Application of Advanced Measuring Methods for Identification of Stresses and Deformations of Automotive Structures

Abstract

1. Introduction

2. Checking the Geometry and Shape of the Assessed Car Roof

2.1. Light Reflection Method

2.2. Laser Tracker Systems

3. Experimental Measurement

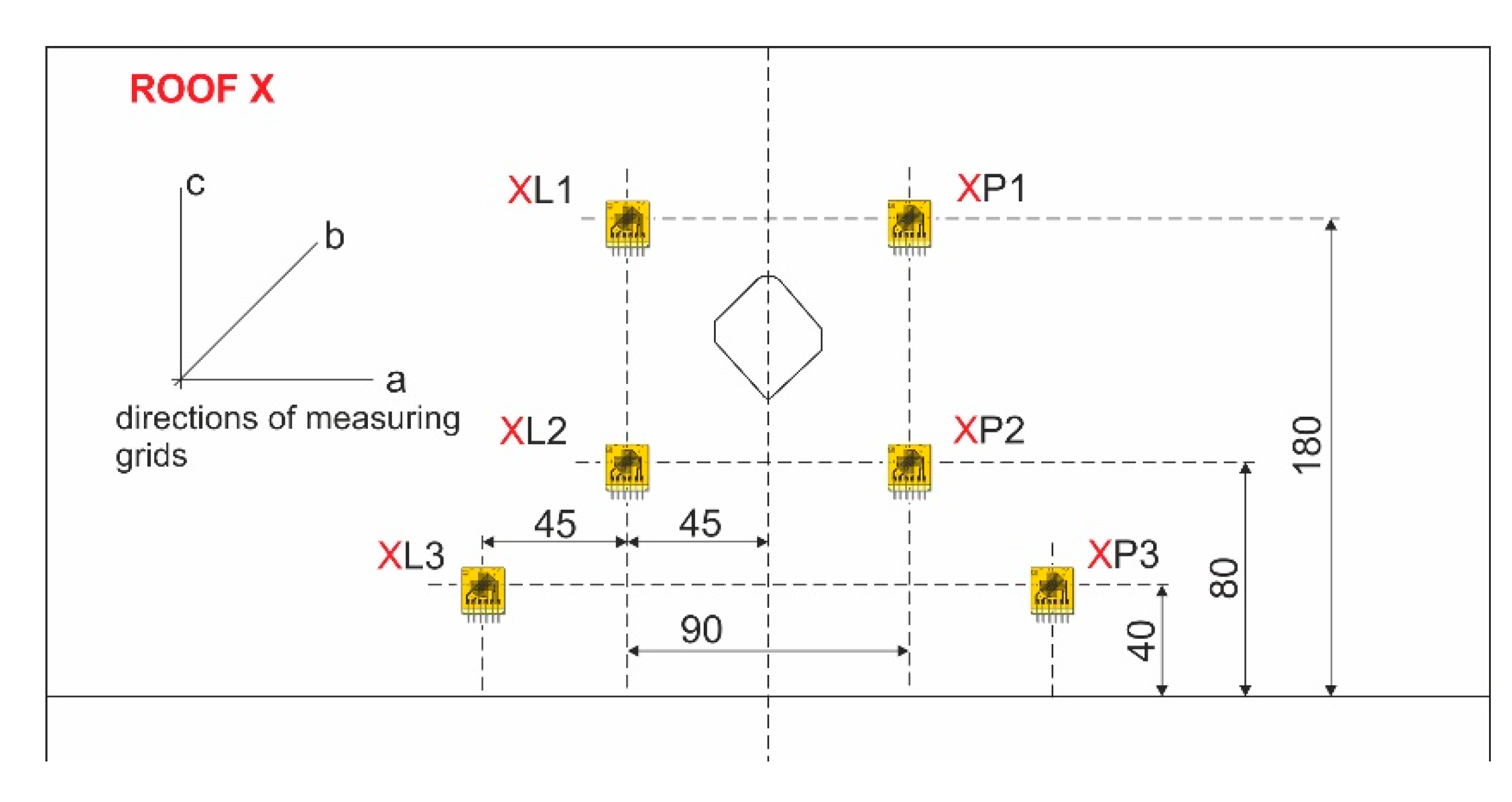

3.1. Design of Methodology for Experimental Measurement of Deformations in Selected Places

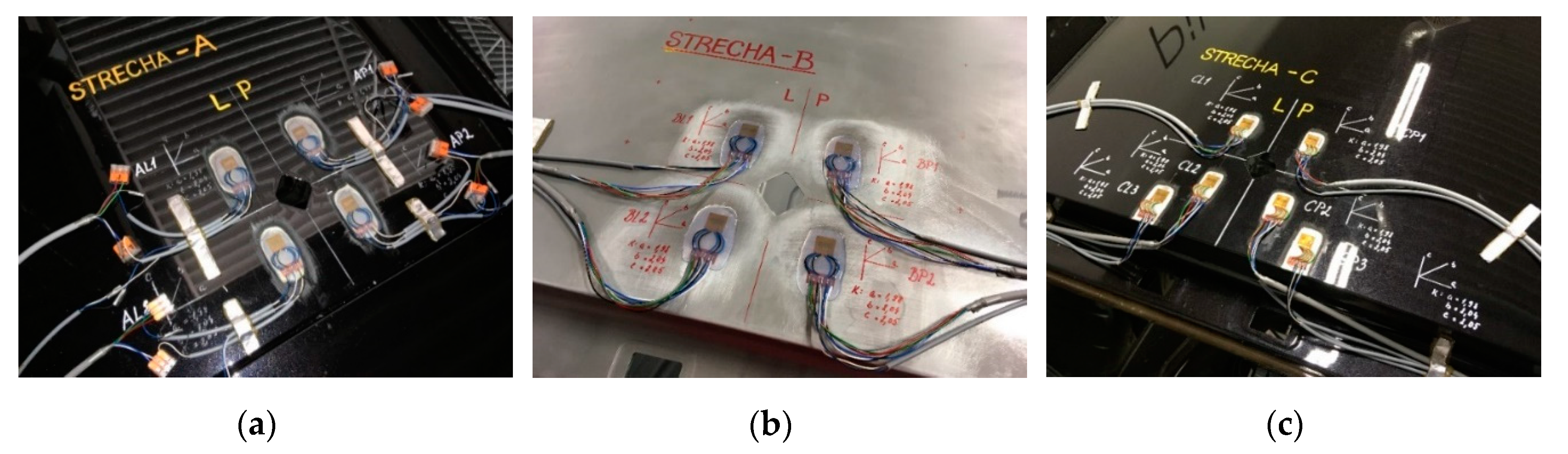

3.2. Realization of Experimental Measurement

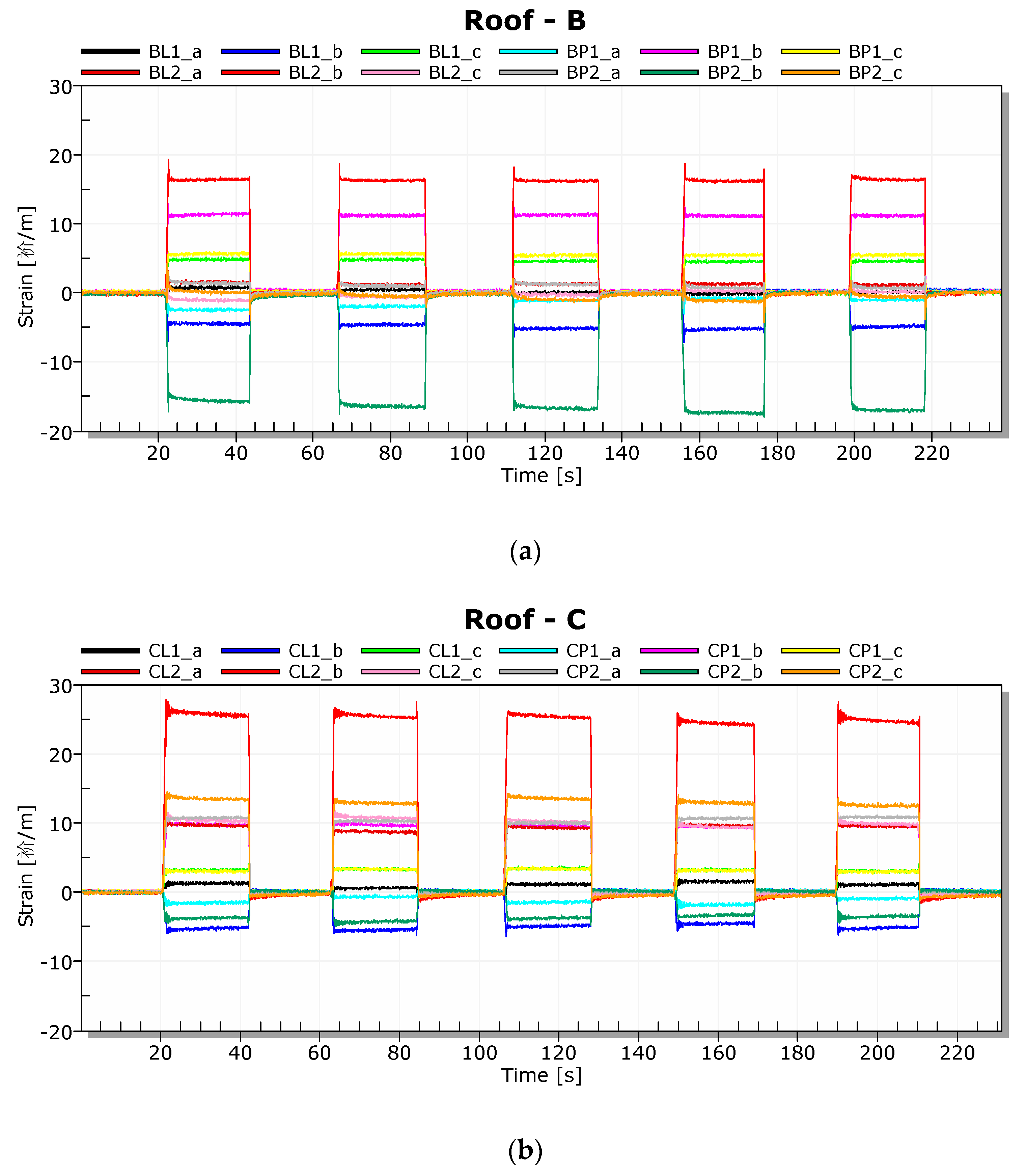

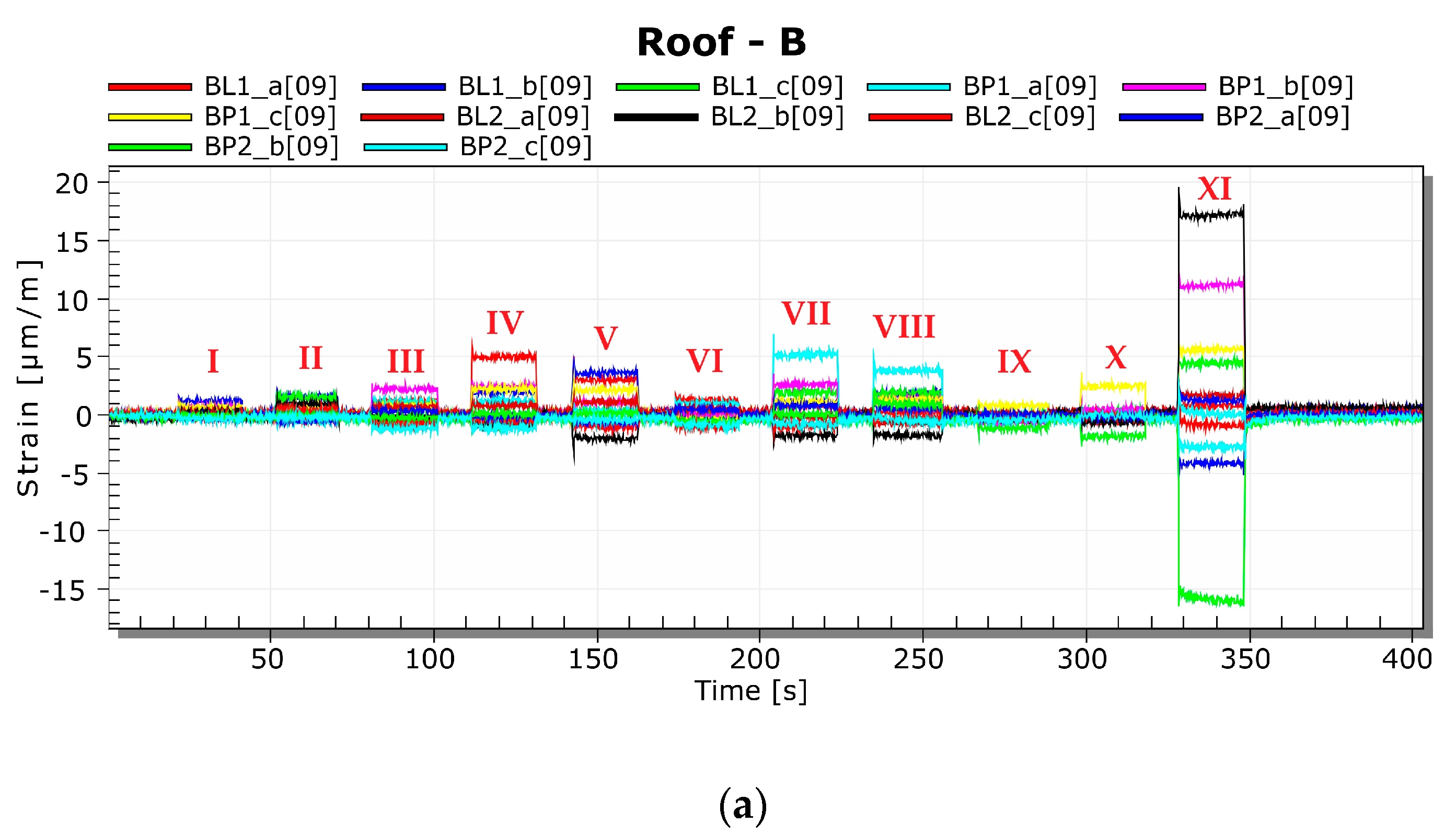

3.2.1. Test Measurement at Unit Load

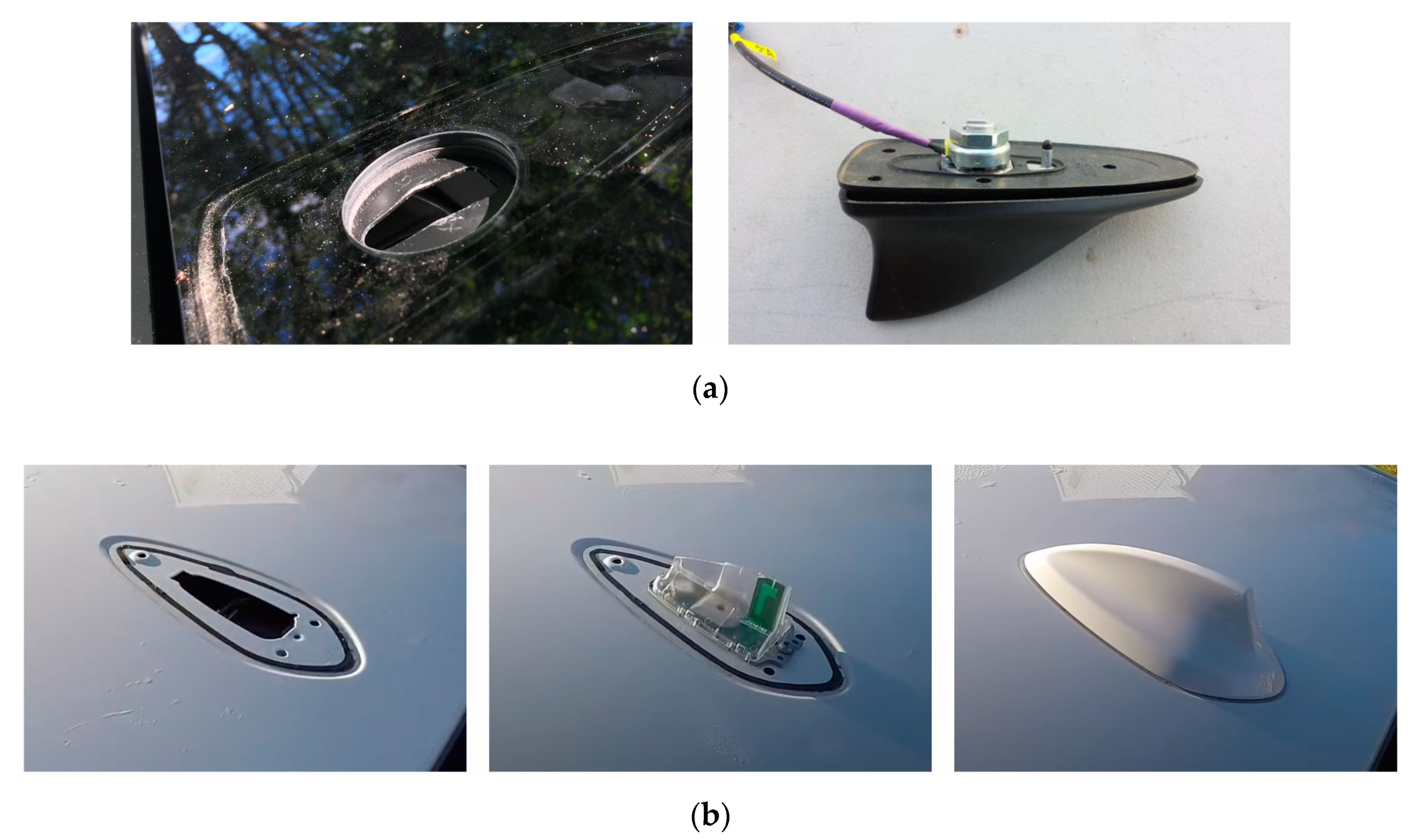

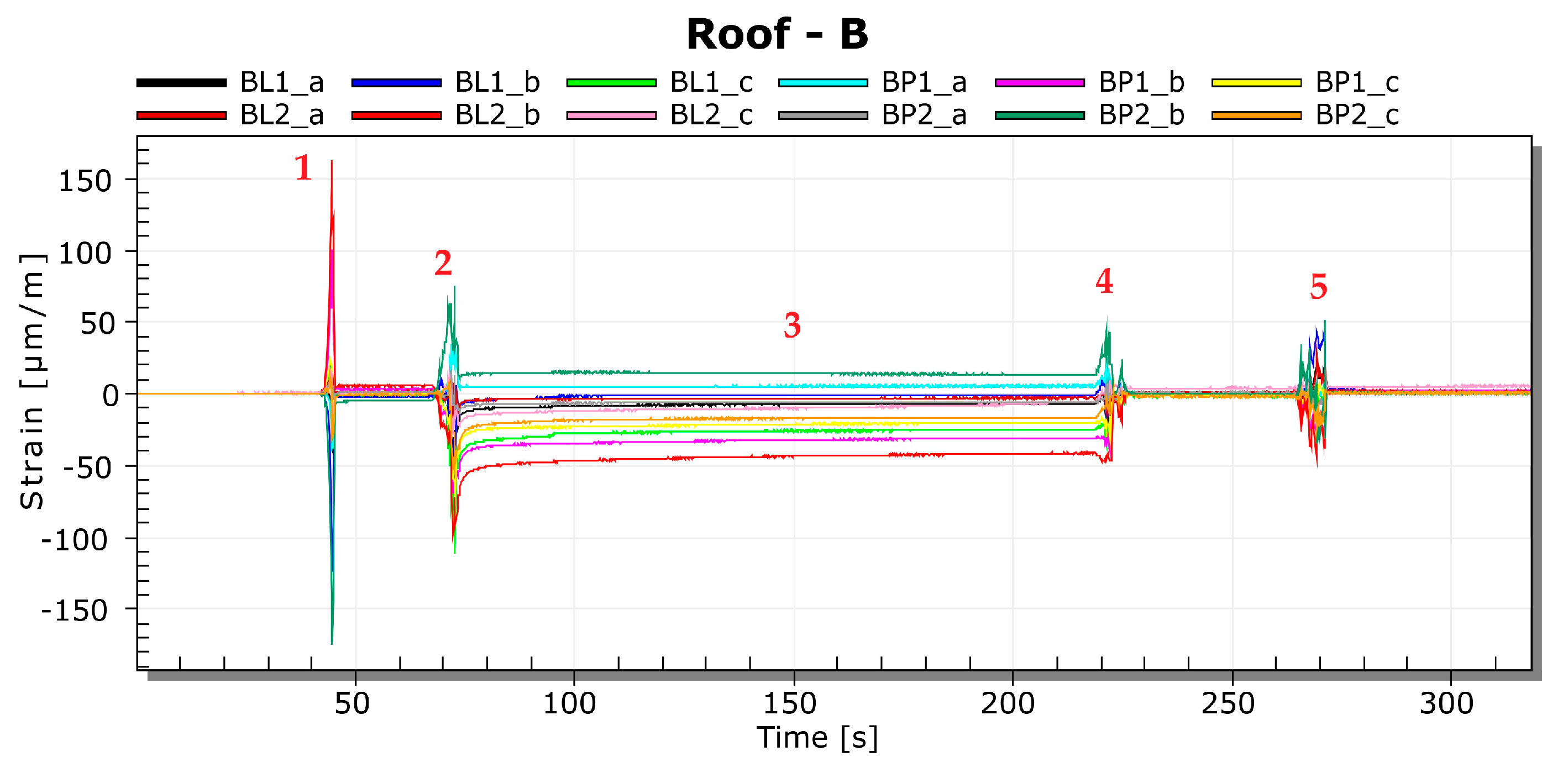

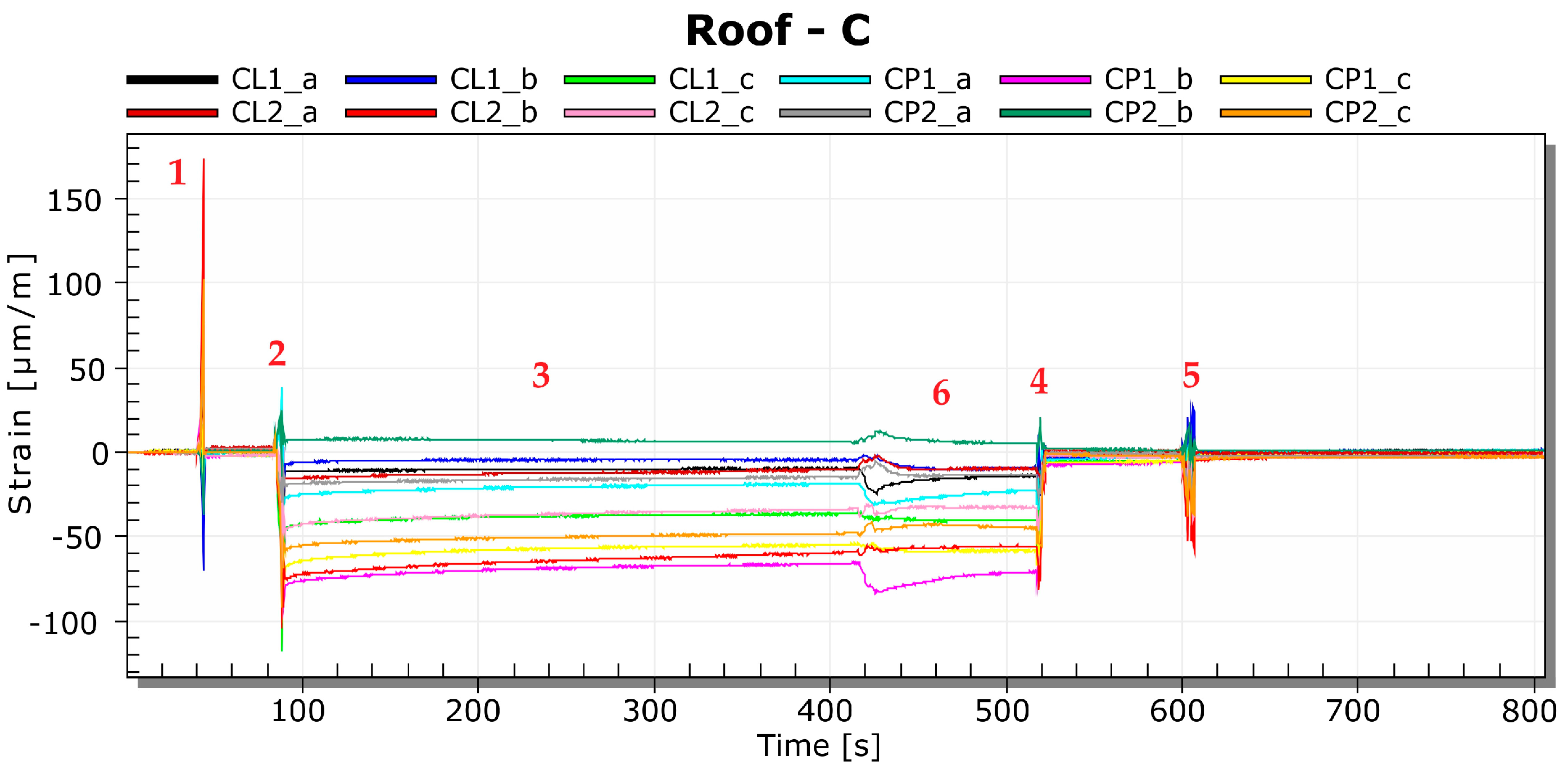

3.2.2. Operational Measurement—Antenna Mounting

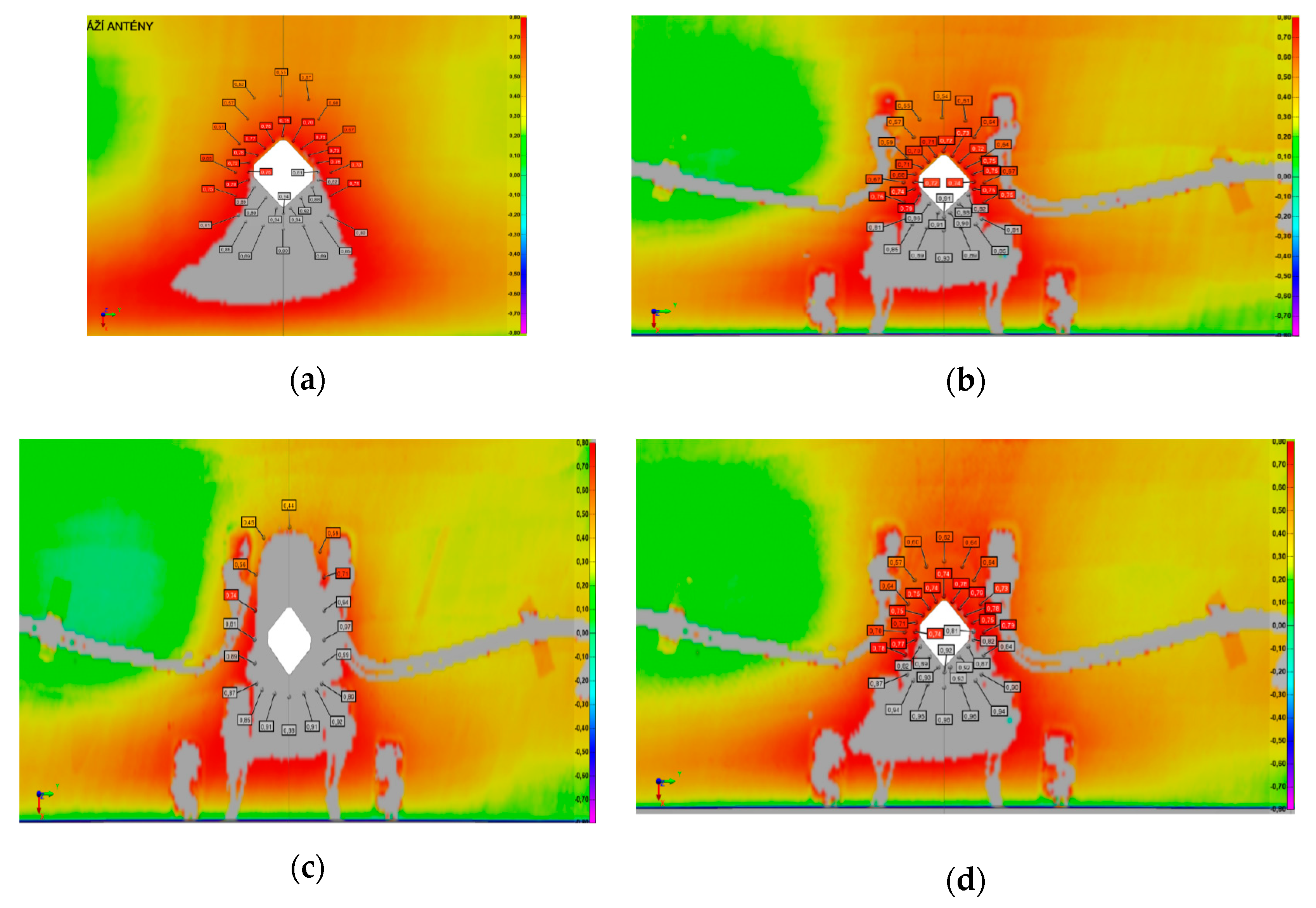

4. Deformation and Stress Analysis Using Numerical Modelling

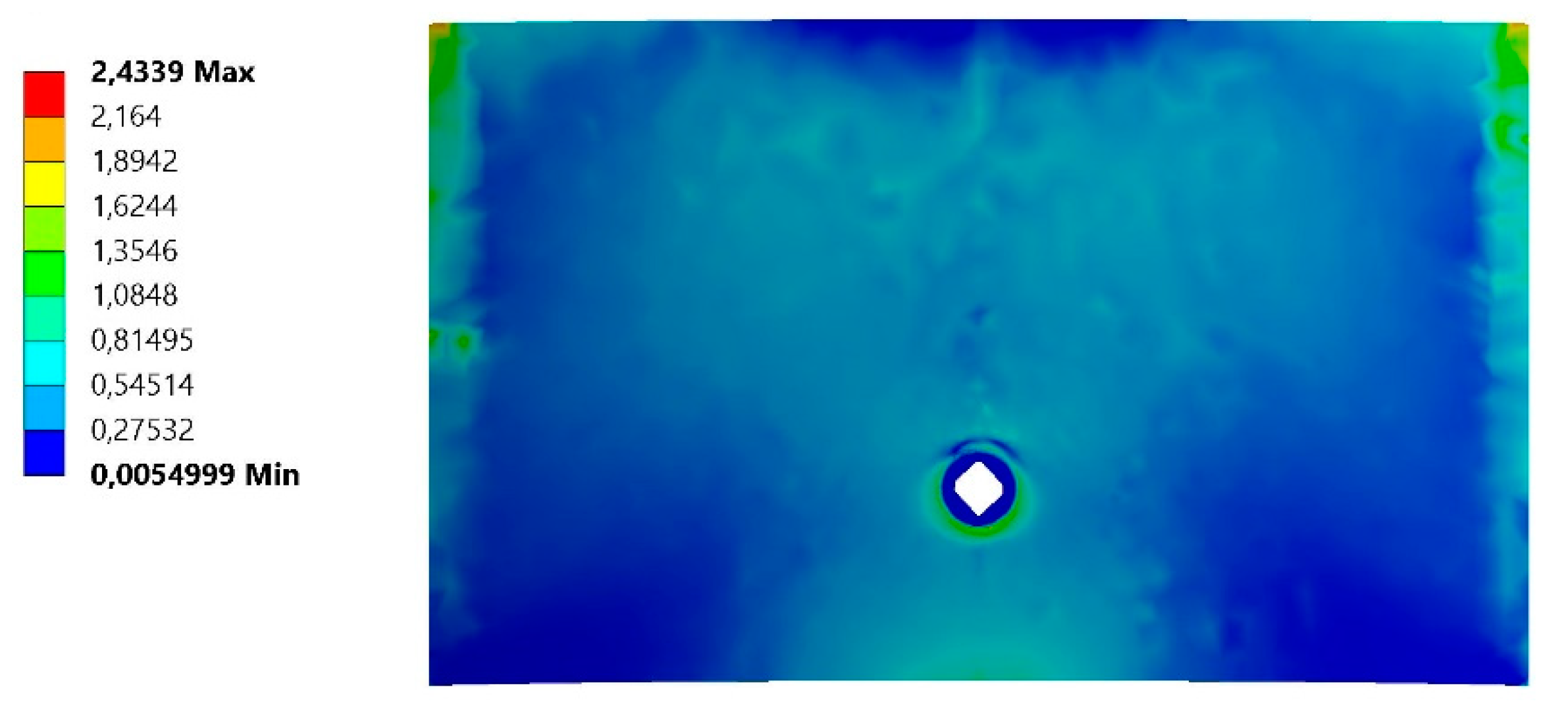

Results of Numerical Modelling

5. Conclusions

- numerical modelling confirmed theoretical assumptions of the distribution of stress and strain fields,

- total displacements determined by 3D scanning after unmounting the antenna on the painted roof were higher in most of the examined places and the differences almost reached 18%,

- different values of deformations/stresses on the right and the left side of the roof determined by strain gauge measurements are directly related to the already deformed shape of the sheet,

- excessive deformation did not occur due to the antenna mounting as originally assumed,

- the antenna was mounted on a 0.8-mm thick roof plate, most likely already deformed due to previous technological operations (pressing, cutting out the mounting hole, painting).

Author Contributions

Funding

Conflicts of Interest

References

- Bing, G.J.A.; Wallbank, J. The effect of using a sprung stripper in sheet metal cutting. J. Mater. Proces. Tech. 2008, 300, 176–184. [Google Scholar] [CrossRef]

- Rodrigues, G.C.; Vorkov, V.; Duflou, J.R. Optimal laser beam configurations for laser cutting of metal sheets. Procedia CIRP 2018, 74, 714–718. [Google Scholar] [CrossRef]

- Salvati, E.; Korsunsky, A.M. An analysis of macro- and micro-scale residual stresses of Type I, II and III using FIB-DIC micro-ring-core milling and crystal plasticity FE modelling. Int. J. Plast. 2017, 98, 123–138. [Google Scholar] [CrossRef]

- Arnal, L.; Solanes, J.E.; Molina, J.; Tornero, J. Detecting dings and dents on specular car body surfaces based on optical flow. J. Manuf. Syst. 2017, 45, 306–321. [Google Scholar] [CrossRef]

- Teodor, V.G.; Păunoiu, V.; Susac, F.; Baroiu, N. Optimization of the measurement path for the car body parts inspection. Measurement 2019, 146, 15–23. [Google Scholar] [CrossRef]

- Muñoz, A.; Mahiques, X.; Solanes, J.E.; Martí, A.; Gracia, L.; Tornero, J. Mixed reality-based user interface for quality control inspection of car body surfaces. J. Manuf. Syst. 2019, 53, 75–92. [Google Scholar] [CrossRef]

- Agrawal, N.; Gautam, A.K.; Rambabu, K. Design and packaging of multi-polarized triple-band antenna for automotive applications. AEU Int. J. Electron. Commun. 2020, 113, 152943. [Google Scholar] [CrossRef]

- Hambli, R.; Potiron, A. Finite element modeling of sheet-metal blanking operations with experimental verification. J. Mater. Process. Tech. 2000, 102, 257–265. [Google Scholar] [CrossRef]

- Metrologic Group. Available online: https://www.metrologicgroup.com (accessed on 22 September 2020).

- Li, C.; Wang, Y.; Xu, L.; Liu, Y.; Lu, N.; Mi, G. Microstructure and Mechanical Property of Compact Graphite/6061Al Composite Prepared by Ultra-High Pressure Sintering. Appl. Sci. 2020, 10, 5107. [Google Scholar] [CrossRef]

- Borazjani, S.; Belingardi, G. Development of an innovative design of a composite-sandwich based vehicle roof structure. Compos. Struct. 2017, 168, 522–534. [Google Scholar] [CrossRef]

- Hexagon. Available online: https://www.hexagonmi.com/en-GB/ (accessed on 22 September 2020).

- Pástor, M.; Lengvarský, P.; Trebuňa, F.; Čarák, P. Prediction of failures in steam boiler using quantification of residual stresses. Eng. Fail. Anal. 2020, 118, 104808. [Google Scholar] [CrossRef]

- Trebuňa, F.; Šimčák, F.; Bocko, J.; Trebuňa, P.; Pástor, M.; Šarga, P. Analysis of crack initiation in the press frame and innovation of the frame to ensure its further operation. Eng. Fail. Anal. 2011, 18, 244–255. [Google Scholar]

- Trebuňa, F.; Šimčák, F.; Buršák, M.; Bocko, J.; Šarga, P.; Pástor, M.; Trebuňa, P. The strain gage method for determination of input working life parameters of pipes in compressor stations. Metalurgija 2007, 46, 201–204. [Google Scholar]

- Trebuňa, F.; Šimčák, F.; Trebuňa, P.; Bobovský, Z.; Pástor, M.; Šarga, P.; Frankovský, P.; Hagara, M. Methodology for experimental verification of safety of packages for transport of spent nuclear fuel. Acta Mech. Slovaca 2012, 16, 34–43. [Google Scholar]

- Chandru, B.T.; Suresh, P.M. Finite Element and Experimental Modal Analysis of Car Roof with and without damper. Mater. Today Proc. 2017, 4, 11237–11244. [Google Scholar] [CrossRef]

| Measuring Place | Displacement (mm) | Measuring Place | Displacement (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | Stage 4 | Stage 1 | Stage 2 | Stage 3 | Stage 4 | ||

| 1 | 0.75 | 0.72 | - | 0.74 | 21 | 0.55 | 0.54 | 0.44 | 0.62 |

| 2 | 0.76 | 0.71 | - | 0.74 | 22 | 0.53 | 0.55 | 0.45 | 0.60 |

| 3 | 0.77 | 0.70 | - | 0.75 | 23 | 0.57 | 0.57 | 0.56 | 0.57 |

| 4 | 0.76 | 0.71 | - | 0.75 | 24 | 0.61 | 0.59 | 0.74 | 0.64 |

| 5 | 0.72 | 0.68 | - | 0.71 | 25 | 0.68 | 0.67 | 0.81 | 0.70 |

| 6 | 0.76 | 0.72 | - | 0.74 | 26 | 0.75 | 0.76 | 0.89 | 0.78 |

| 7 | 0.76 | 0.74 | - | 0.77 | 27 | 0.81 | 0.81 | 0.87 | 0.87 |

| 8 | 0.83 | 0.79 | - | 0.82 | 28 | 0.85 | 0.85 | 0.85 | 0.94 |

| 9 | 0.89 | 0.86 | - | 0.89 | 29 | 0.89 | 0.89 | 0.91 | 0.96 |

| 10 | 0.94 | 0.91 | - | 0.93 | 30 | 0.90 | 0.93 | 0.88 | 0.98 |

| 11 | 0.94 | 0.91 | - | 0.92 | 31 | 0.89 | 0.89 | 0.91 | 0.96 |

| 12 | 0.94 | 0.90 | - | 0.93 | 32 | 0.85 | 0.85 | 0.92 | 0.94 |

| 13 | 0.92 | 0.88 | - | 0.92 | 33 | 0.83 | 0.81 | 0.89 | 0.90 |

| 14 | 0.88 | 0.82 | - | 0.87 | 34 | 0.78 | 0.75 | 0.99 | 0.84 |

| 15 | 0.82 | 0.75 | - | 0.82 | 35 | 0.73 | 0.67 | 0.97 | 0.79 |

| 16 | 0.81 | 0.74 | - | 0.81 | 36 | 0.67 | 0.64 | 0.94 | 0.73 |

| 17 | 0.76 | 0.75 | - | 0.75 | 37 | 0.60 | 0.64 | 0.71 | 0.64 |

| 18 | 0.79 | 0.75 | - | 0.78 | 38 | 0.57 | 0.61 | 0.59 | 0.64 |

| 19 | 0.76 | 0.72 | - | 0.79 | |||||

| 20 | 0.78 | 0.73 | - | 0.78 | |||||

| Measuring Place | Deviation Interval of Measured Values (%) | ||

|---|---|---|---|

| 2/1 | 3/2 | 4/2 | |

| 1–20 | <1.32; 9.09> | Not evaluated | <−9.72; 0.0> |

| 21–38 | <−7.0,2; 8.22> | <−46.88; 18.52> | <−17.91; 0.00> |

| Measuring Place | σmax (MPa) | σmin (MPa) | σred (MPa) |

|---|---|---|---|

| BL1 | 1.83 | −0.51 | 2.13 |

| BL2 | 2.55 | −2.21 | 4.12 |

| BP1 | 2.12 | −0.91 | 2.69 |

| BP2 | 2.65 | −2.50 | 4.46 |

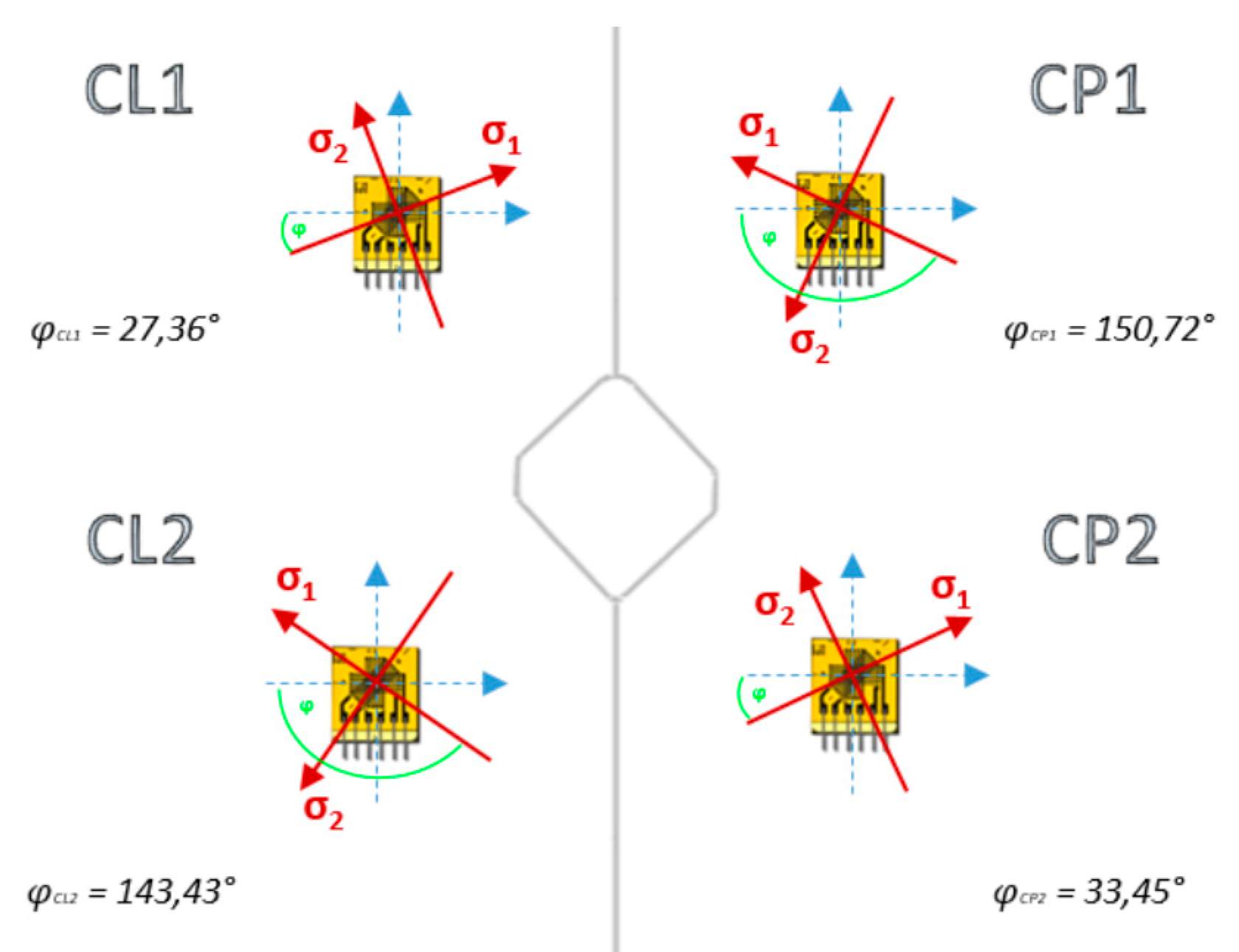

| CL1 | 1.72 | −0.55 | 2.05 |

| CL2 | 5.22 | 0.26 | 5.09 |

| CP1 | 1.61 | −1.16 | 2.41 |

| CP2 | 5.77 | 0.92 | 5.36 |

| Measuring Place | σmax (MPa) | σmin (MPa) | σred (MPa) |

|---|---|---|---|

| BL1 | −1.94 | −7.50 | 6.74 |

| BL2 | 3.93 | −7.33 | 9.90 |

| BP1 | 1.88 | −6.37 | 7.48 |

| BP2 | 0.68 | −7.18 | 7.54 |

| CL1 | −3.14 | −10.22 | 9.07 |

| CL2 | −0.39 | −12.58 | 12.39 |

| CP1 | −5.31 | −15.97 | 14.09 |

| CP2 | −2.69 | −15.53 | 14.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pástor, M.; Živčák, J.; Puškár, M.; Lengvarský, P.; Klačková, I. Application of Advanced Measuring Methods for Identification of Stresses and Deformations of Automotive Structures. Appl. Sci. 2020, 10, 7510. https://doi.org/10.3390/app10217510

Pástor M, Živčák J, Puškár M, Lengvarský P, Klačková I. Application of Advanced Measuring Methods for Identification of Stresses and Deformations of Automotive Structures. Applied Sciences. 2020; 10(21):7510. https://doi.org/10.3390/app10217510

Chicago/Turabian StylePástor, Miroslav, Jozef Živčák, Michal Puškár, Pavol Lengvarský, and Ivana Klačková. 2020. "Application of Advanced Measuring Methods for Identification of Stresses and Deformations of Automotive Structures" Applied Sciences 10, no. 21: 7510. https://doi.org/10.3390/app10217510

APA StylePástor, M., Živčák, J., Puškár, M., Lengvarský, P., & Klačková, I. (2020). Application of Advanced Measuring Methods for Identification of Stresses and Deformations of Automotive Structures. Applied Sciences, 10(21), 7510. https://doi.org/10.3390/app10217510