Numerical Evaluation of the Transient Performance of Rock-Pile Seasonal Thermal Energy Storage Systems Coupled with Exhaust Heat Recovery †

Abstract

1. Introduction

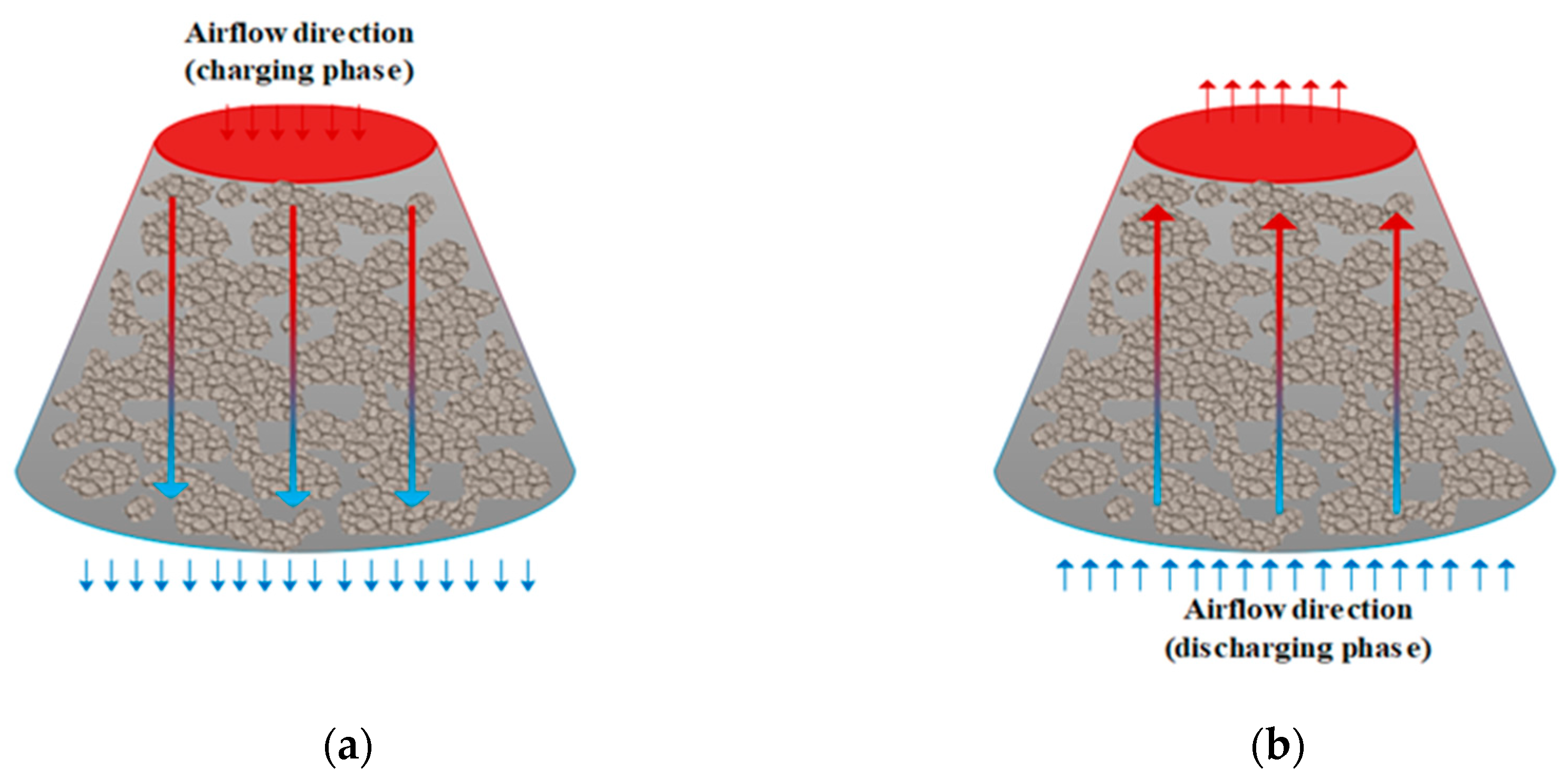

2. Model Description

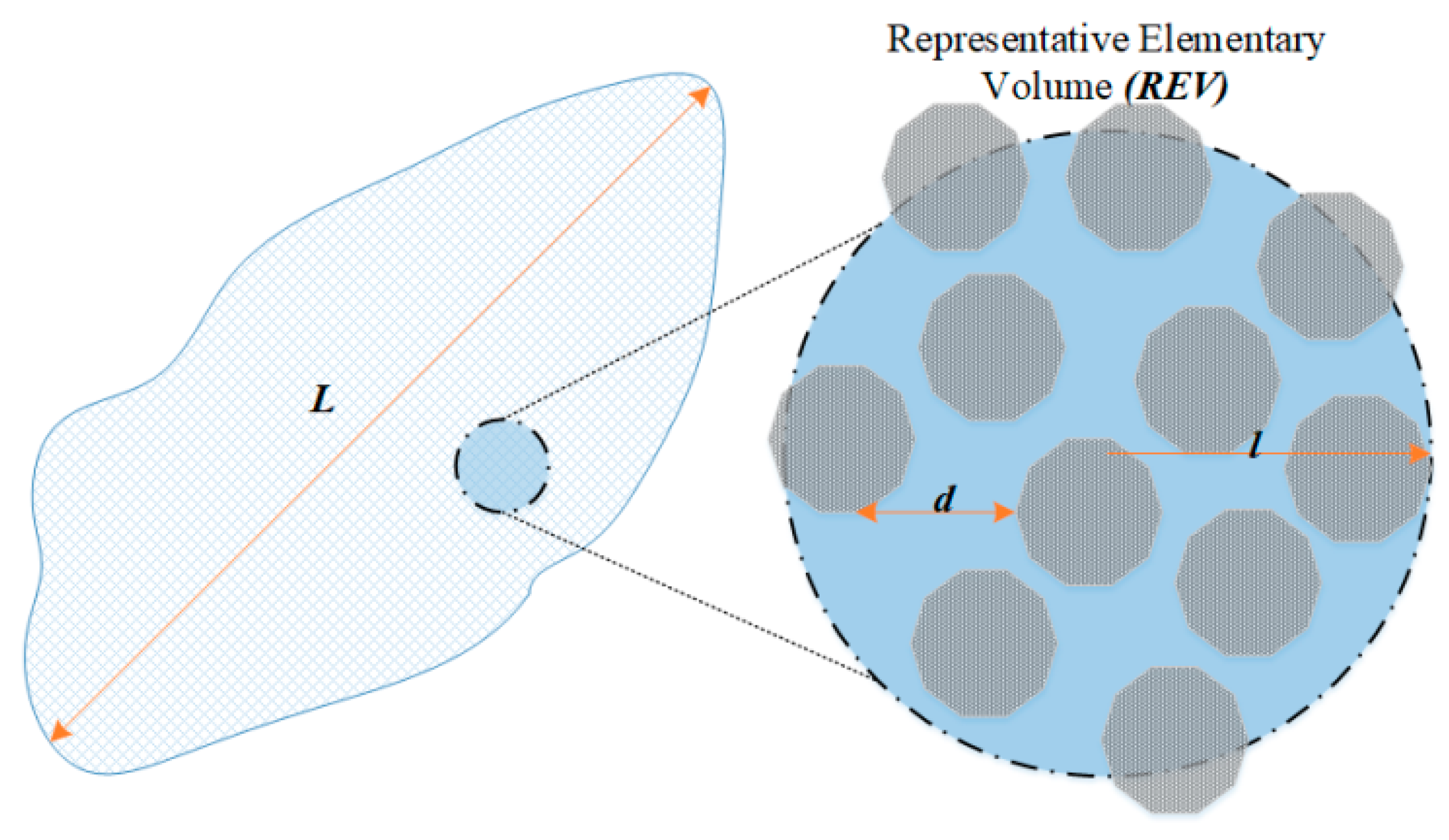

2.1. Heat Transfer Coefficient (HTC) in the Rock Bed

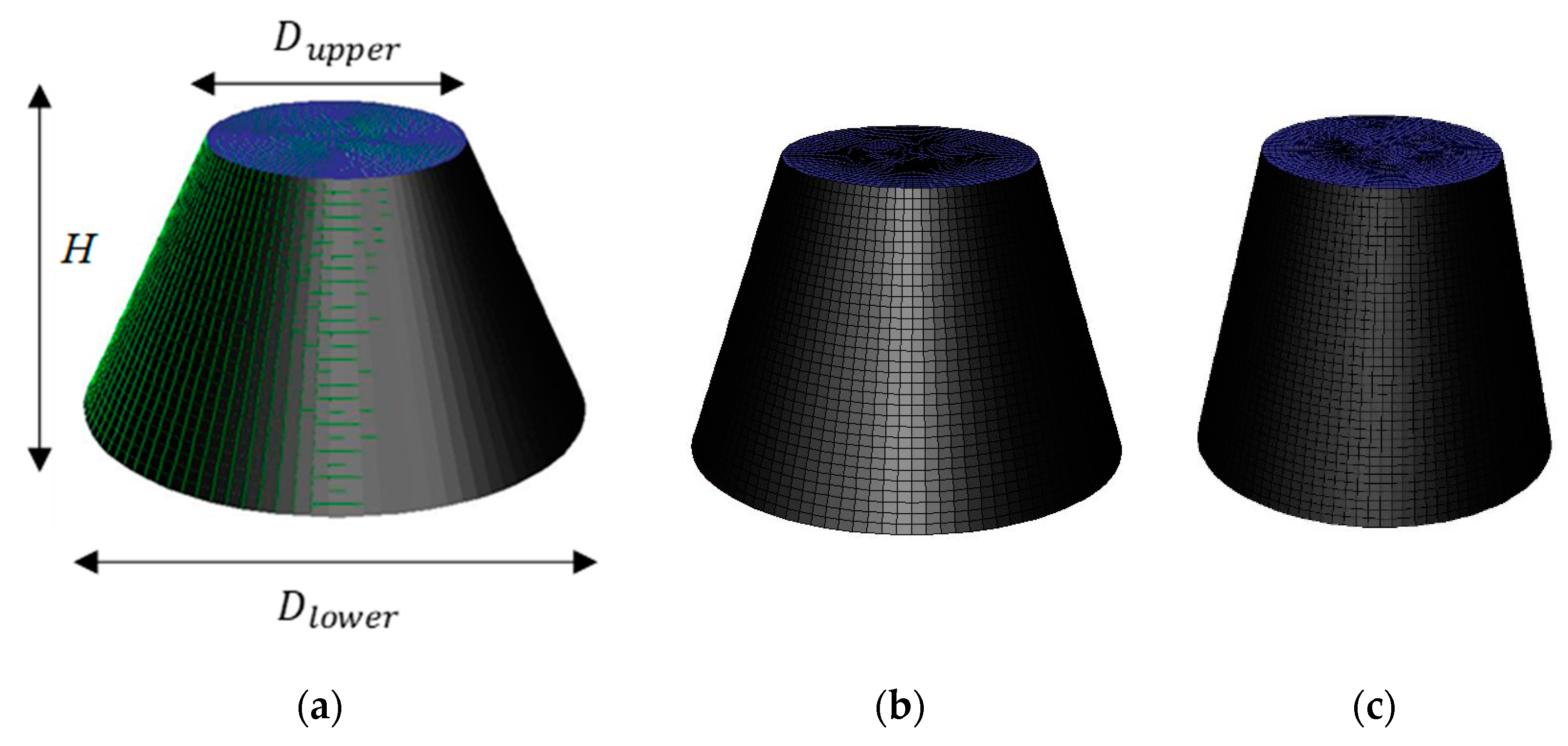

2.2. Geometry and Aspect Ratio

2.3. Thermophysical Properties

2.4. Boundary Conditions

2.5. Mesh Independency Study

3. Results and Discussion

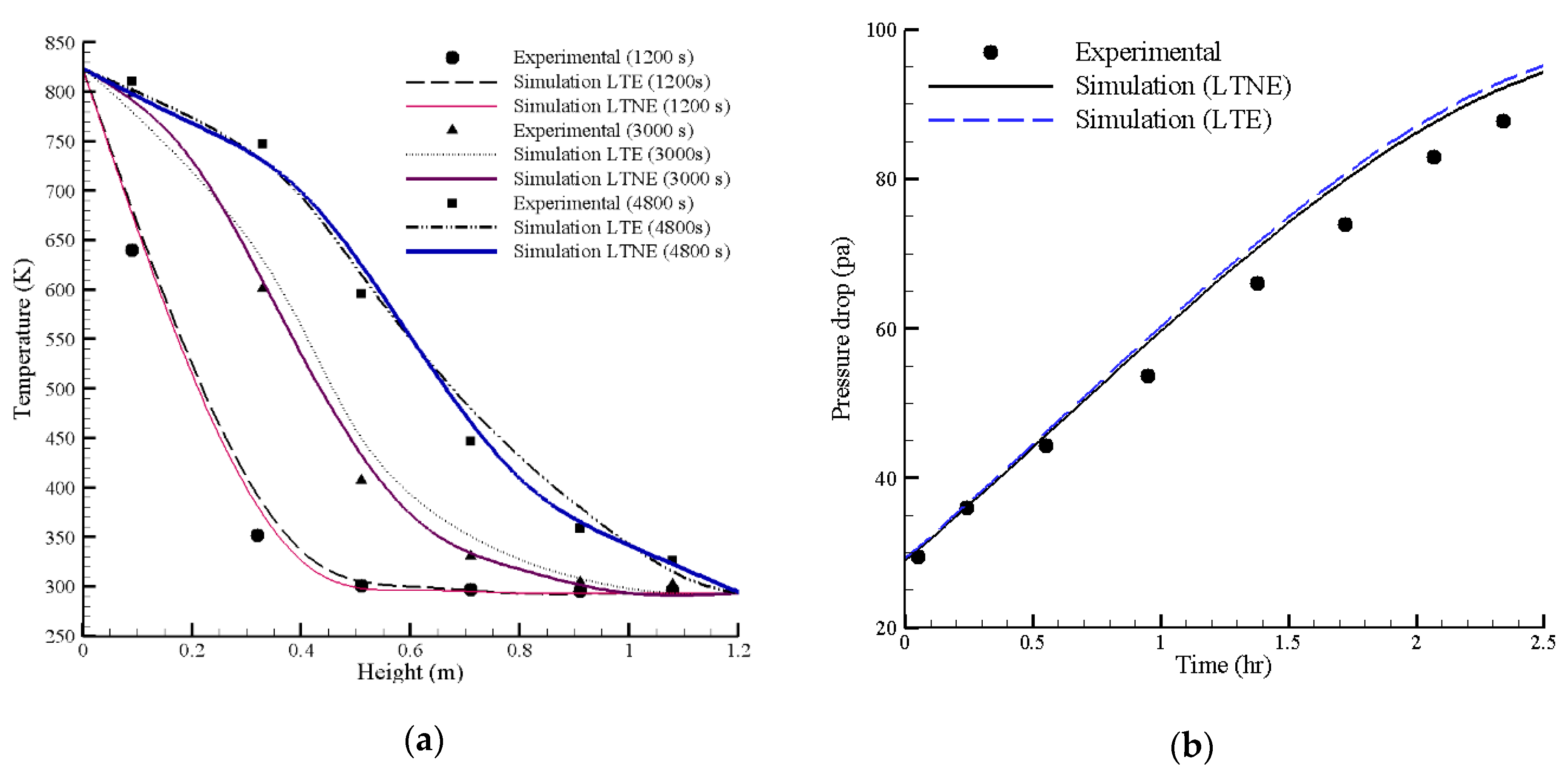

3.1. Validation of the Model

3.2. Parametric Analysis

3.2.1. Aspect Ratios (Rock-Bed Shape)

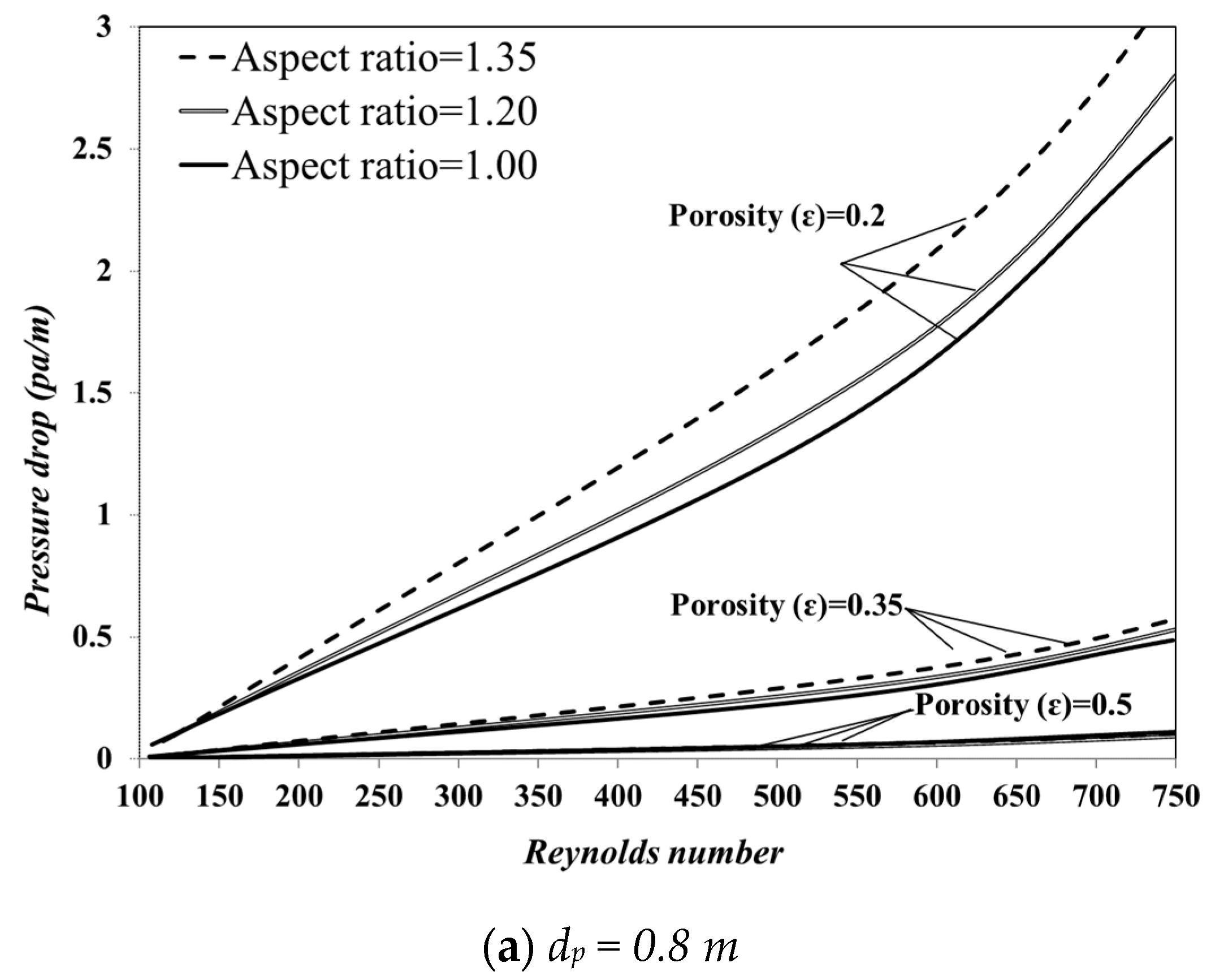

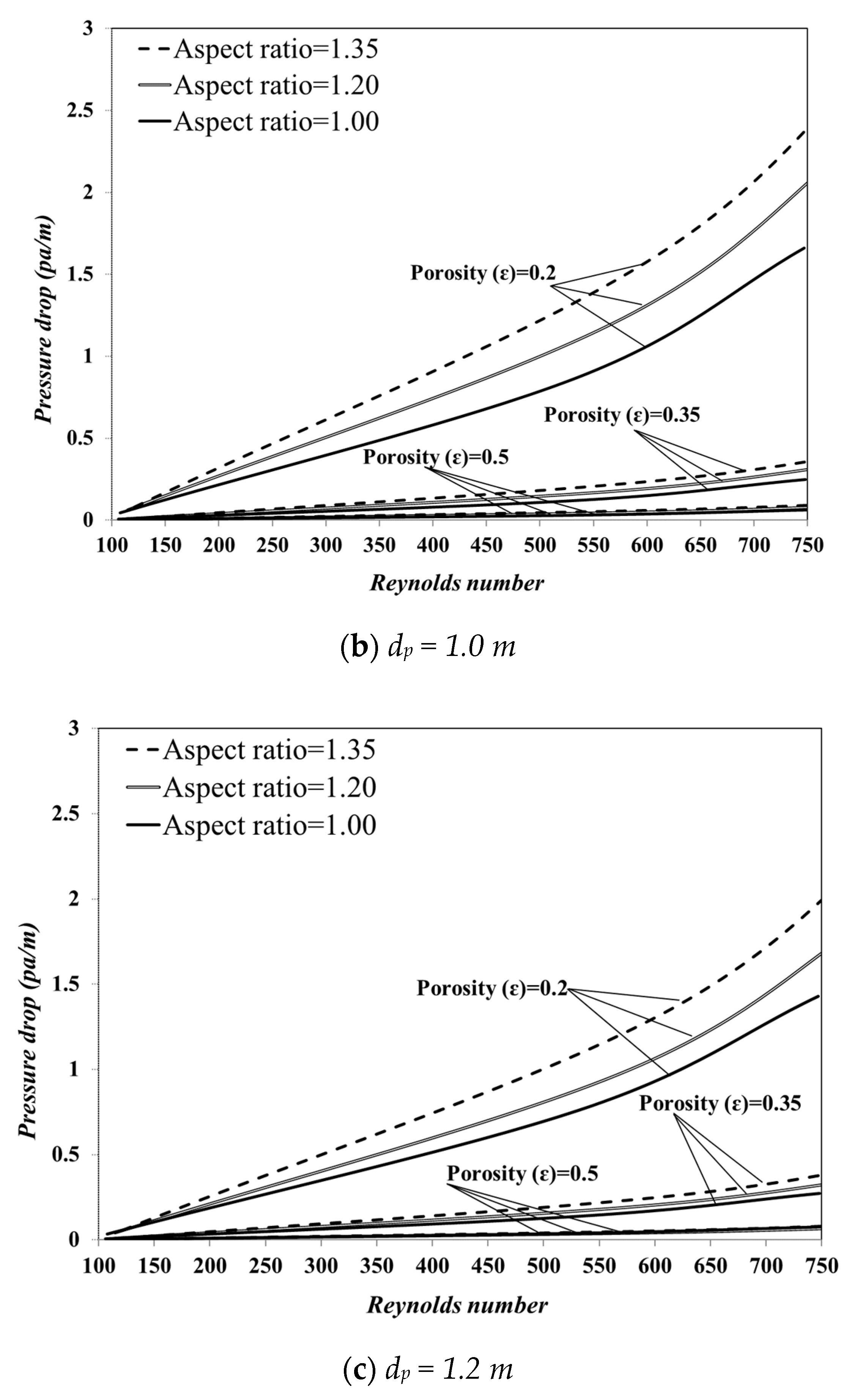

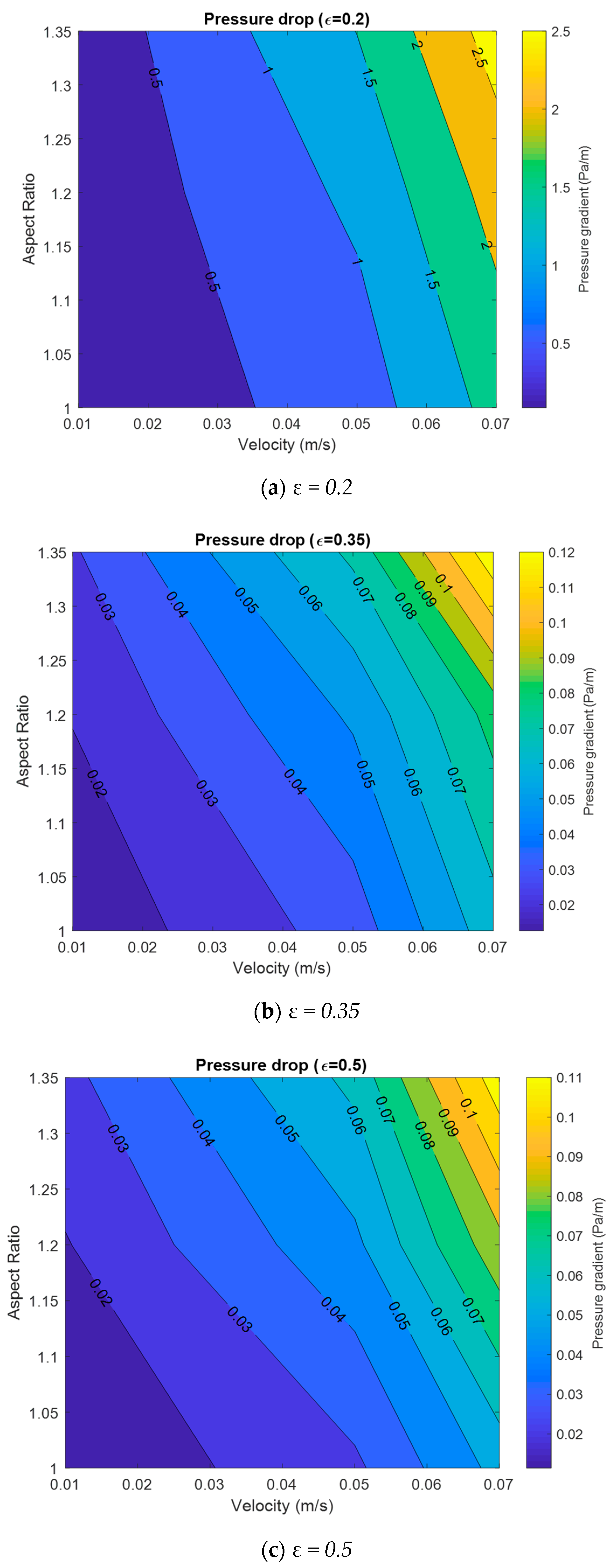

3.2.2. Effect of Porosity, Particle Size and Fluid Velocity

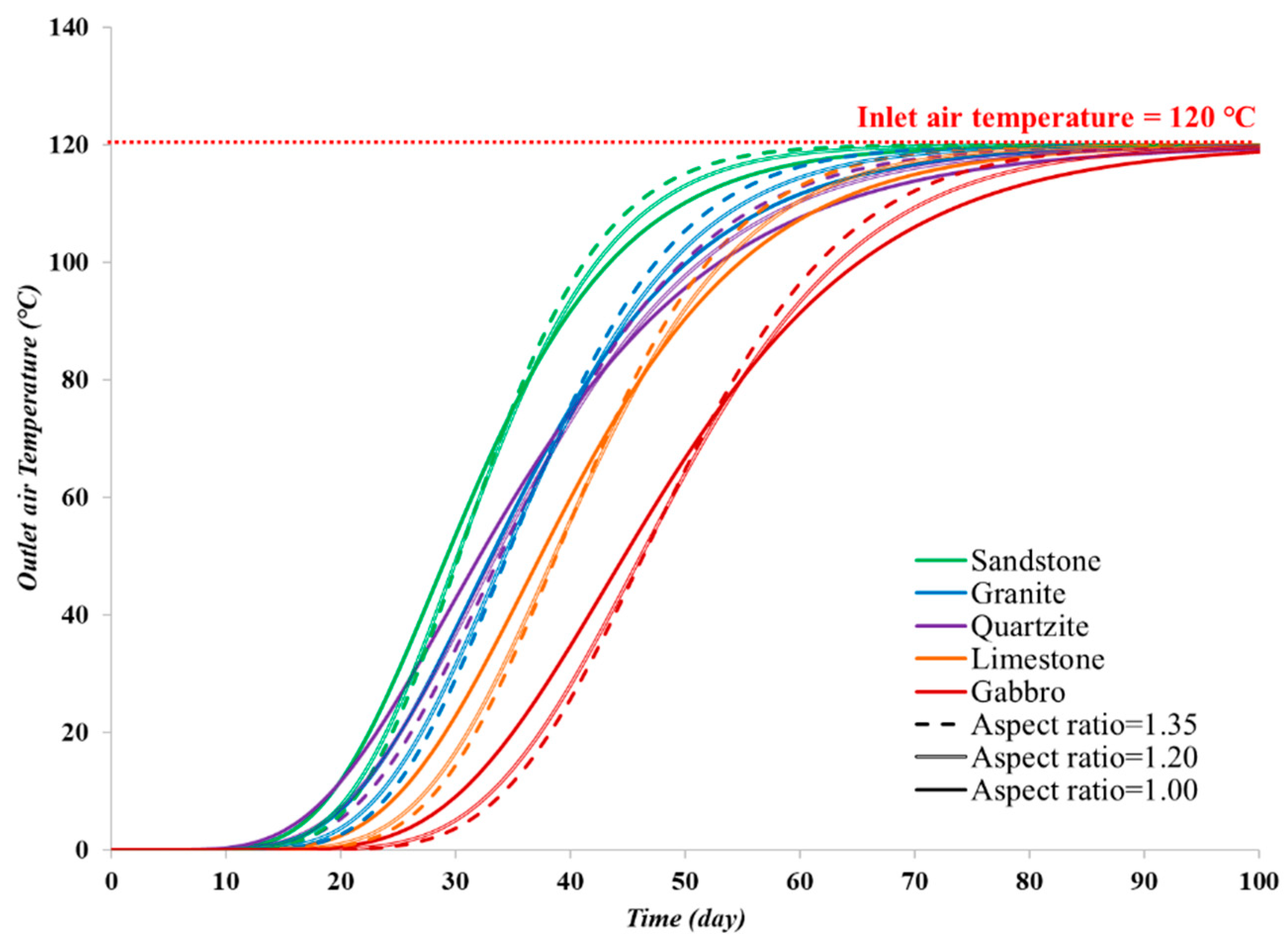

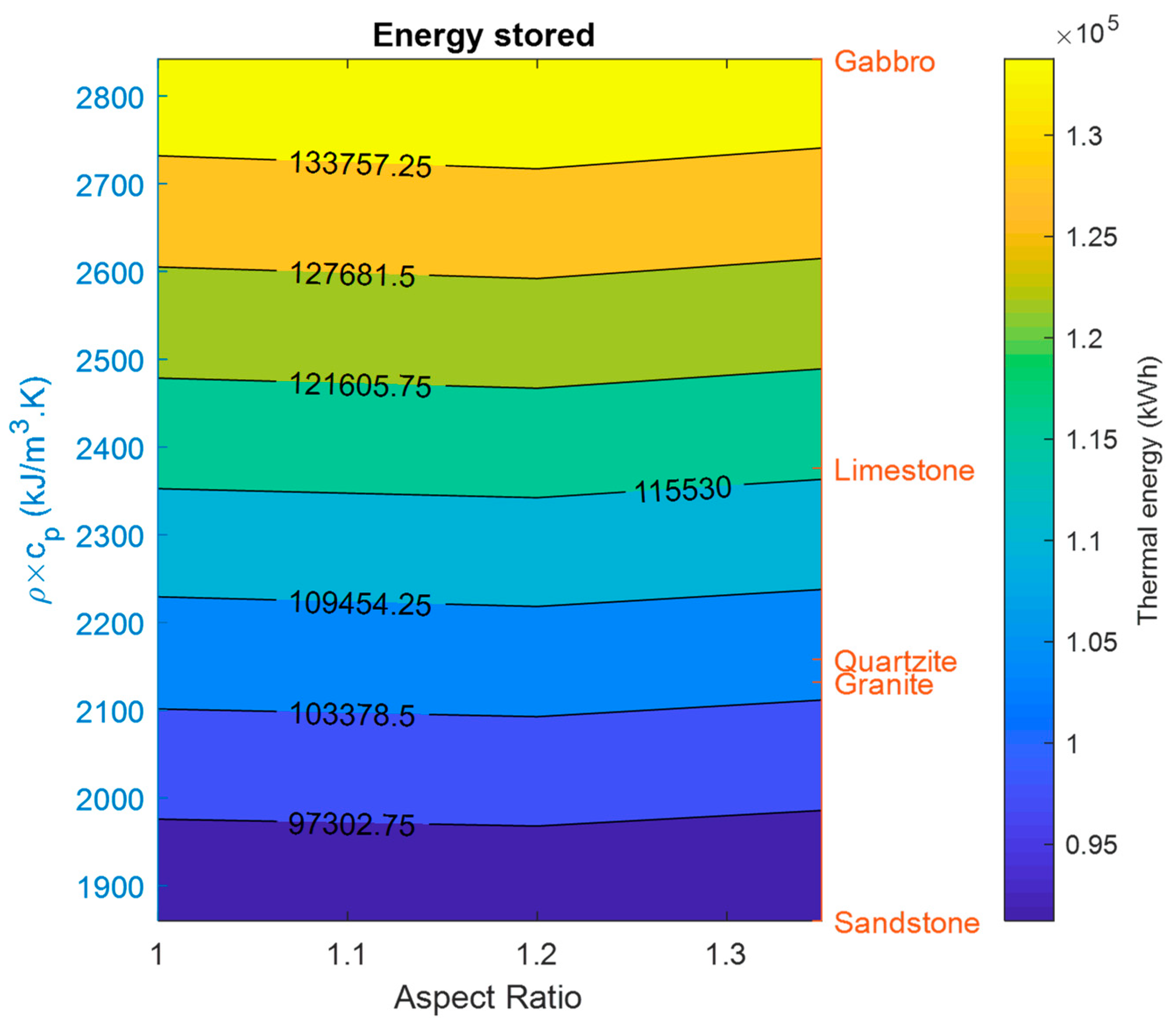

3.2.3. Effect of Rock Thermophysical Properties

3.2.4. Carbon Emission Reduction

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | specific surface area (m−1); |

| cp | isobaric specific heat (J/kg-K); |

| d | average particle diameter (m); |

| D | cone diameter (m); |

| h | convection heat transfer coefficient (W/m2-K); |

| H | cone height (m); |

| k | thermal conductivity (W/m-K); |

| K | permeability (m2); |

| Nu | Nusselt number (non-dimensional); |

| p | static pressure (Pa); |

| Pr | Prandtl number (non-dimensional); |

| Re | Reynolds number (non-dimensional); |

| T | temperature (K); |

| u | superficial velocity vector (m/s). |

| Abbreviations | |

| CFD | computational fluid dynamics; |

| CSP | concentrated solar power; |

| HTC | heat transfer coefficient; |

| HTF | heat transfer fluid; |

| LTE | local thermal equilibrium; |

| LTNE | local thermal non-equilibrium; |

| REV | representative elementary volume; |

| SIMPLE | semi-implicit method for pressure-linked equation; |

| TES | thermal energy storage; |

| UDF | user-defined function; |

| VAM | volume average model. |

| Greek letters | |

| α | viscous resistance coefficient; |

| β | inertial resistance coefficient; |

| γ | aspect ratio; |

| ε | porosity (void fraction); |

| ρ | density; |

| μ | dynamic viscosity. |

| Subscripts and superscripts | |

| * | ancillary; |

| eq | equivalent; |

| f | fluid phase; |

| fs | interphase (fluid-solid) property; |

| lower | cone base; |

| p | particle; |

| s | solid phase; |

| upper | cone top. |

References

- Krishan, O.; Suhag, S. An updated review of energy storage systems: Classification and applications in distributed generation power systems incorporating renewable energy resources. Int. J. Energy Res. 2019, 43, 6171–6210. [Google Scholar] [CrossRef]

- Sarbu, I.; Dorca, A. Review on heat transfer analysis in thermal energy storage using latent heat storage systems and phase change materials. Int. J. Energy Res. 2019, 43, 29–64. [Google Scholar] [CrossRef]

- Sorgulu, F.; Dincer, I. Design and analysis of a solar tower power plant integrated with thermal energy storage system for cogeneration. Int. J. Energy Res. 2019, 43, 6151–6160. [Google Scholar] [CrossRef]

- Abdel-Salam, M.; Aly, S.; El-Sharkawy, A.; Abdel-Rehim, Z. Thermal characteristics of packed bed storage system. Int. J. Energy Res. 1991, 15, 19–29. [Google Scholar] [CrossRef]

- Dincer, I. Thermal energy storage systems as a key technology in energy conservation. Int. J. Energy Res. 2002, 26, 567–588. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, C.-Y. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef]

- Zanganeh, G.; Pedretti, A.; Zavattoni, S.; Barbato, M.; Steinfeld, A. Packed-bed thermal storage for concentrated solar power–Pilot-scale demonstration and industrial-scale design. Sol. Energy 2012, 86, 3084–3098. [Google Scholar] [CrossRef]

- Mertens, N.; Alobaid, F.; Frigge, L.; Epple, B. Dynamic simulation of integrated rock-bed thermocline storage for concentrated solar power. Sol. Energy 2014, 110, 830–842. [Google Scholar] [CrossRef]

- Schmidt, T.; Mangold, D.; Müller-Steinhagen, H. Central solar heating plants with seasonal storage in Germany. Sol. Energy 2004, 76, 165–174. [Google Scholar] [CrossRef]

- Dahash, A.; Ochs, F.; Janetti, M.B.; Streicher, W. Advances in seasonal thermal energy storage for solar district heating applications: A critical review on large-scale hot-water tank and pit thermal energy storage systems. Appl. Energy 2019, 239, 296–315. [Google Scholar] [CrossRef]

- Raftery, A.; Shier, P.; Obilade, T. Domestic space-heating and solar energy in Ireland. Int. J. Energy Res. 1980, 4, 31–39. [Google Scholar] [CrossRef]

- Dincer, I.; Dost, S. A perspective on thermal energy storage systems for solar energy applications. Int. J. Energy Res. 1996, 20, 547–557. [Google Scholar] [CrossRef]

- Singh, P.L.; Deshpandey, S.; Jena, P. Thermal performance of packed bed heat storage system for solar air heaters. Energy Sustain. Dev. 2015, 29, 112–117. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Fahrettin Kuyuk, A.; Rodrigues de Brito, M.A.; Baidya, D.; Torabigoodarzi, Z.; Safari, A. Application of borehole thermal energy storage in waste heat recovery from diesel generators in remote cold climate locations. Energies 2019, 12, 656. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Safari, A.; Amiri, L.; Baidya, D.; de Brito, M.A.R.; Kuyuk, A.F. Investigation of viability of seasonal waste heat storage in rock piles for remote communities in cold climates. Energy Procedia 2019, 159, 66–71. [Google Scholar] [CrossRef]

- Zanganeh, G.; Pedretti, A.; Haselbacher, A.; Steinfeld, A. Design of packed bed thermal energy storage systems for high-temperature industrial process heat. Appl. Energy 2015, 137, 812–822. [Google Scholar] [CrossRef]

- Baidya, D.; de Brito, M.A.R.; Sasmito, A.P.; Scoble, M.; Ghoreishi-Madiseh, S.A. Recovering waste heat from diesel generator exhaust; an opportunity for combined heat and power generation in remote Canadian mines. J. Clean. Prod. 2019, 225, 785–805. [Google Scholar] [CrossRef]

- Ould Amrouche, S.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrog. Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Welsch, B.; Göllner-Völker, L.; Schulte, D.O.; Bär, K.; Sass, I.; Schebek, L. Environmental and economic assessment of borehole thermal energy storage in district heating systems. Appl. Energy 2018, 216, 73–90. [Google Scholar] [CrossRef]

- Galione Klot, P.A.; Pérez Segarra, C.D.; Rodríguez Pérez, I.M.; Torras Ortiz, S.; Rigola Serrano, J. Numerical evaluation of multi-layered solid-PCM thermocline-like tanks as thermal energy storage systems for CSP applications. Energy Procedia 2015, 69, 832–841. [Google Scholar] [CrossRef]

- Amiri, L.; Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P. Effect of buoyancy-driven natural convection in a rock-pit mine air preconditioning system acting as a large-scale thermal energy storage mass. Appl. Energy 2018, 221, 268–279. [Google Scholar] [CrossRef]

- Amiri, L.; Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P. Evaluation of Heat Transfer Performance between Rock and Air in Seasonal Thermal Energy Storage Unit. Appl. Energy 2017, 142, 576–581. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Amiri, L.; Sasmito, A.P.; Hassani, F.P. A conjugate natural convection model for large scale seasonal thermal energy storage units: Application in mine ventilation. Energy Procedia 2017, 105, 4167–4172. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P.; Amiri, L. Performance evaluation of large scale rock-pit seasonal thermal energy storage for application in underground mine ventilation. Appl. Energy 2017, 185, 1940–1947. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P.; Amiri, L. Heat transfer analysis of large scale seasonal thermal energy storage for underground mine ventilation. Energy Procedia 2015, 75, 2093–2098. [Google Scholar] [CrossRef]

- Singh, H.; Saini, R.; Saini, J. A review on packed bed solar energy storage systems. Renew. Sustain. Energy Rev. 2010, 14, 1059–1069. [Google Scholar] [CrossRef]

- Arias, D.A.; McMahan, A.C.; Klein, S.A. Sensitivity of long-term performance simulations of solar energy systems to the degree of stratification in the thermal storage unit. Int. J. Energy Res. 2008, 32, 242–254. [Google Scholar] [CrossRef]

- Hänchen, M.; Brückner, S.; Steinfeld, A. High-temperature thermal storage using a packed bed of rocks–heat transfer analysis and experimental validation. Appl. Therm. Eng. 2011, 31, 1798–1806. [Google Scholar] [CrossRef]

- Barton, N. Simulations of air-blown thermal storage in a rock bed. Appl. Therm. Eng. 2013, 55, 43–50. [Google Scholar] [CrossRef]

- Kuravi, S.; Trahan, J.; Goswami, Y.; Jotshi, C.; Stefanakos, E.; Goel, N. Investigation of a high-temperature packed-bed sensible heat thermal energy storage system with large-sized elements. J. Sol. Energy Eng. 2013, 135, 041008. [Google Scholar] [CrossRef]

- Cascetta, M.; Cau, G.; Puddu, P.; Serra, F. A comparison between CFD simulation and experimental investigation of a packed-bed thermal energy storage system. Appl. Therm. Eng. 2016, 98, 1263–1272. [Google Scholar] [CrossRef]

- Agrawal, P.; Gautam, A.; Kunwar, A.; Kumar, M.; Chamoli, S. Performance assessment of heat transfer and friction characteristics of a packed bed heat storage system embedded with internal grooved cylinders. Sol. Energy 2018, 161, 148–158. [Google Scholar] [CrossRef]

- Rodat, S.; Bruch, A.; Dupassieux, N.; El Mourchid, N. Unique Fresnel demonstrator including ORC and thermocline direct thermal storage: Operating experience. Energy Procedia 2015, 69, 1667–1675. [Google Scholar] [CrossRef]

- Amiri, L.; Ghoreishi-Madiseh, S.A.; Hassani, F.P.; Sasmito, A.P. Friction factor correlation for airflow through broken rocks and its applications in mine ventilation. Int. J. Min. Sci. Technol. 2020, 30, 455–462. [Google Scholar] [CrossRef]

- Amiri, L.; Ghoreishi-Madiseh, S.A.; Hassani, F.P.; Sasmito, A.P. Estimating pressure drop and Ergun/Forchheimer parameters of flow through packed bed of spheres with large particle diameters. Powder Technol. 2019, 356, 310–324. [Google Scholar] [CrossRef]

- Royer, J. Status of remote/off-grid communities in Canada. Nat. Resour. Can. 2011. [Google Scholar]

- Whitaker, S. Flow in porous media I: A theoretical derivation of Darcy’s law. Transp. Porous Media 1986, 1, 3–25. [Google Scholar] [CrossRef]

- Nield, D.; Bejan, A. Convection in Porous Media, Fifth; Springer: New York, NY, USA, 2016. [Google Scholar]

- Amiri, L.; Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P. A porous medium based heat transfer and fluid flow model for thermal energy storage in packed rock beds. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 268, p. 012100. [Google Scholar] [CrossRef]

- Ergun, S.; Orning, A.A. Fluid flow through randomly packed columns and fluidized beds. Ind. Eng. Chem. 1949, 41, 1179–1184. [Google Scholar] [CrossRef]

- McQuillan, F.; Culham, J.; Yovanovich, M. Properties of Some Gases and Liquids at One Atmosphere; Microelectronics Heat Transfer Laboratory Report UW/MHTL 8407 G-02; University of Waterloo: Waterloo, Belgium, 1984. [Google Scholar]

- Bruch, A.; Molina, S.; Esence, T.; Fourmigué, J.; Couturier, R. Experimental investigation of cycling behaviour of pilot-scale thermal oil packed-bed thermal storage system. Renew. Energy 2017, 103, 277–285. [Google Scholar] [CrossRef]

- Tiskatine, R.; Aharoune, A.; Bouirden, L.; Ihlal, A. Identification of suitable storage materials for solar thermal power plant using selection methodology. Appl. Therm. Eng. 2017, 117, 591–608. [Google Scholar] [CrossRef]

- Fundamentals, C. SI: Climatic Design Information; ASHRAE Handbook. Am. Soc. Heat. Refrig. 2013, 14, 111. [Google Scholar]

- Stritih, U.; Zavrl, E.; Paksoy, H.O. Energy Analysis and Carbon Saving Potential of a Complex Heating System with Solar Assisted Heat Pump and Phase Change Material (PCM) Thermal Storage in Different Climatic Conditions. Eur. J. Sustain. Dev. Res. 2019, 3, em0067. [Google Scholar] [CrossRef]

| Property | cp,s | ρs | ks | dp |

|---|---|---|---|---|

| Value | 1000 (J/kg·K) | 3000 (kg/) | 2.68 (W/m·K) | 0.8, 1.0, and 1.2 (m) |

| Rock Type | ||||

|---|---|---|---|---|

| Quartzite | 2600 | 5.0 | 830 | 2158 |

| Granite | 2600 | 2.8 | 820 | 2132 |

| Sandstone | 2400 | 2.3 | 775 | 1860 |

| Limestone | 2700 | 2.2 | 880 | 2376 |

| Gabbro | 2900 | 2.2 | 980 | 2842 |

| Unit | Natural Gas | Oil | Coal |

|---|---|---|---|

| Tons CO2eq/year | 156 | 223 | 276 |

| Tons CO2eq/(m3.year) | 85 | 122 | 151 |

| Tons CO2eq/(Ton rock.year) | 28 | 41 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amiri, L.; de Brito, M.A.R.; Ghoreishi-Madiseh, S.A.; Bahrani, N.; Hassani, F.P.; Sasmito, A.P. Numerical Evaluation of the Transient Performance of Rock-Pile Seasonal Thermal Energy Storage Systems Coupled with Exhaust Heat Recovery. Appl. Sci. 2020, 10, 7771. https://doi.org/10.3390/app10217771

Amiri L, de Brito MAR, Ghoreishi-Madiseh SA, Bahrani N, Hassani FP, Sasmito AP. Numerical Evaluation of the Transient Performance of Rock-Pile Seasonal Thermal Energy Storage Systems Coupled with Exhaust Heat Recovery. Applied Sciences. 2020; 10(21):7771. https://doi.org/10.3390/app10217771

Chicago/Turabian StyleAmiri, Leyla, Marco Antonio Rodrigues de Brito, Seyed Ali Ghoreishi-Madiseh, Navid Bahrani, Ferri P. Hassani, and Agus P. Sasmito. 2020. "Numerical Evaluation of the Transient Performance of Rock-Pile Seasonal Thermal Energy Storage Systems Coupled with Exhaust Heat Recovery" Applied Sciences 10, no. 21: 7771. https://doi.org/10.3390/app10217771

APA StyleAmiri, L., de Brito, M. A. R., Ghoreishi-Madiseh, S. A., Bahrani, N., Hassani, F. P., & Sasmito, A. P. (2020). Numerical Evaluation of the Transient Performance of Rock-Pile Seasonal Thermal Energy Storage Systems Coupled with Exhaust Heat Recovery. Applied Sciences, 10(21), 7771. https://doi.org/10.3390/app10217771