Abstract

The accurate prediction of mine surface subsidence is directly related to the reuse area of land resources. Currently, the probability integral method is the most extensive method of surface subsidence prediction in China. However, its prediction precision largely depends on the accuracy of the selected parameters. When the mining area lacks measured data, or the geological and mining conditions change, particularly for large-scale surface subsidence prediction, the reliability of the prediction of surface subsidence is poor. Moreover, there is a lack of a systematic summary of the correct selection of prediction parameters. Based on this, the paper systematically investigated the influence of geological and mining conditions on the prediction parameters of the probability integral method. The research findings were obtained via theoretical analysis. The research outcomes can provide a scientific basis for properly selecting the prediction parameters of the probability integral method. Last, the results of this paper can be applied to predict the surface subsidence of Pei County in the north, laying the foundation for the integration of Pei County.

1. Introduction

The exploitation of coal resources can cause various environmental and geological disasters [1,2], which mainly refer to surface subsidence. Accurate prediction of surface subsidence is an important means to prevent mining damages and reduce subsidence disasters. Meanwhile, it is directly related to the reuse of the area of land resources. Therefore, the researchers have conducted exhaustive research on the prediction methods of surface subsidence and have achieved fruitful results.

In the mining surface subsidence prediction of the caving mining, Soni adopted the profile function method to conduct surface subsidence prediction of the inclined coal seams [3]. Baryakh established a dynamic prediction method of surface subsidence that incorporated the time factor [4]. A three-dimensional n-k-g influence function was used by Nicieza to predict the surface subsidence [5]. Moreover, Hejmanowski employed the spatial statistical method to learn the surface subsidence prediction method [6]. The probability integral method was proposed by Liu to further perfect Lee Pooh’s random medium theory [7]. Liu also established the Weibull method of surface movement, with the overlying strata as a tatter block [8]. In addition, some scholars also worked on the principles of surface subsidence such as insufficient mining [9,10], deep mining [11,12,13,14], thick soil mining [15,16] and other special mining conditions [17,18,19,20], with the corresponding prediction approaches of surface subsidence proposed. For the prediction of surface subsidence in backfilling mining, Guo put forward the surface subsidence prediction model based on the equivalent mining height theory [21]. The prediction models established above can solve practical issues to a certain extent. However, the probability integral method is the most widely used surface subsidence prediction method.

The prediction parameters of the probability integral approach include subsidence coefficient, horizontal movement coefficient, tangent of major influence angle, mining influence propagation angle and inflection point offset. The five parameters intuitively reflect the relationship between the surface subsidence basin and the area. Through the inversion of measured data, the prediction parameters of most mines in China have been obtained, enabling the probability integral method the most widely applied method. However, the prediction precision of this method largely depends on the accuracy of the selected parameters. When the mining area absences measured data or the geological and mining conditions vary, particularly for large-scale surface subsidence prediction, it will cause the lack of a systematic summary for properly selecting prediction parameters. Therefore, it is necessary to study the influence law of geological and mining conditions on the prediction parameters of the probability integral means. The prediction parameters can be selected according to the relationship between the parameters and the geological and mining conditions. Although some scholars have worked on the influence of geological and mining conditions on the prediction parameters [22,23,24,25], a more systematic analysis and summary still are required. Consequently, this paper systematically investigates the impact of geological and mining conditions on the prediction parameters of the probability integral method based on the theoretical analysis, and the corresponding research results were attained. The findings can offer a scientific basis for properly choosing prediction parameters of the probability integral method. Eventually, the research outcomes of this paper can be used to predict the surface subsidence of northern Pei County and lay the foundation for the integration of this area.

2. Fundamental Parameters of Probability Integral Method

The theoretical basis of the probability integral method is the random medium theory. The fundamental parameters of the probability integral method include subsidence coefficient, horizontal movement coefficient, tangent of major influence angle, mining influence propagation angle and inflection point offset. The accuracy of these selected parameters is directly related to the prediction precision of surface subsidence in the mining areas.

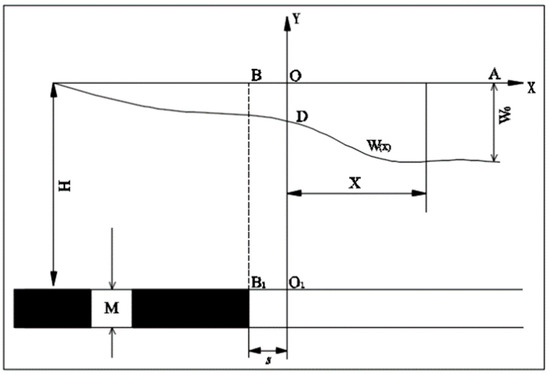

The subsidence coefficient q represents the ratio of maximum surface subsidence value and the projected length of coal seam mining thick in the vertical direction in full mining, as shown in Figure 1. The subsidence coefficient is a key parameter for surface movement and deformation prediction, and its calculation formula is as follows:

where: is the measured maximum surface subsidence value when the strike and tendency reach the full-mining;

Figure 1.

Schematic diagram of the subsidence coefficient.

- q is the surface subsidence coefficient;

- M is the coal seam mining thickness, m;

- is the coal seam dip angle, °.

Where: is the measured maximum surface subsidence when the strike and tendency have reached full-mining, mm; H is the mining depth of coal seam, m; M is the mining thickness, m; W(x) is the surface subsidence function; s is the inflection point offset, m.

The inflection point offset s refers to the offset distance of the inflection point of the subsidence curve from the mining boundary to the goaf. This is due to the cantilever effect of the roof at the mining boundary. The value of the inflection point offset directly affects the shape and area of the surface subsidence basin, as shown in Figure 1.

The horizontal movement coefficient b gives the ratio of maximum surface horizontal movement value and the maximum surface subsidence value. The calculation formula can be expressed as:

where: is the measured maximum surface subsidence when the strike and tendency arrive the full-mining, mm; is the measured maximum surface horizontal movement when the strike and tendency reach the full-mining, mm; b is the horizontal movement coefficient.

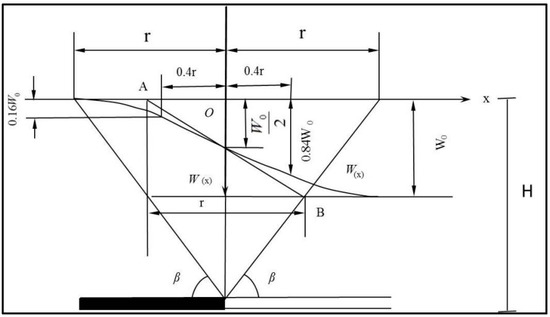

The tangent of major influence angle tan β is the tangent of angle β between the line of main influence area boundary point and the mining boundary point and the horizontal line, as shown in Figure 2. The tangent of major influence angle is the major parameter to determine the area of surface movement and deformation, and the calculation formula is:

where:

Figure 2.

Schematic diagram of the main influence angle.

- H is the mining depth of the coal seam, m;

- r is the main influence radius, m;

- tan β is the tangent of the major influence angle.

Where: is the measured maximum surface subsidence when the strike and tendency the full-mining, mm; r is the main influence radius, m; β is the main influence angle, °; H is the mining depth of the coal seam, m; W(x) is the surface subsidence function.

The mining influence propagation angle is angle θ that is formed by the line of the inflection point of the subsidence curve and the mining boundary point and the horizontal line under the condition of the full mining, which is the index of deviation degree of surface subsidence basin.

3. Prediction Results of Mining Surface Subsidence of Northern Pei County for Reusing Land Resources

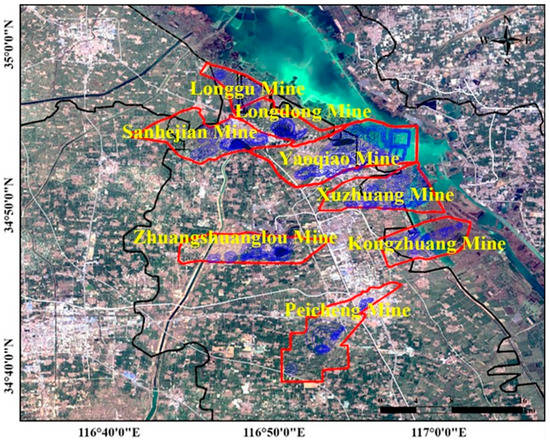

Northern Pei County includes Peichen town, Datun town, Yangtun town, Longgu town and Anguo town, as well as the new urban district and the development zone, with an area of 445 km2, a population of 574,000 and 162 villages under the administration. As the main body of the Xu-Pei coalfield, coal resources are abundant. The proved coal reserves are 2.4 billion tons, and the annual high-quality raw coal output exceeds 13 million tons. There are Yaoqiao coal mine, Kongzhuang coal mine, Xuzhuang coal mine, Longdong coal mine, Zhangshuanglou coal mine, Sanhejian coal mine, Peicheng coal mine and Longgu coal mine. According to the actual situation, a comprehensive development plan for northern Pei County was proposed to promote the integrated development for the urban and rural coordination, finally solving issues of agriculture and enhance economic and social development. Its nature determines northern Pei County as a joint development area with the aim of eliminating region barriers and promoting resource integration. Moreover, integration development involves planning and construction, industrial development, infrastructure development, public service, labor employment, social management, ecological remediation, land in mining area development, etc. Briefly, the integrated development goal will be achieved by coordinated planning, institutional reform, mechanism innovation and policy adjustment.

One of the urgent issues in the process of northern Pei County integration is the use of subsidence land in the mining areas. The development model of subsidence land use in mining areas should be established on the basis of various locational conditions, ponding conditions, ecological environment and social economy. It is related to sustainable development, intensive land use, the overall plan of land use and urban planning. Northern Pei County has a flat terrain with densely distributed river systems, roads and villages, and the underground coal resources are abundant, and the economy is booming. However, the severe surface subsidence and deformation have caused land resources degeneration, road damages, building deformation and ecological environment deterioration due to the application of the caving method for roof management in underground coal mining. The research on the mining-induced surface subsidence prediction in northern Pei County can provide an important scientific basis for coal mining subsidence area governance, land rehabilitation and ecological environment improvement in the area.

3.1. The Influence of Geological and Mining Conditions on Prediction Parameters

The surface subsidence area and value have a great correlation with geological and mining conditions. Generally, the geological and mining conditions include lithology of overlying strata, mining thickness, mining depth, unconsolidated layer thickness, coal seam dip angle, mining degree, multiple mining and roof management methods. This section systematically explores the influence of geological and mining conditions on the prediction parameters of the probability integral method based on theoretical analysis, and the corresponding findings were achieved.

3.1.1. Lithology of Overlying Strata

The lithology overlying strata has an impact on the surface subsidence coefficient. If the overburden is a hard stratum, it can appear a large number of separations in the process of rock stratum movement and destruction. If the overburden is a soft stratum, it is not easy to separate in the process of rock stratum movement and destruction. Therefore, the harder the overlying strata, the smaller the subsidence coefficient. The average consistency coefficient f of the overlying strata is usually used to reflect the overburden lithology. As f increases, the subsidence coefficient will reduce. The calculation method of f is as follows [26]:

In which:

- Mi is the normal thickness of the i stratum, m;

- Ri is the uniaxial compressive strength of the i stratum, Mpa;

- f is the average consistency coefficient.

The lithology of overlying strata also has an influence on the tangent of major influence angle. When the mining depth is the same, the overlying strata is harder, and the tangent of major influence angle tanβ is smaller. The empirical formula of the relationship between tanβ and the lithology of overlying strata is given in the literature [26]:

where: D is the lithology influence coefficient, and it has a relation with the stratum comprehensive evaluation coefficient P; H is the mining depth, m; tan β is the tangent of the major influence angle; is the inclined angle of the coal seam, °.

The strata are at the state of the cantilever beam due to the existence of the voussoir beam in the goaf boundary. This part of the strata is hard to cave under the protection of the voussoir beam. If the overlying strata are hard, the voussoir beam structure possibly is bigger, and the inflection point offset should be larger.

In general, the tangent of the major influence angle has a correlation with the coal seam dip angle. However, the lithology of overlying strata also has a certain influence on the value of the tangent of the major influence angle. When the overlying strata are very soft, no matter how large the coal seam dip angle is, the value of the tangent of the major influence angle is 90°.

3.1.2. Mining Thickness

Mining thickness is an important factor affecting surface subsidence. The bigger the mining thickness, the greater damage to the overburden. Thus, the subsidence coefficient increases with the increase of the mining thickness. The influence of mining thickness on the subsidence coefficient is related to the mining depth. The ratio of depth and thickness can be used to reflect the relationship between the subsidence coefficient, the mining depth and the mining thickness, and their relationship can be expressed as [23]:

where:

- q is the surface subsidence coefficient;

- H is the mining depth, m;

- M is the mining thickness, m;

- h is the unconsolidated layer thickness, m.

The mining thickness does not have much effect on the tangent of major influence angle, the mining influence propagation angle and the inflection point offset.

3.1.3. Mining Depth

The influence of mining depth on subsidence coefficient and horizontal movement coefficient is consistent. As the mining depth increases, the subsidence coefficient and the horizontal coefficient will slightly decrease.

The mining depth has an effect on the tangent of the major influence angle. When the lithology of overlying strata is the same, the tangent of the major influence angle will increase with the increase of the mining depth. The relationship is given in Equation (7) [24].

where:

- tan β is the tangent of the major influence angle;

- H is the mining depth, m.

Last, the depth has a certain influence on the inflection point offset. Generally speaking, with the increase of mining depth, the inflection point offset will increase linearly. In addition, the mining depth does not have much impact on the mining influence propagation angle.

3.1.4. Unconsolidated Layer Thickness

A clay layer may not be consolidated since its mechanical property is special and has no tensile strength. The unconsolidated layer only bends under the mining influence and will not crack, expand and separate. Meanwhile, the unconsolidated layer also produces water loss, consolidation and compression deformation that will increase the surface subsidence. In addition, the separation space is narrowed with the increase of the unconsolidated layer thickness. If the thickness of the unconsolidated layer thick is large, the subsidence coefficient may be greater than 1 in the first mining [9]. Under the condition of the thick alluvial, the relationship between the subsidence coefficient, the mining depth and the unconsolidated layer thickness can be expressed in Equation (8) [25]:

where: q is the surface subsidence coefficient; Dθ is the projection surface length of the working face length according to the mining influence propagation angle, m; HJ is the bedrock thickness, m; H is the mining depth, m; h is the unconsolidated layer thickness, m.

The unconsolidated layer thickness also has an influence on the horizontal movement coefficient. The unconsolidated layer will backfill the subsidence space in the movement process due to its rheological behavior. Meanwhile, the consolidated deformation and compression characteristics of the unconsolidated layer can lead to an increase of degree and area of surface horizontal movement. Consequently, the horizontal movement coefficient increases with the increase of the unconsolidated layer thickness. The relationship between the horizontal movement coefficient and the unconsolidated layer thickness in Hebi mine can be expressed by Equation (9) [27]:

where: H is the mining depth, m; h is the unconsolidated layer thickness, m; b is the horizontal movement coefficient.

The tangent of the major influence angle decreases with the increase of the unconsolidated layer thickness. The reason is that the rheological behavior of the unconsolidated layer leads to the increase of the surface horizontal movement area. The bigger the unconsolidated layer thickness, the larger the area of surface movement basin. The relationship between the tangent of major influence angle and the unconsolidated layer thickness in the thick alluvium areas of Shan-dong province can be expressed by Equation (10) [25]:

where: tan β is the tangent of the major influence angle. H is the mining depth, m; h is the unconsolidated layer thickness, m. M is the mining thickness, m.

The unconsolidated layer thickness also does not have a great effect on the inflection point offset and the mining influence propagation angle.

3.1.5. Coal Seam Dip Angle

Coal seam dip angle has a significant impact on the surface subsidence coefficient. The relationship between the coal seam dip angle and the subsidence coefficient can be expressed by Equation (11):

where: is the measured maximum surface subsidence when the strike and tendency achieve the full-mining, mm; M is the mining thickness, m; α is the inclined angle of the coal seam, °.

The subsidence coefficient is directly associated with the coal seam dip angle according to Equation (11). When the maximum surface subsidence is the same, the subsidence coefficient increases with the increase of the coal seam dip angle.

The bedrock points horizontally move to the uphill coal direction when mining the inclined coal seams, and this can drive the movement of the unconsolidated layers due to the friction role. Therefore, the horizontal movement pointing to district rise increases during the mining of inclined seams. The relationship between the horizontal movement coefficient of the inclined seam and the coal seam dip angle can be expressed by Equation (12) [26]:

where:

- bc is the horizontal movement coefficient of the inclined seam;

- b is the horizontal movement coefficient of the flat coal seam;

- α is the inclined angle of the coal seam, °.

The inclined angle of the coal seam has a certain influence on the inflection point offset. Voussoir beam structure cannot be formed in the boundary of district rise when the inclined angle of the coal seam is large, and the voussoir beam is easy to lose stability in the boundary of descends mountain direction due to the overburden load. Thus, the tangent of the major influence angle decreases with the increase of the coal seam inclined angle.

The mining influence propagation angle is the key parameter for the surface subsidence prediction of the inclined seam, and it is mainly affected by the coal seam inclined angle. The mining influence propagation angle decreases with the increase of coal seam inclined angle. The relationship between the mining influence propagation angle and the coal seam inclined angle can be expressed by Equation (13) [8]:

where: k is the parameter that reflects the lithology of the overlying strata; is the mining influence propagation angle, °.

3.1.6. Mining Degree

Mining degree refers to the surface subsidence extent caused by the mining under the fixed geological and mining conditions. The ratio of mining width and mining depth D/H is usually taken as the measurement of mining degree. When the mining degree is small, the subsidence coefficient and the horizontal movement coefficient increase with the growing value of D/H. When the mining degree reaches the full-mining, the subsidence coefficient and the horizontal movement coefficient basically remain stable.

In addition, the inflection point offset can be influenced by the mining degree. When the mining degree is small, the overlying strata form the voussoir beam structure, and the roof caving is insufficient that causes the inflection point offset to become larger. As the mining degree increase, the inflection point offset will decrease. The inflection point offset keeps a certain value when the mining degree reaches full-mining. Consequently, the mining degree does not have much effect on the mining influence propagation angle and the tangent of the major influence angle.

3.1.7. Multiple Mining

The first mining has softened the overlying strata and decreased the rock mass hulking quantity of multiple mining. Meanwhile, the multiple mining can cause the activation of the abandoned mine goaf and lead to an increase of surface movement and deformation. Therefore, the subsidence coefficient and horizontal movement coefficient of the multiple mining are larger than the corresponding parameters in the first mining. The relationship between the subsidence coefficient of first mining and the subsidence coefficient of the multiple mining can be expressed by Equation (14) [26]:

where: q1 is the subsidence coefficient of the multiple mining; q is the subsidence coefficient of the first mining; a is the activation coefficient of the old goaf.

Multiple mining has a certain influence on the tangent of the major influence angle. The lithology of overlying strata becomes soft after the first mining. Thus, the tangent of the major influence angle of multiple mining is larger than the value of the first mining.

The lithology of overlying strata will be soft under the influence of the first mining and will be decreased inflection point offset. Moreover, the inflection point offset is a negative value when the distance between the working face and the abandoned mine goaf is close. In addition, multiple mining does not have a significant effect on the mining influence propagation angle.

3.1.8. Roof Management Methods

The roof management methods can be usually divided into caving mining, strip mining and backfilling mining. The above research of the influence law of geological and mining conditions on the prediction parameters are for the caving approach.

The basic means of strip mining is to allocate the areas to be mined into the formal stripped shape. The mining operation exploits one strip at a time and keeps one strip. The remaining strip coal pillars can support the load of the overlying strata and cause slight surface movement and deformation, thus realizing the goal of recovering some coal resources and controlling surface subsidence. Compared with caving mining, the mining degree of backfilling mining became smaller. Therefore, the subsidence coefficient and the horizontal movement coefficient of backfilling mining are smaller than the parameters of the caving mining. The correction formula of the subsidence coefficient and the horizontal movement coefficient of strip mining can be expressed By Equations (15) and (16) [28]:

where:

- a is the retaining width of the pillar, m;

- b is the mining width of the pillar, m;

- H is the mining depth, m:

- M is the mining thickness, m;

- is the subsidence coefficient of the strip mining;

- is the subsidence coefficient of the caving mining;

- is the horizontal movement coefficient of the strip mining;

- is the horizontal movement coefficient of the caving mining.

Compared with the caving mining, the surface movement and deformation of the backfilling mining is relatively moderate and leads to the relatively smaller tangent of the major influence angle. The correction formula of the tangent of the major influence angle for strip mining can be expressed by Equation (17) [28]:

where: is the tangent of the major influence angle of the strip mining; P is the comprehensive evaluation coefficient of the overburden strata; H is the mining depth, m; is the tangent of major influence angle of the caving mining.

3.2. Prediction Parameters of Probability Integral Method of the Northern Pei County

According to the measured results of the surface movement observation station in the mines of northern Pei County, the surface subsidence principles of this area are basically in accord with the probability integral model. Many years of real practices in the mines of northern Pei County indicate that the accuracy of surface subsidence predicted by the probability integral method can satisfy the engineering precision requirement. Consequently, the probability integral method also can be applied to predict and assess the surface subsidence of northern Pei County. Based on the analysis results of the measured data of the surface movement in each mine, the fundamental subsidence prediction parameters of every mine can be selected as in Table 1, Table 2 and Table 3.

Table 1.

Fundamental prediction parameters of the coal mines belonged to Datun Coal Electricity Company.

Table 2.

Fundamental prediction parameters of the coal mines affiliated with Xuzhou Coal Mining Group.

Table 3.

Fundamental prediction parameters of the coal mines affiliated with Hua Run Group.

3.3. Situation Analysis of Coal Mining Subsidence in the Northern Pei County by the End of 2014

The accumulated surface subsidence situations in each mine by the end of 2014 are calculated by the probability integral approach based on the mining engineering plan and the influence of geological and mining conditions on the prediction parameters and the fundamental prediction parameters. Table 4 gives the maximum surface movement and deformation of the mines in northern Pei County.

Table 4.

The maximum surface movement and deformation of mines in northern Pei County.

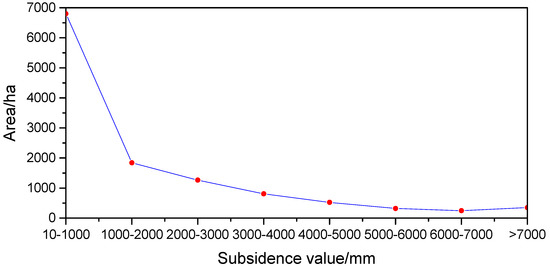

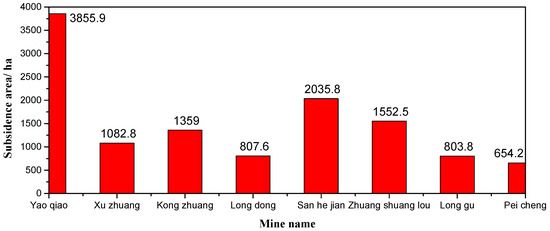

Table 4 indicates that the maximum surface subsidence prediction value in the mining areas of northern Pei County is 7498 mm located above Yaoqiao mine, while the minimum value is 1379 mm located above Peicheng mine. The surface subsidence has a serious influence on the local landform and ecological structure. Figure 3 demonstrates the subsidence area of the different subsidence range in the mines of northern Pei County, and Figure 4 shows the subsidence area for the mines of Pei County.

Figure 3.

The subsidence area of different subsidence range in mines of northern Pei County.

Figure 4.

The subsidence area in every mine in mines of northern Pei County.

Figure 3 and Figure 4 show that the accumulated subsidence area of mines in northern Pei County is 12,151.6 hectares by the end of 2014. Yaoqiao mine has the largest subsidence area, and the subsidence area is 3855.9 hectares, while the subsidence area of Peicheng mine is the least, and the subsidence area is 654.2 hectares. Meanwhile, the surface movement and deformation contour of the mines in northern Pei County can be obtained according to the prediction results. Due to the paper length, only the surface subsidence contour of the Longdong mine is given, as shown in Figure 5.

Figure 5.

The prediction subsidence contour and image addition of Northern Pei County.

Figure 5 suggests that the current situations of the subsidence area above the mines displayed by the image are consistent with the subsidence prediction findings. With the high groundwater level in northern Pei County, it is easy to form the water accumulated area in the larger subsidence area and even form a larger area of the subsidence lakes as shown in the black areas of Figure 5. The subsidence land can be reasonably planned and recycled according to the prediction outcomes of the large area of surface subsidence in northern Pei County. The subsidence lakes can be transformed into the park, the wetland and the stable areas with a little subsidence, which can be transformed into the construction lands, thereby realizing the overall plan of land in the mining areas and the laying foundation for the integration of northern Pei County.

4. Conclusions

This paper systematically explores the influence law of the geological and mining conditions on the prediction parameters of the probability integral method based on the theoretical analysis, and the research findings were achieved. The research outcomes of the paper can be employed to predict the surface subsidence of northern Pei County and can lay the foundation for the integration of this area. Here, the research consequences are summarized as follows:

- (1)

- The geological and mining conditions have different influences on the prediction parameters of the probability integral method. The geological and mining conditions include lithology of overlying strata, mining thickness, mining depth, unconsolidated layers thickness, coal seam dip angle, mining degree, multiple mining and roof management methods. The fundamental prediction parameters of the probability integral method contain subsidence coefficient, horizontal movement coefficient, tangent of major influence angle, mining influence propagation angle and inflection point offset. These factors can be regarded to foresee the large area of the surface subsidence.

- (2)

- The maximum surface subsidence prediction value in the mines of northern Pei County is 7498 mm, located above Yaoqiao mine, while the minimum prediction value is 1379 mm, located above the Peicheng mine by the end of 2014. In addition, the accumulated subsidence area in northern Pei County is 12,151.6 hectares, while the subsidence area of Yaoqiao mine is the largest and the subsidence area is 3855.9 hectares. In addition, the subsidence area of Peicheng mine is the least, and the subsidence area is 654.2 hectares. The subsidence land can be reasonably planned and recycled to achieve the overall planning of the land in the mining areas of northern Pei County.

Author Contributions

Conceptualization, H.L.; writing—original draft preparation, Y.Y.; formal analysis, H.Z.; investigation, Y.Z. and X.Z.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Jiangsu Province (Grant NO. BK20180661) and the China Postdoctoral Science Foundation (Grant NO. 2019M660135). We would like to acknowledge the support of Collaborative Innovation Center for Resource Utilization and Ecological Restoration of Old Industrial Base.

Acknowledgments

Thanks to Collaborative Innovation Center for Resource Utilization and Ecological Restoration of Old Industrial Base.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bian, Z.; Miao, X.; Lei, S.; Chen, S.E.; Wang, W.; Struthers, S. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Tong, X.; Li, X.; Zhou, J.; Wang, S.; Liu, B. Some developments and new insights of environmental problems and deep mining strategy for cleaner production in mines. J. Clean. Prod. 2019, 210, 1562–1578. [Google Scholar] [CrossRef]

- Soni, A.K.; Singh, K.K.K.; Prakash, A. Shallow cover over coal mining: A case study of subsidence at Kamptee Colliery. India B Eng. Geol. Environ. 2007, 66, 311–318. [Google Scholar] [CrossRef]

- Baryakh, A.A.; Telegina, E.A.; Samodelkina, N.A.; Devyatkov, S.Y. Prediction of the intensive surface subsidence in mining potash series. J. Min. Sci. 2005, 41, 312–319. [Google Scholar] [CrossRef]

- Nicieza, C.G.; Fernández, M.I.Á.; Díaz, A.M.; Vigil, A.Á. The new three-dimensional subsidence influence function denoted by n–k–g. Int. J. Rock Mech. Min. Sci. 2005, 42, 372–387. [Google Scholar] [CrossRef]

- Hejmanowski, R.; Malinowska, A. Evaluation of reliability of subsidence prediction based on spatial statistical analysis. Int. J. Rock Mech. Min. Sci. 2009, 46, 432–438. [Google Scholar] [CrossRef]

- Liu, B.C.; Liao, G.H. Fundamental Law of Mining-Induced Surface Movement. China Industrial Press: Beijing, China, 1965. [Google Scholar]

- He, G.Q.; Ling, G.D.; Yang, L. Mining Subsidence; China University of Technology Press: Xuzhou, China, 1991. [Google Scholar]

- Dai, H.Y. Prediction model for surface movement and deformation induced by sub-critical extraction. J. China Coal Soc. 2004, 1, 49. [Google Scholar]

- Guo, Z.Z.; Xie, H.P.; Wang, J.Z. Applying probability distribution density function to predict the surface subsidence caused by subcritical extraction. J. China Coal. Soc. 2004, 29, 155–158. [Google Scholar]

- Xu, N.Z.; Wang, B.; Qi, Y.C. Prediction of Surface Subsidence in the Deep Coal Mining. J. Min. Safe. Eng. 2006, 23, 66–69. [Google Scholar]

- Deng, K.Z.; Zhang, D.Z.; Zhang, Z.Q. Study on Prediction and Control of Surface Subsidence in Deep Mining. J. China Uni. Min. Technol. 2000, 29, 52–55. [Google Scholar]

- Li, P.X. Study on Regularity and Prediction Method of Surface Subsidence Due to Deep Mining—Taking Xuzhou Coal Mining Area as Example; China University of Technology: Xuzhou, China, 2012. [Google Scholar]

- Li, W.X.; Liang, X.L.; Zhao, S. The Elastic-Thin-Plate bending method for predicting ground subsidence due to underground mining. Eng. Mech. 2006, 23, 177–181. [Google Scholar]

- Gu, W. Study on Laws of Overburden and Surface Movement when Mining under Thick Alluvium; China University of Technology: Xuzhou, China, 2013. [Google Scholar]

- Zhou, D.W. The Synergy Mechanism between Rock Mass and Soil in Mining Subsidence and Its Prediction; China University of Technology: Xuzhou, China, 2014. [Google Scholar]

- Yin, S.X.; Yu, X.Y.; Hu, Q.H. Application of curved surface fitting technology in mining subsidence prediction. J. Xi’an Univ. Sci. Technol. 2010, 30, 518–522. [Google Scholar]

- Nie, L.; Wang, H.; Xu, Y. A new prediction model for mining subsidence deformation: The arc tangent function model. Nat. Hazards 2015, 75, 2185–2198. [Google Scholar] [CrossRef]

- Liu, Y.C. Study on The Dynamic Course of The Surface Subsidence and The Model Based on Theory of Key Rock Stratum. Ph.D. Thesis, Chongqing University, Chongqing, China, 2010. [Google Scholar]

- Song, S.J. Study on the Stratification Transfer Prediction Method of the Mining Subsidence Based on the Key Geological and Mining Factors. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2013. [Google Scholar]

- Guo, G.; Zhu, X.; Zha, J. Subsidence prediction method based on equivalent mining height theory for solid backfilling mining. Nonferr. Meta. Soc. 2014, 24, 3302–3308. [Google Scholar] [CrossRef]

- Li, P.X.; Tan, Z.X.; Deng, K.Z. Related Factors Analysis of Calculation Parameters of Probability Integral Method for Surface Movement. Coal. Min. Technol. 2011, 6, 14–18. [Google Scholar]

- Wang, Y.H. The Study on The Character of Strata Subsidence During Repeat Ming. J. China Coal Soc. 1998, 23, 470–475. [Google Scholar]

- Chen, J.J.; Zou, Y.F.; Guo, W.B. Study on the Relationship Between Subsidence Coefficient and Mining Degree Under A Thick Alluvium Stratum. J. Min. Safe. Eng. 2012, 2, 250–254. [Google Scholar]

- Luan, Y.C.; Tong, W.L.; Mo, J. The relationship between surface movement parameters and mining depth and alluvial layer thickness. Mine. Press. Roof Manag. 2001, 1, 61–63. [Google Scholar]

- National Coal Board. Mining Regulations under the Buildings, Water, Railway and the Main Shaft Pillar; Coal Industrial Press: Beijing, China, 2017. [Google Scholar]

- Li, F.M. The relationships between surface movement parameters and the geological and mining conditions in thick alluvium and their characteristics. Coal Sci. Technol. 1996, 24, 29–33. [Google Scholar]

- Guo, W.B.; Deng, K.Z.; Zou, Y.F. Research on surface movement parameters of strip-partial mining. J. China Coal Soc. 2005, 30, 182–186. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).