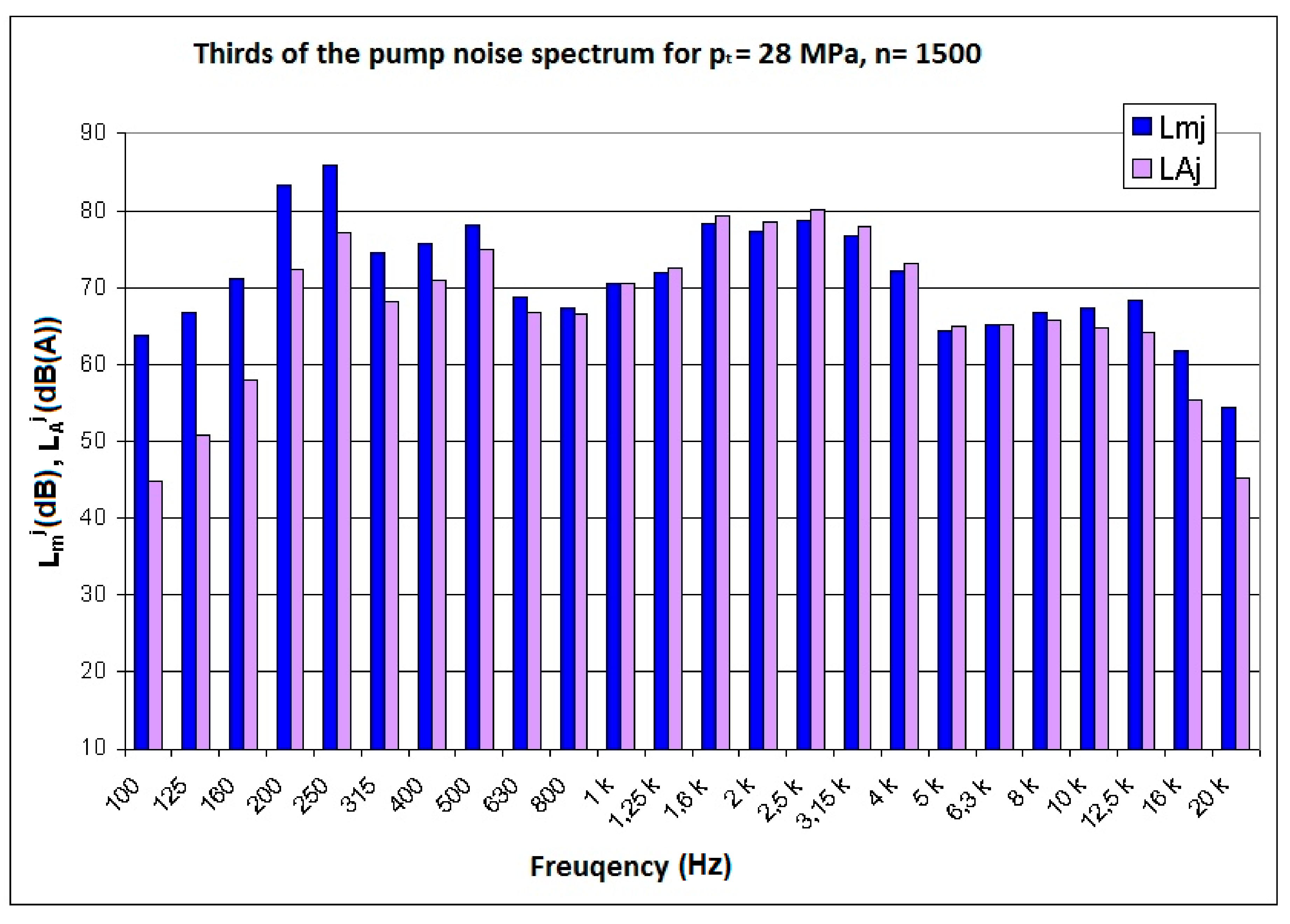

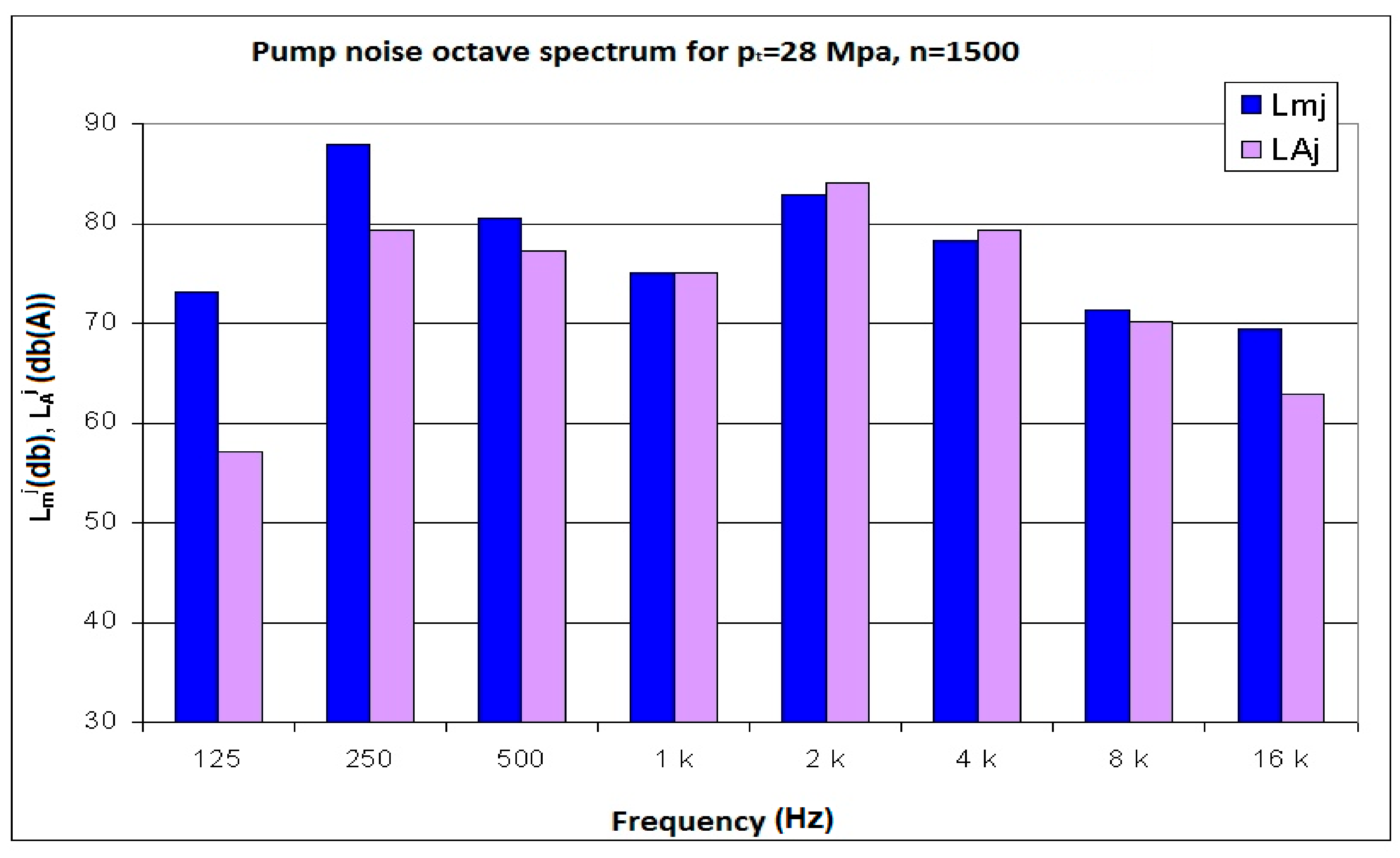

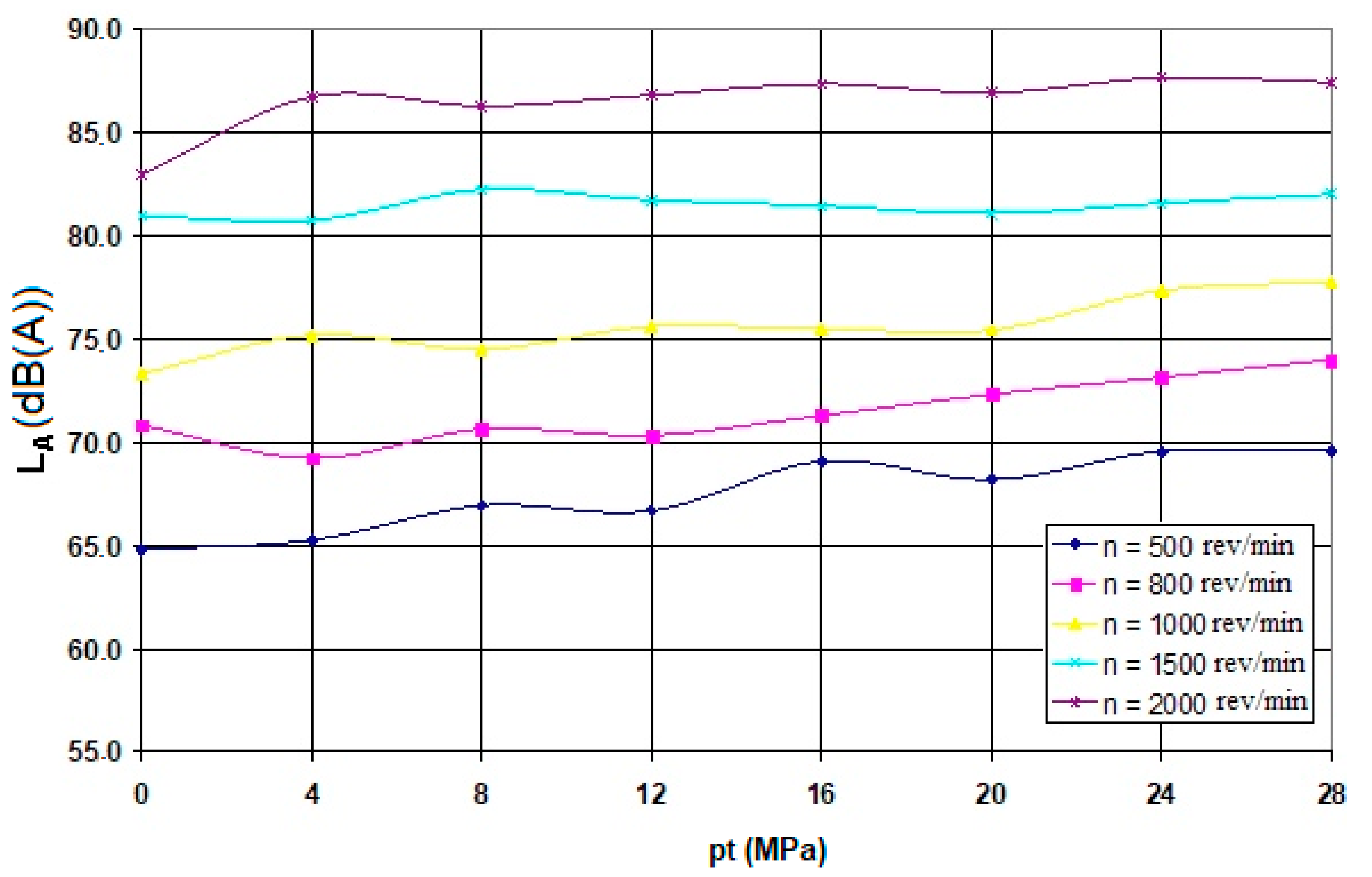

5. Acoustic Measurements of Prototype Pumps

- —sound pressure level at the ith measuring point and

- n—total number of measuring points.

- —sound pressure level at the i-th measuring point and

- n—total number of measuring points.

- —sound pressure level in the j-th frequency band,

- —A-weighted sound level in the j-th frequency band, and

- —correction according to the A characteristic for the j-th frequency band.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Deptuła, A.; Osiński, P. The optimization of three-involute tooth outline with taking into consideration multi-valued logic trees. In RESRB-2016 Proceedings of the 13th International Scientific Conference; Rusiński, E., Pietrusiak, D., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2017; pp. 99–107. [Google Scholar]

- Del Campo, D.; Castilla, R.; Raush, G.A.; Gamez Montero, P.J.; Codina, E. Numerical Analysis of External Gear Pumps Including Cavitation. ASMEJ. Fluids Eng. 2012, 134, 081105. [Google Scholar] [CrossRef]

- Ertürk, N.; Vernet, A.; Castilla, R.; Gamez-Montero, P.J.; Ferré, J.A. Experimental Analysis of the Flow Dynamics in the Suction Chamber of an External Gear Pump. Int. J. Mech. Sci. 2008, 53, 135–144. [Google Scholar] [CrossRef]

- Rundo, M. Models for Flow Rate Simulation in Gear Pumps: A Review. Energies 2017, 10, 1261. [Google Scholar] [CrossRef]

- Zhang, H.X. Analysis on Flow Pulse and Property of Double Helical Gear Pump. Mach. Tool Hydraul. 2011, 39, 8081–8084. [Google Scholar]

- Battarra, M.; Mucchi, E. A method for variable pressure load estimation in spur and helical gear pumps. Mech. Syst. Signal Process. 2016, 76–77, 265–282. [Google Scholar] [CrossRef]

- Baltes, H.; Goebbels, K.; Groben, M.; Post, M.; Weber, N. Primary and secondary measures to reduce the noise of hydraulic fluid power system. In 3rd International Fluid Power Conference; Shaker: Aachen, Germany, 2002. [Google Scholar]

- Dhar, S.; Vacca, A. A fluid—structure interaction model to analyze axial balance in external gearmachines. In Proceedings of the 8th International Fluid Power Conference, Dresden, Germany, 26–28 March 2012. [Google Scholar]

- Feldhaus, F.M. The Technology of Prehistoric Times, Historical Times and Primitive Peoples; Verlag von W. Engelmann: Leipzig, Germany; Berlin, Germany, 1914. [Google Scholar]

- Fröme, I. Loss Analysis on Gear Pumps, Theoretical and Experimental. Master’s Thesis, University of Stuttgart, Stuttgart, Germany, 1971. [Google Scholar]

- Hübsch, H.-G. Investigation of the Noise Behavior and Design Options for Noise Reduction in Gear Pumps That Are Not Pressure Compensated. Master’s Thesis, University of Stuttgart, Stuttgart, Germany, 1969. [Google Scholar]

- Kerres, K. Gear Melt Pump in Extrusion: Process Analysis and Options for Computerized. Master’s Thesis, RWTH Aachen University, Aachen, Germany, 1993. [Google Scholar]

- Kollek, W. Optimization of the efficiency of gear pumps and motors. Konstruktion 1985, 35, 147–151. [Google Scholar]

- Willekens, F.A.M. Instantaneous delivery volume, geometric stroke volume and degree of irregularity of gear pumps. Industrie-Anzeiger 1971, 93, 549–554. [Google Scholar]

- Osiński, P. High Pressure and Low Pulsation Gear Pumps with External Meshing; Publishing House of the Wrocław University of Technology: Wroclaw, Poland, 2013. [Google Scholar]

- Śliwiński, P. Flow of liquid in flat gaps of the satellite motor working mechanism. Pol. Marit. Res. 2014, 21, 50–57. [Google Scholar] [CrossRef]

- Osiński, P.; Kollek, W. Assessment of energetistic measuring techniques and their application to diagnosis of acoustic condition of hydraulic machinery and equipment. Arch. Civ. Mech. Eng. 2013, 13, 313–321. [Google Scholar] [CrossRef]

- Osiński, P.; Deptuła, A.; Partyka, M.A. Discrete optimization of a gear pump after tooth root undercutting by means of multi-valued logic trees. Arch. Civ. Mech. Eng. 2013, 13, 422–431. [Google Scholar] [CrossRef]

- Deptuła, A.; Osiński, P.; Partyka, M. Identification of Influence of Part Tolerances of 3PWR-SE Pump on its Total Efficiency Taking into Consideration Multi-Valued Logic Trees. Pol. Marit. Res. 2017, 24, 47–59. [Google Scholar]

- Osiński, P.; Deptuła, A. Optimization of the polyvalent tooth profile including multi-valued logical structures. In Reports of the Faculty of Mechanical Engineering of the Wroclaw University of Technology; Springer: Wroclaw, Poland, 2015. [Google Scholar]

- LeCun, Y.; Yoshua, B. Convolutional networks for images, speech, and time series. In The Handbook of Brain Theory and Neural Networks; MIT Press: Cambridge, MA, USA, 1995. [Google Scholar]

- Hubel, D.H.; Torsten, N.W. Receptive fields, binocular interaction and functional architecture in the cat’s Visual cortex. J. Physiol. 1962, 160, 106–154. [Google Scholar] [CrossRef] [PubMed]

- Ciregan, D.; Ueli, M.; Schmidhuber, J. Multi-column deep neural networks for image classification. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Providence, RI, USA, 16–21 June 2012. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. In Proceedings of the Twenty-sixth Annual Conference on Neural Information Processing Systems (NIPS), Lake Tahoe, NV, USA, 3–8 December 2012; pp. 1106–1114. [Google Scholar]

- Ultsch, A. Self-organising neural networks for visualisation and classifi-cation. In Information and Classification; Opitz, O., Lausen, B., Klar, R., Eds.; Springer: Berlin, Germany, 1993; pp. 864–867. [Google Scholar]

- Xiaochuan, F.; Kang, Z.; Yuewei, L.; Song, W. Combining local appearance and holistic view: Dual-source deep neural networks for human pose estimation. In Proceedings of the Computer Vision and Pattern Recognition (cs.CV), Boston, MA, USA, 7–12 June 2015. [Google Scholar]

- Pigoli, D.; Pantelis, Z.H.; Coleman, J.S.; Aston, J.A. The statistical analysis of acoustic phonetic data: Exploring differences between spoken Romance languages. Appl. Stat. 2018, 67, 1103–1145. [Google Scholar] [CrossRef]

- Hosokawa, K.; Ogawa, M.; Hashimoto, M.; Inohara, H. Statistical Analysis of the Reliability of Acoustic and Electroglottographic Perturbation Parameters for the Detection of Vocal Roughness. J. Voice 2014, 28, 263.e9–263.e16. [Google Scholar] [CrossRef] [PubMed]

- Bo, P.; González, H.; Calleja, A.; de Lacalle, L.N.L.; Bartoň, M. 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped milling tools—Part I: Modeling and simulation. Precis. Eng. 2020, 62, 204–212. [Google Scholar] [CrossRef]

- Fu, Y.; Zhuo, Y.; Zhou, X.; Wan, B.; Lv, H.; Wang, Z. Theoretical and Experimental Study on Contact Characteristics of Spiral Bevel Gears under Quasi-Static and Large Loading Conditions. Appl. Sci. 2020, 10, 5109. [Google Scholar] [CrossRef]

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Number of teeth | z | - | 9 |

| Modulus | m0 | (mm) | 4.5 |

| Pressure angle | α0 | (°) | 20 |

| Gear wheel width | b | (mm) | 32.2 |

| No. | pt (MPa) | n (min−1) | 2PW No. 1 | 2PW No. 2 | 2PW No. 3 | 2PW No. 4 | 2PW No. 5 | 2PW No. 6 | 2PW No. 7 | 2PW No. 8 | 2PW No. 9 | 2PW No. 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | % | % | |||

| 1 | 0 | 500 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 2 | 92.0 | 96.3 | 99.9 | 95.8 | 98.9 | 96.3 | 99.4 | 97.8 | 99.4 | 98.9 | |

| 3 | 4 | 97.8 | 96.9 | 98.1 | 96.2 | 96.8 | 97.6 | 96.4 | 95.0 | 95.4 | 96.6 | |

| 4 | 6 | 94.8 | 96.5 | 96.1 | 94.3 | 92.3 | 95.0 | 93.6 | 92.2 | 93.1 | 93.0 | |

| 5 | 8 | 91.9 | 93.3 | 92.8 | 89.2 | 90.8 | 90.3 | 92.6 | 89.0 | 84.8 | 89.3 | |

| 6 | 10 | 91.4 | 89.3 | 90.2 | 84.0 | 85.7 | 87.5 | 89.1 | 85.7 | 82.0 | 85.2 | |

| 7 | 12 | 88.6 | 88.7 | 89.7 | 79.1 | 83.8 | 84.1 | 86.0 | 82.8 | 80.8 | 83.6 | |

| 8 | 14 | 89.2 | 88.9 | 87.0 | 75.0 | 83.2 | 84.3 | 84.7 | 80.7 | 77.9 | 80.4 | |

| 9 | 16 | 88.2 | 86.6 | 84.4 | 72.3 | 80.3 | 81.1 | 83.8 | 79.1 | 76.7 | 77.0 | |

| 10 | 18 | 85.8 | 86.3 | 82.8 | 68.8 | 77.8 | 78.7 | 81.2 | 76.6 | 75.2 | 73.8 | |

| 11 | 20 | 83.7 | 84.3 | 80.2 | 66.4 | 74.3 | 75.3 | 77.9 | 73.8 | 73.9 | 69.4 | |

| 12 | 22 | 81.0 | 82.0 | 78.0 | 63.1 | 71.7 | 72.2 | 75.1 | 70.5 | 71.9 | 64.2 | |

| 13 | 24 | 78.5 | 78.8 | 74.3 | 59.3 | 67.3 | 68.4 | 72.3 | 66.8 | 69.5 | 58.3 | |

| 14 | 26 | 71.8 | 73.8 | 67.3 | 55.1 | 59.9 | 59.8 | 65.1 | 61.0 | 64.0 | 49.2 | |

| 15 | 28 | 69.1 | 74.3 | 64.8 | 54.2 | 54.1 | 54.0 | 63.4 | 58.1 | 62.6 | 40.0 | |

| 16 | 30 | 61.5 | 68.7 | 57.2 | 49.4 | 43.9 | 41.5 | 54.5 | 52.2 | 57.0 | 27.8 | |

| 17 | 32 | 47.1 | 60.6 | 49.1 | 45.6 | 29.0 | 24.2 | 41.9 | 41.9 | 50.2 | 0 |

| No. | pt (MPa) | n (min−1) | 2PW No. 1 | 2PW No. 2 | 2PW No. 3 | 2PW No. 4 | 2PW No. 5 | 2PW No. 6 | 2PW No. 7 | 2PW No. 8 | 2PW No. 9 | 2PW No. 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | % | % | |||

| 1 | 0 | 2000 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 2 | 62.1 | 64.1 | 62.1 | 61.0 | 75.3 | 63.7 | 62.5 | 62.1 | 59.1 | 63.7 | |

| 3 | 4 | 77.6 | 77.6 | 77.6 | 78.1 | 86.4 | 80.1 | 76.9 | 77.1 | 77.6 | 80.9 | |

| 4 | 6 | 81.0 | 81.9 | 82.8 | 82.8 | 89.0 | 83.2 | 80.1 | 81.7 | 80.5 | 84.1 | |

| 5 | 8 | 85.1 | 84.2 | 83.7 | 83.8 | 83.7 | 84.6 | 82.1 | 83.3 | 84.4 | 85.3 | |

| 6 | 10 | 85.1 | 85.7 | 85.1 | 83.4 | 82.9 | 85.7 | 84.5 | 84.0 | 85.1 | 85.2 | |

| 7 | 12 | 85.6 | 85.1 | 84.6 | 83.5 | 87.5 | 84.5 | 85.1 | 84.4 | 84.0 | 84.9 | |

| 8 | 14 | 86.3 | 86.0 | 85.8 | 84.7 | 87.5 | 85.6 | 85.4 | 85.0 | 84.3 | 88.1 | |

| 9 | 16 | 86.8 | 85.7 | 86.6 | 84.4 | 87.2 | 85.1 | 85.9 | 84.9 | 85.3 | 85.3 | |

| 10 | 18 | 87.2 | 85.9 | 86.1 | 84.3 | 87.0 | 85.2 | 85.4 | 85.3 | 84.2 | 85.1 | |

| 11 | 20 | 86.4 | 85.1 | 85.6 | 84.1 | 85.4 | 85.6 | 84.4 | 84.7 | 84.4 | 84.8 | |

| 12 | 22 | 86.2 | 85.3 | 85.0 | 83.9 | 85.3 | 84.4 | 84.2 | 84.2 | 83.7 | 83.8 | |

| 13 | 24 | 84.1 | 84.2 | 85.0 | 83.2 | 82.4 | 83.0 | 83.5 | 84.1 | 83.6 | 82.6 | |

| 14 | 26 | 80.1 | 80.8 | 80.8 | 79.3 | 77.9 | 79.2 | 79.7 | 80.3 | 79.4 | 78.3 | |

| 15 | 28 | 82.4 | 83.2 | 82.5 | 81.6 | 79.1 | 80.2 | 81.8 | 82.5 | 81.4 | 79.5 | |

| 16 | 30 | 81.1 | 81.1 | 81.7 | 79.8 | 74.8 | 77.7 | 79.4 | 80.6 | 79.2 | 76.5 | |

| 17 | 32 | 78.4 | 79.7 | 78.5 | 80.4 | 70.2 | 74.2 | 75.9 | 78.4 | 77.5 | 72.7 |

| No. | Symbol/ Tolerance | Measurement Results—Kr | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 1 | KR1 | 55.7 (−0.03) | 55.7009 | 55.6728 | 55.6787 | 55.6774 | 55.6534 | 55.6638 | 55.6680 | 55.6745 | 55.6804 | 55.6902 |

| 2 | KR2 | 55.7 (−0.03) | 55.6985 | 55.6708 | 55.6793 | 55.6753 | 55.6544 | 55.6575 | 55.6671 | 55.6691 | 55.6785 | 55.6878 |

| 3 | KR3 | 55.7 (−0.03) | 55.7024 | 55.6747 | 55.6837 | 55.6788 | 55.6565 | 55.6636 | 55.6688 | 55.6738 | 55.6754 | 55.6862 |

| 4 | KR4 | 55.7 (−0.03) | 55.7006 | 55.6770 | 55.6830 | 55.6792 | 55.6566 | 55.6623 | 55.6614 | 55.6759 | 55.6742 | 55.6830 |

| 5 | KR5 | 55.7 (−0.03) | 55.7042 | 55.6740 | 55.6833 | 55.6816 | 55.6561 | 55.6625 | 55.6625 | 55.6745 | 55.6753 | 55.6829 |

| 6 | KR6 | 55.7 (−0.03) | 55.7033 | 55.6758 | 55.6827 | 55.6824 | 55.6545 | 55.6679 | 55.6631 | 55.6760 | 55.6746 | 55.6823 |

| 7 | KR7 | 55.7 (−0.03) | 55.7050 | 55.6743 | 55.6840 | 55.6850 | 55.6559 | 55.6665 | 55.6654 | 55.6764 | 55.6755 | 55.6834 |

| 8 | KR8 | 55.7 (−0.03) | 55.7052 | 55.6727 | 55.6832 | 55.6815 | 55.6569 | 55.6641 | 55.6708 | 55.6741 | 55.6808 | 55.6911 |

| 9 | KR9 | 55.7 (−0.03) | 55.6998 | 55.6707 | 55.6750 | 55.6702 | 55.6500 | 55.6589 | 55.6652 | 55.6705 | 55.6761 | 55.6849 |

| 10 | KR10 | 55.7 (−0.03) | 55.7007 | 55.6692 | 55.6760 | 55.6742 | 55.6508 | 55.6546 | 55.6650 | 55.6674 | 55.6762 | 55.6856 |

| 19 | KR19 | Pr. (0.02) | 0.0091 | 0.0095 | 0.0115 | 0.0142 | 0.0084 | 0.0108 | 0.0014 | 0.0138 | 0.0000 | 0.0020 |

| 20 | KR20 | Pr. (0.02) | 0.0070 | 0.0023 | 0.0010 | 0.0012 | 0.0047 | 0.0021 | 0.0022 | 0.0005 | 0.0034 | 0.0046 |

| 21 | KR21 | Pr. (0.02) | 0.0066 | 0.0015 | 0.0019 | 0.0015 | 0.0019 | 0.0036 | 0.0006 | 0.0016 | 0.0007 | 0.0046 |

| 22 | KR22 | Pr. (0.02) | 0.0110 | 0.0025 | 0.0052 | 0.0039 | 0.0028 | 0.0037 | 0.0073 | 0.0018 | 0.0100 | 0.0097 |

| No. | Symbol/ Tolerance | Measurement Results—KzP | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 1 | Kzp1 | Ø18 (−0.025/−0.035) | 17.9650 | 17.9660 | 17.9650 | 17.9650 | 17.9660 | 17.9655 | 17.9665 | 17.9655 | 17.9655 | 17.9650 |

| 2 | Kzp2 | Ø18 (−0.025/−0.035) | 17.9640 | 17.9630 | 17.9650 | 17.9660 | 17.9660 | 17.9640 | 17.9640 | 17.9640 | 17.9660 | 17.9660 |

| 3 | Kzp3 | Ø24.8 (+/−0.2) | 24.8800 | 24.8400 | 24.8300 | 24.8300 | 24.8500 | 24.8200 | 24.8400 | 24.8300 | 24.8300 | 24.8400 |

| 4 | Kzp4 | Ø39 (−0.08/−0.096) | 38.9380 | 38.9320 | 38.9300 | 38.9320 | 38.9300 | 38.9320 | 38.9320 | 38.9300 | 38.9320 | 38.9320 |

| 5 | Kzp5 | 11.7 (−0.01) | 11.7010 | 11.6980 | 11.6960 | 11.7010 | 11.7020 | 11.7010 | 11.7010 | 11.7000 | 11.6980 | 11.6960 |

| 6 | Kzp6 | 11.7 (−0.01) | 11.6980 | 11.6970 | 11.6950 | 11.7000 | 11.7000 | 11.7000 | 11.7000 | 11.6990 | 11.6970 | 11.6950 |

| 7 | Kzp7 | C (0.003) | 0.0032 | 0.0040 | 0.0037 | 0.0026 | 0.0034 | 0.0025 | 0.0024 | 0.0034 | 0.0039 | 0.0034 |

| 8 | Kzp8 | R (0.005) | 0.0050 | 0.0100 | 0.0025 | 0.0025 | 0.0050 | 0.0050 | 0.0050 | 0.0075 | 0.0100 | 0.0050 |

| 9 | Kzp9 | C (0.003) | 0.0041 | 0.0047 | 0.0083 | 0.0058 | 0.0041 | 0.0040 | 0.0038 | 0.0050 | 0.0047 | 0.0034 |

| 16 | Kzp16 | 14.602 | 14.5490 | 14.5540 | 14.5380 | 14.5500 | 14.5490 | 14.5560 | 14.5500 | 14.5480 | 14.5490 | 14.5600 |

| 17 | Kzp17 | R | 0.0170 | 0.0100 | 0.0060 | 0.0120 | 0.0060 | 0.0060 | 0.0080 | 0.0180 | 0.0110 | 0.0080 |

| No. | Symbol/ Tolerance | Measurement Results—Kzpn | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 1 | Kzpn1 | Ø18 (−0.025/−0.035) | 17.968 | 17.960 | 17.964 | 17.967 | 17.964 | 17.964 | 17.956 | 17.966 | 17.965 | 17.968 |

| 2 | Kzpn2 | Ø18 (−0.025/−0.035) | 17.968 | 17.964 | 17.968 | 17.968 | 17.970 | 17.962 | 17.964 | 17.968 | 17.968 | 17.967 |

| 3 | Kzpn3 | Ø24.8 (+/−0.2) | 24.800 | 24.970 | 24.970 | 24.930 | 24.740 | 24.930 | 24.980 | 24.980 | 24.900 | 24.780 |

| 4 | Kzpn4 | Ø39 (−0.08/−0.096) | 38.920 | 38.918 | 38.920 | 38.918 | 38.924 | 38.918 | 38.916 | 38.920 | 38.916 | 38.922 |

| 5 | Kzpn5 | 11.7 (−0.01) | 11.697 | 11.694 | 11.692 | 11.699 | 11.705 | 11.702 | 11.698 | 11.698 | 11.694 | 11.692 |

| 6 | Kzpn6 | 11.7 (−0.01) | 11.696 | 11.693 | 11.690 | 11.698 | 11.700 | 11.700 | 11.698 | 11.697 | 11.694 | 11.690 |

| 7 | Kzpn7 | W (0.003) | 0.006 | 0.007 | 0.003 | 0.003 | 0.007 | 0.006 | 0.005 | 0.003 | 0.003 | 0.005 |

| 8 | Kzpn8 | R (0.005) | 0.005 | 0.003 | 0.005 | 0.005 | 0.005 | 0.003 | 0.005 | 0.000 | 0.005 | 0.000 |

| 9 | Kzpn9 | R (0.003) | 0.006 | 0.005 | 0.004 | 0.005 | 0.005 | 0.007 | 0.007 | 0.007 | 0.003 | 0.007 |

| 16 | Kzpn16 | 14.602 | 14.536 | 14.576 | 14.540 | 14.498 | 14.498 | 14.521 | 14.540 | 14.500 | 14.536 | 14.488 |

| 17 | Kzpn17 | R | 0.004 | 0.006 | 0.011 | 0.012 | 0.007 | 0.006 | 0.011 | 0.006 | 0.006 | 0.009 |

| No. | Symbol/ Tolerance | Measurement Results—Płt | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 1 | Płt1 | F (0.02) | 0.0354 | 0.0435 | 0.0391 | 0.0239 | 0.0220 | 0.0372 | 0.0437 | 0.0407 | 0.0351 | 0.0291 |

| 2 | Płt2 | P (0.03) | 0.0296 | 0.0199 | 0.0299 | 0.0267 | 0.0386 | 0.0213 | 0.0187 | 0.0199 | 0.0255 | 0.0217 |

| 3 | Płt3 | 19 (+/−0.2) | 18.9989 | 19.0165 | 18.9837 | 18.9177 | 18.9311 | 18.9898 | 18.9686 | 19.0073 | 19.0161 | 19.0066 |

| 4 | Płt4 | 19 (+/−0.2) | 19.0049 | 19.0258 | 18.9908 | 18.9265 | 18.9183 | 18.9954 | 18.9830 | 19.0205 | 19.0152 | 19.0159 |

| 5 | Płt5 | 19 (+/−0.2) | 18.9791 | 19.0059 | 18.9772 | 18.9036 | 18.9124 | 18.9742 | 18.9656 | 19.0045 | 18.9962 | 18.9985 |

| 6 | Płt6 | 19 (+/−0.2) | 19.0087 | 19.0234 | 19.0071 | 18.9303 | 18.9511 | 18.9948 | 18.9844 | 19.0244 | 19.0217 | 19.0202 |

| 7 | Płt7 | 19 (+/−0.2) | 18.9901 | 19.0250 | 18.9951 | 18.9170 | 18.9188 | 18.9878 | 18.9752 | 19.0107 | 19.0183 | 19.0059 |

| No. | Symbol/ Tolerance | Measurement Results—Kł | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimension | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| 1 | Kł1 | 22 (−0.08/−0.09) | 21.9077 | 21.9078 | 21.9103 | 21.9057 | 21.9030 | 21.9047 | 21.9041 | 21.9021 | 21.9031 | 21.9059 |

| 2 | Kł2 | 22 (−0.08/−0.09) | 21.9078 | 21.9113 | 21.9073 | 21.9059 | 21.9034 | 21.9081 | 21.9083 | 21.9118 | 21.9123 | 21.9141 |

| 3 | Kł3 | 22 (−0.08/−0.09) | 21.9075 | 21.9082 | 21.9057 | 21.9076 | 21.8999 | 21.9072 | 21.9071 | 21.9078 | 21.9116 | 21.9190 |

| 4 | Kł4 | 22 (−0.08/−0.09) | 21.9177 | 21.9096 | 21.9097 | 21.9076 | 21.9034 | 21.9083 | 21.9105 | 21.9108 | 21.9100 | 21.9091 |

| 5 | Kł5 | 22 (−0.08/−0.09) | 21.9063 | 21.9096 | 21.9092 | 21.9072 | 21.9053 | 21.9087 | 21.9186 | 21.9021 | 21.9025 | 21.9031 |

| 6 | Kł6 | 22 (−0.08/−0.09) | 21.9031 | 21.9058 | 21.9013 | 21.9050 | 21.9011 | 21.9042 | 21.9120 | 21.9060 | 21.9044 | 21.9058 |

| 7 | Kł7 | 22 (−0.08/−0.09) | 21.9039 | 21.9048 | 21.9026 | 21.9053 | 21.8990 | 21.9032 | 21.9093 | 21.9068 | 21.9064 | 21.9095 |

| 8 | Kł8 | P (0.004) | 0.0146 | 0.0065 | 0.0090 | 0.0026 | 0.0062 | 0.0055 | 0.0145 | 0.0010 | 0.0098 | 0.0159 |

| 9 | Kł9 | F (0.003) | 0.0083 | 0.0128 | 0.0087 | 0.0115 | 0.0086 | 0.0108 | 0.0104 | 0.0138 | 0.0164 | 0.0180 |

| 10 | Kł10 | 71.5 (−0.015) | 71.4897 | 71.4891 | 71.4620 | 71.4753 | 71.4905 | 71.4919 | 71.5106 | 71.5005 | 71.5027 | 71.4826 |

| 38 | Kł38 | Pr. (0.01) | 0.0002 | 0.0008 | 0.0022 | 0.0028 | 0.0107 | 0.0037 | 0.0024 | 0.0029 | 0.0037 | 0.0001 |

| 39 | Kł39 | Pr. (0.01) | 0.0001 | 0.0064 | 0.0040 | 0.0040 | 0.0007 | 0.0019 | 0.0105 | 0.0132 | 0.0171 | 0.0035 |

| n (rpm) | pt (MPa) | Qrz (/min) | M (Nm) | Nh (kW) | Nm (kW) | nv (%) | nhm (%) | nc (%) |

|---|---|---|---|---|---|---|---|---|

| 500 | 0 | 15.1 | 2.0 | 0.00 | 0.10 | 94.4 | 0.0 | 0.0 |

| 5 | 13.1 | 25.5 | 1.08 | 1.34 | 81.7 | 99.5 | 81.2 | |

| 10 | 11.4 | 52.5 | 1.89 | 2.75 | 71.2 | 96.8 | 68.9 | |

| 15 | 10.0 | 81.0 | 2.50 | 4.24 | 62.5 | 94.2 | 58.9 | |

| 20 | 9.5 | 110.0 | 3.17 | 5.76 | 59.6 | 92.5 | 55.1 | |

| 24 | 9.4 | 139.0 | 3.89 | 7.28 | 58.4 | 91.5 | 53.5 | |

| 30 | 8.6 | 172.0 | 4.30 | 9.01 | 53.8 | 88.8 | 47.7 | |

| 1000 | 0 | 31.7 | 2.2 | 0.00 | 0.23 | 99.2 | 0.0 | 0.0 |

| 5 | 30.4 | 25.5 | 2.53 | 2.67 | 95.1 | 99.5 | 94.6 | |

| 10 | 28.8 | 53.0 | 4.79 | 5.55 | 89.9 | 95.9 | 86.2 | |

| 15 | 27.6 | 81.5 | 6.88 | 8.53 | 86.1 | 93.6 | 80.6 | |

| 20 | 26.5 | 108.0 | 8.84 | 11.31 | 82.9 | 94.2 | 78.1 | |

| 24 | 26.3 | 140.0 | 10.93 | 14.66 | 82.1 | 90.9 | 74.6 | |

| 30 | 25.4 | 172.0 | 12.70 | 18.01 | 79.5 | 88.8 | 70.5 | |

| 1500 | 0 | 48.0 | 2.8 | 0.00 | 0.44 | 100.0 | 0.0 | 0.0 |

| 5 | 47.5 | 26.0 | 3.95 | 4.08 | 99.0 | 97.5 | 96.6 | |

| 10 | 45.7 | 56.5 | 7.60 | 8.87 | 95.2 | 90.0 | 85.6 | |

| 15 | 44.5 | 85.0 | 11.10 | 13.35 | 92.7 | 89.8 | 83.2 | |

| 20 | 43.5 | 113.0 | 14.47 | 17.75 | 90.5 | 90.1 | 81.5 | |

| 24 | 42.8 | 144.0 | 17.82 | 22.62 | 89.2 | 88.3 | 78.8 | |

| 30 | 41.9 | 176.0 | 20.92 | 27.65 | 87.2 | 86.8 | 75.7 | |

| 2000 | 0 | 64.0 | 3.2 | 0.00 | 0.67 | 100.0 | 0.0 | 0.0 |

| 5 | 63.5 | 27.5 | 5.27 | 5.76 | 99.3 | 92.2 | 91.5 | |

| 10 | 61.9 | 56.6 | 10.30 | 11.83 | 96.8 | 90.0 | 87.1 | |

| 15 | 60.8 | 85.0 | 15.19 | 17.80 | 95.0 | 89.8 | 85.3 | |

| 20 | 59.8 | 113.0 | 19.92 | 23.76 | 93.5 | 90.1 | 84.2 | |

| 24 | 59.1 | 143.0 | 24.59 | 29.95 | 92.3 | 89.0 | 82.1 | |

| 30 | 58.0 | 177.0 | 29.00 | 37.07 | 90.7 | 86.3 | 78.2 |

| n (rpm) | pt (MPa) | Qrz (/min) | M (Nm) | Nh (kW) | Nm (kW) | nv (%) | nhm (%) | nc (%) |

|---|---|---|---|---|---|---|---|---|

| 500 | 0 | 15.6 | 0.5 | 0.00 | 0.03 | 100.0 | 0.0 | 0.0 |

| 5 | 14.6 | 28.0 | 1.21 | 1.47 | 93.6 | 88.1 | 82.5 | |

| 10 | 14.1 | 56.0 | 2.34 | 2.93 | 90.4 | 88.4 | 79.9 | |

| 15 | 14.1 | 83.0 | 3.52 | 4.35 | 90.4 | 89.6 | 80.9 | |

| 20 | 14.4 | 110.0 | 4.79 | 5.76 | 92.3 | 90.1 | 83.2 | |

| 24 | 14.7 | 140.0 | 6.12 | 7.33 | 94.2 | 88.6 | 83.5 | |

| 30 | 14.4 | 170.0 | 7.19 | 8.90 | 92.3 | 87.5 | 80.8 | |

| 1000 | 0 | 32.3 | 1.0 | 0.00 | 0.10 | 99.1 | 0.0 | 0.0 |

| 5 | 32.0 | 32.0 | 2.65 | 3.35 | 98.2 | 80.6 | 79.1 | |

| 10 | 31.8 | 60.0 | 5.28 | 6.28 | 97.5 | 86.2 | 84.1 | |

| 15 | 32.0 | 85.0 | 7.98 | 8.90 | 98.2 | 91.4 | 89.7 | |

| 20 | 32.6 | 116.0 | 10.85 | 12.15 | 99.9 | 89.3 | 89.3 | |

| 24 | 32.6 | 141.0 | 13.57 | 14.77 | 99.9 | 91.9 | 91.9 | |

| 30 | 32.5 | 171.0 | 16.23 | 17.91 | 99.7 | 90.0 | 90.7 | |

| 1500 | 0 | 49.9 | 2.0 | 0.00 | 0.31 | 99.8 | 0.0 | 0.0 |

| 5 | 49.9 | 31.0 | 4.13 | 4.87 | 99.8 | 85.1 | 84.9 | |

| 10 | 49.2 | 60.0 | 8.18 | 9.42 | 98.4 | 88.2 | 86.7 | |

| 15 | 49.6 | 89.0 | 12.38 | 13.98 | 99.2 | 89.2 | 88.5 | |

| 20 | 50.0 | 118.0 | 16.64 | 18.54 | 99.9 | 89.8 | 89.8 | |

| 24 | 50.0 | 144.0 | 20.81 | 22.62 | 99.9 | 92.0 | 92.0 | |

| 30 | 49.6 | 175.0 | 24.78 | 27.49 | 99.2 | 90.9 | 90.1 | |

| 2000 | 0 | 66.9 | 4.0 | 0.00 | 0.84 | 99.1 | 0.0 | 0.0 |

| 5 | 67.3 | 33.0 | 5.57 | 6.91 | 99.7 | 80.9 | 80.7 | |

| 10 | 67.2 | 62.0 | 11.17 | 12.99 | 99.6 | 86.4 | 86.0 | |

| 15 | 67.2 | 91.0 | 16.77 | 19.06 | 99.6 | 88.4 | 88.0 | |

| 20 | 67.5 | 120.0 | 22.47 | 25.13 | 99.9 | 89.4 | 89.4 | |

| 24 | 67.1 | 147.0 | 27.92 | 30.79 | 99.4 | 91.2 | 90.7 | |

| 30 | 66.8 | 177.0 | 33.37 | 37.07 | 99.0 | 91.0 | 90.0 |

| f (Hz) | Microphone Numbers | Thirds | Octaves | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Lmj | Smj | KAj | LAj | Lmj | LAj | |

| −1.48 | −0.15 | −0.20 | 0.33 | 0.16 | −0.10 | 0.26 | 0.42 | |||||||

| 25 | 84.1 | 81.8 | 62.5 | 46.8 | 65.4 | 83.8 | 82.4 | 78.1 | 80.1 | 15.4 | −44.7 | 35.4 | ||

| 31.5 | 62.3 | 60.0 | 54.9 | 40.0 | 56.8 | 63.7 | 60.3 | 62.0 | 60.1 | 8.0 | −39.3 | 20.8 | 80.2 | 40.9 |

| 40 | 58.9 | 49.4 | 58.5 | 55.7 | 52.9 | 51.8 | 46.4 | 53.7 | 54.7 | 4.3 | −34.6 | 20.1 | ||

| 50 | 70.8 | 67.8 | 74.2 | 74.9 | 73.0 | 66.0 | 65.3 | 62.2 | 71.1 | 5.0 | −30.2 | 40.9 | ||

| 63 | 71.7 | 76.4 | 76.1 | 75.2 | 71.9 | 66.0 | 78.4 | 59.6 | 74.4 | 6.8 | −26.2 | 48.2 | 77.1 | 50.9 |

| 80 | 75.4 | 73.0 | 67.1 | 69.8 | 64.9 | 63.8 | 68.7 | 69.0 | 70.1 | 3.8 | −22.5 | 47.6 | ||

| 100 | 69.9 | 64.8 | 60.9 | 61.9 | 65.4 | 65.1 | 60.8 | 62.8 | 64.6 | 2.7 | −19.1 | 45.5 | ||

| 125 | 74.6 | 73.3 | 75.1 | 66.6 | 71.0 | 66.2 | 68.5 | 70.0 | 71.5 | 3.3 | −16.1 | 55.4 | 75.0 | 58.9 |

| 160 | 69.8 | 69.1 | 70.5 | 69.5 | 68.6 | 74.1 | 71.9 | 75.1 | 71.8 | 2.8 | −13.4 | 58.4 | ||

| 200 | 81.8 | 71.1 | 76.8 | 74.0 | 69.4 | 78.2 | 76.5 | 74.0 | 76.3 | 3.8 | −10.9 | 65.4 | ||

| 250 | 83.0 | 72.6 | 79.8 | 76.3 | 73.0 | 80.2 | 79.5 | 75.9 | 78.4 | 3.5 | −8.6 | 69.8 | 81.2 | 72.6 |

| 315 | 77.1 | 68.8 | 73.4 | 70.6 | 75.0 | 72.6 | 74.0 | 65.7 | 73.0 | 3.5 | −6.6 | 66.4 | ||

| 400 | 83.4 | 80.6 | 80.2 | 69.9 | 69.7 | 79.6 | 73.2 | 74.2 | 78.2 | 5.2 | −4.8 | 73.4 | ||

| 500 | 84.2 | 81.3 | 80.5 | 71.4 | 70.8 | 80.6 | 74.4 | 75.1 | 79.0 | 4.9 | −3.2 | 75.8 | 81.9 | 78.7 |

| 630 | 65.4 | 67.1 | 69.4 | 71.3 | 73.8 | 68.2 | 70.4 | 71.8 | 70.5 | 3.4 | −1.9 | 68.6 | ||

| 800 | 60.7 | 60.9 | 63.9 | 62.5 | 64.1 | 63.1 | 69.5 | 63.8 | 64.6 | 3.3 | −0.8 | 63.8 | ||

| 1 k | 61.8 | 63.4 | 65.9 | 63.5 | 63.1 | 63.4 | 71.7 | 65.7 | 66.2 | 3.8 | 0 | 66.2 | 71.4 | 71.4 |

| 1.25 k | 68.8 | 68.8 | 71.2 | 69.7 | 67.8 | 66.5 | 65.8 | 66.6 | 68.4 | 1.8 | 0.6 | 69.0 | ||

| 1.6 k | 72.5 | 69.3 | 68.9 | 68.1 | 70.8 | 70.8 | 67.1 | 65.4 | 69.3 | 1.9 | 1 | 70.3 | ||

| 2 k | 72.3 | 72.0 | 72.2 | 70.4 | 69.6 | 72.9 | 71.1 | 71.3 | 71.5 | 0.9 | 1.2 | 72.7 | 74.8 | 76.0 |

| 2.5 k | 70.2 | 69.2 | 70.3 | 69.2 | 67.1 | 68.3 | 69.3 | 67.3 | 68.9 | 1.0 | 1.3 | 70.2 | ||

| 3.15 k | 66.2 | 68.5 | 67.4 | 65.9 | 65.9 | 66.9 | 65.0 | 66.0 | 66.5 | 1.1 | 1.2 | 67.7 | ||

| 4 k | 69.4 | 69.8 | 69.7 | 68.2 | 66.0 | 68.9 | 67.7 | 67.4 | 68.4 | 1.1 | 1 | 69.4 | 71.6 | 72.6 |

| 5 k | 67.5 | 65.1 | 65.2 | 65.4 | 62.5 | 63.5 | 64.3 | 63.0 | 64.6 | 1.2 | 0.5 | 65.1 | ||

| 6.3 k | 67.7 | 64.0 | 63.1 | 64.9 | 63.5 | 62.5 | 66.1 | 63.8 | 64.6 | 1.5 | −0.1 | 64.5 | ||

| 8 k | 68.6 | 65.5 | 65.2 | 64.3 | 63.2 | 65.2 | 64.2 | 64.4 | 65.1 | 1.1 | −1.1 | 64.0 | 69.3 | 68.2 |

| 10 k | 65.5 | 65.6 | 63.5 | 63.1 | 64.3 | 63.8 | 62.9 | 61.9 | 63.8 | 0.9 | −2.5 | 61.3 | ||

| 12.5 k | 66.1 | 63.0 | 63.2 | 62.4 | 61.7 | 61.9 | 60.8 | 62.7 | 62.8 | 1.1 | −4.3 | 58.5 | ||

| 16 k | 59.6 | 57.7 | 56.3 | 58.3 | 56.3 | 54.9 | 55.0 | 55.2 | 56.8 | 1.4 | −6.6 | 50.2 | 63.9 | 57.3 |

| 20 k | 53.2 | 51.4 | 49.8 | 49.3 | 49.0 | 47.3 | 47.7 | 47.6 | 49.6 | 1.6 | −9.3 | 40.3 | ||

| Parameter | Commercial Pump | Model Pump |

|---|---|---|

| Sound level A(dB) | 83–84 | 79 |

| Total efficiency (%) | 73–76 | 87.0 |

| Coefficient of performance unevenness (%) | 19.0–21.0 * | 19.9 |

| Sound vibration level (effective acceleration value) (m/s2) | 0.058–0.074 | 0.049 |

| Power to weight parameter (kW/kg) | 3.2–3.5 ** | 4.5 *** |

| Energy efficiency q/V | 0.27–0.29 * | 0.31 |

| Sealed space compression ratio Vmax/Vmin | 1.1–1.2 * | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deptuła, A.; Osiński, P.; Partyka, M.A. Analysis of Dimensional Tolerances on Hydraulic and Acoustic Properties of a New Type of Prototypal Gear Pumps. Appl. Sci. 2020, 10, 8535. https://doi.org/10.3390/app10238535

Deptuła A, Osiński P, Partyka MA. Analysis of Dimensional Tolerances on Hydraulic and Acoustic Properties of a New Type of Prototypal Gear Pumps. Applied Sciences. 2020; 10(23):8535. https://doi.org/10.3390/app10238535

Chicago/Turabian StyleDeptuła, Adam, Piotr Osiński, and Marian A. Partyka. 2020. "Analysis of Dimensional Tolerances on Hydraulic and Acoustic Properties of a New Type of Prototypal Gear Pumps" Applied Sciences 10, no. 23: 8535. https://doi.org/10.3390/app10238535

APA StyleDeptuła, A., Osiński, P., & Partyka, M. A. (2020). Analysis of Dimensional Tolerances on Hydraulic and Acoustic Properties of a New Type of Prototypal Gear Pumps. Applied Sciences, 10(23), 8535. https://doi.org/10.3390/app10238535