A Novel Precipitate-Type Architected Metamaterial Strengthened via Orowan Bypass-Like Mechanism

Abstract

1. Introduction

2. Materials and Methods

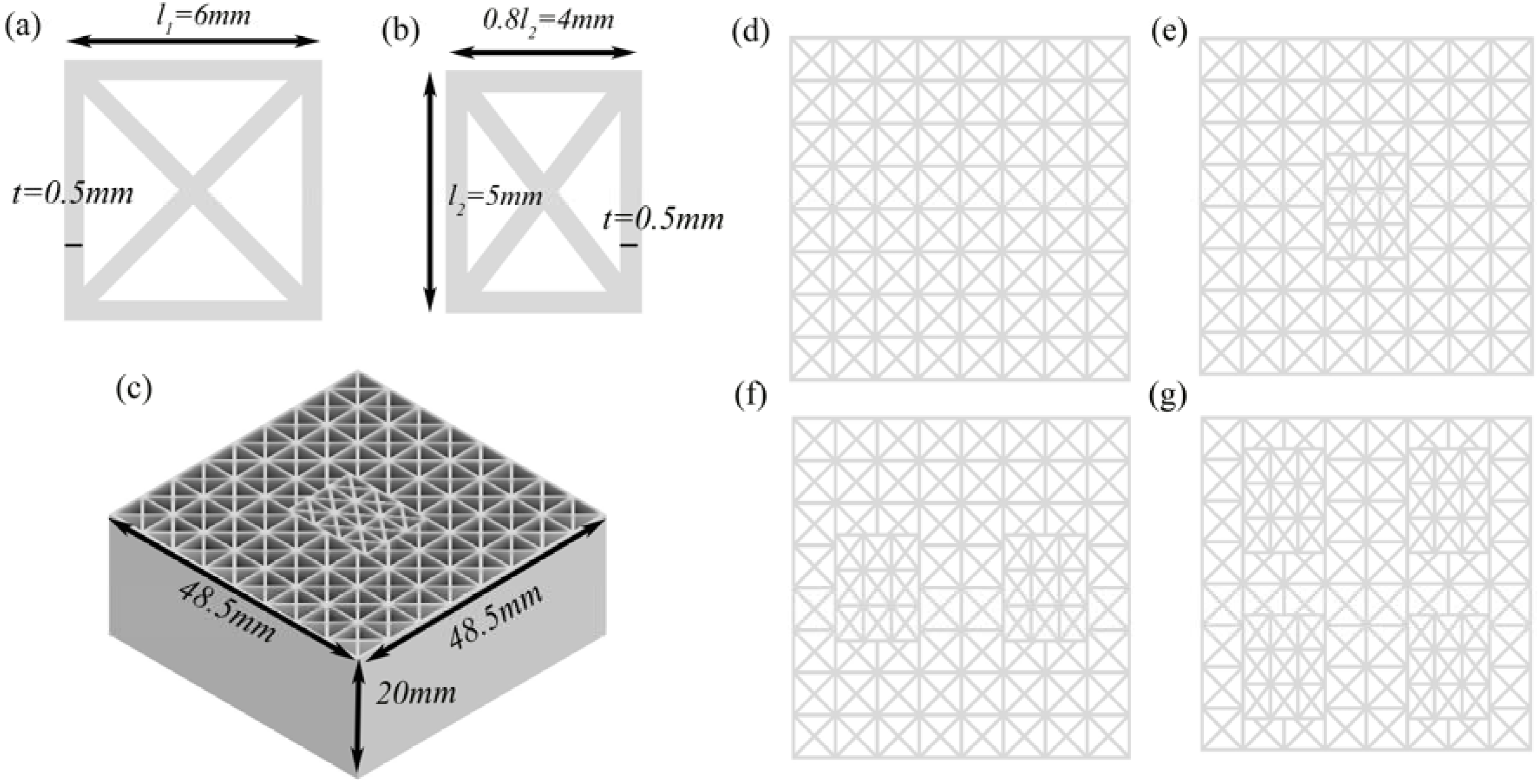

2.1. Design Methodology

2.2. Relative Density

2.3. Sample Preparation

2.4. Quasi-Static Compression Experiment

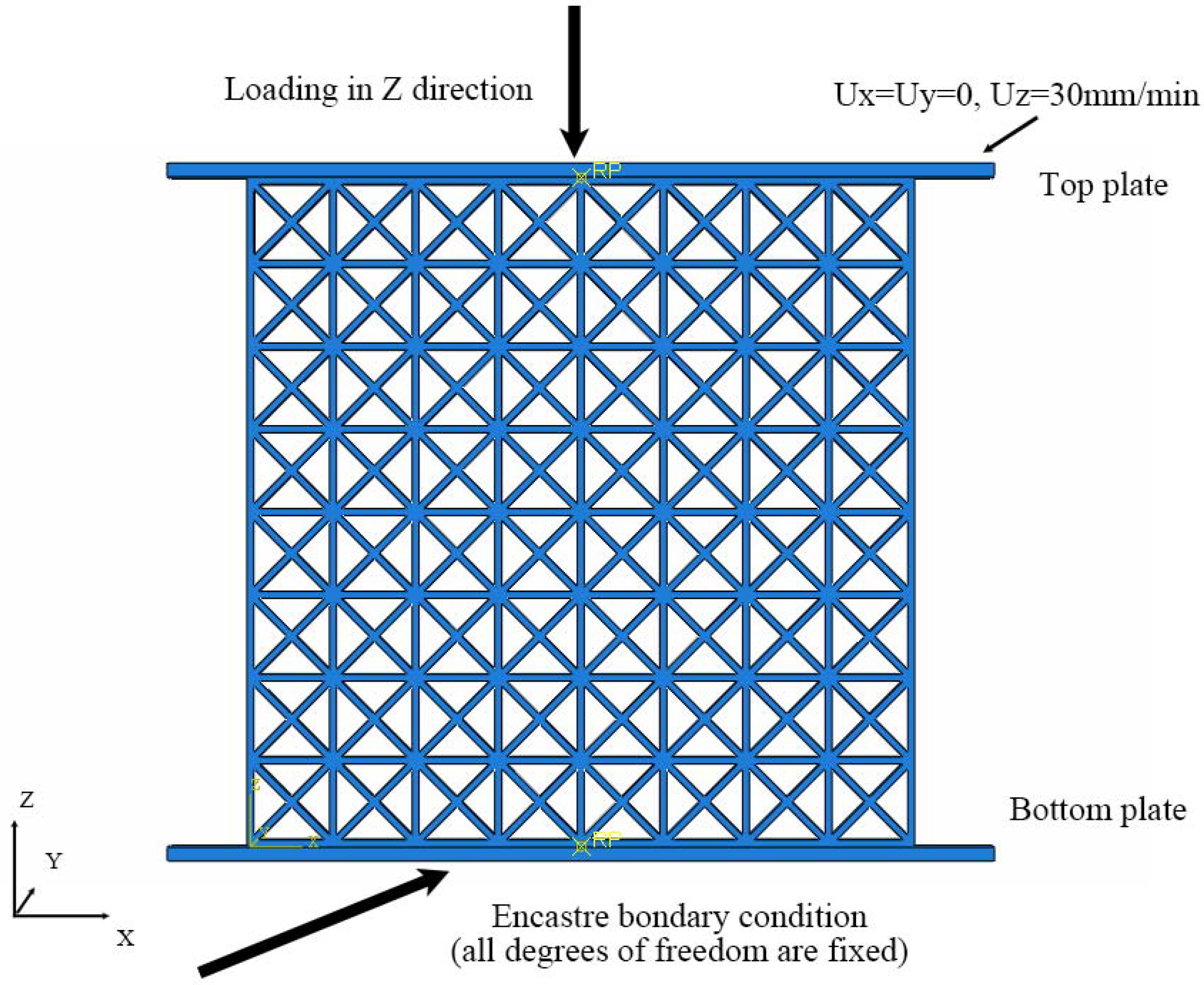

2.5. Finite Element (FE) Simulation

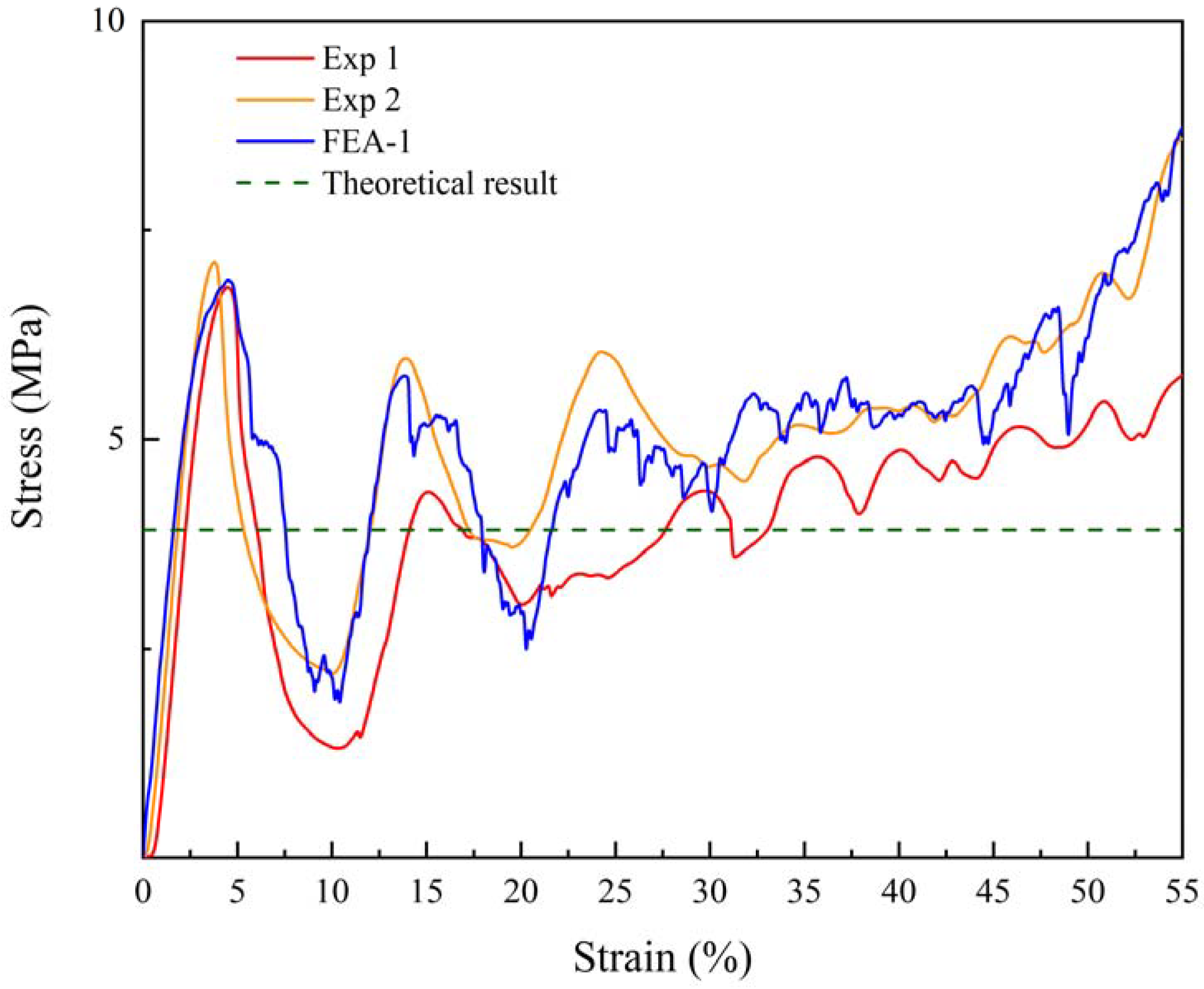

2.6. Verifications of FE Model

3. Results

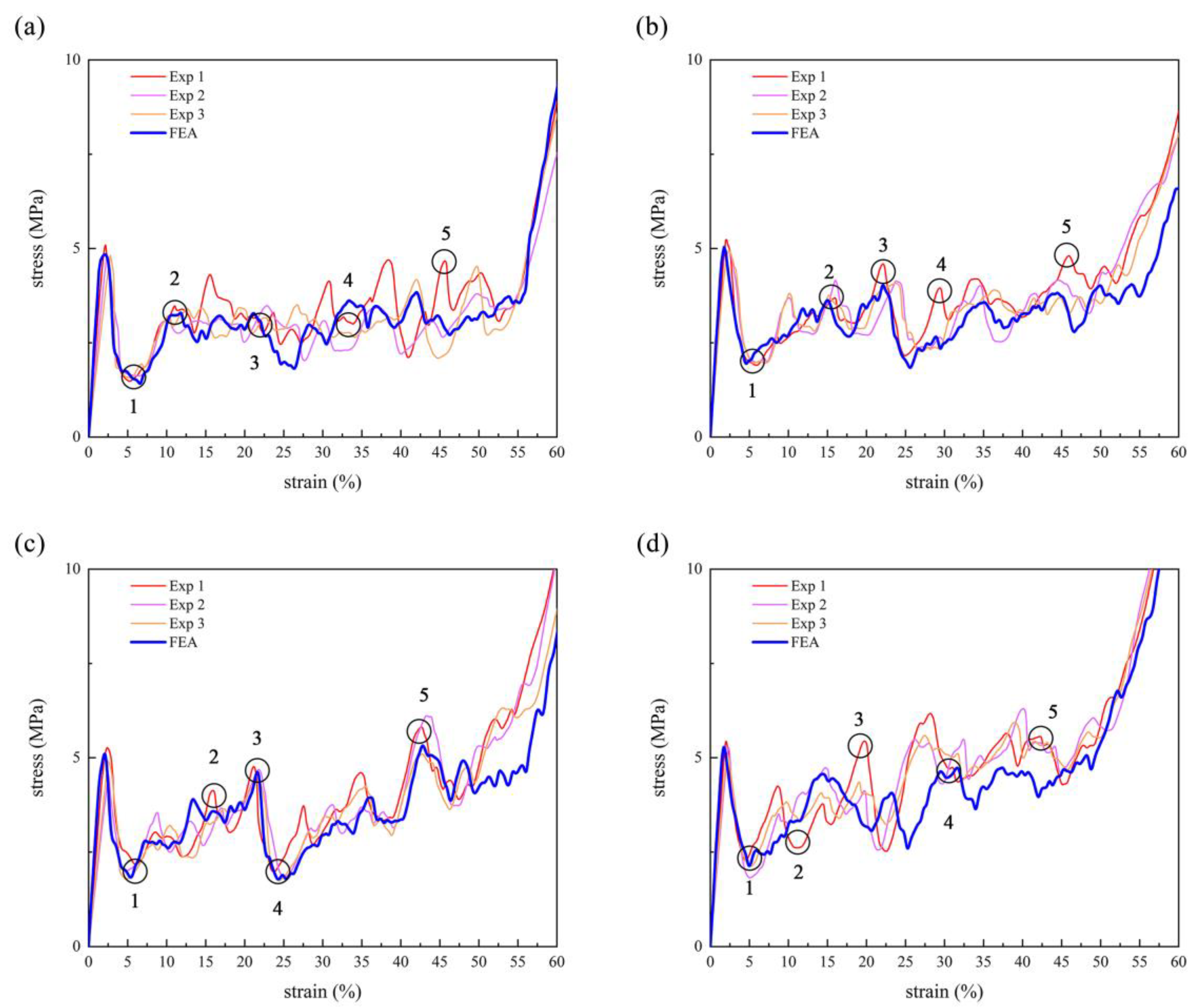

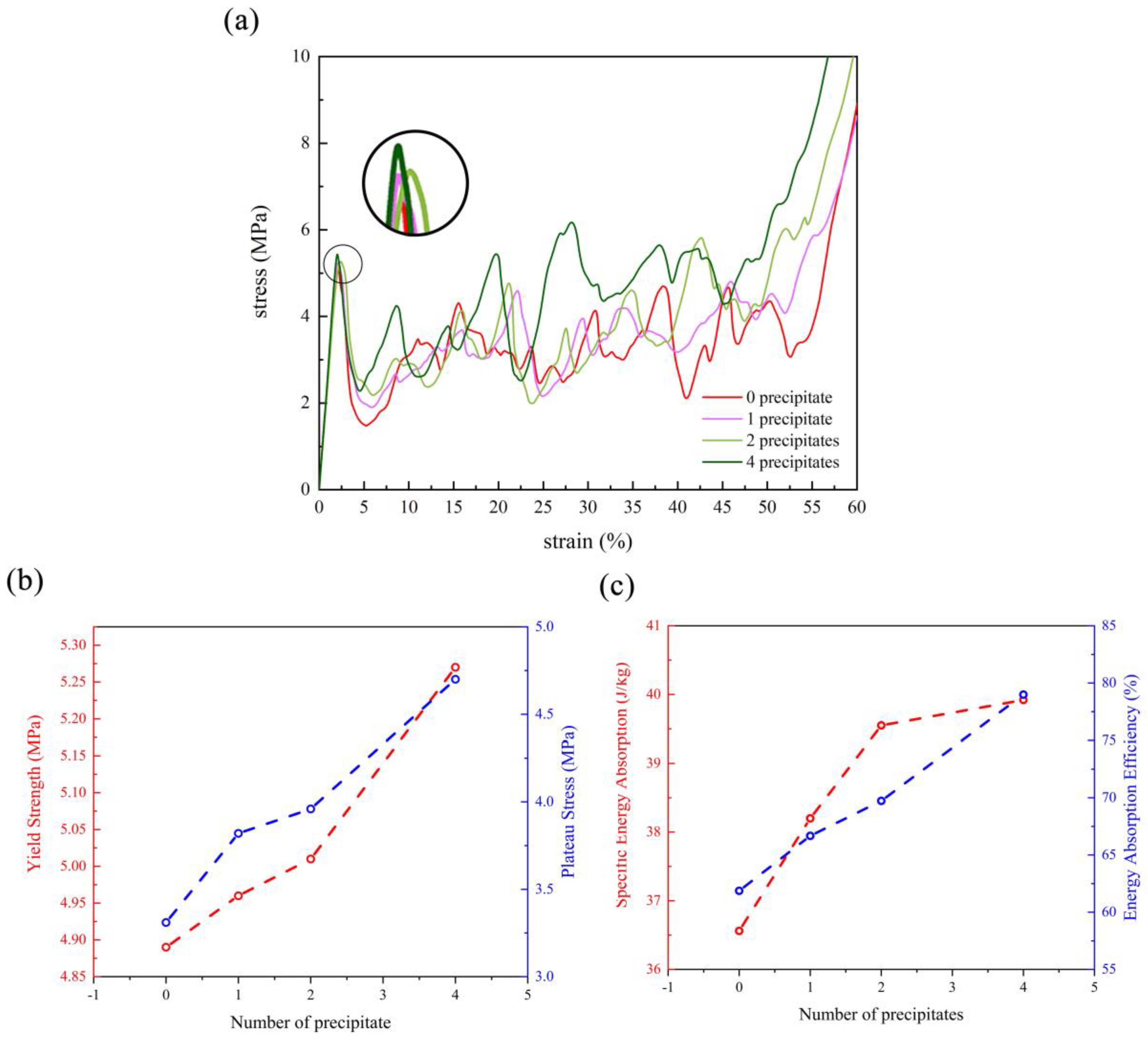

3.1. Mechanical Properties and Energy Absorption

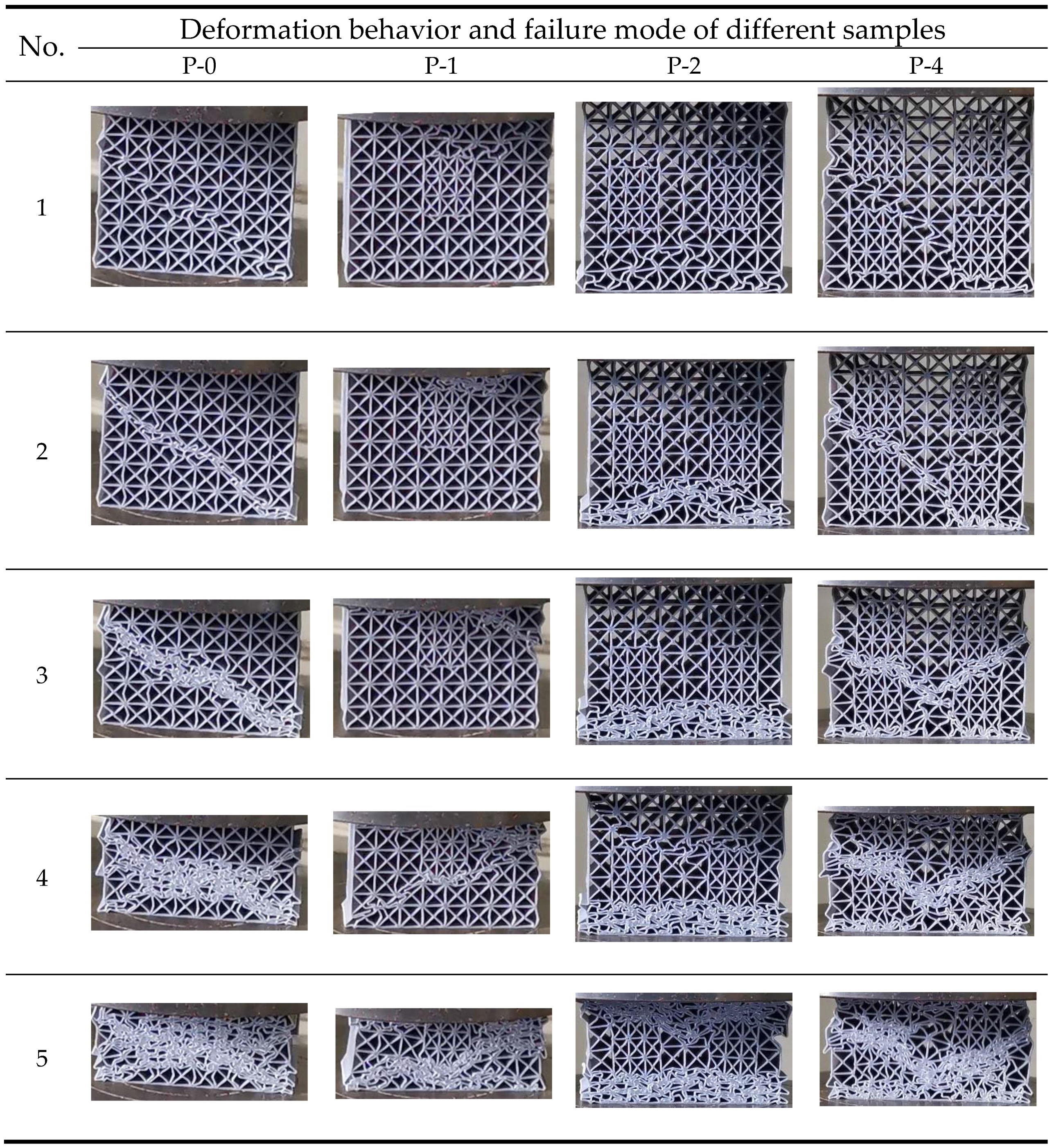

3.2. Deformation Mode

4. Discussion

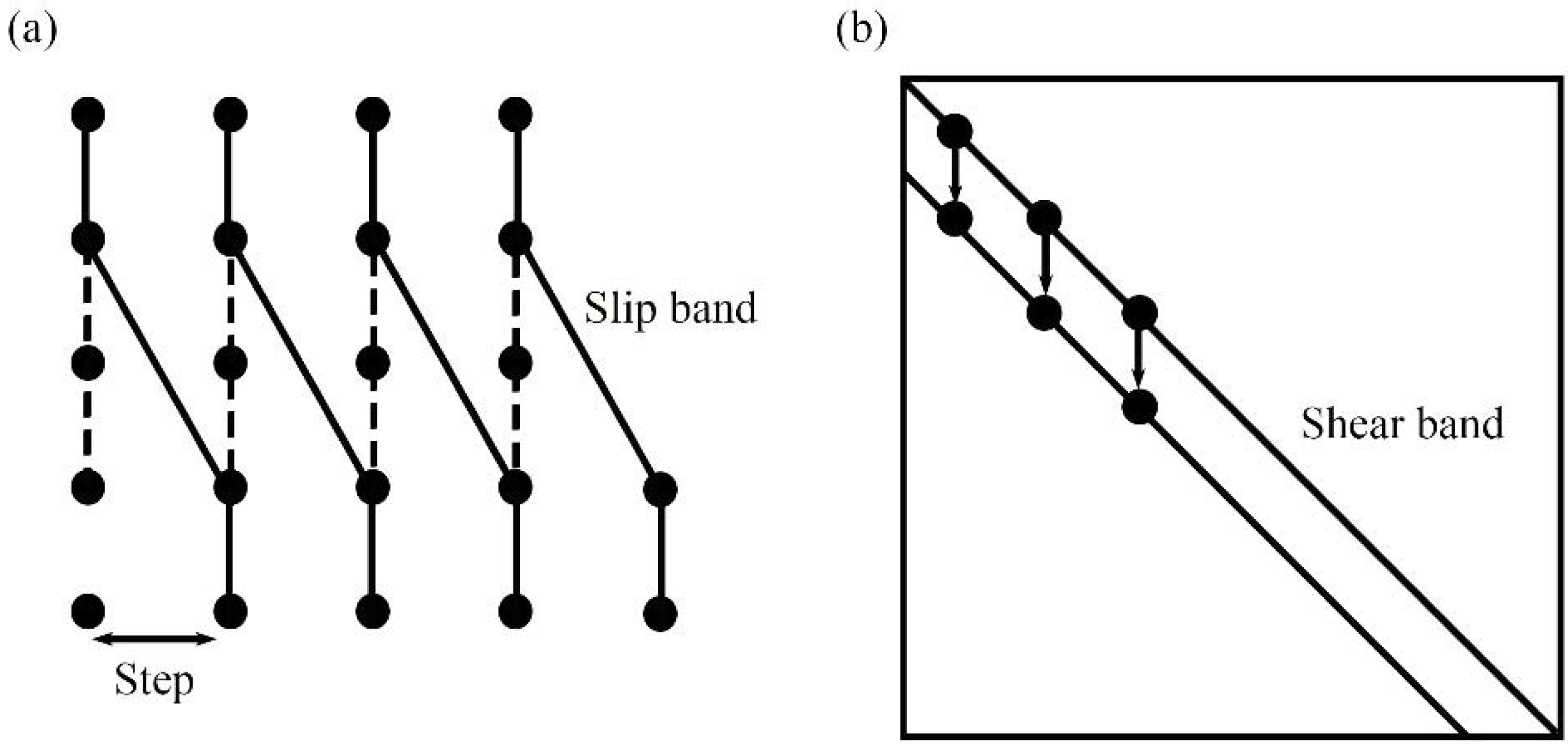

4.1. Feature of Shear Band in Architected Metamaterials

4.2. Orowan Bypass-Like Strengthening Mechanism in Architected Metamaterials

4.2.1. Hindering Effect of Meta-Precipitates

4.2.2. Influence of Volume Fraction of Meta-Precipitates

4.2.3. Difference in Deformation Evolution

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, J.; Gao, L.; Xiao, M.; Gao, J.; Li, H. Isogeometric topology optimization for rational design of ultra-lightweight architected materials. Int. J. Mech. Sci. 2020, 166, 105103. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Carter, W.B. Architected Cellular Materials. Annu. Rev. Mater. Res. 2016, 46, 187–210. [Google Scholar] [CrossRef]

- Schaedler, T.; Jacobsen, A.; Torrents, A.; Sorensen, A.; Lian, J.; Greer, J.; Valdevit, L.; Carter, W. Ultralight Metallic Microlattices. Science 2011, 334, 962–965. [Google Scholar] [CrossRef] [PubMed]

- Yi, F.; Zhu, Z.; Zu, F.; Hu, S.; Yi, P. Strain rate effects on the compressive property and the energy-absorbing capacity of aluminum alloy foams. Mater. Charact. 2001, 47, 417–422. [Google Scholar] [CrossRef]

- Andreassen, E.; Lazarov, B.S.; Sigmund, O. Design of manufacturable 3D extremal elastic microstructure. Mech. Mater. 2014, 69, 1–10. [Google Scholar] [CrossRef]

- Chen, Y.; Jia, Z.; Wang, L. Hierarchical honeycomb lattice metamaterials with improved thermal resistance and mechanical properties. Compos. Struct. 2016, 152, 395–402. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Zhu, F.; Wu, G.; Zhao, L. Response of aluminium corrugated sandwich panels under air blast loadings: Experiment and numerical simulation. Int. J. Impact Eng. 2014, 65, 79–88. [Google Scholar] [CrossRef]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and Mechanics for Stretchable Electronics. Science 2010, 327, 1603. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Niino, T. Additive Manufacturing Technologies—From Rapid Prototyping to Rapid Manufacturing. J. Jpn. Soc. Precis. Eng. 2010, 76, 1340–1344. [Google Scholar] [CrossRef]

- Xue, R.; Cui, X.; Zhang, P.; Liu, K.; Li, Y.; Wu, W.; Liao, H. Mechanical design and energy absorption performances of novel dual scale hybrid plate-lattice mechanical metamaterials. Extreme Mech. Lett. 2020, 40, 100918. [Google Scholar] [CrossRef]

- Wagner, M.A.; Lumpe, T.S.; Chen, T.; Shea, K. Programmable, active lattice structures: Unifying stretch-dominated and bending-dominated topologies. Extreme Mech. Lett. 2019, 29, 100461. [Google Scholar] [CrossRef]

- Mines, R.A.W.; Tsopanos, S.; Shen, Y.; Hasan, R.; McKown, S.T. Drop weight impact behaviour of sandwich panels with metallic micro lattice cores. Int. J. Impact Eng. 2013, 60, 120–132. [Google Scholar] [CrossRef]

- Ushijima, K.; Cantwell, W.; Mines, R.; Tsopanos, S.; Smith, M. An investigation into the compressive properties of stainless steel micro-lattice structures. J. Sandw. Struct. Mater. 2010, 12. [Google Scholar] [CrossRef]

- Tancogne-Dejean, T.; Mohr, D. Elastically-isotropic truss lattice materials of reduced plastic anisotropy. Int. J. Solids Struct. 2018, 138, 24–39. [Google Scholar] [CrossRef]

- Jin, N.; Wang, F.; Wang, Y.; Zhang, B.; Cheng, H.; Zhang, H. Effect of structural parameters on mechanical properties of Pyramidal Kagome lattice material under impact loading. Int. J. Impact Eng. 2019, 132, 103313. [Google Scholar] [CrossRef]

- Trifale, N.; Nauman, E.; Yazawa, K. Systematic Generation, Analysis and Characterization of 3D Micro-architected Meta- materials. ACS Appl. Mater. Interfaces 2016, 8. [Google Scholar] [CrossRef]

- Wendy Gu, X.; Greer, J.R. Ultra-strong architected Cu meso-lattices. Extreme Mech. Lett. 2015, 2, 7–14. [Google Scholar] [CrossRef]

- Wang, B.; Wu, L.; Ma, L.; Sun, Y.; Du, S. Mechanical behavior of the sandwich structures with carbon fiber-reinforced pyramidal lattice truss core. Mater. Des. (1980–2015) 2010, 31, 2659–2663. [Google Scholar] [CrossRef]

- Wang, P.; Fan, H.; Xu, B.; Mei, J.; Wu, K.; Wang, H.; He, R.; Fang, D. Collapse criteria for high temperature ceramic lattice truss materials. Appl. Thermal Eng. 2015, 89, 505–513. [Google Scholar] [CrossRef]

- Pham, M.-S.; Holdsworth, S. Evolution of Relationships Between Dislocation Microstructures and Internal Stresses of AISI 316L During Cyclic Loading at 293 K and 573 K (20 °C and 300 °C). Metall. Mater. Trans. A 2013, 45. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A. Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit. Manuf. 2017, 16, 24–29. [Google Scholar] [CrossRef]

- Qiu, C.; Yue, S.; Adkins, N.J.E.; Ward, M.; Hassanin, H.; Lee, P.D.; Withers, P.J.; Attallah, M.M. Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng. A 2015, 628, 188–197. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A.; Wildman, R.D.; Hague, R.J.M. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A 2016, 670, 264–274. [Google Scholar] [CrossRef]

- Gu, H.; Pavier, M.; Shterenlikht, A. Experimental study of modulus, strength and toughness of 2D triangular lattices. Int. J. Solids Struct. 2018, 152, 207–216. [Google Scholar] [CrossRef]

- Qi, D.; Yu, H.; Liu, M.; Huang, H.; Xu, S.; Xia, Y.; Qian, G.; Wu, W. Mechanical behaviors of SLM additive manufactured octet-truss and truncated-octahedron lattice structures with uniform and taper beams. Int. J. Mech. Sci. 2019, 163, 105091. [Google Scholar] [CrossRef]

- Dimiduk, D.M.; Uchic, M.D.; Parthasarathy, T.A. Size-affected single-slip behavior of pure nickel microcrystals. Acta Mater. 2005, 53, 4065–4077. [Google Scholar] [CrossRef]

- Chalmers, B. Dislocations and Plastic Flow in Crystals. Dislocations in CrystalsA.H. Cottrell. Acta Metall. 1954, 2, 170. [Google Scholar] [CrossRef]

- Pham, M.S.; Holdsworth, S.R.; Janssens, K.G.F.; Mazza, E. Cyclic deformation response of AISI 316L at room temperature: Mechanical behaviour, microstructural evolution, physically-based evolutionary constitutive modelling. Int. J. Plast. 2013, 47, 143–164. [Google Scholar] [CrossRef]

- Argon, A. Strengthening Mechanisms in Crystal Plasticity; University Press Scholarship Online: Oxford, UK, 2008. [Google Scholar] [CrossRef]

- Pham, M.-S.; Liu, C.; Todd, I.; Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 2019, 565, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Lakes, R.S. Size effects and micromechanics of a porous solid. J. Mater. Sci. 1983, 18, 2572–2580. [Google Scholar] [CrossRef]

- Hirsch, P.B.; Humphreys, F.J. The deformation of single crystals of copper and copper-zinc alloys containing alumina particles—I. Macroscopic properties and workhardening theory. Proc. R. Soc. Lond. A Math. Phys. Sci. 1970, 318, 45–72. [Google Scholar] [CrossRef]

- Gibson, L.; Ashby, M. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Corapi, D.; Morettini, G.; Pascoletti, G.; Zitelli, C. Characterization of a Polylactic acid (PLA) produced by Fused Deposition Modeling (FDM) technology. Procedia Struct. Integr. 2019, 24, 289–295. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D printed polymers: An experimental-modelling methodology for the prediction of mechanical properties. Mater. Des. 2020. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Ro, C.J.; Sorensen, A.E.; Eckel, Z.; Yang, S.S.; Carter, W.B.; Jacobsen, A.J. Designing Metallic Microlattices for Energy Absorber Applications. Adv. Eng. Mater. 2014, 16, 276–283. [Google Scholar] [CrossRef]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters for dimensional accuracy using I-optimality criterion. Measurement 2016, 81, 174–196. [Google Scholar] [CrossRef]

- Sha, Y.; Jiani, L.; Haoyu, C.; Ritchie, R.O.; Jun, X. Design and strengthening mechanisms in hierarchical architected materials processed using additive manufacturing. Int. J. Mech. Sci. 2018, 149, 150–163. [Google Scholar] [CrossRef]

- Tankasala, H.C.; Fleck, N.A. The crack growth resistance of an elastoplastic lattice. Int. J. Solids Struct. 2020, 188, 233–243. [Google Scholar] [CrossRef]

- Wang, G.; Chen, X.; Qiu, C. On the macro- and micro-deformation mechanisms of selectively laser melted damage tolerant metallic lattice structures. J. Alloys Compd. 2020, 852, 156985. [Google Scholar] [CrossRef]

- Orowan, E. Classification and Nomenclature of Internal Stresses; Symposium on Internal Stresses in Metals and Alloys Institute of Metals; Royal Institution of Great Britain: London, UK, 1947. [Google Scholar]

- Lloyd, D.J. Precipitation Hardening. In Strength of Metals and Alloys (ICSMA 7); McQueen, H.J., Bailon, J.P., Dickson, J.I., Jonas, J.J., Akben, M.G., Eds.; Elsevier: Pergamon, Turkey, 1986; pp. 1745–1778. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hirsch, P.B. The deformation of single crystals of copper and copper-zinc alloys containing alumina particles—II. Microstructure and dislocation-particle interactions. Proc. R. Soc. Lond. A Math. Phys. Sci. 1970, 318, 73–92. [Google Scholar] [CrossRef]

- Zhou, T.; Ding, H.; Ma, X.; Feng, W.; Zhao, H.; Li, A.; Meng, Y.; Zhang, H. Effect of precipitates on high-temperature tensile strength of a high W-content cast Ni-based superalloy. J. Alloys Compd. 2019, 797, 486–496. [Google Scholar] [CrossRef]

| Sample | Strut Thickness (mm) | Average Thickness (mm) | Theoretical Thickness (mm) | Error | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| P-0 | 0.482 | 0.467 | 0.511 | 0.487 | 0.500 | 2.6% |

| P-1 | 0.458 | 0.493 | 0.487 | 0.479 | 4.2% | |

| P-2 | 0.497 | 0.476 | 0.465 | 0.479 | 4.2% | |

| P-4 | 0.483 | 0.492 | 0.480 | 0.485 | 3.0% | |

| Material | Young’s Modulus, Es | Poisson’s Ratio | ||

|---|---|---|---|---|

| PLA+ | 2.0 GPa | 0.35 | 1.26 g/cm3 | 39 MPa |

| FE Result (MPa) | Experiment Result (MPa) | Theoretical Result (MPa) | Error |

|---|---|---|---|

| 4.56 | 4.33 | 3.92 | 5.04% |

| Sample | Young’s Modulus (GPa) | Yield Strength (MPa) | Energy Absorption (×104 J/m3) | Energy Absorption Efficiency (%) | |

|---|---|---|---|---|---|

| P-0 | 1 | 2.50 | 5.07 | 1.82 | 64.02 |

| 2 | 2.40 | 4.76 | 1.62 | 60.61 | |

| 3 | 2.27 | 4.84 | 1.65 | 60.98 | |

| P-1 | 1 | 3.18 | 4.92 | 1.85 | 65.79 |

| 2 | 3.19 | 5.04 | 1.80 | 67.41 | |

| 3 | 3.04 | 4.91 | 1.82 | 67.62 | |

| P-2 | 1 | 3.27 | 5.24 | 2.07 | 66.81 |

| 2 | 3.16 | 4.91 | 1.84 | 73.76 | |

| 3 | 3.12 | 4.87 | 1.89 | 68.63 | |

| P-4 | 1 | 3.16 | 5.42 | 2.09 | 78.30 |

| 2 | 3.29 | 5.24 | 2.01 | 75.87 | |

| 3 | 3.38 | 5.15 | 2.02 | 82.81 | |

| Sample | Young’s Modulus (GPa) | Yield Strength (MPa) | Energy Absorption (×104 J/m3) | Energy Absorption Efficiency (%) | |

|---|---|---|---|---|---|

| P-0 | Exp | 2.39 | 4.89 | 1.70 | 61.87 |

| FEA | 2.71 | 4.84 | 1.64 | 60.43 | |

| Error | 13.39% | 9.20% | 3.53% | 2.33% | |

| P-1 | Exp | 3.14 | 4.96 | 1.82 | 66.67 |

| FEA | 3.38 | 4.96 | 1.83 | 64.04 | |

| Error | 7.64% | 0.00% | 0.01% | 3.94% | |

| P-2 | Exp | 3.18 | 5.01 | 1.93 | 69.73 |

| FEA | 3.36 | 5.07 | 1.86 | 68.51 | |

| Error | 5.66% | 1.20% | 3.63% | 1.75% | |

| P-4 | Exp | 3.27 | 5.27 | 2.04 | 78.99 |

| FEA | 3.48 | 5.25 | 1.94 | 73.90 | |

| Error | 6.42% | 0.00% | 4.90% | 6.44% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Yan, W.; Yan, P.; Yan, B. A Novel Precipitate-Type Architected Metamaterial Strengthened via Orowan Bypass-Like Mechanism. Appl. Sci. 2020, 10, 7525. https://doi.org/10.3390/app10217525

Lu Z, Yan W, Yan P, Yan B. A Novel Precipitate-Type Architected Metamaterial Strengthened via Orowan Bypass-Like Mechanism. Applied Sciences. 2020; 10(21):7525. https://doi.org/10.3390/app10217525

Chicago/Turabian StyleLu, Zhehao, Wenyuan Yan, Pengfei Yan, and Biao Yan. 2020. "A Novel Precipitate-Type Architected Metamaterial Strengthened via Orowan Bypass-Like Mechanism" Applied Sciences 10, no. 21: 7525. https://doi.org/10.3390/app10217525

APA StyleLu, Z., Yan, W., Yan, P., & Yan, B. (2020). A Novel Precipitate-Type Architected Metamaterial Strengthened via Orowan Bypass-Like Mechanism. Applied Sciences, 10(21), 7525. https://doi.org/10.3390/app10217525