4.1. Experimental Results

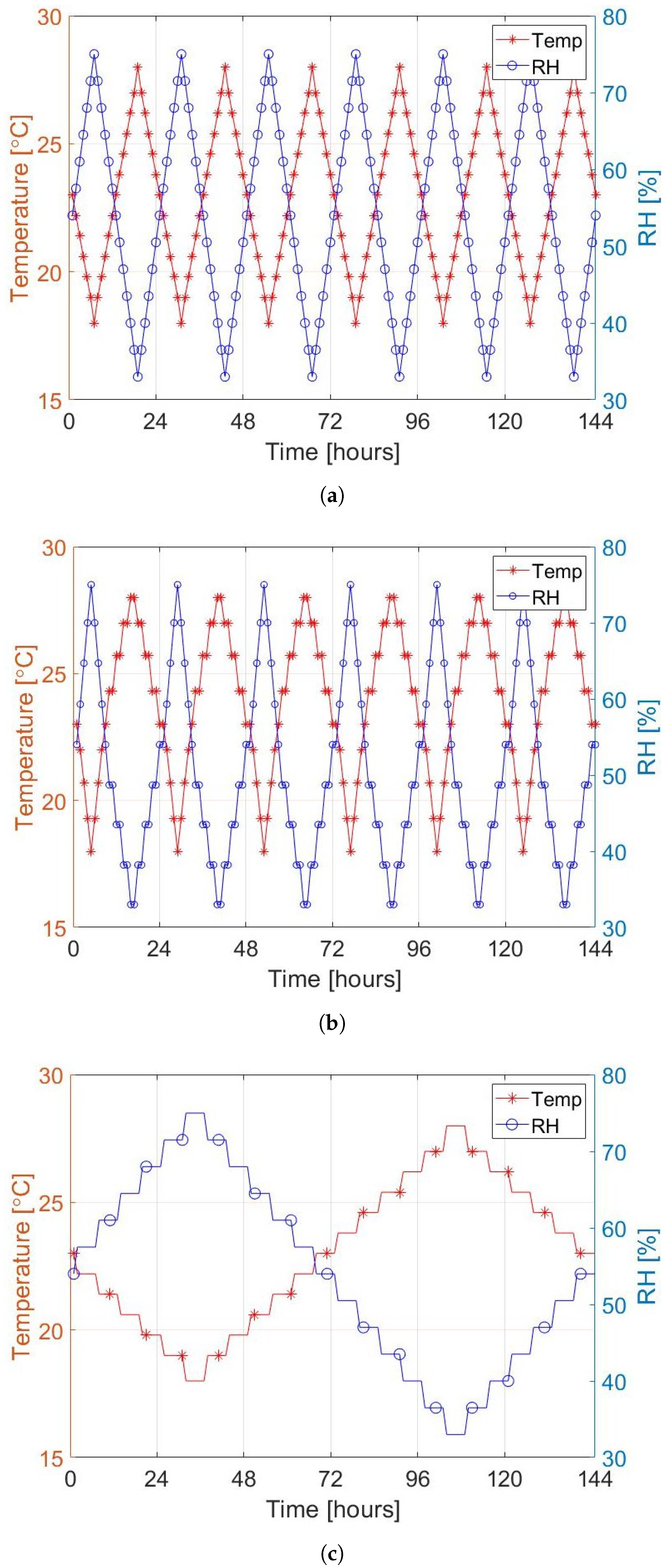

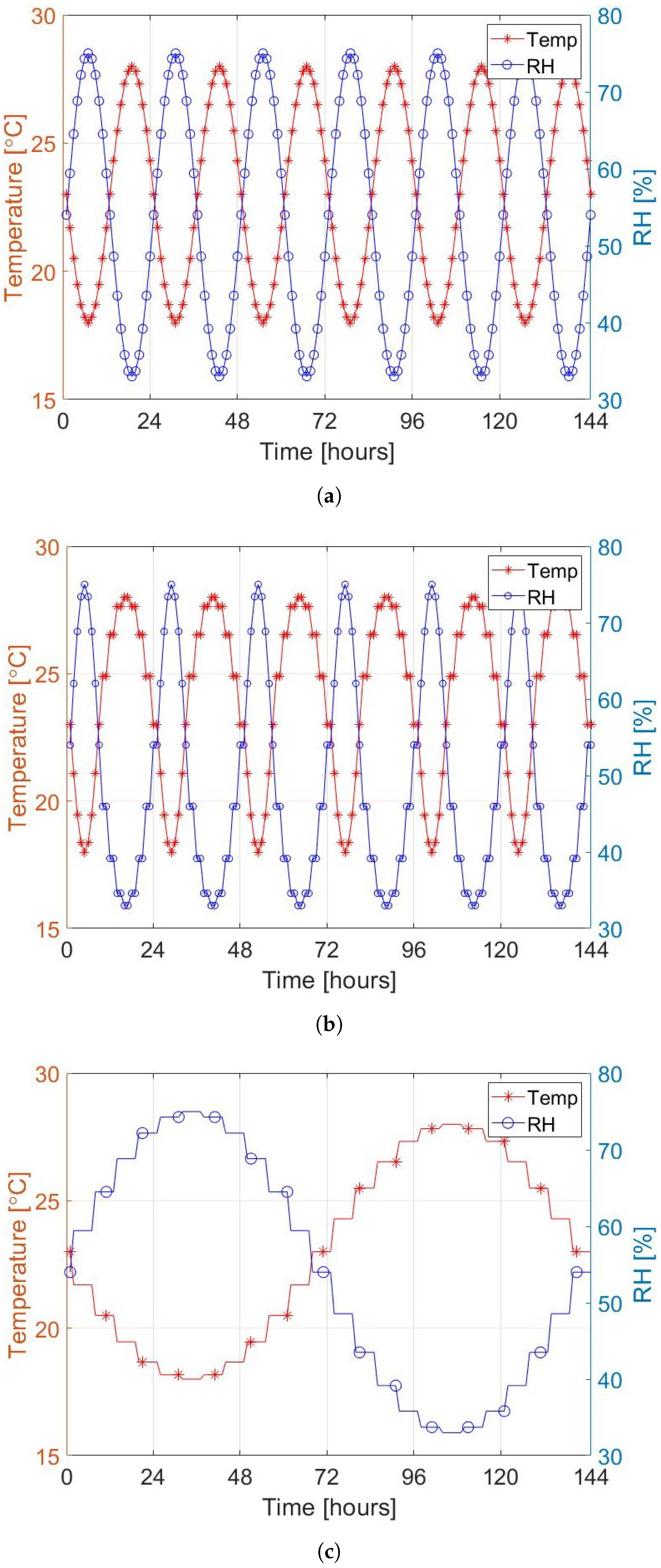

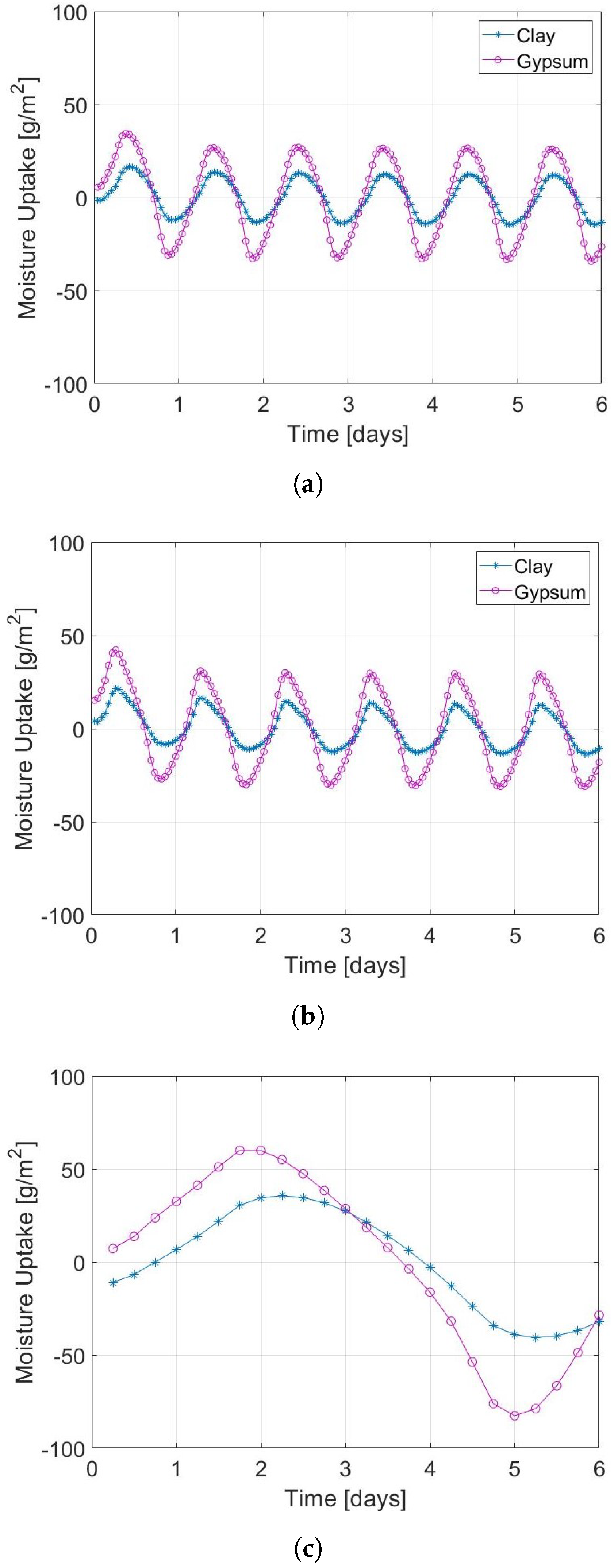

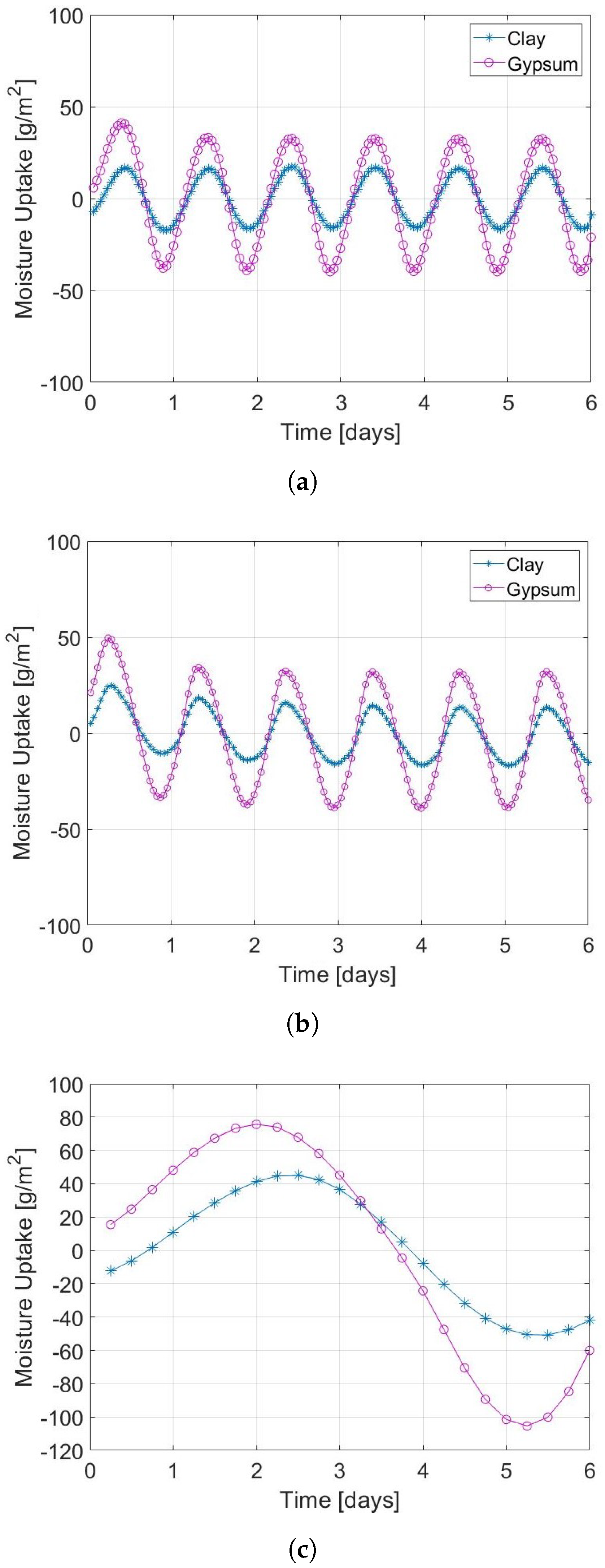

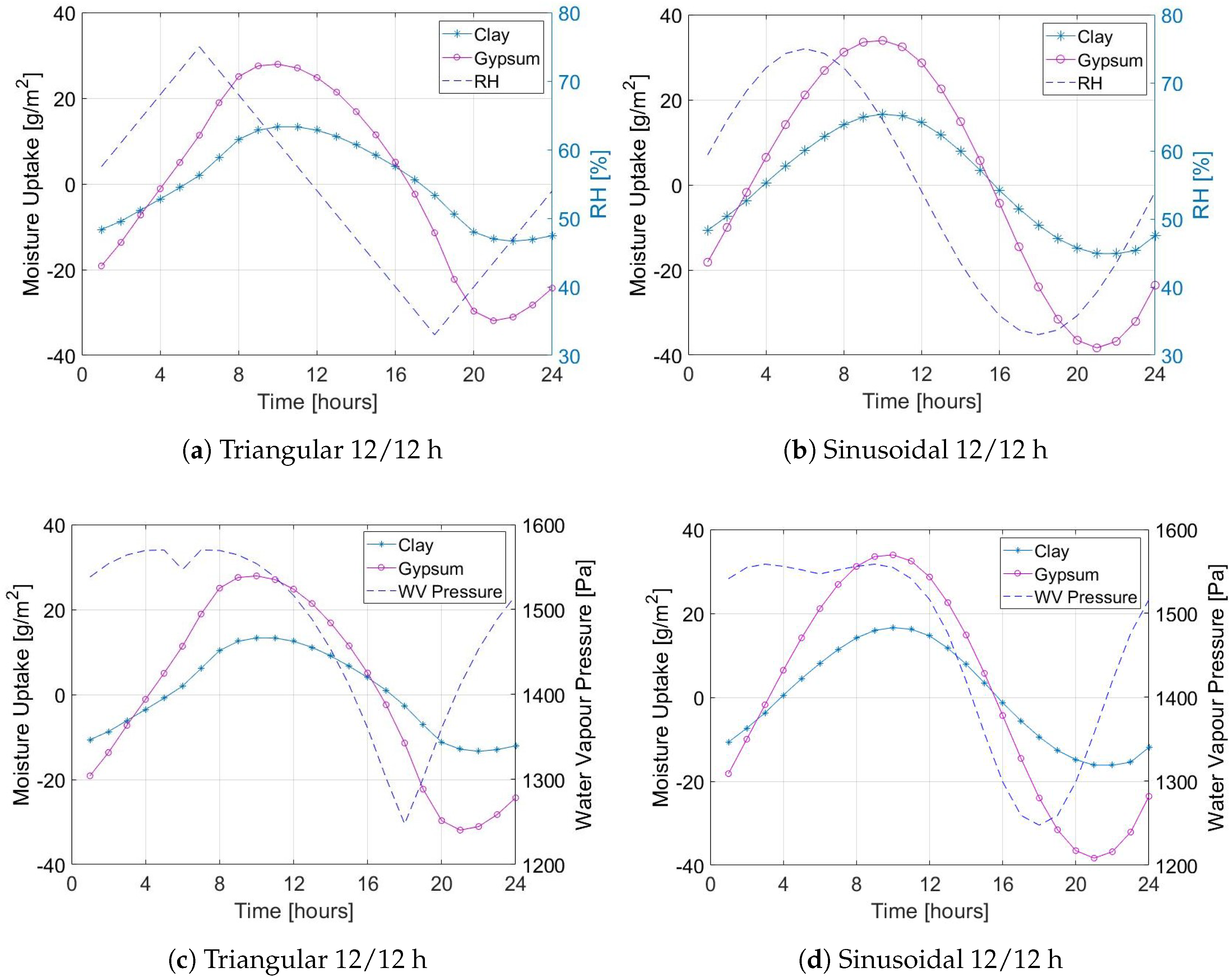

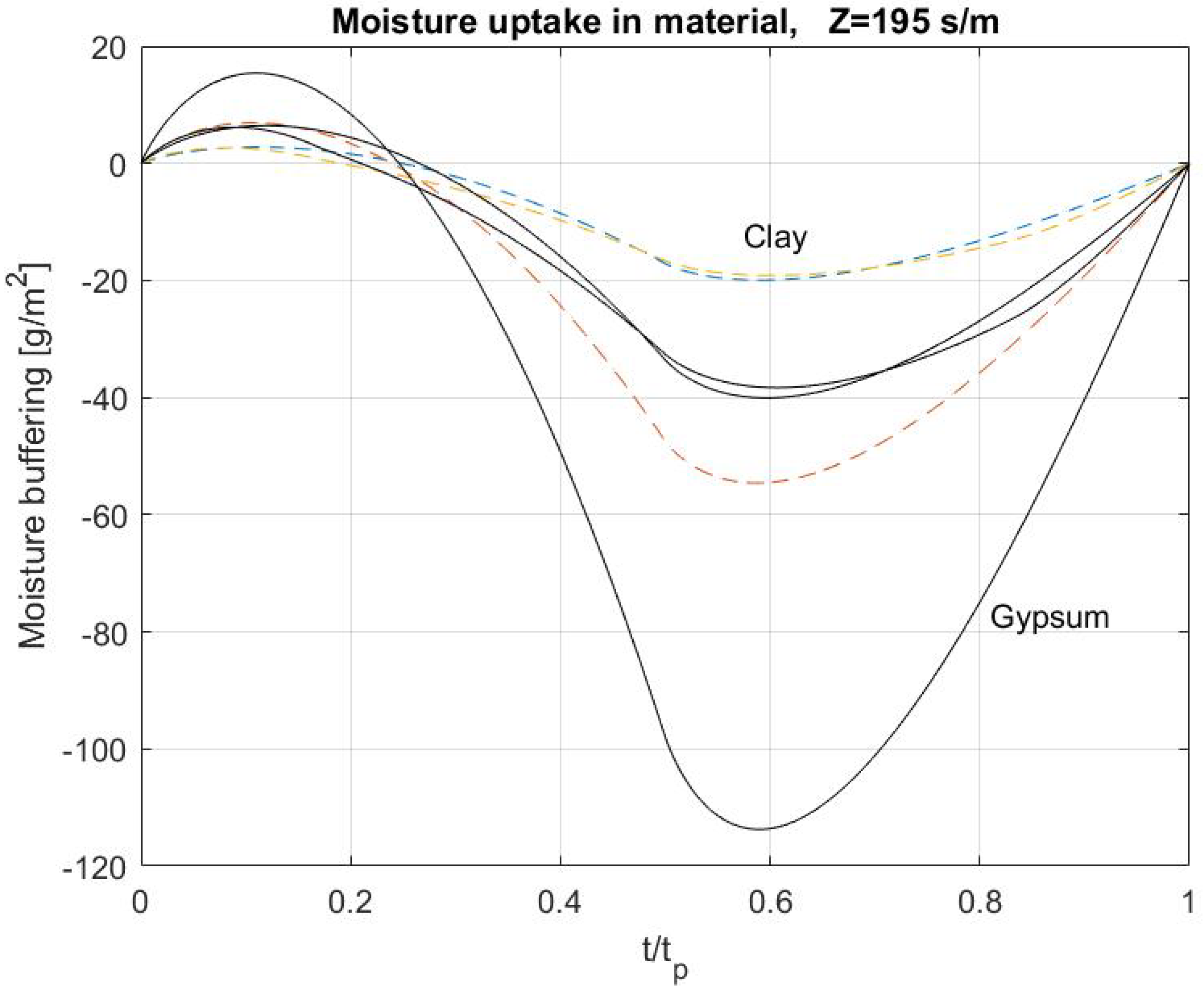

The moisture buffering performance of clay and gypsum under triangular and sinusoidal temperature and RH fluctuations is shown in

Table 3. The average peak to peak sorption capacity was calculated by considering the last three cycle of the 12 h and 8 h, as the changed in weight stabilised after the third cycle in all tests. In general, gypsum had a better moisture capacity than clay (

Figure 4 and

Figure 5), by adsorbing two times more moisture regardless of the shape and time interval of the temperature and RH fluctuations. The performance of gypsum is due to its porosity and pore structure. As explained in [

8], gypsum presented higher porosity than clay, but it also showed a significant presence of micro-pores that increased themoisture uptake of the material. Differences between the 12 h and 8 h curves in the triangular case either for clay and gypsum were negligible, as the same moisture uptake was measured. Between the

Sinusoidal 12/12 and

Sinusoidal 8/16 curves 11% and 5% variations were observed for clay and gypsum, respectively. However, differences were small and not significant, when compared to the differences between triangular and sinusoidal sorption responses. There was 18% and 20% differences between

Triangular 12/12 and

Sinusoidal 12/12 peak to peak sorption capacity, while between

Triangular 8/16 and

Sinusoidal 8/16 clay and gypsum presented 10% and 13% variations, respectively. The

Triangular 72/72 and

Sinusoidal 72/72 tests presented the most significant discrepancy, as clay and gypsum adsorbed 20% and 26% more in the sinusoidal case, respectively. The considerable higher sorption capacity of the 72/72 tests is related to the longer time interval, which allowed materials to adsorb more water.

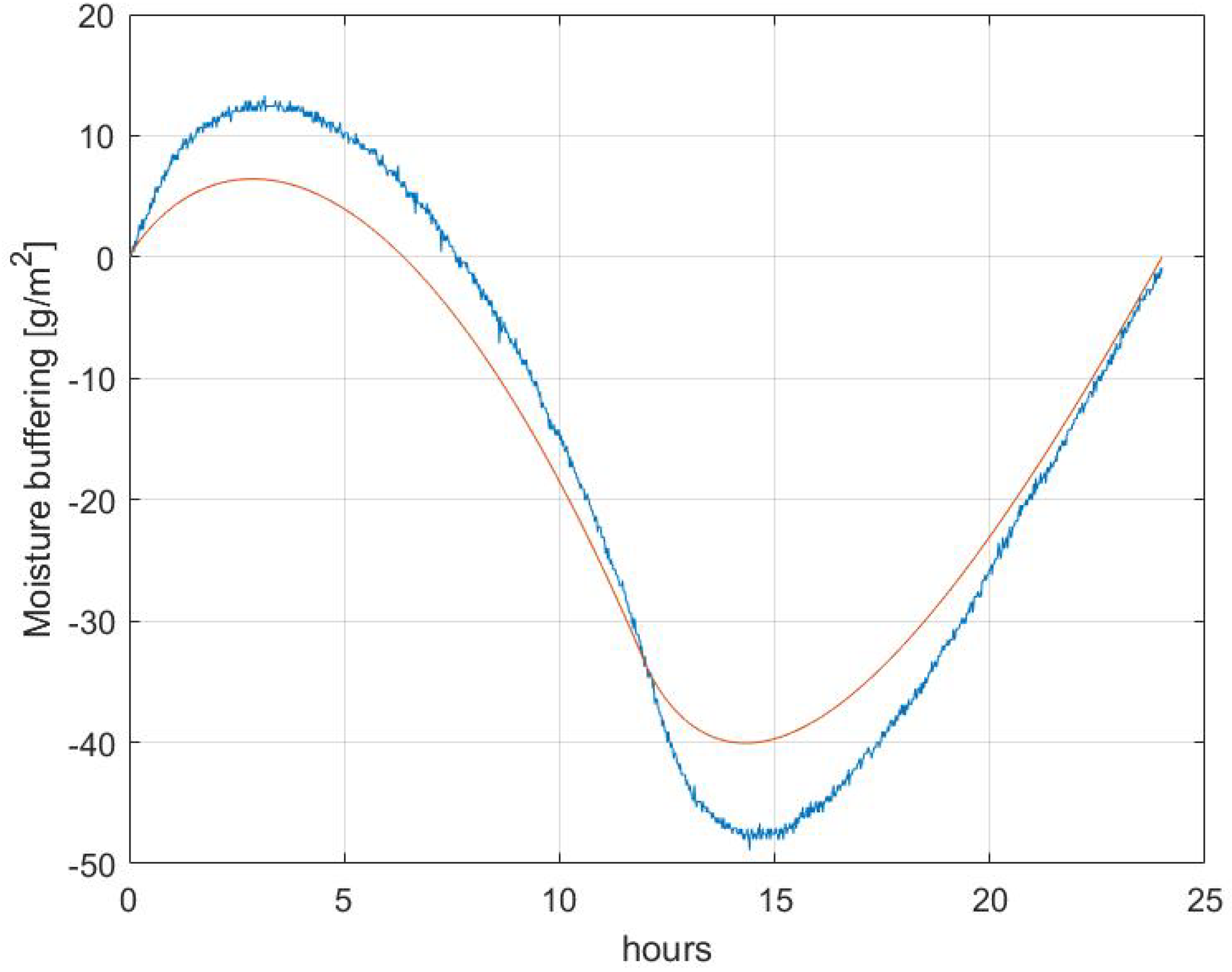

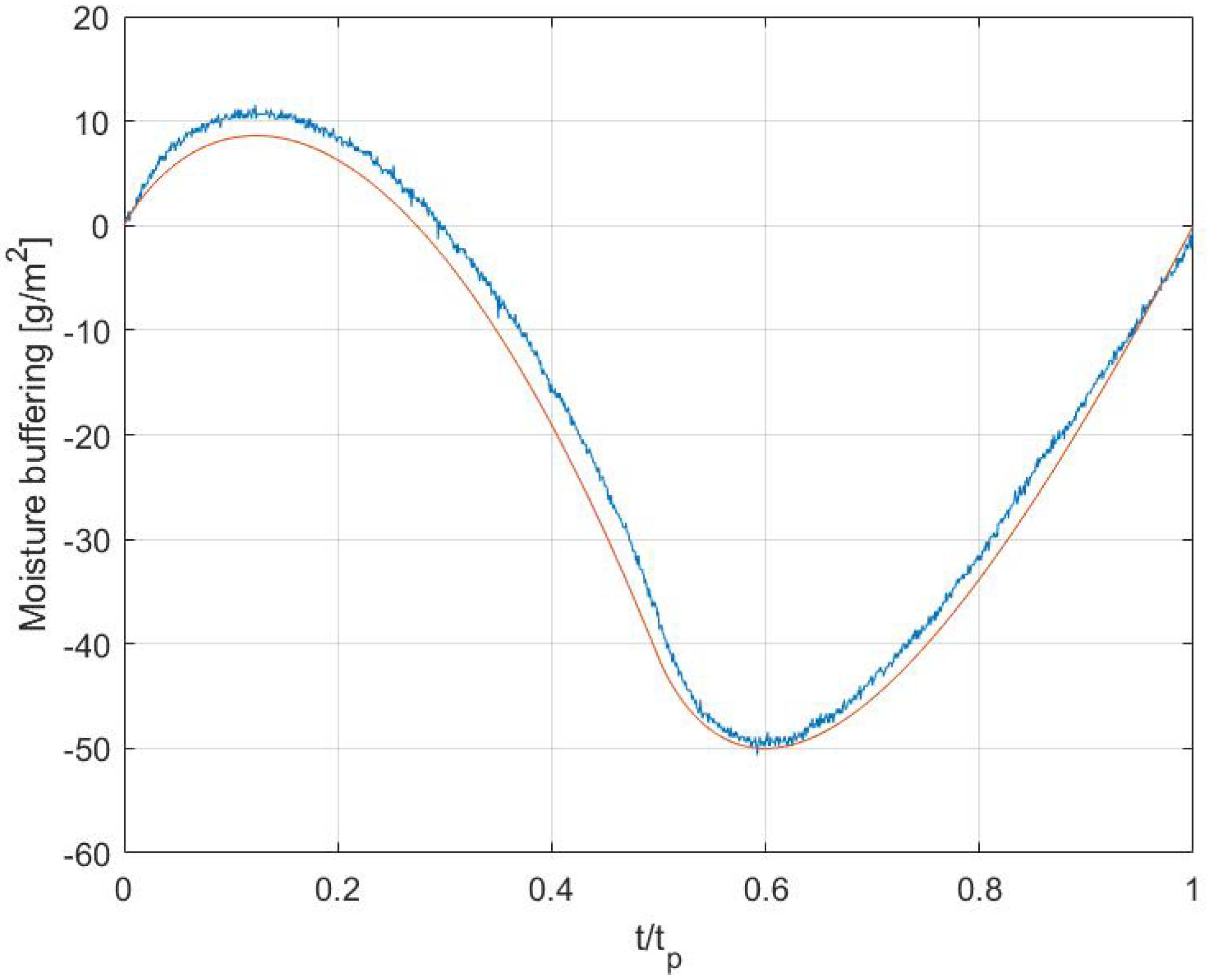

As [

8] also mentioned in a study on sinusoidal environmental variations, the triangular and sinusoidal curves presented a delayed response to the temperature and RH fluctuations (

Figure 6). The hygric lag varied depending on the humidification and de-humidification intervals, the length of each step, the material’s characteristic, but especially on the simultaneous temperature variations.

Table 4 summarises the hygric lags in all the tests, where the first value represents the time between the RH-peak and the moisture uptake peak, while the second represents the time between the lowest RH and the lowest moisture uptake value. In the Triangular and Sinusoidal 12/12 clay and gypsum showed different lags, in which clay always presented a slower response than gypsum either in the adsorption and desorption. Regardless of the materials differences, both plasters showed an asymmetry between the humidification and de-humidification. The desorption lag was 30 min for clay, and 20 and 60 min for gypsum in the

Triangular 12/12 and

Sinusoidal 12/12, respectively. The asymmetry indicated that in the de-humidification the response of the plasters is quicker than the adsorption, probably due to the effect of the air movement in the chamber that slowed the humidity uptake and increase the moisture release.

An opposite pattern can be seen in the

Triangular 8/16 and

Sinusoidal 8/16, where materials presented higher hygric lags in the desorption than the adsorption. The reason could be related to the shorter humidification interval (8 h) and longer de-humidification (16 h), as shown in

Table 4. Moreover, the the longer exposure to lower humidifies and higher temperature may slow down the moisture release. The

Triangular 8/16 the plasters had the same lag in the humidification, but in the desorption clay’s delay increased significantly. In the

Sinusoidal 8/16, clay and gypsum uptake curves had similar lags, which is in line with [

8] test on the same gypsum sample.

The 72/72 test showed the biggest hygric lag, probably due to the longer steps, which allowed the materials to adsorb more moisture. In

Triangular 72/72 and

Sinusoidal 72/72 it was possible to see substantial difference between clay and gypsum. Clay was slower to adsorb water than gypsum, and it took more time to respond to the change of humidity in the air, due to its lower sorption capacity and water vapour permeability. Another important factor that might contribute to the slower response of clay was the different thicknesses of the materials. Clay was 20 mm thicker than gypsum, which means had more moisture storage capacity of gypsum with its 20 mm thickness. This is less noticeable for the 12 h and 8 h due to the quicker humidity variations, while in the 72/72 tests the specimens have got more time to adsorb water from the environment. As [

23] investigated, the amount of moisture that can be adsorbed by materials is strongly dependent on their thickness and penetration depth. The penetration depth depends on the material characteristics and it determines the moisture buffering potential of materials. When the thickness of a material is smaller than its penetration depths, materials can buffer less moisture that what they potentially could adsorb.

To compare the experimental results to simulation, an uncertainty analysis was performed, to check the variability of the moisture uptake, due to experimental error. The size of the specimens and the variability of the moisture uptake were considered. The uncertainty of the single measurements were first analysed and than combined to calculate the overall variations of the moisture uptake.

Table 5 shows the results of the analysis. Four measurements for each dimension were considered for the calculation of the surface area of the specimens, while three repeated moisture buffering tests were used for the climatic chamber and mass balance uncertainty calculation. Delays in the signal transmission between the mass balance and data logger were not detected.

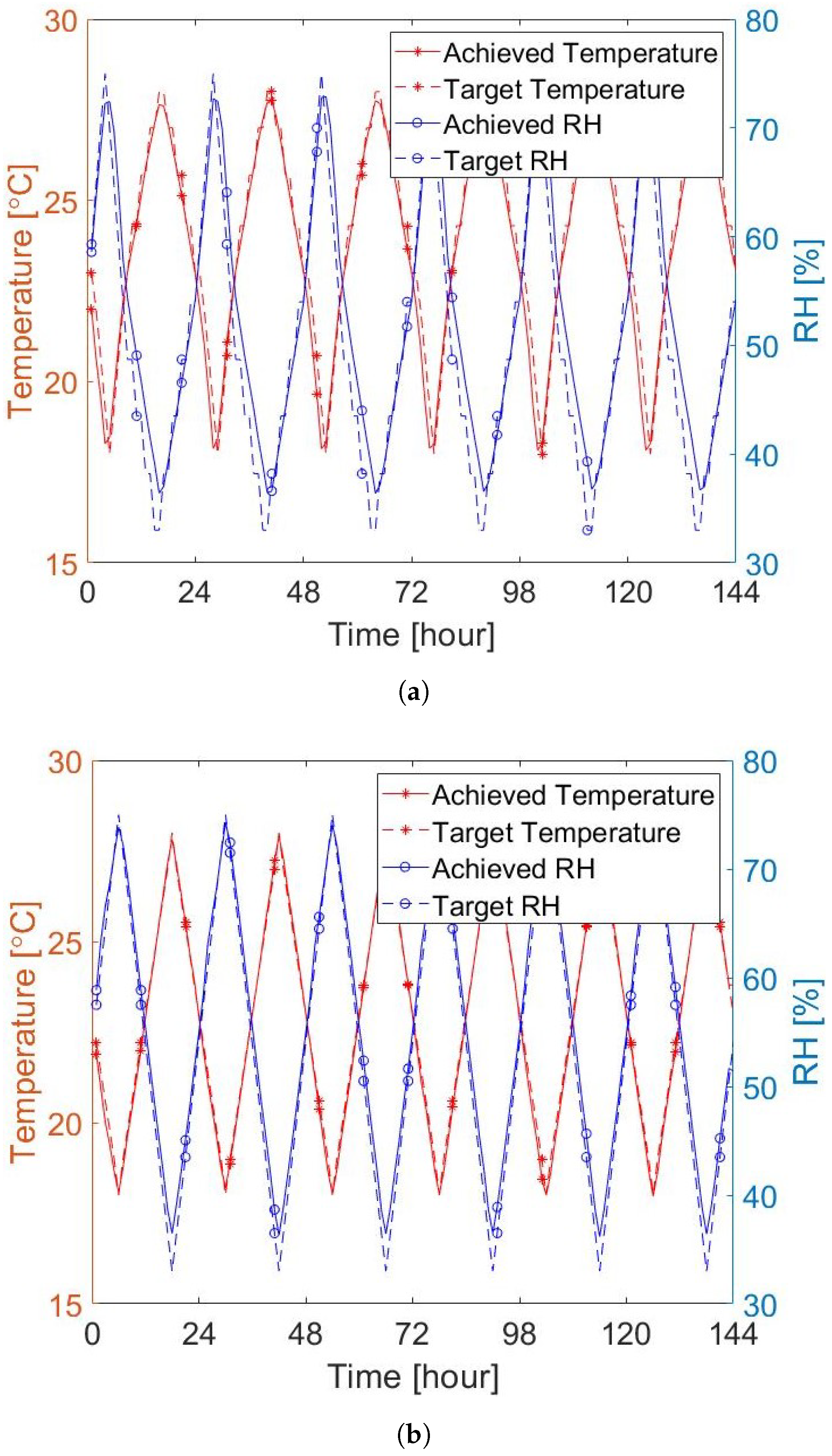

The temperature and RH monitoring in the climatic chamber showed a good agreement between the actual climate conditions with the targeted curves both for the triangular and sinusoidal curves. The Triangular tests are presented in

Figure 7. In

Figure 7a the RH presented on average 2%RH variations from target, up to 5.6%RH during the de-humidification. while temperature showed 0.43

C variations up to 1.40

C. In the symmetric test (

Figure 7a) there was a better match between the actual and target climate. Temperature and RH presented an average variation of 0.17

C and 1.50%RH, respectively, up to 0.79

C and 3.5%RH always during the de-humidification. The temperature and RH fluctuations had smaller amplitudes than the target curves (10

C and 42%RH), as shown in

Table 6. In

Figure 7b it was also observed a delay of 1 h of RH in the de-humidification phase that was than zeroed in the humidification. The reduced RH fluctuation may produce small variations of the moisture buffering results of the two materials. Similar consideration can be done for the sinusoidal variations, as [

8] explained, and as shown in

Table 6.